HP DESIGNJET 5000 User Manual

HP |

DesignJet 5000 and 5500 Series |

Large-Format Printers |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Service Manual

For HP Internal Use Only

©Copyright Hewlett-Packard

Company 2002

This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this document may be photocopied, reproduced, or translated to another language without the prior written consent of HewlettPackard Company.

First Edition, August 2000

Second Edition, January 2001

Third Edition, September 2002

Warranty

The information contained in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this material, including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose.

Hewlett-Packard shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material.

WARNING

The procedures described in this manual are to be performed by HP-qualified service personnel only.

Electrical Shock Hazard

Serious shock hazard leading to death or injury may result if you do not take the following precautions:

-Ensure that the ac power outlet (mains) has a protective earth (ground) terminal.

-Disconnect the Printer from the power source prior to performing any maintenance.

-Prevent water or any other liquids from running onto electrical components or circuits, or through openings in the enclosure.

Electrostatic Discharge

Refer to the beginning of Chapter 8 of this manual, for precautions you should take to prevent damage to the Printer circuits from electrostatic discharge.

Safety Symbols

General definitions of safety symbols are given immediately after the table of contents.

WARNING

The Warning symbol calls attention to a procedure, practice, or the like, which, if not correctly performed or adhered to, could result in personal injury. Do not proceed beyond a Warning symbol until the indicated conditions are fully understood and met.

CAUTION

The Caution symbol calls attention to an operating procedure, practice, or the like, which, if not correctly performed or adhered to, could result in damage to or destruction of part or all of the product. Do not proceed beyond a Caution symbol until the indicated conditions are fully understood and met.

Technical Marketing,

Barcelona Division, Hewlett-Packard Espanola, S.A. Avda. Graells, 501

08190 Sant Cugat del Valles Spain

HP |

DesignJet 5000 and 5500 Series |

Large-Format Printers |

|

|

|

|

|

|

|

|

|

Service Manual

Using this Manual

Purpose

This Service Manual contains information necessary to test, calibrate and service:

HP DesignJet 5000 Printer - 42” Model (P/N C6090A/V)

HP DesignJet 5000 Printer - 60” Model (P/N C6095A/V)

HP DesignJet 5000PS Printer - 42” Model (P/N C6091A/V)

HP DesignJet 5000PS Printer - 60” Model (P/N C6096A/V)

HP DesignJet 5500 Printer - 42” Model (P/N Q1251A/V)

HP DesignJet 5500 Printer - 60” Model (P/N Q1253A/V)

HP DesignJet 5500PS Printer - 42” Model (P/N Q1252A/V)

HP DesignJet 5500PS Printer - 60” Model (P/N Q1254A/V)

For information about using these printers, refer to the corresponding User and Quick Reference Guides.

Readership

The procedures described in this Service Manual are to be performed by HP-qualified Service Personnel only.

Part Numbers

Part Numbers for Printer options, accessories and service parts are located in Chapter 7.

Conventions

A small arrow Ÿis used to indicate other parts of the Service Manual where you can find information related to the topic you are consulting.

2 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

Table of Contents

Table of Contents

Troubleshooting 1-1

System Error Codes 2-1

HP Ink Supplies Troubleshooting 3-1

Service Tests and Utilities 4-1

Service Calibrations 5-1

Print Quality 6-1

Parts and Diagrams 7-1

Removal and Installation 8-1

Preventive Maintenance 9-1

Functional Overview 10-1

HP DesignJet 5000 and 5500 Series Printers Service Manual |

3 |

Table of Contents

4 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

Troubleshooting

Introduction 1-2

Phone Support 1-2

Which Firmware Version Relates to Which Ink System 1-2

Troubleshooting System Error Codes 1-2

Performing a Service Test on a Failed Assembly 1-3

Performing the Necessary Service Calibrations 1-3

Troubleshooting Calibration Error Codes 1-3

Troubleshooting Ink Supplies Error Codes 1-4

Troubleshooting Initialization - Self Diagnostic Errors 1-4

Solving Image Quality Problems 1-4

The Printer does not Power ON 1-5

ALL the Front-Panel LEDs are Lit but Nothing Else Happens 1-6

Troubleshooting Media Jams/Printhead Crashes 1-6

Troubleshooting Shutdowns - User Message "Warning: Switch Power Off" 1-7

Problems with Vacuum 1-10

Vacuum suction much lower at high altitudes 1-10

Printhead Crashes/Smears on High Density Prints Using Coated Media 1-11

Color differences in different HP DesignJet Printers 1-11

Banding at variable extreme environmental conditions 1-12

Banding with unsupported Media 1-12

Banding due to Ink Cartridge replacement while printing 1-12

Hue shift on HP Colorfast Adhesive Vinyl media 1-13

Black Smearing on HP Photo Imaging Gloss 1-13

Magenta Bleeding on HP Photo Imaging Gloss when using the Take-Up Reel 1-13

Loss of Gloss on HP Photo Imaging Gloss when using the Take-Up Reel 1-14

Wrinkles and scratches (cockle) on HP Coated and Heavyweight Coated Media. 1-15

Dry Cockle on High Density Prints Using Paper Based Media 1-14

Worm marks (cockle) on part of plots on paper based media 1-15

Drying Time Too Long for HP Studio Canvas 1-16

Media Skew when Printing a Banner Plot 1-16

User message "Media loaded incorrectly. Remove media" 1-16

User message "Warning: Incorrect type of tubes system" 1-17

User message "Power Supply Error #1" 1-17

Cutter Assembly Problems 1-19

Carriage and Scan-Axis Problems 1-20

Media-Axis Problems 1-20

Electronics Problems 1-21

Language Selection is blocked in a brand new printer 1-23

Firmware Upgrade Does Not Work Through the Parallel Port 1-23

Typical Failures After Exchanging the Ink Tubes 1-24

Solving Media-Handling Problems 1-25

How to Navigate through the Front Panel Menus 1-26

Service Configuration Print 1-37

General Printer Information 1-39

Troubleshooting Take-Up-Reel Problems 1-40

HP DesignJet 5000 and 5500 Series Printers Service Manual |

1-1 |

Troubleshooting

Guide to Troubleshooting the Printer

Introduction

This chapter will guide you through the relevant steps to take when troubleshooting the Printer.

Phone Support

In certain circumstances, a Call Agent can try and troubleshoot the Printer by requesting the Customer to perform a Service Calibration, Test or Utility via the phone. Using this process, it can be determined whether the Printer requires any on-site maintenance.

Which Firmware Version Relates to Which Ink System

A.01.XX - This firmware revision allows the Printers to only use

Imaging Inks.

A.02.XX - This firmware revision allows the Printers to use both the Imaging Inks and the UV Inks.

NOTE

NOTE

Troubleshooting System Error Codes

Chapter 2 - System Error Codes - contains a list of system error codes and their respective descriptions and recommended corrective actions. Only try one recommended action at a time and check if the error code has disappeared.

If you have an error code which is not documented in this Service Manual or you have an error which you cannot resolve, then report the error to the HP Response Center or the nearest HP Support Office.

When reporting the System Error Code, make sure that you supply the full Error Code (including the last 8 numbers where applicable) and the firmware version as well as the status of the Printer when the Error occurred (was it printing, calibrating, processing, etc...). Without this information, HP Support Personnel cannot help you.

When reporting the Error Code, make sure that you supply the full Error Code and the firmware version (displayed during the initialization process when powering ON the Printer or available in the User’s Printer Setup ŸUtilities Ÿ Statistics menu).

1-2 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

NOTE

NOTE

Troubleshooting

Performing a Service Test on a Failed Assembly

If possible, always perform a Service Test on the component/ assembly that you are about to replace, just to make sure that is the component/assembly that has failed.

If the test on that component/assembly passes, you should NOT replace it.

For information on the Service Tests and how to use them see Chapter 4, Service Tests and Utilities.

Performing the Necessary Service Calibrations

Is the Printer calibrated correctly after replacing a component? Refer to the table on Page 5-2 to determine when a calibration is required.

Remember that certain Calibrations are required even if an Assembly has been disassembled to gain access to another Assembly or Component.

For information on the Service Calibrations and how to use them see 5, Service Calibrations.

Troubleshooting Calibration Error Codes

Chapter 5 - Service Calibrations - contains a list of Error Codes that are reported when a Calibration fails.

Calibration error codes consist of a four digit number [XXXX].

If you have an error code which is not documented in this Service Manual or you have an error which you cannot resolve, then report the error to the HP Response Center or the nearest HP Support Office.

HP DesignJet 5000 and 5500 Series Printers Service Manual |

1-3 |

Troubleshooting

Troubleshooting Ink Supplies Error Codes

Chapter 3, HP Ink Supplies Troubleshooting, contains a list of Error Codes that are reported for Ink Supplies i.e. Ink Cartridges, Printheads and Printhead Cleaners. The error codes are described and recommended corrective actions are provided. Only try one recommended action at a time and check if the error code has disappeared.

Ink Supplies error codes consist of a four digit number [XXXX].

Troubleshooting Initialization - Self Diagnostic Errors

Chapter 4 - Service Tests and Utilities - describes the Printer initialization sequence and reports errors that may be reported when Printer initialization is performed.

Self Diagnostic error codes consist of seven alphanumeric characters [XXXXXXX].

If you have an error code which is not documented in this Service Manual or you have an error which you cannot resolve, then report the error to the HP Response Center or the nearest HP Support Office. When reporting the error, have the following information ready:

Which firmware revision the Printer is using.

The complete error number.

Solving Image Quality Problems

Whenever an Image Quality problem appears, it is advisable to print the Diagnostic Print. This will help you differentiate between possible Printhead errors and other problems such as incorrect frontpanel selection, driver or RIP configuration or mechanical problems. For information on solving Image Quality problems see Chapter 6, Print Quality.

1-4 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

Troubleshooting

The Printer does not Power ON

1.Check that the Power Cord is connected correctly to the Printer and to the Power Socket.

2.Check that the Power Switch on the BACK of the Printer is in the ON position.

3.Remove the DIMM’s Cover (See ŸPage 8-77) and check the green

and red Status LED’s on the Main PCA. If they are both NOT lit, replace the Power Supply Unit ŸPage 8-88.

Status

Status

LED’s

4.Check that the Front-Panel Cable is correctly connected to the Electronics Module. Also make sure that the Front-Panel Cable is not damaged.

HP DesignJet 5000 and 5500 Series Printers Service Manual |

1-5 |

Troubleshooting

ALL the Front-Panel LEDs are Lit but Nothing Else

Happens

The BootROM DIMM is NOT correctly installed or is the wrong type.

1.Power OFF the Printer from the back and disconnect the Power

Cord. Reseat the BootROM DIMM (looking from the rear of the Printer, the first slot from the left - See ŸPage 8-77) making sure that it is installed correctly.

2.If the problem persists replace the BootROM DIMM ŸPage 8-77.

NOTE |

For more information, refer to “Electronics Problems” on page 1-21. |

|

Troubleshooting Media Jams/Printhead Crashes |

|

If using HP Coated Media when problem occurred, please also |

NOTE |

|

|

refer to Page 1-11. |

|

|

The failure modes “media jam” and “head crash” are grouped together because in many cases a media jam causes the media to lift up into the carriage path and cause a head crash, thus causing many media jam failures to be reported as head crashes.

1.Did the media jam occur when loading media?

If the client has had media jams, it is common for pieces of media to get stuck in the media path. Clear the media path.

NOTE |

When clearing a media jam, sometimes media is stuck in the |

|

paper path. To clear this, you must lift the media lever and insert |

|

thicker media into the paper path to push out the media that is |

|

still stuck there. |

|

|

2.Is the customer using non-HP media?

The use of non-HP media can easily be the cause of media jams and head crashes (especially head crashes because HP media is specially formulated to avoid cockle, one of the primary causes of head crashes). If the media is not HP approved, advise the customer to use HP media and check to see if the problem is now solved.

3.The Carriage is at the incorrect height in relation to the Center Platen. Adjust the carriage to the correct height ŸPage 5-18 and try to load the media again.

4.Check that the Vacuum Fans work correctly - Refer to Page 1-10, Problems with Vacuum .

1-6 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

Troubleshooting

|

Troubleshooting Shutdowns - User Message |

|

"Warning: Switch Power Off" |

|

If a shutdown occurs, you will get the message “Warning: Switch |

|

Power Off” followed by: |

|

Check Printhead Cleaner Path. |

|

Check Paper Path. |

|

Check Printhead Path (followed by (1), (2) or (3)). |

|

A shutdown in each path will require different steps to resolve the |

|

problem as explained as follows. |

|

In each case, make sure that you power OFF the Printer before |

WARNING |

|

|

attempting any procedures to resolve the problem. |

|

Check Printhead Cleaner Path |

|

|

|

This message appears whenever the Service Station Carriage does |

|

not move, either because of a bad cable connection, a defective |

|

motor or because of some obstacle inside the Service Station. |

|

If the Printer is new, check that the Service Station cable (which is |

|

the grey flat cable with the grey connector) is plugged into the Main |

|

PCA. Make sure that the clips of the connector are closed |

|

completely. Check also that the Service Station cable is not damaged. |

|

In already used Printers, power OFF the Printer and try to move |

|

the Service Station backwards and forwards to see whether it is |

|

blocked. Possible causes are: Printhead Cleaners incorrectly |

|

positioned, damaged or, even, pieces of paper within the Service |

|

Station. Remove the Printhead Cleaners or the pieces of paper |

|

and check whether the problem persists. |

|

If the problem disappears without the Printhead Cleaners, reinsert them |

|

into the Service Station and see whether the problem reappears. If the |

|

problem reappears, replace the complete set of Printhead Cleaners. |

|

If the problem persists even without the Printhead Cleaners, then |

|

replace the Service Station (ŸPage 8-69) and recalibrate the Printer. |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

1-7 |

Troubleshooting

Check Paper Path

NOTE

NOTE

This warning appears whenever the friction on the Paper-Axis is too high: the electrical current needed by the Paper-Axis Motor to move the paper is too high, so before burning the motor or the Main PCA, this warning appears. The common reason for this error is an internal paper jam or at the end of a roll of media the paper is glued to the media core. It can also be due to a defective motor or Main PCA.

Check that there are no pieces of paper left inside the Printer, especially if it happens after a paper jam.

One way to verify this easily is to take a rigid sheet of paper and move it along the paper path with the media load lever lifted.

Also, check that the customer has inserted the spindle hubs completely, otherwise they may rub against the side plate and increase the friction.

If the error still persists, check that the Paper-Axis Motor cables are connected correctly and that they are not damaged.

If the Printer still fails, replace the Paper-Axis Motor ŸPage 8-105.

Turn the Drive Roller by hand once the motor is removed to verify that it turns smoothly. Also, after replacing the Paper-Axis Motor, perform the Media-Axis Test (ŸPage 4-12 and check that the values are within the given limits.

If the Printer still fails, replace the Main PCA ŸPage 8-81.

Check Printhead Path (1)

This warning appears whenever friction on the Scan-Axis is too high: the electrical current needed by the Scan-Axis Motor to move the Carriage is too high, so before burning the motor or the Main PCA, this warning appears. The usual reason for this error is an internal paper jam, an obstacle in the Printhead path, a broken belt, badly installed Ink Supply Tubes, etc.

Apply Oil along the complete axis of the Slider Rods with the User’s Slider Rods Lubrification Kit ŸPage 9-8.

Also, switch OFF the Printer and move the Carriage from side to side to verify that it moves smoothly.

If the Printer still fails, check that the Scan-Axis motor is connected correctly to the Main PCA and that the cable is not damaged.

If the error remains, replace the Belt (ŸPage 8-46) or the ScanAxis Motor ŸPage 8-57.

1-8 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

|

Troubleshooting |

|

|

|

Also, after replacing the Scan-Axis Motor, perform the Scan-Axis Test |

NOTE |

|

|

(ŸPage 4-10 and check that the values are within the given limits. |

|

If the Printer still fails, replace the Main PCA ŸPage 8-81. |

|

|

|

Check Printhead Path (2) |

|

This is a safety shutdown and occurs whenever there is a discontinuity |

|

in the Printhead path, because of an obstacle, oil drops on the Encoder |

|

Strip, the Carriage cover touching the tube guides, etc. |

|

Switch OFF the Printer and move the Carriage from side to side |

|

to verify that it moves smoothly. |

|

If it still fails, check the Encoder Strip and, if necessary, clean it. |

|

Check Printhead Path (3) |

|

This is always caused by high friction in the Printhead path. Only in |

|

very special cases, when it happens inside the Left Hand Cover, |

|

incorrect assembly of the tube system causes it. |

|

Apply Oil along the complete axis of the Slider Rods with the |

|

User’s Slider Rods Lubrification Kit ŸPage 9-8. |

|

Replace Message "xx15 Replace" and "xx16 Replace" |

|

In certain circumstances (e.g. Printhead crash without Printer |

|

shutdown), the message "xx15 Replace" or "xx16 Replace" may |

|

appear on the front panel. This is due to a temporal disconnection |

|

between the Printhead and the flex circuit in the Carriage Assembly. |

|

Clean the Printheads and the Carriage interconnects (refer to page |

|

9-6, Carriage Interconnect Wiper ) and reseat the failing Printheads. |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

1-9 |

Troubleshooting

Problems with Vacuum

If you have problems loading either Roll or Sheet Media, then there could be a problem with the Vacuum Fan or Booster Fan. To verify if there really is a problem with Vacuum, try the following:

1.With the Printer ON, open the Window of the Printer and place a sheet of HP High Gloss Photo Paper (must be D-Size), aligned with the blue lines on the Center Platen. If the Vacuum holds the sheet in place, and then loads it correctly, then the Fans function correctly. If the Vacuum does not hold the sheet in place (no suction), then try the following:

Check that the holes in the Center Platen are NOT blocked.

Clean the Overdrive using the Platen Cleaning Utility ŸPage 9-9.

Check that the Vacuum and Booster Fans are installed correctly.

Replace the Vacuum Fan ŸPage 8-103.

Replace the Booster Fan ŸPage 8-108.

2.If the Vacuum held the sheet in place, but couldn’t correctly load it,

then there could be a problem with the Overdrive. In this case, replace the Center Platen Assembly ŸPage 8-117.

Vacuum suction much lower at high altitudes

At altitudes above 2,000 meters, the vacuum force holding down the media will be lower, therefore the media will not be held in place properly causing:

Ink Smearing on the Media.

Printhead crashes against the Media.

Cut Sheet loading problems (high probability).

Roll Media loading problems (low probability).

To solve the problem, try the following:

Using the “1.3 Altitude Setup” in the Service Utilities, set the altitude to “1.3.2 2000 m or more” (see Altitude Setup 4-23).

1-10 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

Troubleshooting

Printhead Crashes/Smears on High Density Prints Using Coated Media

High density prints can cause cockle mainly on HP Coated Media. This causes two main problems:

1.Cockling in the borders - Because the Printer places too much ink on the Coated Media, the borders of the print become raised, causing the Printhead to crash against the media. To solve the problem, try the following:

Try using Heavy Weight Coated Media instead of Coated Media.

Change the paper margins to “Extended” in the Printer Setup menu/Page Format/Margins or in the Driver. If the customer is printing PostScript images, send them a PPD file containing the extended margins.

Use the Deflectors.

Upgrade the Firmware ŸPage 9-11.

2.Cockling within the print - If the Printer places too much ink within the print, the media starts to ripple, causing the Printhead to smear against the media. To solve the problem, try the following:

Never use HP Coated Media for High Density prints. As a substitute use HP Heavy Weight Coated or Heavy Weight Coated (Economy) Media.

Color differences in different HP DesignJet Printers

Color differences between one image printed on the HP DesignJet 5000 Series and the rest of the DesignJet platforms are due to the different chemistry of the 5000 series inks compared with the rest of the inks for other printers. This color variability among different HP DesignJet Series Printers has been always present. You can try to achieve consistent colors with the following:

Select the same color emulation settings in your Postscript Driver as the one used by the printer you want to emulate.

Select the correct Ink Emulation from the Printer Setup Menu/ Internal RIP Settings.

HP DesignJet 5000 and 5500 Series Printers Service Manual |

1-11 |

Troubleshooting

Banding at variable extreme environmental conditions

The Accuracy Calibration has been done at normal environmental conditions, therefore printing in extreme environmental conditions will cause banding because the advance of the Drive Roller does not correspond to the same conditions that the calibration was done in. To solve the problem, try the following:

Perform the Accuracy Calibration in the new environmental conditions (Refer to the User’s Guide - Media Solutions).

Banding with unsupported Media

The Accuracy Calibration has not been done for the Media now loaded. Banding may occur because the advance of the Drive Roller does not correspond to the same conditions that the calibration was done in. To solve the problem, try the following:

Select the Media loaded in the “Media Options” menu and perform the Accuracy Calibration (Refer to the User’s Guide - Media Solutions).

Banding due to Ink Cartridge replacement while printing

A user has removed the Ink Cartridge while the Printer was printing, which has caused the Printer to stop. If the user does not replace the Ink Cartridge immediately, when the Printer starts to print again, a band will appear in the position where the printing restarted. This is because the wet ink interacts with the dried ink on the media causing the band to appear. To solve the problem, try the following:

Do NOT remove the Ink Cartridge while the Printer is Printing. Only replace/remove Ink Cartridges in between Prints.

If the Ink Cartridge was replaced due to the “Empty” status on the Front Panel, then advise the customer to replace the Ink Cartridge when the “Very Low” status is showing on the Front Panel.

1-12 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

Troubleshooting

Hue shift on HP Colorfast Adhesive Vinyl media

Under high humidity conditions (approx. >65%) the colors tend to fade over time, particularly colors that require Magenta. To solve the problem, try the following:

Reduce the level of humidity (<65%) that the Printer is working in. To find the humidity level, print the Service Configuration Print (Printer Setup Menu / Utilities / Test prints / Service config).

Laminate the prints.

Black Smearing on HP Photo Imaging Gloss

Narrow black lines can smear on this type of media, particularly if the lines are narrow and have white gaps in between them. Try the following:

Increase the Dry Time using the Front Panel (Refer to the User’s Guide).

Laminate the prints.

Magenta Bleeding on HP Photo Imaging Gloss when using the Take-Up Reel

Under high humidity conditions (approx. >70%) this media reduces its capacity to absorb Magenta because of this color’s particular characteristics. When an area fill with magenta is printed and then rolled onto the Take-Up Reel the ink that is not completely dry moves laterally on the media. To solve the problem, try the following:

Reduce the level of humidity (<70%) that the Printer is working in. To find the humidity level, print the Service Configuration Print (Printer Setup Menu / Utilities / Test prints / Service config).

Increase the Dry Time using the Front Panel (Refer to the User’s Guide).

Do not use the Take-Up Reel or Bin for this media when humidity levels are high.

HP DesignJet 5000 and 5500 Series Printers Service Manual |

1-13 |

Troubleshooting

Loss of Gloss on HP Photo Imaging Gloss when using the Take-Up Reel

Under high humidity conditions (approx. >70%) the polymer chain in the coating of this media relaxes and the drying rate decreases. If the printed media is rolled onto a Take-Up Reel or is covered by another print, the contact between the two surfaces could cause blotches in the gloss. Try the following:

Reduce the level of humidity (<70%) that the Printer is working in. To find the humidity level, print the Service Configuration Print (Printer Setup Menu / Utilities / Test prints / Service config).

Increase the Dry Time using the Front Panel (Refer to the User’s Guide).

Do not use the Take-Up Reel or Bin for this media when humidity levels are high.

Dry Cockle on High Density Prints Using Paper Based Media

High density prints can cause dry cockle mainly on Paper Based

Media.

To solve the problem do the following:

Use the Take-Up Reel and Take-Up Reel deflectors.

Set the Printer to Productivity mode to reduce the ink density.

Select Coated media modes

If the problem persists, try the following:

Laminate the prints.

Use a heavier media that is more suitable to high ink density, such as HP Paper based Semi-Gloss or HP Poster Paper.

1-14 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

Troubleshooting

Wrinkles and scratches (cockle) on HP Coated and Heavyweight Coated Media.

Images may be damaged if prints are not handled with care, particularly when handling wide plots. This can happen when images are placed on top of one another and there is movement between them, causing friction and loss of ink from the surface if it is not completely attached. Also, if plots are rolled up, wrinkles can occur. To avoid this problem try the following:

Always handle plots with care.

Use of the Take-Up Reel eliminates handling and avoids wrinkles.

Use heavier media.

For Heavyweight Coated media, select faster print modes such as Heavyweight Coated (Economy) for Media selection, and/or

Productivity Print mode.

If damage is slight, Lamination will help towhead’ defects.

Use of Fixative Sprays immediately after printing may protect the image.

Worm marks (cockle) on part of plots on paper based media

At high temperatures and under dry conditions, worm marks may occur on initial parts of plots when printing solid fill areas in medium tone colors. Try the following:

Advance the media manually by 15 mm.

Select Heavy Coated for Media setting.

Select Productivity mode to reduce ink density.

HP DesignJet 5000 and 5500 Series Printers Service Manual |

1-15 |

Troubleshooting

Drying Time Too Long for HP Studio Canvas

Under conditions of high humidity (> 70%) HP Studio Canvas retains a high amount of water and takes too long to dry, also creating problems in using the Take-Up Reel and Bin. To solve the problem try the following:

Reduce the level of humidity (<70%) that the Printer is working in. To find the humidity level, print the Service Configuration Print (Printer Setup Menu / Utilities / Test prints / Service config).

Increase the drying time using the Front Panel settings (Refer to the User’s Guide).

Do not use the Take-Up Reel or Bin under conditions of high humidity.

Media Skew when Printing a Banner Plot

When printing banners, media skew occurs. This is particularly noticeable in the first plot when media is not perfectly aligned. To solve this problem do the following:

Use extended margins for banner plots (Refer to the User’s Guide).

User message "Media loaded incorrectly. Remove media"

This message appears when the media sensor has detected media, but the line sensor has not detected the leading edge of the media at all or has found it in an incorrect position.

There are three possible situations when this message comes up:

1.The paper is in the incorrect position because the Printer was turned OFF in the middle of a print. It should only happen in printers without the Take-Up Reel (42" model), because with the Take-Up Reel installed the Printer will not search for the leading edge after the Printer has been powered-up or after activating the media load lever. The Printer simply continues to print wherever it stopped.

To verify this setting, check in "Printer Setup Menu > Device setup > TUR installed". It should be set as No for the 42" model Printers and Yes for the 60" model Printers.

1-16 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

Troubleshooting

2.The media sensor is defective. To verify this, remove the media and re-boot the Printer. If the message comes up during initialization, the media sensor is defective. To solve this, try the following:

Check that the media sensor cable is connected correctly

Check that the media sensor cable is not damaged and that the media sensor is clipped correctly.

Replace the Media Sensor ŸPage 8-109.

3.The Line Sensor does not detect the leading edge of the media. To verify this, load media (ideally white media such as Coated or PhotoGloss) into the Printer. If the message comes up during the loading

process, the Lens Cover Assembly is either not installed correctly or it is dirty. In this case, replace the Lens Cover Assembly ŸPage 9-5. If this fails, replace the Carriage Assembly ŸPage 8-46.

User message "Warning: Incorrect type of tubes system"

This error message appears if the electrical connector of the Ink Tubes System is not connected correctly (especially after the Tubes have been replaced). Other causes are defective EEROM in the Ink Tubes System or ISS PCA.

Switch OFF the printer, open the rear left cover and connect or re-connect the Electrical Cable (the colored flat cable) that is connected to the rear of the Ink cartridge Tube Connector.

If the problem persists, check that the Electrical Cable is connected correctly to the ISS PCA.

Replace the ISS PCA (ŸPage 8-91) or the Ink Tubes system (Ÿ Page 8-25).

User message "Power Supply Error #1"

This error indicates a short in the 24V electronics circuits. Do not replace the Power Supply; This message only indicates the failure, and is not the cause. Usually this message appears after the insertion of a Trailing Cable into the connectors. This message means that the Trailing cable is incorrectly connected, and it is creating a short on the 24V circuit.

To isolate the problem, remove the Trailing Cable from the back of the Printer and check whether the Printers powers up correctly.

If the Printer powers up correctly, the problem could have been a bad

HP DesignJet 5000 and 5500 Series Printers Service Manual |

1-17 |

Troubleshooting

Trailing Cable connection, so just reconnect the Trailing Cable again to double-check that the Printer now works. If, after reconnecting the cable, the error appears again, either the Carriage PCA or the Trailing Cable is defective. In this case, first try replacing the Trailing Cable and then the Carriage Assembly.

If the Printer did not initialize correctly, even after removing the Trailing Cable, the problem is either in the Main PCA or the ISS PCA. So, once again, to isolate the failure, disconnect first the ISS cable and check whether the Printer works. If it does, reconnect the cable again to verify the failure and then, if necessary, replace either the ISS cable or the ISS PCA.

If the Printer still does not initialize, even after removing the Trailing Cable and the ISS cable, replace the Main PCA.

1-18 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

Troubleshooting

Cutter Assembly Problems

1.The Printer does not cut (even when using the Form Feed & Cut option in the Front Panel).

In this case it is very likely that the cutter is disabled in the EEROM. This can happen whenever the Diagnostic Print is cancelled in the middle of the print, or if the Printer was turned OFF in the middle of the Diagnostic Print.

To re-activate the Cutter, print the Diagnostic Print again and this time letting it finish to the end without any interruptions.

If the Cutter still doesn’t cut after re-printing the Diagnostic Print, replace the Cutter Assembly ŸPage 8-60.

NOTE |

This problem is solved in any A.02.xx firmware release. |

2.The Cutter does not cut thick paper (Canvas & Non-HP Media).

As in all DesignJets, the Cutter can only cut media up to a certain thickness (such as Heavy Coated or Photo paper). Thicker media or special media (such as Canvas) cannot be cut.

Taking this into consideration, when Canvas is selected on the front panel, the cutter is automatically disabled, but there is nothing wrong with the cutter.

3.The Printer hangs while cutting.

The Printer hangs and the Carriage stops if the window is opened during the cutting operation. In addition, when pressing any key, the Error Code ffff ffff 03450097 may appear on the front panel.

Re-boot the Printer and make sure the customer does not open the window while the Printer is cutting.

NOTE |

This problem is solved in any A.02.xx firmware release. |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

1-19 |

Troubleshooting

Carriage and Scan-Axis Problems

1.Printhead continuity problems.

When installing the Ink Tubes System, it is possible that the crane (the part of the Tubes System that is connected to the front of the Carriage) is not clipped properly. This can cause Printhead continuity problems afterwards, especially in the light cyan and light magenta Printheads (XX16 REPLACE message appears for these Printheads).

Whenever there is a Printhead continuity problem, always check that the crane is completely clipped to the front of the carriage.

2.Unknown Line Sensor ID.

When performing the Scan-Axis Calibration, the Printer asks for the Line Sensor ID. But there is no label on the Line Sensor indicating it.

If the Line Sensor ID is not indicated on the Line Sensor, use the default value which is "0". In the future, if the LED’s are modified, a sticker will be included with the new Line Sensor ID.

3.Line Sensor is shown as "Not calibrated" in the Service Configuration Print.

This is a firmware bug. It is possible that the Line Sensor is calibrated even though the Service Configuration Print indicates that the Calibration has not been performed.

Just ignore this information about the Line Sensor calibration.

If there are any errors related to the Line Sensor, perform the Scan-Axis calibration to make sure that the Line Sensor calibration is completed.

Media-Axis Problems

1.Printer unloads media (it suddenly starts to rewind and unloads the media)

If the window was raised at exactly the same moment when the Printer moved the media (e.g. during media loading) from that moment onwards the Printer will always reject the media unless the Printer is turned OFF and then back ON again.

Problem disappears after re-booting the Printer.

NOTE |

This problem is solved in any A.02.xx firmware release. |

1-20 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

Troubleshooting

Electronics Problems

1.The Printer hangs with the front panel completely blank and the three Image Quality LED’s lit.

The firmware has a bug that creates this situation whenever the Printer is receiving data from an external RIP.

The customer should print using the HP Driver to check that the Printer is printing without any problems.

The only solution to this problem will be to upgrade to the firmware for the UV inks (A.02.XX) when it is available.

NOTE |

This problem is solved in any A.02.xx firmware release. |

2.The Printer hangs at "Initializing Please Wait".

The Printer hangs showing the following front panel message for more than 5 minutes: "Initializing Please Wait, Code Rev. xxxx, Boot ROM. xxx, etc".

The cause for this failure could be either a print sent through the Parallel or LAN port during initialization, or a defective I/O card.

Power OFF the Printer, disconnect the Parallel and/or the Network cable and power ON the Printer again to see if the Printer hangs again.

If the Printer did not hang again, then the problem was due to the Printer receiving data through the ports while the Printer was initializing. Before connecting the cables again, make sure that all the pending print jobs are purged.

If the Printer did hang again, then power OFF the Printer, remove the I/O card and power ON the Printer again to see if the Printer still hangs.

–If the Printer did not hang again, install the I/O card in the second slot and check whether it works there. If the I/O card causes the Printer to hang again, replace the I/O card. If the

Printer continues to hang, even with a new I/O card, then replace the Main PCA ŸPage 8-81.

HP DesignJet 5000 and 5500 Series Printers Service Manual |

1-21 |

Troubleshooting

3.The Printer is printing slower compared to another HP DesignJet 5000.

It is important first to determine whether the differences are during receiving/processing, during printing or once the print is finished.

1.The time the printer takes to start printing is longer.

Check that the "Start printing option" is set the same for all Printers.

NOTE |

For troubleshooting purposes, set this option to "After Processing". |

|

In this way the time reported is the time needed to receive the data |

|

and to process it and the printing time is not taken into account. |

|

If there are differences still, it is probably due to the customer’s |

|

|

|

network configuration. |

|

Make sure that the Printer is not processing or printing another job |

NOTE |

|

|

while doing this test, because this might have affect the outcome. |

|

|

Once finished, return the Printer to the recommended setting, which is "Optimized".

2.The actual printing time is slower.

This may be due to the Carriage stopping at the end of each swath, one Printer making more passes or the Carriage moving slower.

Check that the dry time is turned off.

NOTE |

If the dry time is turned ON, the Carriage might stop at the end of |

|

each swath, because the Printer uses the dry time (i.e. the humidity |

|

and temperature reading) to adjust the printing speed. This is |

|

necessary to ensure that the print is completely dry before it can |

|

either touch the Media Bin or is rolled up with the Take-Up Reel. |

|

Check that the Image Quality setting on the front panel (while the |

|

|

|

Printer is printing) is the same for all Printers. |

|

The setting while the Printer is in the stand-by mode might be |

NOTE |

|

|

different to the actual LED that lights up during printing. |

|

Check that the Image Quality setting in the Driver is the same for |

|

|

|

all the Printers. |

|

Check that the memory size, shown on the front panel, is the |

|

same for the Printers that are being compared. (Standard |

|

configuration: 192Mbyte for C6096A and 128Mbytes for |

|

C6090A/C6091A/C6095A). |

1-22 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

Troubleshooting

3.The dry time at the end of the print is longer.

Normally the Printer uses the temperature and the humidity reading from the ISS PCA to calculate the dry time, which is required for the print to dry before being cut. The specification of these readings is +/- 15%, so a variation in the calculated dry time of up to 30% is within specification.

To check the correct functioning of the sensor, print the "Service Configuration Print" and check that both the temperature and

humidity readings are correct (i.e. within the specification). If not, replace the ISS PCA ŸPage 8-91.

As an alternative solution, turn OFF the dry time, and then all the Printers should finish the print at the same time.

Another alternative is to set the dry time manually on all the Printers.

NOTE |

This dry time will be applied to all the prints. |

NOTE

Language Selection is blocked in a brand new printer

Normally the user has about 2 minutes (initialization time) to select the language in the Front Panel. If the language is not selected within this time period, the Front Panel is locked.

To recover from this problem, just re-boot the Printer and select the language within the specified time (2 minutes).

Firmware Upgrade Does Not Work Through the

Parallel Port

With firmware revisions A.01.10, 11 & 12, the Printer will remain at 90% when doing a Firmware upgrade via the parallel port.

For the customer, recommend using the network to print and to perform the Firmware upgrade.

For Service Engineers:

–Keep the "Top Arrow" key on the Front panel pressed down when turning the Printer ON, and release it once the "Boot Menu" appears.

–Select "Upgrade Firmware" in the Boot Menu.

–Send the firmware through the parallel port.

This problem is solved in any A.02.xx firmware release.

HP DesignJet 5000 and 5500 Series Printers Service Manual |

1-23 |

Troubleshooting

Typical Failures After Exchanging the Ink Tubes

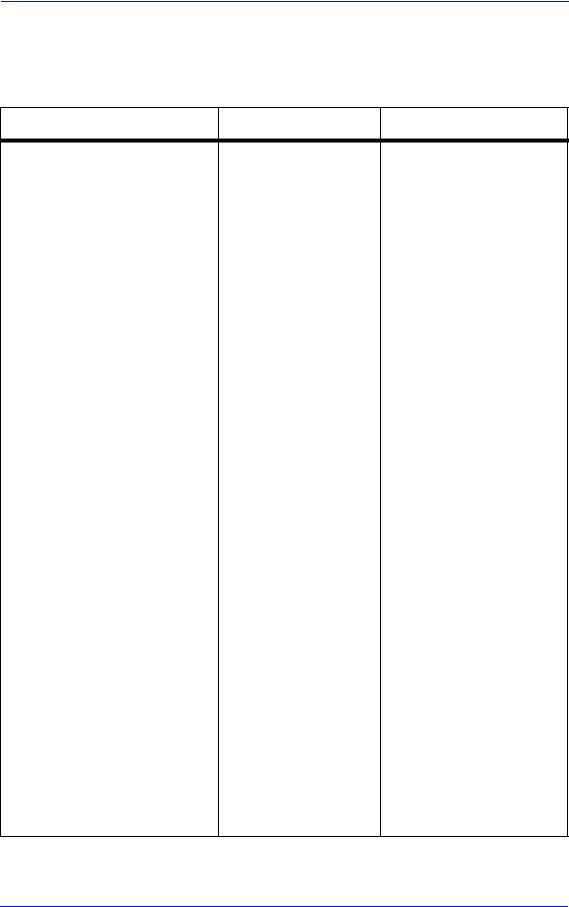

The following table contains typical failures that could appear after changing the Ink Tubes:

Failure |

Description |

Solution |

After completing the |

The electrical |

1 |

Switch OFF the Printer. |

|

initialization process, the Front |

connector has not |

2 |

Connect the electrical |

|

Panel displays: |

been correctly |

|

connector into the Ink |

|

WARNING |

connected to the Ink |

|

Cartridge tube connector. |

|

3 |

Switch ON the Printer. |

|||

Incorrect type of Tubes |

Cartridge connector. |

|||

|

|

|||

System |

|

|

|

|

Switch power off |

|

|

|

|

|

|

|

|

|

When you try to print, the |

The air tube has not |

1 |

Switch OFF the Printer. |

|

Front Panel displays: |

been correctly |

2 |

Connect the air tube into the |

|

System Error |

connected to the Ink |

3 |

Ink Cartridge tube connector. |

|

0a0000 00000002 |

Cartridge connector. |

Switch ON the Printer. |

||

Contact HP Representative |

|

|

|

|

|

|

|

|

|

When you try to insert an Ink |

The three latches at |

1 |

Remove the Ink Cartridges. |

|

Cartridge, you keep getting the |

the rear of the Ink |

2 |

Open the door at the back of |

|

following message for one or |

Cartridge tube |

3 |

the Left Hand Cover. |

|

more Ink Cartridge: |

connector have not |

Correctly lock the 3 latches. |

||

XX02 Reseat |

been locked correctly. |

4 |

Close the door and insert the |

|

|

|

|

Ink Cartridges. |

|

|

|

|

|

|

When you try to insert a |

The Printhead tube |

1 |

Remove any Printhead(s). |

|

Printhead, you keep getting the |

connector has not been |

2 |

Make sure the Printhead tube |

|

following message for one or |

correctly connected to |

|

connector is fully connected |

|

more Printhead: |

the Carriage Assembly. |

|

to the Carriage Assembly. |

|

3 |

Insert the Printheads. |

|||

XX02 Reseat |

|

|||

|

|

|

||

|

|

|

|

|

When you try to insert a |

Normal Printheads are |

1 |

Insert the Setup Printheads |

|

Printhead, you keep getting the |

being inserted BUT |

|

provided with the HP |

|

following message for one or |

the Printer requires |

|

Upgrade Kit that allows |

|

|

automatic printing. |

|||

more Printhead: |

Setup Printheads to |

|

||

|

|

|||

XX11 Reseat |

prime the Ink Tubes. |

|

|

|

|

|

|

|

|

After you have inserted the |

The wrong type of |

1 |

Remove the Printhead |

|

Printhead Cleaners, the Front |

Printhead Cleaners |

2 |

Cleaners. |

|

Panel displays the following |

have been inserted for |

Make sure that they are of the |

||

message: |

the type of Ink System |

|

same type as the rest of the |

|

|

consumables (No.81 or |

|||

XX05 Replace |

installed in the Printer. |

|

||

|

No.83). |

|||

|

|

|

||

|

|

3 |

Replace the incorrect ones. |

1-24 |

HP DesignJet 5000 and 5500 Series Printers Service Manual |

Loading...

Loading...