Abb TPS61-R35 User Manual

Operation Manual

TPS61-R35

HT594627 English

Original Operation Manual

Chapter |

Document-ID |

1 Introduction

HZTL4005_EN_G

2 Safety

HZTL4027_EN_A

3 Safety data sheet |

HT594627 |

4 Product description

HZTL4042_EN_C

ABB Turbocharging

Operating limits and replacement intervals

The recommended replacement intervals and the corresponding operating limits in chapter 3 are jointly defined with the enginebuilder. This information is specific to the product.

Non-observance of the recommended replacement intervals and the operating limits increases the risk of unpredictable component failures.

Operation Manual / 1 Introduction

Table of contents

Introduction |

|

|

1 |

Introduction............................................................................................................ |

2 |

1.1 |

Purpose of the manual.................................................................................................. |

2 |

1.2 |

Symbols, definitions...................................................................................................... |

3 |

1.3 |

Storage of new turbochargers and spare parts ...................................................... |

5 |

1.4 |

Contact information...................................................................................................... |

7 |

© Copyright 2020 ABB. All rights reserved. |

HZTL4005_EN |

Rev.G |

March 2020 |

Operation Manual / 1 Introduction

1 Introduction / 1.1 Purpose of the manual

1 Introduction

1.1Purpose of the manual

Page 2 / 7

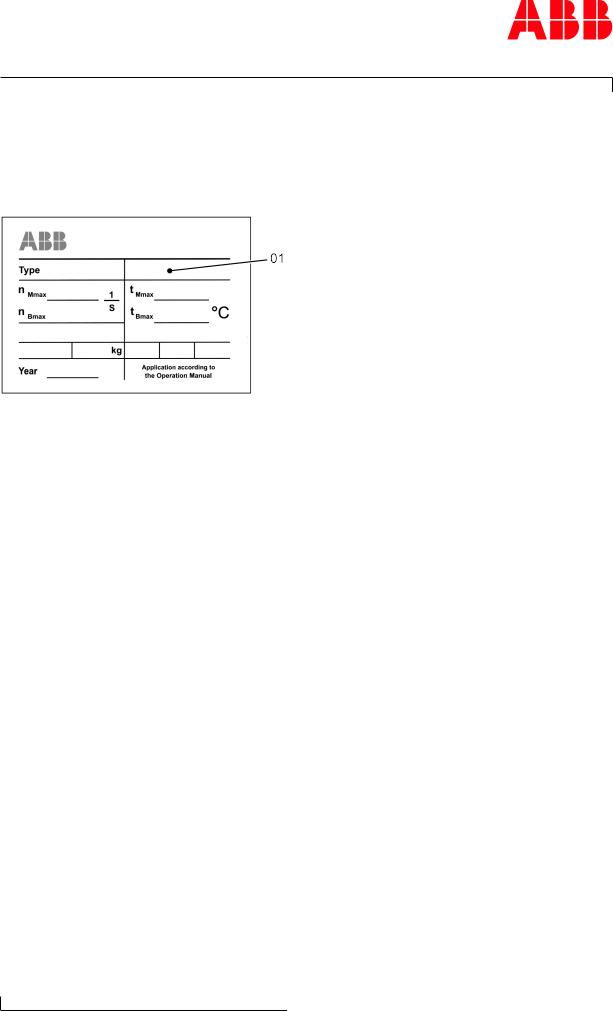

Fig. 1: Serial number (01) on the rating plate

This Operation Manual belongs to the turbocharger with the identical serial number (01), see chapter 3 (Safety data sheet) and the rating plate on the turbocharger.

Operation Manual

The Operation Manual explains the turbocharger and contains instructions for safe operation.

The Operation Manual is a complement to and expansion of existing national regulations for occupational safety, accident prevention and environmental protection.

Target group

The Operation Manual is aimed at engineers and trained mechanics responsible for the proper operation of the engine and for the turbocharger connected to it.

Availability of the Operation Manual

The Operation Manual must be available where the turbocharger is used.

All persons operating or working on the turbocharger must have read and fully understood the Operation Manual.

© Copyright 2020 ABB. All rights reserved. |

HZTL4005_EN |

Rev.G |

March 2020 |

Operation Manual / 1 Introduction

1 Introduction / 1.2 Symbols, definitions

1.2Symbols, definitions

Symbols

The following symbols are used in this document:

u Indicates an action step.

1. Indicates a numbered action step.

→ Refers to a page number

Definition of Note

NOTICE

Note

The note provides advice which facilitates the work.

Definition of mandatory signs

Mandatory signs show the protective equipment to be worn for a task. The mandatory signs are described in chapter Safety and must be complied with.

Definition of Caution / Warning

Caution and warning signs are described in chapter Safety.

ABB Turbocharging

ABB Switzerland Ltd, Turbocharging is identified as ABB Turbocharging or as ABB Turbo Systems in this document.

Official service stations of ABB Turbocharging

Official service stations are regularly audited and certified by ABB Turbocharging. See also chapter Contact information →7.

Page 3 / 7

© Copyright 2020 ABB. All rights reserved. |

HZTL4005_EN |

Rev.G |

March 2020 |

Page 4 / 7

Operation Manual / 1 Introduction

1 Introduction / 1.2 Symbols, definitions

Definition of pictograms

The following pictograms can occur in this document. These point out actions that must be taken in accordance with the meaning of the relevant pictogram.

Pictogram Meaning

Tighten with specified torque

Tighten over specified tightening angle

Hand-tight, tighten without tools

Oil

Apply screw locking paste (e.g. Loctite)

Apply high-temperature grease

Apply other paste in accordance with specifications

Oil free, grease free and dry

Affix

Measure

Note

Visually inspect

Please note text for numbered work step.

See document

Dispose of in an environmentally compatible, professional way and in compliance with locally applicable regulations.

Table 1: Definition of pictograms

© Copyright 2020 ABB. All rights reserved. |

HZTL4005_EN |

Rev.G |

March 2020 |

Operation Manual / 1 Introduction

1 Introduction / 1.3 Storage of new turbochargers and spare parts

1.3Storage of new turbochargers and spare parts

Storage of new turbochargers and spare parts up to 6 months

New turbochargers and spare parts can be stored in sealed packaging without additional mothballing measures for up to 6 months from the date of delivery (marked by the VCI label on the package).

Fig. 2: Volatile Corrosion Inhibitor (VCI)

Only dry rooms in which the relative humidity is between 40…70 % and no condensation can form are suitable for storage.

Storage of new turbochargers and spare parts for more than 6 months

WARNING

WARNING

Protection of health when handling VCIs

VCI products are not hazardous in the sense of the Hazardous Substances Ordinance. Nevertheless, the following points are to be observed when handling VCIs:

uObserve specifications in the safety data sheet

uEnsure good room ventilation.

uDo not eat, drink or keep food at the workplace while working with VCIs.

uClean hands and face after working with VCIs.

uFor further information refer to www.branopac.com.

Wear safety gloves to protect against mechanical hazards.

The following mothballing measures are required every 6 months:

uOpen the package.

uRemove the VCI corrosion protection emitter from the package and replace it with a new, identical VCI corrosion protection emitter. New VCI corrosion protection emitters can be obtained at www.branopac.com.

uDispose of the old VCI corrosion protection emitter in an environmentally compatible manner, professionally and in accordance with local regulations.

uSeal the package. The better the external seal is designed, the more permanent the protection.

Page 5 / 7

© Copyright 2020 ABB. All rights reserved. |

HZTL4005_EN |

Rev.G |

March 2020 |

Operation Manual / 1 Introduction

1 Introduction / 1.3 Storage of new turbochargers and spare parts

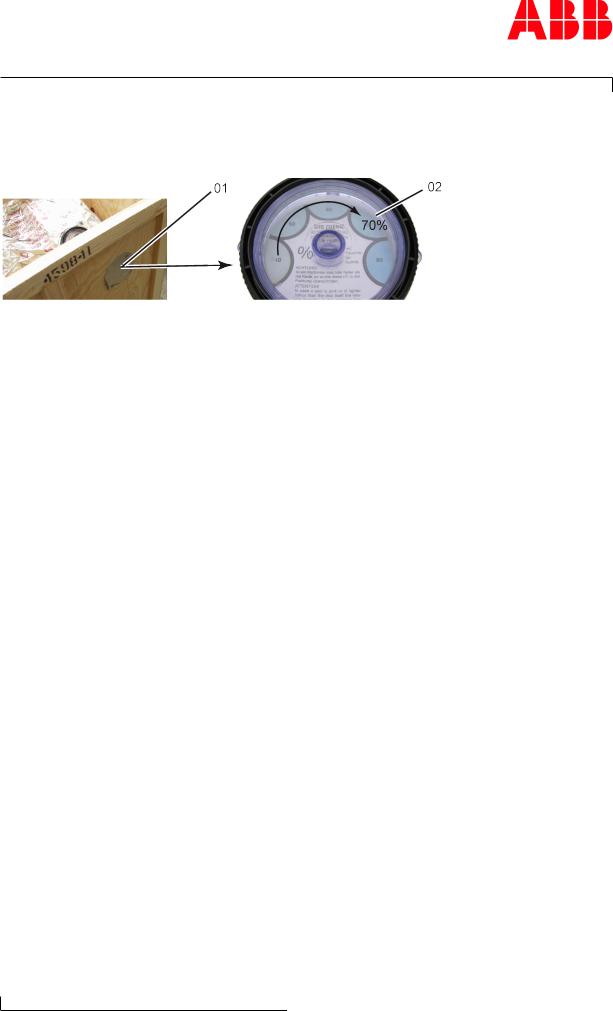

Long-term storage of turbochargers

The turbochargers will be prepared for prolonged storage by ABB Turbo Systems on request. The package is equipped with a hygrometer (see illustration).

Page 6 / 7

Fig. 3: Package with hygrometer

The following measures are required every 6 months:

uCheck the hygrometer (02) in the sight-glass. There is an opening (01) in the wooden crate which allows this check to be carried out. When the display field has changed colour at the 70% level, the maximum permissible humidity has been exceeded. In this case the turbocharger must be inspected by an ABB Turbocharging Service Station and repacked.

uInspect the package for damage. If the package is damaged, the turbocharger must be inspected by an ABB Turbocharging Service Station and repacked.

After every 3 years the following work steps must be performed by an ABB Turbocharging Service Station:

¡Inspect the components

¡Replace the desiccant agent

¡Repackage the components.

If the 70% display field of the hygrometer (02) has not changed colour and the package is undamaged, the turbocharger can be placed into operation without any prior testing by an ABB Turbocharging Service Station.

Unpacking turbochargers

The corrosion protection effect ends after the material is unpacked from the VCI package.

To avoid the formation of condensation, the surroundings and the content of the package must have the same temperature during unpacking.

© Copyright 2020 ABB. All rights reserved. |

HZTL4005_EN |

Rev.G |

March 2020 |

Operation Manual / 1 Introduction

1 Introduction / 1.4 Contact information

1.4Contact information

Contact information for the ABB Turbocharging Service Stations is available online.

u Scan the QR code to access our website.

ABB Switzerland Ltd, Turbocharging

Bruggerstrasse 71a

CH-5401 Baden

Switzerland

www.abb.com/turbocharging

Page 7 / 7

© Copyright 2020 ABB. All rights reserved. |

HZTL4005_EN |

Rev.G |

March 2020 |

Operation Manual / 2 Safety / TPS-R

Table of contents

Safety |

|

|

1 |

Safety ...................................................................................................................... |

2 |

1.1 |

Introduction .................................................................................................................... |

2 |

1.2 |

CE conformity................................................................................................................. |

2 |

1.3 |

Definition of mandatory signs .................................................................................... |

3 |

1.4 |

Definition of safety instructions ................................................................................ |

3 |

1.5 |

Intended use .................................................................................................................. |

4 |

1.6 |

Warning plates on the turbocharger.......................................................................... |

5 |

1.7 |

Turbocharger rating plate........................................................................................... |

6 |

1.8 |

Lifting of loads .............................................................................................................. |

8 |

1.9 |

Prerequisites for operation and maintenance........................................................ |

9 |

1.10 |

Hazards during operation and maintenance ......................................................... |

10 |

1.11 |

Safe operation .............................................................................................................. |

12 |

1.12 |

Safe maintenance ........................................................................................................ |

13 |

© Copyright 2018 ABB. All rights reserved. |

HZTL4027_EN |

Revision A |

April 2018 |

Page 2 / 16

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.1 Introduction

1 Safety

1.1Introduction

Turbochargers manufactured by ABB reflect the state of the art. The respective safety and health protection requirements are met. This ensures safe operation of the turbocharger. Nevertheless, there may be some residual risks during operation of and work on the turbocharger which:

¡Are caused by the turbocharger itself or its accessories.

¡Are caused by the operating equipment used or supplies and materials.

¡Are a consequence of insufficient compliance with safety instructions.

¡Are a consequence of insufficient or inappropriate performance of maintenance and inspection work.

The operating company is responsible for defining measures that regulate safe access to and safe handling of the turbocharger.

All instructions contained in this chapter must be observed for safe and trouble-free operation of the turbocharger and during all work on the turbocharger.

All further safety instructions contained and specifically identified in every chapter of this manual (Definition of safety instructions →3) must also be observed.

1.2CE conformity

Information

ABB turbochargers comply with the Machinery Directive 2006/42/EC and are partly completed machinery as defined by Article 2 g in this directive.

© Copyright 2018 ABB. All rights reserved. |

HZTL4027_EN |

Revision A |

April 2018 |

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.3 Definition of mandatory signs

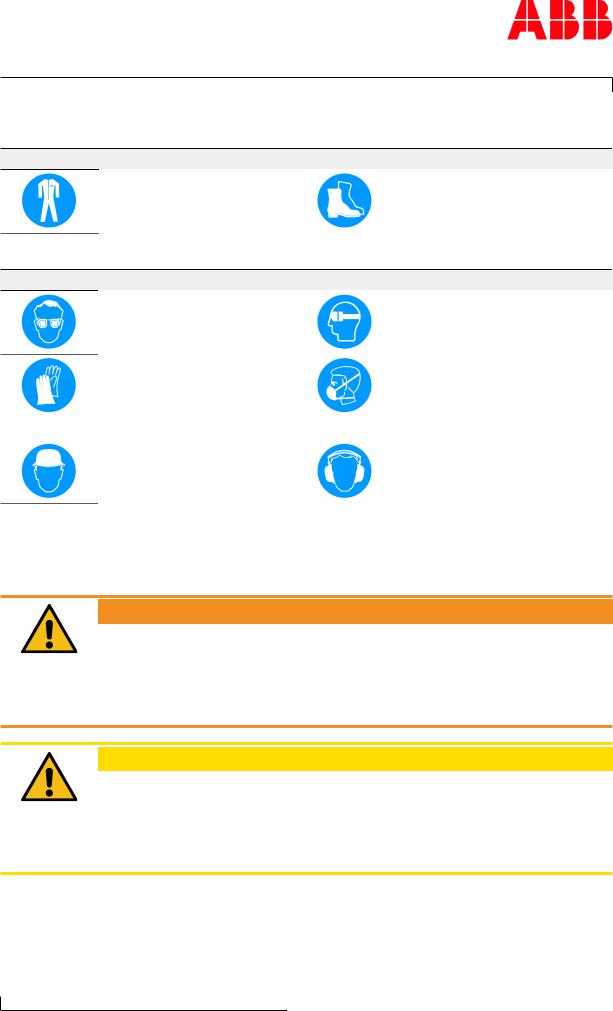

1.3Definition of mandatory signs

To be worn at all times

Protective clothing |

Safety footwear to protect |

|

against mechanical hazard and |

|

risk of falling |

Table 1: Personal protective equipment to be worn at all times

To be worn specific to the respective task

Safety glasses |

Safety goggles |

Safety gloves to protect |

Respiratory mask to protect |

against |

against |

- Mechanical hazard |

- Dusts |

- Chemical hazard |

- Gases |

- Thermal hazard |

|

- Electrical hazard |

|

Safety helmet |

Ear protection |

Table 2: Personal protective equipment to be worn specific to the respective task

1.4Definition of safety instructions

WARNING

WARNING

Definition of Warning

Non-compliance or inaccurate compliance with working or operating instructions indicated by this symbol and the word WARNING can lead to serious injuries to personnel and even to fatal accidents.

u Warning signs must always be observed.

CAUTION

CAUTION

Definition of Caution

Non-compliance or inaccurate compliance with working or operating instructions indicated by this symbol and the word CAUTION can lead to serious damage to engine or property with grave consequences.

u Caution signs must always be observed.

Page 3 / 16

© Copyright 2018 ABB. All rights reserved. |

HZTL4027_EN |

Revision A |

April 2018 |

Page 4 / 16

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.5 Intended use

1.5Intended use

Use on internal combustion engines in general

ABB turbochargers are intended for charging internal combustion engines.

The turbocharger supplies the engine with the air volume or air/gas mixture and the associated charging pressure required for operation.

The turbocharger is solely intended to be operated with a clockwise direction of rotation as viewed from the turbine end.

The specific operating limits of the turbocharger were determined on the basis of information from the enginebuilder about the intended use. These data are given on the rating plate.

ABB accepts no liability and rejects all warranty claims for any non-intended uses.

WARNING

WARNING

Unapproved operation

Any operation of the turbocharger outside of its operating limits can be hazardous to personnel.

uOnly operate the turbocharger within the operating limits.

uOnly trained personnel must operate the turbocharger.

The intended use of the turbocharger includes compliance with all regulations and conditions. In particular, the following must be observed:

¡Operation Manual

¡Instructions of the enginebuilder

State of the art

The turbocharger is designed and manufactured according to the state of the art and is safe to operate.

Perfect condition

The turbocharger must only be used when it is in a technically flawless condition and operated in compliance with its intended use.

ABB excludes any liability for damage resulting from unauthorized modifications to the turbocharger or improper operation.

© Copyright 2018 ABB. All rights reserved. |

HZTL4027_EN |

Revision A |

April 2018 |

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.6 Warning plates on the turbocharger

1.6Warning plates on the turbocharger

Warning plates are attached to the turbocharger, which must be observed. The warning plates must always be present in the intended locations and must be legible.

Fig. 1: Warning plate

If warning plates are not present in the intended locations or are not legible, they must be replaced with new warning plates. The necessary information can be found in the Operation Manual, Chapter 4 Product description.

Turbochargers supplied to the enginebuilder without insulation must be equipped later with warning plates on the insulation. This is the responsibility of the enginebuilder.

Page 5 / 16

© Copyright 2018 ABB. All rights reserved. |

HZTL4027_EN |

Revision A |

April 2018 |

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.7 Turbocharger rating plate

1.7Turbocharger rating plate

Page 6 / 16

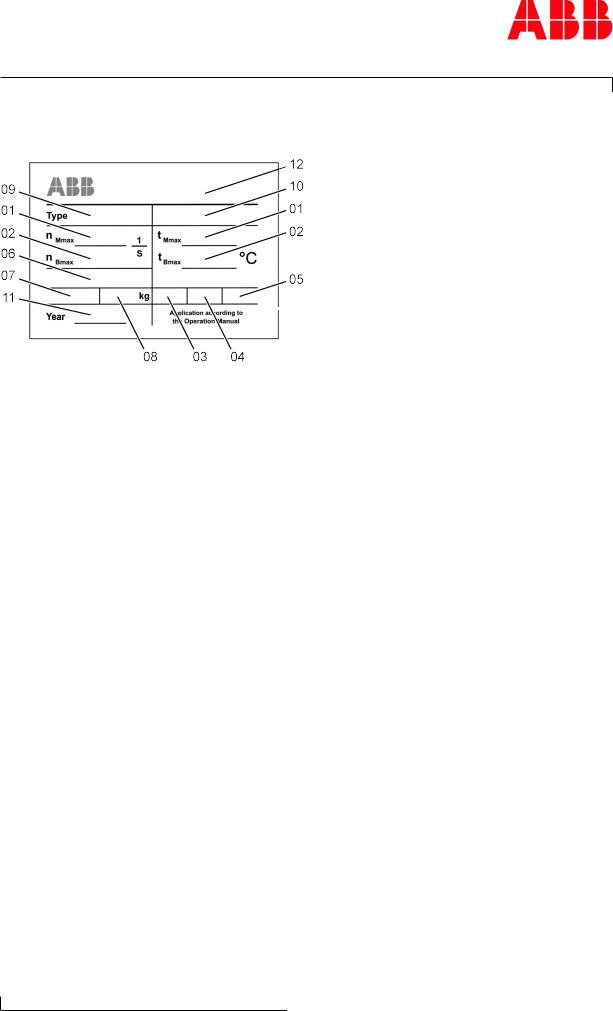

Fig. 2: Rating plate

Operating limits

01Turbocharger operating limits at engine overload (110 %).

In test rig operation only, unless otherwise agreed with the enginebuilder.

02 Turbocharger operating limits during operation

Recommended inspection and replacement intervals of turbocharger components

03 Inspection interval of plain bearings in 1000 h

04 Replacement interval of compressor in 1000 h

05 Replacement interval of turbine in 1000 h

Further data

06 Customer part number

07 Designation for special design

08 Weight of turbocharger in kg

09Turbocharger type

10Serial number

11Year of construction of turbocharger

12Manufacturing plant

© Copyright 2018 ABB. All rights reserved. |

HZTL4027_EN |

Revision A |

April 2018 |

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.7 Turbocharger rating plate

Explanations regarding the rating plate

The recommended inspection and replacement intervals and the corresponding operating limits are jointly defined with the enginebuilder. This information is specific to the system.

Operation above the indicated values nBmax, tBmax can considerably shorten the recommended replacement intervals. In such a case, we recommend that you contact the nearest official service station of ABB Turbo Systems.

nMmax, tMmax normally apply only when running at overload (110 %) during trials on the engine test bed. These limit values can also be permitted during operation for special applications. Operation above nMmax and tMmax is not permitted.

Non-observance of the recommended inspection and replacement intervals increases the risk of unpredictable component failures.

Locations of the rating plates

The locations of the rating plates are defined in the Operation Manual, Chapter 4 Product description.

Page 7 / 16

© Copyright 2018 ABB. All rights reserved. |

HZTL4027_EN |

Revision A |

April 2018 |

Page 8 / 16

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.8 Lifting of loads

1.8Lifting of loads

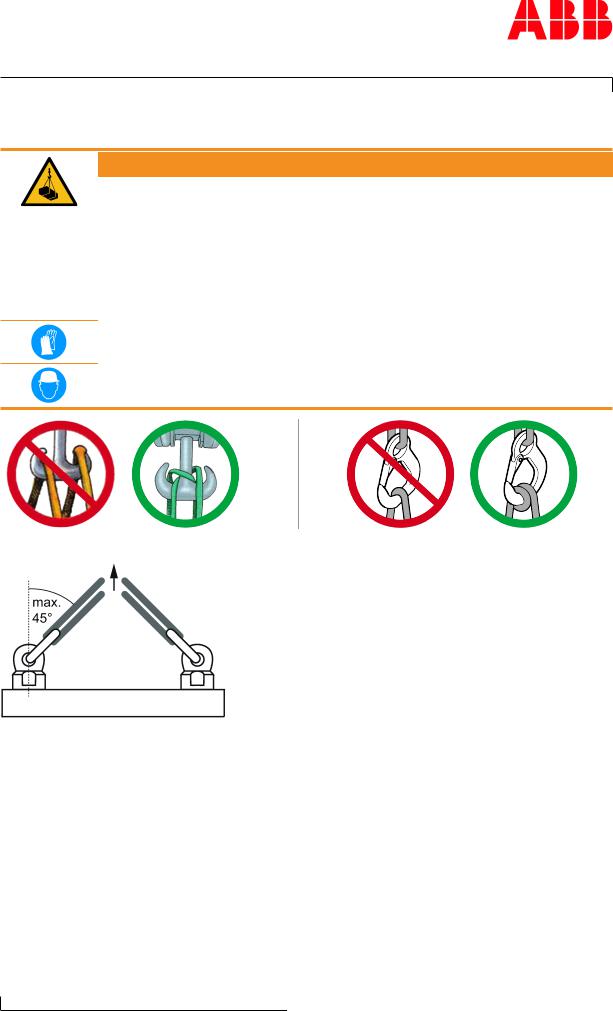

WARNING

WARNING

Suspended loads

Loads that are not attached according to regulations can cause injury to personnel or fatal accidents.

uLoads must always be fastened to properly functional lifting gear with a sufficient load limit.

uPay attention to the correct attachment of loads on the crane hook.

uPeople must not stand beneath suspended loads.

Wear safety gloves to protect against mechanical hazards.

Wear safety helmet.

Fig. 3: Attachment of loads on the crane hook

Fig. 4: Attachment angle

If there are two or more suspension points, the attachment angle of 45° must not be exceeded. This prevents excessive loading due to diagonal pull.

uBefore looping around the components of the turbocharger, let them cool down (maximum 80 °C).

uAttach components of the turbocharger as described in the respective action steps.

uUse a suitable edge guard if there are sharp edges.

uThe assembly devices must be completely screwed in and must not unscrew during use.

uUse assembly devices only for the described applications.

uPut down dismantled components of the turbocharger in such a way that they cannot tip over.

© Copyright 2018 ABB. All rights reserved. |

HZTL4027_EN |

Revision A |

April 2018 |

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.9 Prerequisites for operation and maintenance

1.9Prerequisites for operation and maintenance

Responsibility of the operating company

In awareness of its responsibility, the operating company must ensure that only authorised

personnel work on the turbocharger, who:

¡Are versed in the general and locally applicable regulations for occupational safety and accident prevention

¡Are equipped with the prescribed personal protective equipment

¡Have read and understood the Operation Manual

¡Have been instructed in the use of the turbocharger.

The safety-conscious work of the personnel and adherence to the Operation Manual must be checked periodically.

Suitable working materials and personal protective equipment must be kept in a perfect condition.

Only authorised personnel may remain in the vicinity of the turbocharger when the engine is running.

Competence of personnel

The turbocharger must only be operated and serviced by trained and authorised personnel. Basic mechanical training is a prerequisite.

Modifications to the turbocharger

Modifications to the turbocharger must be approved by ABB Turbo Systems.

WARNING

WARNING

Use original parts

Operation of the turbocharger with non-original parts can impair the safety of the turbocharger and can cause serious damage to property and injury to personnel.

u Only use original parts from ABB.

Original parts and accessories are specially designed for ABB turbochargers.

ABB accepts no liability for any damage resulting from the use of non-original parts and corresponding accessories.

Page 9 / 16

© Copyright 2018 ABB. All rights reserved. |

HZTL4027_EN |

Revision A |

April 2018 |

Page 10 / 16

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.10 Hazards during operation and maintenance

1.10Hazards during operation and maintenance

Noise hazards

The turbocharger's noise emission is influenced by its installation and operating conditions. A noise level exceeding 85 dB(A) is harmful.

WARNING

WARNING

Danger due to noise

Exposure to noise can harm the hearing system, impair health and the psychological state and may lead to lack of attention and irritation.

uWhen the engine is running, always wear ear protection.

uAlways wear ear protection if the sound pressure level exceeds 85 dB(A).

Wear ear protection.

Hazards due to hot surfaces

Surfaces of the turbocharger, attached parts and operating fluids (lubricating oil) get hot during operation. The surface temperature depends on the efficacy of the existing insulation. The temperature may rise to a level that can cause burns.

WARNING

WARNING

Danger of burns

Touching hot surfaces or contact with hot operating fluids can cause burns.

uDo not touch hot surfaces. Observe the warning plate on the turbocharger.

uWear heat-resistant safety gloves and protective clothing.

uWait for the turbocharger to cool down before carrying out any work.

Wear safety gloves to protect against thermal hazards.

© Copyright 2018 ABB. All rights reserved. |

HZTL4027_EN |

Revision A |

April 2018 |

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.10 Hazards during operation and maintenance

WARNING

WARNING

Hot surfaces on a non-insulated turbocharger

Non-insulated turbochargers can cause serious injuries to personnel (burns).

The turbocharger is supplied with or without insulation in accordance with the purchase order received from the enginebuilder. If supply is without insulation, the enginebuilder is responsible for providing the turbocharger with proper insulation and for providing protection against contact with hot surfaces.

uCompliance with the instructions and specifications given by the enginebuilder to protect against hot turbocharger surfaces is compulsory.

Wear safety gloves to protect against thermal hazards.

Hazards due to rotating parts

WARNING

WARNING

Physical hazards

Contact with rotating parts can cause severe injury. The turbocharger must never be used without the filter silencer or the air suction branch. With the engine stopped, the rotor can rotate due to the stack draught alone.

uOperate the turbocharger in compliance with the specifications.

uSecure the rotor against unintentional rotation during maintenance.

Wear safety gloves to protect against mechanical hazards.

Page 11 / 16

© Copyright 2018 ABB. All rights reserved. |

HZTL4027_EN |

Revision A |

April 2018 |

Loading...

Loading...