Trane OA B D 000, OA G D 000, OA B E 000, OA G E 000, OA B D 036 Installation, Operation And Maintenance Manual

...

Installation, Operation,

and Maintenance

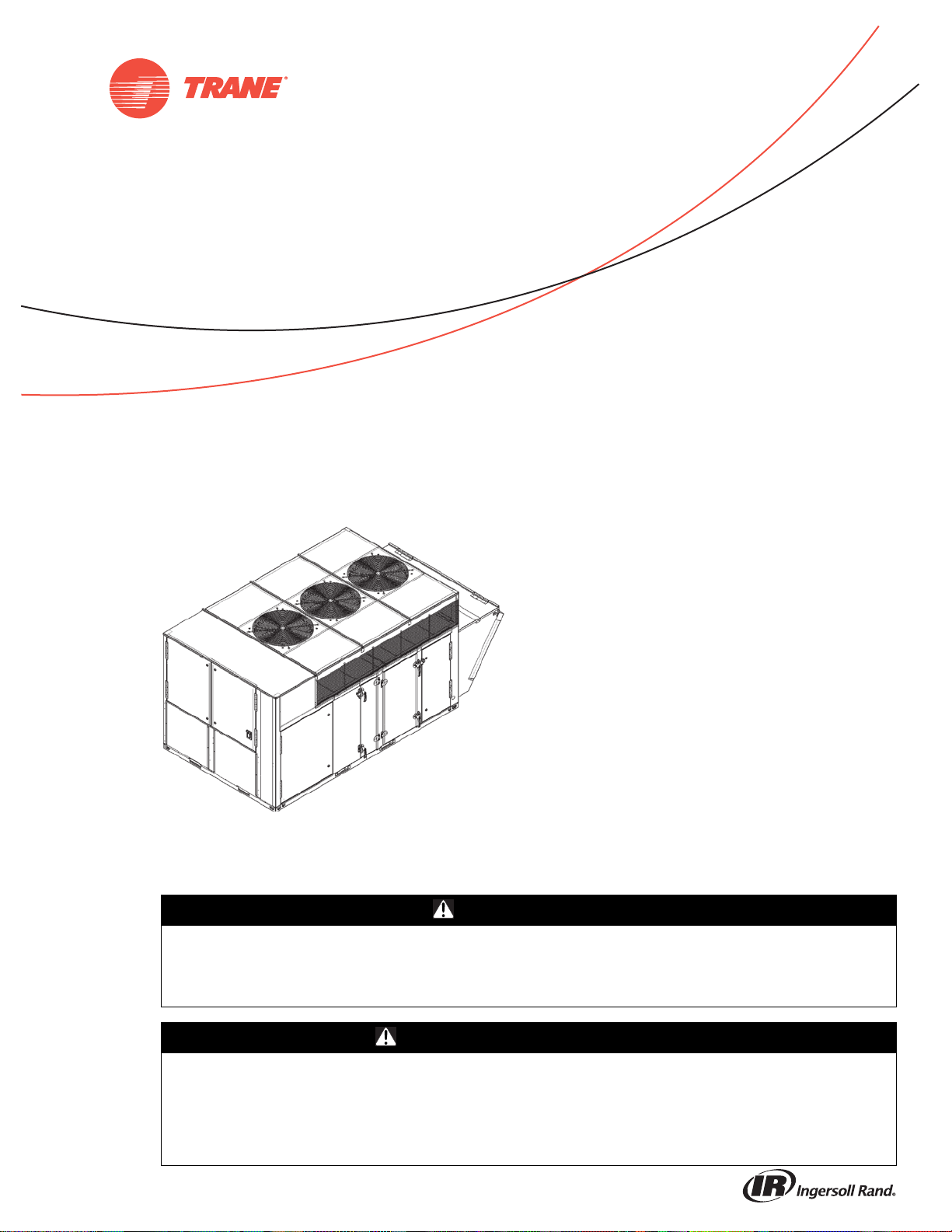

Horizon™ Outdoor Air Unit

Direct Gas-Fired

Model: OAB, OAG

Important: Proper execution of the tasks outlined in this Installation, Operation, and Maintenance manual

require and assume the technician has been certified as a start up technician for the Horizon Outdoor

Air unit. This includes working knowledge of the Tracer TU program.

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing

of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and

training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the literature and on the tags,

stickers, and labels that are attached to the equipment.

AVERTISSEMENT DE SÉCURITÉ

L’installation et l’entretien de cet équipement doivent être assurés exclusivement par du personnel qualifié.

L’installation, la mise en service et l’entretien d’équipements de chauffage, de ventilation et de climatisation

(CVC) présentent un danger et requièrent des connaissances et une formation spécifiques. Une installation,

un réglage ou une modification inappropriés d’un équipement par une personne non qualifiée peut provoquer

des blessures graves, voire la mort. Lors de toute intervention sur l’équipement, respectez les consignes de

sécurité figurant dans la documentation, ainsi que sur les pictogrammes, autocollants et étiquettes apposés

sur l’équipement.

November 2019

OAU-SVX005C-EN

Introduction

Read this manual thoroughly before operating or servicing

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Your personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment. Trane advocates the responsible handli ng of

all refrigerants-including industry replacements for CFCs

and HCFCs such as saturated or unsaturated HFCs and

HCFCs.

AVERTISSEMENT

Câblage sur site et mise à la terre corrects

nécessaires!

Le non-respect de la réglementation peut entraîner des

blessures graves, voire mortelles. Il est IMPÉRATIF de

confier l’ensemble du câblage sur site à un électricien

qualifié. Un câblage sur site mal installé ou mal mis à la

terre constitue des risques D’INCENDIE et

D’ÉLECTROCUTION. Pour éviter ces risques, il est

IMPÉRATIF de respecter les obligations en matière de

pose de câblage sur site et de mise à la terre tel que

stipulé dans les règles du NEC et dans les

réglementations électriques locales/nationales.

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified according to local rules. For

the USA, the Federal Clean Air Act (Section 608) sets forth

the requirements for handling, reclaiming, recovering and

recycling of certain refrigerants and the equipment that is

used in these service procedures. In addition, some states

or municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

© 2019 Ingersoll Rand OAU-SVX005C-EN

Introduction

WARNING

Personal Protective Equipment (PPE)

Required!

Failure to wear proper PPE for the job being undertaken

could result in death or serious injury. Technicians, in

order to protect themselves from potential electrical,

mechanical, and chemical hazards, MUST follow

precautions in this manual and on the tags, stickers,

and labels, as well as the instructions below:

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut resistant gloves/sleeves,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of energized electrical contact, arc, or

flash, technicians MUST put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

AVERTISSEMENT

Équipements de protection individuelle

(EPI) obligatoires!

En cas d’équipement de protection individuelle

inadapté au travail entrepris, les techniciens s’exposent

à des risques de blessures graves voire mortelles. Afin

de se prémunir d’éventuels risques électriques,

mécaniques et chimiques, les techniciens DOIVENT

respecter les consignes préconisées dans le présent

manuel, sur les étiquettes et les autocollants, ainsi que

les instructions suivantes :

• Avant d’installer/réparer cette unité, les techniciens

doivent IMPÉRATIVEMENT porter tout l’équipement

de protection individuelle (EPI) recommandé pour le

travail entrepris (exemples: gants/manchons

résistants aux coupures, gants en caoutchouc butyl,

lunettes de protection, casque de chantier/antichoc,

protection contre les chutes, EPI pour travaux

électriques et vêtements de protection contre les arcs

électriques). Consulter SYSTÉMATIQUEMENT les

fiches de données de sécurité et les directives de

l’OSHA pour connaître la liste des EPI adaptés.

• Lors d’une intervention avec ou à proximité de

produits chimiques dangereux, consulter

SYSTÉMATIQUEMENT les fiches de données de

sécurité appropriées et les directives de l’OSHA/du

SGH (système général harmonisé de classification et

d’étiquetage des produits chimiques) afin d’obtenir

des renseignements sur les niveaux admissibles

d’exposition personnelle, la protection respiratoire

adaptée et les recommandations de manipulation.

• En cas de risque d’éclair, d’arc électrique ou de

contact électrique avec un équipement électrique

sous tension, et AVANT de réparer l’unité, les

techniciens doivent IMPÉRATIVEMENT porter tout

l’équipement de protection individuelle (EPI)

conformément à l’OSHA, à la norme NFPA 70E ou à

toute autre exigence propre au pays pour la

protection contre les arcs électriques. NE JAMAIS

COMMUTER, DÉBRANCHER ou EFFECTUER DE TEST

DE TENSION SANS PORTER UN EPI POUR TRAVAUX

ÉLECTRIQUES OU UN VÊTEMENT DE PROTECTION

APPROPRIÉ CONTRE LES ARCS ÉLECTRIQUES. IL

CONVIENT DE S’ASSURER QUE LES COMPTEURS ET

ÉQUIPEMENTS ÉLECTRIQUES CORRESPONDENT À

LA TENSION NOMINALE PRÉVUE.

OAU-SVX005C-EN 3

Introduction

WARNING

Follow EHS Policies!

Failure to follow instructions below could result in

death or serious injury.

• All Ingersoll Rand personnel must follow Ingersoll

Rand Environmental, Health and Safety (EHS)

policies when performing work such as hot work,

electrical, fall protection, lockout/tagout, refrigerant

handling, etc. All policies can be found on the BOS

site. Where local regulations are more stringent than

these policies, those regulations supersede these

policies.

• Non-Ingersoll Rand personnel should always follow

local regulations.

AVERTISSEMENT

Respecter les politiques EHS!

Le non-respect des consignes suivantes peut être à

l’origine de blessures graves, voire mortelles.

• Tous les membres du personnel du groupe Ingersoll

Rand sont tenus de respecter les règles établies par

Ingersoll Rand en matière d’environnement,

d’hygiène et de sécurité (EHS) lors d’une

intervention, notamment en cas de travaux à chaud,

de risque d’électrocution et de chute, de procédures

de verrouillage/mise hors service, de manipulation

de fluide frigorigène, etc. Toutes les politiques sont

disponibles sur le site BOS. Si les réglementations

locales sont plus strictes que les règles imposées par

le groupe, elles deviennent prioritaires.

• Le personnel extérieur au groupe Ingersoll Rand est,

quant à lui, systématiquement tenu d’observer les

réglementations en vigueur à l’échelle locale.

WARNING

Refrigerant under High Pressure!

Failure to follow instructions below could result in an

explosion which could result in death or serious injury

or equipment damage. System contains oil and

refrigerant under high pressure. Recover refrigerant to

relieve pressure before opening the system. See unit

nameplate for refrigerant type. Do not use nonapproved refrigerants, refrigerant substitutes, or

refrigerant additives.

AVERTISSEMENT

Fluide frigorigène sous haute pression!

Tout manquement aux instructions indiquées cidessous peut provoquer une explosion pouvant causer

des blessures graves voire mortelles ou des dommages

matériels. Le système contient de l’huile et du fluide

frigorigène sous haute pression. Avant d’ouvrir le

circuit, récupérez le fluide frigorigène pour éliminer

toute pression dans le circuit. Consultez la plaque

constructeur de l’unité pour connaître le type de fluide

frigorigène employé. Utilisez uniquement des fluides

frigorigènes, substituts et additifs agréés.

WARNING

Hazard of Explosion and Deadly Gases!

Failure to follow all proper safe refrigerant handling

practices could result in death or serious injury.

Never solder, braze or weld on refrigerant lines or any

unit components that are above atmospheric pressure

or where refrigerant may be present. Always remove

refrigerant by following the guidelines established by

the EPA Federal Clean Air Act or other state or local

codes as appropriate. After refrigerant removal, use dry

nitrogen to bring system back to atmospheric pressure

before opening system for repairs. Mixtures of

refrigerants and air under pressure may become

combustible in the presence of an ignition source

leading to an explosion. Excessive heat from soldering,

brazing or welding with refrigerant vapors present can

form highly toxic gases and extremely corrosive acids.

AVERTISSEMENT

Risque d’explosion et gaz mortels!

Le non-respect de toutes les consignes de manipulation

des fluides frigorigènes peut entraîner la mort ou des

blessures graves.

N’effectuez en aucune circonstance des opérations de

brasage ou de soudage sur des conduites de fluide

frigorigène ou des composants de l’unité sous pression

ou pouvant contenir du fluide frigorigène. Récupérez

systématiquement le fluide frigorigène en respectant

les directives de la loi américaine sur la propreté de l’air

(Agence fédérale pour l’environnement) ou toute autre

réglementation nationale ou locale en vigueur. Après la

récupération du fluide frigorigène, utilisez de l’azote

déshydraté pour ramener le système à la pression

atmosphérique avant de l’ouvrir pour procéder aux

réparations. Les mélanges de fluide frigorigène et d’air

sous pression peuvent devenir combustibles en

présence d’une source d’inflammation et provoquer

une explosion. La chaleur excessive découlant de

travaux de soudage ou de brasage associée à la

présence de vapeurs de fluide frigorigène peut entraîner

la formation de gaz hautement toxiques et d’acides

extrêmement corrosifs.

4 OAU-SVX005C-EN

Introduction

WARNING

Hazard of Explosion and Deadly Gases!

Failure to follow instructions could result in death or

serious injury.

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

AVERTISSEMENT

Risque d’explosion et gaz mortels!

Le non-respect de toutes les consignes de sécurité cidessous peut entraîner la mort ou des blessures graves.

Si vous sentez une odeur de gaz:

1. Ouvrez les fenêtres.

2. Ne touches à aucun interrupteur.

3. Éteignez toute flamme nue.

4. Avertissez immédiatement votre fournisseur de gaz.

AVERTISSEMENT

Risque d’explosion et gaz mortels!

Le non-respect de toutes les consignes de sécurité cidessous peut entraîner la mort ou des blessures graves.

Il est dangereux d’utiliser ou d’entreposer de l’essence

ou autres liquides ou vapeurs inflammables dans des

récipients ouverts à proximité de cet appareil.

Copyright

This document and the information in it are the property of

Trane, and may not be used or reproduced in whole or in

part without written permission. Trane reserves the right

to revise this publication at any time, and to make changes

to its content without obligation to notify any person of

such revision or change.

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

Added French language translations of warnings.

WARNING

Hazardous Service Procedures!

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or

death. Read the installation, operating and

maintenance instructions thoroughly before installing

or servicing this equipment.

AVERTISSEMENT

Procédures d’entretien dangereuses!

Une installation, un réglage, une modification, une

réparation ou un entretien incorrect peut entraîner des

dommages matériels, des blessures ou la mort. Lisez

attentivement les instructions d’installation, de

fonctionnement et d’entretien avant de procéder à

l’installation ou à l’entretien de cet équipement.

WARNING

Hazard of Explosion and Deadly Gases!

Failure to follow instructions could result in death or

serious injury.

The use and storage of gasoline or other flammable

vapors and liquids in open containers in the vicinity of

this appliance is hazardous.

OAU-SVX005C-EN 5

Table of Contents

Model Number Descriptions . . . . . . . . . . . . . . 8

Horizon Outdoor Air Unit . . . . . . . . . . . . . . . 8

General Information . . . . . . . . . . . . . . . . . . . . 11

Overview of Manual . . . . . . . . . . . . . . . . . 11

Model Number Description . . . . . . . . . . . 11

Unit Nameplate . . . . . . . . . . . . . . . . . . . . 11

Compressor Nameplate . . . . . . . . . . . . . . 11

Unit Description . . . . . . . . . . . . . . . . . . . . 11

Indoor Fan Failure Input . . . . . . . . . . . . . 11

Low Pressure Control ReliaTel Control . 11

Refrigerant Circuits . . . . . . . . . . . . . . . . . 11

High Pressure Control ReliaTel Control . 11

Space Temperature / RH Sensor (Optional)

12

High Temperature Sensor . . . . . . . . . . . . 12

Outdoor Air Temperature and Relative Hu-

midity Sensor . . . . . . . . . . . . . . . . . . . . . . 12

Control Input (Occupied / Unoccupied) . 12

Hot Gas Reheat . . . . . . . . . . . . . . . . . . . . . 12

100 Percent Outdoor Air Hood with Damper

and Filters . . . . . . . . . . . . . . . . . . . . . . . . . 12

Through the Base Electrical with Disconnect

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hinged Access Doors . . . . . . . . . . . . . . . . 12

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . 12

First Aid Measures . . . . . . . . . . . . . . . . . . 13

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Unit Clearances . . . . . . . . . . . . . . . . . . . . 13

Filter Installation . . . . . . . . . . . . . . . . . . . . .19

Field Installed Power Wiring . . . . . . . . . . .20

Main Unit Power . . . . . . . . . . . . . . . . . . . . . .21

Standard Wiring . . . . . . . . . . . . . . . . . . . . .21

Voltage Imbalance . . . . . . . . . . . . . . . . . . .21

Electrical Phasing (Three-Phase Motors) .22

Compressor Crankcase Heaters . . . . . . . .23

Main Unit Display and ReliaTel Controls .23

Field-Installed Control Wiring . . . . . . . . . .23

Control Power Transformer . . . . . . . . . . .23

Controls Using 24 Vac . . . . . . . . . . . . . . . . 24

Controls Using DC Analog Input/Output

(Standard Low Voltage Multiconductor Wire)

24

DC Conductors . . . . . . . . . . . . . . . . . . . . . . . .25

System Configuration and Pre-Start . . . . . . .26

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Direct Heating Startup . . . . . . . . . . . . . . . . .29

Direct Gas-Fired Heating Start-Up Procedure

30

Initiate . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Normal Start-up Pre-purge . . . . . . . . . . . .33

Ignition Trials . . . . . . . . . . . . . . . . . . . . . . .33

Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Settings and Adjustments . . . . . . . . . . . . .34

Operation of the Direct Spark Ignition Control

Gas Valve . . . . . . . . . . . . . . . . . . . . . . . . . .34

Unit Clearances, Curb Dimensions, and Dimensional Data

Direct-Fired OAB Units . . . . . . . . . . . . . . . 14

Direct-Fired OAG Units . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Unit Weight and Rigging . . . . . . . . . . . . . . . . 16

Unit Weight . . . . . . . . . . . . . . . . . . . . . . . . 16

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . 18

General Unit Requirements . . . . . . . . . . . 18

Main Electrical Power Requirements . . . 19

Condensate Drain Configuration . . . . . . 19

6 OAU-SVX005C-EN

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Monthly Maintenance . . . . . . . . . . . . . . . . . .36

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Supply/Return Air Smoke Detector Mainte-

nance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Cooling Season . . . . . . . . . . . . . . . . . . . . .36

Heating Season . . . . . . . . . . . . . . . . . . . . .36

Condenser Coil Cleaning . . . . . . . . . . . . . .36

Direct-Fired Unit Maintenance Schedule . .38

Lubrication Requirements . . . . . . . . . . . . .39

Pillow Block Bearings . . . . . . . . . . . . . . . . 40

Frequency of Lubrication . . . . . . . . . . . . . .40

Dampers . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Belt Tensions and Adjustments . . . . . . . 41

Suggested Belt Tension Method . . . . . . . 41

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Annual Maintenance . . . . . . . . . . . . . . . . 41

Heater Maintenance . . . . . . . . . . . . . . . . . 41

Inspection and Maintenance of Gas Ports 43

Final Process . . . . . . . . . . . . . . . . . . . . . . . . . 43

Performance Data . . . . . . . . . . . . . . . . . . . . . . 45

Superheat and Refrigeration Circuit Data 49

Alarms and Troubleshooting . . . . . . . . . . . . 51

Microprocessor Control . . . . . . . . . . . . . . 51

System Alarms . . . . . . . . . . . . . . . . . . . . . 51

Sensor Failure Alarm Display . . . . . . . . . 51

RTRM Failure Modes . . . . . . . . . . . . . . . . 53

Airflow Troubleshooting . . . . . . . . . . . . . 53

Direct-Fired OAB and OAG Unit Flame Relays

£ 400 MBh . . . . . . . . . . . . . . . . . . . . . . . . . 54

Direct-Fired OAG Unit Flame Relays >

400 MBh . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table of Contents

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

OAU Filter Guide . . . . . . . . . . . . . . . . . . . . . 59

OAU-SVX005C-EN 7

Model Number Descriptions

Horizon Outdoor Air Unit

Digit 1, 2 — Unit Type

OA = Outdoor Air

Digit 3 — Cabinet Size

B = 500 cfm–3,000 cfm

G = 1,250 cfm–7,500 cfm

Digit 4 — Major Design

Sequence

D = Revision 1

E = Heat Pump

Digit 5, 6, 7 — Normal Gross

Cooling Capacity (MBh)

000 = No Cooling

036 = 3 Tons High Efficiency

048 = 4 Tons High Efficiency

060 = 5 Tons High Efficiency

072 = 6 Tons High Efficiency

084 = 7 Tons High Efficiency

096 = 8 Tons High Efficiency

108 = 9 Tons High Efficiency

120 = 10 Tons High Efficiency

144 = 12 Tons High Efficiency

180 = 15 Tons High Efficiency

210 = 17 Tons High Efficiency

240 = 20 Tons High Efficiency

264 = 22 Tons High Efficiency

300 = 25 Tons High Efficiency

360 = 30 Tons High Efficiency

Digit 8 — Minor Design

Sequence

A = Vertical Discharge/Vertical Return

B = Vertical Discharge/

C = Horizontal Discharge/

D = Horizontal Discharge/

Horizontal Return

Vertical Return

Horizontal Return

Digit 9 — Voltage Selection

1 = 115/60/1

2 = 208-230/60/1

3 = 208-230/60/3

4 = 460/60/3

5 = 575/60/3

Digit 10 — Reserved for Future

Use

Digit 11 — Evaporator Type

0 = No Cooling

A = DX 3-Row

B = DX 4-Row

C = DX 4-Row Interlaced

D = DX 6-Row Interlaced

E = DX 8-Row

F = Glycol/Chilled Water Coil

G = DX 4-Row with

MSP

®

Technology

Digit 12 — Hot Gas Reheat

0= No HGRH

1 = Fin and Tube Modulating

2 = Fin and Tube On/Off

3 = Microchannel Modulating

4 = Microchannel On/Off

Digit 13 — Compressor

0= No Compressors

A = Scroll Compressors

B = Digital Scroll (1

C = Digital Scroll (1

D = Variable Speed Scroll (1

E = Variable Speed Scroll (1

Circuit Only)

nd

Circuit)

2

st

Circuit Only)

st

and 2nd Circuit)

st

st

and

Digit 14 — Condenser

0 = No Condenser

1 = Air-Cooled Fin and Tube

2 = Air-Cooled Fin and Tube

3 = Water-Cooled DX Condenser

4 = Air-Cooled Fin and Tube

5 = Air-Cooled Microchannel

6 = Air-Cooled Microchannel

7 = Air-Cooled Microchannel

8 = Water-Cooled DX Condenser

w/Head Pressure On/Off Control

Copper/Steel

w/Head Pressure Variable Speed

w/Head Pressure On/Off Control

Variable Speed

Copper/Nickel

Digit 15 — Refrigerant Capacity

Control

0 = No RCC Valve

A = RCC Valve on 1

B = RCC Valve on 1

C = ERCC Valve on 1

D = ERCC Valve on 1

E = HGBP Valve on 1

F = HGBP Valve on 1

nd

2

Circuit

st

Circuit

st

and 2nd Circuit

st

Circuit

st

and 2nd Circuit

st

Circuit

st

and

Digit 16 — Indoor Fan Motor

(IFM)

0 = ECM w/Backward Curved

1 = Direct Drive w/ VFD

2 = Belt Drive

3 = Belt Drive w/VFD

4 = Special Motor Option

Plenum Fan

Digit 17 — Indoor Fan Wheel

A = 355

B = 450

C = 450 X 2

D = 12/9 T2 (Single Fan—Belt Drive)

E = 12/9 BT (Dual Fan—Belt Drive)

Digit 18 — Indoor Fan Motor

Power (hp)

ECM Belt Drive

A = 1 kW 2 hp

B = 2 kW 3 hp

C = 3 kW 5 hp

D = 4 kW 7.5 hp

E = 10 hp

F = 15 hp

Digit 19 — Reserved for Future

Use

Digit 20 — Heat Type (PRI/SEC)

0 = No Heat

A = Indirect-Fired (IF)

B = No Primary Heat, Direct-Fired

(DF) Secondary

C = Electric—Stage

D = Electric—SCR Modulating

E = Dual Fuel (PRI-IF/SEC-DF)

F = Dual Fuel (PRI-ELEC/SEC-DF)

G = Dual Fuel (PRI-IF/SEC-ELEC)

H = Dual Fuel

(PRI-ELEC-SCR/SEC-ELEC)

J = Hot Water

K = Steam

L = No Primary Heat,

Secondary ELEC

M = Dual Fuel

(PRI-ELEC-STAGED/SEC-DF)

N = Dual Fuel

(PRI-ELEC-STAGED/SEC-ELEC)

Digit 21 — Primary Fuel Type

0 = No Heat

1= Natural Gas

2 = Propane

3 = Electric—Open Coil

4 = Electric—Sheathed Coil

5 = Hot Water

6 = Steam

8 OAU-SVX005C-EN

Model Number Descriptions

Digit 22 — Heat Capacity

(Primary Heat Source)

IF ELEC

0 = No Heat No Heat

A = 50 MBh 5 kW

B = 75 MBh 10 kW

C = 100 MBh 15 kW

D = 125 MBh 20 kW

E = 150 MBh 24 kW

F = 200 MBh 28 kW

G = 250 MBh 32 kW

H = 300 MBh 40 kW

J = 350 MBh 48 kW

K = 400 MBh 60 kW

L = 500 MBh 68 kW

M = 600 MBh 79 kW

N = 99 kW

O = 111 kW

P = 119 kW

X = Special Heater Option

Digit 23 — Heat Capacity

(Secondary Heat Source)

ELEC DF

0 = No Heat/No Secondary Heat

A = 5 kW 6-in. Burner—

Up to 300 MBh

B = 10 kW 12-in. Burner—

Up to 400 MBh

C = 15 kW 12-in. Burner—

Up to 600 MBh

D = 20 kW 18-in. Burner—

Up to 400 MBh

E = 24 kW 18-in. Burner—

Up to 900 MBh

F = 28 kW

Digit 24 — Corrosive

Environment Package

0 = No Corrosive Package

1 = S/S Interior, S/S Evap Coil Casing

2 = S/S Interior, Eco Coated Coils

3 = S/S Interior,

Copper/Copper Evap Coil

4 = S/S Coil Casing

5 = S/S Interior

6 = Eco-Coated Coils

7 = S/S Coil Casing with

Eco-Coated Coils

8 = Copper/Copper Evap,

HGRH Coils

Digit 25, 26 — Unit Controls

00 = Non-DDC—Electromechanical

AA = Trane—Discharge Air Control

AB = Trane—Space Control w/LON

AC = Trane—Discharge Air Control

AD = Trane—Space Control

AF = Trane—Discharge Air Control

AG = Trane—Space Control

AI = Trane—Discharge Air Control

AJ = Trane—Space Control

AK = Trane—Multi-Zone VAV Control

AL = Trane—Multi-Zone VAV Control

AM = Trane—Multi-Zone VAV Control

AN = Trane—Multi-Zone VAV Control

AO = Trane—Single-Zone VAV Control

AP = Trane—Single-Zone VAV Control

AQ = Trane—Single-Zone VAV Control

AR = Trane—Single-Zone VAV Control

XX = Control Special

w/LON Read-Write w/Display

Read-Write w/Display

®

w/BACnet

w/BACnet (No Display)

w/BACnet w/Display

w/BACnet w/Display

w/LON Read-Write (No Display)

w/LON Read-Write (No Display)

w/LON Read-Write w/Display

w/BACnet w/Display

w/LON Read-Write (No Display)

w/BACnet (No Display)

w/LON Read-Write w/Display

w/BACnet w/Display

w/LON Read-Write (No Display)

w/BACnet (No Display)

(No Display)

Digit 27 — Powered Exhaust Fan

Motor (PFM) and Exhaust

Dampers

0 = No Powered Exhaust

1 = Direct Drive w/VFD

2 = Direct Drive (VFD by Others)

3 = Belt Drive

4 = Belt Drive w/VFD

5 = Special Motor Option

6 = ECM w/Backward Curved

7 = ECM w/Backward Curved

8 = ECM w/Backward Curved

9 = Barometric Relief Dampers

Plenum Fan

Plenum Fan and Barometric

Relief Damper

Plenum Fan and Isolation

Dampers w/End Switch

(NO PFM)

Digit 28 — Powered Exhaust Fan

Wheel

0 = No Powered Exhaust

A = 355

B = 450

C = 450 X 2

D = 12/9 T2 (Single Fan—Belt Drive)

E = 12/9 BT (Dual Fan—Belt Drive)

Digit 29 — Powered Exhaust Fan

Motor Power

ECM Belt Drive

0 = No Powered Exhaust

A = 1 kW 2 hp

B = 2 kW 3 hp

C = 3 kW 5 hp

D = 4 kW 7.5 hp

E = 10 hp

F = 15 hp

Digit 30 — Reserved for Future

Use

Digit 31 — ERV (Requires

Powered Exhaust)

0= No ERV

A = ERV-Composite Construction

w/Bypass

B = ERV—Composite Construction

with Frost Protection w/VFD

C = ERV—Aluminum Construction

w/Bypass

D = ERV—Aluminum Construction

with Frost Protection w/VFD

Digit 32 — ERV Size

0= No ERV

1 = 3014

2 = 3622

3 = 4136

4 = 4634

5 = 5856

Digit 33 — Damper Options

0 = 100% OA 2-Position Damper

1 = 100% OA 2-Position Damper

w/RA 2-Position Damper

2 = Modulating OA and RA Dampers

w/Economizer

OAU-SVX005C-EN 9

Model Number Descriptions

Digit 34 — Filtration Options

A = No Filters

B = MERV-8,30%

C = MERV-13, 80%

D = MERV-14, 95%

E = MERV-8 30%, MERV-13 80%

F = MERV-8 30%, MERV-14 95%

G = MERV-8, 30% with UVC

H = MERV-13, 80% with UVC

J = MERV-14, 95% with UVC

K = MERV-8 30%, MERV-13 80%,

and UVC

L = MERV-8 30%, MERV-14 95%,

and UVC

M = MERV-8 30% and TCACS

N = MERV-13 80% and TCACS

P = MERV-14 95% and TCACS

Q = MERV-8 30%, MERV-13 80%,

and TCACS

R = MERV-8 30%, MERV-14 95%,

and TCACS

X = Special Filter Options

Digit 35 — Smoke Detector

(Factory-Installed)

0 = No Smoke Detector

1 = Supply Smoke Detector

2 = Return Smoke Detector

3 = Supply and Return Smoke

Detectors

Digit 36 — Electrical Options

0 = Terminal Block

A = Non-Fused Disconnect Switch

B = Fused Disconnect Switch

C = Non-Fused Disconnect Switch

w/Convenience Outlet

D = Fused Disconnect Switch

w/Convenience Outlet

E = Dual Point Power

F = Dual Point Power

w/Convenience Outlet

G = 65 SCCR Electrical Rating

w/Non-Fused Disconnect

H = 65 SCCR Electrical Rating

w/Fused Disconnect

J = 65 KAIC Electrical Rating

w/Non-Fused Disconnect

K = 65 KAIC Electrical Rating

w/Fused Disconnect

L = 65 KAIC Non-Fused

w/Convenience Outlet

M = 65 KAIC Fused

w/Convenience Outlet

N = 65 SCCR Non-Fused

w/Convenience Outlet

Digit 37 — Air Flow Monitoring

0 = No Airflow Monitoring

1 = Airflow Monitoring—IFM

Piezo Ring

2 = Airflow Monitoring—PE

Piezo Ring

3 = Airflow Monitoring—Outdoor Air

with Display and IFM

w/Piezo Ring

4 = Airflow Monitoring—IFM

Piezo Ring and PE Piezo Ring

5 = Airflow Monitoring—Outdoor Air

Monitoring w/Display Supply Air

and Exhaust Air w/Piezo Rings

6 = Airflow Monitoring—Outdoor Air

Monitoring for Direct-Fired

Heat Units

Digit 38 — Accessories

0 = No Options

A = Hailguards

B = Hailguards and LED Service

Light in Supply Fan Section

C = LED Service Light in Supply

Fan Section

D = Hailguards and LED Service

Light in

Exhaust Fan Section

E = Hailguards and LED Service

Light in Supply

and Exhaust

Fan Section

F = LED Service Light in Exhaust

Fan Section

G = LED Service Light in Supply and

Exhaust Fan Section

Digit 39 — Altitude

0 = Sea Level to 1,000 Feet

1 = 1,001 to 2,000 Feet

2 = 2,001 to 3,000 Feet

3 = 3,001 to 4,000 Feet

4 = 4,001 to 5,000 Feet

5 = 5,001 to 6,000 Feet

6 = 6,001 to 7,000 Feet

7 = Above 7,000 Feet

10 OAU-SVX005C-EN

General Information

Overview of Manual

Note: One copy of this document ships inside the control

panel of each unit and is customer property. It must

be retained by the unit’s maintenance personnel.

This booklet describes proper installation, operation, and

maintenance procedures for air cooled systems. By

carefully reviewing the information within this manual

and following the instructions, the risk of improper

operation and/or component damage will be minimized.

It is important that periodic maintenance be performed to

help assure trouble free operation. A maintenance

schedule is provided at the end of this manual. Should

equipment failure occur, contact a qualified service

organization with qualified, experienced HVAC techn icians

to properly diagnose and repair this equipment.

Model Number Description

All products are identified by a multiple-character model

number that precisely identifies a particular type of unit.

An explanation of the alphanumeric identification code is

provided (see the Model Number chapter). Its use will

enable the owner/operator, installing contractors, and

service engineers to define the operation, specific

components, and other options for any specific unit.

When ordering replacement parts or requesting service,

be sure to refer to the specific model number and serial

number printed on the unit nameplate.

Unit Nameplate

A Mylar® unit nameplate is located on the unit’s corner

support next to the control box. It includes the unit model

number, serial number, electrical characteristics,

refrigerant charge, as well as other pertinent unit data.

and RTRM receive information from sensors and

customer binary contacts to satisfy the applicable request

for ventilation, cooling, dehumidification and heating.

Indoor Fan Failure Input

The Indoor Fan Failure Switch (IFFS) is connected to verify

indoor fan operation.

When there is a call for the indoor fan to be energized, the

differential pressure switch, connected to the Main Unit

Display, must prove airflow within 60 seconds or the Main

Unit Display will shut off all mechanical operations, lock

the system out and send a diagnostic alarm to the Unit

Display. The system will remain locked out until a reset is

initiated through the MCM via the Alarm Reset Function on

the Unit Display.

Low Pressure Control ReliaTel Control

This input incorporates the compressor low pressure

control (CLP 1/2) of each refrigeration circuit and can be

activated by opening a field supplied contact installed on

the OAUTS.

If this circuit is open before the compressor is started, the

ReliaTel™ control will not allow the affected compressor to

operate. Anytime this circuit is opened for 1 continuous

second during compressor operation, the compressor is

immediately turned “Off.” The compressor will not be

allowed to restart for a minimum of 3 minutes should the

contacts close.

If four consecutive open conditions occur during the first

three minutes of operation, the compressor will be locked

out, and a manual reset will be required to restart the

compressor.

Refrigerant Circuits

Compressor Nameplate

The nameplate for the compressors are located on the side

of the compressor.

Unit Description

Before shipment, each unit is leak tested, dehydrated,

charged with refrigerant and compressor oil, and run

tested for proper control operation.

The condenser coils are aluminum fin, mechanically

bonded to copper tubing.

Direct-drive, vertical discharge condenser fans are

provided with built-in thermal overload protection.

The Outdoor Air Unit Main Unit Display and ReliaTel™

Control Module (RTRM) are microelectronic control

systems. The acronym RTRM is extensively throughout

this document when referring to the control system

network.

The optional Main Unit Display and the RTRM are

mounted in the Main Control Panel. The Main Unit Display

OAU-SVX005C-EN 11

Units shall incorporate a 4- or 6-row evaporator coil. All

circuits shall have thermal expansion valves (TXVs),

service pressure ports, sight glass, and refrigerant line

filter drier as standard. An area will be provided for

replacement suction line driers. Each refrigerant circuit is

equipped with a factory installed and preset refrigerant

capacity control (RCC) to prevent evaporator coil

temperatures below approximately 38°F (114 lb suction).

The refrigerant capacity device is not installed when the

unit is equipped with a digital scroll.

High Pressure Control ReliaTel Control

The compressor high pressure controls (CHP 1/2) are

wired in series between the compressor outputs on

RTRM1 (CHP 1/2) and the compressor contactor coils. If

one of the high pressure control switches opens, the RTRM

senses a lack of current while calling for cooling and locks

the compressor out.

General Information

Space Temperature / RH Sensor (Optional)

Field installed, wall mounted temperature sensor

(BAYSENS036A) and humidity to control space cooling,

heating and dew point.

High Temperature Sensor

The Discharge Air Temperature Sensor (DTC) supplies a

continuous signal to the MCM. If the MCM does not sense

a signal from the DTC, the unit will go into LOCKOUT and

require a manual restart once the proper operation of the

DTC has been confirmed. If DAT exceeds Discharge Air

High Temperature Cutoff (DHCS) of 125°F for 10 minutes,

the unit will shut down and require manual restart.

Outdoor Air Temperature and Relative Humidity Sensor

This factory installed combination outdoor air sensor

located in the outdoor air hood is designed to sense both

outdoor air temperature and relative humidity for use by

the microprocessor controller to make required

ventilation, cooling, dehumidification and heating

decisions.

Control Input (Occupied / Unoccupied)

Terminals are provided on the terminal strip labeled

OAUTS for a field installed dry contact or switch closure to

put the unit in the Occupied or Unoccupied modes.

Hot Gas Reheat

This option shall consist of a hot-gas reheat coil located on

the leaving air side of the evaporator.

100 Percent Outdoor Air Hood with Damper and Filters

Factory-installed and -integrated 100 percent outdoor air

hood with damper controlled by a direct coupled actuator.

Through the Base Electrical with Disconnect Switch

Factory installed 3-pole, molded case disconnect switch

with provisions for through the base electrical connections

will be included. The disconnect switch, with integral

overcurrent circuit breaker, will be installed in the unit in a

water tight enclosure with access through a hinged door.

Factory wiring will be provided from the switch to the unit

high voltage terminal block. The switch will be UL/CSA

agency recognized.

Hinged Access Doors

Hinged access doors with hold open brackets will be

factory-installed.

Unit Inspection

WARNING

Fiberglass Wool!

Product may contain fiberglass wool. Disturbing the

insulation in this product during installation,

maintenance or repair will expose you to airborne

particles of glass wool fibers and ceramic fibers known

to the state of California to cause cancer through

inhalation. Glass wool fibers may also cause

respiratory, skin or eye irritation.

AVERTISSEMENT

Laine de verre!

Le produit peut contenir de la laine de verre. Des

interventions inappropriées sur l’isolation de ce produit

pendant les opérations d’installation, d’entretien ou de

réparation vous exposent à des particules aériennes de

fibres de verre ou de fibres céramiques, responsables

selon la législation américaine (état de Californie) de

risques de cancers par inhalation. Les fibres de verre

peuvent aussi provoquer des phénomènes d’irritation

au niveau du système respiratoire, de la peau ou des

yeux.

As soon as the unit arrives at the job site:

Verify that the nameplate data matches the data on

the sales order and bill of lading (including electrical

data).

Verify that the power supply complies with the unit

nameplate specifications.

Visually inspect the exterior of the unit, including the

roof, for signs of shipping damage.

Visually inspect the internal components for shipping

damage as soon as possible after delivery and before

it is stored. Do not walk on the sheet metal base pans.

If conce aled damage is discovered, notify the carrier’s

terminal of damage immediately by phone and by

mail. Concealed damage must be reported within

15 days.

Request an immediate joint inspection of the damage

by the carrier and the consignee. Do not remove

damaged material from the receiving location. Take

photos of the damage, if possible. The owner must

provide reasonable evidence that the damage did not

occur after delivery.

Notify the appropriate sales representative before

installing or repairing a damaged unit.

• Avoid breathing fiberglass dust.

• Use a NIOSH approved dust/mist respirator.

• Avoid contact with the skin or eyes. Wear long-sleeved,

loose-fitting clothing, gloves, and eye protection.

12 OAU-SVX005C-EN

• Wash clothes separately from other clothing: rinse

washer thoroughly.

• Operations such as sawing, blowing, tear-out, and

spraying may generate fiber concentrations requiring

additional respiratory protection. Use the appropriate

NIOSH approved respiration in these situations.

First Aid Measures

Eye Contact

Flush eyes with water to remove dust. If symptoms persist,

seek medical attention.

Skin Contact

Wash affected areas gently with soap and warm water

after handling.

Storage

Take precautions to prevent condensate from forming

inside the unit’s electrical compartments and motors if:

• the unit is stored before it is installed; or,

• the unit is set on the roof curb, and temporary heat is

provided in the building. Isolate all side panel service

entrances and base pan openings (e.g., conduit holes,

S/A and R/A openings, and flue openings) from the

ambient air until the unit is ready for startup.

Note: Do not use the unit’s heater for temporary heat

without first completing the startup procedure

detailed in “Startup,” p. 29.

The manufacturer will not assume any responsibility for

equipment damage resulting from condensate

accumulation on the unit’s electrical and/or mechanical

components.

General Information

Unit Clearances

Unit Clearances, Curb Dimensions, and Dimensional Data

chapter contains figures that illustrate the minimum

operating and service clearances for either a single or

multiple unit installation. These clearances are the

minimum distances necessary to assure adequate

serviceability, cataloged unit capacity, and peak operating

efficiency.

Providing less than the recommended clearances may

result in condenser coil starvation, “short-circuiting” of

exhaust or recirculation of hot condenser air.

OAU-SVX005C-EN 13

Unit Clearances, Curb Dimensions, and Dimensional

84

72

36

36

48

36

48.500

25.500

25.000

3.750

93.500

9.250

27.500

9.250

12.750

13.750

1.250

3.438

122.688

RETURN

SUPPLY

55.143

55.489

52.554

52.000

22.000

3.180

15.676

ELECTRIC

DISCONNECT

FRONT VIEW

12.979

18.149

144.349

126.200

97.000 29.200

RIGHT SIDE VIEW

3.250

12.000

SUPPLY

24.000

SUPPLY

16.000

26.500

RETURN

12.750

12.750

14.500

RETURN

32.450

22.000

4.498

THROUGH BASE

ELECTRIC

BOTTOM VIEW

Data

Curb Dimensions

WARNING

Combustible Materials!

Failure to maintain proper clearance between the unit

heat exchanger, vent surfaces and combustible

materials could cause a fire which could result in death

or serious injury or property damage. Refer to unit

nameplate and installation instructions for proper

clearances.

AVERTISSEMENT

Matériaux combustibles!

Tout manquement à l’obligation de maintenir une

distance appropriée entre l’échangeur de chaleur de

l’unité, les surfaces de ventilation et les matériaux

combustibles peut provoquer un incendie pouvant

résulter en des blessures corporelles graves, voire

mortelles, ou des dommages matériels. Reportez-vous

à la plaque signalétique de l’unité et aux instructions

d’installation pour connaître les distances appropriées.

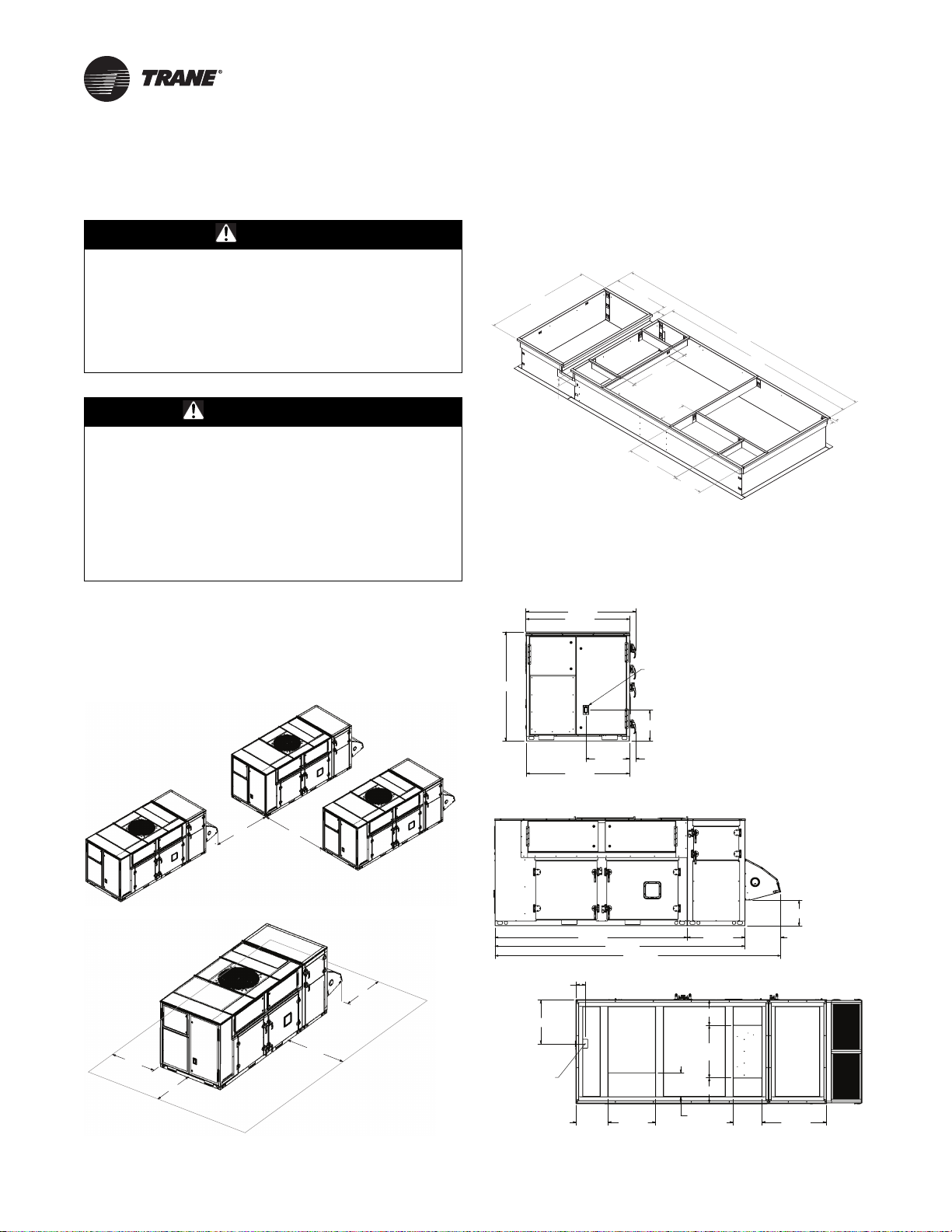

Figure 2. Unit curb data for direct-fired OAB tons (in.)

Dimensional Data

Figure 3. Unit dimensional data for direct-fired OAB

(in.)

Direct-Fired OAB Units

Unit Clearances

Figure 1. Typical installation clearances for direct-fired

OAB unit (in.)

14 OAU-SVX005C-EN

Unit Clearances, Curb Dimensions, and Dimensional Data

72

84

36

36

48

36

70.500

22.625

21.000

8.750

15.000

25.000

RETURN

SUPPLY

53.000

8.750

117.500

23.375

35.375

11.875

121.371

66.096

ELECTRIC

DISCONNECT

SWITCH

THROUGH BASE

ELECTRIC

74.000

17.323

33.751

121

3.078

GAS INLET

5.5852

Direct-Fired OAG Units

Unit Clearances

Figure 4. Typical installation clearances for direct-fired

OAG unit (in.)

Dimensional Data

Figure 6. Unit dimensional data for direct-fired OAG

(in.)

Curb Dimensions

Figure 5. Unit curb data for direct-fired OAG tons (in.)

OAU-SVX005C-EN 15

Unit Weight and Rigging

WARNING

Heavy Objects!

Failure to follow instructions below or properly lift unit

could result in unit dropping and possibly crushing

operator/technician which could result in death or

serious injury, and equipment or property-only damage.

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift.

AVERTISSEMENT

Objets lourds!

Le non-respect des instructions ci-dessous ou un levage

inapproprié de l’unité peut provoquer sa chute voire

écraser l’opérateur/le technicien, ce qui peut

occasionner des blessures graves voire mortelles, et

éventuellement endommager l’équipement ou

provoquer des dégâts matériels. Assurez-vous que

l’équipement de levage utilisé est adapté au poids de

l’unité à soulever. Chaque câble (chaîne ou élingue),

crochet ou manille utilisé pour le levage de l’unité doit

être assez robuste pour supporter le poids total de

l’unité. Les câbles, chaînes ou élingues de levage ne

doivent pas être de longueur identique. Procédez au

réglage afin de soulever l’unité de manière équilibrée.

Unit Weight

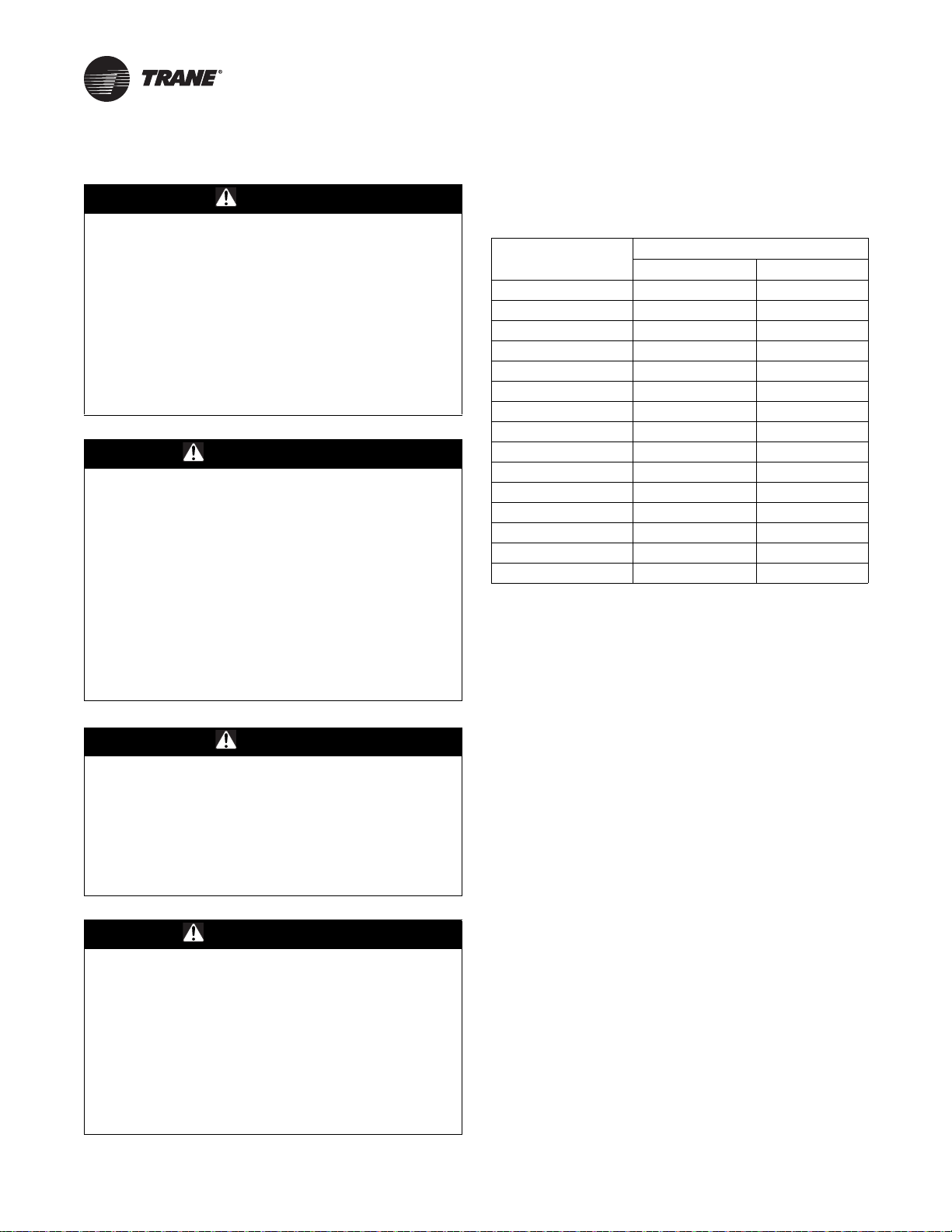

Table 1. Typical unit weight

Operating Weight (lb)

Model Number

OABD036* 1655 1839

OABD048* 1655 1839

OABD060* 1655 1839

OABD072* 1695 1879

OABD084* 1695 1879

OABD096* 1695 1879

OABD108* 1736 1920

OAGD120* 2912 3198

OAGD144* 2912 3198

OAGD180* 2913 3199

OAGD210* 3062 3348

OAGD240* 3134 3439

OAGD264* 3135 3439

OAGD300* 3175 3489

OAGD360* 3186 3500

Note: Minimum and maximum weights vary widely due to the highly

configurable nature of the product.

Min Max

WARNING

Improper Unit Lift!

Failure to properly lift unit could result in unit dropping

and possibly crushing operator/technician which could

result in death or serious injury, and equipment or

property-only damage. Test lift unit approximately

24 inches to verify proper center of gravity lift point. To

avoid dropping of unit, reposition lifting point if unit is

not level.

AVERTISSEMENT

Levage inapproprié de l’unité!

Le non-respect des instructions ci-dessous ou un levage

inapproprié de l’unité peut provoquer sa chute voire

écraser l’opérateur/le technicien, ce qui peut

occasionner des blessures graves voire mortelles, et

éventuellement endommager l’équipement ou

provoquer des dégâts matériels. Faites un test de

levage de l’unité d’environ 60 cm (24 po) afin de vérifier

que le point de levage correspond au centre de gravité

de l’appareil. Pour éviter une chute de celle-ci, ajustez

son point de levage si elle n’est pas à l’horizontale.

16 OAU-SVX005C-EN

Unit Weight and Rigging

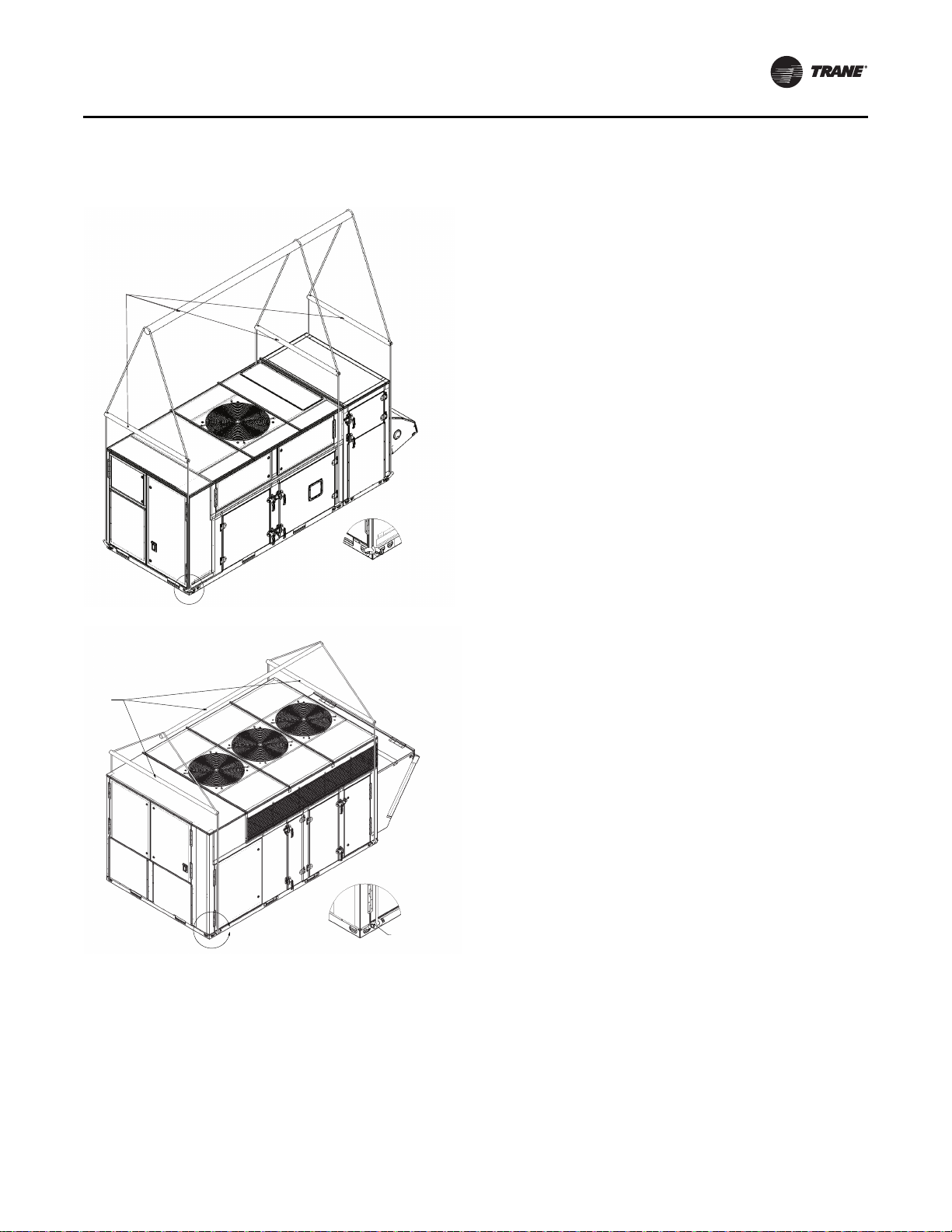

A

DETAIL A

SCALE 1 : 12

SCREW PIN SHACKLE

4 LOCATIONS

SPREADER BARS

6-point lift

(Model: Direct-fired OAB)

SPREADER

BARS

A

SCALE 1 : 12

DETAIL A

SCREW PIN SHACKLE

4 LOCATIONS

4-point lift

(Model: Direct-fired OAG)

Rigging

Figure 7. Rigging

3. Test-lift the unit to ensure it is properly rigged and

balanced, make any necessary rigging adjustments.

4. Lift the unit and position it into place. Remove fork

pockets prior to setting on the curb.

5. Downflow units; align the base rail of the unit with the

curb rail while lowering the unit onto the curb. Make

sure that the gasket on the curb is not damaged while

positioning the unit.

Before proceeding, refer to Table 1, p. 16 for typical unit

operating weights and Figure 7, p. 17 for rigging drawing.

1. Rig the unit as shown in Figure 7, p. 17. Attach

adequate strength lifting slings to all four lifting

brackets in the unit base rail. Do not use cables, chains,

or slings except as shown.

2. Install a lifting bar, as shown in Figure 7, p. 17, to

protect the unit and to facilitate a uniform lift. The

minimum distance between the lifting hook and the

top of the unit should be 7 feet.

OAU-SVX005C-EN 17

Installation

48" Minimum

Airflow

WARNING

Hazardous Service Procedures!

Failure to follow all precautions in this manual and on

the tags, stickers, and labels could result in death or

serious injury.

Technicians, in order to protect themselves from

potential electrical, mechanical, and chemical hazards,

MUST follow precautions in this manual and on the

tags, stickers, and labels, as well as the following

instructions: Unless specified otherwise, disconnect all

electrical power including remote disconnect and

discharge all energy storing devices such as capacitors

before servicing. Follow proper lockout/tagout

procedures to ensure the power can not be

inadvertently energized. When necessary to work with

live electrical components, have a qualified licensed

electrician or other individual who has been trained in

handling live electrical components perform these

tasks.

AVERTISSEMENT

Procédures d’entretien dangereuses!

Le non-respect de toutes les précautions contenues

dans ce manuel ainsi que sur les étiquettes et les

autocollants peut entraîner des blessures graves voire

mortelles.

Les techniciens, afin d’être protégés des éventuels

risques électriques, mécaniques et chimiques,

DOIVENT suivre les précautions contenues dans ce

manuel, sur les étiquettes et les autocollants, ainsi que

les instructions suivantes : Sauf indication contraire,

coupez toute l’alimentation électrique y compris les

disjoncteurs à distance et déchargez tous les dispositifs

de stockage d’énergie comme les condensateurs avant

l’entretien. Respectez les procédures de verrouillage et

d’étiquetage appropriées pour éviter tout risque de

remise sous tension accidentelle. S’il est nécessaire de

travailler avec des composants électriques sous

tension, demandez à un électricien qualifié et agréé ou

à une autre personne ayant la formation nécessaire

pour manipuler des composants électriques sous

tension d’exécuter ces tâches.

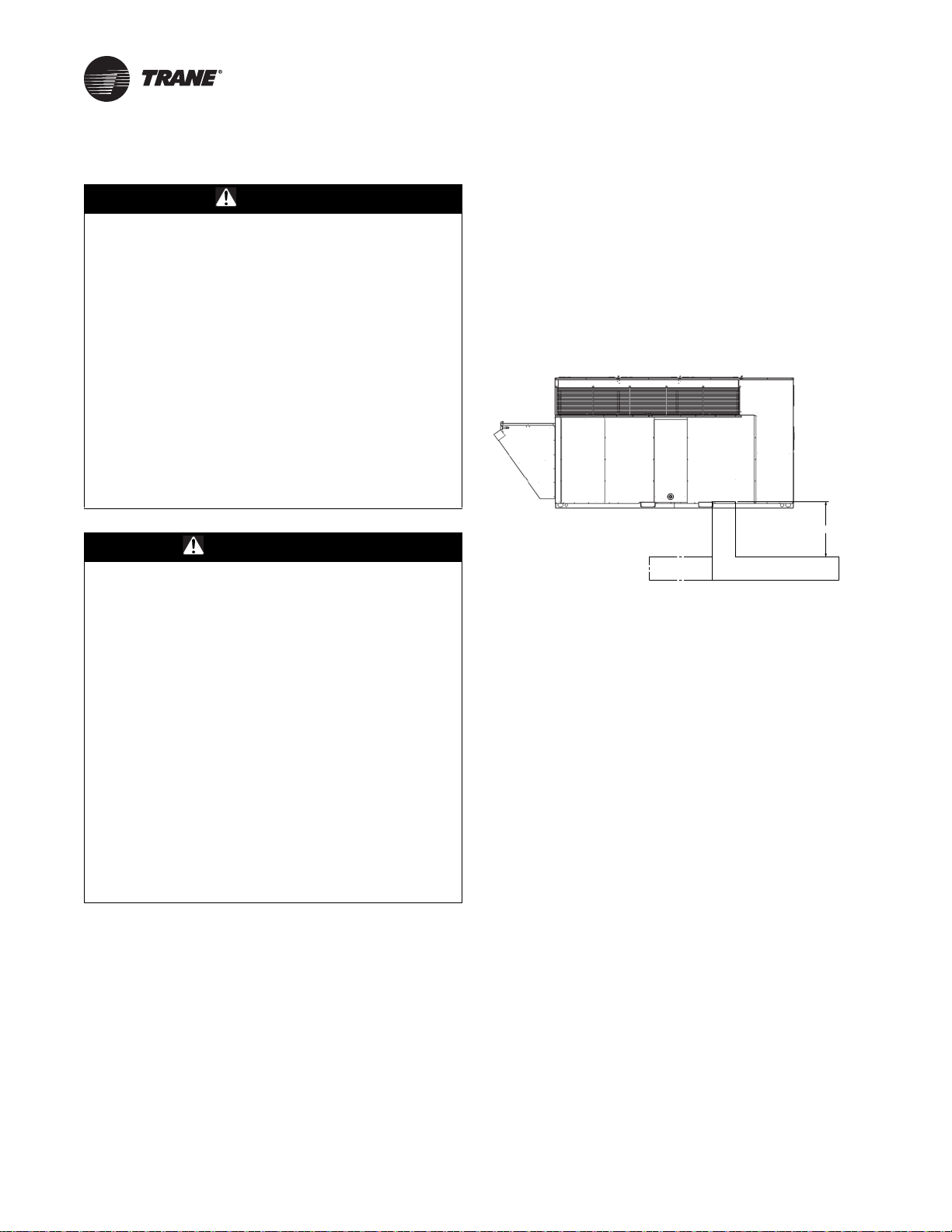

Ductwork

Elbows with turning vanes or splitters are recommended

to minimize air noise due to turbulence and to reduce static

pressure.

When attaching the ductwork to the unit, provide a watertight flexible connector at the unit to prevent operating

sounds from transmitting through the ductwork.

All outdoor ductwork between the unit and the structure

should be weather proofed after installation is completed.

Note: For sound consideration, cut holes in the roof deck

only for the ductwork penetrations. Do not cut out

the roof deck within the entire curb perimeter. All

duct work must be installed and connected to top of

roof curb before the unit is set on curb.

If a Curb Accessory Kit is not used:

1. Be sure to use flexible duct connections at the unit.

2. Gaskets must be installed around the curb perimeter

flange and the supply and return air opening flanges.

Note: For units will electric heat in the primary heating

position, refer to Figure 8.

Figure 8.

Important: Bottom discharge units with open coil

electric heater in primary heat location

require discharge duct with 90° elbow. This

is a MANDATORY installation requirement.

Note: A minimum 48" of straight duct is required before

an elbow. This is a requirement for both vertical and

horizontal discharge regardless of heat type.

General Unit Requirements

The checklist listed below is a summary of the steps

required to successfully install a commercial unit. This

checklist is intended to acquaint the installing personnel

with what is required in the installation process. It does

not replace the detailed instructions called out in

the applicable sections of this manual.

Check the unit for shipping damage and material

shortage. File a freight claim and notify appropriate

sales representative if damage or shortage is

discovered.

Verify that the unit nameplate model, options, and

voltage are correct.

Verify that the installation location of the unit will

provide the required clearance for proper operation.

Assemble and install the roof curb (if applicable).

Refer to the latest edition of the curb installers guide

that ships with each curb kit. Check curb for level

installation; if not level, shim as required.

Rigging unit (refer to “Unit Weight and Rigging,”

p. 16).

18 OAU-SVX005C-EN

Loading...

Loading...