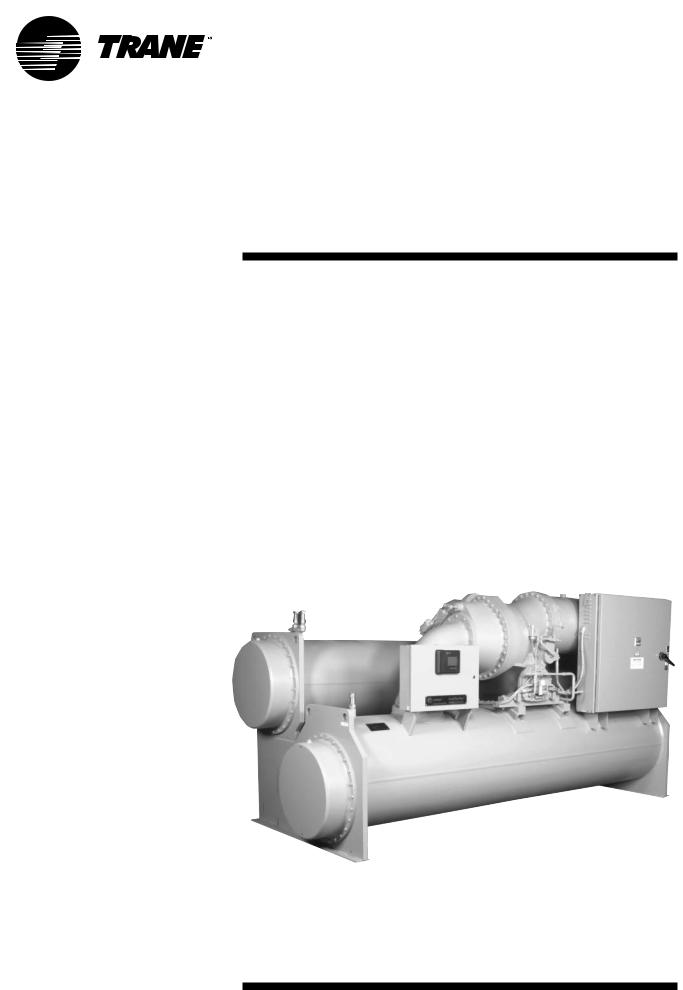

Trane Centrifugal Water Chillers CVGF User Manual

Centrifugal

Water Chillers

Model CVGF

Water-Cooled Hermetic Centrifugal

Refrigeration Capacities From

400 to 1000Tons (1400 kW-3510 kW)

50 and 60 Hz

September 2004 |

CTV-PRC001-GB |

Introduction

Introducing Trane’s Model CVGF

Centrifugal Water Chiller

Introduction

The basic gear driven centrifugal water chiller design was introduced in 1976 and has been proven in thousands of installations. The Trane Company continues to deliver its reliability and energy fitness commitment on its newest line of gear drive centrifugal water chillers, the Model CVGF.The major advantages of the Model CVGF are:

•High reliability

•Low sound levels

•Compact size

•High efficiency at a competitive market price

•Designed to use environmentally responsible HFC-134a refrigerant.

The Model CVGF chiller is ideal for office, hospital, school, hotel, retail store and industrial buildings. The Trane centrifugal chiller line offers hundreds of individual evaporator- condenser-compressor combination selections, permitting precise tailoring of the machine capacity to system requirements. Machine selections can be computer optimized to provide low first cost, low operating cost or other criteria important for a particular selection. Centrifugal Water Chiller computer selection program is certified in accordance with ARI standard 550/ 590.Trane Sales Engineers are available to assist in selecting the optimum machine to satisfy the particular project requirements.

Turn to the Model CVGF for energy efficiency provided by the two stage gear drive centrifugal water chillers with economizers. TheTrane Model CVGF is your choice for energy fit operation year after year.

© 2004 American Standard Inc. All rights reserved. |

CTV-PRC001-GB |

Contents

Introduction |

2 |

Features and Benefits |

|

4 |

|

Application Considerations |

|

|

|

9 |

|

General Data |

|

|

|

10 |

|

Jobsite Connections |

|

|

|

12 |

|

Controls |

|

|

|

13 |

|

Physical Dimensions |

|

|

|

17 |

|

Mechanical Specifications |

|

|

|

19 |

|

Conversion Table |

|

|

|

23 |

|

|

|

CTV-PRC001-GB |

3 |

Features and

Benefits

Standard CVGF Features

The following features are provided as standard with allTrane Model CVGF chillers:

•Hermetic two-stage centrifugal compressor-motor assembly with integral lubrication system and economizer cycle

•Evaporator and condenser assembly

•Prewired instrument and control panel

•Oil charge

•Integral oil heaters

•Isolation pads

•Wiring and oil system interconnection to main control panel

•Advance motor protection

•Two-stage gear drive with economized cycle for high efficiency and high reliability

•Liquid cooled hermetic induction motor; the motor operates at lower temperatures for longer motor life

Optional Features

•Unit and remote wye-delta mounted starters

•Unit mounted, floor mounted, and wall mounted solid state starters.

•Across-the-line, Primary Reactor, and AutoTransformer Remote mounted starter for medium/high voltage

•Marine waterboxes for evaporator and condenser

•Factory-applied thermal insulation

•One-inch deflection spring isolators for vibration-sensitive installations

•Refrigerant available from a local distributor

•Building automation systems (BAS) Interface

•Factory testing

Applications

•Comfort cooling

•Industrial process cooling

Patents

•Polygon drive for refrigeration compressor impellers

•Centrifugal compressor sump demister

•Internal oil filter

•Thermosiphonic oil cooler

•Compressor height and alignment adjustment

•Oil return using hot gas for motive force

•Centrifugal impeller assembly

•Internal oil filter

Orifice System

•Simplified orifice system with improved part load performance down to 20 percent part load

Advanced Heat Transfer Surfaces

•Evaporator and condenser tubes use the latest heat transfer surfaces

•Less refrigerant needed due to advanced patented evaporator design

Compact Size

•Designed with the retrofit and replacement market in mind

•The 400 to 500 NTON sizes can fit through most double-width doors

•Small footprint of the CVGF chiller saves valuable equipment room space

Simple Installation

•Simplified piping; the only water piping required is for the evaporator and condenser

•Simple power connection

•Unit mounted starter eliminates additional jobsite labor requirements

Environmental Features and

Benefits

Improved Efficiency:

•High Efficiency: 0.55 kW/Ton at ARI conditions

•Motor cooling vented to economizer cycle, efficiency advantage

•HFC-134 optimized inlet guide vanes and impellers for improved cycle efficiency using computational fluid dynamics

Reduced Emissions:

•Over 30 percent joint reduction in compressor/motor assembly compared to previous designs

•Patented integral heaters imbedded into the compressor casting, no seals no leaks

•Beaded flat gasket technology instead of O-rings, lower susceptibility to developing leaks

•Minimal NPT pipe threads on chiller system, SAE O-ring boss fitting, lower leak potential

•Oil sump internal to compressor/ motor assembly with internal pump/ motor; eliminates vent and drain lines, leak prevention

•Patented internal oil filter prevents leaks and contamination from pipes; filter is isolated and easily replaced

•Advanced evaporator design minimizes the refrigerant charge; a reduced charge reduces the exposure to the environment in the event of a catastrophic charge loss

Additional Features and

Benefits

•Patented polygon attachment instead of a keyed shaft, self-balancing

•Easy to replace motor terminals

•Motor/stator assembly is easily removed; speed assembly can be removed independent of the highspeed assembly

•Rolling element bearings

•Hydrodynamic bearings

•Advanced evaporator design: no eliminator necessary with an advanced suction baffle design

•All metric fasteners

4 |

CTV-PRC001-GB |

|

Features and

Benefits

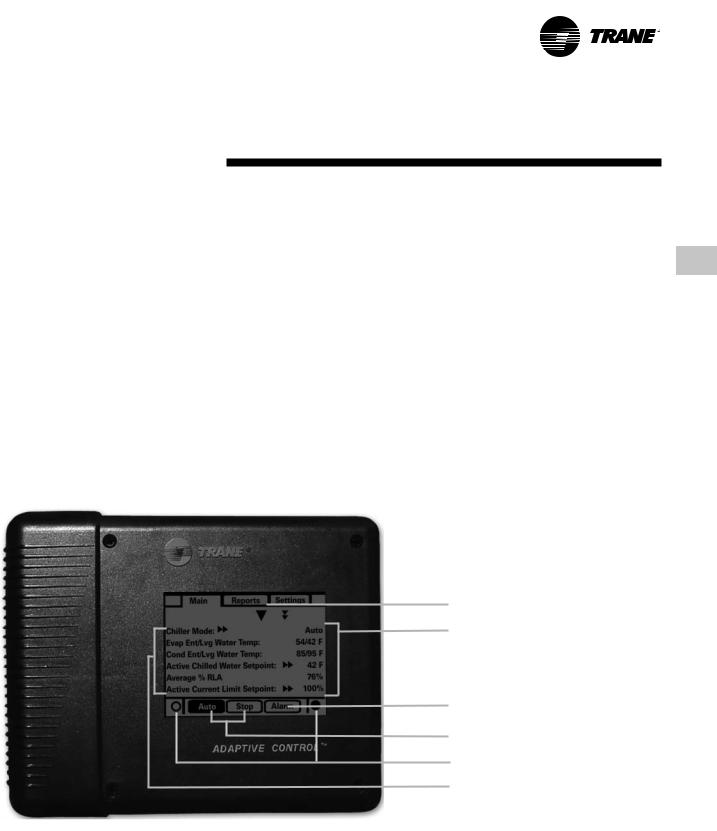

Microprocessor Controls with CH530

DynaView Operator Interface

DynaView™ is the unit-mounted control panel and also serves as the main processor and operator interface. It has a touch-sensitive overlay on a 1/4

VGA display.

DynaView presents information through an intuitive, tabbednavigation system. Alternate languages can be downloaded to the control panel, which can hold English plus two other languages at one time.

DynaView receives information from and communicates information to the other devices on the chiller’s communications link. DynaView performs the Leaving Chilled Water Temperature and Limit Control algorithms, arbitrating capacity against any operating limit against which the chiller may find itself working.

•Auto/Stop commands

•Status (all subsystems)

•Setpoint adjustment (daily user points)

•10 active diagnostics

•Mode overrides

•ASHRAE chiller log

DynaView can be connected to the service tool using a standard 9-pin male, 9-pin female RS-232 serial cable. The serial connection is located at the bottom of the DynaView panel behind a sliding door.

Touch sensitive screen provides information and navigation at the same time

Change setpoints and settings with touch screen commands

Displays chiller status and operating points. Touch for more information

lf diagnostic exists, an alarm indicator will appear. Press for detail.

Auto / Stop

Contrast Control

Extensive diagnostics customized to the chillar type installed-centrifugal, helical rotary, or absorption

CTV-PRC001-GB |

5 |

Features and

Benefits

Serviceability

PreviousTrane chiller controllers included a user interface that presented all chiller data necessary for both daily tasks and service or maintenance tasks. The amount of information presented on a limited display made a number of tasks difficult. A service technician’s ability to assess and resolve chiller problems was hampered by the limited presentation of multiple pieces of chiller information.

TheTracer chiller controller adds a level of sophistication better served by a PC application that improves service technician effectiveness and minimizes chiller downtime. The Tracer chiller controller provides a user interface and main processor, DynaView, that is intended to serve only typical daily tasks. The portable, PC-based service tool software,TechView, supports service and maintenance tasks.

TheTracer chiller controller will be gradually applied to allTrane chillers. TechView will then serve as a common interface to allTrane chillers, and will customize itself based on the properties of the chiller with which it is communicating. Thus, the service technician learns only one service interface.

The panel bus is easy to troubleshoot, using LED verification of sensors. Only the defective device is replaced.

Captive screws ensure that the appropriate mounting hardware is available.TechView can communicate with individual devices or groups of devices.

TechView™

All chiller status, machine configuration settings, customizable limits, and up to 60 active or historic diagnostics are displayed through the service-tool software interface. Any PC that meets the system requirements may download the service interface software and DynaView updates from Trane’s Web site at www.trane.com.

TechView is designed to run on a customer’s laptop, which connects to DynaView with a serial cable. DynaView’s serial port is located behind a sliding door on the bottom of the DynaView enclosure. It uses a standard 9-pin male and 9-pin female RS-232 cable.

Hardware requirements for TechView:

•Pentium II, III, or higher processor

•128 MB RAM

•1024 x 768 resolution

•CD-ROM

•56K modem

•9-pin RS232 serial connection

•Windows® 95, 98, 2000

6 |

CTV-PRC001-GB |

|

Features and

Benefits

Feedforward Adaptive

Control

TheTracer chiller controller allows the system designer to explore energy saving strategies and allows the centrifugal chiller to be used in ways that were never thought possible.

Feedforward Adaptive Control

Feedforward is an open-loop, predictive control strategy designed to anticipate and compensate for load changes. It uses evaporator enteringwater temperature as an indication of load change. This allows the controller to respond faster and maintain stable leaving-water temperatures.

Soft Loading

The chiller controller uses soft loading except during manual operation. Large adjustments due to load or setpoint changes are made gradually, preventing the compressor from cycling unnecessarily. It does this by internally filtering the setpoints to avoid reaching the differential-to-stop or the current limit. Soft loading applies to the leaving chilled-water temperature and current-limit setpoints.

Multi-Objective Limit Arbitration

There are many objectives that the controller must meet, but it cannot satisfy more than one objective at a time.Typically, the controller’s primary objective is to maintain the evaporator leaving-water temperature.

Whenever the controller senses that it can no longer meet its primary objective without triggering a protective shutdown, it focuses on the most critical secondary objective. When the secondary objective is no longer critical, the controller reverts to its primary objective.

Fast Restart

While the inlet guide vanes are closing, the controller will allow the centrifugal chiller to restart and going to a postlube operational mode. If the chiller shuts down on a nonlatching diagnostic, the diagnostic has 30–60 seconds to clear itself and initiate a fast restart. This includes momentary power losses.

Building Automation and

Chiller Plant Control

For a preprogrammable and flexible building automation and chiller plant control,Trane has developed theTracer Summit™. It can control the operation of the complete installation: chillers, pumps, cooling towers, isolating valves, air handlers and terminal units. Trane can undertake full responsibility for an optimized automation and energy management for the entire chiller plant.

The main functions are:

•Chiller sequencing: equalizes the number of running hours of the chillers. Different control strategies are available depending on the configuration of the installation.

•Control of the auxiliaries: includes input/output modules to control the operation of the various auxiliary equipments (water pumps, valves, cooling towers, etc.)

•Time of day scheduling: allows the end user to define the occupancy period, i.e. time of the day, holiday periods and exception schedules.

•Optimization of the start/stop time of the installation: based on the programmed schedule of occupancy and on the historical record of the behavior of the temperatures, calculates the optimal time of start and stop of the installation to get the best compromise between energy savings and comfort of the occupants.

•Soft loading: the soft loading function minimizes the number of chillers that are operated to satisfy the building morning pull down, thus preventing an overshoot of the actual capacity required. Unnecessary starts are avoided and the peak current demand is lowered.

CTV-PRC001-GB |

7 |

Features and

Benefits

•Communication capabilities: several communication levels are provided:

—local, through a PC workstation keyboard. Summit can be programmed to send messages to local or remote workstations and or a pager in the following cases:

—Analog parameter exceeding a programmed value.

—Maintenance warning.

—Component failure alarm.

—Critical alarm messages. In this latter case, the message is displayed until the operator acknowledges the receipt of the information. From the remote station it is also possible to access and modify the chiller plant’s control parameters.

•Remote communication through a modem: As an option, a modem can be connected to communicate the plant operation parameters through voice grade phone lines.

The remote terminal is a PC workstation equipped with a modem and software to display the remote plant parameters.

Chiller-Tower Optimization

Tracer Summit™ chiller-tower optimization extends Adaptive Control™ to the rest of the chiller plant. Chillertower optimization is a unique control algorithm for managing the chiller and cooling-tower subsystem. It considers the chiller load and real-time ambient conditions, then optimizes the tower setpoint temperature to maximize the efficiency of the subsystem.

Integrated Comfort™ System (ICS)

The onboardTracer chiller controller is designed to be able to communicate with a wide range of building automation systems.To take full advantage of the capabilities of the chiller, incorporate your chiller into a Tracer Summit building automation system.

But the benefits do not stop at the chiller plant. AtTrane, we realize that all energy used in your cooling system is important. That is why we worked closely with other equipment manufacturers to predict the energy required by the entire system. We used this information to create patented control logic for optimizing the HVAC system efficiency.

The building owner’s challenge is to tie components and applications expertise into a single reliable system that provides maximum comfort, control and efficiency.Trane’s Integrated Comfort™ systems (ICS) are a concept that combines system components, controls and engineering applications expertise into a single, logical and efficient system. These advanced controls are fully commissioned and available on every piece ofTrane equipment, from the largest chiller to the smallest VAV box. As a manufacturer, onlyTrane offers this universe of equipment, controls and factory installation and verification.

8 |

CTV-PRC001-GB |

|

Loading...

Loading...