Trane Force-Flo Cabinet Heater Air Terminal Devices Catalogue

Product Catalog

Force-Flo™ Cabinet Heater

Air Terminal Devices

Horizontal and Vertical

Sizes 02–12

May 2012 |

CAB-PRC001-EN |

Introduction

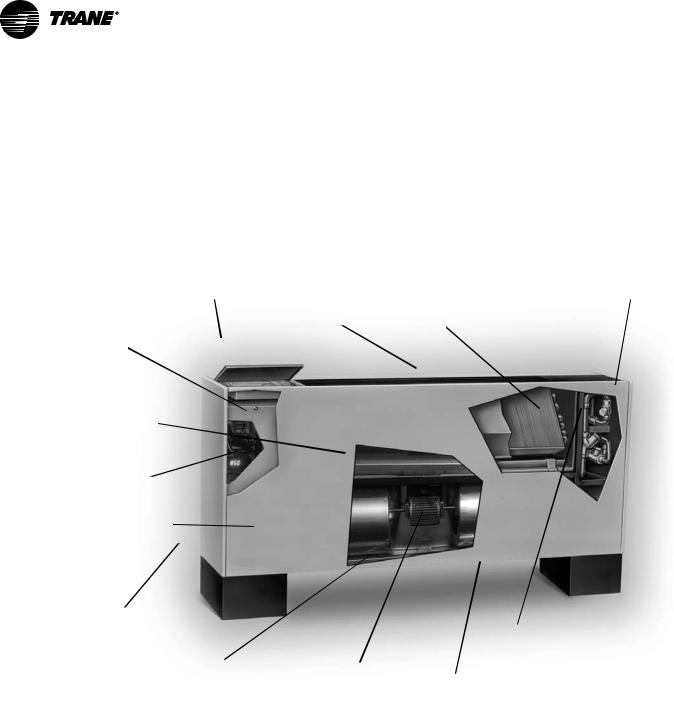

Trane has redesigned the traditional cabinet heater to lead the industry in:

•indoor air quality (IAQ) features

•easy installation and maintenance

•high quality and durability

•advanced controls

|

|

Factory-assembled, -installed, |

|

|

and -tested piping package |

Smaller unit footprint. |

|

with IAQ drain pan to collect |

|

Two-, three-, or |

condensate. |

Quiet operation. |

four-row coils. |

|

Factory-installed and -tested controls.

Removable, noncorrosive, positively-sloped drain pan  that’s easy to clean.

that’s easy to clean.

Build in field service tool with real language LED

Easy-to-remove fan assembly.

16-gage steel construction.

|

|

Cleanable closed-cell |

|

|

|

insulator (non-fiberglass). |

|

Easy filter access |

Energy efficient |

Damper allows up |

|

without front panel |

electronically |

||

to 100% fresh air. |

|||

removal. |

commutated motor |

||

|

|||

|

(ECM) |

|

Revision History

The revision of this literature dated 08 May 2012 includes information for Tracer™ UC400 controls, coil performance updates, and revised performance table formats per new AHRI listing requirements.

Trademarks

Force-Flo, Integrated Comfort, Rover, TOPSS, Tracer, Tracer Summit, Trane, and the Trane logo are trademarks of Trane in the United States and other countries. All trademarks referenced in this document are the trademarks of their respective owners.

© 2012 Trane All rights reserved |

CAB-PRC001-EN |

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Model Number Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

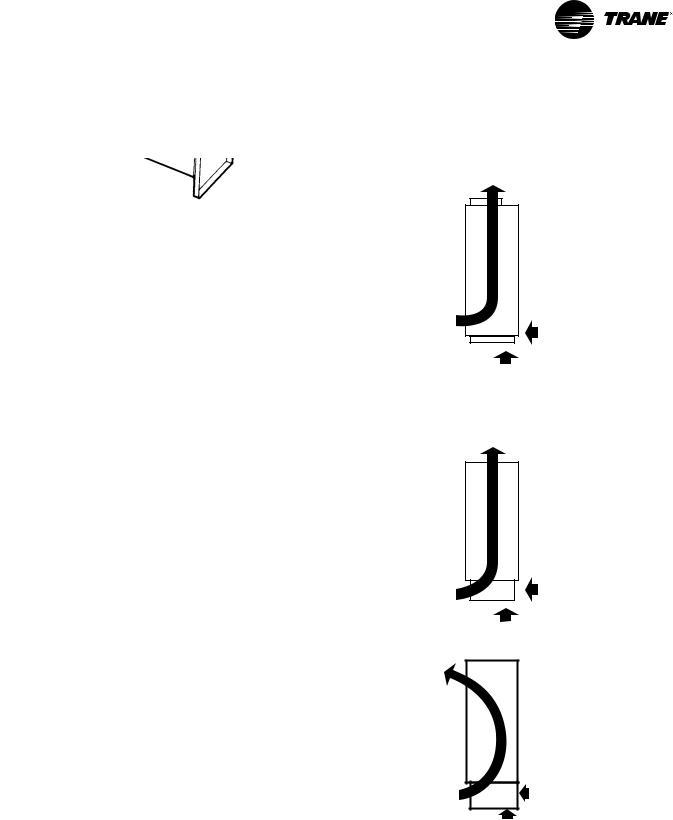

Model A, Vertical Concealed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Model B, Vertical Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

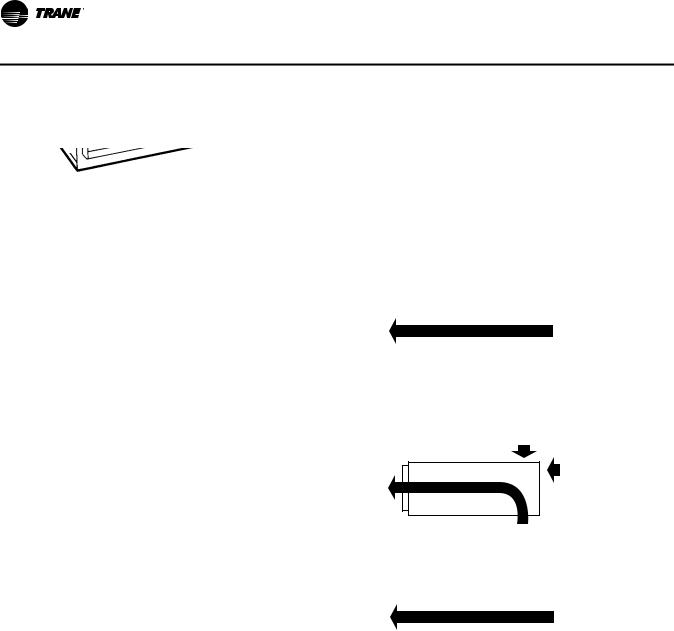

Model C, Horizontal Concealed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

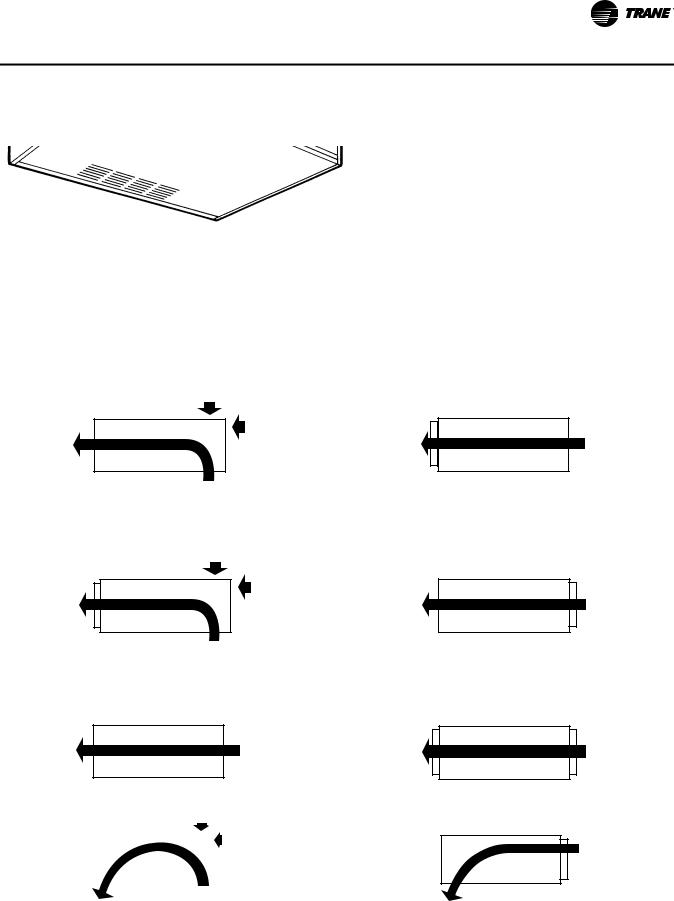

Model D, Horizontal Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Model E, Horizontal Recessed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Model F, Vertical Wall Hung Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Model H, Vertical Recessed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Model J, Vertical Cabinet Slope Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Model M, Inverted Vertical Concealed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Model N, Inverted Vertical Recessed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Factory-Installed Piping Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Horizontal Concealed, Horizontal Recessed, Vertical Recessed, Inverted

Vertical Recessed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Vertical Concealed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Horizontal Cabinet, Vertical Cabinet, Inverted Vertical Cabinet . . . . . . . 25

Vertical Slope Top Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Horizontal Concealed, Horizontal Recessed, Vertical Recessed, Horizontal

Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Vertical Concealed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

ECM Engine Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Control Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Manual Fan Mode Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Customer Supplied Terminal Interface (CSTI) . . . . . . . . . . . . . . . . . . . . . 31

Tracer Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Zone Sensor Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Control Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Tracer ZN520 and UC400 Additional Features . . . . . . . . . . . . . . . . . . . . . 39

End Device Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Vertical Concealed, Model A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Vertical Cabinet, Model B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Horizontal Concealed, Model C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Horizontal Cabinet, Model D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

CAB-PRC001-EN |

3 |

Horizontal Recessed, Model E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 Vertical Wall Hung Cabinet, Model F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 Vertical Recessed, Model H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 Vertical Slope Top, Model J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 Inverted Vertical Cabinet, Model M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 Inverted Vertical Recessed, Model N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Coil Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 Fresh Air Opening Locations-Horizontal Units Models C, D, and E . . . . 57 Fresh Air Opening Locations-Vertical Units Models A, B, F, and J . . . . . 58 Wall Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 Projection Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Force-Flo Cabinet Heater Mechanical Specifications . . . . . . . . . . . . . . . . 61

Piping Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4 |

CAB-PRC001-EN |

Features and Benefits

The Force-Flo cabinet heater meets the standards of today’s market, as well as the anticipated needs of tomorrow’s market. The tradition that company founder Reuben Trane began in 1913 continues with the latest generation of cabinet heaters from Trane.

The Force-Flo cabinet heater is the leader in these key areas:

•Energy Efficiency

•Indoor Air Quality (IAQ)

•Controls

•Flexibility

•Quality

•Serviceability

Today’s HVAC market is concerned with issues such as indoor air quality (IAQ) and CFCs that demand a change in HVAC products. In addition, renovation has overtaken new construction in the cabinet heater market - demanding a design that caters to renovation issues. Trane is concerned with these issues, too. That’s why we designed the Force-Flo cabinet heater as an integral part of the company’s system solutions with standard IAQ-related features that comply with ASHRAE 62.

Energy Efficiency

Trane’s commitment to providing premium quality products has led to the exclusive use of Electronically Commutated Motors (ECM) in all fan coil models. These brushless DC motors incorporate the latest technology for optimized energy efficiency, acoustical abatement, maintenance free and extended motor life. Each motor has a built-in microprocessor that allows for programmability, soft ramp-up, better airflow control, and serial communication.

•Trane units equipped with ECMs are significantly more efficient than the standard Permanent Split Capacitor (PSC) motor.

•Lower operating costs on average of 50 percent (versus a PSC motor).

•The Reduced FLA feature allows units to ship with a nameplate FLA rating much lower than a typical ECM unit.

IAQ Design

•Closed-cell insulation is standard on all units to help prevent fiberglass in the airstream.

•Easy filter access encourages frequent changing.

•Force-Flo cabinet heaters have a blow-thru design.

Controls

•This is the industry’s first solution that is factory mounted, wired and programmed for infinite modulation of fan speed based on space loads, using the UC400.

•Auto Fan Speed control with the Tracer ZN520 ramps the fan speed up and down to meet space loads.

•All controls are factory-mounted and tested to minimize field setup and improve reliability.

•Controls are wired with a 24 Vac transformer to keep only a single source power connection requirement to the unit.

•All wall-mounted zone sensors require only low voltage control wiring from the device to the unit control box. (No line voltage.)

•The random startup feature helps reduce electrical demand peaks by randomly staggering multiple units at startup.

•Occupied/unoccupied operation allows the controller to utilize unoccupied temperature setpoints for energy savings.

CAB-PRC001-EN |

5 |

Features and Benefits

•Warm-up energy feature is standard with Trane controls.

•Continuous fan or fan cycling is available with Tracer ZN010 or ZN510.

•Monitor unit operation using Tracer SC building management system with Tracer ZN510.

•To customize unit control, Tracer TU or Rover™ software will allow field modification of Tracer ZN510, ZN520 and UC400 default settings.

•Maximize cabinet heater system efficiency with modulating valves on units with Tracer ZN520 and UC400.

Flexibility

•Two-, three-, and four row hot water coils allow greater design flexibility. Steam distributing or electric heat coils are also available.

•Fan motors are available for either high static (0.4-inch external static pressure) or free discharge applications.

•Piping is factory-assembled, -mounted, and -tested. Units are also available without piping.

•Factory piping options include interconnecting piping, control valves, and end valves. Deluxe piping also has unions and a strainer.

•Control options range from a simple fan speed switch to a DDC controller that can tie into a Tracer SC building automation system.

•The extended end pocket option adds 8 inches (20 cm) to the piping end of cabinet style units.

•Slope-top vertical cabinet units are an excellent application for school and dormitories to prevent items from being placed on top of the units.

•Vertical wall hung units are used in vestibules, bathrooms, stairwells, or other applications when the unit cannot be installed on the floor.

•Inverted unit models allow heating to circulate from the bottom of the unit.

Quality

•Coils and piping packages are air and leak-tested before mounting on the unit.

•Coil piping connections are also air and leak-tested after mounting on the unit.

•All control end devices and moving components (fans and motors) are computer-tested after units are complete.

Serviceability

•Touch-safe control box.

•Integrated user interface with real language LED display.

•Built-in tachometer.

•Filters are easily removable and changed without removing the front panel on vertical cabinet units.

•Motors are easy to disconnect from the fan board, allowing easy service.

•The manual output test function is an invaluable troubleshooting tool. By simply pressing the test button on the Tracer ZN510, ZN520, or ZN010; service personnel can manually exercise outputs in a pre-defined sequence.

6 |

CAB-PRC001-EN |

Model Number Descriptions

Force-Flo Cabinet

Heater Model

Number Description

Following is a complete description of the cabinet heater model number. Each digit in the model number has a corresponding code that identifies specific unit options.

Note: Some options may not be available with all cabinet styles. Contact your local Trane representative for more information.

Digit 1, 2 - Unit Type

FF = Force-Flo

Digit 3 - Cabinet Type

A= Vertical Concealed

B= Vertical Cabinet

C= Horizontal Concealed

D= Horizontal Cabinet

E= Horizontal Recessed

F= Vertical Wall Hung Cabinet

H |

= |

Vertical Recessed |

J |

= |

Vertical Cabinet Slope Top |

M= Inverted Vertical Cabinet

N= Inverted Vertical Recessed

Digit 4 - Development Sequence

“B”

Digit 5, 6, 7 - Unit Size

020 |

040 |

080 |

030 |

060 |

100 |

|

|

120 |

Digit 8 - Unit Voltage

1 |

= |

115/60/1 |

6 |

= |

230/60/3 |

2 |

= |

208/60/1 |

7 |

= |

480/60/3 |

3 |

= |

277/60/1 |

8 |

= |

110–120/50/1 |

4 |

= |

230/60/1 |

9 |

= |

220–240/50/1 |

5 |

= |

208/60/3 |

A |

= |

220–240/50/3 |

|

|

|

B |

= |

380–415/50/3 |

Digit 9 - Piping System/

Placement

A= No Piping, RH

B= No Piping, LH

E= No Piping, RH, Extended End Pocket

F= No Piping, LH, Extended End Pocket

J= With Piping Package, RH

K= With Piping Package, LH

L= With Piping Package, RH, Extended End Pocket

M= With Piping Package, LH, Extended End Pocket

Digit 10, 11 - Design Sequence

“M0”

Digit 12 - Inlets

A= Front Toe Space

B= Front Bar Grille

C= Front Stamped Louver

D= Bottom Stamped Louver

E= Bottom Toe Space

F= Back Duct Collar

G= Back Open Return

H= Back Stamped Louver

J = Top Duct Collar

Digit 13 - Fresh Air Damper

0 = None

A= Manual, Bottom Opening

B= Manual, Back Opening

C= Manual, Top Opening

D= Auto, 2-Position, Bottom FA Opening

E= Auto, 2-Position, Back FA Opening

F= Auto, 2-Position, Top FA Opening

K= No Damper, Bottom Opening

L= No Damper, Back Opening

M= No Damper, top Opening

Digit 14 - Outlets

A= Front Duct Collar

B= Front Bar Grille

C= Front Stamped Louver

D= Front Quad Grille

E= Bottom Duct Collar

F= Bottom Stamped Louver

G= Top Quad Grille

H= Top Bar Grille

J = Top Duct Collar

Digit 15 - Color

0= No Paint (Concealed Units Only)

1= Deluxe Beige

4 |

= |

Driftwood Grey |

2 |

= |

Soft Dove |

5 |

= |

Stone Grey |

3 |

= |

Cameo White |

6 |

= |

Rose Mauve |

Digit 16 - Tamperproof Locks/

Leveling Feet

0 = None

B= Keylock Access Door

C= Keylock Panel and Access Door

D= Leveling Feet

F= Keylock Access Door w/Leveling Feet

G= Keylock Panel and Access Door w/Leveling Feet

Digit 17 - Motor

A= Free Discharge ECM

B= High Static ECM

Digit 18 - Coil

G= 2-Row Hot Water

H= 3-Row Hot Water

J |

= |

4-Row Hot Water |

N |

= |

Electric Heat, Single-Stage |

U= Electric Heat, Two-Stage

V= Electric Heat, Low kW, One-Stage

W= Steam Distributing

Digit 19 - Coil Series

1= 108 fpf (Steam Only)

2= 144 fpf (Hot Water Only)

Digit 20 - Coil Air Vent

A |

= |

Automatic Air Vent |

M |

= |

Manual Air Vent |

Digit 21, 22, 23 - Electric Heat kW (208 V derate)

000= |

No Electric Heat |

|

010 = |

1.0 kW (0.75 kW) |

|

020 |

= 2.0 kW (1.5 kW) |

|

030 |

= |

3.0 kW (2.3 kW) |

045 |

= |

4.5 kW (3.3 kW) |

060 |

= |

6.0 kW (4.5 kW) |

075 |

= |

7.5 kW (5.7 kW) |

090 |

= |

9.0 kW (6.6 kW) |

100 |

= |

10.0 kW |

105 = 10.5 kW (7.9 kW) |

||

110 = |

11.0 kW (9.0 kW) |

|

120 = |

12.0 kW |

|

135 = 13.5 kW (10.2 kW)

150 = 15.0 kW

180 = 18.0 kW (13.5 kW)

200 = 20.0 kW (15.0 kW)

Digit 24 - Not Used

0

Digit 25 - Disconnect Switch

0 |

= |

None |

D |

= |

Disconnect Switch |

CAB-PRC001-EN |

7 |

Model Number Descriptions

Digit 26 - Filter

0 = None

1= 1” Throwaway Filter

2= 1” Throwaway MERV 8 Filter

3= 1” Throwaway, 1 Extra

4= 1” Throwaway MERV 8, 1 Extra

5= 1” Throwaway, 2 Extras

6= 1” Throwaway MERV 8, 2 Extras

7= 1” Throwaway, 3 Extras

8= 1” Throwaway MERV 8, 3 Extras

A= 1” Throwaway MERV 13 Filter

B= 1” Throwaway MERV 13, 1 Extra

C= 1” Throwaway MERV 13, 2 Extras

D= 1” Throwaway MERV 13, 3 Extras

Digit 27 - Main Control Valve

0 |

= |

None |

1 |

= |

Field Supplied Analog valve |

A= 2-Way, 2-Position, NO (30 psig)

B= 3-Way, 2-Position, NO (28 psig)

C= 2-Way, 2-Position, NC (30 psig)

D= 3-Way, 2-Position, NC (20 psig)

E= 2-Way, 2-Position, NO (50 psig)

F= 3-Way, 2-Position, NO (28 psig)

G= 2-Way, 2-Position, NC (60 psig)

H= 3-Way, 2-Position, NC (28 psig)

J= 2-Way, Mod., 0.7 Cv (60 psig)

K= 3-Way, Mod., 0.7 Cv (60 psig)

L= 2-Way, Mod., 1.5 Cv (60 psig)

M= 3-Way, Mod., 1.5 Cv (60 psig)

N= 2-Way, Mod., 2.5 Cv (60 psig)

P= 3-Way, Mod., 2.5 Cv (60 psig)

Q= 2-Way, Mod., 4.0 Cv (60 psig)

R= 3-Way, Mod., 4.0 Cv (60 psig)

X= Field-Supplied, NO

Y= Field-Supplied, NC

Z= Field-Supplied 3-Wire Modulating

Digit 28 - Not Used

0

Digit 29 - Piping Packages

0 = None

A= Basic Ball Valve supply and Return

B= Basic Ball Valve Supply/Manual Circuit Setter

C= Basic Ball Valve Supply and Return w/Auto Circuit Setter

D= Deluxe Ball Valve Supply and Return

E= Deluxe Ball Valve Supply/Manual Circuit Setter

F= Deluxe Ball Valve Supply and Return w/Auto Circuit Setter

Digit 30 - Control Type

A = Fan Speed Switch

E= Tracer ZN010

F= Tracer ZN510

G= Tracer ZN520

H= Customer Supplied Terminal Interface

J = Tracer UC400, Single Zone VAV

Digit 31 - Control Option

D |

= |

Unit-Mounted Fan Mode Switch |

K |

= |

Wall-Mounted Fan Mode Switch |

V= Unit-Mounted Fan Speed Switch w/Setpoint Dial Zone Sensor

W= Wall-Mounted Fan Speed Switch w/Setpoint Dial Zone Sensor

X= Unit-Mounted Fan Speed Switch w/Wall-Mounted Setpoint Dial Zone Sensor

Y= Unit-Mounted Fan Speed Switch & Wall-Mounted Setpoint Dial w/Comm.

Z= Unit-Mounted Fan Speed Switch, On/Cancel, Setpoint Dial

w/ Comm.

1= Wall-Mounted On/Cancel w/ Comm.

2= Wall-Mounted Fan Speed Switch, Setpoint Dial, On/Cancel

w/ Comm.

0 = Without Control Option

3= Unit-Mounted Low Voltage Fan Speed Switch (Off /Hi /Med /Low)

4= Wall-Mounted Digital Zone Sensor (OALMH, Setpoint, On/Cancel, Comm Jack)

5= Wall-Mounted Digital Zone Sensor (On/Cancel, Comm Jack)

6= Wireless Zone Sensor

7= Wireless Display Sensor, UnitMounted Receiver

Digit 32 - Not Used

0

Digit 33 -FLA Motor Option

0 |

= |

Standard FLA ECM Mode |

A |

= |

Reduced FLA ECM Mode |

Digit 34 - Future Control

Functions

0 = None

Digit 35 - Control Function #3

0 = None

Digit 36 - Control Function #4

0 = None

Digit 37 - Control Function #5

0 = None

Digit 38 - Control Function #6

0 = None

Digit 39 - Projection Panels and

Falsebacks

0 = None

A= 5/8” Standard Recessed Panel (Vertical Recessed Units Only)

B= 2” Projection Panel

C= 2.5” Projection Panel

D= 3” Projection Panel

E= 3.5” Projection Panel

F= 4” Projection Panel

G= 4.5” Projection Panel

H= 5” Projection Panel

J |

= |

5.5” Projection Panel |

L |

= |

2” Falseback |

K |

= |

6” Projection Panel |

M |

= |

3” Falseback |

N |

= |

4” Falseback |

P= 5” Falseback

Q= 6” Falseback

R= 7” Falseback

T= 8” Falseback

Digit 40 - Main Autoflow gpm

A |

= |

0.5 |

H |

= |

3.5 |

B |

= |

0.75 |

J |

= |

4.0 |

C |

= |

1.0 |

K |

= |

4.5 |

D |

= |

1.5 |

L |

= |

5.0 |

E |

= |

2.0 |

M |

= |

6.0 |

F |

= |

2.5 |

N |

= |

7.0 |

G |

= |

3.0 |

P |

= |

8.0 |

Digit 41 - Not Used

0

Digit 42 - Subbases

0 = None

A= 2” Subbase

B= 3” Subbase

C= 4” Subbase

D= 5” Subbase

E= 6” Subbase

F= 7” Subbase

Digit 43 - Recessed Flange

0 |

= |

None |

A |

= |

Recessed Flange |

Digit 44 - Wall Boxes

0 |

= |

None |

A |

= |

Anodized Wall Box |

8 |

CAB-PRC001-EN |

General Data

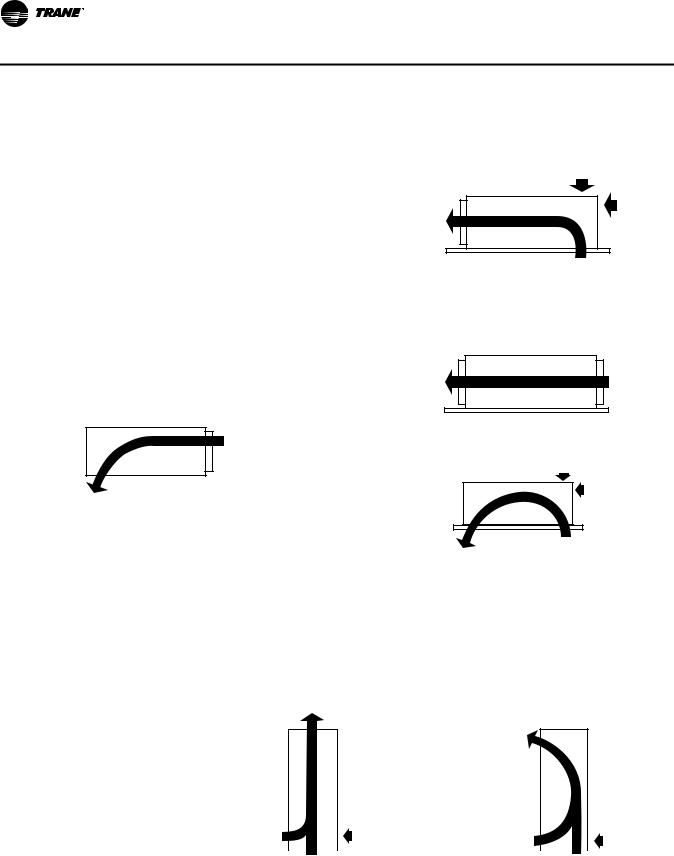

Model A, Vertical Concealed

Inlet

Front Toe Space

Model B, Vertical Cabinet

Inlet

Front Toe Space,

Front Bar Grille

Outlet

Front Stamped Louver

Inlet

Front Toe Space,

Front Bar Grille

Outlet

Top Duct Collar

Fresh Air

Bottom or Back

Outlet

Top Quad Grille, Top Bar Grille

Fresh Air

Bottom or Back

Fresh Air

Bottom or Back

CAB-PRC001-EN |

9 |

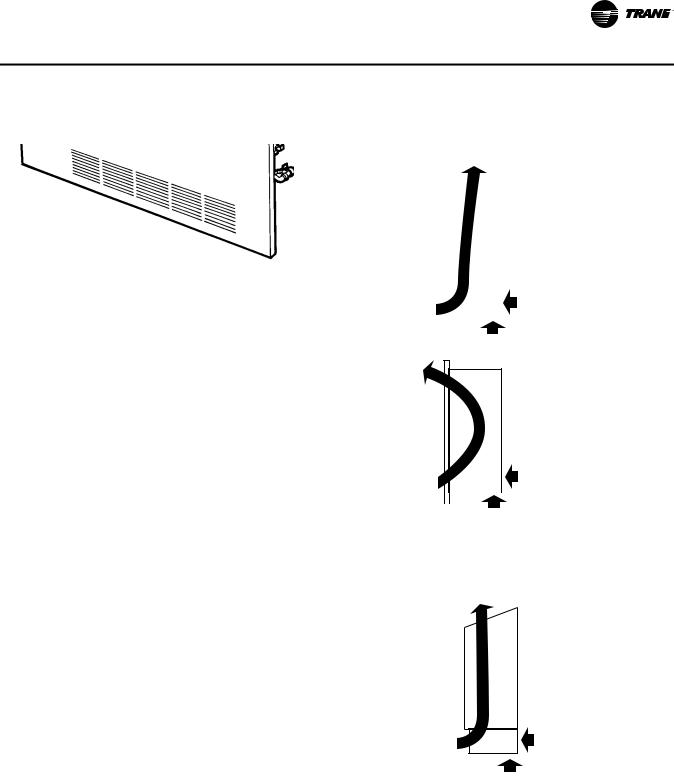

General Data

Model C, Horizontal Concealed

Outlet |

|

|

|

Inlet |

|

|

|

||

Front Duct Collar |

|

|

|

Back Duct Collar |

|

|

|

|

|

|

|

|

|

|

Fresh Air

N/A

Fresh Air

Top or Back

Outlet

Front Duct Collar

Inlet

Bottom Toe Space

Outlet |

|

|

Inlet |

|

|

||

Front Duct Collar |

|

|

Open Return |

|

|

|

No Filter |

|

|

|

|

|

|

|

|

|

|

Fresh Air |

|

|

|

N/A |

|

10 |

CAB-PRC001-EN |

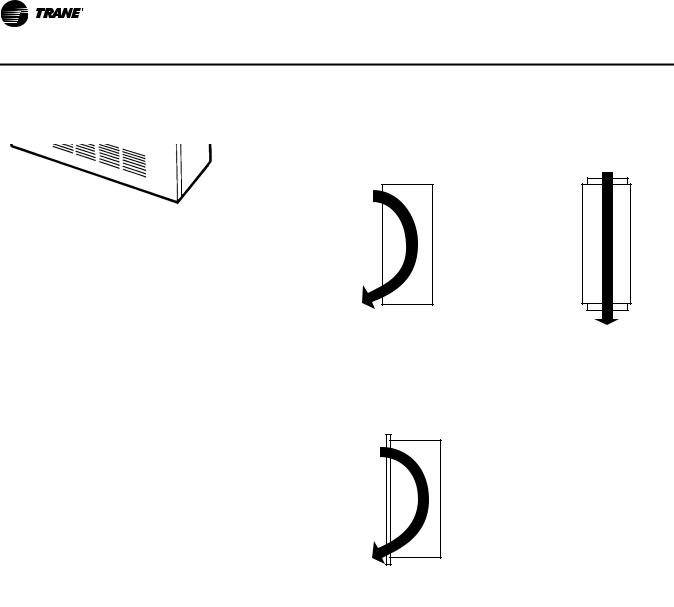

General Data

Model D, Horizontal Cabinet

Fresh Air

Top or Back

Outlet

Front Quad

Grille, Front Bar Grille Inlet

Bottom Stamped Louver

Fresh Air

Top or Back

Outlet

Front Duct Collar Inlet

Bottom Stamped

Louver

Fresh Air

N/A

Inlet

Back Stamped

Outlet Louver

Front Quad

Grille, Front Bar Grille

Fresh Air

Top or Back

|

|

Inlet |

|

Outlet |

|||

Bottom Stamped |

|||

Bottom Stamped |

Louver |

||

Louver |

|

||

Fresh Air

N/A

Outlet

Front Duct Collar

Fresh Air

N/A

Outlet

Front Quad

Grille, Front Bar Grille

Fresh Air

N/A

Outlet

Front Duct Collar

Fresh Air

N/A

Outlet

Bottom Stamped

Louver

Inlet

Back Stamped

Louver

Inlet

Back Duct

Collar

Inlet

Back Duct

Collar

Inlet

Back Duct

Collar or

Stamped

Louver

CAB-PRC001-EN |

11 |

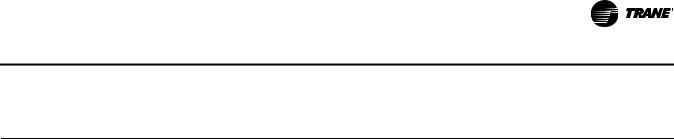

General Data

Model E, Horizontal Recessed

Fresh Air

Top or Back

Outlet |

|

Front Duct Collar |

Inlet |

|

Bottom Stamped |

|

Louver |

|

|

Fresh Air |

|

|

N/A |

|

|

Inlet |

|

|

Back Duct |

|

Outlet |

Collar |

|

|

|

Inlet |

Front Duct Collar |

|

|

|

|

Back Duct |

|

Fresh Air |

Collar |

|

|

|

Top or Back |

|

|

|

Outlet

Bottom Stamped

Louver

Outlet |

Inlet |

|

Bottom Stamped |

||

Bottom Stamped |

||

Louver |

||

Louver |

||

|

Model F, Vertical Wall Hung Cabinet

Outlet

Top Quad Grille,

Top Bar Grille

Outlet

Front Stamped

Louver

Inlet |

|

Fresh Air |

Inlet |

|

|

Bottom & Front |

|

|

Fresh Air |

||

|

Bottom & Front |

|

|||

|

Back |

|

|||

Stamped Louver |

|

Stamped Louver |

|

Back |

|

|

|

|

12 |

CAB-PRC001-EN |

General Data

Model H, Vertical Recessed

Outlet

Top Duct Collar

Inlet |

|

|

|

|

Fresh Air |

|

|

|

|

||

|

|

|

|

||

Front Stamped |

|

|

|

|

|

|

|

|

|

Bottom or Back |

|

Louver |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Outlet

Front

Stamped

Louver

Inlet |

|

|

|

Fresh Air |

Front |

|

|

|

|

|

|

|

Bottom or Back |

|

Stamped |

|

|

|

|

|

|

|

|

|

Louver |

|

|

|

|

|

|

|

|

Model J, Vertical Cabinet Slope Top

Outlet

Top Quad Grille, Top Bar Grille

Fresh Air

Inlet Bottom or Back

Front Toe Space,

Front Bar Grille

CAB-PRC001-EN |

13 |

General Data

Model M, Inverted Vertical Concealed

Inlet

Front Stamped

Louver

Outlet

Front Stamped

Louver

Model N, Inverted Vertical Recessed

Inlet

Front Stamped

Louver

Outlet

Front Stamped

Louver

Inlet

Top Duct

Collar

Outlet

Top Duct

Collar

14 |

CAB-PRC001-EN |

General Data

Table 1. Force-Flo cabinet heater general data

Unit Size |

02 |

03 |

04 |

06 |

08 |

10 |

12 |

|

|

|

|

|

|

|

|

Coil Data |

|

|

|

|

|

|

|

Face Area-ft2 |

0.8 |

0.8 |

1.1 |

1.6 |

2.1 |

3.2 |

3.2 |

LxDxH-in. |

|

|

|

|

|

|

|

2-Row |

15x1.7x8 |

15x1.7x8 |

20x1.7x8 |

29.5x1.7x8 |

38x1.7x8 |

57x1.7x8 |

57x1.7x8 |

3-Row |

15x2.6x8 |

15x2.6x8 |

20x2.6x8 |

29.5x2.6x8 |

38x2.6x8 |

57x2.6x8 |

57x2.6x8 |

4-Row |

15x3.5x8 |

15x3.5x8 |

20x3.5x8 |

29.5x3.5x8 |

38x3.5x8 |

57x3.5x8 |

57x3.5x8 |

Volume-gal. |

|

|

|

|

|

|

|

1-Row |

0.06 |

0.06 |

0.08 |

0.11 |

0.14 |

0.21 |

0.21 |

2-Row |

0.12 |

0.12 |

0.15 |

0.22 |

0.28 |

0.42 |

0.42 |

3-Row |

0.18 |

0.18 |

0.23 |

0.33 |

0.42 |

0.62 |

0.62 |

4-Row |

0.24 |

0.24 |

0.30 |

0.44 |

0.56 |

0.83 |

0.83 |

Fins/ft |

|

|

|

|

|

|

|

2-Row |

144 |

144 |

144 |

144 |

144 |

144 |

144 |

3-Row |

144 |

144 |

144 |

144 |

144 |

144 |

144 |

4-Row |

144 |

144 |

144 |

144 |

144 |

144 |

144 |

|

|

|

|

|

|

|

|

Fan/Motor Data |

|

|

|

|

|

|

|

Fan Quantity |

1 |

1 |

1 |

2 |

2 |

3 |

3 |

Size-Dia.” x Width” |

6.31x4 |

6.31x6.5 |

6.31x7.5 |

6.31x6.5 |

6.31x7.5 |

(1) 6.31x7.5 |

6.31x7.5 |

|

|

|

|

|

|

(2) 6.31x6.5 |

|

Motor Quantity |

1 |

1 |

1 |

1 |

1 |

2 |

2 |

|

|

|

|

|

|

|

|

Filter Data |

|

|

|

|

|

|

|

1” TA and Pleated Media |

|

|

|

|

|

|

|

Quantity |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Size-in. |

8-7/8x19-1/8 |

8-7/8x19-1/8 |

8-7/8x24-1/8 |

8-7/8x33-5/8 |

8-7/8x42-1/8 |

8-7/8x61-1/8 |

8-7/8x61-1/8 |

1” Fresh Air Filter (Only on Cabinet Styles D, E, and H with Bottom Return and Fresh Air Opening)

Quantity |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Size-in. |

5-1/2x19-1/8 |

5-1/2x19-1/8 |

5-1/2x24-1/8 |

5-1/2x33-5/8 |

5-1/2x42-1/8 |

5-1/2x61-1/8 |

5-1/2x61-1/8 |

|

|

|

|

|

|

|

|

CAB-PRC001-EN |

15 |

General Data

Table 2. |

Cabinet heater air flow |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ESP |

|

|

|

|

|

|

|

|

|

|

|

FD Motor |

|

High Static Motor |

|

|

|

|

|

|

|

|

|

Unit Size |

Coil |

0.05 |

0.1 |

0.2 |

0.3 |

0.4 |

|

|

|

|

|

|

|

02 |

2R144 |

246 |

344 |

314 |

283 |

251 |

|

3R144 |

242 |

352 |

319 |

284 |

249 |

|

4R144 |

222 |

326 |

295 |

263 |

230 |

|

|

|

|

|

|

|

03 |

2R144 |

313 |

410 |

380 |

350 |

319 |

|

3R144 |

309 |

391 |

358 |

324 |

290 |

|

4R144 |

276 |

360 |

330 |

299 |

267 |

|

|

|

|

|

|

|

04 |

2R144 |

381 |

446 |

410 |

373 |

336 |

|

3R144 |

365 |

544 |

506 |

467 |

427 |

|

4R144 |

340 |

506 |

470 |

434 |

397 |

|

|

|

|

|

|

|

06 |

2R144 |

609 |

757 |

700 |

642 |

582 |

|

3R144 |

604 |

880 |

824 |

766 |

707 |

|

4R144 |

557 |

812 |

760 |

706 |

652 |

|

|

|

|

|

|

|

08 |

2R144 |

790 |

1014 |

950 |

885 |

819 |

|

3R144 |

724 |

992 |

927 |

861 |

794 |

|

4R144 |

676 |

930 |

870 |

808 |

745 |

|

|

|

|

|

|

|

10 |

2R144 |

1015 |

1284 |

1199 |

1113 |

1024 |

|

3R144 |

1052 |

1456 |

1360 |

1262 |

1162 |

|

4R144 |

988 |

1366 |

1276 |

1183 |

1089 |

|

|

|

|

|

|

|

12 |

2R144 |

1105 |

1424 |

1330 |

1234 |

1134 |

|

3R144 |

1074 |

1514 |

1419 |

1320 |

1219 |

|

4R144 |

993 |

1421 |

1330 |

1238 |

1144 |

|

|

|

|

|

|

|

Note: This is data is based on horizontal concealed model only, with duct inlet, duct outlet and no filter, dry coil, all voltages except 208 V.

Electric Heat

All Force-Flo cabinet heaters, except inverted models M and N, are available with electric heating coils as a standard option.

Coil Construction

Electric heat coils are open wire type with a nickel chromium element design.

Power Supply

Units have single-point power since the electric heating elements operate on line voltage. Electric heat is available as 208/60/1, 230/60/1, 277/60/1, 208/60/3, or 480/60/3. Electric heat coils operate on the same voltage as the unit, except for units with 480/60/3 electric heat. In this case, the unit operates at 277/60/1, thus requiring a 4-wire supply. All fans and motors are single phase. In addition, all control options are 24-volt, utilizing a factory-installed transformer.

Power Supply Location

All electric heat cabinet heaters have a terminal block for main power on the unit’s right-hand side.

Control Type

Single-stage electric heat units are controlled by either Tracer UC400, ZN010, ZN510, or ZN520 control options. Two-stage electric heat is controlled by the Tracer UC400, ZN520 only. Both control options use PWM (pulse-width modulation) outputs to calculate the electric heat output

16 |

CAB-PRC001-EN |

General Data

based on the capacity request and the electric heat cycles per hour. For example, if the electric heat cycles per hour is configured for six cycles (as Trane recommends) the controller bases the output on or off time on six 10-minute periods. If the capacity request is 40 percent, the controller controls the electric heat output on for approximately four minutes each period.

Safety Features

•Fan/valve operation to ensure safe operation and to ensure that two modes of heat are not operating simultaneously.

•All Force-Flo units with standard electric heat are UL listed.

•Units require only a single-point electrical connection.

•All electric heating coils are interlocked with the fan motor switch. Therefore, electric heat operation is only possible when the fan is running.

•Each unit has a transformer, eliminating the need for field installation of a stepdown transformer.

•Unit-mounted quiet magnetic relays are supplied on all unit voltages.

•A line-break high temperature cutout with automatic reset is provided as an integral part of the elements to de-energize the electric heat in the event of an overheat condition.

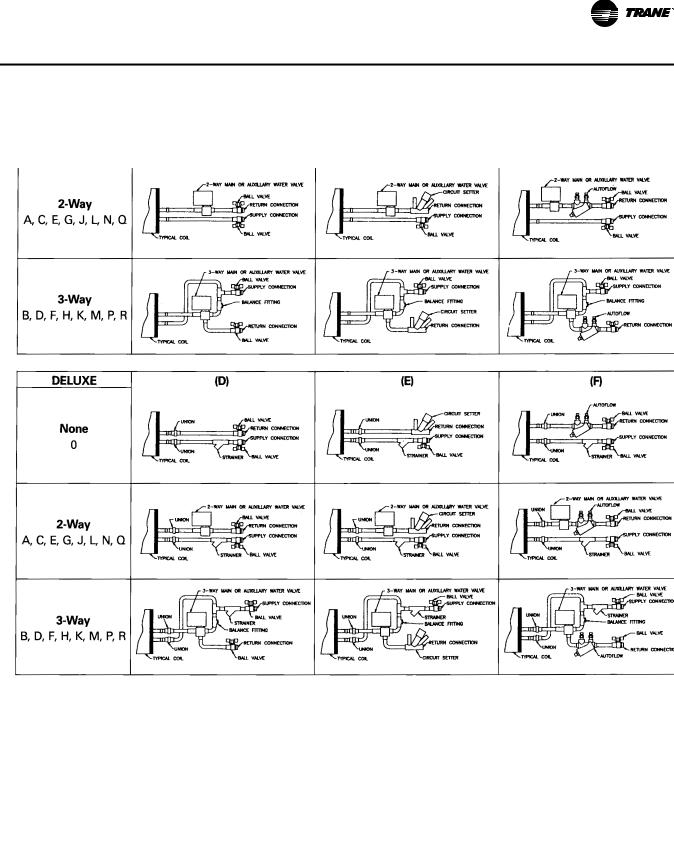

Factory-Installed Piping Packages

Force-Flo cabinet heaters have standard piping packages available as a factory built and installed option. Factory built assures all piping packages are fully tested under water for leaks and are built within strict tolerances. Factory-installed means that supply and return pipes are the only field connections required. The installer doesn’t have to sweat connect piping packages onto coil connections in a tight end pocket. Field connections are brought to a point near the exterior of the unit for easy access.

Piping Package Components

Force-Flo piping packages consist of a variety of components for each application. The following section provides a detailed description of the piping components. Following this section are additional illustrations and specifications.

Piping System/Placement

Factory piping packages are available with right or left hand connections. A simple coil connection (a unit without a piping package) is also available in either a right or left hand configuration for those applications requiring field piping.

Interconnecting Piping

Interconnecting piping refers to the copper piping that attaches the coil connections and all other components such as control valves, end valves, etc. Piping is 1/2” nominal OD copper and extends near the unit exterior to one inlet and one outlet connection.

Deluxe or Basic Piping Package

The basic piping package includes only the main components of the piping package: interconnecting piping, control valves, and end valves.

The deluxe piping package also includes a strainer on the entering water pipe and unions at the coil connections along with the basic components listed above. The strainer body is cast brass construction, with a stainless steel mesh strainer that is easily removed for cleaning. The unions are forged brass construction and close with a minimum amount of effort.

CAB-PRC001-EN |

17 |

General Data

End Valves

Each piping package includes a ball valve for the entering water pipe and one of the following end valves on the leaving water pipe: ball valve, manual circuit setter, or an auto circuit setter. These valves serve as the field connection points on all Force-Flo piping packages.

Ball Valves

Ball valves, also known as stop or end valves, allow the unit to be cut off for service purposes. These valves have a two-inch handle that rotates 90° to a fully open position. The valve body is cast brass, and the ball is polished brass with a Teflon® seat. Ball valves are available as end valves on both the entering and leaving water pipes.

Manual Circuit Setter

In lieu of a ball valve on the leaving water pipe, a manual circuit setter, also known as a manual flow control valve, acts as both a flow setting device and a stop valve. This valve allows water flow through the cabinet heater to be set quickly and accurately.

The manual circuit setter includes Schrader ports in the valve body. These ports are used to measure the pressure drop across the valve. This pressure drop can be compared to factory supplied curves that relate the pressure drop to a specific flow rate. This valve also has a memory stop that helps find the correct setting quickly.

Auto Circuit Setter

An auto circuit setter is an automatic flow control device available on the leaving water pipe. The auto circuit setter includes a cartridge within the valve body that is sized to allow a specific flow rate through the coil. This valve sets flow through the coil without any action required by a system piping balancer. The auto circuit setter is available on the leaving water pipe with a ball valve.

The auto circuit setter also includes two P/T’s plugs in the valve body to allow measurement of the pressure drop temperature through the valve.

Control Valves

Piping packages are available with or without control valves. All control valve options are factory mounted and wired to the Force-Flo unit controls.

Two-Way/Two-Position Valves

These valves will either fully open or close in response to a 24 Vac signal from the Tracer controller. Control valves are direct-acting valves. The control valve is factory mounted in the leaving water pipe downstream of the coil. Always use some means of relieving pump head pressure with twoway valve applications. Normally open or normally closed valves are available.

Three-Way/Two-Position Valves

These valves will either allow full water flow through the coil or divert the flow through a bypass line. The valves respond to a 24 Vac signal from the Tracer controller. Control valves are direct acting valves. All three-way valve packages include a balance fitting in the bypass line to allow flow balancing in the bypass position. Three-way valves are factory mounted in the leaving water pipe downstream of the coil. Normally open or normally closed valves are available.

Two-Way Modulating Valves

These valves modulate the water flow through the coil in response to a signal from the Tracer controller. Modulating valves are three-wire floating point equal percentage valves, and are factory mounted in the leaving water pipe downstream of the coil.

Three-Way Modulating Valves

These valves modulate the water flow through the coil in response to a signal from the Tracer controller. Three-way valves allow water that is directed through the coil to mix with water directed through the bypass line. This mixture exits through the leaving water pipe. Modulating valves are

18 |

CAB-PRC001-EN |

General Data

three-wire floating point equal percentage valves, and are factory mounted in the leaving water pipe downstream of the coil.

Figure 1. Piping package options

Auto Flow Valve (C)

CAB-PRC001-EN |

19 |

General Data

Selecting the Correct Modulating Valve Size

Modulating valves are available in any of four port sizes: 0.7, 1.5, 2.5 or 4.0 Cv (coefficient of flow values). The coefficient of flow is defined as the volume of water flow through a control valve in the fully open position with a 1 psig differential across the valve. Calculate the coefficient of flow using the formula:

Cv = Q/square root P where:

Cv = flow coefficient

Q = flow rate (gpm)

P = pressure drop across the valve or coil (psig).

For good control, the valve Cv should be approximately equal to the Cv of the water coil.

Modulating Valve Selection Example

Assume a size 06 vertical cabinet heater is selected to operate at the following conditions:

EWT = 180°F

LWT = 150°F

EAT = 70°F

The coil selection is a four-row coil. Select the best modulating valve size for this unit.

1. Find the P across the water coil. Refer to the ARI performance table to determine the P across the water coil or use the Trane Official Product Selection System, TOPSS™, selection program. The water pressure drop is found to be 5.7’ of water at a flow rate of 3.59 gpm. This converts to a pressure drop of 2.47 psig (1.0 feet of water = 0.4328 psig.)

2.Calculate the Cv of the water coil.

Cv = gpm/Square root P. Cv = 3.59/Square root 2.47 Cv = 2.29

Therefore, select the 2.5 Cv valve because it is closest to the water coil.

Table 3 and Table 4, p. 21 illustrate possible valve selections at ARI conditions for horizontal concealed units with a high static motor and vertical cabinet units with a free discharge motor. For other applications, use TOPSS to determine flowrate and make calculations using the formulas above.

Table 3. Modulating valve selections for horizontal concealed units, high static motor, 70°F EAT, 180°F EWT, 30°F T

Unit Size |

Coil |

gpm |

Coil WPD |

Coil Cv |

Valve Cv |

|

|

|

|

|

|

02 |

2-Row |

1.19 |

6.0 |

0.74 |

0.7 |

|

|

|

|

|

|

|

3-Row |

1.52 |

13.8 |

0.62 |

0.7 |

|

|

|

|

|

|

|

4-Row |

1.59 |

3.8 |

1.24 |

1.5 |

|

|

|

|

|

|

03 |

2-Row |

1.53 |

10.3 |

0.72 |

0.7 |

|

|

|

|

|

|

|

3-Row |

1.82 |

4.3 |

1.33 |

1.5 |

|

|

|

|

|

|

|

4-Row |

1.98 |

6.2 |

1.21 |

1.5 |

|

|

|

|

|

|

04 |

2-Row |

1.73 |

3.3 |

1.45 |

1.5 |

|

|

|

|

|

|

|

3-Row |

2.57 |

9.1 |

1.29 |

1.5 |

|

|

|

|

|

|

|

4-Row |

2.81 |

13.4 |

1.17 |

1.5 |

|

|

|

|

|

|

06 |

2-Row |

2.87 |

9.9 |

1.39 |

1.5 |

|

|

|

|

|

|

|

3-Row |

3.96 |

5.9 |

2.48 |

2.5 |

|

|

|

|

|

|

|

4-Row |

4.37 |

8.2 |

2.32 |

2.5 |

|

|

|

|

|

|

20 |

CAB-PRC001-EN |

General Data

Table 3. Modulating valve selections for horizontal concealed units, high static motor, 70°F EAT, 180°F EWT, 30°F T (continued)

Unit Size |

Coil |

gpm |

Coil WPD |

Coil Cv |

Valve Cv |

|

|

|

|

|

|

08 |

2-Row |

3.71 |

4.7 |

2.60 |

2.5 |

|

|

|

|

|

|

|

3-Row |

4.74 |

9.1 |

2.39 |

2.5 |

|

|

|

|

|

|

|

4-Row |

5.22 |

12.7 |

2.23 |

2.5 |

|

|

|

|

|

|

10 |

2-Row |

4.71 |

8.1 |

2.52 |

2.5 |

|

|

|

|

|

|

|

3-Row |

6.50 |

18.1 |

2.32 |

2.5 |

|

|

|

|

|

|

|

4-Row |

7.13 |

25.3 |

2.15 |

2.5 |

|

|

|

|

|

|

12 |

2-Row |

5.48 |

11.4 |

2.47 |

2.5 |

|

|

|

|

|

|

|

3-Row |

7.19 |

14.5 |

2.87 |

2.5 |

|

|

|

|

|

|

|

4-Row |

7.83 |

10.5 |

3.67 |

4.0 |

|

|

|

|

|

|

Table 4. Modulating valve selections for vertical cabinet units, free discharge motor, 70°F EAT, 180°F EWT, 30°F T

Unit Size |

Coil |

gpm |

Coil WPD |

Coil Cv |

Valve Cv |

|

|

|

|

|

|

02 |

2-Row |

1.06 |

4.8 |

0.74 |

0.7 |

|

|

|

|

|

|

|

3-Row |

1.31 |

10.5 |

0.61 |

0.7 |

|

|

|

|

|

|

|

4-Row |

1.34 |

2.8 |

1.22 |

1.5 |

|

|

|

|

|

|

03 |

2-Row |

1.40 |

8.8 |

0.72 |

0.7 |

|

|

|

|

|

|

|

3-Row |

1.70 |

3.8 |

1.33 |

1.5 |

|

|

|

|

|

|

|

4-Row |

1.81 |

5.3 |

1.20 |

1.5 |

|

|

|

|

|

|

04 |

2-Row |

1.71 |

3.2 |

1.45 |

1.5 |

|

|

|

|

|

|

|

3-Row |

2.12 |

6.4 |

1.27 |

1.5 |

|

|

|

|

|

|

|

4-Row |

2.28 |

9.1 |

1.15 |

1.5 |

|

|

|

|

|

|

06 |

2-Row |

2.70 |

8.9 |

1.38 |

1.5 |

|

|

|

|

|

|

|

3-Row |

3.31 |

4.2 |

2.46 |

2.5 |

|

|

|

|

|

|

|

4-Row |

3.59 |

5.7 |

2.29 |

2.5 |

|

|

|

|

|

|

08 |

2-Row |

3.39 |

4.0 |

2.58 |

2.5 |

|

|

|

|

|

|

|

3-Row |

4.11 |

6.9 |

2.38 |

2.5 |

|

|

|

|

|

|

|

4-Row |

4.45 |

9.4 |

2.21 |

2.5 |

|

|

|

|

|

|

10 |

2-Row |

4.32 |

6.8 |

2.52 |

2.5 |

|

|

|

|

|

|

|

3-Row |

5.55 |

13.4 |

2.30 |

2.5 |

|

|

|

|

|

|

|

4-Row |

6.00 |

18.3 |

2.13 |

2.5 |

|

|

|

|

|

|

12 |

2-Row |

4.99 |

9.6 |

2.45 |

2.5 |

|

|

|

|

|

|

|

3-Row |

6.10 |

10.5 |

2.86 |

2.5 |

|

|

|

|

|

|

|

4-Row |

6.48 |

7.3 |

3.65 |

4.0 |

|

|

|

|

|

|

CAB-PRC001-EN |

21 |

Loading...

Loading...