Trane SCXG-SVX01B-EN User Manual

Installation, Operation, &

Maintenance

IntelliPak TM

Commercial Self-Contained

Modular Series, 20-35 tons

“JO” and later design sequence

Models:

SCWG -020, -025, -030, -032, -035

SIWG -020, -025, -030, -032, -035

SCRG -020, -025, -030, -032

SIRG -020, -025, -030, -032

March 2008 |

SCXG-SVX01B-EN |

Introduction

About This Manual

Literature Change History

Use this manual for commercial selfcontained models SCWG, SIWG, SCRG, and SIRG.This is the second or “B” revision of this manual. It provides specific installation, operation, and maintenance, instructions for “JO” and later design sequences.The “JO” design sequence includes the addition of 407c refrigerant option andVFD change from Square D 58 to theTraneTR-1. Also, this literature contains changes in the filter sizes and quantities for some unit sizes. For previous design sequences, contact your localTrane representative.

Hazard Identification

Warnings and cautions appear at appropriate sections throughout this manual. Read these carefully.

WARNING

Indicates a potentially hazardous situation, which could result in death or serious injury if not avoided.

CAUTION

Indicates a potentially hazardous situation, which may result in minor or moderate injury if not avoided. Also, it may alert against unsafe practices.

NOTICE

Indicates a situation that may result in equipment or property-damage-only accidents.

WARNING

Grounding Required!

Follow proper local and state electrical code on requirements for grounding. Failure to follow code could result in death or serious injury.

SampleWarnings and Cautions

WARNING HazardousVoltage w/Capacitors!

Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/tagout procedures to ensure the power cannot be inadvertently energized. For variable frequency drives or other energy storing components provided byTrane or others, refer to the appropriate manufacturer’s literature for allowable waiting periods for discharge of capacitors.Verify with an appropriate voltmeter that all capacitors have discharged. Failure to disconnect power and discharge capacitors before servicing could result in death or serious injury.

Note: For additional information regarding the safe discharge of capacitors, see PROD-SVB06A-EN or PROD-SVB06A-FR.

NOTICE

Use Copper Conductors Only!

Unit terminals are not designed to accept other type conductors. Failure to use copper conductors may result in equipment damage.

Common HVACAcronyms

For convenience, a number of acronyms and abbreviations are used throughout this manual.These acronyms are alphabetically listed and defined below.

BAS = Building automation systems CFM = Cubic-feet-per-minute

CKT. = Circuit

CV = Constant volume CW = Clockwise

CCW = Counterclockwise E/A = Exhaust air

ECEM = Exhaust/comparative enthalpy module

F/A = Fresh air

GBAS = Generic building automation system

HGBP = Hot gas bypass HI = Human Interface

HVAC = Heating, ventilation and air conditioning

IGV = Inlet guide vanes I/O = Inputs/outputs IOD= Installation/owner/ diagnosticmanual

IPC = Interprocessor communications IPCB = Interprocessor communications bridge

LH = Left-hand

MCM = Multiple compressor module MWU = Morning warmup

NSB = Night setback O/A = Outside air

psig = Pounds-per-square-inch, gauge pressure

R/A = Return air RH = Right-hand

RPM = Revolutions-per-minute RTM = Rooftop module

S/A = Supply air

SCM = Single circuit module SZ = Single-zone (unit airflow) LCI-I communications module UCM = Unit control modules VAV =Variable air volume

VCM =Ventilation control module VOM =Ventilation override module w.c. =Water column

WSM =Waterside module ZSM = Zone sensor module

Special Note on Refrigeration Emissions

World environmental scientists have concluded that ozone in our upper atmosphere is being reduced due to the release of CFC fully halogenated compounds.

Trane urges all HVAC service personnel to make every effort to prevent any refrigerant emissions while installing, operating, or servicing equipment. Always conserve refrigerants for continued use.

© 2008Trane All rights reserved |

SCXG-SVX01B-EN |

Contents

Cross reference to related publications/information:

•Product Catalog, PKG-PRC003-EN, Modular Series Commercial Self-Contained

•IntelliPak• Self-Contained Programming Guide, PKG-SVP01B-EN

•Remote Air-Cool-Condenser Installation, Owner, and Diagnostic Manual, CXRC- SVX01B-EN

Installation …………………………........…....…6

general information …………………………………………6

pre-installation considerations… …………………………11

dimensions & weights ………………………………...…19

mechanical specifications …………………………………30

electrical requirements ……………………………………33

pre-startup requirements …………………………………35

programming ………………………………….……………57

startup …………………………………………………….…67

Operation ………………………………………70

general information ………………………………………70

sequence of operation ………………………………….…84

Maintenance ……………………………………91

maintenance procedures ………………………………92

troubleshooting ………………………………………..…105

diagnostics ………………………………………………..106

SCXG-SVX01B-EN |

3 |

Features and

Benefits

Refrigerant Handling

Procedures

Environmental Accountability Policy

Trane urges that all HVAC servicers to make every effort to eliminate, if possible, or vigorously reduce the emission of CFC, HCFC, and HFC refrigerants to the atmosphere. Always act in a responsible manner to conserve refrigerants for continued usage even when acceptable alternatives are available.

Recover and Recycle Refrigerants

Never release refrigerant to the atmosphere! Always recover and/or recycle refrigerant for reuse, reprocessing (reclaimed), or properly dispose if removing from equipment. Always determine the recycle or reclaim requirements of the refrigerant before beginning the recovery procedure. Obtain a chemical analysis of the refrigerant if necessary. Questions about recovered refrigerant and acceptable refrigerant quality standards are addressed in ARI Standard 700.

Refrigerant Handling and Safety

Consult the manufacturer’s material safety data sheet (MSDS) for information on refrigerant handling to fully understand health, safety, storage, handling, and disposal requirements. Use the approved containment vessels and refer to appropriate safety standards. Comply with all applicable transportation standards when shipping refrigerant containers.

Service Equipment and Procedures

To minimize refrigerant emissions while recovering refrigerant, use the manufacturer’s recommended recycling equipment per the MSDS. Use equipment and methods which will pull the lowest possible system vacuum while recovering and condensing refrigerant. Equipment capable of pulling a vacuum of less than 1,000 microns of mercury is recommended.

Do not open the unit to the atmosphere for service work until refrigerant is fully removed/recovered. When leak-testing with trace refrigerant and nitrogen, use HCFC-22 (R-22) rather than CFC-12 (R- 12) or any other fully-halogenated refrigerant . Be aware of any new leak test methods which may eliminate refrigerants as a trace gas. Perform evacuation prior to charging with a vacuum pump capable of pulling a vacuum of 1,000 microns of mercury or less. Let the unit stand for 12 hours and with the vacuum not rising above 2,500 microns of mercury.

A rise above 2,500 microns of mercury indicates a leak test is required to locate and repair any leaks. A leak test is required on any repaired area.

Charge refrigerant into the equipment only after equipment does not leak or

contain moisture. Reference proper refrigerant charge requirements in the maintenance section of this manual to ensure efficient machine operation. When charging is complete, purge or drain charging lines into an approved refrigerant container. Seal all used refrigerant containers with approved closure devices to prevent unused refrigerant from escaping to the atmosphere.Take extra care to properly maintain all service equipment directly supporting refrigerant service work such as gauges, hoses, vacuum pumps, and recycling equipment .

When cleaning system components or parts, avoid using CFC-11 (R-11) or CFC113 (R-113). Use only cleaning-solvents that do not have ozone depletion factors. Properly dispose of used materials. Refrigeration system cleanup methods using filters and driers are preferred.

Keep abreast of unit enhancements, conversion refrigerants, compatible parts, and manufacturer’s recommendations that will reduce refrigerant emissions and increase equipment operating efficiencies.

4 |

SCXG-SVX01B-EN |

Features and

Benefits

Modular Series Self-Contained

Unit Components

Commercial self contained units are complete HVAC systems used in floor-by- floor applications. Units are easy to install because they feature a single point power connection, factory installed and tested controls, single water point connection, factory installed options, and an internally trapped drain connection. Modular self-contained units can ship as split-apart units for installation ease. Splitapart units ship with a dry nitrogen charge and require field refrigerant charging.

Units consist of multiple compressors, water-cooled condensers (water-cooled units only), an evaporator coil, dual forward curved fans, and control panel. Air-cooled units require a remote aircooled condenser, model CXRC.The hermetically sealed 3-D scroll compressor motors utilize internal motor protection and time delays to prevent excessive cycling. Unit controls are either an electromechanical thermostat or microprocessor controls on the IntelliPak unit. See Figure I-GI-1 for a typical unit.

The hermetically sealed 3-D scroll compressor motors utilize internal motor protection and time delays to prevent excessive cycling.

The water-cooled condensers are shell and tube type with an internal subcooler. Condensers are available as mechanically or chemically cleanable.The evaporator fan is double width, double inlet and forward curved with a fixed pitch belt drive assembly. Frequency drives or inlet guide vanes are optional. Motor options include open drip proof, high efficiency,TEFC, or mill and chem spec.

All water-cooled units ship with a full refrigerant and oil charge. Air-cooled units ship with oil and a dry nitrogen holding charge and require field-piping

refrigerant connections to the air cooled condensing unit. Also, air-cooled units have two refrigerant circuits.Watercooled units have four refrigerant circuits; which include a filter drier, pressure relief valve, liquid line service valve, sight glass/ moisture indicator, thermal expansion valve with a sensing bulb and external equalizing line, discharge line shrader valve, a suction line shrader valve, and high and low pressure cutout switches. Water-cooled units also include a liquid line service valve for each circuit.

For more detailed information, see the Owner’s section of this manual.

Figure I-GI-1. IntelliPak® commercial self-contained Modular Series unit.

SCXG-SVX01B-EN |

5 |

general Installation information

Control Options

Units may be ordered with either conventional thermostat interface or IntelliPakTM Direct Digital Control (DDC). IntelliPakTM controls include a Human Interface (HI) panel with two line by forty (40) character clear English display for easy operator interface to unit setup and control parameters. All basic setup parameters are preset from the factory.

Human Interface Panel

The HI is unit mounted and accessible without opening the unit’s front panel. It allows easy setpoint adjustment using the HI keypad. In addition, the HI displays all unit operating parameters and conditions in a clear language display, which can be configured for either English, French, or Spanish.

The optional remote human interface (RHI) will control up to four self-contained units, each containing an interprocessor communications bridge (IPCB). It has all the same features as the unit-mounted HI except for the service mode.

For more information on setpoint defaults and ranges and unit programming, see the IntelliPak Self-Contained Programming Guide, PKG-SVP01B-EN. A copy ships with each unit.

IntelliPakTM DDC Control

IntelliPakTM DDC Control provides “smart” unit control with safety features and control relays for pumps, dampers, etc. The Modular Series IntelliPak selfcontained unit is controlled by a microelectronic control system that consists of a network of modules.These modules are referred to as unit control modules (UCM). In this manual, the acronym UCM refers to the entire control

system network.

These modules perform specific unit functions using proportional/integral control algorithms.They are mounted in the unit control panel and are factory wired to their respective internal components. Each module receives and interprets information from other unit modules, sensors, remote panels, and customer binary contacts to satisfy the applicable request; i.e., economizing, mechanical cooling, heating, ventilation. See the Operation section of this manual for a detailed description of each module’s function.

Optional Controls

Optional controls include a disconnect switch, dirty filter switch, water flow switch (water-cooled only), supply air temperature reset, or external setpoint inputs. Daytime heating is available on units with electric, steam, or hot water heat control options. Morning warmup operation is available on all units.

The static pressure probe, zone night heat/morning warmup, supply air temperature reset sensor options ship separate inside the unit control panel for field installation. For more detailed information on the unit control options, see the Owner’s section of this manual.

Unit Nameplate

The unit nameplate identifies the unit model number, appropriate service literature, and wiring diagram numbers. It is mounted on the left end of the unit control panel.

6 |

SCXG-SVX01B-EN |

Model

Number

Description SCWG

Model Number Description

Each IntelliPak self-contained unit has a multiple character model number unique to that unit.To determine a unit’s specific options, reference the model number on the unit nameplate using the model number explanation below.

S C |

W G N 20 |

4 |

2 JO A |

B 2 |

10 085 |

B |

A |

1 0 1 0 A A C F |

|

A |

|

1 |

1 0 T 2 0 |

||||

1 |

2 |

3 |

4 |

5 |

67 |

8 |

9 10 11 12 |

13 14 |

15 16 17 18 19 |

20 |

21 |

22 23 24 25 26 27 28 29 |

30 |

31 |

32 33 34 35 36 |

||

Digit 1 - Unit Model

S = Self Contained

Digit 2 - UnitType

C = Commercial

I = Industrial

Digit 3 - Condenser Medium

W = Water-Cooled

R = Remote Air-Cooled

Digit 4 - Development Sequence

G = Modular Series

Digit 5 - Refrigerant Circuit Configuration

N = Independent, R-22 Refrigerant

R = Independent, 407C Refigerant

Digit 6, 7 - Unit Nominal Capacity

20 = 20Tons (Water or Air Cooled)

25 = 25Tons (Water or Air Cooled)

30 = 30Tons (Water Cooled Only)

32 = 32Tons (Air Cooled Only)

35 = 35Tons (Water Cooled Only)

Digit 8 - UnitVoltage

6 = 200Volt/60 Hz/3 ph

4= 460Volt/60 Hz/3 ph

5= 575Volt/60 Hz/3 ph

Digit 9 -AirVolume/Temp Control

1= I-Pak & IGV and Supply AirTemp Ctrl

2= I-Pak & VFD and Supply Air Temp Ctrl

3= I-Pak & VFD w/ Bypass and Supply AirTemp Ctrl

4= I-Pak w/oVol. CTRL, w/ ZoneTemp Cool

5= I-Pak w/oVol. CTRL, w/ ZoneTemp Heat/Cool

6= I-Pak w/oVol. CTRL, w/ Supply Air Temp Ctrl

8 = Thermostat Interface

Digit 10, 11 - Design Sequence

JO= “J” Design

Digit 12 - Unit Construction

A= Vertical Discharge

B= Vertical Discharge with DoubleWall

C= Horizontal Discharge

D= Horizontal Discharge w/ Double Wall

E= Vertical Discharge, Ship Separate

F= Vertical Discharge w/ DoubleWall, Ship Separate

G= Horizontal Discharge, Ship Separate

H= Horizontal Discharge w/ Double Wall, Ship Separate

Digit 13 - PlenumType

B= Std Plenum w/ Factory Cut Holes

C= Low Plenum w/ Factory Cut Holes

E= Std Plenum w/ Field Cut Holes

F= Low Plenum w/ Field Cut Holes

H= Std Plenum Double Wall (Perf) w/ Field Cut Holes

J= Low Plenum Double Wall (Perf) w/ Field Cut Holes

L= Std. Plenum w/Factory Cut Holes, Ship Separate

M= Low Plenum with Factory Cut Holes, Ship Separate

P= Std Plenum w/ Field Cut Holes, Ship Separate

R= Low Plenum w/ Field Cut Holes, Ship Separate

U= Std Plenum Double Wall (Perf) w/ Field Cut Holes, Ship Separate

V= Low Plenum Double Wall (Perf) w/ Field Cut Holes, Ship Separate

0 = Without Plenum

Digit 14 - MotorType

1= Std. Efficiency ODP

2= Premium Eff. ODP

3= Std. EfficiencyTotally Enclosed

Digit 15, 16 - Motor HP

05 = 5 HP Motor

07 = 7.5 HP Motor

10 = 10 HP Motor

15 = 15 HP Motor

20 = 20 HP Motor

25 = 25 HP Motor

Digit 17, 18, 19 - Fan RPM

085 = 850 rpm

090 = 900 rpm

095 = 950 rpm

100 = 1000 rpm

105 = 1050 rpm

110 = 1100 rpm

115 = 1150 rpm

120 = 1200 rpm

125 = 1250 rpm

130 = 1300 rpm

135 = 1350 rpm

140 = 1400 rpm

145 = 1450 rpm

150 = 1500 rpm

155 = 1550 rpm

160 = 1600 rpm

165 = 1650 rpm

170 = 1700 rpm

175 = 1750 rpm

180 = 1800 rpm

185 = 1850 rpm

Digit 20 - HeatingType

A= Steam Coil, LH

B= Hot Water Coil, LH

C= Electric Heat, 1 Stage

F= Hydronic Heat Ctrl Interface

G= Elec. Heat Ctrl Interface, 1 stage

K= Steam Coil Ship Separate, LH

L= Hot Water Coil Ship Separate, LH

M= Steam Coil, RH

N= Hot Water Coil, RH

P= Steam Coil Ship Separate, RH

R= HotWater Coil Ship Separate, RH

T= Hi-cap. hot water coil, LH

U= Hi-cap, hot water coil LH, Ship Seperate

V= Hi-cap. hot water coil, RH

W= Hi-cap. hot water coil, RH, Ship Seperate

0 = None

Digit 21 - Unit Isolators

A= Isopads

B= Spring Isolators 0 = None

SCXG-SVX01B-EN |

7 |

Model

Number

Description SCWG

Digit 22 - Unit Finish

1= Paint - Executive Beige

2= Protective Coating

3= Protective Coating w/ Finish Coat

Digit 23

0 = None

Digit 24 - Unit Connection

1= Disconnect Switch

2= Terminal Block

3= Dual Point Power

Digit 25 - Industrial Options

A= Protective Coated Evaporator Coil

B= Silver Solder

C= Stainless Steel Screws

D= A and B

E= A and C

F= B and C

G= A, B and C

0 = None

Digit 26 - Drain PanType

A= Galvanized Sloped

B= Stainless Steel Sloped

Digit 27 -Waterside Economizer

A= Mechanical Clean Full Cap. (4-row)

B= Mechanical Clean Low Cap. (2-row)

C= Chemical Clean Full Cap. (4-row)

D= Chemical Clean Low Cap. (2-row)

E= Mechanical Clean Full Capacity

(4-row) Ship Separate

F= Mechanical Clean Low Capacity (2-row) Ship Separate

G= Chemical Clean Full Capacity (4-row) Ship Separate

H= Chemical Clean Low Capacity

(2-row) Ship Separate

0 = None

Digit 28 -Ventilation Control

B= Airside Econ w/Traq™ Damper (Top O/A Inlet)

C= Airside Econ w/ Standard Dampers (Top O/A Inlet)

E= Airside Econ w/Traq™ Damper and Comparative Enthalpy

(Top O/A Inlet)

F= Airside Econ w/ Std Dampers and Comparative Enthalpy (Top O/A Inlet)

G= Traq DamperVentilation Interface

H= Ventilation For 2 Pos. Cntrl Interface 0 = None

Digit 29 -Water Piping

A= Right Hand Condenser Connection

B= Left Hand Condenser Connection

C= Right Hand Basic Piping

D= Left Hand Basic Piping

E= Right Hand Intermediate Piping

F= Left Hand Intermediate Piping

J= Right Hand Basic w/ Flow Switch

K= Left Hand Basic w/ Flow Switch

L= Right Hand Intermediate

w/ Flow Switch

M= Left Hand Intermediate w/ Flow Switch

0 = None

Digit 30 - CondenserTubeType

A= Standard CondenserTubes

B= 90/10 CuNi CondenserTubes 0 = None

Digit 31 - Compressor ServiceValves

1 = With Service Valves

0 = None

Digit 32 - Miscellaneous System Control

1= Timeclock

2= Interface for Remote HI

3= Dirty Filter Switch

4= 1 and 2

5= 1 and 3

6= 2 and 3

7= 1, 2, and 3

0 = None

Digit 33 - Control Interface Options

A= Generic BAS Module (GBAS)

B= Ventilation Override Module (VOM)

D= Remote Human Interface (RHI)

G= GBAS andVOM

H= GBAS and RHI

J= VOM and RHI

M= GBAS,VOM, and RHI 0 = None

1 = Tracer/LCI-I (COMM5) interface module

2 = Tracer/LCI-I and GBAS

3= Tracer/LCI-I andVOM

4= Tracer/LCI-I and RHI

5= Tracer/LCI-I, GBAS andVOM

6= Tracer/LCI-I, GBAS and RHI

7= Tracer/LCI-I,VOM and RHI

8= Tracer/LCI-I, GBAS,VOM and RHI

Digit 34 - Agency

T = UL Agency Listing

0 = None

Digit 35 - FilterType

1= 2-inch ConstructionThrowaway

2= 2-inch Med Eff. Throwaway

Digit 36 - Miscellaneous Control Option

A= Low Entering AirTemp. Protect Device (LEATPD)

B= High DuctTempT-Stat

C= Plenum High Static Switch

D= Kit for Heat Mode Output (w/t’stat)

E= A and B

F= A and C

G= B and C

H= A, B, and C

0 = None

8 |

SCXG-SVX01B-EN |

Model

Number

Description PSWG

Self-Contained Ship-WithAccessory Model Number Description

P |

S |

W |

G |

S |

A |

1 |

1 |

0 |

JO |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 11 |

Digit 1 - Parts/Accessories

P = Parts/Accessories

Digit 2 - Unit Model

S= Self-Contained

Digit 3 - Shipment

W = With Unit

Digit 4 - Development Sequence

F = Signature Series

G = Modular Series

Digit 5 - Sensors and Other Accessories

S = Sensors

Digit 6 - Sensors and Thermostats (field installed)

A = BAYSENS077 - ZoneTemp Only (CV andVAV)

B = BAYSENS073 - ZoneTemp with Timed Override Button (CV andVAV)

C = BAYSENS074 - ZoneTemp with Timed Override Button, Setpoint Dial (CV andVAV)

D = BAYSENS023 - Remote Min. Position Potentiometer Control (OA Damper)

E = BAYSENS108 - CV Zone Sensor-dual setpoint, man/auto changeover

F = BAYSENS110 - CV Zone Sensor-dual setpoint, man/auto changeover w, indicator lights

G = BAYSENS019 - CV Programmable Night Setback Sensor

H = BAYSENS021 -VAV Zone Sensor with Indicator Lights

J = BAYSENS020 -VAV Programmable Night Setback Sensor

K = Remote Sensor Kit

L= Outside AirTemperature Sensor Kit

M= OutsideAir Humidity Sensor Kit

N= BAYSTAT010 - 2 Heat/2 Cool Thermostat

P= BAYSTAT037A - 2 Heat/2 Cool ProgrammableThermostat

0 = None

Digit 7 - Mixed AirTemperature Protection Kit (field installed)

1 = Mixed AirTemperature Protection Kit

0 = None

Digit 8 - Carbon Dioxide Sensor (field installed)

1 = Carbon Dioxide Sensor Kit

0 = None

Digit 9 - Future Option

0 = None

Digit 10, 11 - Design Sequence

J0 = J Design

SCXG-SVX01B-EN |

9 |

Model

Number

Description PSWG

“After-Shipment”Accessory Model Number

P S A G W N 20 4 ** 1 10 0 0 0 1 0 1 0 1 0 1 0 0 1 1 0 0 0 0 0 L 1 0 0 7 0 0

1 |

2 |

3 |

4 |

5 |

6 |

7 8 |

9 10 11 12 |

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 |

34 |

35 36 37 38 39 40 |

||||

0 |

|

0 |

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

41 42 43 44 45 |

|

|

|

|

|

|

|

|

||||||

Digit 1 - Parts/Accessories |

|

Digit 13, 14 - Motor HP |

Digit 21 - Sensors andThermostats |

|||||||||||

P = Parts/Accessories |

|

|

05 = 5 HP Motor |

A = BAYSENS077 - ZoneTemp Only (CV |

||||||||||

Digit 2 - Unit Model |

|

|

07 = 7.5 HP Motor |

andVAV) |

|

|

||||||||

|

|

10 = 10 HP Motor |

B = BAYSENS073 - ZoneTemp with |

|||||||||||

S= Self-Contained |

|

|

||||||||||||

|

|

15 = 15 HP Motor |

Timed Override Button (CV andVAV) |

|||||||||||

Digit 3 - Shipment |

|

|

||||||||||||

|

|

20 = 20 HP Motor |

C = BAYSENS074 - ZoneTemp with |

|||||||||||

A = After Unit |

|

|

|

|

25 = 25 HP Motor |

Timed Override Button, Setpoint Dial |

||||||||

Digit 4 - Development Sequence |

|

30 = 30 HP Motor |

(CV andVAV) |

|||||||||||

F = Signature Series |

|

|

40 = 40 HP Motor |

E = BAYSENS108 - CV Zone Sensor-dual |

||||||||||

G = Modular Series |

|

|

50 = 50 HP Motor (460V & 575V Only) |

setpoint, man/auto changeover |

||||||||||

Digit 5 - Condenser Medium |

|

0 |

= Not Defined |

F = BAYSENS110 - CV Zone Sensor-dual |

||||||||||

|

Digit 15 - Exhaust/Comparative Enthalpy |

setpoint, man/auto changeover w, |

||||||||||||

W = Water Cooled |

|

|

||||||||||||

|

|

indicator lights |

||||||||||||

R = remote Air Cooled |

|

Module (Field Installed) |

||||||||||||

|

G = BAYSENS019 - CV Programmable |

|||||||||||||

|

|

|

|

|

|

|

|

|

1 |

= ECEM Kit |

||||

Digit 6 - Refrigerant Circuit Configuration |

Night Setback Sensor |

|||||||||||||

0 |

= None |

|||||||||||||

N = Independent (Water-Cooled) |

|

H = BAYSENS021 -VAV Zone Sensor |

||||||||||||

|

Digit 16 - Generic BAS Module |

|||||||||||||

M = Manifolded (Air-Cooled) |

|

with Indicator Lights |

||||||||||||

Digits 7, 8 - Unit Nominal Capacity |

1 |

= GBAS 0-5 VDC Kit |

J = BAYSENS020 -VAV Programmable |

|||||||||||

0 |

= None |

Night Setback Sensor |

||||||||||||

20 = 20Tons (Water or Air) |

|

|||||||||||||

|

Digit 17 - Heat Module |

K = Remote Sensor Kit |

||||||||||||

22 = 22Tons (Water Only) |

|

|||||||||||||

|

L = Outside AirTemperature Sensor Kit |

|||||||||||||

25 = 25Tons (Water or Air) |

|

1 |

= Electric Heat Module Kit |

|||||||||||

|

M = Outside Air Humidity Sensor Kit |

|||||||||||||

29 = 29Tons (Water or Air) |

|

2 |

= Hydronic Heat Module Kit |

|||||||||||

|

0 = None |

|

|

|||||||||||

30 = 30Tons (Air Only) |

|

0 |

= None |

|

|

|||||||||

|

Digit 22 - Low Entering AirTemperature |

|||||||||||||

32 = 32Tons (Water Only) |

|

Digit 18 - Remote Human Interface and |

||||||||||||

35 = 35Tons (Water or Air) |

|

Protection Device |

||||||||||||

|

IPCB |

|||||||||||||

38 = 38Tons (Water Only) |

|

1 = Low Entering AirTemperature |

||||||||||||

|

1 |

= Remote Human Interface Panel Kit |

||||||||||||

40 = 40Tons (Air Only) |

|

|

(RHI Only) |

Protection Device Kit |

||||||||||

42 = 42Tons (Water Only) |

|

|

0 = None |

|

|

|||||||||

|

2 |

= Interprocessor Communications |

|

|

||||||||||

46 = 46Tons (Water Only) |

|

|

|

|

||||||||||

|

|

Module Kit (IPCB Only) |

Digit 23 - High DuctTemperature |

|||||||||||

50 = 50Tons (Air Only) |

|

|

||||||||||||

|

3 = RHI and IPCB Kit |

Thermostat |

|

|

||||||||||

52 = 52Tons (Water Only) |

|

|

|

|||||||||||

|

0 |

= None |

1 = High DuctTemp.Thermostat Kit |

|||||||||||

58 = 58Tons (Water Only) |

|

|||||||||||||

|

Digit 19 - LonTalk Communications |

0 = None |

|

|

||||||||||

60 = 60Tons (Air Only) |

|

|

|

|||||||||||

|

|

|

|

|||||||||||

|

Interface Kit (LCI) |

Digit 24 - Plenum High Static Switch |

||||||||||||

65 = 65Tons (Water Only) |

|

|||||||||||||

72 = 72Tons (Water Only) |

|

2 |

=Tracer/LCI-I Comm Interface Kit |

1 = Plenum High Static Switch Kit |

||||||||||

80 = 80Tons (Water Only) |

|

0 |

= None |

0 = None |

|

|

||||||||

Digit 9 - UnitVoltage |

|

|

Digit 20 -Ventilation Override Module Kit |

Digits 25 — 45 - Future Use |

||||||||||

6 = 200Volt/60 Hz/3 ph |

|

(VOM) |

0 = None |

|

|

|||||||||

4 = 460Volt/60 Hz/3 ph |

|

1 = VOM Kit |

|

|

|

|||||||||

|

0 |

= None |

|

|

|

|||||||||

5 = 575Volt/60 Hz/3 ph |

|

|

|

|

||||||||||

|

|

|

|

|

|

|||||||||

0 = Not Defined

Digits 10, 11 - Design Sequence

** = Factory Assigned

Digit 12 - Unit Power Connection

1 = Single Point Power

2 = Dual Point Power

0 = Not Defined

10 |

SCXG-SVX01B-EN |

pre-installation Installation considerations

Receiving and Handling

Shipping Package

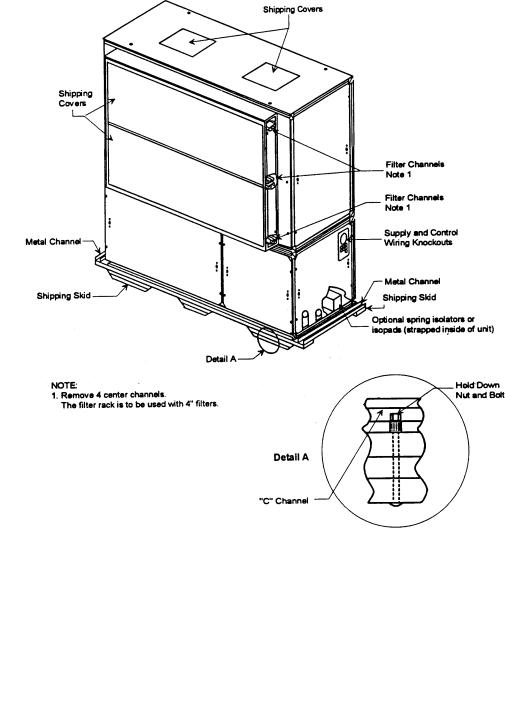

Commercial self-contained units ship assembled with protective coverings over the coil and discharge openings.

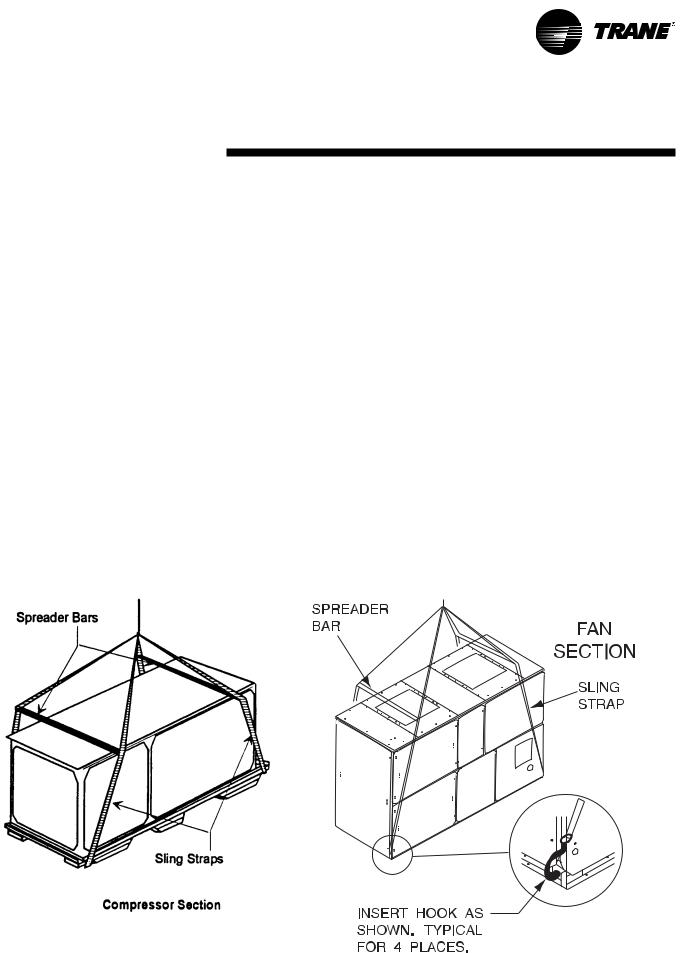

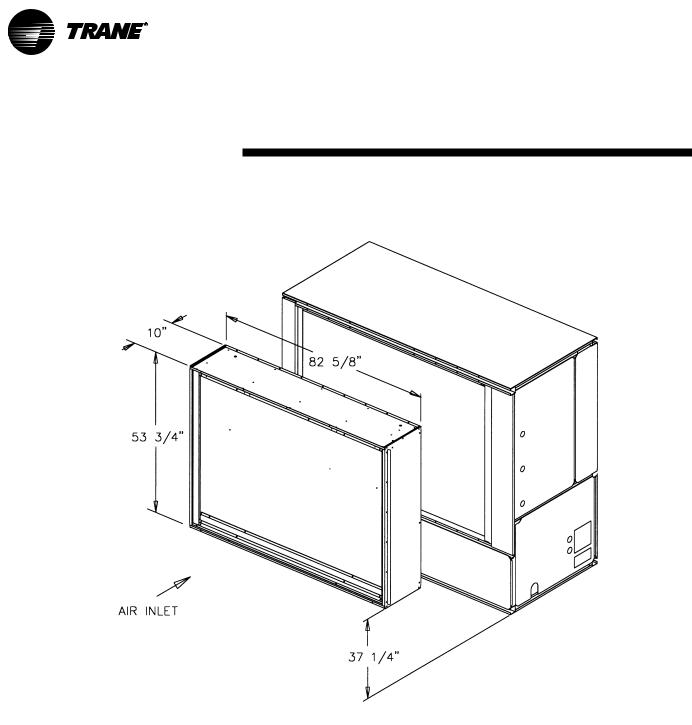

Figure I-PC-1 illustrates a typical shipping package.

Ship-Separate Accessories

Field-installed sensors ship separately inside the unit’s main control panel. Extra filters, sheaves, and belts ship in the unit’s fan motor section. Condenser plugs, spring isolators, and isopads ship in the unit’s bottom left side.

Receiving Checklist

Complete the following checklist immediately after receiving unit shipment to detect possible shipping damage.

Inspect individual cartons before accepting. Check for rattles, bent carton corners, or other visible indications of shipping damage.

If a unit appears damaged, inspect it immediately before accepting the shipment. Make specific notations concerning the damage on the freight bill. Do not refuse delivery.

Inspect the unit for concealed damage before it is stored and as soon as possible after delivery. Report concealed damage to the freight line within the allotted time after delivery. Check with the carrier for their allotted time to submit a claim.

Do not move damaged material from the receiving location. It is the receiver’s responsibility to provide reasonable evidence that concealed damage did not occur after delivery.

Do not continue unpacking the shipment if it appears damaged. Retain all internal packing, cartons, and crate. Take photos of damaged material if possible.

Notify the carrier’s terminal of the damage immediately by phone and mail. Request an immediate joint inspection of the damage by the carrier and consignee.

Notify yourTrane representative of the damage and arrange for repair. Have the carrier inspect the damage before making any repairs to the unit.

Figure I-PC-1. Typical unit mounted on shipping skid.

SCXG-SVX01B-EN |

11 |

pre-installation Installation considerations

Installation Preparation

Before installing the unit, perform the following procedures to ensure proper unit operation.

1.Verify the floor or foundation is level. Shim or repair as necessary.To ensure proper unit operation, install the unit level (zero tolerance) in both horizontal axis. Failure to level the unit properly can result in condensate management problems, such as standing water inside the unit. Standing water and wet surfaces inside units can result in microbial growth (mold) in the drain pan that may cause unpleasant odors and serious health-related indoor air quality problem.

2.Allow minimum recommended clearances for maintenance and routine service. See “Service Access” section on page 13.

3.Position the unit and skid assembly in its final location. If unit shipped splitapart, follow the procedure in the “Split-Apart Unit Assembly” section on page 16 before completing this step.Test lift the unit to determine exact unit balance and stability before hoisting it to the installation location. See Figure I-PC-7 and I-PC-8 on page 15 for typical rigging procedures, including cautions and proper uses of such equipment as fork lifts, spreader bars, and hooks.

4.Remove the skids from under the unit. See the “Rigging and Handling” section on page 14. Refer to the “Skid Removal” section on page 18. If you find internal damage, file a claim immediately to the delivering carrier.

5. Remove the protective shipping covers from the unit. Refer to the “Unit Protective Covers” section on page 35.

Note: Unit height and connection locations will change if external vibration isolators are used. The unit may be raised an additional 5-7/8 inches with spring-type isolators.

Note: Unit height and connection locations will change if the unit is constructed to be split-a-part in the field. See unit submittal drawings for connection locations.

6.Electrical supply power must meet specific balance and voltage requirements, as described in the “Electrical Requirements” section on page 33.

7.Water-cooled units only (model SCWG): The installer must furnish and install a condenser main and standby water pump, cooling tower, pressure gauges and all components for the waterside piping. See the “Water Piping” section on page 30 for general waterside recommendations.

8.Air-cooled units only (model SCRG): These units require field-installation of a remote air-cooled condenser and refrigerant piping. See the “Refrigerant Piping” section on page 32 for general piping recommendations.

12 |

SCXG-SVX01B-EN |

pre-installation Installation considerations

ServiceAccess

WARNING HazardousVoltage w/Capacitors!

Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/tagout procedures to ensure the power cannot be inadvertently energized. For variable frequency drives or other energy storing components provided byTrane or others, refer to the appropriate manufacturer’s literature for allowable waiting periods for discharge of capacitors.Verify with an appropriate voltmeter that all capacitors have discharged. Failure to disconnect power and discharge capacitors before servicing could result in death or serious injury.

Note: For additional information regarding the safe discharge of capacitors, see PROD-SVB06A-EN or PROD-SVB06A-FR.

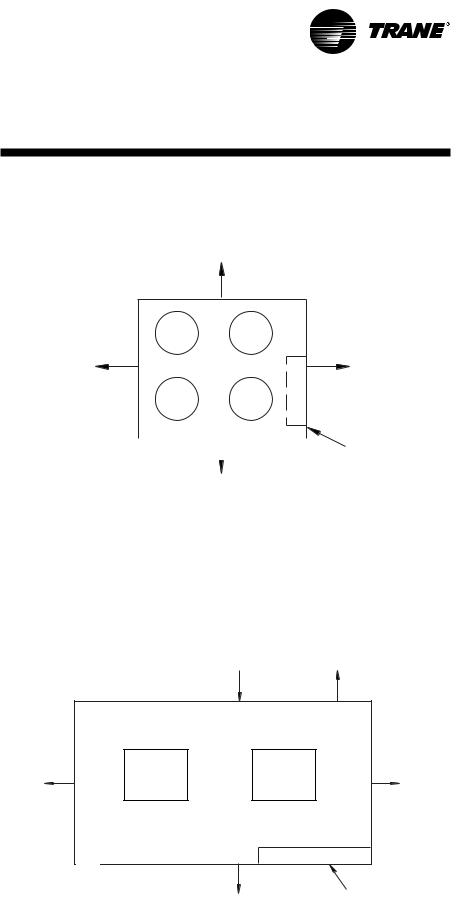

See Figure I-PC-2 andTable I-PC-1 for recommended service and code clearances. Access to thermostat unit controls is through a hinged access panel door on the front, lower left of the unit’s compressor section.

IntelliPak unit controls access is through a panel on the middle right of the fan section. The panel is secured with an automatic latch and quick-acting fasteners, which require a screwdriver to open.

Removable front unit panels provide access to compressors, fan, motor, inlet guide-vane actuator, and belts.

Removable left side panels give access to drive side, fan bearing, inlet guide-vanes, condensers, and waterside economizer control valve.The compressor, condenser and fan motor access panels are secured with quick-acting fasteners. Access panels for evaporator coils, expansion and water valves, and left fan bearing are sheet metal screws. Access to other components for service requires removal of panels secured with sheet metal screws. During operation, sight glasses are viewable through portholes on the upper right side panel of the fan section.

Variable Frequency Drives are shipped separately and field installed. See page 29 forVFD related dimensions and weights.

96” (2132 mm)

TopView

CCRC/CIRC 20, 29, 32

48” (1066 mm) |

48” (1066 mm) |

|

|

|

|

|

|

Control |

|

|

|

|

|

||

|

|

|

|

|

|

Panel |

|

|

|

|

96” (2132 mm) |

||

Table I-PC-1. Service and code clearance requirements |

||||||

|

|

|

|

|

|

|

Side |

Distance |

|

Purpose |

|||

front |

42 in. (20-38 tons) |

|

NEC code requirement |

|||

left |

18 in. |

|

|

air-cooled units only |

||

|

36 in. |

|

|

refrigeration & waterside component service |

||

|

77 in. |

|

fan shaft removal |

|||

right |

36 in. |

|

provides uniform airflow |

|||

inlet |

18 in. |

|

provides uniform airflow |

|||

air inlet |

18” minimum |

|

See table |

36”minimum |

42” minimum

Control

Panel

Figure I-PC-2.Top view of self-contained unit showing recommended service and code clearances

SCXG-SVX01B-EN |

13 |

pre-installation Installation considerations

Rigging and Unit Handling

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper center of gravity lift point. To avoid dropping of unit, reposition lifting point if unit is not level. Failure to properly lift unit could result in death or serious injury or possible equipment or property-only damage.

WARNING

Lifting Equipment Capacity!

Ensure lifting equipment capacity exceeds unit weight by an adequate safety factor to prevent injury, death, or unit damage.

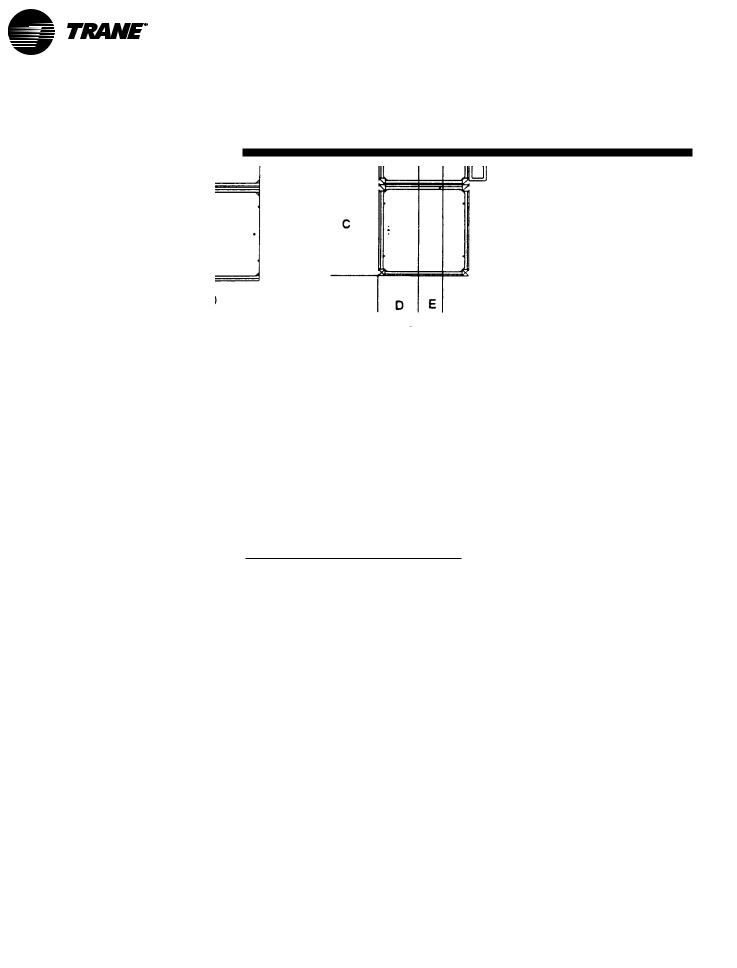

Before lifting the unit or modular component, determine the approximate center of gravity for lifting safety. See Figure I-PC-5 for assembled modular units and Figure I -PC-6 for split-apart units. The center of gravity may vary slightly within the gravity block depending on unit options.

Always test-lift the unit to determine the exact unit balance and stability before hoisting it to the installation location. See Figures I-PC-7 and I-PC-8 for typical rigging procedures and proper rigging equipment usage.

Figure I-PC-5.Assembled unit gravity block location.

Table I-PC-2. Gravity Block Dimensions

Model |

A |

B |

C |

D |

SCWG |

36 |

14 |

38 |

12 |

SCRG |

36 |

16 |

40 |

12 |

Fan Section Only

Compressor Section Only

Figure I-PC-6. Split-apart unit gravity block location.

14 |

SCXG-SVX01B-EN |

pre-installation Installation considerations

Unit Handling Procedure

NOTICE

Do not use hooks to lift unit or hook into open channels to lift unit. This could cause unit damage.

1.Position rigging sling under wood shipping skid.

2.Use spreader bars to avoid unit damage.

3.When using a forklift, exercise caution to prevent unit damage.

4.Use the standard fork length to lift one end and drag or pull unit while skidding the opposite end.

5.The unit center of gravity will fall within center of gravity block at various locations depending on unit options.

6.Use hooks to lift fan section only. Do not hook into open channels to lift unit.

7.See unit nameplate for unit weight.

8.Do not stack units.

Figure I-PC-7.Assembled modular unit proper rigging.

Figure I-PC-8. Split-apart modular unit proper rigging.

SCXG-SVX01B-EN |

15 |

pre-installation Installation considerations

Split-Apart Unit Assembly

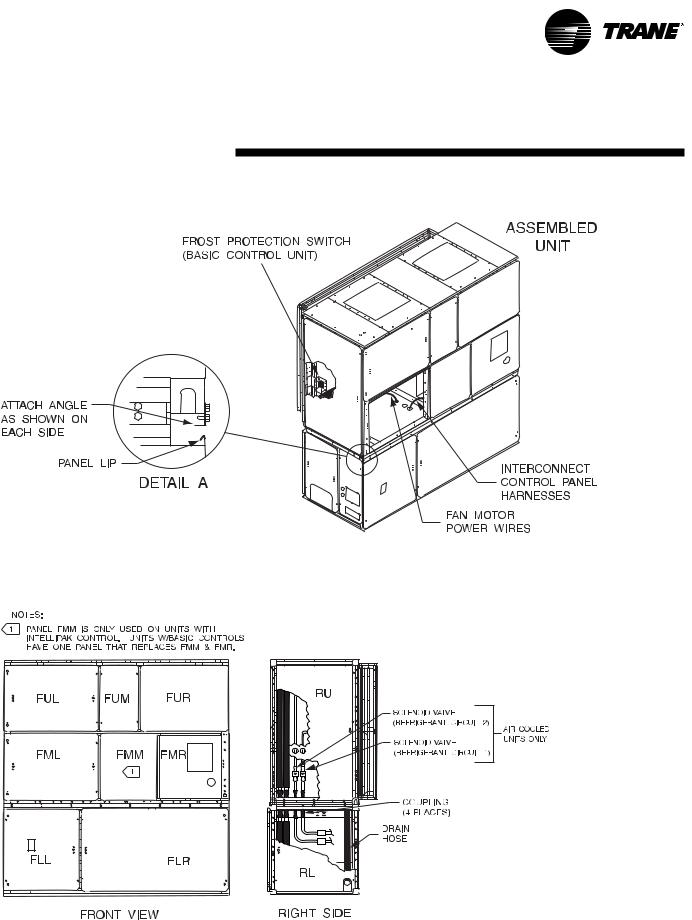

1.Ensure the tagging information on the fan section nameplate matches that on the compressor nameplate.

2.Remove the connector brackets holding the the sheet metal shipping cover on compressor section. Retain brackets and screws.

3.Remove shipping cover from the compressor section and verify the shipwith packge contains:

•suction and discharge line couplings

•insulation

•sheet metal screws

4.Lift fan section onto the compressor section using the rigging method in Figure I-PC-8 on page 13.

5.Remove skid from the fan section, placing the fan section onto the compressor section. Reference Figure I- PC-9.

6.Install the connection brackets with the sheet metal screws (referenced in step 2) on all sides of the unit. Reference Detail “A” in Figure I-PC-9.

7.Remove the unit panels labeled RU and RL in Figure I-PC-10 on page 17. To remove panels, first remove the four shipping screws located in the corner of each panel. Next, turn the remaining 1/4 turn fasteners to the unlatch position. The panel is supported by a “lip” channel. So, lift the panel up and off the unit to remove it. See Detail “A”in Figure I-PC-9.

8.Connect the drain hose to the drainpan outlet fitting and secure it with the drain hose clamp provided.

9.Circulate nitrogen thoughout refrigerant circuits.

10.Unbraze and remove the caps on the discharge and suction lines in both the compressor and fan sections.

11.Install and braze discharge and suction line couplings.

12.Insulate discharge and suction lines with the insulation provided.

13.Remove panel FLR and open the bottom control panel door, FLL. Pull the fan motor leads (coiled in the fan section) through the knockout in the bottom of the fan section to the control panel. Ensure that the bushing is installed in the hole to prevent the wires from chafing. Refer to the unit wiring diagrams to connect the fan motor leads properly and ensure correct phase sequencing.

IntelliPak Units(UCM) Only

14.Remove panels FML, FMM, and FMR.

15.Pull the circular plug connector (CPC) from the compressor section through the knockouts into the fan section.

Install the bushings (provided on the wiring harnesses) in the knockouts.

16.Using the CPC wiring diagram, connect the male CPC to the female CPC in the top control panel.

17.If the unit has the mixed air temperature option, route the capillary tube on back of the filter rack.

Units with Thermostat Only

18.Remove panel FMR. See Note 1 on Figure I-PC-10.

19.Pull frost protection wires from the bottom control panel throughknockouts in bottom of fan section. Route wires to the appropriate frost protection switches on the evaporator coil. Reference the unit wiring diagrams to connect frost protection wiring connectors.

Air-Cooled Units Only:

20. Route the refrigerant circuit wires for circuits 1 and 2 from the bottom control panel through the knockouts to the solenoid valves. The solenoid valves are located in the liquid refrigerant lines on the right-hand side of the unit. Refer to the unit wiring diagrams to make splice connections.

16 |

SCXG-SVX01B-EN |

pre-installation Installation considerations

Figure I-PC-9 How to assemble the split apart modular unit

Figure I-PC-10 Modular unit panel description and internal connections

SCXG-SVX01B-EN |

17 |

pre-installation Installation considerations

Skid Removal

The unit ships on skids to provide forklift locations from the front or rear.The skid allows easy maneuverability of the unit during storage and transportation.

Remove the skids before placing the unit in its permanent location.

Remove the skids using a forklift or jack. Lift one end of the unit off of the skids. See Figure I-PC-5 and I-PC-6 for unit gravity block location. Slide the skids out and lower the unit at the installation location.

Note: External isolation is not necessary since units are internally isolated. Consult a vibration specialist before “doubleisolating” the unit.

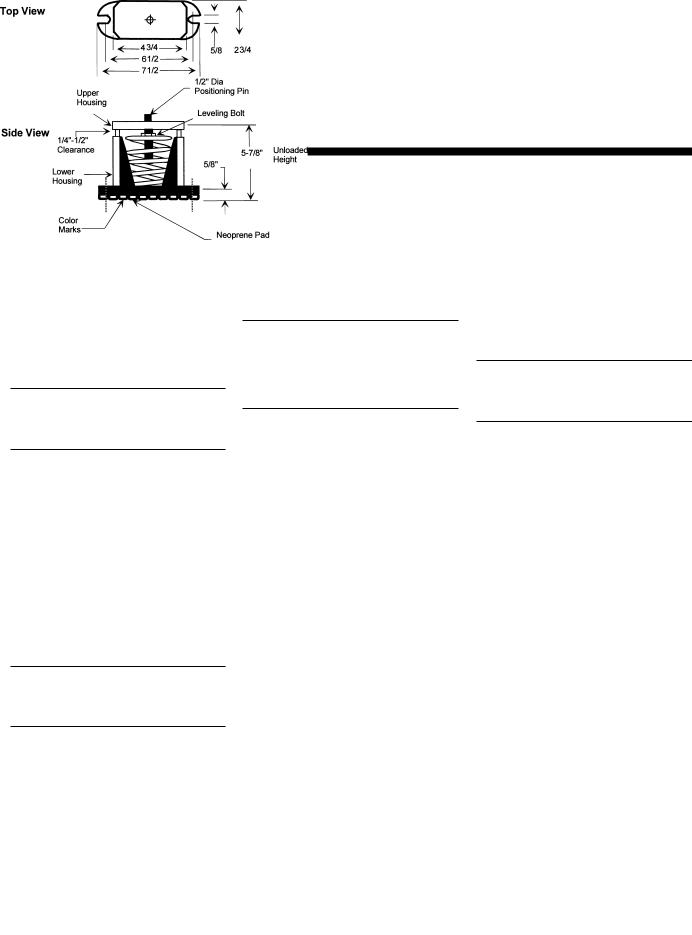

External Unit Isolation

If your job requires external vibration isolation, two options are available: isopads or spring-type isolators. Isopads should be placed under the unit at locations indicated on the factoryprovided isolator sheet.

Set the spring-type isolators (Figure I-PC- 9) in position after the unit is removed from skids before making electrical, piping, or duct connections. All units require a minimum of four isolators per unit. But some may require six isolators, depending upon unit options.

Note: Trane strongly recommends you consult a vibration specialist before double-isolating the unit. Double isolation is not recommended.

If you decide to externally isolate the unit, use spring-flex, type CP isolators. The spring number is marked on the outer housing. See Figure I-PC-9.

To install external isolators, complete the following procedure.

1.Locate the isolators under unit base at the locations indicated on the factoryprovided isolator placement sheet. Lift one end of the unit at a time to position isolators to the floor, using anchor bolts.

2.Level the unit by adjusting isolator heights. Unit weight may cause the upper housing to rest on the lower housing of the spring isolators. The isolator clearance shown in the side

view of Figure I-PC-9, must be 1/4 - 1/2 inches.To increase the clearance, lift the unit off the isolator and turn the leveling bolt counterclockwise. Recheck the unit level and the housing clearances. Maximum allowable difference between isolator heights is 1/4 inch. Shim as required under the isolators.

Note: The compressors and fan assembly are internally isolated on most units. Due to this, the addition of external isolation devices (spring mounting isolators) is at the discretion of the building or HVAC system designer.

Pre-Installation Checklist

Complete the following checklist before beginning unit installation.

Verify the unit size and tagging with the unit nameplate.

Make certain the floor or foundation is level, solid, and sufficient to support the unit and accessory weights. Level or repair the floor before positioning the unit if neccesary.

Allow minimum recommended clearances for routine maintenance and service. Refer to unit submittals for dimensions.

Allow three fan diameters above the unit for the discharge ductwork. Return air enters the rear of the unit and conditioned supply air discharges through the top.

Electrical connection knockouts are on the top, left side of the unit.

Allow adequate space for piping access and panel removal. Condenser water piping, refrigerant piping, and condensate drain connections are on the lower left end panel.

Note: Unit height and connection locations will change if using vibration isolators. The unit height may increase up to 5 7/8” with spring type isolators.

Electrical supply power must meet specific balance and voltage requirements as described in the “Electrical Requirements” section.

Water-cooled units only: The installer is responsible for providing a condenser main, standby water pump, cooling tower, pressure gauges, strainers, and all components for waterside piping. See the “Water Piping” section for general waterside recommendations.

Air-cooled units only: The installer is responsible for providing and installing the remote air-cooled condenser and refrigerant piping, including filter driers.

Figure I-PC-9. Optional spring isolator dimensional data.

18 |

SCXG-SVX01B-EN |

Dimensions & |

SCWG |

Weights |

SIRG |

|

|

|

|

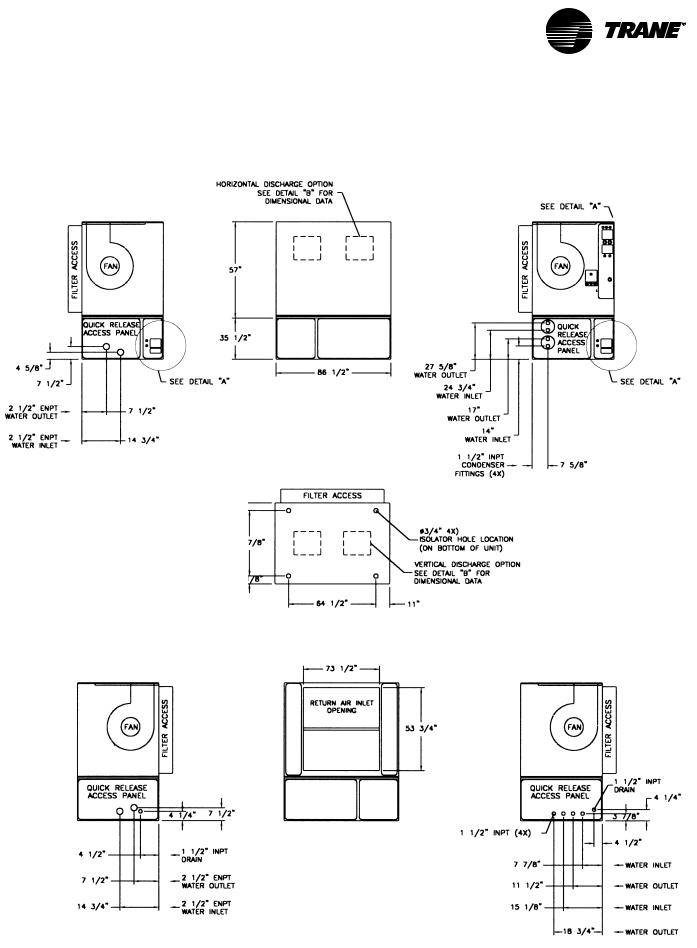

SCWG/SIWG Dimensions, in.

|

|

|

|

|

|

|

|

|

|

|

|

|

left-side view |

|

|

|

factory-piped units |

|

|

SCWG/SIWG weight, lbs. |

|

||

|

|

|

|

unit tons |

base weight |

|

|

20 |

2260 |

|

|

25 |

2730 |

|

|

30 |

2864 |

|

|

35 |

3000 |

|

|

Notes:

1.All unit weights include refrigerant, water, inlet guide vanes and controllers, electric heat and valves.

2.Add 150 lbs. to total weight to obtain approximate shipping weight.

3.Split-apart unit weights are approximately: 60% total unit weight = compressor section, 40% total unit weight = fan section.

right-side view factory-piped units

front view

left-side view

direct condenser connections

top view

back view

right-side view direct-condenser connections

SCXG-SVX01B-EN |

19 |

Dimensions & |

SCRG / |

Weights |

SIRG |

|

|

|

|

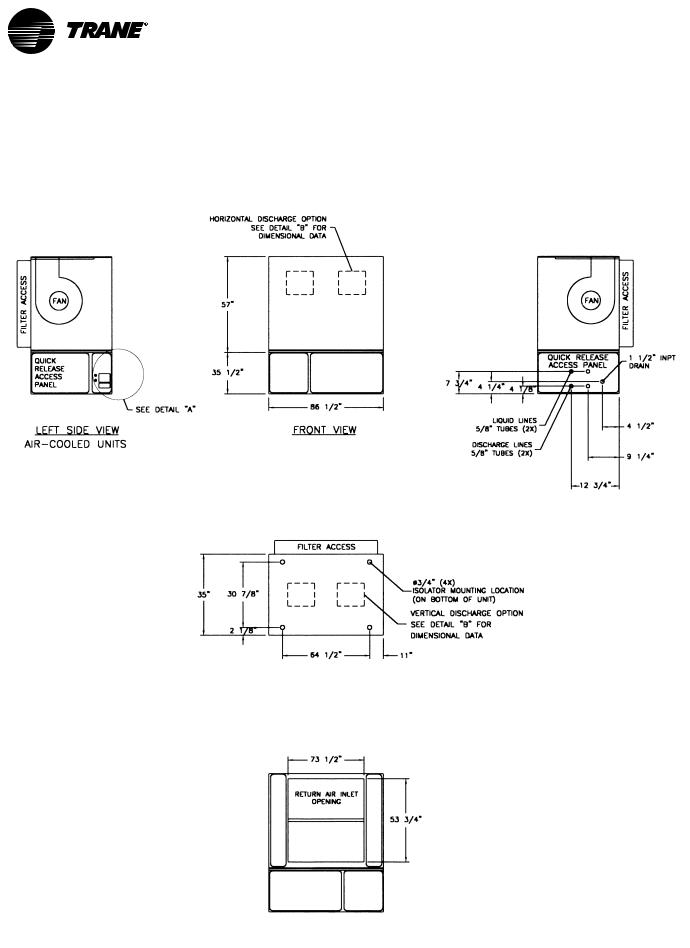

SCRG/SIRG Dimensions, in.

|

|

front view |

|

left-side |

view |

||

|

|||

|

|

|

|

|

|

|

right-side view

top view

SCRG/SIRGWeight, lbs.

unit tons |

base weight |

20 |

2344 |

25 |

2479 |

32 |

2614 |

Notes:

1. All unit weights include refrigerant, water, inlet guide vanes and controllers, electric heat and valves.

2. Add 150 lbs. to total weight to obtain approximate shipping weight.

3. Split-apart unit weights are approximately: 60% total unit weight = compressor section, 40% total unit weight = fan section.

back view

20 |

SCXG-SVX01B-EN |

Dimensions &

Weights

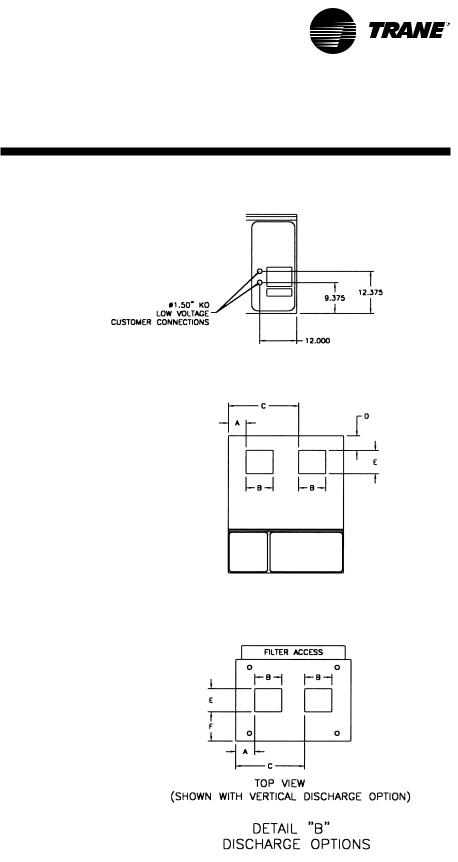

SCRG/SIRG/SCWG/SIWG Detail “A”

Electrical Connections, in.

Detail “B” Discharge Options , in.

front view

shown with horizontal discharge option

|

|

|

|

|

|

|

top view |

|

|

|

|

|

|

|

shown with vertical discharge |

option |

|||

Detail Dimensions, in. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

model |

A |

B |

C |

|

D |

E |

F |

|

|

SCWG/SCRG 20 |

20 |

10 3/4 |

58 1/2 |

5 1/8 |

13 1/4 |

11 1/2 |

|

|

|

SCWG/SCRG 25 |

19 1/4 |

12 1/4 |

57 5/8 |

5 1/8 |

13 1/4 |

11 1/2 |

|

|

|

SCWG 30 - 35/SCRG 32 |

|

18 |

14 5/8 |

56 1/2 |

5 1/8 |

13 1/4 |

|

|

|

11 1/2 |

|

|

|

|

|

|

|

|

|

SCXG-SVX01B-EN |

21 |

Dimensions & |

CCRC / |

Weights |

CIRC |

|

|

|

|

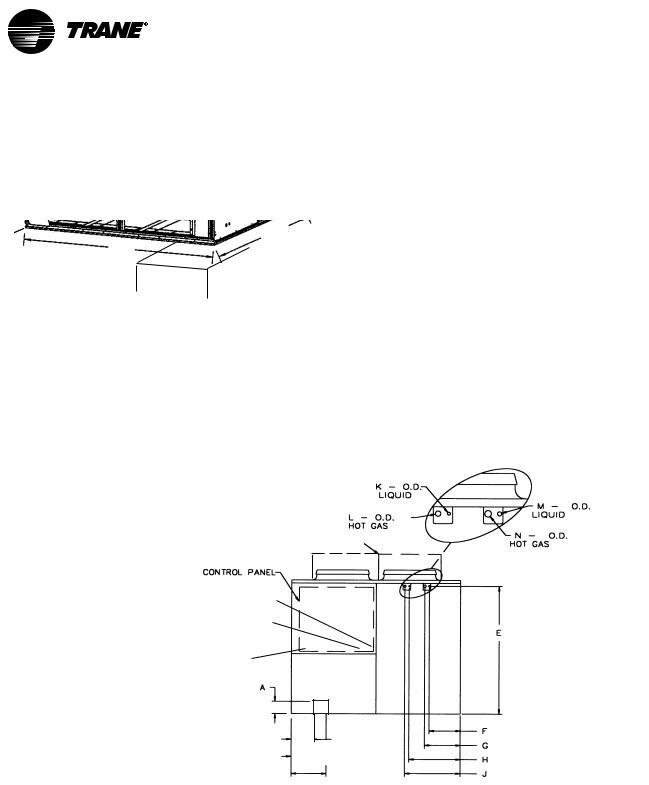

CCRC/CIRC —Air-Cooled Condenser

OPTIONAL LOW AMBIENT DAMPER (ONE DAMPER PER CIRCUIT)

REFRIGERANT

LINE

CONNECTIONS

FRONTAL VIEW

AC

REFRIGERANT CIRCUIT 2

REFRIGERANT CIRCUIT 1

OPTIONAL LOW

AMBIENT DAMPER

24VOLTWIRE ENTRY HOLE SIZED FOR 3/4” CONDUIT

115VOLTWIRE ENTRY HOLE SIZED FOR

3/4” CONDUIT

SUPPLYVOLTAGEWIRE ENTRY HOLE

SIZED FOR 1” CONDUIT

B

C

(LIQUID LINE CONNECTION REFRIG. CIRCUIT 1) (HOT GAS CONNECTION REFRIG. CIRCUIT 1)

(LIQUID LINE CONNECTION REFRIG. CIRCUIT 2) (HOT GAS CONNECTION REFRIG. CIRCUIT 2)

CCRC/CIRC Air-cooled condenser dimensions & weight, in-lbs.

|

|

|

|

shipping |

operating |

model |

AA |

AB |

AC |

weight |

weight |

CCRC/CIRC 20 |

70 1/8 |

88 |

88 |

2030 |

1906 |

CCRC/CIRC 29 |

70 1/8 |

88 |

88 |

2084 |

1960 |

CCRC/CIRC 32 |

70 1/8 |

88 |

88 |

2138 |

2014 |

CCRC/CIRC Electrical connections, in.

model |

A |

B |

C |

CCRC/CIRC 20-32 |

4 1/2 |

10 1/2 |

17 1/2 |

CCRC/CIRC Refrigerant connections, in.

model |

E |

F |

G |

H |

J |

K |

L |

M |

N |

CCRC/CIRC 20-32 |

66 7/8 |

14 3/8 |

18 1/2 |

24 3/4 |

29 |

5/8 |

1 1/8 |

5/8 |

1 1/8 |

22 |

SCXG-SVX01B-EN |

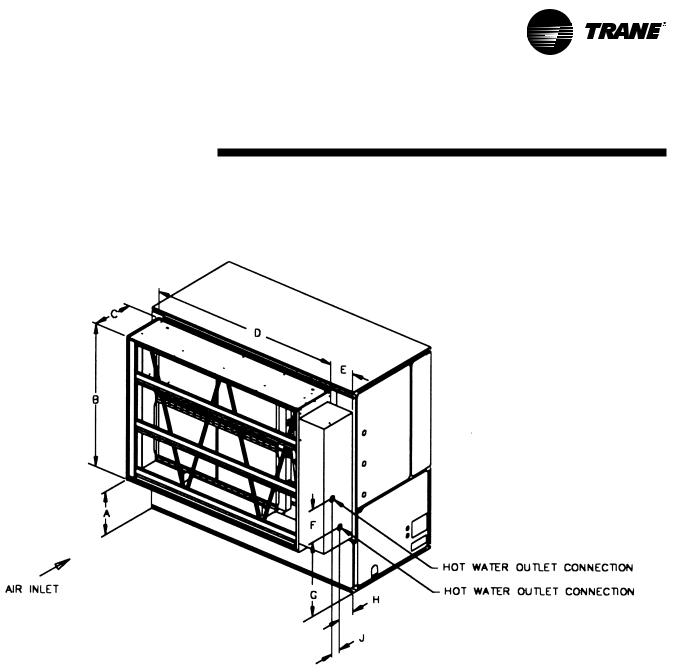

Dimensions &

Weights

HotWater Coil

Hot water coil dimensions & weight, in-lbs.

unit size |

A |

B |

C |

D |

E |

F |

G |

H |

J |

weight |

20 - 35 tons |

37 1/4 |

53 3/4 |

16 5/8 |

73 1/2 |

14 7/8 |

16 1/4 |

43 1/4 |

5 5/8 |

7 3/4 |

460 |

SCXG-SVX01B-EN |

23 |

Dimensions &

Weights

Steam Coil

Steam coil dimensions, in-lbs.

unit size |

A |

B |

C |

D |

E |

K |

L |

M |

N |

P |

Q |

R |

weight |

20 - 35 tons 37 1/4 |

53 3/4 |

16 5/8 |

73 1/2 |

10 7/8 |

22 1/2 |

3 3/8 |

15 7/8 |

1 |

41 |

9 3/8 |

4 3/8 |

460 |

|

24 |

SCXG-SVX01B-EN |

Dimensions &

Weights

Electric Heat Coil

Electric heat coil dimensions & weight, in-lbs.

unit size |

A |

B |

C |

D |

weight |

20 tons |

70 1/4 |

4 7/8 |

11 1/2 |

19 |

460 |

25 tons |

70 1/4 |

4 1/8 |

11 1/2 |

19 |

460 |

30 - 35 tons |

70 1/4 |

2 7/8 |

11 1/2 |

19 |

460 |

Note: Coil box height is 8 in.

Flexible Horizontal Discharge

Plenum

Flexible horizontal discharge plenum dimensions & weights, in-lbs.

20-35 tons |

A |

B |

C |

weight |

low height |

35 |

17 1/4 |

86 1/2 |

262 |

standard height |

|

35 |

25 1/4 |

86 1/2 352 |

SCXG-SVX01B-EN |

25 |

Dimensions &

Weights

Waterside Economizer

Waterside economizer weight, in-lbs.

|

weight |

unit size |

2-row 4-row |

20 - 35 tons |

488 584 |

26 |

SCXG-SVX01B-EN |

Dimensions & |

Airside |

Weights |

Economizer |

|

|

|

|

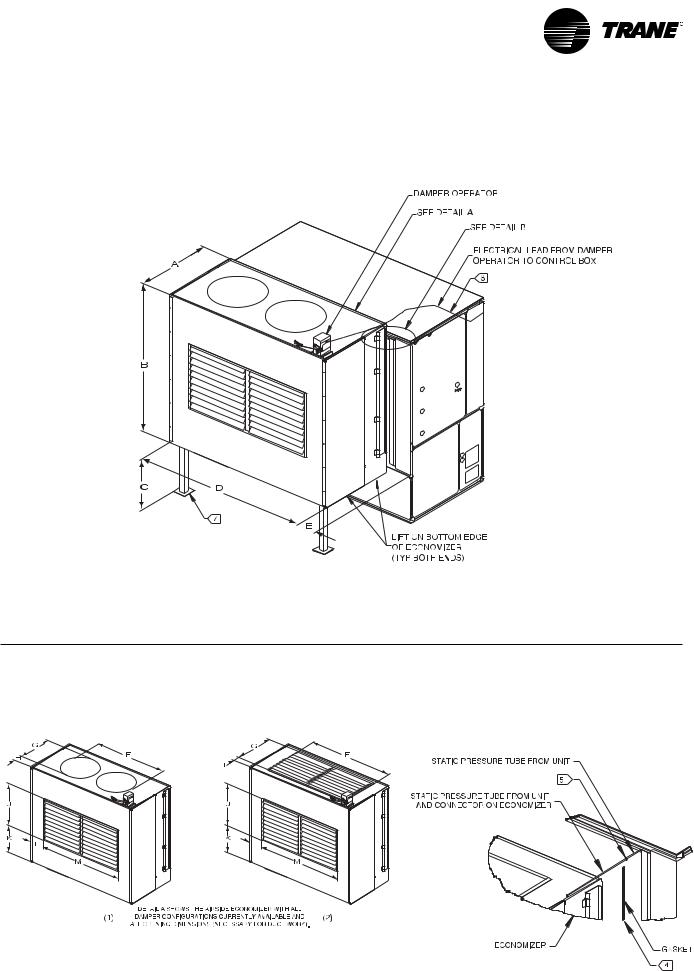

Airside Economizer

Airside economizer dimensions & weight, in-lbs.

unit size |

A |

B |

C |

D |

|

E |

F (1) |

F (2) |

G (1) |

G (2) |

H (1) |

H (2) |

J |

|

K |

|

L |

M |

weight |

SCWG/SIWG 20, 25 |

36 |

65 5/8 |

37 |

74 1/4 |

6 1/8 |

56 1/2 |

49 3/4 |

23 1/4 |

20 1/2 |

5 5/8 |

7 |

20 1/2 |

17 1/8 |

12 |

49 3/4 |

273 |

|||

SCRG/SIRG 20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SCWG/SIWG 30, 35 |

36 |

65 5/ |

37 |

74 1/ |

6 |

1/ |

61 3/ |

62 3/ |

28 1/ |

20 1/ |

3 1/ |

7 |

20 |

1/ |

17 1/ |

5 |

1/ |

62 3/ |

273 |

|

|

8 |

|

4 |

|

8 |

8 |

4 |

8 |

2 |

4 |

|

|

2 |

8 |

|

2 |

4 |

|

SCRG/SIRG 25, 32

Detail “A”

Detail “B”

SCXG-SVX01B-EN |

27 |

Dimensions &

Weights VFD

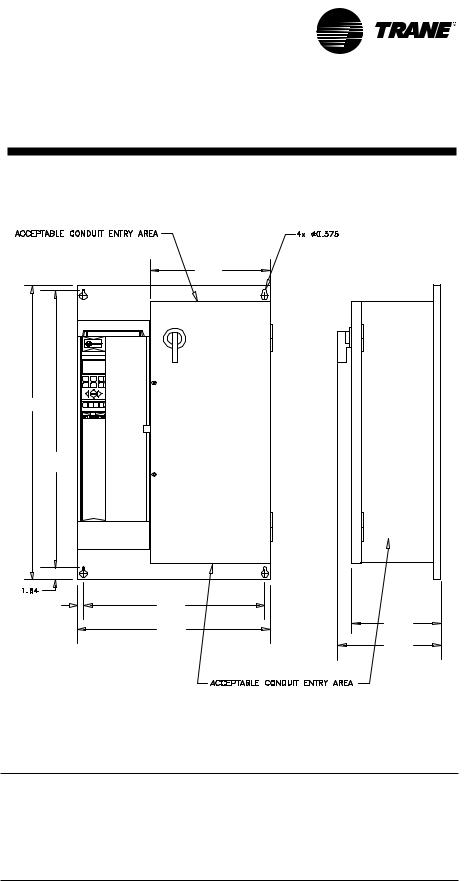

Variable Frequency Drive

Option (VFD)

WARNING

Control and LineVoltage!

Control and line voltage wiring from the VFD to the unit must be in accordance with all local and National Electric Codes. Do not touch circuit components until main power has been turned off and “charge” lamp is extinguished.The capacitors are still charged and could

result in death or serious injury.

Mounting Requirements

Proper location of theVFD is important to achieve proper performance and normal operating life. Installation must be in an area where it will be protected from:

•Direct sunlight, rain or moisture.

•Corrosive gases or liquids.

•Vibration, airborne dust, or metallic particles.

For effective cooling as well as proper maintenance, install theVFD vertically to the ground using four mounting screws.

There must be a minimum eight inch clearance above and below theVFD. A minimum two inch clearance is required on each side.

Also, allow enough clearance for opening theVFD cabinet door.This will ensure sufficient air space for cooling.

Refer to the “Dimensions andWeights” section beginning on page 19 forVFD dimensions and weights.

WARNING HazardousVoltage w/Capacitors!

Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/tagout procedures to ensure the power cannot be inadvertently energized. For variable frequency drives or other energy storing components provided byTrane or others, refer to the appropriate manufacturer’s literature for allowable waiting periods for discharge of capacitors.Verify with an appropriate voltmeter that all capacitors have discharged. Failure to disconnect power and discharge capacitors before servicing could result in death or serious injury.

Note: For additional information regarding the safe discharge of capacitors, see

PROD-SVB06A-EN or PROD-SVB06A-FR.

NOTICE

Use Copper Conductors Only!

Unit terminals are not designed to accept other types of conductors. Failure to use copper conductors may result in equipment damage.

The variable frequency drive (VFD) option can only be used with IntelliPak units.The VFD andVFD w/bypass is available from 5 to 25 hp and is aTraneTR1. AllVFD’s are pre-configured and run tested at the factory prior to shipping.TheVFD is wall mounted.

A

B

G

F

C

E D

VFD dimensions, in.

voltage |

hp |

A |

B |

C |

D |

E |

F |

G |

460 |

7.5 |

15.55 |

15.12 |

7.87 |

8.66 |

0.39 |

0.24 |

7.87 |

|

10 |

|

|

|

|

|

|

|

208 |

7.5 |

22.05 |

21.26 |

7.87 |

9.53 |

0.83 |

0.30 |

10.24 |

|

10 |

|

|

|

|

|

|

|

46015

20

25

208 |

15 |

27.56 |

26.77 |

10.63 |

12.13 |

0.83 |

0.30 |

11.05 |

|

20 |

|

|

|

|

|

|

|

46030

40

208 |

30 |

31.50 |

30.71 |

10.63 |

12.13 |

0.75 |

0.30 |

11.65 |

460 |

50 |

|

|

|

|

|

|

|

|

60 |

|

|

|

|

|

|

|

208 |

40 |

31.49 |

30.71 |

10.63 |

14.57 |

1.97 |

- |

13.19 |

28 |

SCXG-SVX01B-EN |

Dimensions &

Weights VFD

Electrical Installation Procedure

Refer to the National Electric Code, section 310-16 for sizing wires 4B - 9B. All other control wires should be twisted shielded or twisted pair shielded, 20 - 14 AWG, with lead length not to exceed 164 feet. When using shielded wire, the shield sheath must be connected at the VFD only.The connection on units withVFD is J13-S.The connection on unis withVFD/ bypass is ITBI-10.

Variable Frequency Drive with Bypass

C

A

B

F D

G

E

H

VFD with bypass dimensions, in.

voltage |

hp |

A |

B |

C |

D |

E |

F |

G |

H |

460 |

7.5 |

30.40 |

28.03 |

16.14 |

23.35 |

24.85 |

0.75 |

8.59 |

10.63 |

|

10 |

|

|

|

|

|

|

|

|

208 |

7.5 |

41.28 |

38.89 |

16.14 |

24.00 |

25.5 |

0.75 |

10.95 |

12.99 |

|

10 |

|

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

46015

20

25

208 |

25 |

50.81 |

48.35 |

21.36 |

31.61 |

33.41 |

0.90 |

12.36 |

14.41 |

SCXG-SVX01B-EN |

29 |

Mechanical

Specifications

Duct Connections

WARNING

Hazardous Voltage w/Capacitors!

Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/tagout procedures to ensure the power cannot be inadvertently energized. For variable frequency drives or other energy storing components provided byTrane or others, refer to the appropriate manufacturer’s literature for allowable waiting periods for discharge of capacitors.Verify with an appropriate voltmeter that all capacitors have discharged. Failure to disconnect power and discharge capacitors before servicing could result in death or serious injury.

Note: For additional information regarding the safe discharge of capacitors, see PROD-SVB06A-EN or PROD-SVB06A-FR.

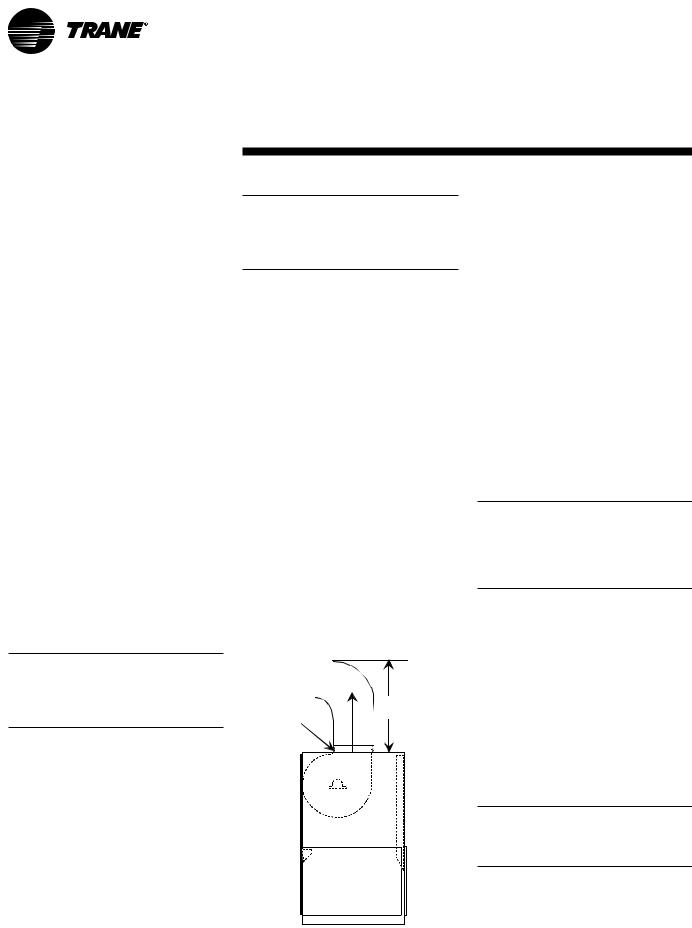

Return air enters the rear of the unit and conditioned supply air discharges through the top. Attach supply air ductwork directly to the unit’s top panel, around the fan discharge opening. A duct collar is not provided.

Note: Units equipped with the flexible horizontal discharge plenum option may include a duct collar when holes are factory cut. If discharge openings are field-cut, refer to the “Plenum Installation” section.

Install all air ducts according to the National Fire Protection Association standards for the “Installation of Air Conditioning andVentilation Systems other than ResidenceType (NFPA 90A) and ResidenceTypeWarm Air Heating and Air Conditioning Systems (NFPA 90B).

Make duct connections to the unit with a flexible material such as heavy canvas. If a fire hazard exists,Trane recommends using Flexweave 1000, type FW30 or equivalent canvas. Use three inches for the return duct and three inches for the discharge duct. Keep the material loose to absorb fan vibration.

Note:The compressors and fan assembly are internally isolated.Therefore, external isolation devices (spring mounting isolators) are at the discretion of a vibration specialist consulted by the building or HVAC system designer.

Run the ductwork straight from the opening for a minimum of three fan diameters. See Figure I-MR-1. Extend remaining ductwork as far as possible without changing size or direction. Do not make abrupt turns or transitions near the unit due to increased noise and excessive static losses. Use elbows with splitters or turning vanes to minimize static losses.

Poorly constructed turning vanes may cause airflow generated noise. Align the fan outlet properly with the ductwork to decrease noise levels in the duct and to increase fan performance. To complete trunk ductwork to theVAV terminal units, refer to theVAV box manuals for specific requirements. Check total external static pressures against fan characteristics to be sure the required airflow is available throughout the ductwork.

To achieve maximum acoustical performance, minimize the duct static pressure setpoint.

Discharge

Duct

3 Fan

3-inch Diameters

Flexible

Duct

Return

Air

Water Piping

WARNING

High PressureWater!

Provide relief valves on system water piping to prevent instantaneous release of high pressure water. Failure to provide relief valves could result in death or serious injury or water pump damage or unit failure.

Condenser Connections

Condenser water piping knockouts are in the lower left end panel. If necessary, remove insulation to gain access. All field installed piping must conform to applicable local, state, and federal codes. To complete condenser water connections follow the procedure below.

Note: Four condenser waterline drain plugs ship in a bag in the unit’s left end. The installer must field install these four plugs using pipe thread sealer. An additional plug is provided for units with a waterside economizer.

1.Attach the water supply line to the inlet connection, and the return line to the outlet connection. Entering and leaving water connections for all condensers are factory manifolded and require only single connections for entering and leaving water. If the unit has a waterside economizer and/or control valves, the factory pipes between these components.

2.If using a cooling tower, refer to Figure

I-MR-2 for a typical piping circuit from the unit.

3. Ensure the water pressure to the unit does not exceed 400 psig.

Note: To prevent water pump damage, design system piping to provide relief when using energy saving waterside economizer valves.

Figure I-MR-1. Duct connection recommendations

30 |

SCXG-SVX01B-EN |

Loading...

Loading...