Trane Commercial Self-Contained Intellipak Catalogue

Product Catalog

Commercial Self-Contained

Intellipak™ Signature Series

Remote Air-Cooled Condenser

20 - 110 Tons — Water-Cooled

20 - 60 Tons — Air-Cooled

June 2014

PKG-PRC002U-EN

Introduction

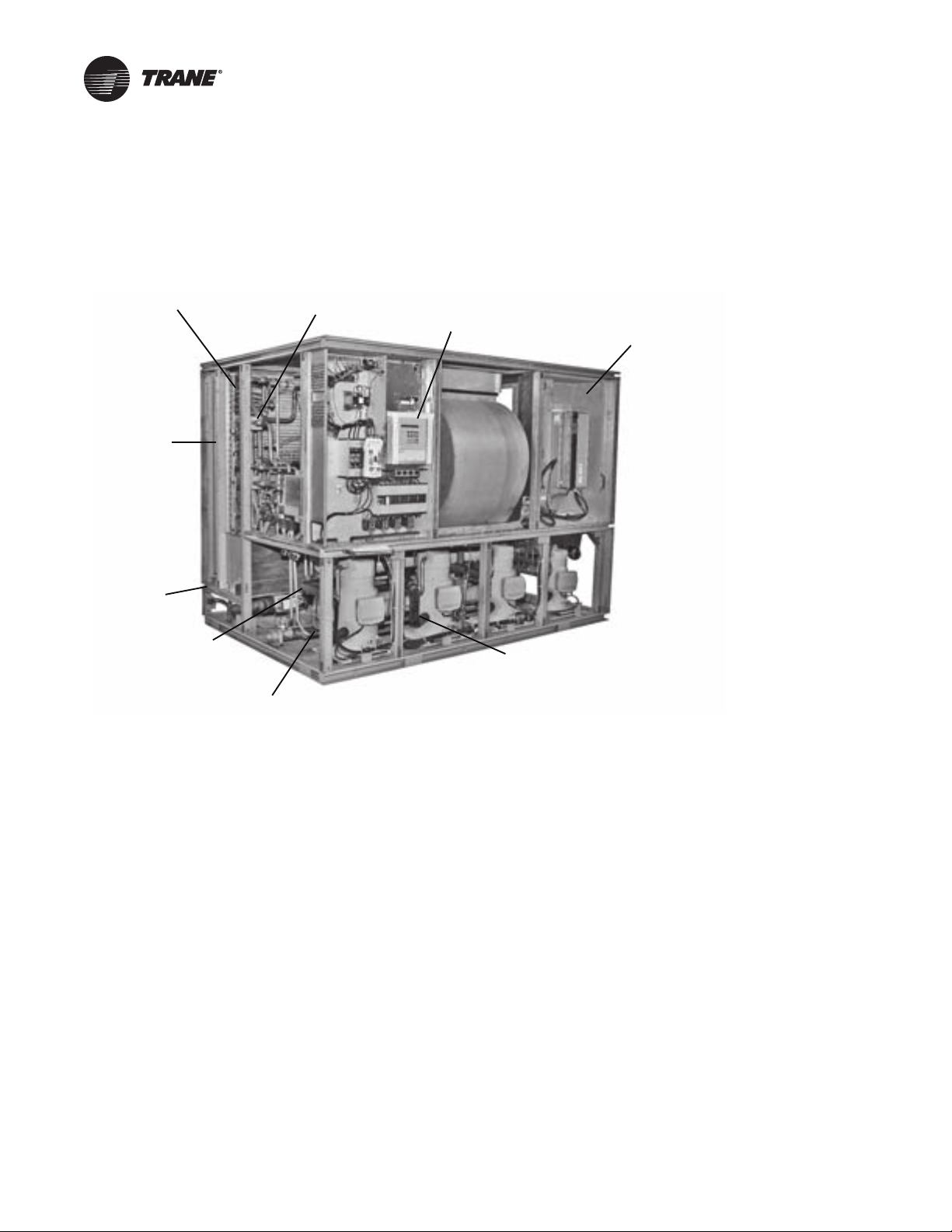

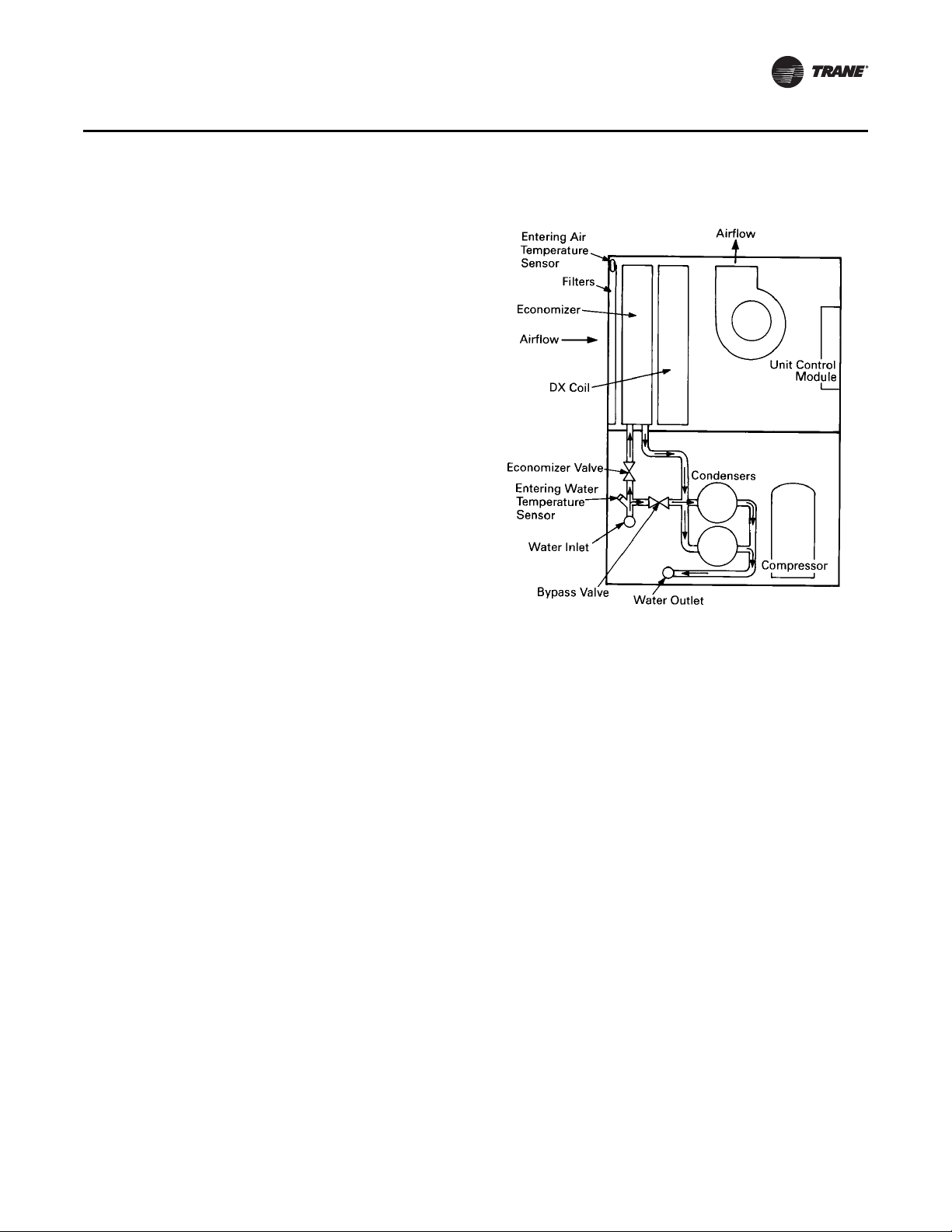

Waterside economizer

(cleanable option shown)

Sight glasses with

ports for viewing

while unit is running

Unit mounted microprocessor

control with easy-to-read human

interface panel

Swing out VFO panel with

Tri-VFO for efficie nt VAV

operation

Trane 3-D® Scroll Compressor

for reliability, efficiency and

quiet operation

Two-bolt connection on

cleanable condenser for

quick, easy maintenance

Waterside valve

package option

to enhance system

efficiency

Internally trapped

drain for low cost

installation

2-inch flat filter

box inside unit

casing

Affordable Self-Contained Value from Trane…

IntelliPak™ Signature Series Self-Contained Units

Copyright

This document and the information in it are the property of Trane, and may not be used or

reproduced in whole or in part without written permission. Trane reserves the right to revise this

publication at any time, and to make changes to its contents without obligation to notify any person

of such revision or change.

Trademarks

Trane and the Trane logo are trademarks of Trane in the United States and other countries. All

trademarks referenced in this document are the trademarks of their respective owners.

Revision History

PKG-PRC002-EN (26 Jun 2014). Updated evaporator fan and low flow fan information in

General Data tables. Reordered General Data tables

PKG-PRC002-EN (04 Apr 2013). Add wireless comm interface (WCI).

PKG-PRC002-EN (18 Oct 2012). Corrected Table 60 values. Updated fan FLA and LRA values

in Electrical Data tables.

© 2014 Trane All rights reserved PKG-PRC002U-EN

Table of Contents

Introduction ......................................................2

Affordable Self-Contained Value from Trane… ....................... 2

IntelliPak™ Signature Series Self-Contained Units .................... 2

Table of Contents ..................................................3

Features and Benefits ..............................................4

Application Considerations .........................................10

Selection Procedure ...............................................15

Model Number Descriptions ........................................17

Self-Contained Ship-With Accessory Model Number ................. 19

Remote Air-Cooled Condenser Model Number Description ............ 19

General Data .....................................................20

Performance Data ................................................27

Controls ........................................................84

IntelliPak™ Signature Series Self-Contained Units ................... 84

Zone Temperature Control Unit Sequence Of Operation .............. 92

Zone Sensor Options ........................................... 95

Electrical Data ....................................................98

Selection Procedures ........................................... 98

Determination of minimum circuit ampacity (MCA) .................. 98

Dimensions and Weights .........................................101

Field Installed Zone Sensors .................................... 112

Mechanical Specifications .........................................117

PKG-PRC002U-EN 3

Features and Benefits

Why consider Signature Series self-contained floor-by-floor systems?

Improved Cash Management

• Factory-installed and tested options reduce field labor and installation risk, while improving

system reliability

•Requires less sophisticated maintenance than built-up systems

Tenant Satisfaction

• Complete HVAC system on each floor minimizes tenant inconvenience during routine

maintenance

• Tenants can control system after hours to increase productivity and minimize expense

Low First Cost

• Reduce field labor, installation time, and cost with factory packaged controls and piping

• Reduce installed tonnage up to 20 percent by taking advantage of building diversity and VAV

flexibility

• Flexible air discharge arrangement matches most building configurations

Lower Installed Cost

• Single point power connection

• Single point water connection

• Factory commissioned and tested controls

• Factory installed options

• Internally trapped drain connection

Economical Operation

• Free cooling with waterside or airside economizer

• Energy savings with floor-by-floor system since only units on floors requiring cooling need to

operate

• Significant annual energy consumption reduction due to partial occupancy after-hours, when

compared to a central chilled water system

• Simple heating alternatives include perimeter radiation and fan-powered VAV

• Energy savings from the integrated water valve control using pump unloading

Assured Acoustical Performance

• Flexible, horizontal discharge plenum provides smooth airflow, reducing static pressure losses

for optimum acoustical performance

• Multiple compressor design reduces acoustical levels. Scroll compressor design smooths gas

flow for quieter operation

Indoor Air Quality (IAQ) Features

• Sloped drain pan

• Stainless steel sloped drain pan option

• Internally trapped drain connection

• Double wall construction option

• Matt-faced fiberglass insulation

• High efficiency throwaway filter option

4 PKG-PRC002U-EN

Features and Benefits

• Easily cleanable evaporator, condensers, and waterside economizers

• Filter access door allows easy removal to encourage frequent filter changing

• Airside economizer with Traq™ damper allows direct measurement and control of outdoor air

Enhanced Serviceability

• Self-supporting removable panels

• Quick access service panel fasteners

• Eye level control/service center

• Refrigerant line sight glasses in view during operation

Competitive Advantage

• Increased capacity to meet today’s growing floor plates and building loads

• Compact cabinet to minimize mechanical room requirements

• Up to 17% more efficient than competitive units

• Low leaving air temp capability to reduce fan motor energy, improve acoustical performance,

and minimize duct sizes

• Factory-installed and tested IntelliPak™ microprocessor controller

Standard Features

• 20 through 110 ton industrial/commercial water-cooled self-contained units

• 20 through 60 ton industrial/commercial remote air-cooled self-contained units

• Fully integrated, factory-installed, and commissioned microelectronic controls

• Unit mounted human interface panel with a two line x 40 character clear language (English,

Spanish, or French) display and a 16-function keypad that includes custom, diagnostics, and

service test mode menu keys

• Improved Trane 3-D™scroll compressor

• Compressor lead/lag

• CV or VAV system control

• Low ambient compressor lockout adjustable control input

• EISA efficiency open drip proof (ODP) and totally enclosed fan (TEFC) cooled supply fan motor

options

• FROSTAT™ coil frost protection on all units

• Daytime warm-up (occupied mode) on units with heat and morning warm-up operation on all

units

• Supply air static over pressurization protection on units with variable frequency drives (VFDs)

• Supply airflow proving

• Supply air tempering control with heating option

• Supply air heating control on VAV with hydronic heating option

• Emergency stop input

• Mappable sensors and setpoint sources

• Occupied/unoccupied switching

• Timed override activation

• Refrigeration circuits are completely factory piped and tested on water-cooled units

• Factory piped and tested, mechanically cleanable water-cooled condensers

PKG-PRC002U-EN 5

Features and Benefits

• Two-bolt removable condenser waterboxes for quick and easy cleaning

• Sloped drain pans to ensure complete condensate removal for IAQ

• Internally trapped drain connection with cleanout

• Internally isolated centrifugal supply fan

• Sturdy-gauge galvanized steel framework with easily removable painted galvanized steel

• UL listing on standard options

• Fan belts and grease lines are easily accessible

• Access panels and clearance provided to clean both evaporator and waterside economizer coil

• Condensing pressure control on all variable water flow systems with valves

• Programmable water purge during unoccupied mode

• High entering air temperature limit

• Low entering air temperature limit with waterside economizer or hydronic heat

• Shipped with protective shrink wrap covering of unit and any indoor modules shipped loose

Optional Features

• Trane communication interface module: ICS interface control module

• BACnet Communication Interface Module

• Generic BAS interface

• Comparative enthalpy control

• Ventilation override from up to five external inputs

• Remote human interface controls up to four units

• Fully integrated, factory-installed/commissioned variable frequency drive control with or

• Waterside economizer with factory installed piping and controls

• Waterside modulating condensing temperature control valves include factory installed piping

• Removable cast iron headers on cleanable waterside economizer

• Flexible horizontal discharge plenum with or without factory cut holes

• Heating options include hot water, steam, and electric

• Refrigerant suction discharge line service (shut-off) valves

• Protective coatings for the unit and/or evaporator coils

• Double wall construction

• Stainless steel sloped drain pan

• Medium efficiency throwaway filters

• Through-the-door non-fused disconnect switch

• Trane’s air quality Traq™ damper in airside economizer mixing box

• High duct temperature thermostat

• Dual electrical power connection

• CO2 reset input

• 2 and 4-inch filter racks for all sizes

• Hi-capacity coils available on many models

exterior panels

fins

without optional integrated bypass

and control wiring

6 PKG-PRC002U-EN

Variable Frequency Drives (VFD)

Var ia bl e f re quency drives are factory installed, wired, and tested to provide supply fan motor speed

modulation. VFDs are quieter and more efficient than inlet guide vanes and may even be eligible

for utility rebates. The VFDs are available with and without a manual integrated bypass option,

controlled through the human interface (HI) panel. Bypass control provides full nominal airflow

control to CV zone setpoints in the unlikely event of a drive failure by manually placing the drive

in the bypass mode.

Field Installed Accessories

• Airside economizer control with or without mixing box

• Wireless comm interface (WCI)

• Programmable sensors with or without night set back for CV and VAV systems

• ICS zone sensors used with Tracer™ system for zone control

• Field installed module kits available for field upgrade of controls

• Ultra low leak dampers for 0-100 percent modulating fresh air economizer

Integrated Self-Contained Systems

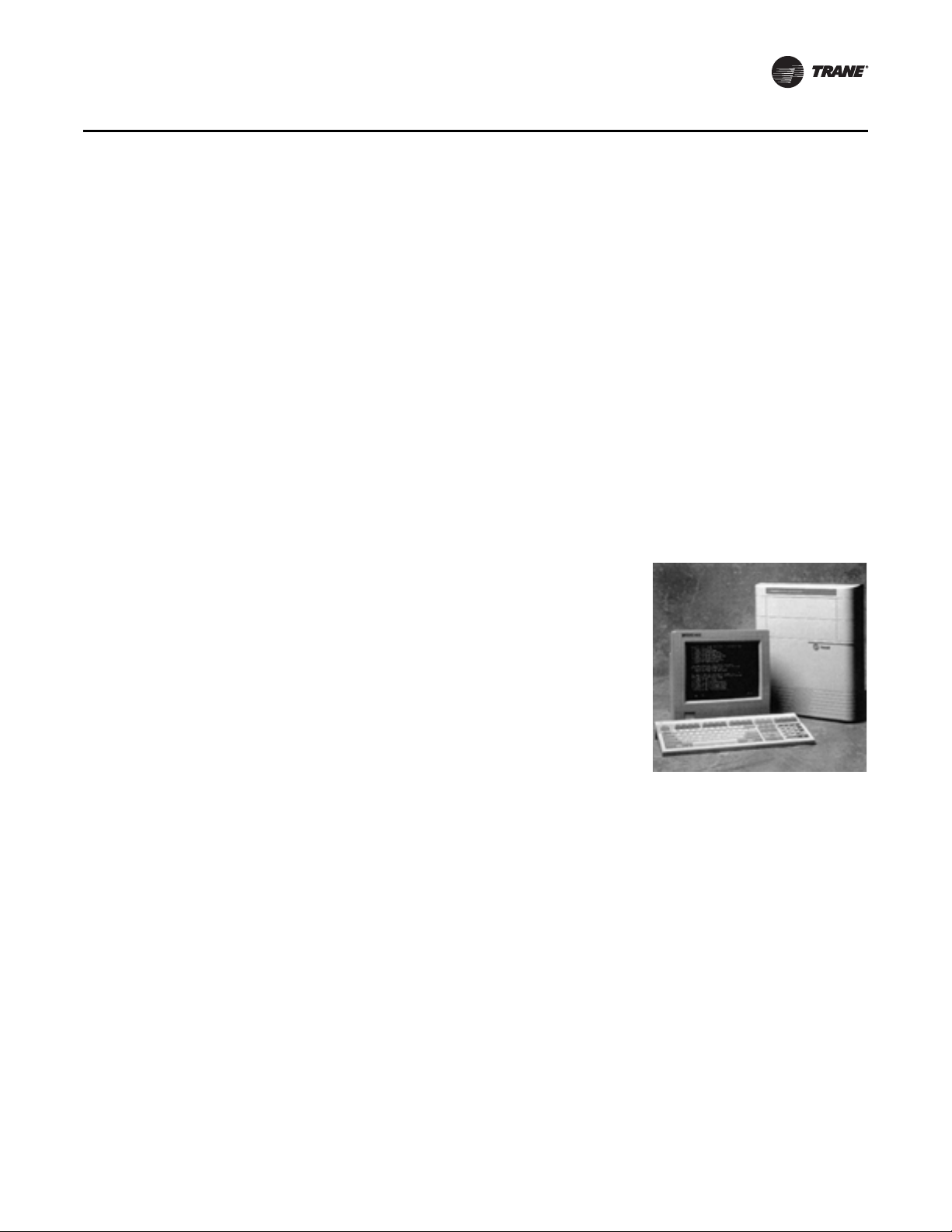

Integrated Comfort™ System (ICS)

Trane’s Integrated Comfort system (ICS) increases job control by

combining IntelliPak™ Signature Series self-contained units and

a Tracer™ building management system. This integrated system

provides total building comfort and control. Building owners

and managers not only save energy when using ICS. They have

the ability to automate their facilities and the convenience of a

control system interface.

Features and Benefits

Simplifying The Comfort System

Trane’s designers combined new technology and innovation to

bring you more system capabilities and flexibility. Our

Integrated Comfort System (ICS) with HVAC equipment is easy

to use, install, commission, and service.

Everything you need to know about your self-contained VAV system is available using Tracer,

Trane’s family of building automation products. Tracer is a software package that minimizes custom

programming requirements and allows easy system setup and control using your personal

computer. By enabling all CSC units to communicate using the LonTalk interface, transforming

your heating and cooling units into a true system is made simple.

Operating data from all system components is readily available for evaluation. You can control,

monitor, and service your facility—all from your personal computer. That is why all Tracer controls

have been designed to be LonTalk compatible.

The IntelliPak self-contained unit, as part of Trane ICS, provides powerful maintenance monitoring,

control, and reporting capabilities. Tracer places the self-contained unit in the appropriate

operating mode for: system on/off, night setback, demand limiting, setpoint adjustment based on

outside parameters and much more. You can monitor unit diagnostic conditions through Tracer

such as: sensor failures, loss of supply airflow, and an inoperative refrigerant circuit.

PKG-PRC002U-EN 7

Features and Benefits

Tracer points monitored for IntelliPak Signature Series Self-Contained include:

• Compressor on/off status

• Ventilation status

• Condenser water flow status

• Heat status

• Supply air pressure

• Supply air temperature

• Suction temperature of each circuit

• Entering economizer water temperature

• Zone temperature

• Entering condenser water temperature

• Supply air temperature reset signal

• Morning warm-up sensor temperature

• Entering air temperature

Tracer control points available for IntelliPak Signature Series self-contained include:

• Cooling and heating setpoints

• VAV discharge air temperature setpoints

• Supply air pressure setpoint

• Cooling and heating enable/disable

• Air economizer enable/disable

• Airside economizer minimum position

• Unit priority shutdown

Commissioning, control, efficiency, and information…it simply all adds up to one reliable

source…Trane.

Interoperability with BACnet™

The Trane Tracer SC BACnet Control Interface (BCI) for IntelliPak self-contained offers a building

automation control system with outstanding interoperability benefits. BACnet, which is an industry

standard, is an open, secure and reliable network communication protocol for controls, created by

American Society of Heating, refrigerating and Air-Conditioning Engineers, Inc. (ASHRAE).

Interoperability allows application or project engineers to specify the best products of a given type,

rather than one individual supplier's entire system. It reduces product training and installation

costs by standardizing communications across products. Interoperable systems allow building

managers to monitor and control IntelliPak equipment with Tracer SC controls or a 3rd party

building automation system. It enables integration with many different building controls such as

access/intrusion monitoring, lighting, fire and smoke devices, energy management, and a wide

variety of sensors (temperature, pressure, humidity, occupancy, CO

and air velocity).

2

Trane Wireless Comm Interface (WCI)

The Trane® Wireless Comm Interface (WCI) is the perfect alternative to Trane’s BACnet™ wired

communication links (for example, Comm links between a Tracer™ SC and a Tracer™ UC400).

Minimizing communication wire used between terminal products, zone sensors, and system

controllers has substantial benefits. Installation time and associated risks are reduced. Projects are

completed with fewer disruptions. Future re-configurations, expansions, and upgrades are easier

and more cost effective.

8 PKG-PRC002U-EN

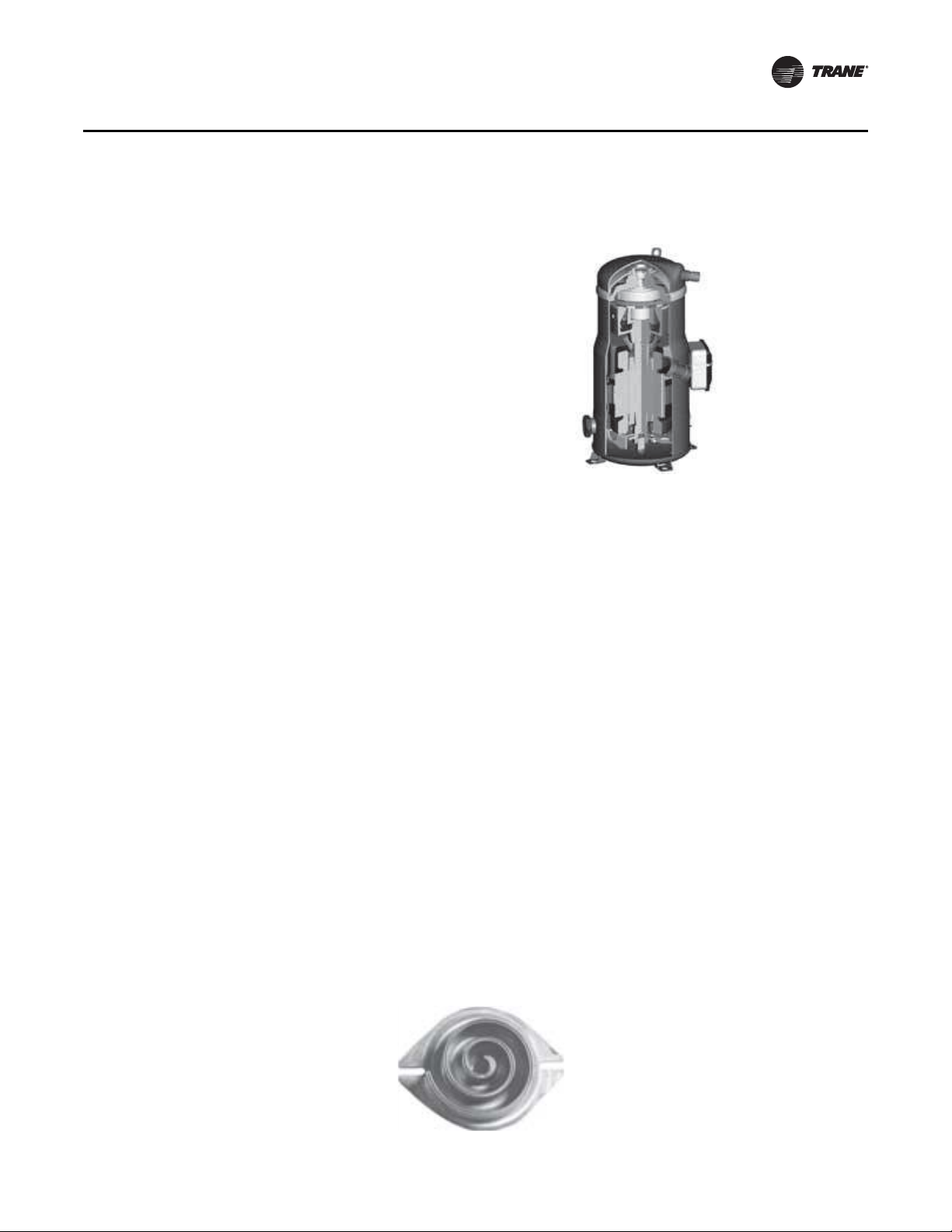

Trane R-410A 3-D™ Scroll Compressor

The R-410A Trane 3-D™ Scroll provides

important reliability and efficiency benefits

inherent in its design. The 3-D™ Scroll allows

the orbiting scrolls to touch in all three

dimensions, forming a completely enclosed

compression chamber which leads to increased

efficiency. In addition, the orbiting scrolls only

touch with enough force to create a seal,

eliminating wear between the scroll involutes.

The fixed and orbiting scrolls are made of high

strength cast iron which results in less thermal

distortion and minimal leakage. In addition,

improved part isolation provides reduced

compressor sound levels compared to previous

designs.

Features listed below optimize the compressor design and performance:

• Optimized scroll profile

• Heat shield protection to reduce heat transfer between discharge and suction gas

• Improved sealing between high side and low side

Additional features are incorporated in the compressor design for greater reliability:

• Patented design motor cap for improved motor cooling

• Improved bearing alignment

• Improved resistance to dry start-up

• Oil sight glass for evaluating proper oil levels

Features and Benefits

Low Torque Variation

The 3-D™ Scroll has a very smooth compression cycle, imposing very little stress on the motor and

resulting in greater reliability. Low torque variation reduces noise and vibration.

Suction Gas Cooled Motor

Compressor motor efficiency and reliability is further optimized with the latest scroll design. The

patented motor cap directs suction gas over the motor, resulting in cooler motor temperatures for

longer life and better efficiency.

Proven Design through Testing and Research

The new R-410A 3-D™ Scroll compressor is the next generation of reliable Trane 3-D™ Scroll

compressors provided by Trane, the leader in scroll compressor technology.

Figure 1. One of two matched scroll plates - the distinguishing feature of the scroll compressor

PKG-PRC002U-EN 9

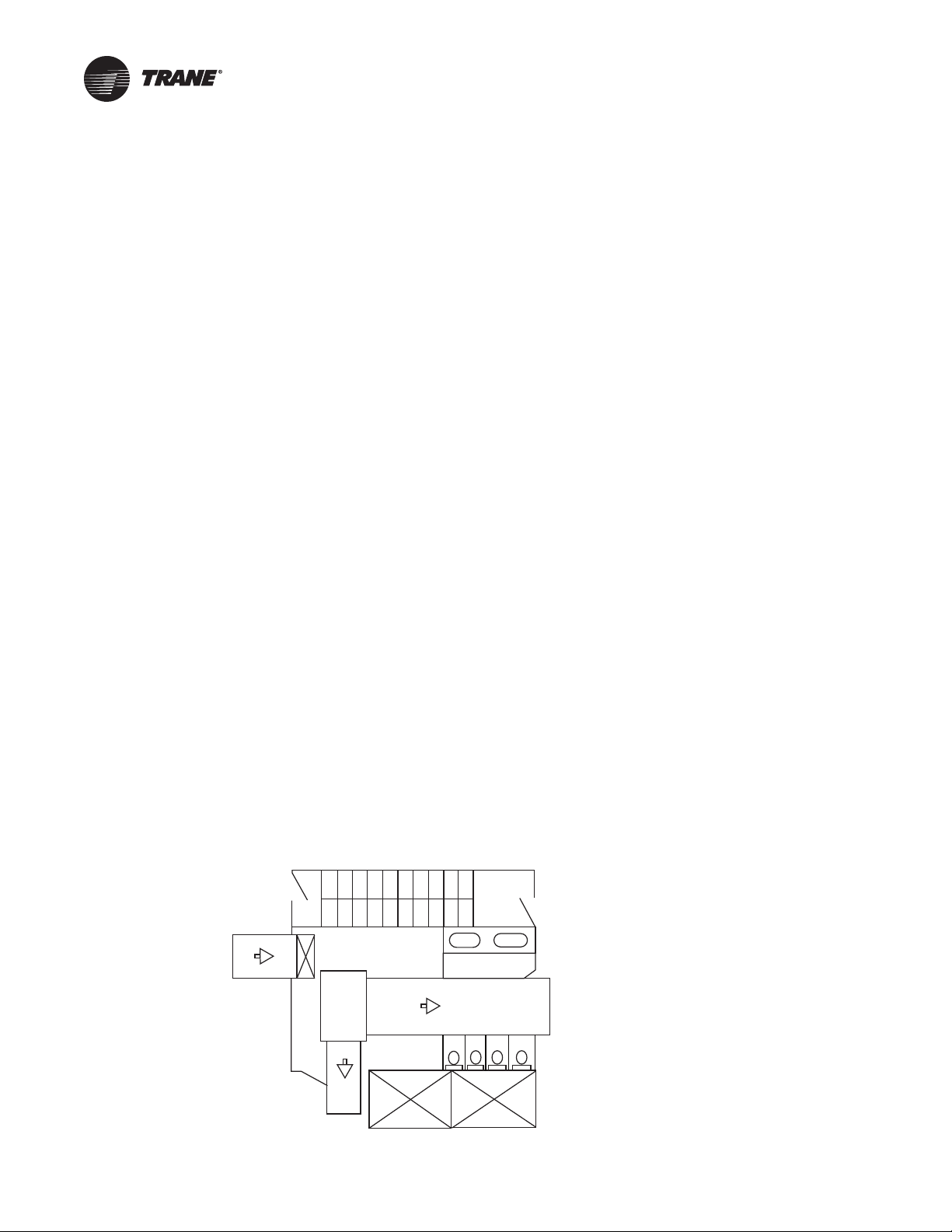

Application Considerations

Elevator

Elevator

Supply

Air

Supply Air

Mechanical

Room

Self

Contained

Unit

Bathroom

Stairwell

Return Air

Self-Contained Acoustical Recommendations

Successful acoustical results are dependent on many system design factors.

Following are general acoustical recommendations. For more information, or if there is concern

about a particular installation, contact a professional acoustical consultant.

Location and Orientation of the Mechanical Equipment Room

Locate the equipment room adjacent to stairwells, utility rooms, electrical closets, and rest rooms

if possible (See figure below). This minimizes the acoustic effects and risk of workmanship or

installation errors. Place the discharge and return air ductwork over these less acoustically

sensitive areas, using vertical or horizontal fresh air shafts. Consult code requirements for fresh air

and smoke purge constraints.

Return Air Ductwork

Duct the return air into the mechanical equipment room. Connect ductwork to the unit if local code

dictates. The return air ductwork must have an elbow inside the equipment room. This elbow will

reduce sound transmissions through the return duct. Extend the ductwork from the elbow far

enough to block the “line of sight” to the exterior of the equipment room. Use a minimum ductwork

length of 15 feet to the equipment room exterior. Line the duct with two-inch, three-pound density

insulation. Use multiple, small return ducts for better acoustical performance to the occupied

space.

Supply Air Ductwork

Insulate the supply air duct with two-inch, three-pound density insulation. Extend this lining at least

15 feet out from the equipment room wall, keeping the duct aspect ratio as small as possible.

Minimize large flat panels since they transmit sound. In addition, small aspect ratios will minimize

potential “oil canning” of the duct due to flow turbulence.

The flexible horizontal discharge plenum option helps avoid complicated ductwork transitions.

Ductwork turning vanes typically improve pressure drop but degrade acoustical performance.

Recommended Maximum Air Velocities

The maximum recommended velocity for the discharge air duct is 2,000 fpm. The maximum

recommended velocity for the return air duct is 1,000 fpm. Limit air velocities below these

operating points to minimize the risk of flow turbulence that causes regenerated noise. Using

round supply duct and static regain allows maximum discharge air velocities up to 3,000 fpm.

Lining round supply duct also substantially lowers frequency noise attenuation. However, flow

regenerated noise potential increases dramatically at air velocities over 3000 fpm.

Figure 2. Equipment room location and orientation

10 PKG-PRC002U-EN

Application Considerations

Equipment Room Construction Options

The preferred equipment room wall construction is

concrete block. If this is not feasible then a double

stud offset wall is suggested (See figure). This

removes physical contact that would transmit sound

through the equipment room wall to the occupied

space. Interweave fiberglass insulation between the

wall studs. Use two layers of sheetrock on each side

of the wall.

Workmanship details are critical to acoustical

performance. Seal all wall and floor penetrations by

the ductwork, water piping, and equipment room

access doors with a flexible material such as caulk

and/or gasketing to stop noise and air leaks.

Locate the equipment room door away from acoustically sensitive areas like conference rooms.

The door should swing out of the equipment room, if possible, so that the low pressure in the

equipment room pulls the door in to help maintain a tight seal.

Equipment Options

The flexible horizontal discharge plenum allows multiple tested outlet options. This minimizes the

risk of acoustic and/or pressure drop problems by avoiding complex transitions close to the fan

discharge.

Static Pressure Versus Acoustics

Design the system to minimize the total static pressure required from the self-contained unit fan.

Typically a change in static pressure of only 0.5 inches can reduce NC level by approximately 2 or

3 in the occupied space.

Isolation Recommendations

Unit

The Signature Series unit fan and compressors are internally isolated. Therefore, external isolation

is not required. Consult a vibration specialist before considering external or double vibration

isolation.

Ductwork

Design duct connections to the unit using a flexible material. Consult local codes for approved

flexible duct material to prevent fire hazard potential.

Piping Connections

Rubber isolator connectors are recommended for condenser piping to prevent vibration

transmission to or from the building plumbing. The Signature Series self-contained unit is

internally isolated and does not require additional isolation. However, ensure proper system

vibration isolation design prevents vibration transmission from the building plumbing to the unit.

Also be sure to properly isolate the drain line.

Condenser Water Piping

Piping Location and Arrangement

Provide at least 24 inches of clearance between the piping and the unit for service. Place the risers

away from the side of the unit if possible. Be sure to allow sufficient space for valves and unions

between the piping and the self-contained unit. Lay out condenser piping in reverse returns to help

balance the system. This is accomplished by equalizing the supply and return pipe length. Multi-

PKG-PRC002U-EN 11

Application Considerations

story buildings may use a direct return system with balancing valves at each floor. Install all heat

exchangers and most cooling tower piping below the sump operating water level to prevent

overflow during unit and/or system shut down.

Recommended Pump Location

Locate pump downstream of the cooling tower and upstream of the self-contained unit. This

provides smoother and more stable unit operation.

When the tower and pump are both roof mounted, be sure to provide the necessary net positive

suction head pressure to prevent cavitation. Raise the tower or submerge the pump in a sump to

provide positive suction. To prevent an on-line pump failure, use a standby pump to avoid a

complete system shutdown.

Several partial capacity pumps or variable speed pumps may be used. Review the economics of

these alternate pumping options.

Strainers and Water Treatment

Water strainers are required at the unit inlet to eliminate potential unit damage from dirty water.

Specify a water basket-type strainer to avoid an incorrect stream strainer application. Untreated or

poorly treated water may result in equipment damage. Consult a water treatment specialist for

treatment recommendations.

Isolation Valves

Install isolation valves at each unit before the strainer and after the condenser. This allows periodic

servicing of the unit or strainer while allowing other units in the system to remain in operation.

Pressure Gauges

Install pressure gauges on the inlet and outlet of the self-contained unit. Select the gauge’s scale

so that the unit design operating point is approximately mid-scale.

Thermometers

Install thermometers on the condenser water inlet and outlet lines to each unit for system analysis.

Trane Company recommends using a thermometer temperature range of 40 to 140°F, using a 2°F

temperature increment.

Drains

The unit condensate drain is internally trapped to offset the pressure differential that exists during

fan operation. Install a trapped drain in the low point of the mechanical equipment room floor to

collect water from cleaning operations.

Condensing Pressure Control (Water-Cooled condensers)

Often cold condensing water applications between 35°F and 54°F require a condensing pressure

control valve. Any unit with variable-flow waterside valves can modulate water flow to maintain

a user defined condensing temperature. However, to utilize this feature, the building water system

must be capable of operating at reduced water flow rates through the self-contained units. It is

imperative to install variable volume pumps or an external bypass in the water distribution system.

12 PKG-PRC002U-EN

Waterside Economizer Flow

Control

Units equipped with waterside

economizer control valves can be set

up for variable or constant water flow.

Use constant water flow setup on

water systems that are not capable of

unloading water supply to the unit.

The economizer and condenser

valves will operate in complement to

one another to provide continuous

water flow.

Use variable water flow setup with

water flow systems that can take

advantage of pump unloading for

energy savings. Since non-cooling

operation restricts water flow during

part load economizing or condensing

temperature control, it is imperative

to install variable volume pumps or an

external bypass in the water

distribution system.

Application Considerations

Free Cooling Opportunities and Alternatives

Free cooling is available with either the airside or waterside economizer options.

Waterside Economizer

The waterside economizer substantially reduces the compressor energy requirements because it

uses the cooling water before it enters the condensers. Additional equipment room space is not

required since the coils are contained within the overall unit dimensions.

Disadvantages include higher airside pressure drop and a higher head on condenser water pumps.

The coils may be mechanically cleanable (optional) for ease in maintenance versus expensive and

difficult chemical cleaning methods.

Airside Economizer

The airside economizer substantially reduces compressor, cooling tower, and condenser water

pump energy requirements using outside air for free cooling. It also reduces tower make up water

needs and related water treatment.

Disadvantages include building requirements that locate the mechanical room and self-contained

unit toward an exterior wall to minimize ductwork, building barometric control, or additional air

shafts. Also, airside economizers require additional mechanical room space.

Unit Operating Limits

Airflow

The minimum recommended airflow for proper VAV system staging and temperature control is 35

percent of nominal design airflow. Adjusting VAV boxes with the appropriate minimum settings

will prevent the self-contained unit from operating in a surge condition at airflows below this point.

Continuous operation in a surge condition can cause fan failure. Reference General Data Tables on

Table 1, p. 20 for minimum airflow conditions.

PKG-PRC002U-EN 13

Application Considerations

Signature Series self-contained units use fixed pitch sheaves. Adjust air balancing by obtaining

alternate fixed pitch sheave selections from the local Trane sales office.

Water Flow

Use 3 gpm/ton for optimum unit capacity and efficiency. Use 2.5 or 2 gpm/ton to reduce pump

energy, cooling tower and piping costs. However, these reduced water flows may impact unit

capacity and efficiency by one or two percent. Consult General Data Tables on pages 17-20 for unit

specific water flow ranges.

Remote Air-Cooled Condenser

Unit Location

Unobstructed condenser airflow is essential to maintaining capacity and operating efficiency.

When determining unit placement, give careful consideration to assure sufficient airflow across the

condenser coils. Avoid these two detrimental conditions: warm air recirculation and coil starvation.

Both warm air recirculation and coil starvation cause reductions in unit efficiency and capacity

because of the higher head pressure associated with them. In more severe cases, nuisance unit

shutdowns will result from excessive head pressures.

Clearance

Ensure vertical condenser air discharge is unobstructed. While it is difficult to predict the degree

of warm air recirculation, a unit installed with a ceiling or other obstruction above it will experience

a capacity reduction that will reduce the maximum ambient operation limit. Nuisance high head

pressure trips may also occur.

The coil inlet must also be unobstructed. A unit installed closer than the minimum recommended

distance to a wall or other vertical riser will experience a combination of coil starvation and warm

air recirculation. This may result in unit capacity and efficiency reductions, as well as possible

excessive head pressures. Reference the service clearance section on page 111 for recommended

lateral distances.

Ambient Limitations

Standard ambient control allows operation down to 45°F with cycling of condenser fans. Units with

the low ambient option are capable of starting and operating in ambient temperatures down to 0°F.

Optional low ambient units use a condenser fan damper arrangement that controls condenser

capacity by modulating damper airflow in response to saturated condenser temperature.

Maximum ambient operating temperature of a standard condenser is 115°F. Operation at design

ambient above 115°F can result in excessive head pressures. For applications above 115°F, contact

the local Trane sales office.

14 PKG-PRC002U-EN

Selection Procedure

Following is a sample selection for a standard applied water-cooled self-contained at particular

operating conditions. Use Trane Official Product Selection System, TOPSS™, for making all final

selections or contact your local Trane representative.

Unit Capacities

1. Determine entering air temperature dry bulb and wet bulb and entering water temperature.

2. See chapter “Performance Data,” p. 27 to find gross total and sensible capacity that best meets

capacity requirements.

3. Apply the cfm correction factors from the capacity correction factor Ta bl e 13, p. 37 to determine

gross total and gross sensible capacities at desired cfm.

4. Multiply condenser water delta T by the total capacity cfm correction factor to determine new

condenser water delta T.

5. Using design cfm, determine static air pressure drops for accessories from the air pressure

drop Charts

external supply and return static air pressure drops. Use the total air pressure drop to determine

rpm and brake horsepower requirements from the appropriate fan curve. Note: The fan curves

include refrigerant coil and internal cabinet static loses.

6. Calculate supply fan motor heat by using the following equation:

Fan motor heat (MBh) = 2.8 x fan motor brake horsepower

7. Determine net total capacity and net sensible capacity by subtracting fan motor heat from gross

total capacity and gross sensible capacity.

8. Refer to Trane psychometric chart to determine leaving air temperatures.

Figure 1, p. 27 through Figure 21, p. 33. Add accessory static pressure drops to

Waterside Economizer Capacity

After determining that the unit will meet the required mechanical cooling capacity, determine the

waterside economizer capacity by referring to the appropriate two-row (low capacity) or four-row

(high capacity) waterside economizer capacity found in one of Table 15, p. 38 through Ta b le 48 ,

p. 72.

9. Determine entering air temperature dry bulb and wet bulb, condenser water flow (gpm), and

economizer entering water temperature.

10. Refer to the appropriate waterside economizer table to find gross total and sensible capacity

and the leaving water temperature.

11. Apply the cfm correction factor for the waterside economizer from the appropriate table to

determine the gross total and sensible capacities at the desired cfm.

12. Multiply the condenser water delta T by the total capacity cfm correction factor to determine

the new delta T.

13. Calculate supply fan motor heat by using the following equation:

Fan motor heat (MBh) = 2.8 x fan motor brake horsepower

14. Determine net total and sensible capacity by subtracting fan motor heat from gross total and

sensible capacity.

15. Refer to the Trane psychometric chart to determine leaving air temperatures.

Selection Example

Design Conditions

Total gross capacity required = 420 MBh = 35.2 Tons

Total sensible capacity required = 315 MBh

Entering air temperature = 80/67°F

PKG-PRC002U-EN 15

Selection Procedure

Unit includes:

Unit Selection

Tentatively select a 35 ton unit: Model SCWF 35.

Refer to Table 26, p. 49 to obtain gross total and sensible unit capacities, and gpm at the design

conditions:

Since the design cfm is greater than the nominal cfm, adjust the capacities and condenser water

delta T to reflect the higher cfm: design cfm 14840 = +6% of nom. Cfm nominal 14000 cfm

Refer to Tab l e 1 3 , p. 37 to obtain the capacity correction factors for +6% of nominal cfm:

Multiply the capacities by the correction factors:

The SCWF 35 meets the total and sensible design requirements.

Multiply the delta T of 10.1°F by the cooling capacity correction factor of 1.009 to obtain new delta

T of 10.19°F and add this to the entering water temperature to obtain the actual leaving water

temperature of 95.19°F.

Entering water temperature = 85°F

Water flow rate = 105 gpm

Airflow = 14840 cfm at 2.5-inch duct static pressure

• Constant Volume

• Waterside economizer

• Medium velocity throwaway filters

Total capacity = 432.0 MBh

Sensible capacity = 329.0 MBh

Leaving water temperature = 95.1°F

Cooling capacity multiplier = 1.009

Sensible capacity multiplier = 1.027

• 432 MBh x 1.009 = 435.89 MBh

• 329 MBh x 1.027 = 337.88 MBh

16 PKG-PRC002U-EN

Model Number Descriptions

Self-Contained

Digit 1 - Unit Model

S = Self Contained

Digit 2 - Unit Type

C = Commercial

I = Industrial

Digit 3 - Condenser Medium

W = Water-cooled

R = Air-cooled

Digit 4 - Development Sequence

F = Signature Series

Digit 5 - Refrigerant Circuit

Configuration

U = Standard Capacity

V = High Capacity

Digit 6, 7 - Unit Nominal

Capacity

20 = 20 tons (water or air)

22 = 22 tons (water only)

25 = 25 tons (water or air)

29 = 29 tons (water or air)

30 = 30 tons (air only)

32 = 32 tons (water only)

35 = 35 tons (water or air)

38 = 38 tons (water only)

40 = 40 tons (air only)

42 = 42 tons (water only)

46 = 46 tons (water only)

50 = 50 tons (air only)

52 = 52 tons (water only)

58 = 58 tons (water only)

60 = 60 tons (air only)

65 = 65 tons (water only)

72 = 72 tons (water only)

80 = 80 tons (water only)

90 = 90 tons (water only)

C0 =100 tons (water only)

C1 =110 tons (water only)

Digit 8 - Unit Voltage

6 = 200 volt/60 hz/3 ph

4 = 460 volt/60 hz/3 ph

5 = 575 volt/60 hz/3 ph

Digit 9 - Air Volume/Temp

Control

2 = VFD and supply air temp ctrl

3 = VFD w/ bypass and supply

air temp ctrl

4 = Constant volume, zone temp cool

only

5 = Constant volume, w/ zone temp

heat/cool

6 = Constant volume and supply air

temp ctrl

Digit 10, 11 - Design Sequence

** = Factory Assigned

Digit 12 - Unit Construction

A = Vertical Discharge

B = Vertical Discharge With Double Wall

Digit 13 - Flexible Horizontal

Discharge Plenum Type

B = STD plenum w/ factory-cut holes

C = Low plenum w/ factory-cut holes

E = Std plenum w/ field-cut holes

F = Low plenum w/ field-cut holes

H = STD plenum double wall w/ field-cut

holes

J = Low plenum double wall w/ field-cut

holes

K = Extended height plenum w/factory-cut

holes, ship separate

L = STD plenum w/factory-cut holes, ship

separate

M =Low plenum w/factory-cut holes, ship

separate

N = Extended height plenum w/field-cut

holes, ship separate

P = STD plenum w/field-cut holes, ship

separate

R = Low plenum w/field-cut holes, ship

separate

T = Extended height double-wall plenum

w/ field-cut holes, ship separate

U = STD double-wall plenum w/field-cut

holes, ship separate

V = Low double-wall plenum w/field-cut

holes, ship separate

W =STD double-wall (perf) plenum

w/field-cut holes (90-110 ton only)

X = Low double-wall (perf) plenum

w/field-cut holes (90-110 ton only)

Y = Extended height double-wall (perf)

plenum w/field-cut holes, ship

separate (90-110 ton only)

0 = None

Digit 14 - Motor Type

2 = ODP motor

3 = TEFC motor

Digit 15, 16 - Motor HP

05 = 5 hp

07 = 7.5 hp

10 = 10 hp

15 = 15 hp

20 = 20 hp

25 = 25 hp

30 = 30 hp

40 = 40 hp

50 = 50 hp (400V, 460V, 575V only)

60 = 60 hp (90-110 ton only)

Digit 17, 18, 19 - Fan rpm

040 = 400 rpm

045 = 450 rpm

050 = 500 rpm

052 = 525 rpm

055 = 550 rpm

057 = 575 rpm

060 = 600 rpm

065 = 650 rpm

070 = 700 rpm

075 = 750 rpm

080 = 800 rpm

085 = 850 rpm

090 = 900 rpm

095 = 950 rpm

100 = 1000 rpm

105 = 10 50 rpm

110 = 11 0 0 r pm

115 = 1150 rpm

120 = 1200 rpm

125 = 1250 rpm

130 = 1300 rpm

135 = 1350 rpm

Digit 20 - Heating Type

A = Steam coil

B = Hot water coil

C = Electric heat, 1 stage

D = Electric Heat (2 Stage)

F = Hydronic heat ctrl interface

G = Elec. heat ctrl interface, 1 stage

H = Elec. heat ctrl interface, 2-stage (90-

110 ton only)

J = Elec. heat ctrl interface, 3 stage (90-1

10 ton only)

K = Steam coil ship separate, LH

L = Hot water coil ship separate, LH

T = Hot water coil, high capacity, LH

U = Hot water coil, high capacity, LH, ship

separate

0 = None

Digit 21 - Unit Isolators

A = Isopads

B = Spring isolators

0 = None

Digit 22 - Unit Finish

1 = Paint - slate gray

2 = Protective coating

3 = Protective coating w/ finish coat

Digit 23 - Supply Fan Options

0 = Standard fan

1 = Low CFM fan

Digit 24 - Unit Connection

1 = Disconnect switch

2 = Terminal block

3 = Dual point power (2 blocks)

PKG-PRC002U-EN 17

Model Number Descriptions

Digit 25 - Industrial Options

A = Protective coating evaporator coil

B = Silver solder

C = Stainless steel screws

D = A and B

E = A and C

F = B and C

G = A, B, and C

0 = none

Digit 26 - Drain Pan Type

A = Galvanized sloped

B = Stainless steel sloped

Digit 27 - Waterside Economizer

A = Mechanical clean full capacity (4-row)

B = Mechanical clean low capacity (2-row)

C = Chemical clean full capacity (4-row)

D = Chemical clean low capacity (2-row)

0 = None

Digit 28 - Ventilation Control

B = Airside econ w/ Traq damper, top O/A

C = Airside econ w/ std damper, top O/A

E = Airside econ w/ Traq damper &

comparative enthalpy, top O/A

F = Airside econ w/ std damper &

comparative enthalpy, top O/A

H = 2-position damper ventilation

interface

J = Airside economizer interface

K = Airside economizer interface w/

comparative enthalpy

Digit 29 - Water Piping

D = Left hand basic piping

F = Left hand Intermediate piping

K = Left hand basic w/ flow switch

M = Left hand intermediate w/ flow switch

0 = None

Digit 30 - Condenser Tube Type

A = Standard condenser tubes

B = 90/10 CuNi condenser tubes

0 = None (air-cooled only)

Digit 31 - Compressor Service

Valves

1 = With service valves

0 = None

Digit 32 - Miscellaneous System

Control

1 = Timeclock

2 = Interface For remote HI (IPCB)

3 = Dirty filter switch

4 = 1 and 2

5 = 1 and 3

6 = 2 and 3

7 = 1, 2 and 3

0 = None

G = GBAS and VOM

H = GBAS and RHI

J = VOM and RHI

M =GBAS, VOM, and RHI

N = BACnet Communications Interface

(BCI)

P = BCI and GBAS

Q = BCI and VOM

R = BCI and RHI

T = BCI and GBAS and VOM

U = BCI and GBAS and RHI

V = BCI and VOM and RHI

W= BCI and GBAS and VOM and RHI

0 = None

1 = Lontalk Comm5 Interface (LCI)

2 = LCI and GBAS

3 = LCI and VOM

4 = LCI and RHI

5 = LCI and GBAS and VOM

6 = LCI and GBAS and RHI

7 = LCI and VOM and RHI

8 = LCI and GBAS and VOM and RHI

Digit 34 - Agency

T = UL agency listing

0 = None

Digit 35 - Filter Type

1 = 2” T/A w/ 2” rack

2 = 2” med. eff. T/A w/ 2” rack

3 = 4” bolt-on rack w/ 2” med eff. filter

4 = 6” rack w/ 2” construction T/A

pre-filter & 4” filter space

5 = 6” rack w/ 2” med. eff. T/A pre-filter &

4”filter space

Digit 36 - Miscellaneous Control

Option

A = Low entering air temp. protect device

(LEATPD)

B = High duct temp t-stat, ship separate

C = Plenum high static switch, ship

separate

E = A and B

F = A and C

H = B and C

L = A, B, and C

0 = None

Digit 33 - Control Interface

Options

A = Generic BAS Module; 0-5 VDC (GBAS)

B = Ventilation Override Module (VOM)

D = Remote Human Interface (RHI)

18 PKG-PRC002U-EN

Model Number Descriptions

Self-Contained ShipWith Accessory

Model Number

Digit 1 - Parts/Accessories

P = parts/accessories

Digit 2 - Unit Model

S=self-contained

Digit 3 - Shipment

W = with unit

Digit 4 - Development Sequence

F = signature series

G = modular series

Digit 5 - Sensors and Other

Accessories

S = sensors

Digit 6 - Sensors and

Thermostats (Field Installed)

A = BAYSENS077 - zone temp only

(CV and VAV)

B = BAYSENS073- zone temp with

timed override button (CV and

VAV)

C = BAYSENS074 - zone temp with

timed override button, setpoint

dial (CV and VAV)

E = BAYSENS108 - CV zone sensor

-dual setpoint, man/auto

changeover

F = BAYSENS110 - CV zone sensor-

dual setpoint, man/auto

changeover w, indicastor lights

G = BAYSENS119 - CV/VAV program-

mable night setback Sensor

H = BAYSENS021 - VAV zone sensor

with indicator lights

L = outside air temperature sensor kit

M = outside air humidity sensor kit

0 = none

Digit 7 - Mixed Air Temperature

Protection Kit (Field Installed)

1 = mixed air temperature protection

kit

0 = none

Digit 8 - Carbon Dioxide Sensor

(Field Installed)

1 = carbon dioxide sensor kit

0 = none

Digit 9 - Future Option

0 = none

Digits 10, 11 - Design Sequence

** = Factory Assigned

Remote Air-Cooled Condenser Model Number Description

Digit 1 - Unit Model

C = Condenser

Digit 2 - Unit Type

C = Commercial

I = Industrial

Digit 3 - Condenser Medium

R = Remote

Digit 4 - Development Sequence

C = C

Digit 5, 6, 7 - Nominal Capacity

020 = 20 tons

029 = 29 tons

035 = 35 tons

040 = 40 tons

050 = 50 tons

060 = 60 tons

Digit 8 - Unit Voltage

4 = 460 volt/60 hz/3 ph

5 = 575 volt/60 hz/3 ph

6 = 200 volt/60 hz/3 ph

Digit 9 - Control Option

0 = No low ambient damper, I-Pak.

A = No low ambient damper, t-stat.

B = Low ambient, I-Pak.

C = Low ambient, t-stat.

Digit 10, 11 - Design Sequence

** = Factory Assigned

Digit 12 - Unit Finish

1 = Paint, slate gray

2 = Protective coating

3 = Protective coating with

finish coat

Digit 13 - Coil Options

A = Non-coated aluminum

C = Protective coating aluminum

Digit 14 - Unit Isolators

0 = None

A = Spring isolators

B = Isopads

Digit 15 - Panels

1 = Louvered panels

Digit 16 - Agency Listing

0 = None

U = With UL listing

PKG-PRC002U-EN 19

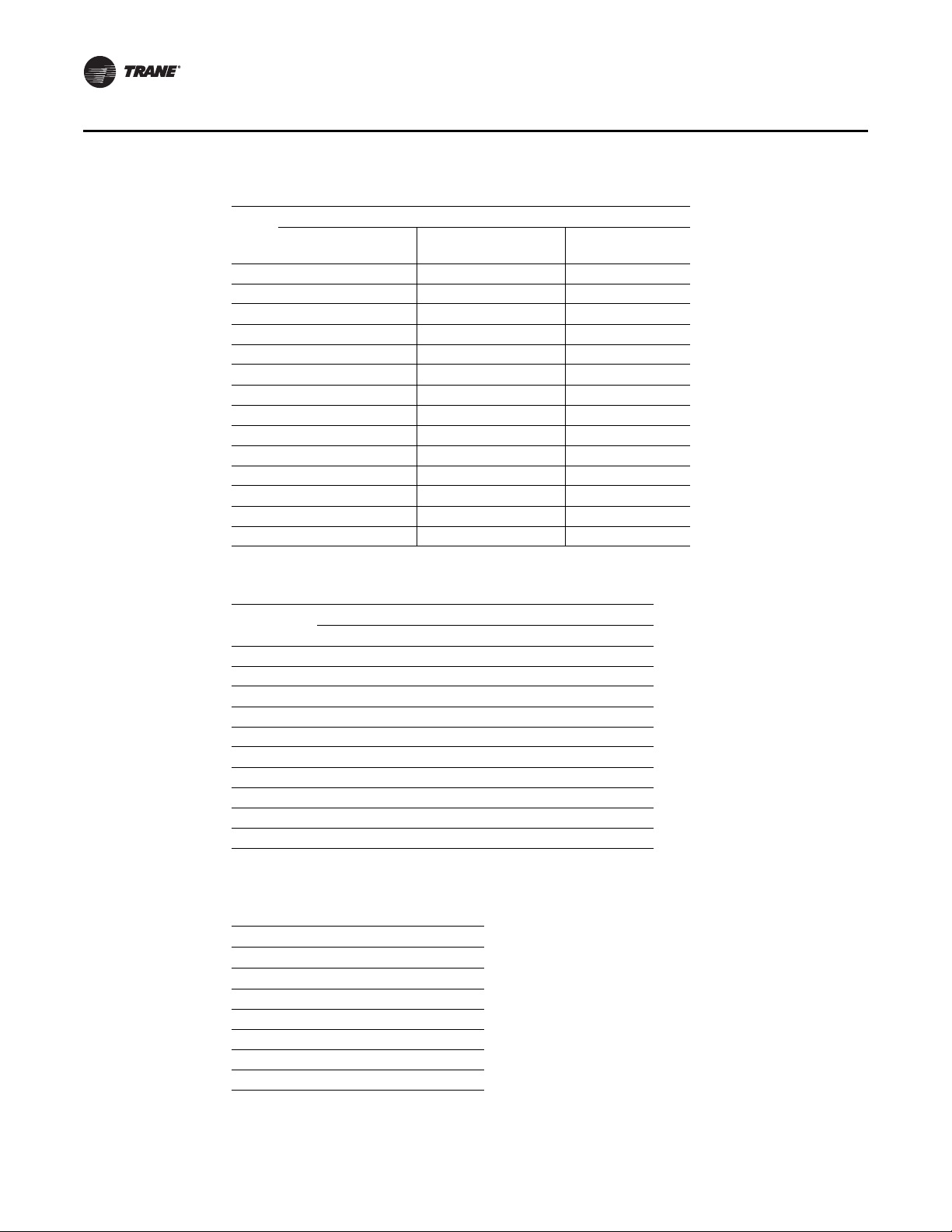

General Data

Table 1. SCWF/SIWF Water-cooled self-contained, 20 to 42 tons

Unit Size 20 22 25 29 32 35 38 42

Compressor Data

Quantity 2 2 2 1/1 1/1 3 3 2/1

Nominal Ton/comp 10 10 10 15/10 15/10 10 10 10/15

Circuits 222223 33

Evaporator Coil Data

Rows 2 2 3 or 6 2 4 or 6 3 4 or 6 3

Sq. Ft. 21.81 21.81 21.81 29.98 29.98 31.35 31.35 38.57

Fpf 144 144 144 144 144 144 144 144

Condenser Data

Minimum Gpm W/o Econ 36 36 36 46 46 54 54 64

Minimum Gpm W/ Econ 41 41 41 60 60 65 65 64

Maximum Gpm 80 80 80 102 102 119 119 142

Evaporator Fan Data

Quantity 11111111

Diameter 18” 18” 18” 18” 18” 20" 20" 25”

Minimum Hp 55555557. 5

Minimum Kw (3.73) (3.73) (3.73) (3.73) (3.73) (3.73) (3.73) (5.39)

Maximum Hp 20 20 20 20 20 25 25 30

Maximum Kw (14.91) (14.91) (14.91) (18.64) (18.64) (18.64) (18.64) (22.37)

Minimum Design Cfm 6325 6325 6500 8700 8700 9100 9880 11200

Maximum Design Cfm 8500 9350 10625 12325 13600 14875 16150 17850

High Capacity Option

Rows — — 6 — 6 — 6 —

Optional Low Flow Fan

Diameter — — — — 18” —

Min/max Design Cfm — — — — 6000/10625 —

General Data R-410A

EER 14.0 14.0 14.0 14.0 14.3 14.0 14.2 14.2

IEER (CV) 15.3 15.3 15.0 15.6 15.2 15.2 14.9 15.6

IEER (VAV) 17.4 17.4 17.5 18.1 18.8 18.0 18.5 18.3

Refrigerant Charge, lbs. R-410A

Circuit A 19.5 19.5 21.5 22.0 28.5 21.5 23.5 22.0

Circuit B 19.5 19.5 21.5 19.5 23.5 21.5 23.5 22.0

Circuit C – – – – – 21.5 23.5 22.0

Capacity Steps - % 100/53/0 100/53/0 100/53/0 100/62/39/0 100/59/39/0 100/65/31/0 100/65/30/0

Notes:

1. Compressors are Trane 3-D™ scroll.

2. EER and IEER are rated in accordance to AHRI Standard 340/360-2010. Based on 80/67° F (26.7/19.4 °C) to evaporator coil, nominal airflow and

85-95 °F (29.4/35 °C) condenser water.

3. All units operate with R-410A. Units ships with full operating charge.

4. Maximum cfm limits are set to prevent moisture carryover on the evaporator coil.

5. Minimum cfm limits are set to ensure stable thermal expansion valve operation at low load conditions.

6. Optional low flow fan (unit model number digit 23 = 1) is available ONLY when High Capacity option is selected (unit model number digit 5 = V).

6

100/71/

43/26/0

20 PKG-PRC002U-EN

General Data

Table 2. SCWF/SIWF Water-cooled self-contained, 46-110 tons

Unit Size 46 52 58 65 72 80 90 100 110

Compressor Data

Quantity 2/1 3 3 3/1 3/1 4 5 2/4 6

Nominal Ton/Comp 10/15 15 15 15/10 15/10 15 15 10/15 15

Circuits 3 33444566

Evaporator Coil Data

Rows 4 or 6 2 4 or 6 3 4 or 6 6 6 6 6

Sq. Ft. 38.57 49.09 49.09 49.09 49.09 49.09 56.81 56.81 56.81

FPF 144 144 144 144 144 144 144 144 144

Condenser Data

Min GPM w/o Econ 64 84 84 102 102 112 140 168 168

Min GPM w/ Econ 64 84 84 102 102 112

Maximum GPM 142 186 186 226 226 248 300 350 350

Evaporator Fan Data

Quantity 1 11111111

Size (Dia.) 25” 25” 25” 27.5” 27.5” 27.5” 27.5” 27.5” 27.5”

Minimum HP 7.5 10 10 10 10 10 15 15 15

Minimum kW (5.59) (7.46) (7.46) (7.46) (7.46) (7.46) (11.19) (11.19) (11.19)

Maximum HP 30 50 50 50 50 50 60 60 60

Maximum kW (22.37) (37.29) (37.29) (37.29) (37.29) (37.29) (44.74 ) (44.74) (44.74)

Min Design CFM 11960 14250 15080 16900 18700 20800 17500 17500 17500

Max Design CFM 19550 22100 24650 27625 29800 29800 35000 35000 35000

High Capacity Option

Rows 6—6—6—888

Optional Low Flow Fan

Size (Dia.) 18” 18” 20”

Min./Max Design CFM 7700/13600 —

General Data R-410A

EER 14.3 14.0 14.3 14.0 14.0 14.0 14.1 14.1 14.0

IEER (CV) 15.2 15.7 15.3 15.4 14.9 14.6 16.3 16.3 16.3

IEER (VFD) 18.8 17.9 18.9 18.2 18.5 19.3 18.6 18.5 18.1

Refrigerant Charge — lbs. R-410A

Circuit A 24.5 21.0 26.5 22.0 24.5 28.0 24.5 24.5 24.5

Circuit B 24.5 21.0 26.5 22.0 24.5 28.0 24.5 24.5 24.5

Circuit C 24.5 21.0 26.5 22.0 24.5 28.0 24.5 24.5 24.5

Circuit D – – – 21.0 22.0 28.0 24.5 24.5 24.5

Circuit E – – – – – – 24.5 24.5 24.5

Circuit F – – – – – – – 24.5 24.5

Capacity Steps - % 100/70/41/30/0

Notes:

1. Compressors are Trane 3-D™ scroll.

2. EER and IEER are rated in accordance to ARI Standard 340/360-2 007. Based on 80/6 7° F (26.7/19.4 ° C) to ev apor ator coil, no minal airflow and 85-

95 °F (29.4/35 °C) condenser water.

3. All units operate with R-410A. Units ships with full operating charge.

4. Maximum cfm limits are set to prevent moisture carryover on the evaporator coil.

5. Minimum cfm limits are set to ensure stable thermal expansion valve operation at low load conditions.

100/65/

32/0

8900/

13600

100/65/

30/0

—

100/71/

44/24/0

10700/

16150

100/71/43/

23/0

—

100/73/46/

20/0

100/80/40/

20/0

100/75/38/

19/0

100/66/33/

17/0

PKG-PRC002U-EN 21

General Data

Table 3. SCRF/SIRF Air-cooled self-contained

Unit Size 20 25 29 30 35 40 50 60

Compressor Data

Quantity 21/11/13 32/13 4

Nominal Ton/Comp 10 15/10 15/10 10 10 10/15 15 15

Circuits 22222222

Evaporator Coil Data

Rows 32434446

Sq. Ft. 21.81 29.98 29.98 31.35 31.35 38.57 49.09 49.09

FPF 144 144 144 120 144 144 144 144

Evaporator Fan Data

Quantity 11111111

Size (Dia.) 18” 18” 18” 20” 20” 25” 25” 27.5”

Minimum HP 555557.51010

Minimum kW (3.73) (3.73) (3.73) (3.73) (3.73) (5.59) (7.46) (7.46)

Maximum HP 20 20 20 25 25 30 40 50

Maximum kW (14.91) (18.64) (18.64) (18.64) (18.64) (22.37) (37.29) (37.29)

Minimum Design CFM 6500 8700 8700 9100 9880 11960 15080 20800

Maximum Design CFM 10625 12325 13600 14875 16150 19550 24650 29800

General Data

EER 10.0 10.0 10.5 10.4 10.6 10.7 10.5 10.3

IEER (CV) 10.8 11.6 12.2 12.5 12.0 12.7 12.1 11.2

IEER (VAV) 11.9 12.8 13.7 13.5 13.9 14.4 13.7 14.1

Refrigerant Charge See Note 6

Capacity Steps - % 100/53/0 100/62/39/0 100/59/39/0 100/65/31/0 100/65/30/0

CCRC/CIRC Unit Match 20 29 29 35 35 40 50 60

Notes:

1. Compressors are Trane 3-D™ scroll.

2. EER and IEER are rated in accordance to ARI Standard 340/360-2007. Based on 80/67° F (26.7/19.4 °C) to evaporator coil, nominal airflow and 85-

95 °F (29.4/35 °C) condenser water.

3. All units operate with R-410A. Units ship with a dry nitrogen holding charge. Field refrigerant system charge required. Refer to Table 5, p. 23 for

amounts required.

4. Maximum cfm limits are set to prevent moisture carryover on the evaporator coil.

5. Minimum cfm limits are set to ensure stable thermal expansion valve operation at low load conditions.

100/70/41/

30/0

100/65/30/0

100/73/46/

20/0

22 PKG-PRC002U-EN

General Data

Table 4. CCRC/CIRC Remote air-cooled condenser

Unit Size 20 29 35 40 50 60

Condenser Fan Data

Number/Type/Drive 4/Prop/Direct 4/Prop/Direct 6/Prop/Direct 6/Prop/Direct 8/Prop/Direct 8/Prop/Direct

Size (inches) 26 26 26 26 26 26

Size (mm) (660.4) (660.4) (660.4) (660.4) (660.4) (660.4)

HP ea. 111111

Nominal CFM 18,800 21,200 35,600 39,800 46,200 56,400

Nominal (liters / sec) (8873) (10005) (16801) (18784) (21804) (26618)

Condenser Coil Data

Circuit 1 Size (in.) 1/46x71 1/64x71 2/46x71 2/46x71 2/64x71 2/64x71

Circuit 1 Size (mm) (1/1168x1803) (1/1626x1803) (2/1168x1803) (2/1168x1803) (2/1626x1803) (2/1626x1803)

Circuit 2 No./Size (in.) 1/46x71 1/46x71 1/46x71 1/64x71 1/64x71 2/64x71

Circuit 2 No./Size (mm) (1/1168x1803) (1/1168x1803) (1/1168x1803) (1/1626x1803) (1/1626x1803) (2/1626x1803)

Face Area (sq. ft.) 45.4 54.2 68 76.9 94.7 126.2

Face Area (sq.m) (4.2) (5) (6.3) (7.1) (8.8) (11.7)

Rows/fpf 4/144 4/144 4/144 4/144 4/144 4/144

Ambient Temperature Operating Range

Standard Ambient (F) 50-115 50-115 50-115 50-115 50-115 50-115

Standard Ambient (C) (10 - 46.1) (10 - 46.1) (10 - 46.1) (10 - 46.1) (10 - 46.1) (10 - 46.1)

Low Ambient Option (F) 0-115 0-115 0-115 0-115 0-115 0-115

Low Ambient Option (C) (-17.8 - 46.1) (-17.8 - 46.1) (-17.8 - 46.1) (-17.8 - 46.1) (-17.8 - 46.1) (-17.8 - 46.1)

Note: Units ship with dry nitrogen charge. field refrigerant system charge required. See Table 5 for amounts required.

Table 5. SCRF/SIRF Air–cooled self–contained and CCRC/CIRC remote air-cooled condenser refrigerant data

SCRF/SIRF & CCRC/CIRC

Unit Size 20/20 25/29 29/29 30/35 35/35 40/40 50/50 60/60

No. of Refrigerant Circuits 22222222

Operating Charge - lbs. R-410A 35.5/35.5 44.5/33.5 51/37.5 71/35.5 75/37.5 86.5/39.5 98/50 101.5/101.5

Operating Charge - kg R-410A 16.1/16.1 20.2/15.2 23.1/17 32.2/16.1 34/17 39.2/17.9 44.5/22.7 46/46

Cond. Storage Cap. - lbs. R-410A 37/37 51/37 51/37 74/37 74/37 74/51 102/51 102/102

Cond. Storage Cap. - kg R-410A 16.8/16.8 23.1/16.8 23.1/16.8 33.6/16.8 33.6/16.8 33.6/23.1 46.3/23.1 46.3/46.3

Notes:

1. Refrigerant charges are listed as circuit 1 circuit 2 and provide only an estimate. Final charge requires sound field charging practice.

2. Operating charge is for entire system, which includes the air–cooled self–contained, remote air–cooled condenser, and 25 feet of interconnecting

refrigerant piping.

3. At conditions of 95° F (35° C), condenser storage capacity is 95% full.

4. To determine the correct amount of refrigerant needed for a particular application, reference the Trane Reciprocating Refrigeration Manual.

Table 6. SCWF/SIWF water flow volumes

Water Volume in U.S. Gallons / Liters

Unit

Size

W/o Economizer

Gallons Liters Gallons Liters Gallons Liters

20 9.0 34.1 17.4 65.9 16.9 64.0

22 9.0 34.1 17.4 65.9 16.9 64.0

25 9.0 34.1 17.4 65.9 16.9 64.0

With Mech. Cleanable

Econ

With Chem.

Cleanable Econ

PKG-PRC002U-EN 23

General Data

Table 6. SCWF/SIWF water flow volumes (continued)

Water Volume in U.S. Gallons / Liters

Unit

Size

100 23.0 87.1 50.6 191.5 N/A N/A

110 24.0 90.8 51.6 195.3 N/A N/A

W/o Economizer

29 9.0 34.1 20.5 77.6 18.8 71.2

32 9.0 34.1 20.5 77.6 18.8 71.2

35 10.0 37.9 21.9 82.9 20.2 76.5

38 10.0 37.9 21.9 82.9 20.2 76.5

42 15.0 56.8 32.2 121.9 31.4 118.9

46 15.0 56.8 32.2 121.9 31.4 118.9

52 15.0 56.8 36.9 139.7 35.9 135.9

58 15.0 56.8 36.9 139.7 35.9 135.9

65 16.0 60.6 37.9 143.5 36.9 139.7

72 16.0 60.6 37.9 143.5 36.9 139.7

80 16.0 60.6 37.9 143.5 36.9 139.7

90 22.5 85.2 50.1 189.6 N/A N/A

With Mech. Cleanable

Econ

With Chem.

Cleanable Econ

Table 7. SCWF/SIWF Refrigerant circuits, number of compressors by circuit

Circuit

Unit Size 1 2 3 4 5 6

20/22/25 Ton 1- 10T 1- 10T

29/32 Ton 1- 15T 1- 10T

35/38 Ton 1- 10T 1- 10T 1- 10T

42/46 Ton 1- 15T 1- 10T 1- 10T

52/58 Ton 1- 15T 1- 15T 1- 15T

60/72 Ton 1- 15T 1- 15T 1- 15T 1- 10T

80 Ton 1- 15T 1- 15T 1- 15T 1- 15T

90 Ton 1- 15T 1- 15T 1- 15T 1- 15T 1- 15T

100 Ton 1-15T 1-15T 1-15T 1-15T 1-10T 1-10T

110 Ton 1- 15T 1- 15T 1- 15T 1- 15T 1- 15T 1- 15T

Note: This table depicts compressor location in unit, plan view from left corner.

Table 8. SCRF/SIRF Refrigerant circuits, number of compressors by circuit

Circuit 1 2

Unit Size

20 Ton 1-10T 1- 10T

25/29 Ton 1-15T 1-10T

30/35 Ton 2-10T 1-10T

40 Ton 1-10T, 1-15T 1-10T

50 Ton 2-15T 1-15T

60 Ton 2-15T 2-15T

Note: This table depicts compressor location in

unit, plan view from left corner.

24 PKG-PRC002U-EN

Table 9. Filter data, water-cooled units models SCWF & SIWF

Unit Size 20- 38 tons 40-85 tons 90-110 tons

Number - Size (In.) 8 - 20x18 12 - 25 x 20 15 - 24 x 24

4 - 20 x 20 6 - 20 x 20 3 - 24 x 12

Units With Hot Water Or Steam

Number - Size (In.) 4 - 16x20 4 - 25 x 20

4 - 20 x 20 2 - 20 x 20

4 - 18 x 20 8 - 25 x 16

4 - 20 x 16

n/a

Table 10. Filter data, air-cooled units models SCRF & SIRF

Unit size 20- 35 tons 40-60 tons

Number - Size (in.) 8 - 20x18 12 - 25 x 20

4 - 20 x 20 6 - 20 x 20

Units With Hot Water Or Steam

Number - Size (in.) 4 - 16x20 4 - 25 x 20

4 - 20 x 20 2 - 20 x 20

4 - 18 x 20 8 - 25 x 16

4 - 20 x 16

General Data

Table 11. Self-Contained Heating Coil

Unit Size SCWF 20 - 38 SCWF 42 - 80 SCRF 20 - 35 SCRF 40 - 60

Steam Coil

Coil Type NS NS NS NS

Rows 1111

No./Size (inches) ((2) 24x58) ((2) 30x81) ((2) 24x58) ((2) 30x81)

No./Size (mm) ((2) 609.6x1473.2) ((2) 762x2057.4) ((2) 609.6x1473.2) ((2) 762x2057.4)

FPF 42424242

Hot Water Coil

Coil Type 5W 5W 5W 5W

Rows 1 or 2

No./Size (inches) (2) 24x58 (2) 30x81 (2) 24x58 (2) 30x81

No./Size (mm) ((2) 609.6x1473.2) ((2) 762x2057.4) ((2) 609.6x1473.2) ((2) 762x2057.4)

FPF 80 or 108 80 or 108 8 0 or 108 80 or 108

Notes:

1. Hot water and steam heating coils have Prima-Flo® fins without turbulators.

2. For coil capacities, use TOPSS™ (Trane Official Product Selection Program).

3. Full capacity coils consist of two coils stacked and piped in parallel.

PKG-PRC002U-EN 25

General Data

Table 12. Waterside Economizer Coil Physical Data

Model Unit Size Type Rows FPF

Height

SCXF 20, 22 & 25 Chemically Cleanable 2 108 40 78.5

SCXF 20, 22 & 25 Mechanical Cleanable 2 108 40 78.5

SCXF 20, 22 & 25 Chemically Cleanable 4 108 40 78.5

SCXF 20, 22 & 25 Mechanical Cleanable 4 108 40 78.5

SCXF 29 & 32 Chemically Cleanable 2 108 55 78.5

SCXF 29 & 32 Mechanical Cleanable 2 108 55 78.5

SCXF 29 & 32 Mechanical Cleanable 4 108 55 78.5

SCXF 29 & 32 Chemically Cleanable 4 108 55 78.5

SCXF 35 & 38 Chemically Cleanable 2 108 57.5 78.5

SCXF 35 & 38 Mechanical Cleanable 2 108 57.5 78.5

SCXF 35 & 38 Chemically Cleanable 4 108 57.5 78.5

SCXF 35 & 38 Mechanical Cleanable 4 108 57.5 78.5

SCXF 42 & 46 Chemically Cleanable 2 144 55 101

SCXF 42 & 46 Mechanical Cleanable 2 144 70 101

SCXF 42 & 46 Chemically Cleanable 4 144 55 101

SCXF 42 & 46 Mechanical Cleanable 4 144 70 101

SCXF 52, 58, 65, 72, 80, 85 Chemically Cleanable 2 144 70 101

SCXF 52, 58, 65, 72, 80, 85 Mechanical Cleanable 2 144 70 101

SCXF 52, 58, 65, 72, 80, 85 Chemically Cleanable 4 144 70 101

SCXF 52, 58, 65, 72, 80, 85 Mechanical Cleanable 4 144 70 101

SCXF 90, 100 & 110 Mechanical Cleanable 4 144 70 119.3

(in)

Length

(in)

26 PKG-PRC002U-EN

Performance Data

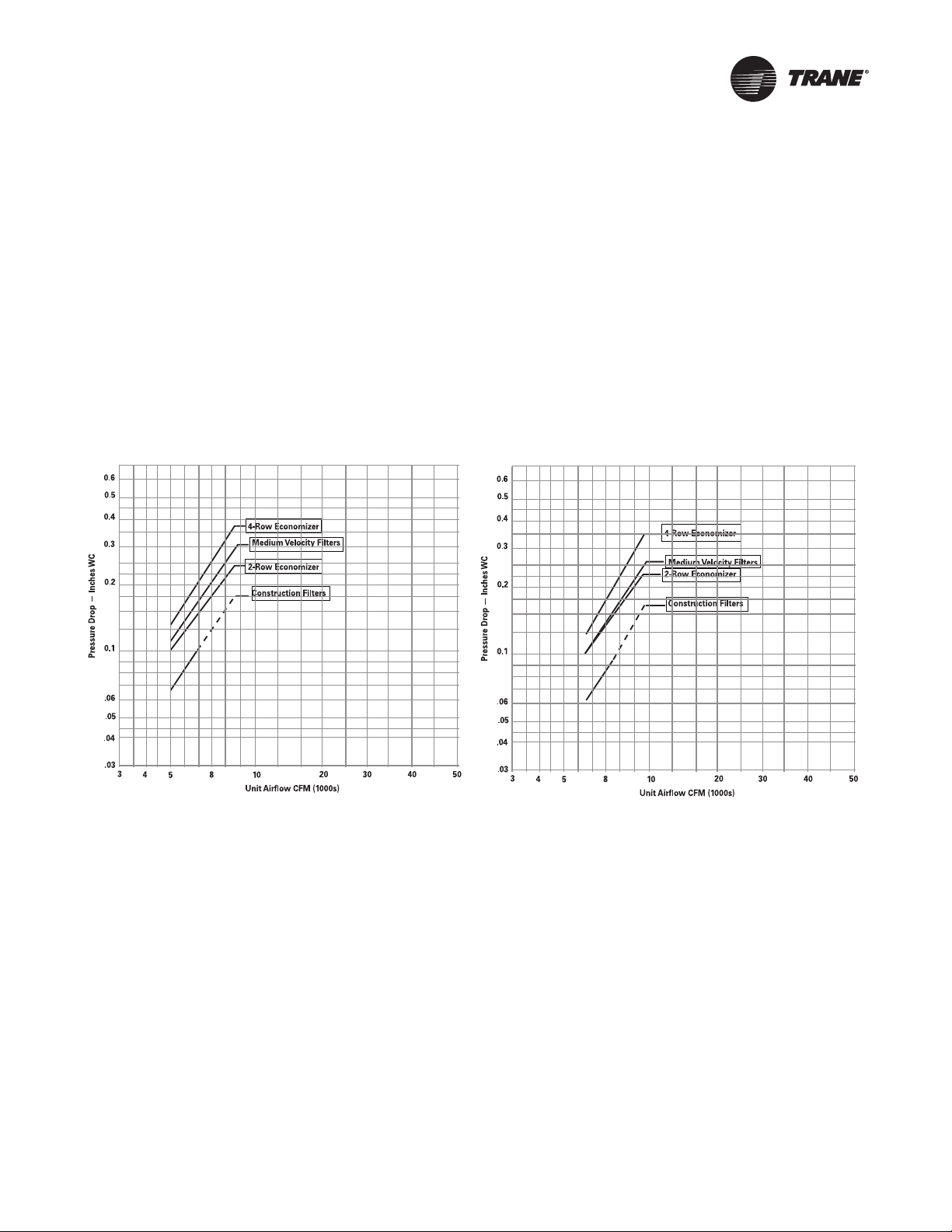

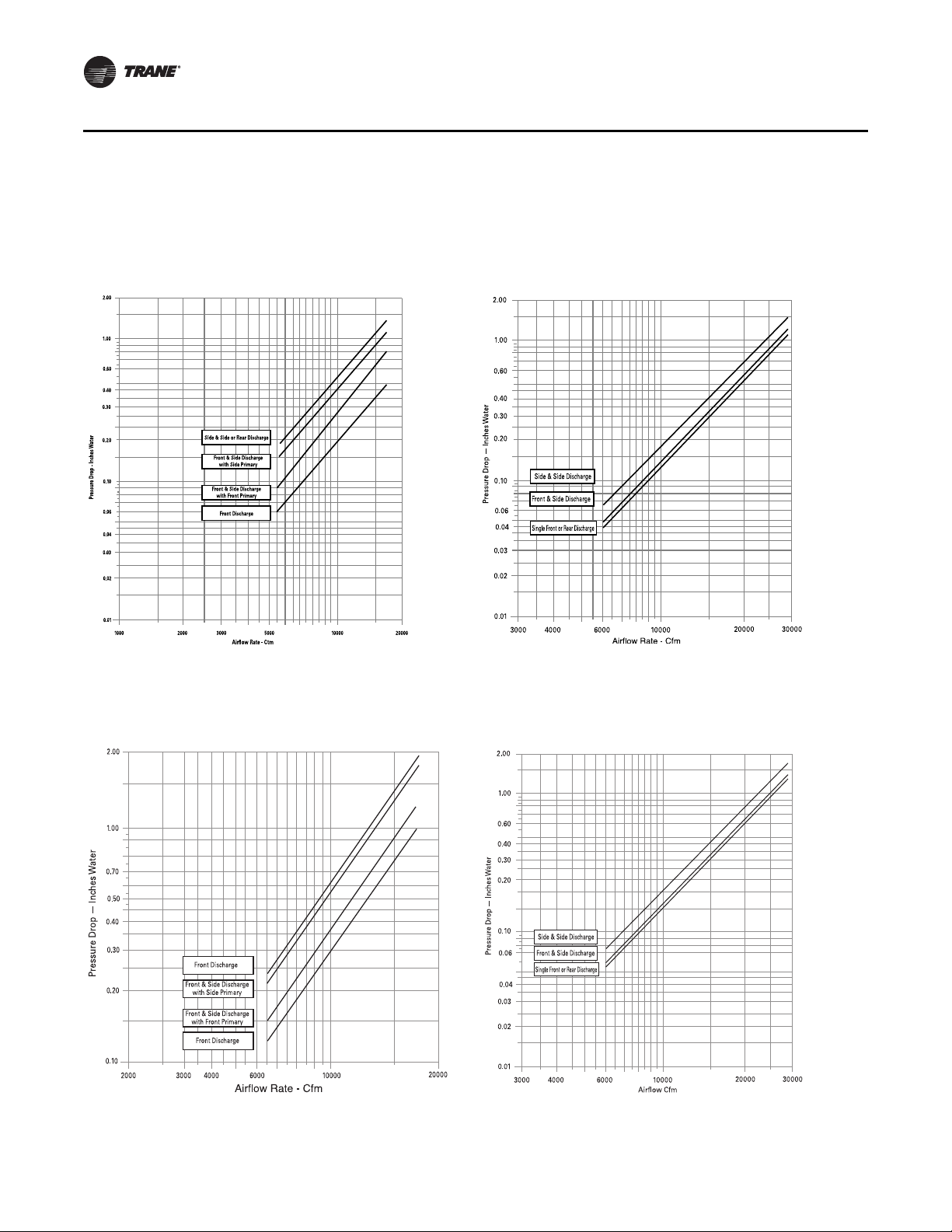

Figure 1. Airside Pressure Drop SCWF/SIWF 20, 22, 25

and SCRF/SIRF 20

Figure 2. Airside Pressure Drop SCWF/SIWF 29, 32 and

SCRF/SIRF 25, 29

Airside Pressure Drops

The dotted line on construction filters indicates cfm where face velocity exceeds manufacturer’s

recommended maximum of 300 fpm. After startup, construction filters must be replaced with

medium velocity or high velocity filters.

Air pressure drops through electric heat is 0.5 inches WC.

See “Discharge Plenum,” p. 30 for pressure drop through flexible horizontal discharge plenum and

“Heating Coils,” p. 29 for pressure drop through heating coils.

For 4-inch cartridge filters, air pressure drops must be added to the external static pressure design

point.

PKG-PRC002U-EN 27

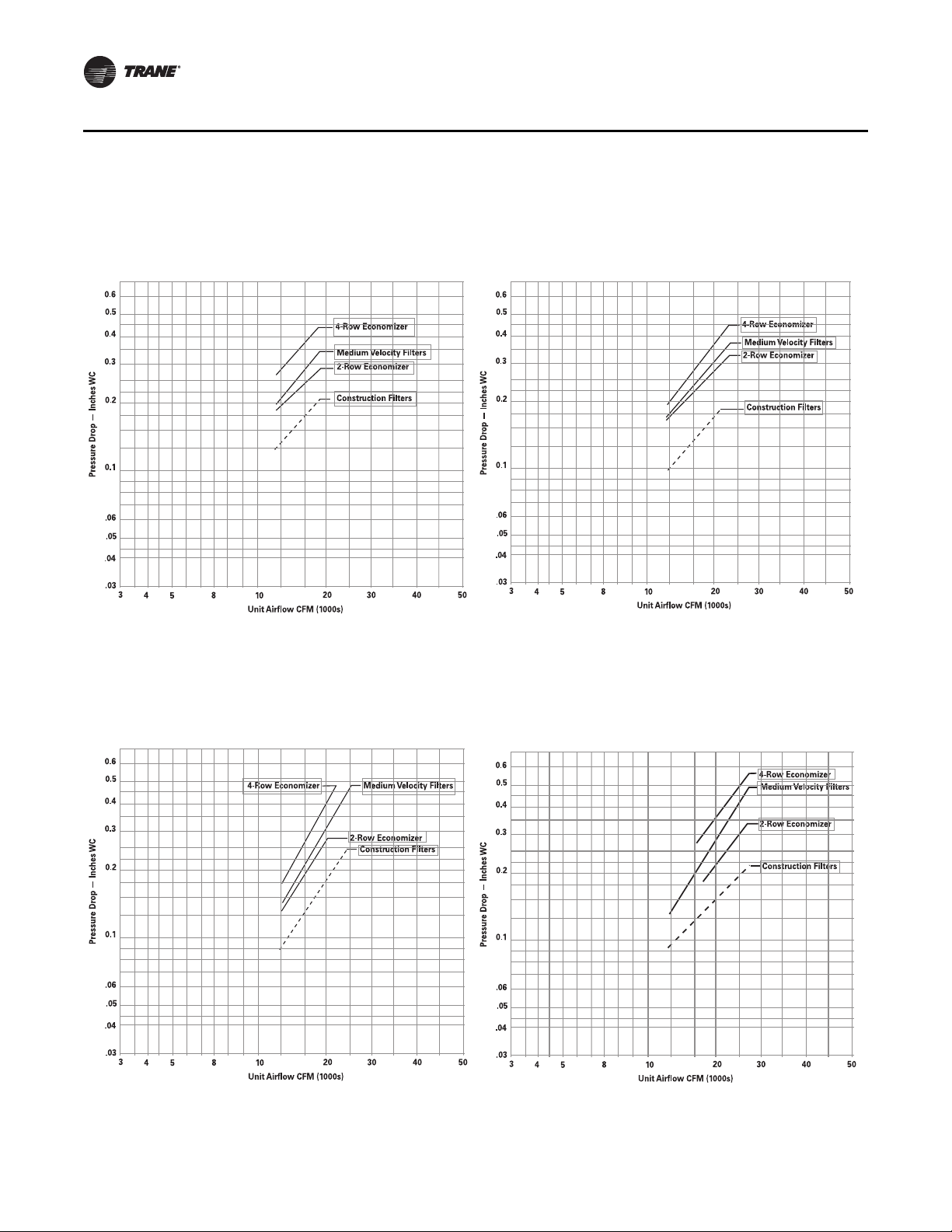

Performance Data

Figure 3. Airside Pressure Drop SCWF/SIWF 35, 38 and

SCRF/SIRF 30, 35

Figure 4. Airside Pressure Drop SCWF/SIWF 42, 46 and

SCRF/SIRF 40

Figure 5. Airside Pressure Drop SCWF/SIWF 52, 58 and

SCRF/SIRF 50

Figure 6. Airside Pressure Drop SCWF/SIWF 65, SCWF/

SIWF 72, SCWF/SIWF 80 and SCRF/SIRF 60

28 PKG-PRC002U-EN

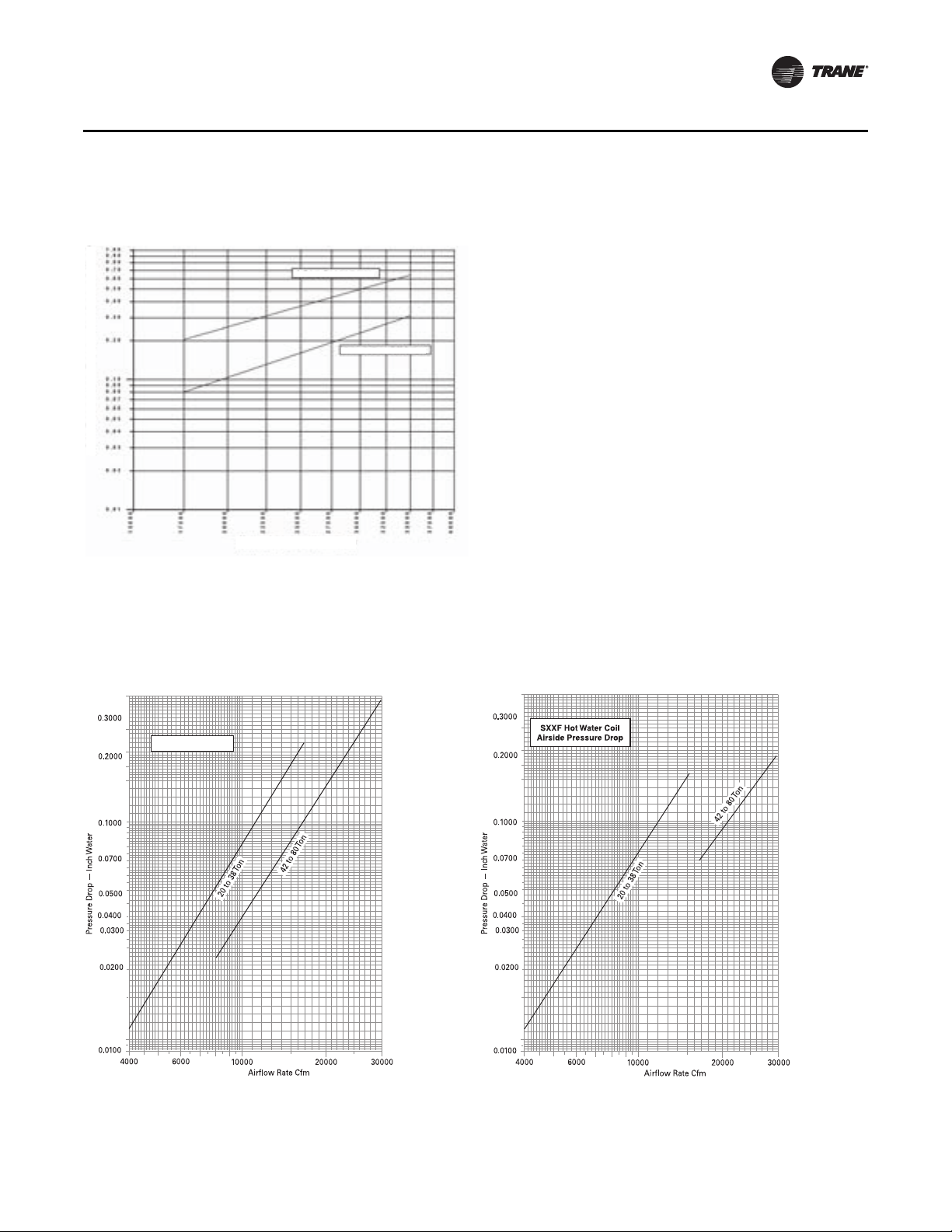

Performance Data

Figure 7. Airside Pressure Drop SCWF/SIWF 90-110

4 Row Economizer

2 Inch Med Eff Filter

Airflow - CFMAirflow - CFMAirflow - CFM

Air Pressure Drop - Inches of WaterAir Pressure Drop - Inches of Water

Figure 8. Airside Pressure Drop Steam Coil 20 to 80-Ton

Units

For NS Coils

Figure 9. Airside Pressure Drop Hot Water Coil 20 to 80-

Ton Units

Heating Coils

PKG-PRC002U-EN 29

Performance Data

Figure 10. Airside Pressure Drop, Standard Height

Discharge Plenum 20 to 38 Ton Unit

Figure 11. Airside Pressure Drop, Standard Height

Discharge Plenum 42 to 80 Ton Unit

Figure 12. Airside Pressure Drop, Low Height Discharge

Plenum 20 to 38 Ton Unit

Figure 13. Airside Pressure Drop, Low Height Discharge

Plenum 42 to 80 Ton Unit

Discharge Plenum

30 PKG-PRC002U-EN

Loading...

Loading...