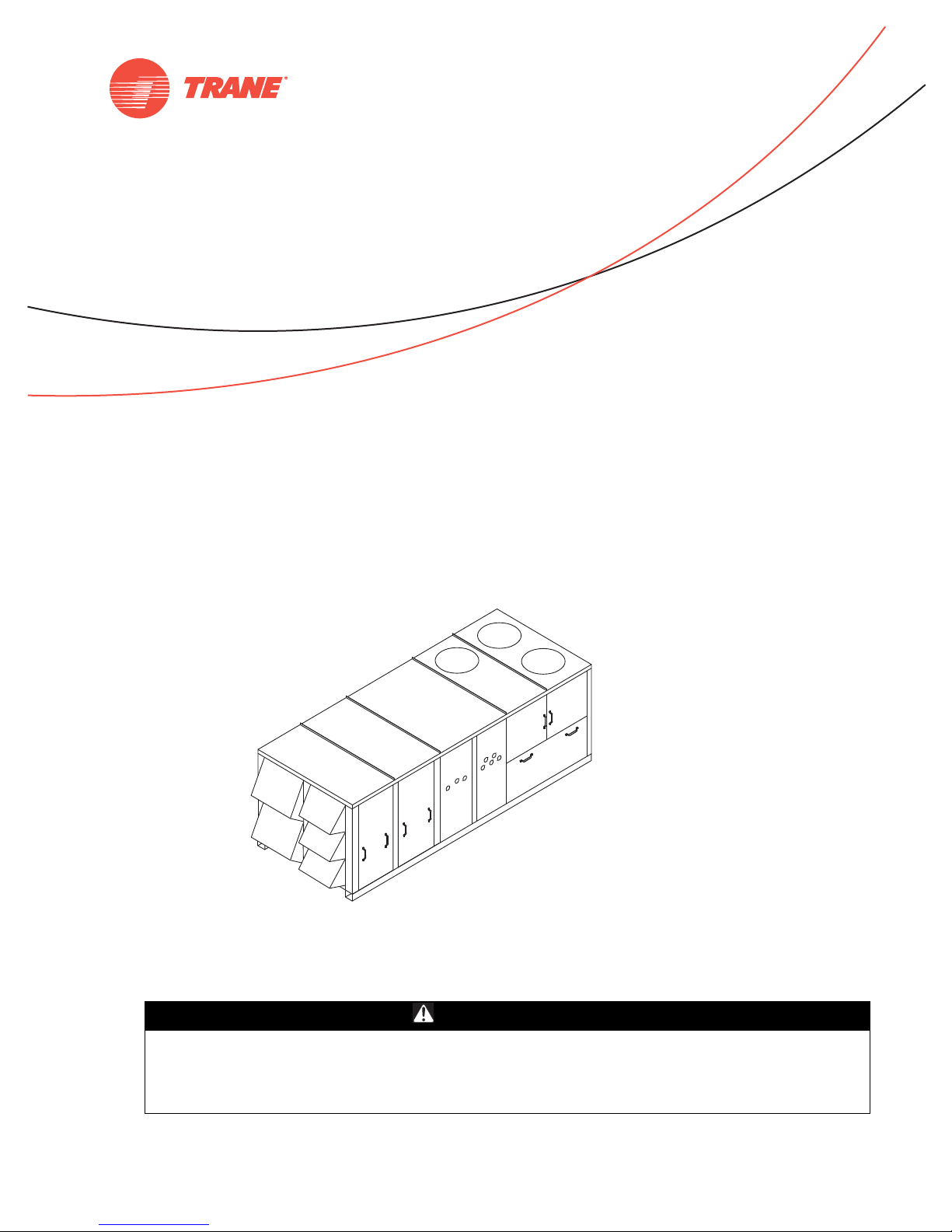

Trane TCD330B, TCD360B, TCD420B, TCD480B, TCD600B Installation And Maintenance Manual

...

Installation, Operation,

and Maintenance

Voyager™ Commercial

27.5 to 50 Ton 60 Hz

22.9 to 41.7 Ton 50 Hz

CV, VAV, or SZ VAV Rooftop Air Conditioners

with ReliaTel™ Controls, R-410A Refrigerant

Model Numbers

“B” and later design sequence

TC*, TE*, YC*330B, 360B, 420B, 480B, 600B (60 Hz/3 phase)

TC*, TE*, YC*275B, 305B, 350B, 400B, 500B (50 Hz/3 phase)

Only qualified personnel should install and service the equipment. The installation, starting up, and

servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific

knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could

result in death or serious injury. When working on the equipment, observe all precautions in the literature

and on the tags, stickers, and labels that are attached to the equipment.

August 2012 RT-SVX34F-EN

SAFETY WARNING

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings,

cautions and notices appear at appropriate intervals

throughout this manual. Warnings are provided to alert

installing contractors to potential hazards that could result

in personal injury or death. Cautions are designed to alert

personnel to hazardous situations that could result in

personal injury, while notices indicate a situation that could

result in equipment or property-damage-only accidents.

Your personal safety and the proper operation of this

machine depend upon the strict observance of these

precautions.

ATT EN TI ON : Warnings, Cautions and Notices appear at

appropriate sections throughout this literature. Read these

carefully:

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servicing this unit, technicians

MUST put on all Personal Protective Equipment (PPE)

recommended for the work being undertaken.

ALWAYS refer to appropriate MSDS sheets and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS sheets and

OSHA guidelines for information on allowable

personal exposure levels, proper respiratory

protection and handling recommendations.

• If there is a risk of arc or flash, technicians MUST put

on all Personal Protective Equipment (PPE) in

accordance with NFPA 70E or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit.

Failure to follow recommendations could result in death

or serious injury.

WARNI NG

Important

Environmental Concerns!

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and Carbon

(HCFCs). Not all refrigerants containing these compounds

have the same potential impact to the environment. Trane

advocates the responsible handling of all refrigerantsincluding industry replacements for CFCs such as HCFCs

and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified. The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain refrigerants

and the equipment that is used in these service procedures.

In addition, some states or municipalities may have

additional requirements that must also be adhered to for

responsible management of refrigerants. Know the

applicable laws and follow them.

WARNI NG

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

Overview of Manual

One copy of the appropriate service literature ships inside

the control panel of each unit. The procedures discussed in

this manual should only be performed by qualified,

experienced HVAC technicians.

Note: Do not release refrigerant to the atmosphere! If

adding or removing refrigerant is required, the

service technician must comply with all federal,

state, and local laws.

This booklet describes the proper installation, startup,

operation, and maintenance procedures for TC_, TE_, and

YC_22.9 to 50 Ton CV (Constant Volume), VAV (Variable Air

Volume), and SZ VAV (Single Zone Variable Air Volume)

applications. Refer to the table of contents for a listing of

specific topics. Refer to “Diagnostics,” p. 104 for

troubleshooting information.

© 2012 Trane All rights reserved RT-SVX34F-EN

By carefully reviewing the information within this manual

and following the instructions, the risk of improper

operation and/or component damage will be minimized.

It is important that periodic maintenance be performed to

help assure trouble free operation. A maintenance

schedule is provided at the end of this manual. Should

equipment failure occur, contact a qualified service

organization with qualified, experienced HVAC technicians

to properly diagnose and repair this equipment.

Revision History

RT-SVX34F-EN (10 August 2012)

• Motors with Internal Shaft Grounding Ring

• Updated Model Number Description, Installation

Electrical, Unit Wiring Diagrams

Warnings, Cautions and Notices

60 Hz units with standard options are certified by

Underwriters Laboratory.

RT-SVX34F-EN 3

Table of Contents

Model Number Description . . . . . . . . . . . . . . . 7

60 Hz Description . . . . . . . . . . . . . . . . . . . . . . 7

50 Hz Description . . . . . . . . . . . . . . . . . . . . . . 9

General Information . . . . . . . . . . . . . . . . . . . . 11

Commonly Used Acronyms and Abbrevia-

tions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

About the Unit . . . . . . . . . . . . . . . . . . . . . 11

Precautionary Measures . . . . . . . . . . . . . 12

Unit Inspection . . . . . . . . . . . . . . . . . . . . . 12

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Unit Dimensions and Weights . . . . . . . . . . . 13

Recommended Clearances . . . . . . . . . . . . . 13

Roof Curb and Ductwork . . . . . . . . . . . . . . . 13

Horizontal Ductwork . . . . . . . . . . . . . . . . . 13

Unit Rigging and Placement . . . . . . . . . . . 19

Installation General Requirements . . . . . . . 21

Condensate Drain Connection . . . . . . . . . . 21

O/A Sensor & Tubing Installation . . . . . . . 21

Units with Statitrac™ . . . . . . . . . . . . . . . . . 21

Installation Electrical . . . . . . . . . . . . . . . . . . . . 23

Disconnect Switch External Handle (Factory

Mounted Option)

. . . . . . . . . . . . . . . . . . . . . 23

Main Power Wiring . . . . . . . . . . . . . . . . . . . 23

Through-the-Base Electrical (Optional Acces-

sory) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Electrical Wire Sizing and Protection Device

Equations

Low Voltage Wiring . . . . . . . . . . . . . . . . . 28

Control Power Transformer . . . . . . . . . . . 28

Field Installed AC Control Wiring . . . . . . 28

Field Installed DC Control Wiring . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Remote Panels and Sensors . . . . . . . . . . . 32

Constant Volume and Single Zone VAV Con-

trol Options . . . . . . . . . . . . . . . . . . . . . . . . 32

Variable Air Volume (non-SZ VAV) Control

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installation Piping . . . . . . . . . . . . . . . . . . . . . . 36

General Requirements . . . . . . . . . . . . . . . . 36

Connecting the Gas Supply Line to the Fur-

nace Gas Train . . . . . . . . . . . . . . . . . . . . . 36

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Unit Control Modules . . . . . . . . . . . . . . . . . .38

RTRM - ReliaTel Refrigeration Module . . .38

ECA - Economizer Actuator (Optional) . . .38

PEA - Power Exhaust Actuator (Optional) 38

RTAM - ReliaTel Air Handler Module (Stan-

dard with Traditional VAV) . . . . . . . . . . . .38

Conventional Thermostat Connections

(Available Only with CV) . . . . . . . . . . . . . .39

TCI - Trane Communication Interface (Option-

al) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

LCI - LonTalk® Communication Interface (Op-

tional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

BCI - BACnet® Communication Interface (Op-

tional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Manual Motor Protectors (380V Through

575V Only) . . . . . . . . . . . . . . . . . . . . . . . . .40

System Operation . . . . . . . . . . . . . . . . . . . . .40

Economizer Operation with a Conventional

Thermostat (CV Only) . . . . . . . . . . . . . . . .40

Microelectronic Control Features . . . . . . .40

Economizer Operation with CV Controls .41

Modulating Power Exhaust . . . . . . . . . . . .41

Mechanical Cooling without an Economizer

(CV and SZ VAV) . . . . . . . . . . . . . . . . . . . . 42

Zone Temperature - Occupied Cooling (CV

and SZ VAV) . . . . . . . . . . . . . . . . . . . . . . . .42

Zone Temperature - Occupied Heating (CV

and SZ VAV) . . . . . . . . . . . . . . . . . . . . . . . .42

Supply Fan (CV and SZ VAV) . . . . . . . . . .42

Supply Air Tempering (CV and SZ VAV) .42

Variable Air Volume Applications (Single

Zone VAV)

Supply Fan Output Control . . . . . . . . . . . .43

Minimum Supply Fan Output . . . . . . . . . .43

Supply Fan Mode Operation . . . . . . . . . . .43

Setpoint Arbitration . . . . . . . . . . . . . . . . . .44

Ventilation Control . . . . . . . . . . . . . . . . . . .44

Space Pressure Control . . . . . . . . . . . . . . .46

Supply Air Temperature Control - Heating

and Cooling . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4 RT-SVX34F-EN

Table of Contents

Variable Air Volume Applications (Traditional

VAV)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Supply Air Temperature Control - Occupied

Cooling and Heating . . . . . . . . . . . . . . . . 47

Supply Air Temperature Control with an

Economizer . . . . . . . . . . . . . . . . . . . . . . . . 47

VHR Relay Output . . . . . . . . . . . . . . . . . . . 47

Zone Temperature Control without a

Night Setback Panel or ICS - Unoccupied

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Zone Temperature Control without a

Night Setback Panel or ICS - Unoccupied

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Morning Warm-up (MWU) Control . . . . . 47

Daytime Warm-up (DWU) Control . . . . . 47

Supply Duct Static Pressure Control . . . 48

Supply Air Temperature Reset . . . . . . . . 48

VAV Supply Air Tempering (Only Available

with Modulating Gas Heat) . . . . . . . . . . . 48

Constant Volume or Variable Air Volume Applications (Single Zone or Traditional)

Off Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Zone Temperature - Unoccupied Cooling (CV

or SZ VAV Only) . . . . . . . . . . . . . . . . . . . . 49

Zone Temperature - Unoccupied Heating 49

Mechanical Cooling with an Economizer 49

Gas Heat Control . . . . . . . . . . . . . . . . . . . 49

Electric Heat Control . . . . . . . . . . . . . . . . 50

Clogged Filter Option . . . . . . . . . . . . . . . . 50

Ventilation Override . . . . . . . . . . . . . . . . . 50

Emergency Stop . . . . . . . . . . . . . . . . . . . . 50

Phase Monitor . . . . . . . . . . . . . . . . . . . . . 50

Low Pressure Control . . . . . . . . . . . . . . . . 51

Dehumidification Low Pressure Control . 51

High Pressure Cutout and Temperature Dis-

charge Limit . . . . . . . . . . . . . . . . . . . . . . . 51

Power Exhaust Control (Standard) . . . . . 51

Space Pressure Control - Statitrac . . . . . 51

Power Exhaust Control (Tracking) . . . . . 52

Lead/Lag Control . . . . . . . . . . . . . . . . . . . 52

Coil Frost Protection . . . . . . . . . . . . . . . . . 52

Dehumidification Frost Protection . . . . . 52

VFD Programming Parameters . . . . . . . . 52

. . . 49

Condenser Fan Sequencing Control . . . . .52

Preparing the Unit for Operation . . . . . . . .53

Electrical Phasing . . . . . . . . . . . . . . . . . . . .54

Voltage Supply and Voltage Imbalance . .54

Starting the Unit . . . . . . . . . . . . . . . . . . . . . . .55

Test Modes . . . . . . . . . . . . . . . . . . . . . . . . .55

Verifying Proper Fan Rotation . . . . . . . . . .59

Verifying Proper Air Flow (CFM) -

CV or VFD's . . . . . . . . . . . . . . . . . . . . . . . . .59

Exhaust Fan Operation . . . . . . . . . . . . . . .72

Economizer Damper Adjustment . . . . . . . .74

Economizer (O/A) Dampers . . . . . . . . . . . .74

Manual Fresh Air Damper . . . . . . . . . . . . .75

Starting the Compressor . . . . . . . . . . . . . . .76

Starting 27.5 to 35 Ton Units . . . . . . . . . . 76

Starting 40 to 50 Ton Units . . . . . . . . . . . . 76

Compressor Oil . . . . . . . . . . . . . . . . . . . . .77

Scroll Compressor Operational Noises . .85

Compressor Crankcase Heaters . . . . . . . .85

Charging by Subcooling . . . . . . . . . . . . . .85

Measuring Subcooling . . . . . . . . . . . . . . .85

Gas Heat Units . . . . . . . . . . . . . . . . . . . . . . . . 85

Electric Heat Units . . . . . . . . . . . . . . . . . . . . .86

Final Unit Checkout . . . . . . . . . . . . . . . . . . . .86

For Constant Volume Units . . . . . . . . . . . .86

For Variable Air Volume Units . . . . . . . . .86

For Single Zone Variable Air Volume

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . .88

General Unit Requirements . . . . . . . . . . . . .88

Downflow/Upflow Models: . . . . . . . . . . . .88

All Units: . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Electrical Requirements . . . . . . . . . . . . . . . .88

Field Installed Control Wiring . . . . . . . . . . 88

Gas Heat Requirements . . . . . . . . . . . . . . . .88

Sequence of Operation . . . . . . . . . . . . . . . . . . .89

Mechanical Cooling Sequence

Of Operation

Units Without an Economizer . . . . . . . . . .89

Economizer Operation Based on Dry Bulb 89

. . . . . . . . . . . . . . . . . . . . . . . . . .89

RT-SVX34F-EN 5

Table of Contents

Economizer Operation Based on Reference

Enthalpy . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Economizer Operation Based on Compara-

tive Enthalpy . . . . . . . . . . . . . . . . . . . . . . . 90

Dehumidification (Modulating Hot Gas Reheat) Sequence of Operation

. . . . . . . . . . . 90

Gas Heat Sequence Of Operation . . . . . . . 91

Constant Volume (CV) Unit Fan Operation 91

Variable Air Volume (VAV) Unit Fan Operation (2 Stage and Modulating Gas Heat) 91

Variable Air Volume (VAV) Unit Fan Opera-

tion (Modulating Gas Heat Only) . . . . . . 92

Ignition Control Module . . . . . . . . . . . . . . 92

High Temperature Limit Operation and Loca-

tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Electric Heat Sequence Of Operation . . . . 92

Constant Volume (CV) . . . . . . . . . . . . . . . 92

Variable Air Volume (VAV) . . . . . . . . . . . 92

Variable Air Volume Applications (Single

Zone VAV) Sequence of Operation

Occupied Cooling Operation . . . . . . . . . . 92

Occupied Heating Operation . . . . . . . . . . 93

Unoccupied Cooling and

Heating Operation . . . . . . . . . . . . . . . . . . 94

Dehumidification Operation . . . . . . . . . . 94

Failure and Overriding Conditions . . . . . 95

. . . . . . 92

Low Pressure Control (LPC) Sequence of Operation (ReliaTel Control)

. . . . . . . . . . . . . . 95

High Pressure Control and Temperature Discharge Limit (ReliaTel Control)

. . . . . . . . . 95

Electrical Phasing . . . . . . . . . . . . . . . . . . .102

Precision Suction Restrictor . . . . . . . . . .102

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

System Status/Diagnostics . . . . . . . . . . . .104

Terminal locations . . . . . . . . . . . . . . . . . . 104

System Status / Diagnostics checkout proce-

dure (DC volt meter required) . . . . . . . . . 104

Diagnostics (CV and SZ VAV Units Only) 105

Diagnostics (VAV only) . . . . . . . . . . . . . .105

Resetting Cooling and Ignition Lockouts 106

Zone Temperature Sensor (ZSM) Service In-

dicator . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

RTRM Zone Sensor Module (ZSM) Tests 107

Programmable & Digital Zone Sensor

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

ReliaTel Refrigeration Module (RTRM) .108

Economizer Actuator (ECA)

Test Procedures . . . . . . . . . . . . . . . . . . . .108

ReliaTel Air Module (RTAM) Tests . . . . .109

ReliaTel Air Module (RTOM) Tests . . . . .110

Compressor—Blink Codes . . . . . . . . . . . .110

Troubleshooting . . . . . . . . . . . . . . . . . . . . . .111

TR-200 VFD Programming Parameters . .116

Unit Wiring Diagram Numbers . . . . . . . . . . .118

Warranty and Liability Clause . . . . . . . . . . . .122

COMMERCIAL EQUIPMENT - 20 TONS AND

LARGER AND RELATED ACCESSORIES

.122

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Fan Belt Adjustment . . . . . . . . . . . . . . . . . . 96

Monthly Maintenance . . . . . . . . . . . . . . . . . 98

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Cooling Season . . . . . . . . . . . . . . . . . . . . 98

Heating Season . . . . . . . . . . . . . . . . . . . . 99

Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . 100

Fall Restraint . . . . . . . . . . . . . . . . . . . . . . . . 100

Refrigeration System . . . . . . . . . . . . . . . . . 101

Refrigerant Evacuation and Charging . 101

Charge Storage . . . . . . . . . . . . . . . . . . . . 101

Compressor Oil . . . . . . . . . . . . . . . . . . . . 101

Compressor Replacements . . . . . . . . . . . 102

6 RT-SVX34F-EN

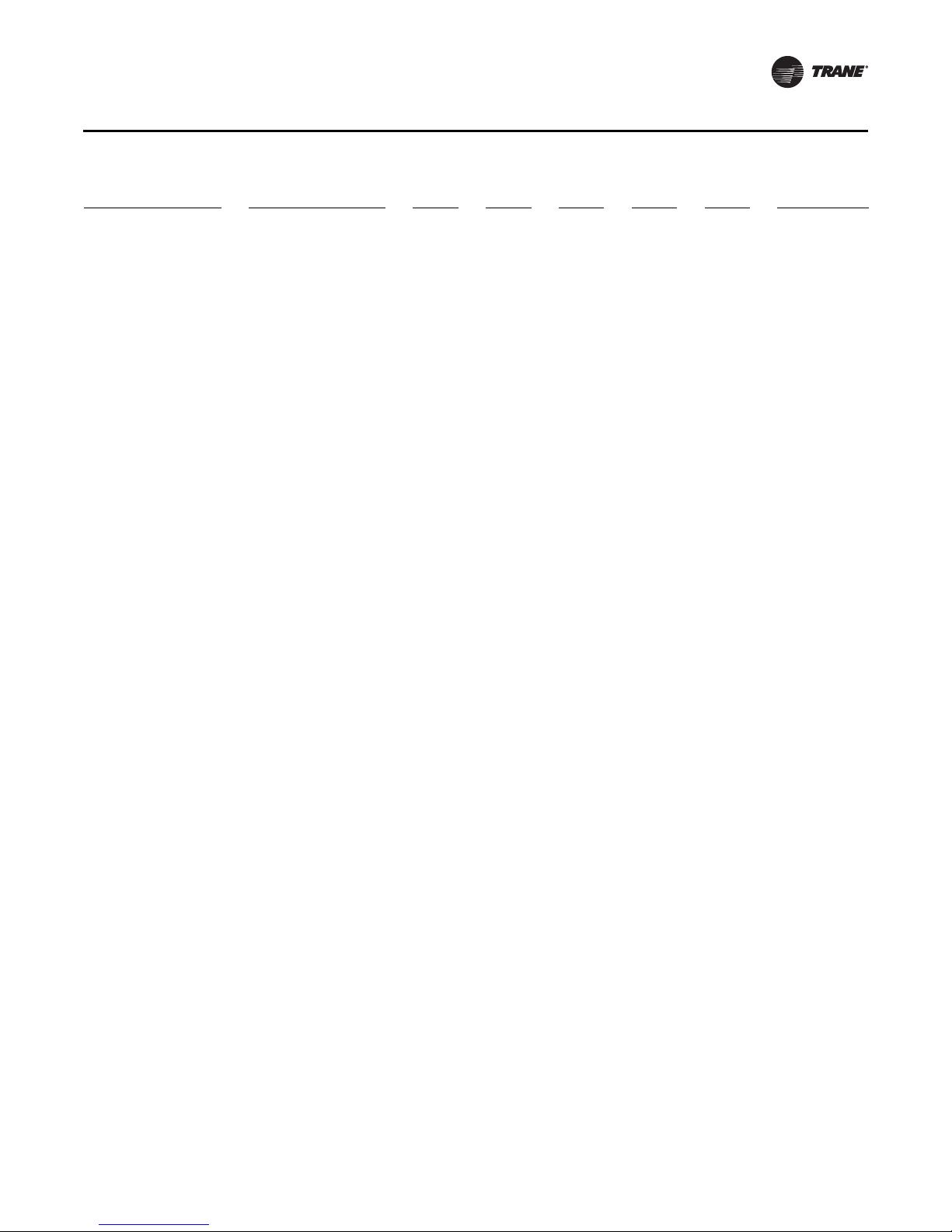

Model Number Description

YCD 330 B E L A 0 A1

123 456 7 8 9 10 11 1213

60 Hz Description

Digit 1, 2 — Unit Function

TC = DX Cooling, No Heat

TE = DX Cooling, Electric Heat

YC = DX Cooling, Natural Gas Heat

Digit 3 — Unit Airflow Design

D = Downflow Supply and Return

H = Horizontal Supply and Return

F = Horizontal Supply and Upflow

Return

R = Downflow Supply and Horizontal

Return

Digit 4, 5, 6 — Nominal Cooling

Capacity

330 = 27½ Tons

360 = 30 Tons

420 = 35 Tons

480 = 40 Tons

600 = 50 Tons

Digit 7 — Major Development

Sequence

B = R-410A Refrigerant

Digit 8 — Power Supply

E = 208/60/3

F = 230/60/3

4 = 460/60/3

5 = 575/60/3

Digit 9 — Heating Capacity

0 = No Heat (TC only)

Note: The following digits apply to YC

units only.

L = Low Heat (YC only)

H = High Heat (YC only)

J = Low Heat-Stainless Steel Gas

Heat Exchanger (YC only)

K = High Heat-Stainless Steel Gas

Heat Exchangers (YC only)

M = Low Heat-Stainless Steel Gas

Heat Exchanger w/

Modulating control

(27.5-35 ton YC only)

P = High Heat-Stainless Steel Gas

Heat Exchangers w/

Modulating control

(27.5-35 ton YC only)

R = Low Heat-Stainless Steel Gas

Heat Exchanger w/

Modulating control

(40-50 ton YC only)

T = High Heat-Stainless Steel Gas

Heat Exchangers w/

Modulating control

(40-50 ton YC only)

1

4

Note: The following digits apply to TE

A = 36 kW (27 kW for 208v)

B = 54 kW (41 kW for 208v)

C = 72 kW

D = 90 kW

E = 108 kW

units only.

Digit 10 — Design Sequence

A = First

Digit 11 — Exhaust

0= None

1 = Barometric Relief (Available

w/ Economizer only)

2 = 100% Power Exhaust Fan

(Available w/ Economizer only)

3 = 50% Power Exhaust Fan

(Available w/ Economizer only)

4 = 100% Fresh Air Tracking Power

Exhaust Fan (Available

w/ Economizer only)

5 = 50% Fresh Air Tracking Power

Exhaust Fan (Available

w/ Economizer only)

6 = 100% Power Exhaust w/

Statitrac™

6

Digit 12 — Filter

A = 2” MERV 4, Std Eff, Throwaway

B = 2” MERV 8, High Eff, Throwaway

C = 4” MERV 8, High Eff, Throwaway

D = 4” MERV 14, High Eff, Throwaway

Filters

Filters

Filters

Filters

Digit 13 — Supply Fan Motor, HP

1= 7.5 Hp

2=10 Hp

3= 15 Hp

4 = 20 Hp

Digit 14 — Supply Air Fan Drive

3

Selections

A = 550 RPM H = 500 RPM

B = 600 RPM J = 525 RPM

C = 650 RPM K = 575 RPM

D = 700 RPM L = 625 RPM

E = 750 RPM M = 675 RPM

F = 790 RPM N = 725 RPM

G = 800 RPM

Digit 15 — Fresh Air Selection

A= No Fresh Air

B = 0-25% Manual Damper

C = 0-100% Economizer, Dry Bulb

Control

D = 0-100% Economizer,

Reference Enthalpy Control

E = 0-100% Economizer,

Differential Enthalpy Control

F = “C” Option and Low Leak

Fresh Air Damper

G = “D” Option and Low Leak

Fresh Air Damper

H = “E” Option and Low Leak

Fresh Air Damper

Digit 16 — System Control

1 = Constant Volume w/Zone

Temperature Control

2 = Constant Volume w/ Discharge Air

Control

4 = VAV Supply Air Temperature

Control w/Variable Frequency

Drive w/o Bypass

5 = VAV Supply Air Temperature

Control w/Variable Frequency

Drive and Bypass

6 = Single Zone VAV w/VFD w/o

Bypass

7 = Single Zone VAV w/VFD w/

Bypass

A = VAV Supply Air Temperature

Control w/VFD w/o Bypass w/

Motor Shaft Grounding Ring

B = VAV Supply Air Temperature

Control w/VFD w/Bypass w/Motor

Shaft Grounding Ring

C = Single Zone VAV w/VFD w/o

Bypass w/ Motor Shaft Grounding

Ring

D = Single Zone VAV w/VFD w/

Bypass w/Motor Shaft Grounding

Ring

Note: Zone sensors are not included

with option and must be ordered

as a separate accessory.

Miscellaneous Options

Digit 17

A = Service Valves

2

Digit 18

B = Through the Base Electrical

Provision

Digit 19

C = Non-Fused Disconnect Switch

w/External Handle

RT-SVX34F-EN 7

Model Number Description

Digit 20

D = Factory-Powered 15A GFI

Convenience Outlet and

Non-Fused Disconnect Switch

w/External Handle

Digit 21

E = Field-Powered 15A GFI

Convenience Outlet

Digit 22

F = Trane Communication

Interface (TCI)

Digit 23

G = Ventilation Override

Digit 24

H = Hinged Service Access

Digit 25

H = Tool-less Condenser Hail Guards

J = Condenser Coil Guards

Digit 26

K = LCI (LonTalk)

B = BACnet Communications

Interface (BCI)

Digit 27

*=Unused Digit

Digit 28

M = Stainless Steel Drain Pans

Digit 29 — Condenser Coil

Options

0 = Standard Efficiency

Condenser Coil

J = Corrosion Protected Condenser

Coil

Digit 30-31 — Miscellaneous

Options

P = Discharge Temperature

Sensor

R = Clogged Filter Switch

Digit 32 — Dehumidification

Option

T = Modulating Hot Gas Reheat

Model Number Notes

1. All voltages are across the line

starting only.

2. Option includes Liquid, Discharge,

Suction Valves.

3. Supply air fan drives A thru G are

used with 27½-35 ton units only and

drives H thru N are used with 40 & 50

ton units only.

4. Electric Heat KW ratings are based

upon voltage ratings of 208/240/480/

600 V. For a 240 V heater derated to

208 V, the resulting kW rating

decreases from 36 kW to 27 kW, and

from 54 kW to 41 kW. Voltage

offerings are as follows: (see Tab l e 17,

p. 46 for additional information):

Electric

Heater

Rated

Tons

Voltage

27½

to 35

40

and

50

5. The service digit for each model

number contains 32 digits; all 32

digits must be referenced.

6. Ventilation override exhaust mode is

not available for the exhaust fan with

fresh air tracking power exhaust. VOM

is available for the exhaust fan

without fresh air tracking power

exhaust.

27/3641/

208 x x

240 x x

480 xxxx

600 x x x

208 x

240 x

480 x x x x

600 x x x x

KW

54 72 90 108

8 RT-SVX34F-EN

Model Number Description

YCD 275 B C L A 0 A1

123 456 7 8 9 10 11 1213

50 Hz Description

Digits 1, 2 – Unit Function

TC = DX Cooling, No Heat

TE = DX Cooling, Electric Heat

YC = DX Cooling, Natural Gas Heat

Digit 3 – Unit Airflow Design

D = Downflow Supply and Return

H = Horizontal Supply and Return

F = Horizontal Supply and Upflow

Return

R = Downflow Supply and Horizontal

Return

Digits 4, 5, 6 – Nominal Cooling

Capacity

275 = 22.9 Tons (82 kW)

305 = 25.4 Tons (89 kW)

350 = 29.2 Tons (105 kW)

400 = 33.3 Tons (120 kW)

500 = 41.7 Tons (148 kW)

Digit 7 – Major Development

Sequence

B = R-410A Refrigerant

Digit 8 – Power Supply

C = 380/50/3

D = 415/50/3

Digit 9 – Heating Capacity

0 = No Heat (TC only)

L = Low Heat (YC only)

H = High Heat (YC only)

Note: When second digit is “E” for

Electric Heat, the following values

apply in the ninth digit.

380V / 415V

A = 23 kW / 27 kW

B = 34 kW / 40 kW

C = 45 kW / 54 kW

D = 56 kW / 67 kW

E = 68 kW / 81 kW

Digit 10 – Design Sequence

A= First

Digit 11 – Exhaust6

0= None

1 = Barometric Relief (Available

w/Economizer only)

2 = 100% Power Exhaust Fan

(Available w/ Economizer only)

3 = 50% Power Exhaust Fan

(Available w/ Economizer only)

4 = 100% Fresh Air Tracking Power

Exhaust Fan (Available

w/Economizer only)

5 = 50% Fresh Air Tracking Power

Exhaust Fan (Available

w/ Economizer only)

6 = 100% Power Exhaust w/

Statitrac™

1

4

Digit 12 – Filter

A = 2” (51 MM) MERV 4, Std Eff,

B = 2” (51 MM) MERV 8, High Eff,

C = 4” (102 MM) MERV 8, High Eff,

D = 4” (102 MM) MERV 14, High Eff,

Throwaway Filters

Throwaway Filters

Throwaway Filters

Throwaway Filters

Digit 13 – Supply Fan Motor, HP

1 = 7.5 Hp (5.6 kW)

2 = 10 Hp (7.5 kW)

3=15 Hp (10 kW)

4 = 20 Hp (15 kW)

Digit 14 – Supply Air Fan Drive

Selections

A = 458 RPM H = 417 RPM

B = 500 RPM J = 437 RPM

C = 541 RPM K = 479 RPM

D = 583 RPM L = 521 RPM

E = 625 RPM M = 562 RPM

F = 658 RPM N = 604 RPM

G = 664 RPM

3

Digit 15 – Fresh Air Selection

A= No Fresh Air

B = 0-25% Manual Damper

C = 0-100% Economizer, Dry Bulb

D = 0-100% Economizer,

E = 0-100% Economizer,

F = “C” Option and Low Leak

G = “D” Option and Low Leak

H = “E” Option and Low Leak

Control

Reference Enthalpy Control

Differential Enthalpy Control

Fresh Air Damper

Fresh Air Damper

Fresh Air Damper

Digit 16 – System Control

1 = Constant Volume w/ Zone

2 = Constant Volume w/ Discharge Air

4 = VAV Supply Air Temperature

5 = VAV Supply Air Temperature

6 = Single Zone VAV w/VFD w/o

7 = Single Zone VAV w/VFD w/

A = VAV Supply Air Temperature

B = VAV Supply Air Temperature

Temperature Control

Control

Control w/Variable Frequency

Drive w/o Bypass

Control w/Variable Frequency

Drive and Bypass

Bypass

Bypass

Control w/VFD w/o Bypass w/

Motor Shaft Grounding Ring

Control w/VFD w/Bypass w/Motor

Shaft Grounding Ring

C = Single Zone VAV w/VFD w/o

Bypass w/ Motor Shaft Grounding

Ring

D = Single Zone VAV w/VFD w/

Bypass w/Motor Shaft Grounding

Ring

Note: Zone sensors are not included

with option and must be ordered

as a separate accessory.

Miscellaneous Options

Digit 17

A = Service Valves

2

Digit 18

B = Through the Base Electrical

Provision

Digit 19

C = Non-Fused Disconnect Switch

with External Handle

Digit 20

D= Factory-Powered 15A GFI

Convenience Outlet and

Non-Fused Disconnect Switch

with External Handle

Digit 21

E = Field-Powered 15A GFI

Convenience Outlet

Digit 22

F = Trane Communication

Interface (TCI)

Digit 23

G = Ventilation Override

Digit 24

H = Hinged Service Access

Digit 25

H = Tool-less Condenser Hail Guards

J = Condenser Coil Guards

Digit 26

K = LCI (LonTalk)

B = BACnet Communications

Interface (BCI)

Digit 27

* = Unused Digit

Digit 28

M = Stainless Steel Drain Pans

Digit 29 — Condenser Coil

Options

0 = Standard Efficiency

Condenser Coil

J = Corrosion Protected Condenser

Coil

RT-SVX34F-EN 9

Model Number Description

Digit 30-31 — Miscellaneous

Options

P = Discharge Temperature Sensor

R = Clogged Filter Switch

Digit 32 — Dehumidification

Option

T = Modulating Hot Gas Reheat

Model Number Notes

1. All voltages are across-the-line

starting only.

2. Option includes Liquid, Discharge,

Suction Valves.

3. Supply air fan drives A thru G are

used with 22.9-29.2 ton (82-105 kW)

units only and drives H through N are

used with 33.3 and 41.7 ton (120-148

kW) units only.

4. Electric Heat kW ratings are based

upon voltage ratings of 380/415 V.

Heaters A, B, C, D are used with 22.9-

29.2 ton (82-105 kW) units only and

heaters B, C, D, E are used with 33.3-

41.7 ton (120-148 kW) units only.

5. The service digit for each model

number contains 32 digits; all 32

digits must be referenced.

6. Ventilation override exhaust mode is

not available for the exhaust fan with

fresh air tracking power exhaust. VOM

is available for the exhaust fan

without fresh air tracking power

exhaust.

10 RT-SVX34F-EN

General Information

Commonly Used Acronyms and

Abbreviations

BAS = Building Automation System PGA = Power Exhaust Actuator

CFM = Cubic Feet per Minute PSIG = Pounds Per Square Inch Gauge pressure

CLV = Cooling Valve (Reheat only) PHM = Phase monitor

COMM = Module Designation for TCI/LCI R/A = Return Air

CV = Constant Volume RAH = Return Air Humidity

CW = Clockwise RAT = Return Air Temperature sensor

CCW = Counterclockwise RH = Right Hand

DSP = Direct Space Pressure control RHP = Reheat Pumpout Solenoid

DTS = Discharge Air Sensor RHV = Reheat Valve

DWU = Daytime Warm-up RLP = Reheat Low Pressure Cutout

E/A = Exhaust Air RPM = Revolutions Per Minute

ECA = Economizer Actuator RTAM = ReliaTel Air Handler Module

EET = Entering Evaporator Temperature Sensor RTDM = ReliaTel Dehumidification Module

F/A = Fresh Air RTVM = ReliaTel Ventilation Module

FFS = Fan Failure Switch RTOM = ReliaTel Options Module

ICS = Integrated Comfort System (See BAS) RTRM = ReliaTel Refrigeration Module

IDM = Indoor Fan Motor S/A = Supply Air

I/O = Input/Output SPC = Space Pressure Calibration Solenoid

IOM =

LCI = LonTalk® Communication Interface SPT = Static Pressure Transducer

LCI-R = LonTalk Communication Interface with ReliaTel SZVAV = Single Zone Variable Air Volume

LH = Left Hand TCI = Trane Communication Interface

MAS = Mixed Air Sensor TCO = Temperature Cutout

MAT = Mixed Air Temperature TDL = Temperature Discharge Limit

MCHE Microchannel VAV = Variable Air Volume

MWU = Morning Warm Up VFD = Variable Frequency Drive

NSB = Night Setback (programmable ZSM BAYSENS119*) VHR = Ventilation Heat Relay (VAV box relay)

O/A = Outside Air W.C. = Water Column

OAH = Outside Air Humidity XFSP = Exhaust Fan Setpoint

OAT = Outside Air Temperature ZSM = Sensor, Zone Sensor, Zone Sensor Module, Zone Panel

Installation, Operation and Maintenance manual (Ships

with each unit)

SPP = Space Pressure Transducer

About the Unit

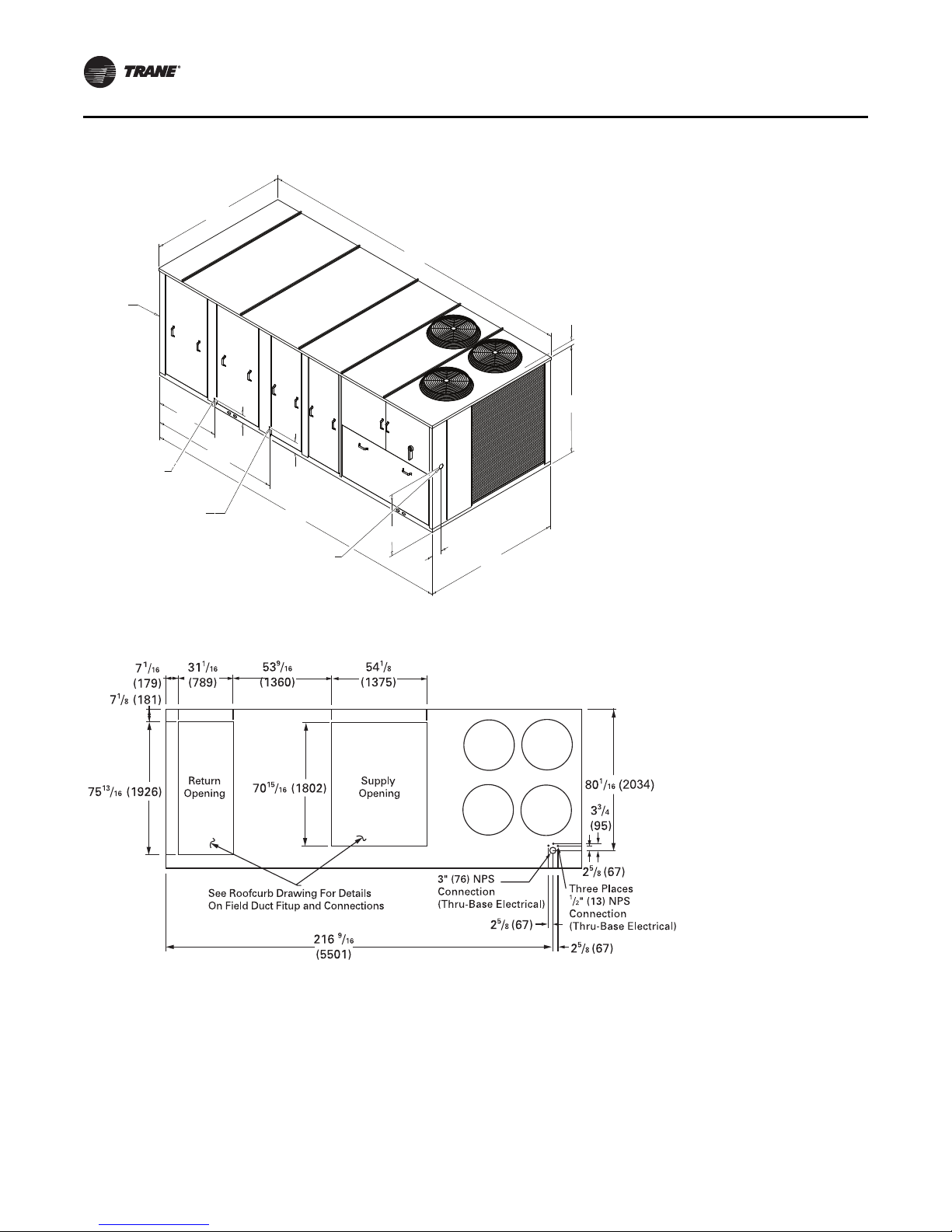

Overall unit dimensional data is illustrated in Figure 1,

p. 13 to Figure 9, p. 17. Each package rooftop unit ships

fully assembled and charged with the proper refrigerant

quantity from the factory. They are controlled by a

microelectronic unit control processor. Several solid state

modules are grouped to form the “Control System”. The

number of modules within any given control system will

be dependent upon the options and accessories ordered

with the unit. Acronyms are used extensively throughout

this manual when referring to the “Control System”.

RT-SVX34F-EN 11

Basic unit components include:

• Scroll compressors

• One (1) Intertwined Evaporator Coil

• One (1) Supply Fan

• Three (3) to Four (4) Condenser Fans

• One (1) Microchannel Condenser Coil

• Filters (type is dependent on option selection)

General Information

Precautionary Measures

WARN ING

Fiberglass Wool!

Product contains fiberglass wool. Disturbing the

insulation in this product during installation,

maintenance or repair will expose you to airborne

particles of glass wool fibers and ceramic fibers known

to the state of California to cause cancer through

inhalation. You MUST wear all necessary Personal

Protective Equipment (PPE) including gloves, eye

protection, mask, long sleeves and pants when working

with products containing fiberglass wool. Exposition to

glass wool fibers without all necessary PPE equipment

could result in cancer, respiratory, skin or eye irritation,

which could result in death or serious injury.

- Avoid breathing fiberglass dust.

- Use a NIOSH approved dust/mist respirator.

- Avoid contact with the skin or eyes. Wear long-sleeved,

loose-fitting clothing, gloves, and eye protection.

- Wash clothes separately from other clothing: rinse

washer thoroughly.

- Operations such as sawing, blowing, tear-out, and

spraying may generate fiber concentrations requiring

additional respiratory protection. Use the appropriate

NIOSH approved respiration in these situations.

First Aid Measures

Eye Contact - Flush eyes with water to remove dust. If

symptoms persist, seek medical attention.

Skin Contact - Wash affected areas gently with soap and

warm water after handling.

An optional roof curb, specifically designed for the Voyager

commercial rooftop units is available from Trane. The roof

curb kit must be field assembled and installed according to

the latest edition of the curb installation guide.

Unit Inspection

As soon as the unit arrives at the job site:

• Verify that the nameplate data corresponds to the sales

order and bill of lading (including electrical data).

• Visually inspect the exterior of the unit, including the

roof, for physical signs of shipping damage.

• Check for material shortages. Figure 11 , p. 18 illustrates

where “ship with” items are placed inside the unit.

If the job site inspection reveals damage or material

shortages, file a claim with the carrier immediately. Specify

the type and extent of the damage on the “bill of lading”

before signing. Do not install a damaged unit without the

Appropriate Trane sales representative's approval!

• Visually check the internal components for shipping

damage as soon as possible after delivery and before it

is stored. Do not walk on the sheet metal base pans.

WARNI NG

No Step Surface!

Do not walk on the sheet metal drain pan. Walking on

the drain pan could cause the supporting metal to

collapse, resulting in the operator/technician to fall.

Failure to follow this recommendation could result in

death or serious injury.

Bridging between the unit's main supports may consist of

multiple 2 by 12 boards or sheet metal grating.

• If concealed damage is discovered, notify the carrier's

terminal office immediately by phone and by mail.

Concealed damage must be reported within 15 days.

• Request an immediate joint inspection of the damage

by the carrier and the consignee. Do not remove the

damaged material from the receiving location. Take

photos of the damage, if possible. The owner must

provide reasonable evidence that the damage did not

occur after delivery.

Storage

Take precautions to prevent condensate formation inside

the unit electrical components and motors when:

a. The unit is stored before it is installed; or,

b. The unit is set on the roof curb and temporary

auxiliary heat is provided in the building.

Isolate all side panel service entrances and base pan

openings (e.g., conduit holes, S/A and R/A openings, and

flue openings) to minimize ambient air from entering the

unit until it is ready for startup.

Do not use the unit heater as temporary heat without

completing the startup procedures detailed under

“Startup,” p. 38.

Trane will not assume responsibility for equipment

damage resulting from accumulation of condensate on the

unit electrical components.

12 RT-SVX34F-EN

Unit Dimensions and Weights

Recommended Clearances

Adequate clearance around and above each Voyager

Commercial unit is required to ensure proper operation

and to allow sufficient access for servicing.

If the unit installation is higher than the typical curb

elevation, a field constructed catwalk around the unit is

recommended to provide safe, easy access for

maintenance and servicing. Table 1, p. 19 lists the

recommended clearances for single and multiple unit

installation. These clearances are necessary to assure

adequate serviceability, cataloged capacities, and peak

operating efficiency.

If the clearances available on the job site appear to be

inadequate, review them with your Trane sales

representative.

Roof Curb and Ductwork

The curbs for the 27.5 to 50 Ton commercial rooftop units

enclose the entire unit base area. They are referred to as

“full perimeter” type curbs.

Step-by-step instructions for the curb assembly and

installation with curb dimensions and curb configuration

for “A”, “B”, and “C” cabinets ship with each Trane

accessory roof curb kit. (See the latest edition of the curb

installation guide) Follow the instructions carefully to

assure proper fit when the unit is set into place.

The S/A and R/A ductwork adjoining the roof curb must be

fabricated and installed by the installing contractor before

the unit is set into place. Trane curbs include flanges

around the openings to accommodate duct attachment.

Ductwork installation recommendations are included in

the instruction booklet that ships with each Trane

accessory roof curb kit.

Note: For sound consideration, cut only the holes in the

roof deck for the supply and return duct

penetration. Do Not remove the roof decking from

the inside perimeter of the curb.

the unit into the ductwork. Refer to figures beginning on

page 13 for the S/A and R/A opening dimensions.

All outdoor ductwork between the unit and the structure

should be weather proofed after installation is completed.

If optional power exhaust is selected, an access door must

be field-installed on the horizontal return ductwork to

provide access to exhaust fan motors.

Figure 1. 60 Hz 27½-35, 50 Hz 23-29 Tons (TCD, TED,

YCD l ow heat)

If a Trane curb accessory kit is not used:

a. The ductwork can be attached directly to the S/A

and R/A openings. Be sure to use a flexible duct

connector at the unit.

b. For “built-up” curbs supplied by others, gaskets

must be installed around the curb perimeter flange,

Supply Air opening, and Return Air openings.

c. Insulation must be installed on the bottom of the

condenser section of the unit.

Horizontal Ductwork

When attaching the ductwork to a horizontal supply or

horizontal return unit, provide a water tight flexible

connector at the unit to prevent noise transmission from

RT-SVX34F-EN 13

Unit Dimensions and Weights

1 1/4

(32)

3 1/4

(81)

NOTES:

1. SEE DETAIL HOOD DRAWING FOR HORIZONTAL /

DOWNFLOW UNITS FOR ADDITIONAL DIMENSION

AND LOCATION.

179 3/4"

4565.65mm

42"

1066.8mm

83 13/16"

2128.8mm

90 1/16"

2287.5mm

180 5/16"

4579.9mm

90 3/8"

2295.5mm

5 3/8"

136.5mm

7 9/16"

192.1mm

3.25 [82.55mm] TO TOP OF FAN GRILLE

70 7/16"

1789.1mm

40 3/16"

1020.7mm

6 7/8"

174.6mm

1 1/4" [31.7mm]

FEMALE

PVC PIPE

3/4" [19.0mm] NPT

GAS INLET

SEE NOTE 2

CUSTOMER

CONNECTION POINT

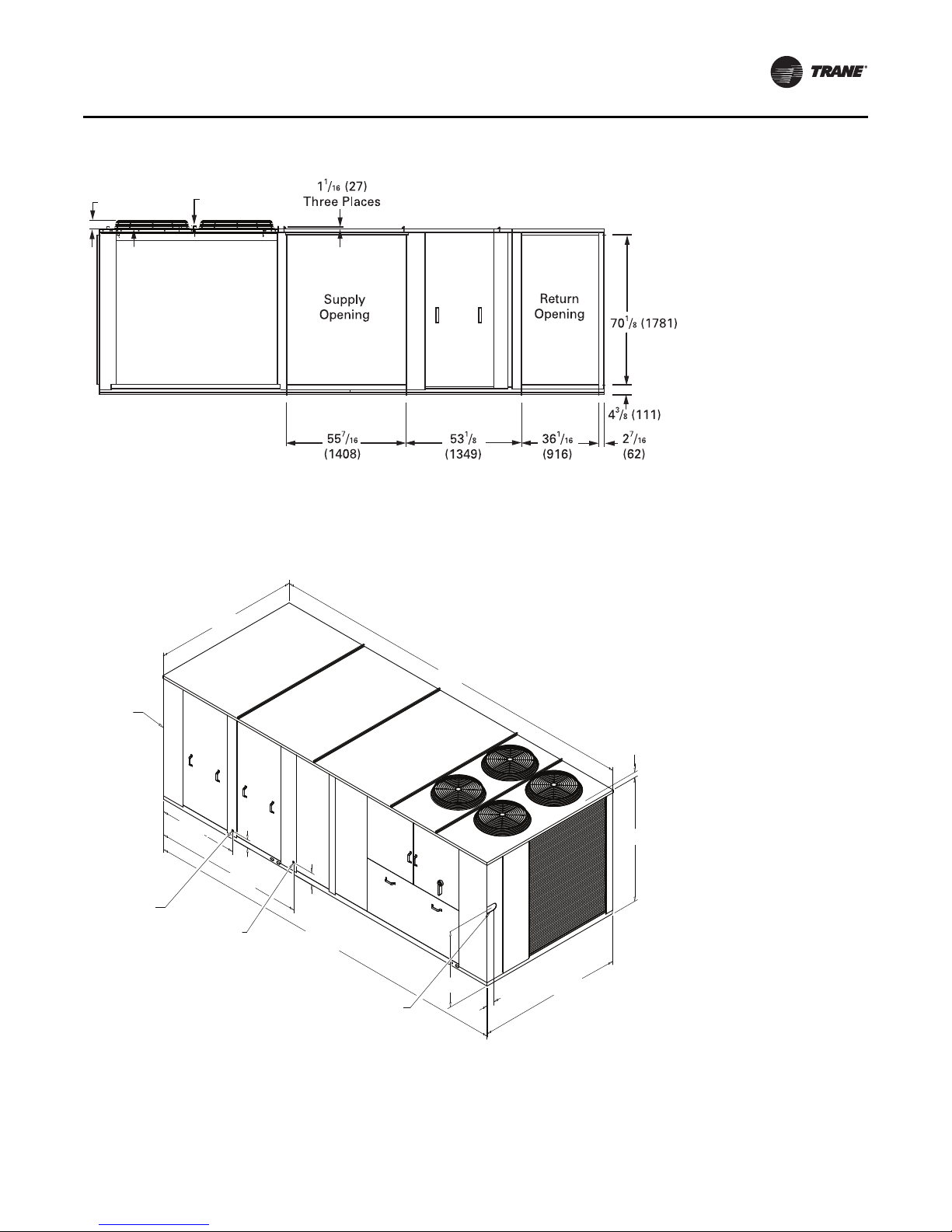

Figure 2. Rear view showing duct openings for horizontal supply and return, 60 Hz 27½-35, 50 Hz 23-29 Tons (TCH,

TEH, YCH low heat)

Notes:

• For combination of horizontal and downflow openings

• On horizontal units, the VFD is located between the

supply and return ductwork, which makes access

limited.

Figure 3. 60 Hz 27½-35, 50 Hz 23-29 Tons (TC, TE, YC low heat)

(digit 3 = F or R) see Figure 1, p. 13 for appropriate

downflow/upflow dimensions and Figure 2, p. 14 for

appropriate horizontal dimensions.

Note: Dimensions in ( ) are mm, 1”= 25.4 mm.

14 RT-SVX34F-EN

Figure 4. 60 Hz 27½-35, 50 Hz 23-29 Tons (YD high heat)

1 1/4

(32)

3 1/4

(81)

191

Figure 5. Duct openings, 60 Hz 27½-35, 50 Hz 23-29 Tons (YH high heat)

Unit Dimensions and Weights

Notes:

• On horizontal units, the VFD is located between the

supply and return ductwork, which makes access

limited.

• For combination of horizontal and downflow openings

(digit 3 = F or R) see Figure 4, p. 15 for appropriate

downflow/upflow dimensions and Figure 5, p. 15 for

appropriate horizontal dimensions.

RT-SVX34F-EN 15

Unit Dimensions and Weights

5270.5mm

207 1/2"

42"

5 3/8"

83 13/16"

2128.8mm

7 9/16"

208 1/16"

5284.7mm

90 5/8"

2301.8mm

90 1/16"

70 7/16"

40 3/16"

6 15/16"

PVC PIPE FEMALE

1" [25.4MM] NPT

GAS INLET

NOTES:

1. SEE ROOFCURB DRAWING FOR DETAILS

ON FIELD DUCT FITUP AND CONNECTIONS

2. SEE DETAIL HOOD DRAWING FOR HORIZONTAL /

DOWNFLOW UNITS FOR ADDITIONAL DIMENSION

AND LOCATION.

SEE NOTE 2

CUSTOMER

CONNECTION POINT

1066.8mm

2287.5mm

136.5m

192.1m

3.25 [82.55mm] TO

TOP OF FAN GRILLE

1789.1mm

1020.7mm

174.6mm

1 1/4" [31.7mm]

Figure 6. 60 Hz 27½-35, 50 Hz 23-29 Tons (YC high heat)

Note: Dimensions in ( ) are mm, 1”= 25.4 mm.

Figure 7. 60 Hz 40-50, 50 Hz 33-42 Tons (TD, TD, YD low and high heat)

16 RT-SVX34F-EN

Unit Dimensions and Weights

1 1/4

(32)

3 1/4

(81)

7 9/16"

232 3/8"

5902.3mm

232 3/4"

5911.8mm

90 5/8"

49 9/16"

1258.8mm

93 3/8"

2371.7mm

5 5/16"

90 1/16"

77"

1955.8mm

46 15/16"

1192.2mm

4 3/4"

120.6mm

NOTES:

1. SEE ROOFCURB DRAWING FOR DETAILS

ON FIELD DUCT FITUP AND CONNECTIONS

2. SEE DETAIL HOOD DRAWING FOR HORIZONTAL /

DOWNFLOW UNITS FOR ADDITIONAL DIMENSION

AND LOCATION.

SEE NOTE 2

CUSTOMER

CONNECTION POINT

2301.8mm

PVC PIPE FEMALE

1" [25.4MM] NPT

HIGH HEAT GAS INLET

2287.5mm

136.5m

192.1m

3.25 [82.55mm] TO

TOP OF FAN GRILLE

1 1/4" [31.7mm]

3/4" [19MM] NPT

LOW HEAT GAS INLET

Figure 8. Duct openings, 60 Hz 40-50, 50 Hz 33-42 Tons (TH, TH, YH low and high heat)

Notes:

• On horizontal units, the VFD is located between the

supply and return ductwork, which makes access

limited.

• For combination of horizontal and downflow openings

(digit 3 = F or R) see Figure 7, p. 16 for appropriate

downflow/upflow dimensions and Figure 8, p. 17 for

appropriate horizontal dimensions.

Figure 9. 60 Hz 40-50, 50 Hz 33-42 Tons (TC, TE, YC low and high heat)

Note: Dimensions in ( ) are mm, 1”= 25.4 mm.

RT-SVX34F-EN 17

Unit Dimensions and Weights

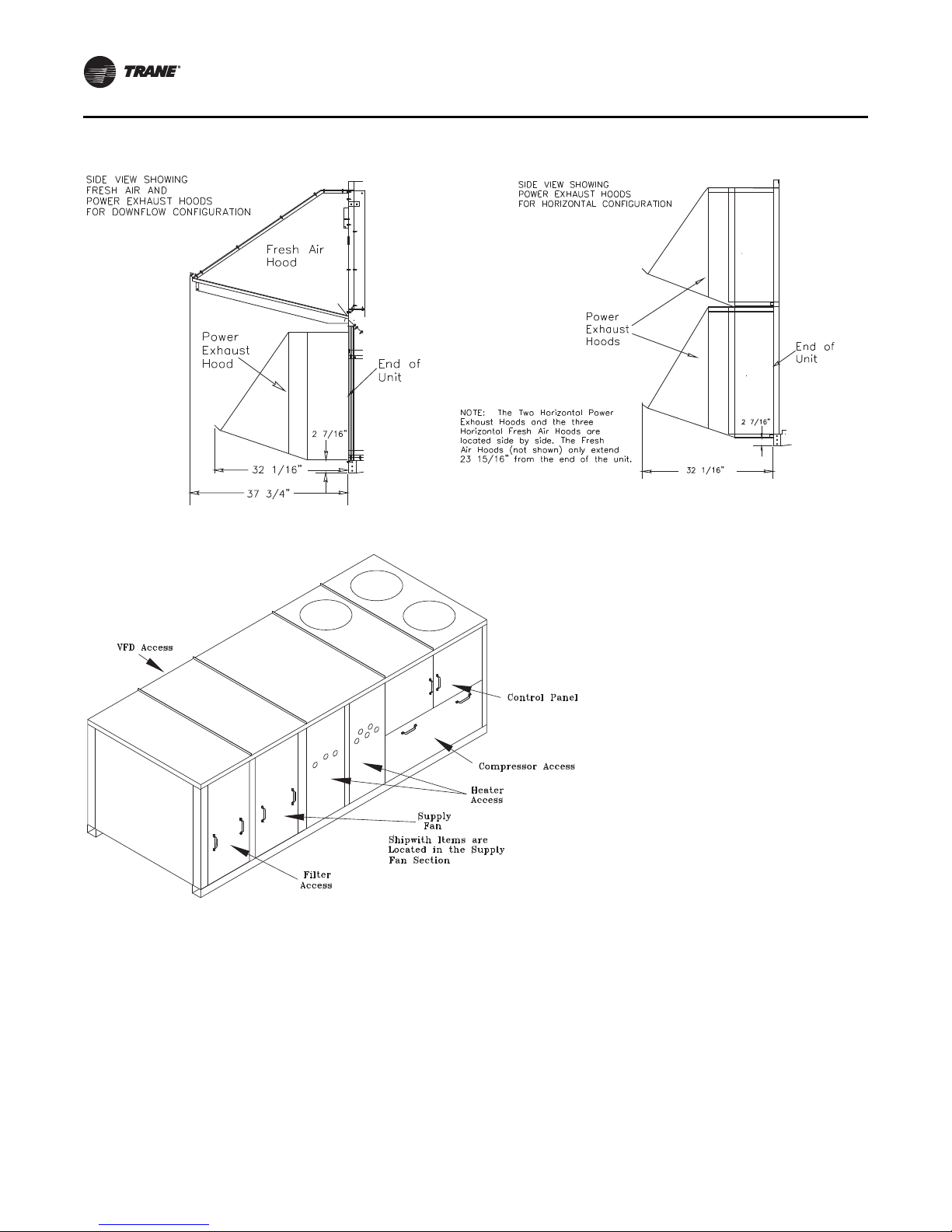

Figure 10. Fresh air and power exhaust dimensions for TC*, TE*, and YC* units

Figure 11. Location of “Ship With” items for TC*, TE*, and YC* units

18 RT-SVX34F-EN

Unit Dimensions and Weights

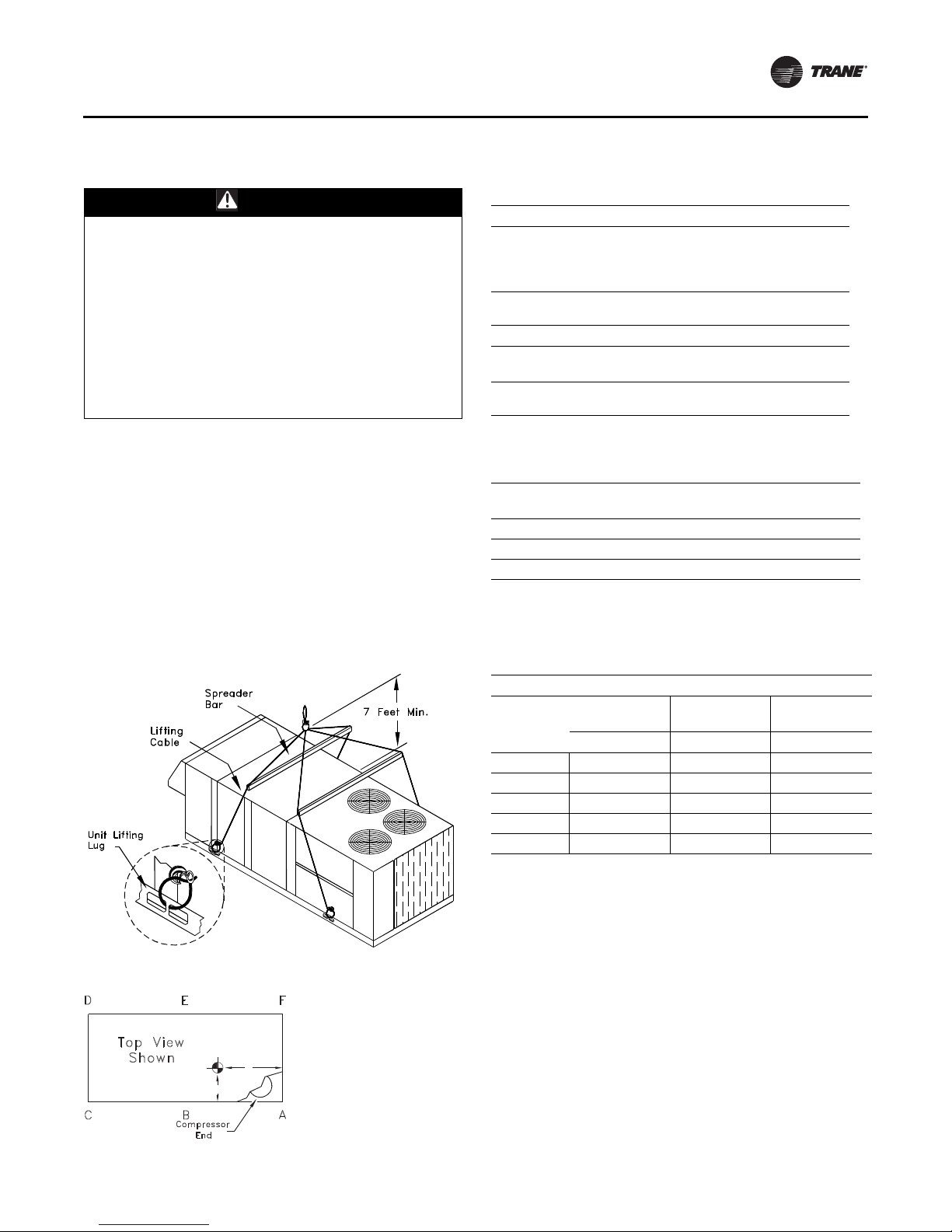

Unit Rigging and Placement

WARN ING

Heavy Objects!

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift. Other lifting arrangements could cause

equipment or property damage. Failure to follow

instructions above or properly lift unit could result in

unit dropping and possibly crushing operator/

technician which could result in death or serious injury.

Use spreader bars as shown in the diagram. Refer to the

Installation manual or nameplate for unit weight. Refer to

the Installation instructions located inside the control

panel for further rigging information.

1. Verify that the roof curb has the proper gaskets

installed and is level and square to assure an adequate

curb-to-unit seal.

The units must be as level as possible in order to

assure proper condensate flow out of the unit. The

maximum side-to-side and end-to-end slope allowable

in any application is listed in Table 2, p. 19.

Table 1. Minimum operating clearances installation

(horizontal, downflow, and mixed airflow

configurations)

Recommended Clearances

Condenser

(a)

Coil

Single Unit

TC*, TE*, YC*

27.5 to 50 Tons

Multiple Unit

TC*, TE*, YC*

27.5 to 50 Tons

(a) Condenser coil is located at the end and side of the unit.

Economizer/

Exhaust End

6 Feet 8 Feet 4 Feet

Distance Between Units

Economizer/

Exhaust End End/Side

12 Feet 16 Feet 8 Feet

Orientation

End/Side

Service Side

Access

Service Side

Access

Table 2. Maximum slope

Cabinet

“A” (27.5 - 35 Ton Low Heat) 3 1/2 1 5/8

“B” (27.5 - 35 Ton High Heat) 4 1 5/8

“C” (All 40 and 50 Ton Units) 4 1/2 1 5/8

Note: Do not exceed these allowances. Correct the improper slope by

building up the curb base. The material used to raise the base must

be adequate to support both the curb and the unit weight.

End to End

(inches)

Side to Side

(inches)

Figure 12. Unit rigging

Figure 13. Center of gravity

Y

Z (see note 2)

X

Table 3. Center of gravity

Center-of-Gravity (inches)

YC Low Heat

Dimension

Unit Model

***330/275* 41 76 33 41 84 33 42 76 33

***360/305* 43 77 33 43 85 33 44 77 33

***420/350* 42 78 33 42 86 33 43 78 33

***480/400* 42 111 35 42 111 35 42 111 35

***600/500* 43 108 35 43 108 35 43 108 35

Note: Center-of-gravity dimensions are approximate, and are based on the

unit equipped with: standard efficiency coils, standard efficiency

motors, economizer, and throwaway filters.

Note: Z dimension is upward from the base of the unit.

Example:

Locating the center-of-gravity for a YC-360 MBH High Heat unit with 100%

exhaust.

X = 43 inches inward from the control panel side

Y = 85 inches inward from the compressor end

Z = 33 inches upward from the base

XY ZXY ZXY Z

YC High Heat

Dimension

TC/TE

Dimension

RT-SVX34F-EN 19

Unit Dimensions and Weights

DE F

TOP VIEW

OF UNIT

COMPRS

CBA

Table 4. Approximate units operating weights — lbs./

Unit

Model

**D330/275 3750 1701 4130 1873 3620 1642 3640 1651

**H330/275 3790 1719 4220 1914 3660 1660 3680 1669

**D360/305 3845 1744 4225 1916 3715 1685 3735 1694

**H360/305 3885 1762 4315 1957 3755 1703 3775 1712

**D420/350 3970 1801 4350 1973 3840 1742 3860 1751

**H420/350 4010 1819 4440 2014 3880 1760 3900 1769

**D480/400 4764 2161 4884 2215 4539 2059 4564 2070

**H480/400 4859 2204 4984 2261 4599 2091 4634 2102

**D600/500 5174 2347 5294 2401 4949 2245 4974 2256

**D600/500 5269 2390 5394 2447 5019 2277 5044 2288

Notes:

1. Basic unit weight includes minimum horsepower supply fan

motor.

1

kg

Basic Unit Weights

1

YC

Low HeatYCHigh Heat TC TE

Table 5. Point loading average weight

1,2

— lbs./kg

Model A B C D E F

**D330/275 846 384 688 313 743 337 745 338 604 275 503 228

**H330/275 867 393 707 321 767 348 753 342 613 279 513 233

**D360/305 836 379 680 309 779 353 741 336 621 285 568 258

**H360/305 897 407 696 316 766 348 729 330 590 268 636 288

**D420/350 892 405 692 314 779 353 765 347 633 288 590 268

**H420/350 867 393 869 395 690 313 758 344 601 273 654 297

**D480/400 820 372 856 388 937 425 742 336 762 346 769 349

**H480/400 841 381 876 397 957 434 754 342 775 352 782 355

**D600/500 894 406 955 428 970 440 756 343 862 391 866 393

**H600/500 915 415 966 438 990 449 768 348 875 397 879 399

Notes:

1. Point Loading is identified with corner A being the corner with the

compressors. As you move clockwise around the unit as viewed

from the top, mid-point B, corner C, corner D, mid-point E and

corner F.

2. Point load calculations provided are based on the unit weight for YC

high heat gas models.

Table 6. Approximate operating weights1— optional components — lbs./kg

Unit

Model

**D330/275 110/50 165/74 50/23 260/117 85/39 115/52 18/8 6/3 30/14 85/38 310/141 330/150

**H330/300 145/65 200/90 50/23 285/128 85/39 115/52 18/8 6/3 30/14 85/38 310/141 330/150

**D360/305 110/50 165/74 50/23 260/117 85/39 115/52 18/8 6/3 30/14 85/38 310/141 330/150

**H330/305 145/65 200/90 50/23 285/128 85/39 115/52 18/8 6/3 30/14 85/38 310/141 330/150

**D420/350 110/50 165/74 50/23 260/117 85/39 115/52 18/8 6/3 30/14 85/38 310/141 330/150

**H420/350 145/65 200/90 50/23 285/128 85/39 115/52 18/8 6/3 30/14 85/38 310/141 330/150

**D480/400 110/50 165/74 50/23 290/131 115/52 150/68 18/8 6/3 30/14 85/38 365/169 365/169

**H480/400 145/65 200/90 50/23 300/135 115/52 150/68 18/8 6/3 30/14 85/38 365/169 365/169

**D600/500 110/50 165/74 50/23 290/131 115/52 150/68 18/8 6/3 30/14 85/38 365/169 365/169

**H600/500 145/65 200/90 50/23 300/135 115/52 150/68 18/8 6/3 30/14 85/38 365/169 365/169

Note:

1. Basic unit weight includes minimum horsepower supply fan motor.

Baro.

Relief

Power

Exhaust

0-25%

Man

Damper Econ.

20 RT-SVX34F-EN

Var. Freq.

Drives (VFD’s)

Bypass Lo Hi

Valves

Serv

Through-

the

base

Elec.

Non-

Fused

Discon.

Switch

Factory.

GFI with

Discon.

Switch

Roof CurbW/O With

Installation General Requirements

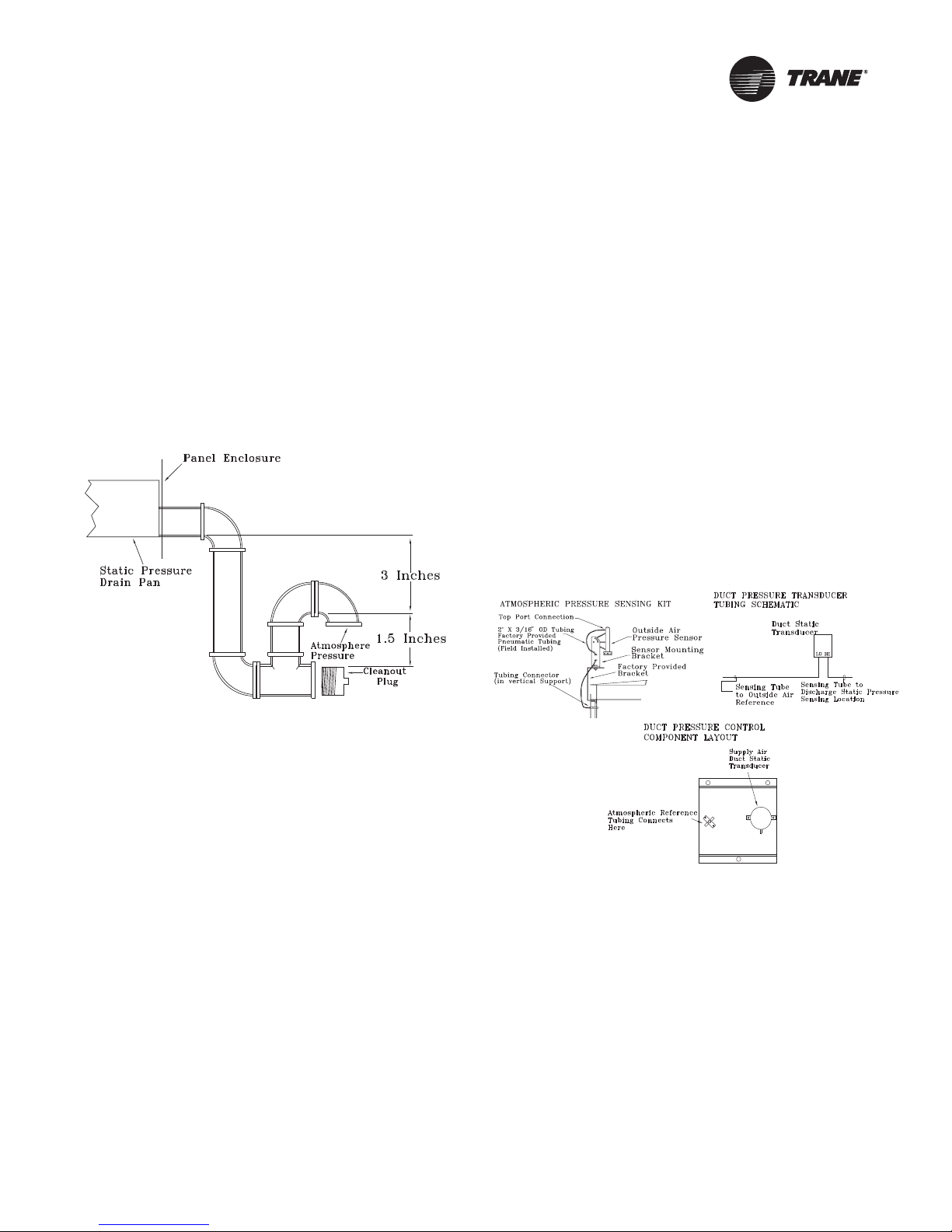

Condensate Drain Connection

Each commercial rooftop unit is equipped with one (1) 11/4 inch Female PVC condensate drain connection.

Refer to Figure 11, p. 18 for the location of the connector.

A condensate trap must be installed due to the drain

connection being on the “negative pressure” side of the

fan. Install a P-Trap at the unit using the guidelines in

Figure 14, p. 21.

Pitch the drain line at least 1/2 inch for every 10 feet of

horizontal run to assure proper condensate flow.

Ensure that all condensate drain line installations comply

with applicable building and waste disposal codes.

Figure 14. Condensate trap installation

4. Remove the dust cap from the tubing connector

located below the sensor in the vertical support.

5. Attach one end of the 50' x 3/16” O.D. factory provided

pneumatic tubing to the sensor's top port, and the

other end of the tubing to the connector in the vertical

support. Discard any excess tubing.

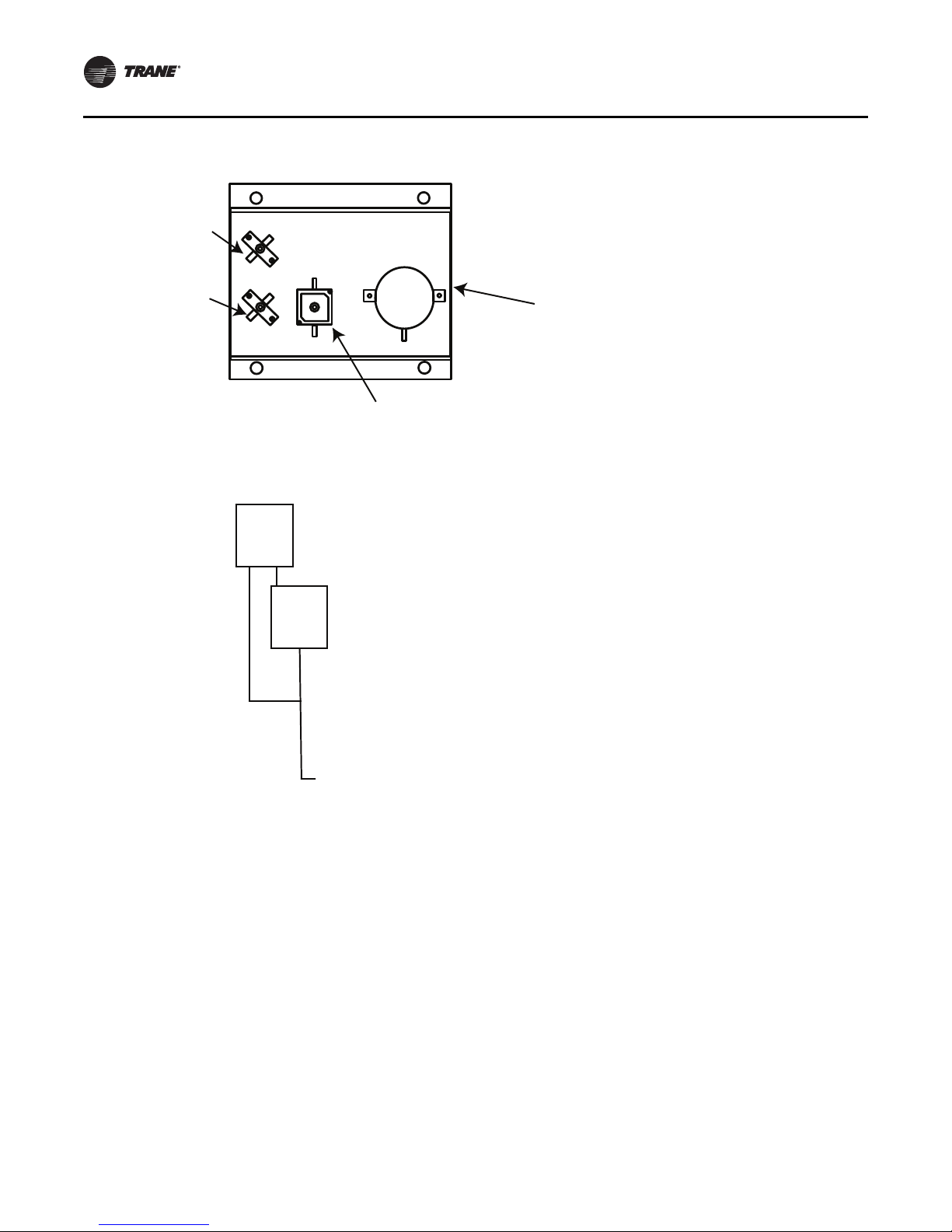

Units with Statitrac™

1. Open the filter access door, and locate the Statitrac

Transducer Assembly illustrated in Figure 16, p. 22.

There are two tube connectors mounted on the left of

the solenoid and transducers. Connect one end of the

field provided 1/4” (length 50-100 ft.) or 3/8” (length

greater than 100 ft.) O.D. pneumatic tubing for the

space pressurization control to the fitting indicated in

the illustration.

2. Route the opposite end of the tubing to a suitable

location inside the building. This location should be

the largest open area that will not be affected by

sudden static pressure changes.

Figure 15. Pressure tubing

O/A Sensor & Tubing Installation

An Outside Air Pressure Sensor is shipped with all units

designed to operate on traditional variable air volume

applications (non-SZ VAV) and units with Statitrac™.

A duct pressure transducer and the outside air sensor is

used to control the discharge duct static pressure to within

a customer-specified controlband. Refer to the illustration

in Figure 15, p. 21 and the following steps to install the

sensor and the pneumatic tubing.

1. Remove the O/A pressure sensor kit located inside the

fan section. The kit contains the following items;

• an O/A static pressure sensor

• a sensor mounting bracket

• 50’ of 3/16” O.D. pneumatic tubing

• mounting hardware

2. Using two #10-32 x 1-3/4” screws provided, install the

sensor's mounting bracket to the factory provided

bracket (near the fan section).

3. Using the #10-32 x 1/2” screws provided, install the O/

A static pressure sensor vertically to the sensor

bracket.

RT-SVX34F-EN 21

Installation General Requirements

Static Reference

Tubing Connects

Here (O/A Sensor)

Space Pressure

Sensing Tube

Connects Here

Space Pressure

Calibration

Solenoid

Space Pressure

Transducer

LO

HI

CNO

NC

Sensing Tube

to Outside Air

Reference

Space Pressure

Transducer

Sensing Tube

to Space

Pressure

Figure 16. Statitrac transducer assembly

22 RT-SVX34F-EN

Installation Electrical

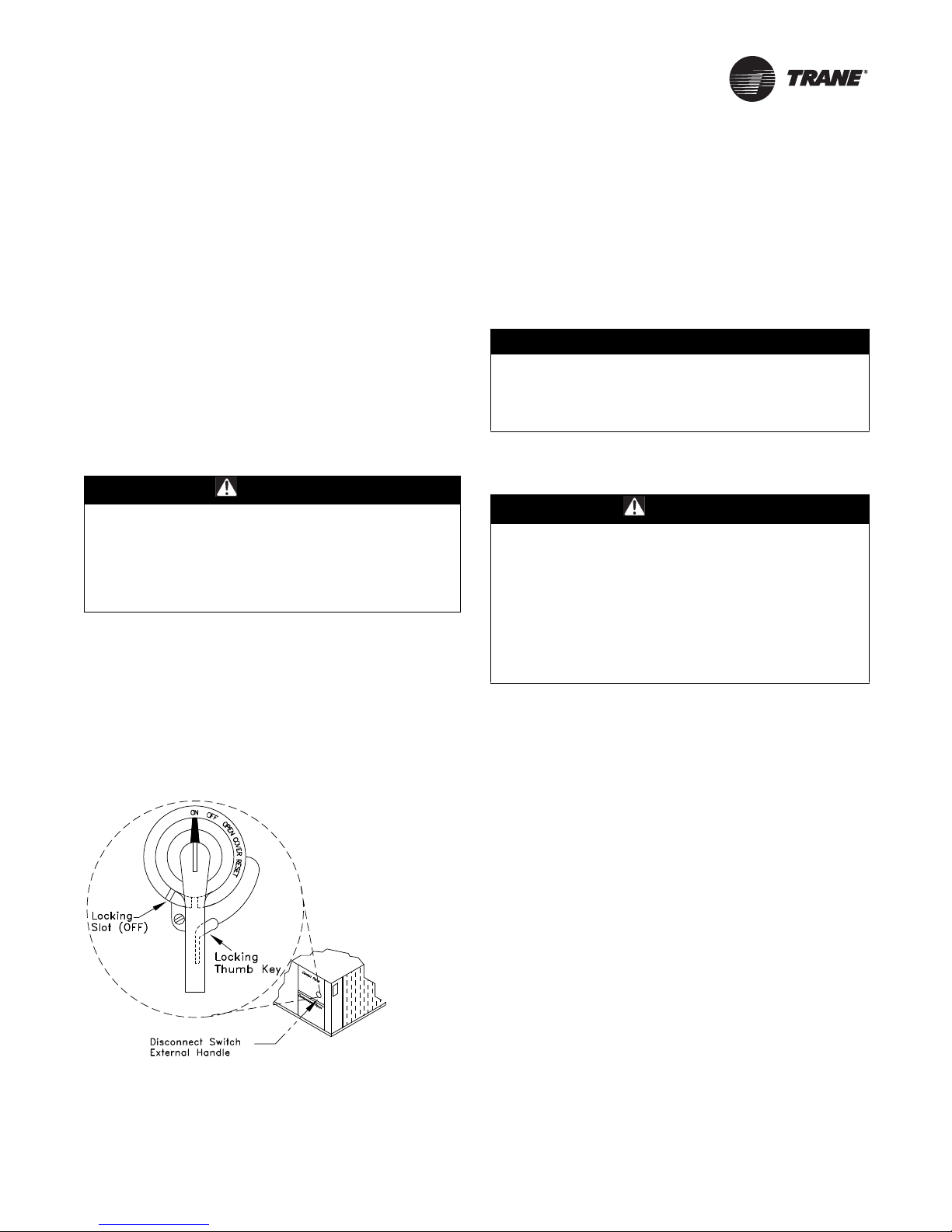

Disconnect Switch External

Handle (Factory Mounted Option)

Units ordered with the factory mounted disconnect switch

come equipped with an externally mounted handle. This

allows the operator to disconnect power from the unit

without having to open the control panel door. The handle

location and its three positions are shown below;

ON - Indicates that the disconnect switch is closed,

allowing the main power supply to be applied at the unit.

OFF - Indicates that the disconnect switch is open,

interrupting the main power supply at the unit.

OPEN COVER/RESET - Turning the handle to this position

releases the handle from the disconnect switch, allowing

the control panel door to be opened.

WARNI NG

Hazardous Voltage!

Disconnect all electric power, including remote

disconnects before servicing. Follow proper lockout/

tagout procedures to ensure the power can not be

inadvertently energized. Failure to disconnect power

before servicing could result in death or serious injury.

Once the door has been opened, it can be closed with the

handle in any one of the three positions outlined above,

provided it matches the disconnect switch position. The

handle can be locked in the “OFF” position. While holding

the handle in the “OFF” position, push the spring loaded

thumb key, attached to the handle, into the base slot. Place

the lock shackle between the handle and the thumb key.

This will prevent it from springing out of position.

Figure 17. Disconnect switch

An overall layout of the field required power wiring is

illustrated in Figure 18, p. 24. To insure that the unit supply

power wiring is properly sized and installed, follow the

guidelines outlined below.

Note: All field installed wiring must conform to NEC

guidelines as well as State and Local codes.

Verify that the power supply available is compatible with

the unit's name plate ratings for all components. The

available power supply must be within 10% of the rated

voltage stamped on the nameplate. Use only copper

conductors to connect the 3-phase power supply to the

unit.

NOTICE:

Use Copper Conductors Only!

Unit terminals are not designed to accept other types of

conductors. Failure to use copper conductors could

result in equipment damage.

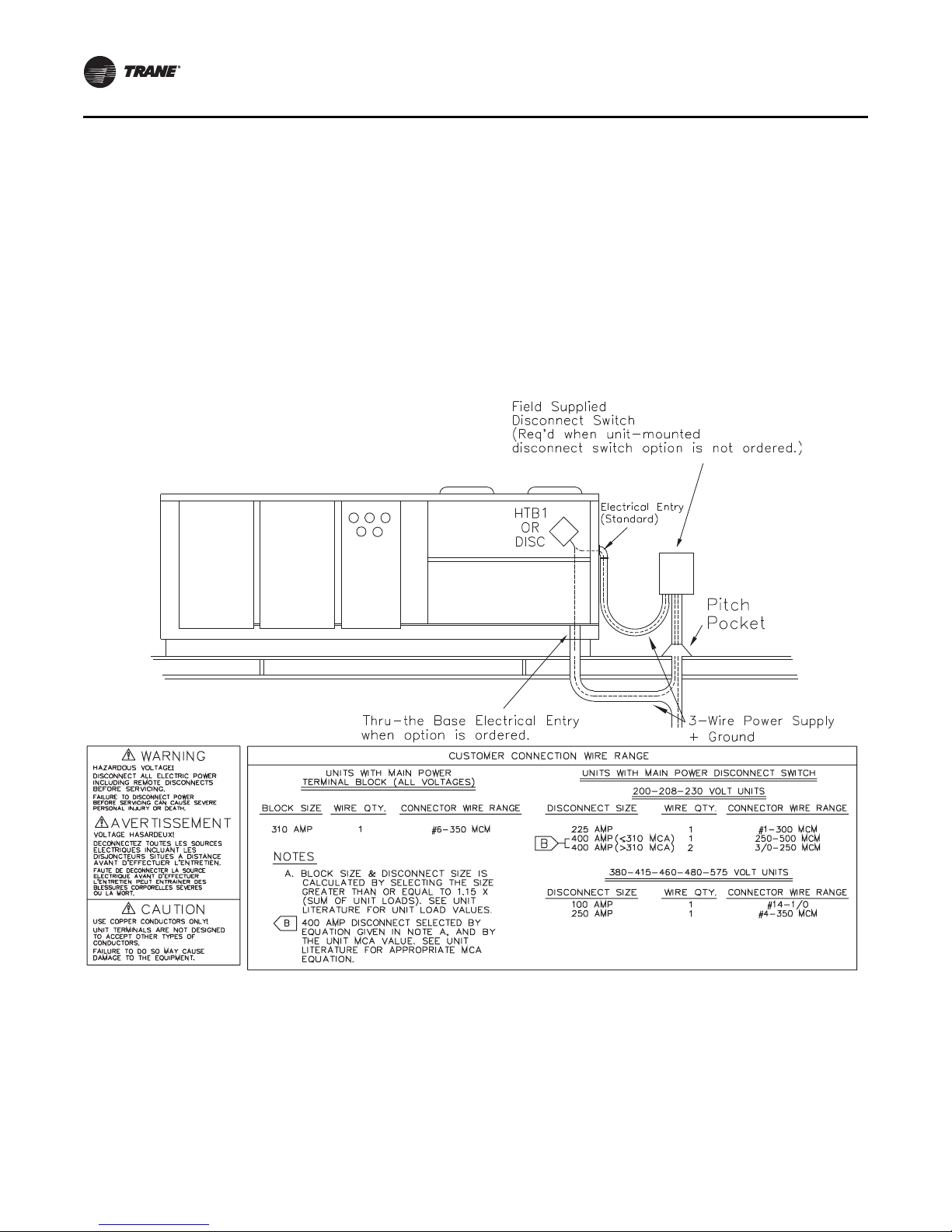

Main Power Wiring

WARNI NG

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

1. Table 7, p. 25 and Ta b le 10 , p . 2 6 list the electrical

service sizing data. The electrical service must be

protected from over current and short circuit

conditions in accordance with NEC requirements.

Protection devices must be sized according to the

electrical data on the nameplate. Refer to “Electrical

Wire Sizing and Protection Device Equations” on

page 27 for determining:

a. The appropriate electrical service wire size based

on “Minimum Circuit Ampacity” (MCA),

b. The “Maximum Over current Protection” (MOP)

device.

c. The “Recommended Dual Element fuse size” (RDE).

2. If the unit is not equipped with an optional factory

installed Nonfused disconnect switch, a field supplied

disconnect switch must be installed at or near the unit

in accordance with the National Electrical Code (NEC

latest edition). Refer to DSS calculations

Wire Sizing and Protection Device Equations” on

page 27 for determining correct size.

Location for the electrical service entrance is shown in

the unit dimensional drawings beginning with

Figure 1, p. 13. Complete the unit's power wiring

connections onto either the main terminal block HTB1,

“Electrical

RT-SVX34F-EN 23

Installation Electrical

or the factory mounted nonfused disconnect switch

inside the unit control panel.

Note: When the factory installed through-the-base

option is not used, the installing contractor is

required to seal any holes made in the base of the

unit to prevent water from leaking into the building.

3. Provide proper grounding for the unit in accordance

with local and national codes.

Figure 18. Typical field power wiring

Through-the-Base Electrical (Optional

Accessory)

Liquid-tight conduit couplings are secured to the base of

the unit for both power and control wiring. Liquid-tight

conduit must be field installed between the couplings and

the unit control box to prevent water leaks into the

building.

Note: If the unit is set on the roof curb and temporary

auxiliary heat is provided in the building, it is

recommended that the electrical and control wiring

conduit opening in the control box be temporarily

sealed to provide a vapor barrier.

24 RT-SVX34F-EN

Installation Electrical

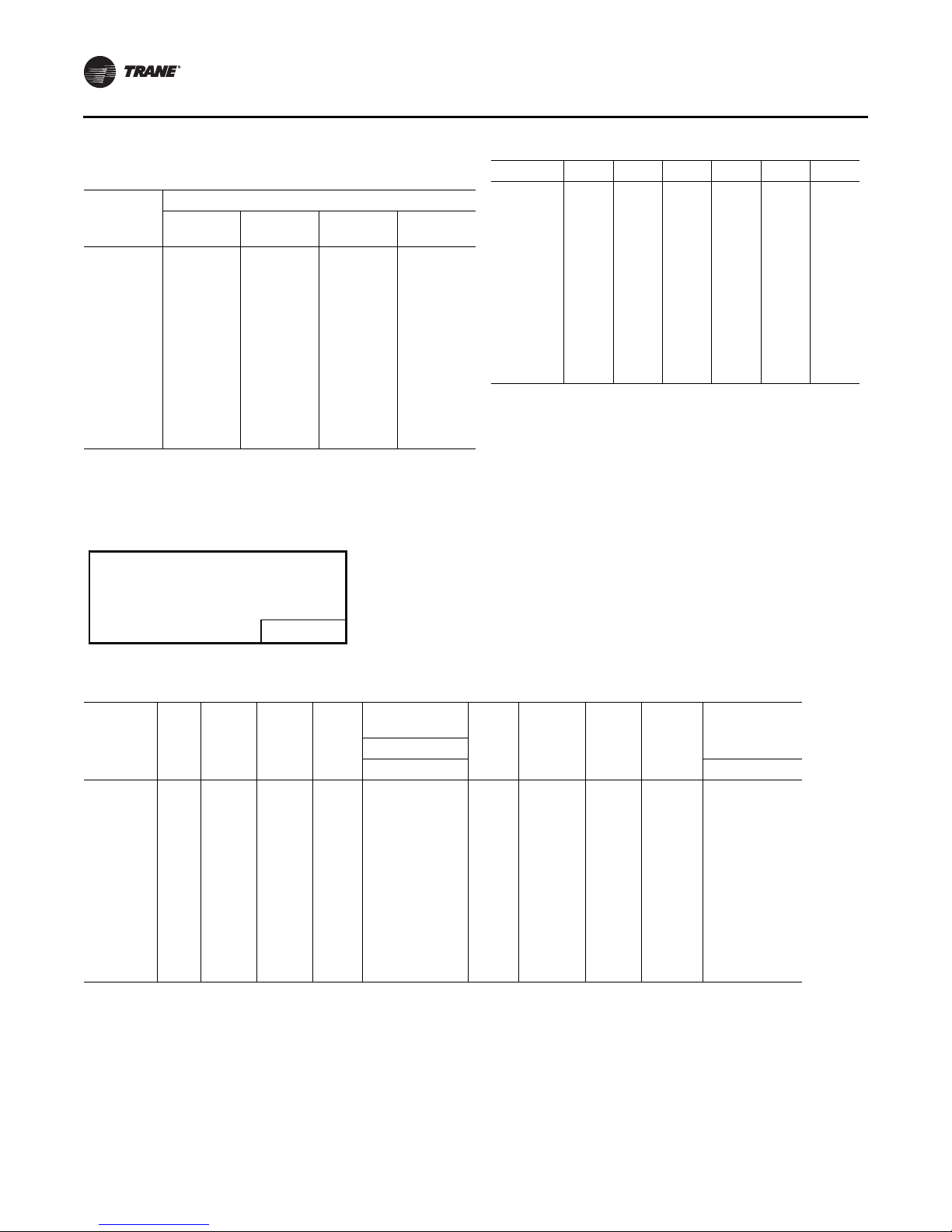

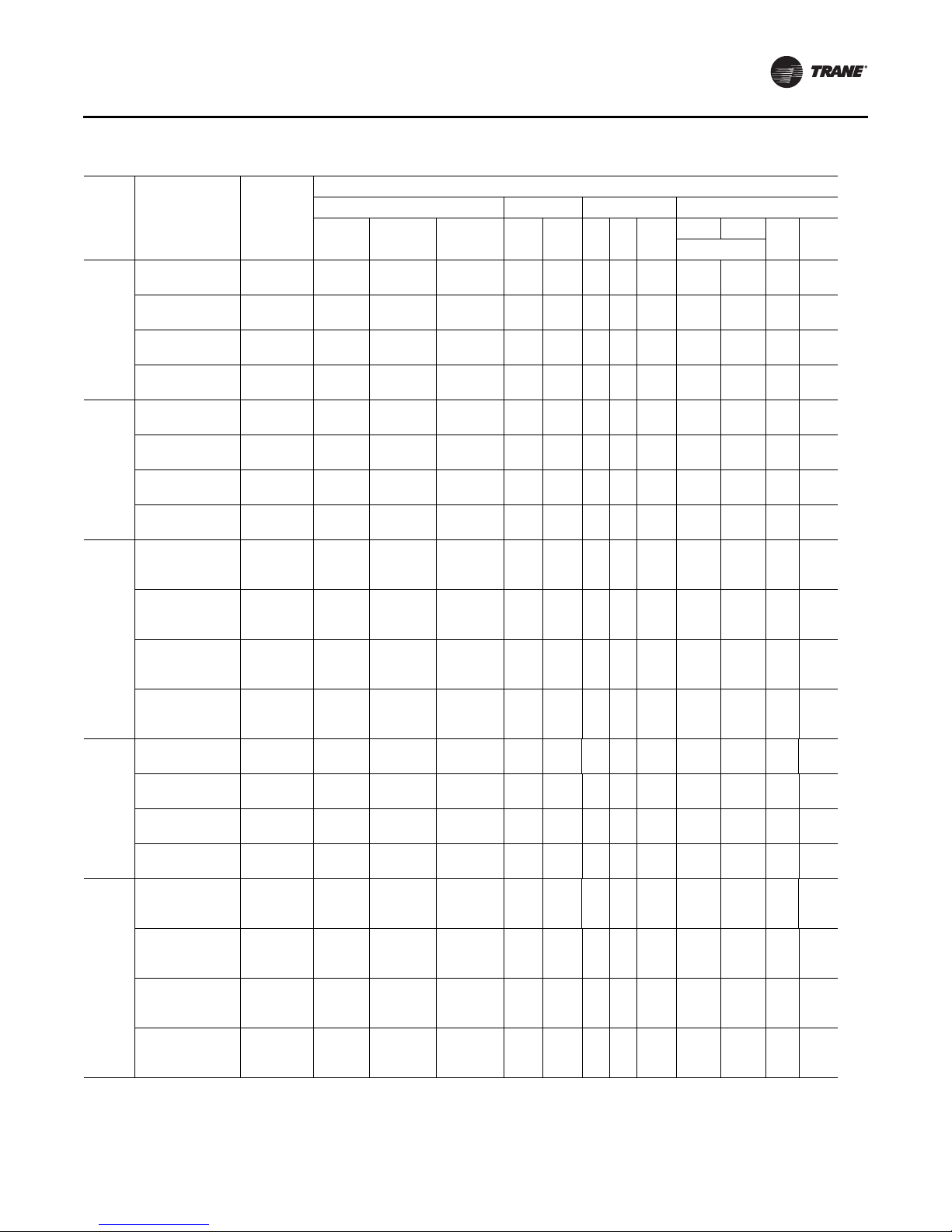

Table 7. 27½-50 ton electrical service sizing data—60Hz

1

Fan Motors

Model

TC/TE/

YC*330

TC/TE/

YC*360

TC/TE/

YC*420

TC/TE/

YC*480

TC/TE/

YC*600

Notes:

1. All customer wiring and devices must be installed in accordance with local and national electrical codes.

2. 100% Power Exhaust is with or without Statitrac™.

Characteristics

208/60/3 187-229

230/60/3 207-253

460/60/3 414-506

575/60/3 517-633

208/60/3 187-229 2/13 50.5 315/315

230/60/3 207-253 2/13 50.5 315/315

460/60/3 414-506 2/13 23.0 158/158

575/60/3 517-633 2/13 19.0 136/136

208/60/3 187-229

230/60/3 207-253

460/60/3 414-506

575/60/3 517-633

208/60/3 187-229

230/60/3 207-253

460/60/3 414-506

575/60/3 517-633

208/60/3 187-229

230/60/3 207-253

460/60/3 414-506

575/60/3 517-633

Electrical

Voltage

Range

No/Ton RLA (Ea.) LRA (Ea.) HP FLA No HP

1/12,1/

1/12,1/

1/12,1/

1/12,1/

1/13,1/

1/13,1/

1/13,1/

1/13,1/

1/13,1/

1/13,1/

1/13,1/

1/13,1/

2/13,1/

2/13,1/

2/13,1/

2/13,1/

Allowable

Compressor Supply Condenser Exhaust

7.5

44.0/50.5 304/315

13

44.0/50.5 304/315

13

21.0/23.0 147/158

13

17.5/19.0 122/136

13

50.5/56.0 315/351

15

50.5/56.0 315/351

15

15

23.0/27.5 158/197

15

19.0/23.0 136/146

50.5/83.9 315/485

20

50.5/83.9 315/485

20

23.0/34.0 158/215

20

19.0/27.3 136/175

20

50.5/56.0 315/351

15

50.5/56.0 315/351

15

23.0/27.5 158/197

15

19.0/23.0 136/146

15

10.0

7.5

10.0

7.5

10.0

7.5

10.0

7.5

10.0

7.5

10.0

7.5

10.0

7.5

10.0

7.5

10.0

15.0

7.5

10.0

15.0

7.5

10.0

15.0

7.5

10.0

15.0

10.0

15.0

10.0

15.0

10.0

15.0

10.0

15.0

10.0

15.0

20.0

10.0

15.0

20.0

10.0

15.0

20.0

10.0

15.0

20.0

22.2

3 1.1 7.0 1 2 1.0 4.1

29.5

18.8

3 1.1 7.0 1 2 1.0 4.1

25.2

9.4

3 1.1 3.5 1 2 1.0 1.8

12.6

7.8

3 1.1 2.8 1 2 1.0 1.4

10.1

22.2

3 1.1 7.0 1 2 1.0 4.1

29.5

18.8

3 1.1 7.0 1 2 1.0 4.1

25.2

9.4

3 1.1 3.5 1 2 1.0 1.8

12.6

7.8

3 1.1 2.8 1 2 1.0 1.4

10.1

22.2

29.5

3 1.1 7.0 1 2 1.0 4.1

40.7

18.8

25.2

3 1.1 7.0 1 2 1.0 4.1

35.4

9.4

12.6

3 1.1 3.5 1 2 1.0 1.8

17.7

7.8

10.1

3 1.1 2.8 1 2 1.0 1.4

15.1

29.5

4 1.1 7.0 1 2 1.5 5.4

40.7

25.2

4 1.1 7.0 1 2 1.5 5.4

35.4

12.6

4 1.1 3.5 1 2 1.5 2.7

17.7

10.1

4 1.1 2.8 1 2 1.5 2.2

15.1

29.5

40.7

4 1.1 7.0 1 2 1.5 5.4

56.1

25.2

35.4

4 1.1 7.0 1 2 1.5 5.4

49.4

12.6

17.7

4 1.1 3.5 1 2 1.5 2.7

24.7

10.1

15.1

4 1.1 2.8 1 2 1.5 2.2

19.6

FLA

(Ea.)

50% 100%

HP

FLA

(Ea.)No.

RT-SVX34F-EN 25

Installation Electrical

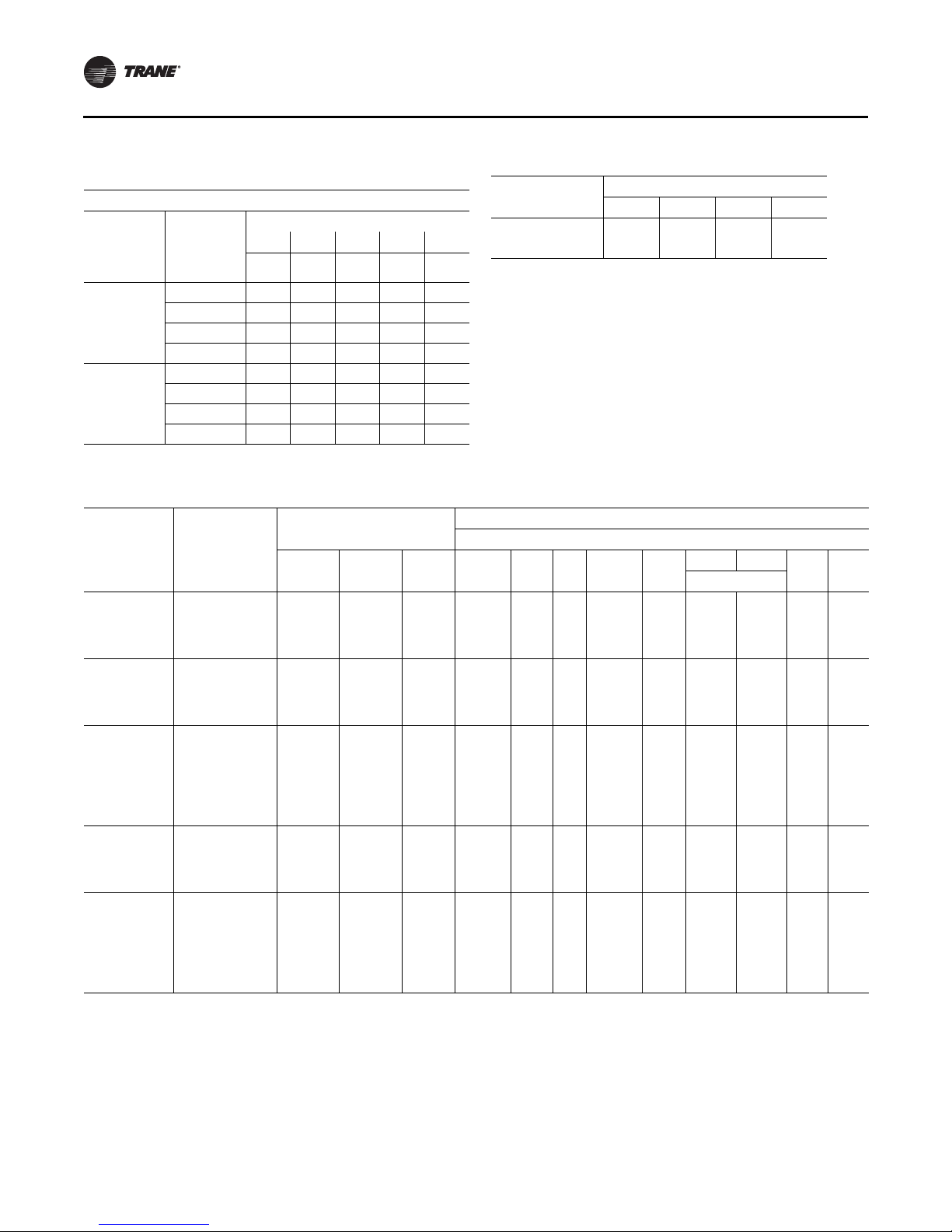

Table 8. Electrical service sizing data — electric heat

module (electric heat only) — 60 Hz

Models: TE(D,H,F,R) 330—600 Electric Heat FLA

KW Heater

Nominal

Unit Size

(Tons)

27½-35

40- 50

Note: All FLA in this table are based on heater operating at 208, 240, 480,

and 600 volts.

Nominal

36 54 72 90 108

Unit

Voltage

208 74.9 112.4 — — —

230 86.6 129.9 — — —

460 43.3 65.0 86.6 108.3 —

575 — 52.0 69.3 86.6 —

208 — 112.4 — — —

230 — 129.9 — — —

460 — 65.0 86.6 108.3 129.9

575 — 52.0 69.3 86.6 103.9

FLA FLA FLA FLA FLA

Table 9. Electrical service sizing data — crankcase

heaters (heating mode only) — 60Hz

Nominal

Unit Size (Tons)

27½ - 35 1111

40, 50 2211

FLA Add Unit Voltage

200 230 460 575

Table 10. Electrical service sizing data — 50Hz

Fan Motors

Compressor

Model

TC/TE/YC*275 380-415/50/3 1/10, 1/11 21.0/23.0 147/ 158 7.5 (5.6)

TC/TE/YC*305 380-415/50/3 2/11 23.0 158 7.5 (5.6)

TC/TE/YC*350 380-415/50/3 1/11, 1/12 23.0/27.5 158/ 197 7.5 (5.6)

TC/TE/YC*400 380-415/50/3 1/11, 1/17 23.0/34.0 158/ 215 10 (6.8)

TC/TE/YC*500 380-415/50/3 2/11, 1/12 23.0/27.5 158/ 197 10 (6.8)

Notes:

1. All condenser fan motors are single phase.

2. All customer wiring and devices must be installed in accordance with local and national electrical codes.

3. Allowable voltage range for the 380V unit is 342-418V, allowable voltage range for the 415V unit is 373-456.

4. 100% Power Exhaust is with or without Statitrac.

Characteristics

No/Ton

Electrical

RLA

(Ea.)

LRA

(Ea.) HP(kW) FLA No. HP(kW)

Supply Condenser

10 (6.8)

10 (6.8)

10 (6.8)

15 (10.5)

15 (10.5)

15 (10.5)

20 (12.8)

13.6/

16.0/

13.6/

16.0/

13.6/

16.0/

24.0/

16.0/

24.0/

16.0/

24.0/

29.0/

3 .75 (.56) 4.4 1 2

14.1

15.5

3

14.1

15.5

3

14.1

15.5

26.0

4

15.5

26.0

4

15.5

26.0

28.0

0.75

(0.56)

0.75

(0.56)

0.75

(0.56)

0.75

(0.56)

1

50% 100%

FLA

(Ea.)

4.4 1 2

4.4 1 2

4.4 1 2

4.4 1 2

Exhaust

4

(kW)

(0.56)

(0.56)

(0.56)

(0.75)

(0.75)

HP

0.75

0.75

0.75

1.0

1.0

FLA

(Ea.)No.

1.7

1.7

1.7

2.5

2.5

26 RT-SVX34F-EN

Table 11. Electrical service sizing data – electric heat

module (electric heat units only)—50Hz

Models: TE(D,H,F,R) 275 through 500 Electric Heat FLA

Nominal

Unit Size

(Tons)

23-29

33, 42

Note: All FLA in this table are based on heater operating at 380 or 415 volts

as shown above.

Nominal

Unit

Voltage

380 34.5 51.1 68.9 85.5 –

415 37.6 55.6 – – –

380 – 51.1 68.9 85.5 103.4

415 – 55.6 75.1 93.2 112.7

KW Heater (380/415V)

23/27 34/40 45/54 56/67 68/81

Table 12. Electrical service sizing data — crankcase

heaters (heating mode only) — 50Hz

FLA Add

Nominal Unit Size

(Tons)

23 - 29 1 1

33 - 42 1 1

Unit Voltage

380 415

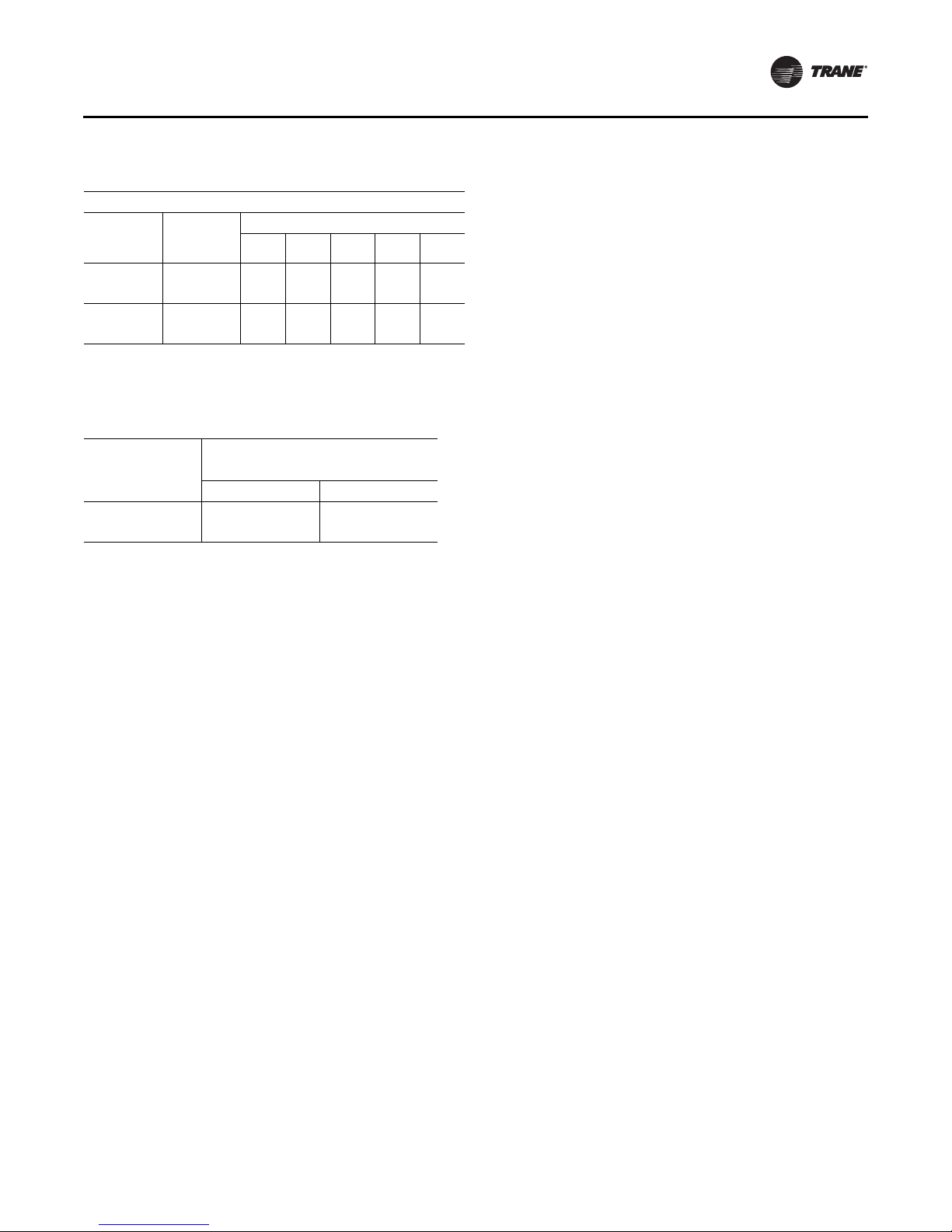

Electrical Wire Sizing and

Protection Device Equations

To correctly size the main power wiring based on MCA

(Minimum Circuit Ampacity), use the appropriate

equation listed below. Read the definitions that follow and

then use Calculation #1 for determining MCA (Minimum

Circuit Ampacity), MOP (Maximum Over current

Protection), and RDE (Recommended Dual Element fuse

size) for TC (Cooling Only) units and YC (Cooling with Gas

Heat) units. Use Calculation #2 for TE (Cooling with Electric

Heat) units.

Load Definitions:

• LOAD 1 = CURRENT OF THE LARGEST MOTOR

(Compressor or Fan Motor)

• LOAD 2 = SUM OF THE CURRENTS OF ALL

REMAINING MOTORS

• LOAD 3 = FLA (Full Load Amps) OF THE ELECTRIC

HEATER

• LOAD 4 = ANY OTHER LOAD RATED AT 1 AMP OR

MORE

• CRANKCASE HEATERS FOR HEATING MODE ONLY:

• 208/230 VOLT

– 27.5 - 35 Ton Units, Add 1 Amp

– 40 - 50 Ton Units, Add 2 Amps

• 460/575 VOLT

– 27.5 - 35 Tons Units, Add 1 Amp

– 40 - 50 Ton Units, Add 1 Amp

Installation Electrical

Calculation #1 - TC*, YC*-27.5 to 50 Ton Units

MCA = (1.25 x Load 1) + Load 2 + Load 4

MOP = (2.25 x Load 1) + Load 2 + Load 4 (See Note 1)

RDE = (1.5 x Load 1) + Load 2 + Load 4 (See Note 2)

Calculation # 2 - TE*-27.5 to 50 Ton Units

A. Single Source Power (all voltages)

To calculate the correct MCA (Minimum Circuit Ampacity),

MOP (Maximum Over current Protection), and RDE

(Recommended Dual Element fuse size), two (2) sets of

calculations must be performed;

1. Calculate the MCA, MOP and/or RDE values using the

above equation as if the unit is operating in the cooling

mode.

2. Calculate the MCA, MOP and/or RDE values as if the

unit is operating in the heating mode, as follows:

Note: When determining loads, the compressors and

condenser fan motors do not operate during the

heating cycle.

Units with less than 50 KW Heaters

MCA = 1.25 x (Load 1 + Load 2 + Load 4) + (1.25 x Load 3)

Units with 50 KW or Larger Heaters

MCA = 1.25 x (Load 1 + Load 2 + Load 4) + Load 3

The MCA value stamped on the nameplate is the largest of

the two calculated values.

MOP = (2.25 x Load 1) + Load 2 + Load 3 + Load 4 (See Note

1)

The MOP value stamped on the nameplate is the largest of

the two calculated values.

RDE = (1.5 x Load 1) + Load 2 + Load 3 + Load 4 (See Note 2)

Note: Select an over current protection device equal to

the MOP value. If the calculated MOP value does

not equal a standard size protection device listed in

NEC 240-6, select the next lower over current

protection device. If the calculated MOP value is

less than the MCA value, select the lowest over

current protection device which is equal to or larger

than the MCA, providing the selected over current

device does not exceed 800 amps.

Note: Select a Dual Element Fuse equal to the RDE value.

If the calculated RDE value does not equal a

standard dual element fuse size listed in NEC 2406, select the next higher fuse size. If the calculated

RDE value is greater than the MOP value, select a

Dual Element fuse equal to the calculated MOP

(Maximum Over current Protection) value

RT-SVX34F-EN 27

Installation Electrical

Disconnect Switch Sizing (DSS)

Calculation A. - YC*, TC*, and TE* Units:

DSS = 1.15 X (LOAD1 + LOAD2 + LOAD4)

For TE* units, use calculations A and B.

Calculation B. - TE* Units:

DSS = 1.15 X (LOAD3 + Supply Fan FLA + Exhaust

Fan FLA).

Use the larger value of calculations A or B to size the

electrical disconnect switch.

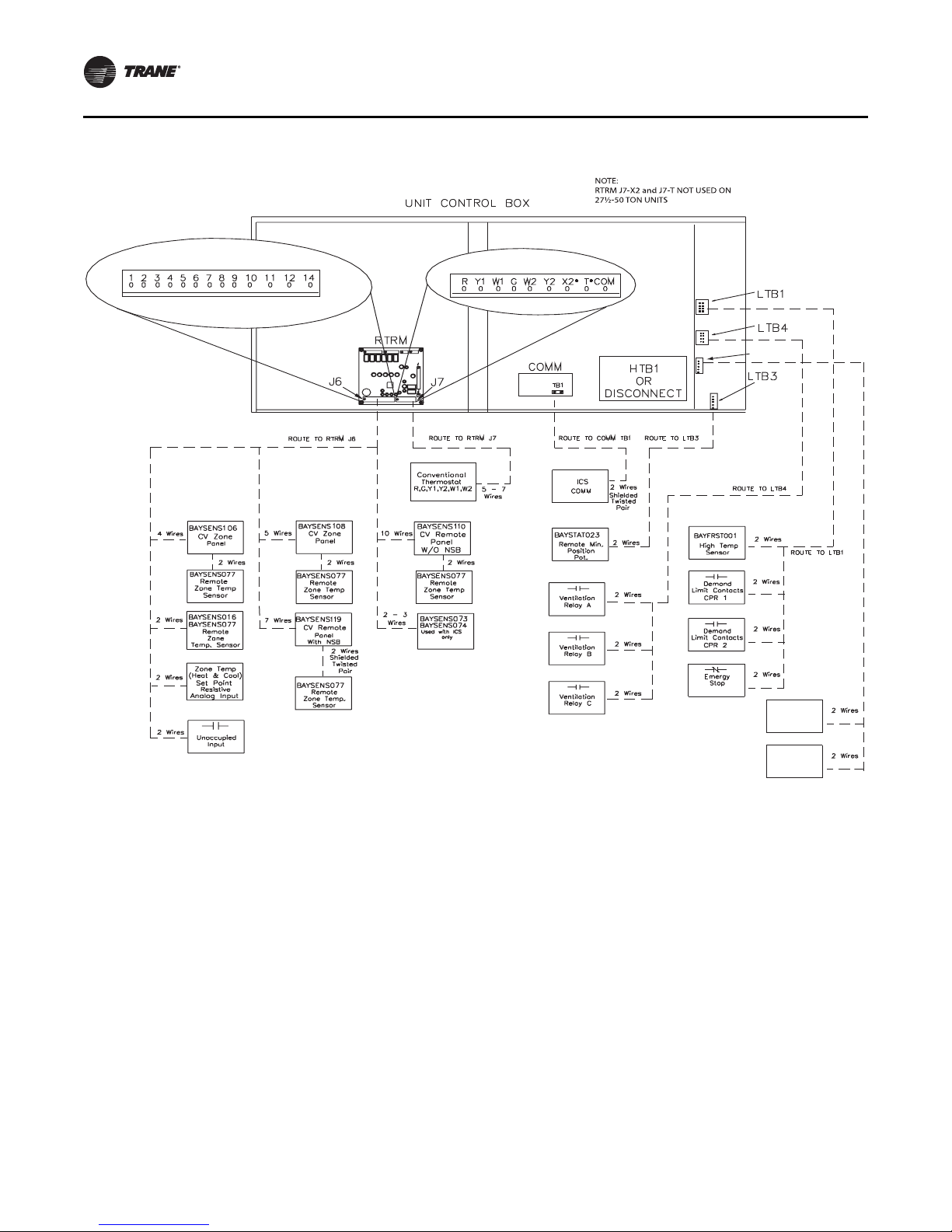

Low Voltage Wiring

An overall layout of the various control options available

for a Constant Volume application is illustrated in

Figure 19, p. 30 and Figure 20, p. 31 illustrates the various

control options for a Variable Air Volume application. The

required number of conductors for each control device are

listed in the illustration.

A typical field connection diagram for the sensors and

other options are shown in the following section “Remote

Panels and Sensors”. These diagrams are representative of

standard applications and are provided for general

reference only. Always refer to the wiring diagram that

shipped with the unit for specific electrical schematic and

connection information.

Note: All field wiring must conform to NEC guidelines as

well as state and local codes.

Control Power Transformer

WARN ING

Hazardous Voltage!

Disconnect all electric power, including remote

disconnects before servicing. Follow proper lockout/

tagout procedures to ensure the power can not be

inadvertently energized. Failure to disconnect power

before servicing could result in death or serious injury.

The 24 volt control power transformers are equipped with

internal circuit breakers. They are to be used only with the

accessories called out in this manual. If a circuit breaker

trips, be sure to turn off all power to the unit before

attempting to reset it.

On units equipped with the VFD option, an additional

control power transformer is used. The secondary is

protected with fuses. Should the fuse blow, be sure to turn

off all power to the unit before attempting to replace it.

Field Installed AC Control Wiring

WARNI NG

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

NOTICE:

Use Copper Conductors Only!

Unit terminals are not designed to accept other types of

conductors. Failure to use copper conductors could

result in equipment damage.

Before installing any connecting wiring, refer to Tab l e 13 ,

p. 28 for conductor sizing guidelines and;

• Use copper conductors unless otherwise specified.

• Ensure that the AC control voltage wiring between

the controls and the unit's termination point does

not exceed three (3) ohms/conductor for the length

of the run.

Note: Resistance in excess of 3 ohms per conductor may