Trane SAHF-C40, SAHF-C20, SAHF-C50, SAHF-C55, SAHF-C60 Installation And Operating Manual

...

Installation RT-SVX10C-EN

Operation

Maintenance

Library Service Literature

Product Section Unitary

Product Rooftop Air Conditioning (Comm. SZ, 20 - 130 Tons)

Model SAH_, SEH_, SFH_, SLH_, SSH_, SXH_

Literature Type Installation/Operation/Maintenance

Sequence 10C

Date January 2005

File No. SV-UN-RT-RT-SVX10C-EN-01-05

Supersedes RT-SVX10C-EN 11/04

™™

™

INTELLIPAK

Commercial Single-Zone Rooftop Air

Conditioners with CV or VAV Controls

™™

®

Models

SAHF -C20, -C25, -C30, -C40, -C50, -C55, -C60, -C70, -C75

SEHF -C20, -C25, -C30, -C40, -C50, -C55, -C60, -C70, -C75

SFHF -C20, -C25, -C30, -C40, -C50, -C55, -C60, -C70, -C75

SLHF -C20, -C25, -C30, -C40, -C50, -C55, -C60, -C70, -C75

SSHF -C20, -C25, -C30, -C40, -C50, -C55, -C60, -C70, -C75

SXHF -C20, -C25, -C30, -C40, -C50, -C55, -C60, -C70, -C75

SXHG -C90, -D11, -D12, -D13 SEHG -C90, -D11, -D12, -D13

SFHG -C90, -D11, -D12, -D13 SLHG -C90, -D11, -D12, -D13

SSHG -C90, -D11, -D12, -D13

© 2004 American Standard Inc. All rights reserved

"5" and later Design Sequence

"X" and later Design Sequence

With 3-D

TM

Scroll Compressors

- Units whose model numbers

have a "1" in digit 20 are certified

by Underwriters Labortory.

- Units whose model numbers

have a "2" in digit 20 are certified

by the Canadian Standards

Association (CSA).

Trane has a policy of continuous product and product data improvement and

reserves the right to change design and specifications without notice. Only

qualified technicians should perform the installation and servicing of

equipment referred to in this publication.

About The Manual

Note: This document is customer property and

must be retained by the unit's owner for use by

maintenance personnel.

Literature Change History

RT-SVX10C-EN (November 2004)

Re-issue of manual for minor corrections to Connection

Sizes Table 3-5; provides specific installation, operation

and maintenance instructions for S_HF with “6” and

later design sequence and S_HG with “Y” and later design sequence with constant volume (CV) or variable air

volume (VAV) controls.

RT-SVX10C-EN (October 2004)

Re-issue of manual for minor corrections to warranty and

updated sensor numbers (BAYSENS019, 20); provides

specific installation, operation and maintenance instructions for S_HF with “6” and later design sequence and

S_HG with “Y” and later design sequence with constant

volume (CV) or variable air volume (VAV) controls.

RT-SVX10C-EN (July 2004)

Re-issue of manual for minor WARNING and CAUTIONS

and Warranty information updates; provides specific installation, operation and maintenance instructions for

S_HF with “6” and later design sequence and S_HG

with “Y” and later design sequence with constant volume

(CV) or variable air volume (VAV) controls.

RT-SVX10C-EN (December 2003)

Re-issue of manual for minor changes to programming

parameters; provides specific installation, operation and

maintenance instructions for S_HF with “6” and later design sequence and S_HG with “Y” and later design sequence with constant volume (CV) or variable air volume

(VAV) controls.

RT-SVX10B-EN (October 2003)

Updated issue of this manual; provides specific installation,

operation and maintenance instructions for S_HF with “6”

and later design sequence and S_HG with “Y” and later design sequence with constant volume (CV) or variable air volume (VAV) controls.

RT-SVX10A-EN (May 2003)

Updated issue of this manual; provides specific installation,

operation and maintenance instructions for S_HF with “5”

and later design sequence and S_HG with “X” and later design sequence with constant volume (CV) or variable air volume (VAV) controls.

SXH_-IOM-9 (November 2002)

Re-issue of manual for minor clarity issues; provides specific

installation, operation and maintenance instructions for “3”

and later design sequence on S_HF units and "W" and later

design sequence on S_HG units with constant volume (CV)

or variable air volume (VAV) controls.

SXH_-IOM-9 (June 2002)

Original issue of manual; provides specific installation, operation and maintenance instructions for “3” and later design

sequence on S_HF units and "W" and later design sequence

on S_HG units with constant volume (CV) or variable air volume (VAV) controls.

These units are equipped with electronic Unit Control Modules (UCM) which provides operating functions that are significantly different than conventional units. Refer to the "StartUp" and "Test Mode" procedures within this Installation, Operation, & Maintenance manual and the latest edition of the

appropriate programming manual for CV or VAV applications

before attempting to operate or service this equipment.

Note: The procedures discussed in this manual

should only be performed by qualified, experienced

HVAC technicians.

Overview of Manual

This booklet describes proper installation, start-up, operation, and maintenance procedures for 20 through 130 Ton

rooftop air conditioners designed for Constant Volume (CV)

and Variable Air Volume (VAV) applications. By carefully reviewing the information within this manual and following the

instructions, the risk of improper operation and/or component

damage will be minimized.

Note: One copy of the appropriate service literature

ships inside the control panel of each unit.

It is important that periodic maintenance be performed to help

assure trouble free operation. Should equipment failure occur,

contact a qualified service organization with qualified, experienced HVAC technicians to properly diagnose and repair this

equipment.

Note: Do Not release refrigerant to the atmosphere!

If adding or removing refrigerant is required, the service

technician must comply with all federal, state, and local

laws.

2

Table of Contents

Section One

About The Manual ...............................................................2

Literature Change History................................................2

Overview of Manual .........................................................2

Section Two

General Information.............................................................4

Model Number Description ..............................................4

Hazard Identification ........................................................6

Commonly Used Acronyms .............................................6

Unit Description................................................................ 6

Input Devices & System Functions..................................8

Constant V olume & V ariab le Air Volume Units ................8

Constant V olume (CV) Units ..........................................10

Variable Air Volume (VAV) Units ....................................11

Space Temperature Averaging.......................................12

Unit Control Modules (UCM) ..........................................12

Section Three

Installation..........................................................................14

Unit Inspection ...............................................................14

Storage ...........................................................................14

Unit Clearances .............................................................14

Unit Dimensions & Weight Information..........................14

Roof Curb and Ductwork ...............................................22

Pitch Pocket Location ....................................................23

Unit Rigging & Placement..............................................23

General Unit Requirements ...........................................25

Main Electrical Power Requirements.............................25

Field Installed Control Wiring.........................................25

Requirements for Electric Heat Units ............................25

Requirements for Gas Heat ...........................................25

Requirements for Hot Water Heat (SLH_).....................25

Requirements for Steam Heat (SSH_) ..........................26

O/A Pressure Sensor and Tubing Installation ...............26

Condensate Drain Connection.......................................27

Shipping Fasteners ........................................................27

O/A Sensor & Tubing Installation...................................31

Units with Statitrac™; ....................................................31

Gas Heat Units (SFH_) ..................................................32

Connecting the Gas Supply Line to the Furnace

Gas Train ........................................................................32

Flue Assembly Installation .............................................34

Hot Water Heat Units (SLH_) ........................................34

Steam Heat Units (SSH_)..............................................35

Disconnect Switch External Handle...............................38

Electric Heat Units (SEH_) ............................................38

Main Unit Power Wiring .................................................38

Disconnect Switch Sizing (DSS)....................................44

Field Installed Control Wiring.........................................45

Controls using 24 VAC...................................................45

Controls using DC Analog Input/Outputs.......................45

Constant V olume System Controls ................................45

Variable Air Volume System Controls............................46

Constant V olume or V ariable Air Volume System

Controls ..........................................................................46

Section Four

Unit Start-Up ......................................................................55

Cooling Sequence of Operation ....................................55

Gas Heating Sequence of Operation.............................56

Fenwal Ignition System..................................................56

Honeywell Ignition System.............................................56

Modulating Gas Sequence of Operation .......................57

Flame Failure .................................................................57

Electric Heat Sequence of Operation ............................58

Wet Heat Sequence of Operation..................................58

Electrical Phasing .......................................................... 59

Voltage Supply and Voltage Imbalance.........................60

Service Test Guide for Component Operation...............61

Verifying Proper Fan Rotation .......................................63

If all of the fans are rotating backwards;........................63

System Airflow Measurements ......................................63

Constant V olume Systems .............................................63

Variable Air Volume Systems......................................... 65

Exhaust Airflow Measurement .......................................66

TraqTM Sensor Airflow Measurement ............................ 66

Economizer Damper Adjustment ................................. 80

Compressor Start-Up ................................................... 82

Compressor Operational Sounds ................................ 83

Thermostatic Expansion Valves................................... 93

Charging by Subcooling .............................................. 93

Low Ambient Dampers ................................................. 93

Electric, Steam and Hot Water Start-Up ...................... 94

Gas Furnace Start-Up .................................................. 94

Two Stage Gas Furnace ............................................... 95

Full Modulating Gas Furnace....................................... 97

Limited Modulating Gas Furnace ................................ 98

Final Unit Checkout...................................................... 99

Section Five

Service & Maintenance....................................................100

Fan Belt Adjustment.....................................................104

Scroll Compressor Replacement.................................105

VFD Programming Parameters ...................................106

Monthly Maintenance...................................................107

Filters............................................................................107

Cooling Season............................................................107

Heating Season............................................................108

Coil Cleaning................................................................108

Final Process .............................................................. 109

Index ........................................................................... 111

Warranty ..................................................................... 114

3

General Information

S/

g

C

g

g

g

y

C

g

SENS

g

(

S

q

g

g

CS

g

y, p

C

g

C

g

g

g

O

g

G

C

g

Model Number Description

All products are identified by a multiple character model

number listed on the unit nameplate. An explanation of the

alphanumeric identification code is provided below. Its use

can define the unit's specific components, type of application, i.e. CV or VAV, for a particular unit.

Sample Model No.: S X H F - C20 4 0 A 1 0 A 1 5 B 1 D 0 1 A,R,L,etc.

Digit No .: 1 2 3 4 5,6,7 8 9 10 11 12 13 14 15 16 17 18 19 20 21+

Digit 1 - Unit Type Digit 10 - Design Sequence Digit 17 - System Control

S = Self-Contained 3 = Disconnect Redesign 1 = CV Control (Zone Control)

Di

it 2 - Unit Function A thru Z, or any digit 1 thru 9.

A = DX Cooling, No Heat 3 = VAV-(S/A T emp Co ntr ol

E = DX

F = DX Cooling, Natural Gas Heat 0 = None 4 = Space Pressure Control with Exhaust VFD

L = DX Cooling, Hot Water Heat 1 = Barometric without Bypas s

S = DX Cooling, Steam He at 2 = 100% - 1.5 HP* 5 = Space Pressure Control with Exhaus t VFD

X = DX Cooling, Extended Casings 3 = 100% - 3 HP* and Bypass

# = DX Cooling, Propane Gas Heat 4 = 100% - 5 HP* 6 = VAV Supply Air Temperature Control

Di

H = Single-Zone 7 = 100% - 15 HP* with VFD and Bypass

Di

F = Sixth B = 50% - 3 HP 9 = Supply and Exhaust Fan with VFD

Di

C25 = 25 Tons C60 = 60 Tons F = 100% - 3 HP** 0 = None

C30 = 30 Tons C70 = 70 Tons G = 100% - 5 HP** A = BAYSENS008*

C40 = 40 Tons C75 = 75 Tons H = 100% - 7.5 HP** B = BAYSENS010*

C50 = 50 Tons J = 100% - 10 HP** C = BAYSENS013*

Digit 8 - Power Supply

4 = 460/60/3 XL # = 50% w/ Statitrac F = BAYSENS020*

5 = 575/60/3 XL * w/Statitrac G = BAYSENS021*

E = 200/60/3 XL ** w/o Statitrac (CV only)

F = 230/60/3 XL

Note: SEHF units

electric h eat) ut iliz ing 208V or

230V re

Digit 9 - Heating Capacity

Not e: When th e second di

calls for "F" (Gas Heat), the Digit 13 - F ilter Type Not e: Inclu des UL clsssified gas heating

fo llo w in

Additionall

M available ONLY on 50 To n

models and above.

H = High Heat - 2 Stage E = Cartridge with Prefilters 21 A = Unit Disconnect Switch

L = Low Heat - 2 Stage F = No F ilters (T/A Ra ck Only) 22 B = Hot Gas Bypas s

0 = No Heat G = No F ilters ( Bag/Cart. Ra ck O nly) 23 C = Economizer Co ntrol w/Comparative

J = Limited Modulating High Heat Enthalpy

G = Limited Modulating Low Heat

P = Full Modulating High Heat 1 = 3.0 HP 6 = 20.0 HP Enthalpy

M = Full Modulating Low Heat 2 = 5.0 HP 7 = 25.0 HP 23 W = Econom izer

Not e: When th e second digit

calls for "E" (elect ric h eat) , the

fo llo w in

D = 30 KW R = 130 KW 26 G = High Capac ity Evapor ator Coil

H = 50 KW U = 150 KW

L = 70 KW V = 170 KW 5 = 500 RPM B = 1100 RPM 28 K = Generic B.A.S. Module

N = 90 KW W = 190 KW 6 = 600 RPM C = 1200 RPM 29 L = High-Efficiency Motors (Supply & Exhaust)

Q = 110 KW 7 = 700 RPM D = 1300 RPM 30 M = Remote Human Interfac e

Not e: When th e second di

"L" (H ot Wa ter) o r "S" (St eam)

Heat, one of the followin

size values must be in Digit 9:

High Heat Coil: 1 = 50", 2 = .75",

3 = 1", 4 = 1.25", 5 = 1.5", 6 = 2". A = No Fresh Air 35 Y = Tr ane Communication Interfac e Module

Low Heat Coil: A = .50", B = .75", B = 0-25% Manual 35 7 = LonTalk® Communication Interface Module

C = 1", D = 1.25", E = 1.5", F = 2". D = 0-100% Economizer 36 8 = Spring Is olators

1. Available as s tandard 460 volt only for 70 and 75 ton models.

ooling, Electric Heat

it 3 - Unit Airflow

it 4 - Development Sequence

its 5, 6, 7 - Nominal Capacit

20 = 20 Tons C55 = 55 Tons E = 100% - 1.5 HP**

unit with Digit 12 - Exhaust Fan Drive

uire dual pow er source.

it

values apply:

lease n ot e G and

values apply:

it calls

valve

Not e: Sequence may b e any lett er

Digit 11 - Exhaust Option

5 = 100% - 7.5 HP* with VFD w/o Bypass

6 = 100% - 10 HP* 7 = VAV Supply Air Temperature Control

8 = 100% - 20 HP* 8 = Supply and Exhaust Fan with VFD

A = 50% - 1.5 HP without Bypass

C = 50% - 5 HP and Bypas s

D = 50% - 7.5 HP

K = 100% - 15 HP** D = BAYSENS01 4*

L = 100% - 20 HP** E = BAY

0 = None 8 = 800 PRM 1 = 0 Degr ee Fahrenheit

4 = 400 RPM 9 = 900 RPM

5 = 500 RPM A = 1000 RPM

6 = 600 RPM B = 1100 RPM 0 = None (UL G as Heater, s ee note)

7 = 700 RPM 1 = UL

A = Throwaway

B =

leanable Wire Mesh

C = High-Efficiency Throwaway

D = Bag with Prefilters

Digit 14 - Supply Fan Horsepower

3 = 7.5 HP 8 = 30.0 HP 23 O = None W/O Economizer

4 = 10.0 HP 9 = 40.0 HP

5 = 15.0 HP 25 F = High Duct Temperature Thermostat

Di

it 15 - Supply Fan Drive

8 = 800 RPM E = 1400 RPM 31 N = Ventilation

9 = 900 RPM F = 1500 RPM 32 R = Extended Gr ease Lines

A = 1000 RPM

it 16 - Fresh Air Section

Di

1

= 1600 RPM 33 T = Access Doors

When ordering replacement parts or requesting service, be

sure to refer to the specific model number, serial number,

and DL number (if applicable) stamped on the unit nameplate.

2 = VAV-(

without Inlet Guide Vanes)

with Inlet Guide Vanes)

Di

Di

0 =

Di

2 =

section only wh en second digit of

Mo del N o . is a "F ".

Di

23 Z = Economizer Control w/Reference

24 E = Low Leak Fresh Air Dampers

27 H = Copper Fins (Cond. only)

34 V = Interprocess or

35 0 = No communication module

37 6 = Factory-Powered 15A GFI Convenience

Outlet

38 0 = None

A Temp Control

it 18 - Accessory Panel

019*

it 19 - Ambient Control

tandard

it 20 - Agency Approval

A

its 21 - 38 - Miscellaneous

ontrol w/Dry Bulb

ve rride Modu le

ommunic ations Bridge

4

Sample Model No.: S X H G - D 1 1 4 0 A H 7 C G 8 D 1 0 0 1 AT ,etc

Digit No.: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21+

Digit 1 - Unit Type Digit 12 - Exhaust Air Fan Drive Digit 18 - Accessory Panel

S = Self-Contained 0 = None 0 = None

5 = 500 RPM A = BAYSENS008*

Digit 2 - Unit Function(s)

6 = 600 RPM B = BAYSENS010*

E = DX Cooling, Electric Heat 7 = 700 RPM C = BAYSENS013*

F = DX Cooling, Natural Gas Heat 8 = 800 RPM D = BAYSENS014*

L = DX Cooling, Hot Water Heat E = BAYSENS019*

S = DX Cooling, Steam Heat

Digit 13 - Filter

F = BAYSENS020*

X = DX Cooling, Extended Cas ings A = Throwaway G = BAYSENS021*

C = High-Efficiency Throwaway

Digit 3 - Unit Airflow

D = Bag with Prefilter

Digit 19 - Ambient Control

H = Single-Zone E = Cartridge with Prefilter 0 = Standard

F = Throwaway Filter Rack Less Filter

Digit 4 - Development Sequence

Media

Digit 20 - Agency Approval

G = Seventh G = Bag Filter Rack Less Filter Media 0 = None (UL Gas Heater See Note 1)

1 = UL

Digits 5, 6, 7 - Nominal Capacity Digit 14 - Supply Air Fan HP

C90 = 90 Tons C = 30 HP (2-15 HP)

D11 = 105 Tons D = 40 HP (2-20 HP)

D12 = 115 Tons E = 50 HP (2-25 HP)

2 = CSA

Note: Includes UL classified gas

heating section only when second

digit of Model No. is a "F".

D13 = 130 Tons F = 60 HP (2-30 HP)

Digit 8 Power Supply

4 = 460/60/3 XL

G = 80 HP (2-40 HP)

Digit 15 - Supply Air Fan Drive

Digits 21 - 36 - Miscellaneous

21 A = Unit Disconnect Switch

22 B = Hot Gas Bypass

5 = 575/60/3 XL A = 1000 RPM 23 C = Economizer Control

E = 200/60/3 XL B = 1100 RPM with Comparative Enthalpy

F = 230/60/3 XL C = 1200 RPM 23 Z = Economizer Control

D = 1300 RPM with Reference Enthalpy

Digit 9 - Heating Capacity

E = 1400 RPM 23 W = Economizer Control w/Dry Bulb

0 = No Heat F = 1500 RPM 23 0 = None W/O Economizer

H = High Heat - 2 Stage G = 1600 RPM 24 E = Low- Leak Fresh Air Dampers

J = Limited Modulating High Heat 25 F = High Duct Temperature Thermostat

P = Full Modulating High Heat 26 G = High Capacity Evaporator

Not e: When the seco nd digit calls Digit 16 - Fresh Air

for "E" (electric heat), the follow ing

D = 0-100% Economizer (Std.) 27 K = Generic BAS Module

values apply in the ninth digit:

W=190 kw

Note: When the second digit calls for

"L" or "S", one of the following valve

size values m ust be in Dig it 9:

Digit 17 - System Control

1 = Constand Volume Control 29 M = Remote Human Interface

2 = VAV Supply Air T emperature 30 N = Ventilation Override Module

Control without Inlet Guide Vanes 31 R = Extended G rease Lines

Coil (90 - 105 Only)

28 L = High Efficiency Motors

(Supply and Ex haus t)

High Heat Coil: 3 = 1.0", 4 = 1.25", 3 = VAV - Supply Air Temperatur e 32 T = Acc es s Door s

5 = 1.50", 6 = 2.0", 7 = 2.5" Control with Inlet Guide Vanes 33 V = Inter-proc essor Communication

Low Heat Coil: C = 1.0", D = 1.25", 4 = Space Pres s ure Control with Bridge

E = 1.50", F = 2.0", G = 2.5" Exhaus t VFD w/o Bypass 34 0 = No communication module

5 = Space Pressure Control with 34 Y = Trane Communication Interface Module

Digit 10 - Design Sequence

Exhaus t and Bypass 34 7 = LonTalk® Communication Interfac e Module

W = Disc onnect Redesign 6 = VAV Supply Air Temperature Control 35 0 = None

Not e: Seq uence m ay be any letter

A thru Z, or any digit 1 thru 9.

with VFD without Bypass 36 6 = Factory-Powered 15A G FI

7 = VAV Supply Air T emperature Control Conv enienc e O utlet

with VFD and By pass

8 = Supply and Exhaust Fan with

Digit 11 - Exhaust Option

VFD and without Bypas s

O = None 9 = Supply and Exhaust Fan with

7 = 100%, 15 HP w/ Statitrac VFD and Bypas s

8 = 100%, 20 HP w/ Statitrac

9 = 100%, 25 HP w/ Statitrac

F = 50%, 15 HP

H = 100%, 30 HP w/ Statitrac

J = 100%, 40 HP w/ Statitrac

K = 100%, 15 HP w/o Statitrac (CV O nly)

L = 100%, 20 HP w/o Statitrac (CV Only)

M = 100%, 25 HP w/o Statitrac (CV O nly)

N = 100%, 30 HP w/o Statitrac (CV Only)

P = 100%, 40 HP w/o Statitrac (CV O nly)

Echelon, LON, LONWORKS, LonBuilder, NodeBuilder, LonManager,

LonTalk, LonUsers, Neuron, 3120, 3150, the Echelon logo, and the

LonUsers logo are trademarks of Echelon Corporation registered in the

United States and other countries. LonLink, LonResponse, LonSupport,

LonMaker, and LonPoint are trademarks of Echelon Corporation.

5

General Information (Continued)

Unit Nameplate

One Mylar unit nameplate is located on the outside upper

left corner of the control panel door. It includes the unit

model number, serial number, electrical characteristics,

weight, refrigerant charge, as well as other pertinent unit

data. A small metal nameplate with the Model Number, Serial Number, and Unit Weight is located just above the Mylar

nameplate, and a third nameplate is located on the inside of

the control panel door.

Compressor Nameplate

The Nameplate for the Scroll Compressor is located on the

compressor lower housing.

Hazard Identification

WARNING– Indicates a

situation which, if not avoided, could result in death or

serious injury.

potentially hazardous

CAUTION – Indicates a potentially hazardous

situation which, if not avoided, may result in minor or

moderate injury. It may also be used to alert against

unsafe practices.

WARNING

Fiberglass Wool

Product contains fiberglass wool. Disturbing the insulation in this product during installation, maintenance or

repair will expose you to airborne particles of glass

wool fibers and ceramic fibers known to the state of

California to cause cancer through inhalation. Glass

wool fibers may also cause respiratory, skin or eye irritation.

Precautionary Measures

- Avoid breathing fiberglass dust.

- Use a NIOSH approved dust/mist respirator.

- Avoid contact with the skin or eyes. Wear long-

sleeved, loose-fitting clothing, gloves, and eye

protection.

- Wash clothes separately from other clothing:

rinse washer thoroughly.

- Operations such as sawing, blowing, tear-out, and

spraying may generate fiber concentrations requiring

additional respiratory protection. Use the appropriate

NIOSH approved respiration in these situations.

First Aid Measures

Eye Contact - Flush eyes with water to remove

dust. If symptoms persist, seek medical attention.

Skin Contact - Wash affected areas gently with soap

and warm water after handling.

Commonly Used Acronyms

For convenience, a number of acronyms and abbreviations

are used throughout this manual. These acronyms are alphabetically listed and defined below.

BAS = Building automation systems

CFM = Cubic-feet-per-minute

CKT. = Circuit

CV = Constant volume

CW = Clockwise

CCW = Counterclockwise

E/A = Exhaust air

ECEM = Exhaust/comparative enthalpy module

F/A = Fresh air

GBAS = Generic building automation system

HGBP = Hot gas bypass

HI = Human Interface

HVAC = Heating, ventilation and air conditioning

IGV = Inlet guide vanes

I/O = Inputs/outputs

IOM = Installation/operation/ maintenance manual

IPC = Interprocessor communications

IPCB = Interprocessor communications bridge

LCI-I = LonTalk Communication Interface for IntelliPak

LH = Left-hand

MCM = Multiple compressor module

MWU = Morning warm-up

NSB = Night setback

O/A = Outside air

psig = Pounds-per-square-inch, gauge pressure

R/A = Return air

RH = Right-hand

RPM = Revolutions-per-minute

RT = Rooftop unit

RTM = Rooftop module

S/A = Supply air

SCM = Single circuit module

SZ = Single-zone (unit airflow)

TCI = Tracer communications module

UCM = Unit control modules

VAV = Variable air volume

VCM = Ventilation control module

VOM = Ventilation override module

w.c. = Water column

Unit Description

Each Trane commercial, single-zone rooftop air conditioner

ships fully assembled and charged with the proper refrigerant quantity from the factory.

An optional roof curb, specifically designed for the S_HF

and S_HG units is available from Trane. The roof curb kit

must be field assembled and installed according to the latest edition of SAHF-IN-5 or SXHG-IN-2 respectively.

Trane Commercial Rooftop Units are controlled by a microelectronic control system that consists of a network of modules and are referred to as Unit Control Modules (UCM).

The acronym UCM is used extensively throughout this

document when referring to the control system network.

These modules through Proportional/Integral control algorithms perform specific unit functions which provide the best

possible comfort level for the customer.

They are mounted in the control panel and are factory

wired to their respective internal components. They receive

and interpret information from other unit modules, sensors,

remote panels, and customer binary contacts to satisfy the

applicable request for economizing, mechanical cooling,

heating, and ventilation. Refer to the following discussion for

an explanation of each module function.

6

Rooftop Module (RTM - 1U48 Standard on all units)

R

)

The Rooftop Module (RTM) responds to cooling, heating,

and ventilation requests by energizing the proper unit components based on information received from other unit modules, sensors, remote panels, and customer supplied binary inputs. It initiates supply fan, exhaust fan, exhaust

damper, inlet guide vane positioning or variable frequency

drive output, and economizer operation based on that information.

RTM Resistance Input vs Setpoint Temperatures

RTM c ooling or RTM cooling

heating setpoint input

setpoint input used as the Resistance

used as the source for (Ohms) Max.

source fo r a SUPPLY AI

ZON E temp temp setpoint

setpoint (

o

F) cooling (oF)

Tolerance 5%

40 40 1084

45 45 992

50 50 899

55 55 796

60 60 695

65 65 597

70 70 500

75 75 403

80 80 305

n/a 85 208

n/a 90 111

General Information (Continued)

Ventilation Override Module (V OM - Optional 1U51)

The Ventilation Override module initiates specified functions such as; space pressurization, exhaust, purge, purge

with duct pressure control, and unit off when any one of the

five (5) binary inputs to the module are activated. The compressors and condenser fans are disabled during the ventilation operation. If more than one ventilation sequence is

activated, the one with the highest priority is initiated.

Interprocessor Communications Board (IPCB Optional 1U55 used with the Optional Remote Human

Interface)

The Interprocessor Communication Board expands communications from the rooftop unit UCM network to a Remote

Human Interface Panel. DIP switch settings on the IPCB

module for this application should be; Switches 1 and 2

"Off", Switch 3 "On".

Trane Communications Interface Module (TCI - Optional

1U54 used on units with Trane ICS

The Trane Communication Interface module expands communications from the unit UCM network to a Trane Tracer

TM

or a Tracer SummitTM system and allows external

100

setpoint adjustment and monitoring of status and diagnostics. DIP Switch settings on the TCI

module for these applications should be:

Tracer 100 (Comm3): Switches 1, 2, and 3 are "Off";

Tracer Summit (Comm4): Switch 1 is "On", switches 2, and

3 are "Off"

TM

)

RTM Resistance Value vs System Operating Mode

Resistance

applied to RTM

MODE input Constant Volume U nits

Terminals (Ohms

Max. Tolerance Fan System

5%

2320

4870

7680

10770

13320

16130

19480

27930

Mode Mode

Auto Off

Auto Cool

Auto Auto

On Off

On Cool

On Auto

Auto Heat

On Heat

Compressor Module (SCM & MCM - 1U49 standard on

all units)

The Compressor module, (Single Circuit & Multiple Circuit),

upon receiving a request for mechanical cooling, energizes

the appropriate compressors and condenser fans. It monitors the compressor operation through feedback information

it receives from various protection devices.

Human Interface Module (HI - 1U65 standard on all

units)

The Human Interface module enables the operator to adjust

the operating parameters for the unit using it's 16 key keypad. The 2 line, 40 character LCD screen provides status

information for the various unit functions as well as menus

for the operator to set or modify the operating parameters.

Heat Module (1U50 used on heating units)

The Heat module, upon receiving a request for Heating, energizes the appropriate heating stages or strokes the Modulating Heating valve as required.

Lontalk Communication Interface Module (LCI - Optional

1U54 - used on units with T rane ICS

TM

or 3rd party Build-

ing AutomationSystems)

The LonTalk Communication Interface module expands

communications from the unit UCM network to a Trane

Tracer SummitTM or a 3rd party building automation system,

utilizing LonTalk, and allows external setpoint and configuration adjustment and monitoring of status and diagnostics.

Exhaust/Comparative Enthalpy Module (ECEM Optional 1U52 used on units with Statitrac and/or

comparative enthalpy options)

The Exhaust/Comparative Enthalpy module receives information from the return air humidity sensor, the outside air

humidity sensor, and the return air temperature sensor to

utilize the lowest possible humidity level when considering

economizer operation. In addition, it receives space pressure information which is used to maintain the space pressure to within the setpoint controlband. Refer to the table

below for the Humidity vs Voltage input values.

7

General Information (Continued)

TM

Ventilation Control Module (VCM - Design special

option only)

The Ventilation Control Module (VCM) is located in the filter

section of the unit and is linked to the unit's UCM network.

Using a "velocity pressure" sensing ring located in the fresh

air section, allows the VCM to monitor and control the quantity of fresh air entering the unit to a minimum airflow setpoint.

An optional temperature sensor can be connected to the

VCM which enables it to control a field installed fresh air

preheater.

An optional CO

control CO

CFM upward as the CO

maximum effective (reset) setpoint value for fresh air enter-

sensor can be connected to the VCM to

2

reset. The reset function adjust the minimum

2

concentrations increase. The

2

ing the unit is limited to the systems operating CFM. The

following table lists the Minimum Outside Air CFM vs Input

Voltage.

Minimum Ou tside Air Setpoint

w/VC M Module & T raq

Sensing

Unit Input Volts CFM

20 & 25 Ton 0.5 - 4.5 vdc 0 - 14000

30 Ton 0.5 - 4.5 vdc 0 - 17000

40 Ton 0.5 - 4.5 vdc 0 - 22000

50 & 55 Ton 0.5 - 4.5 vdc 0 - 28000

60 thru 75 Ton 0.5 - 4.5 vdc 0 - 33000

90 thru 130 Ton 0.5 - 4.5 vdc 0 - 46000

The velocity pressure transducer/solenoid assembly is illustrated below. Refer to the "TraqTM Sensor Sequence of Operation" section for VCM operation.

Velocity Pressure Transducer/Solenoid Assembly

For complete application details of the module, refer to Engineering Bulletin RT-EB-109.

Input Devices & System Functions

The descriptions of the following basic Input Devices used

within the UCM network are to acquaint the operator with

their function as they interface with the various modules.

Refer to the unit's electrical schematic for the specific module connections.

Constant V olume & Variable Air Volume Units

Supply Air Temperature Sensor (3RT9)

Is an analog input device used with CV & VAV applications.

It monitors the supply air temperature for; supply air temperature control (VAV), supply air temperature reset (VAV),

supply air temperature low limiting (CV), supply air tempering (CV/VAV). It is mounted in the supply air discharge section of the unit and is connected to the RTM (1U48).

Return Air Temperature Sensor (3RT6)

Is an analog input device used with a return humidity sensor on CV & VAV applications when the compar ative enthalpy option is ordered. It monitors the return air temperature and compares it to the outdoor temperature to establish which temperature is best suited to maintain the cooling

requirements. It is mounted in the return air section and is

connected to the ECEM (1U52).

Evaporator Temperature Sensor (3RT14 and 3RT15)

Is an analog input device used with CV & VAV applications.

It monitors the refrigerant temperature inside the evaporator

coil to prevent coil freezing. It is attached to the suction line

near the evaporator coil and is connected to the SCM/MCM

(1U49). It is factory set for 30 F and has an adjustable

range of 25 F to 35 F. The compressors are staged "Off" as

necessary to prevent icing. After the last compressor stage

has been turned "Off", the compressors will be allowed to

restart once the evaporator temperature rises 10 F above

the "coil frost cutout temperature" and the minimum three

minute "Off" time has elapsed.

Generic Building Automation System Module

(GBAS - Optional 1U51 used with non-Trane building

control systems)

The Generic Building Automation System (GBAS) module

allows a non-Trane building control system to communicate

with the rooftop unit and accepts external setpoints in form

of analog inputs for cooling, heating, supply air pressure,

and a binary Input for demand limit. Refer to the "Field Installed Control Wiring" section for the input wiring to the

GBAS module and the various desired setpoints with the

corresponding DC voltage inputs for both VAV and CV applications.

Filter Switch (3S21)

Is a binary input device used on CV & VAV applications. It

measures the pressure differential across the unit filters. It

is mounted in the filter section and is connected to the RTM

(1U48). A diagnostic SERVICE signal is sent to the remote

panel if the pressure differential across the filters is at least

0.5" w.c.. The contacts will automatically open when the

pressure differential across the filters decrease to 0.4" w.c..

The switch differential can be field adjusted between 0.17"

w.c. to 5.0" w.c. ± 0.05" w.c..

Supply and Exhaust Airflow Proving Switches (3S68

and 3S69)

3S68 is a binary input device used on CV & VAV applications to signal the RTM when the supply fan is operating. It

is located in the supply fan section of the unit and is connected to the RTM (1U48). During a request for fan operation, if the differential switch is detected to be open for 40

consecutive seconds; compressor operation is turned "Off",

heat operation is turned "Off", the request for supply fan operation is turned "Off" and locked out, IGV's (if equipped)

are "closed", exhaust dampers (if equipped) are "closed",

economizer dampers (if equipped) are "closed", and a

manual reset diagnostic is initiated.

8

General Information (Continued)

3S69 is a binary input device used on all rooftop units

equipped with an exhaust fan. It is located in the exhaust

fan section of the unit and is connected to the RTM (1U48).

During a request for fan operation, if the differential switch

is detected to be open for 40 consecutive seconds, the

economizer is closed to the minimum position setpoint, the

request for exhaust fan operation is turned "Off" and locked

out, and a manual reset diagnostic is initiated. The fan failure lockout can be reset; at the Human Interface located in

the unit's control panel, by Tracer, or by cycling the control

power to the RTM (1S70 Off/On).

Lead-Lag

Is a selectable mode of operation on 40 thru 130 Ton units

within the Human Interface. It alternates the starting between the first compressor of each refrigeration circuit. Only

the compressor banks will switch, not the order of the compressors within a bank, providing the first compressor in

each circuit had been activated during the same request for

cooling.

Supply and Exhaust Fan Circuit Breakers (1CB1, 1CB2)

The supply fan and exhaust fan motors are protected by circuit breakers 1CB1 and 1CB2 respectively. They will trip

and interrupt the power supply to the motors if the current

exceeds the breaker's "must trip" value. The rooftop module

(RTM) will shut all system functions "Off" when an open fan

proving switch is detected.

Low Pressure Control

Is accomplished using a binary input device on CV & VAV

applications. LP cutouts are located on the suction lines

near the scroll compressors.

The LPC contacts are designed to close when the suction

pressure exceeds 22 ± 4 psig. If the LP control is open

when a compressor is requested to start, none of the compressors on that circuit will be allowed to operate. They are

locked out and a manual reset diagnostic is initiated.

The LP cutouts are designed to open if the suction pressure

approaches 7 ± 4 psig. If the LP cutout opens after a compressor has started, all compressors operating on that circuit will be turned off immediately and will remain off for a

minimum of three minutes.

If the LP cutout trips four consecutive times during the first

three minutes of operation, the compressors on that circuit

will be locked out and a manual reset diagnostic is initiated.

Saturated Condenser Temperature Sensors (2RT1 and

2RT2)

Are analog input devices used on CV & VAV applications

mounted inside a temperature well located on a condenser

tube bend. They monitor the saturated refrigerant temperature inside the condenser coil and are connected to the

SCM/MCM (1U49). As the saturated refrigerant temperature

varies due to operating conditions, the condenser fans are

cycled "On" or "Off" as required to maintain acceptable operating pressures.

denser fans "On". If the operating fans can not bring the

condensing temperature to within the controlband, more

fans are turned on. As the saturated condensing temperature approaches the lower limit of the controlband, fans are

sequenced "Off". The minimum "On/Off" time for condenser

fan staging is 5.2 seconds. If the system is operating at a

given fan stage below 100% for 30 minutes and the saturated condensing temperature is above the "efficiency

check point" setting, a fan stage will be added. If the saturated condensing temperature falls below the "efficiency

check point" setting, the fan control will remain at the

present operating stage. If a fan stage cycles four times

within a 10 minute period, the control switches from controlling to the "lower limit" to a temperature equal to the "lower

limit" minus the "temporary low limit suppression" setting. It

will utilize this new "low limit" temperature for one hour to

reduce condenser fan short cycling.

High Pressure Controls

High Pressure controls are located on the discharge lines

near the scroll compressors. They are designed to open

when the discharge pressure approaches 405 ± 7 psig. The

controls reset automatically when the discharge pressure

decreases to approximately 300 ± 20 psig. However, the

compressors on that circuit are locked out and a manual reset diagnostic is initiated.

Outdoor Air Humidity Sensor (3U63)

Is an analog input device used on CV & VAV applications

with 100% economizer. It monitors the outdoor humidity levels for economizer operation. It is mounted in the fresh air

intake section and is connected to the RTM (1U48).

Return Air Humidity Sensor (3U64)

Is an analog input device used on CV & VAV applications

with the comparative enthalpy option. It monitors the return

air humidity level and compares it to the outdoor humidity

level to establish which conditions are best suited to maintain the cooling requirements. It is mounted in the return air

section and is connected to the ECEM (1U52).

Low Ambient Control

The low ambient modulating output on the compressor

module is functional on all units with or without the low ambient option. When the compressor module has staged up

to it's highest stage (stage 2 or 3 depending on unit size),

the modulating output will be at 100% (10 VDC). When the

control is at stage 1, the modulating output (0 to 10 VDC)

will control the saturated condensing temperature to within

the programmable "condensing temperature low ambient

control point".

Status/Annunciator Output

Is an internal function within the RTM (1U48) module on CV

& VAV applications that provides;

a. diagnostic and mode status signals to the remote

panel (LEDs) and to the Human Interface.

b. control of the binary Alarm output on the RTM.

Head Pressure Control

is accomplished using two saturated refrigerant temperature sensors on CV & VAV applications. Dur ing a request

for compressor operation, when the condensing temperature rises above the "lower limit" of the controlband, the

Compressor Module (SCM/MCM) starts sequencing con-

c. control of the binary outputs on the GBAS module to

inform the customer of the operational status and/or

diagnostic conditions.

9

General Information (Continued)

Low Ambient Compressor Lockout

Utilizes an analog input device for CV & VAV applications.

When the system is configured for low ambient compressor

lockout, the compressors are not allowed to operate if the

temperature of the outside air falls below the lockout setpoint. When the temperature rises 5 F above the lockout

setpoint, the compressors are allowed to operate. The setpoint for units without the low ambient option is 50 F. For

units with the low ambient option, the setpoint is 0 F. The

setpoints are adjustable at the Human Interface inside the

unit control panel.

Space Pressure Transducer (3U62)

Is an analog input device used on CV & VAV applications

with the Statitrac option. It modulates the exhaust dampers

to keep the space pressure within the building to a customer designated controlband. It is mounted in the filter

section just above the exhaust damper actuator and is connected to the ECEM (1U52). Field supplied pneumatic tubing must be connected between the space being controlled

and the transducer assembly.

4.0

3.5

3.0

2.5

2.0

Volts

1.5

1.0

0.5

0.0

Transducer Voltage Output vs Pressure Input

-0.5 0.0 0.5 1.0 1.5 2. 0 2.5 3. 0 3.5 4.0 4.5 5.0

P r e ssure ( i nche s w . c. )

Morning W arm-Up - Zone Heat

When a system changes from an unoccupied to an occupied mode, or switches from STOPPED to AUTO, or power

is applied to a unit with the MWU option, the heater in the

unit or external heat will be brought on if the space temperature is below the MWU setpoint. The heat will remain

on until the temperature reaches the MWU setpoint. If the

unit is VAV, then the VAV box/unocc relay will continue to

stay in the unoccupied position and the VFD/IGV output

will stay at 100% during the MWU mode. When the MWU

setpoint is reached and the heat mode is terminated, then

the VAV box/unocc relay will switch to the occupied mode

and the VFD/IGV output will be controlled by the duct static

pressure. During Full Capacity MWU the economizer

damper is held closed for as long as it takes to reach

setpoint. During Cycling Capacity MWU the economizer

damper is allowed to go to minimum position after one

hour of operation if setpoint has not been reached.

Compressor Motor Winding Thermostats (2B7S1,

2B17S2, 2B27S5, 2B8S3, 2B18S4 & 2B28S6)

A thermostat is embedded in the motor windings of each

Scroll compressor. Each thermostat is designed to open if

the motor windings exceeds approximately 221 F. The thermostat will reset automatically when the winding temperature decreases to approximately 181 F. Rapid cycling, loss

of charge, abnormally high suction temperatures, or the

compressor running backwards could cause the thermostat

to open. During a request for compressor operation, if the

Compressor Module (SCM) detects a problem outside of

it's normal parameters, it turns any operating

compressor(s) on that circuit "Off", locks out all compressor

operation for that circuit, and initiates a manual reset diagnostic.

Supply Air T emperature Lo w Limit

Uses the supply air temperature sensor input to modulate

the economizer damper to minimum position in the event

the supply air temperature falls below the occupied heating

setpoint temperature.

Freezestat (4S12)

Is a binary input device used on CV & VAV units with Hydronic Heat. It is mounted in the heat section and connected to the Heat Module (1U50). If the temperature of the

air entering the heating coil falls to 40 F, the normally open

contacts on the freezestat closes signalling the Heat Module (1U50) and the Rooftop Module (RTM) to:

a. drive the Hydronic Heat Actuator (4U15) to the full

open position.

b. turn the supply fan "Off".

c. closes the outside air damper;

d. turns "On" the SERVICE light at the Remote Panel.

e. initiates a "Freezestat" diagnostic to the Human

Interface.

High Duct Temp Thermostats (Optional 3S16, 3S17)

Are binary input devices used on CV & VAV applications

with a Trane Communication Interface Module (TCI). They

provide "high limit" shutdown of the unit and requires a

manual reset. They are factory set to open if the supply air

temperature reaches 240 F, or the retur n air temperature

reaches 135 F. Once tripped, the thermostat can be reset

by pressing the button located on the sensor once the air

temperature has decreased approximately 25 F below the

cutout point.

Compressor Circuit Breakers (1CB8, 1CB9, 1CB10,

1CB11 & 1CB14, 1CB15, 1CB16, 1CB17)

The Scroll Compressors are protected by circuit breakers

which interrupt the power supply to the compressors if the

current exceeds the breakers “must trip” value. During a request for compressor operation, if the Compressor Module

(SCM) detects a problem outside of it's normal parameters,

it turns any operating compressor(s) on that circuit "Off",

locks out all compressor operation for that circuit, and initiates a manual reset diagnostic.

Constant Volume (CV) Units

Zone T emperature - Cooling

Relies on input from a sensor located directly in the space,

while a system is in the occupied "Cooling" mode. It modulates the economizer (if equipped) and/or stages the mechanical cooling "On and Off" as required to maintain the

zone temperature to within the cooling setpoint deadband.

Zone Temperature - Heating

Relies on input from a sensor located directly in the space,

while a system is in the occupied "Heating" mode or an unoccupied period, to stage the heat "on and off" or to modulate the heating valve (hydronic heat only) as required to

maintain the zone temperature to within the heating setpoint

deadband. The supply fan will be requested to operate any

time there is a requested for heat. On gas heat units, the

fan will continue to run for 60 seconds after the furnace is

turned off.

Supply Air T empering

On CV units equipped with staged heat, if the supply air

temperature falls 10 F below the occupied heating setpoint

temperature while the heater is "Off", the first stage of heat

will be turned "On". The heater is turned "Off" when the supply air temperature reaches 10 F above the occupied heating setpoint temperature.

10

General Information (Continued)

Variable Air Volume (VAV) Units

Occupied Heating - Supply Air Temperature

When a VAV units is equipped with "Modulating Heat", and

the system is in an occupied mode, and the field supplied

changeover relay contacts (5K87) have closed, the supply

air temperature will be controlled to the customer specified

supply air heating setpoint. It will remain in the heating status until the changeover relay contacts are opened.

Occupied Cooling - Supply Air T emperature

When a VAV unit is in the occupied mode, the supply air

temperature will be controlled to the customers specified

supply air cooling setpoint by modulating the economizer

and/or staging the mechanical cooling "On and Off" as required. The changeover relay contacts must be open on

units with "Modulating Heat" for the cooling to operate.

Daytime Warm-up

On VAV units equipped with heat, if the zone temperature

falls below the daytime warm-up initiate temperature during the occupied mode, the system will switch to full airflow. Dur ing this mode, the VAV box/unocc relay, RTM K3,

will be energized (this is to signal the VAV boxes to go to

100%). After the VAV box max stroke time has elapsed

(factory set at 6 minutes), the VFD/IGV output will be set to

100%. The airflow will be at 100% and the heat will be

turned on to control to the occupied heating setpoint.

When the zone temperature reaches the daytime warm-up

termination setpoint, the heat will be turned off, the K3 relay will be de-energized, releasing the VAV boxes, the

VFD/IGV output will go back to duct static pressure control

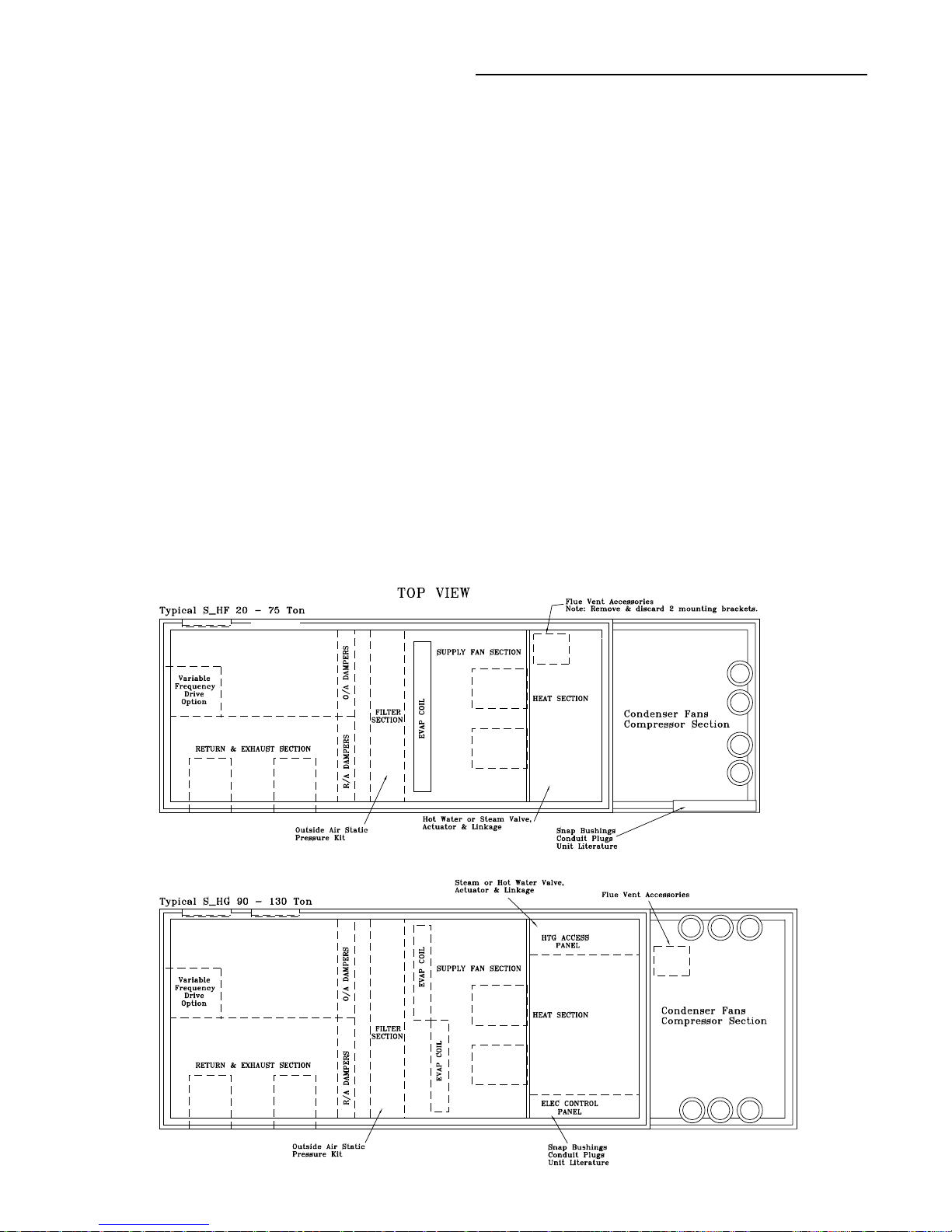

Unit Component Layout and "Shipwith" Locations

and the unit will return to discharge air control. If the occ

zone heating setpoint is less than the DWU terminate

setpoint, the heat will turn off when the occ zone heat

setpoint is reached, but it will stay in DWU mode and cycle

the heat to maintain setpoint.

Unoccupied Heating - Zone Temperature

When a VAV unit is equipped with gas, electric, or hydronic

heat and is in the unoccupied mode, the zone temperature

will be controlled to within the customers specified setpoint

deadband. During an unoccupied mode for a VAV unit, the

VAV box/unocc relay will be in the unoccupied position and

the VFD/IGV output will be at 100%. This means that if

there is a call for heat (or cool) and the supply fan comes

on, it will be at full airflow and the VAV boxes in the space

will need to be 100% open as signaled by the VAV box/

unocc relay.

Supply Air T empering

On VAV units equipped with "Modulating Heat", if the supply air temperature falls 10

ture setpoint, the hydronic heat valve will modulate to

maintain the supply air temperature to within the low end

of the setpoint deadband.

Supply Duct Static Pressure Control (Occupied)

The RTM relies on input from the duct pressure transducer

when a unit is equipped with Inlet Guide Vanes or a Variable Frequency Drive to position the Inlet Guide Vanes or

set the supply fan speed to maintain the supply duct static

pressure to within the static pressure setpoint deadband.

Refer to the Transducer Voltage Output vs Pressure Input

values listed in the Space Pressure Transducer (3U62)

section.

F below the supply air tempera-

11

General Information (Continued)

RTM

1U48

J1-1

J2-1

SCM

1U49

Bracke

Heat MOD

1U50

Mounting

Plate

LCI MOD

1U54

TCI MOD

1U54

Bracke

J2-1

J1-1

OR

1PCB MOD

1U55

ECEM

1U52

VOM

1U53

GBAS MOD

1U51

J1-1

J2-1

1TB9

J2-1

J1-1

J2-1

J1-1

J2-1

J1-1

J1-1

J2-1

Bracke

Bracke

Bracke

Bracke

Mounting

Plate

Mounting

Plate

RTM

1U48

J1-1

J2-1

SCM

1U49

GBAS MOD

1U51

J2-1

J1-1

Bracke

Bracke

Bracke

Bracke

Bracke

Bracke

VOM

1U53

Mounting

Plate

J1-1

J2-1

Heat MOD

1U50

Mounting

Plate

LCI MOD

1U54

TCI MOD

1U54

OR

1PCB MOD

1U55

ECEM

1U52

J1-1

1TB9

J2-1

J1-1

J2-1

J1-1

J1-1

J2-1

J2-1

Space Temperature Avera ging

Space temperature averaging for Constant Volume applications is accomplished by wiring a number of remote sensors

in a series/parallel circuit.

The fewest number of sensors required to accomplish

space temperature averaging is four. Figure 8 illustrates a

single sensor circuit (Single Zone), four sensors wired in a

series/parallel circuit (Four Zone), nine sensors wired in a

series/parallel circuit (Nine Zone). Any number squared, is

the number of remote sensors required.

Wiring termination will depend on the type of remote panel

or control configuration for the system. Refer to the wiring

diagrams that shipped with the unit.

Space Temperature Averaging with Multiple Sensors

Unit Control Modules (UCM)

Unit control modules are microelectronic circuit boards designed to perform specific unit functions. These modules

through Proportional/Integral control algorithms provide the

best possible comfort level for the customer. They are

mounted in the control panel and are factory wired to their

respective internal components. They receive and interpret

information from other unit modules, sensors, remote panels, and customer binary contacts to satisfy the applicable

request for economizing, mechanical cooling, heating, and

ventilation. Figure 9 below illustrates the typical location of

each "1U" designated module.

Control Module Locations for S_HF 20 & 25 Ton Units

Bracke

t

Bracke

1TB9

Bracke

J1-1

t

Bracke

t

J2-1

GBAS MOD

1U51

Mounting

Plate

J2-1

J1-1

t

Bracke

J2-1

Heat MOD

1U50

Mounting

Plate

J2-1

J1-1

OR

LCI MOD

1U54

1PCB MOD

1U55

J2-1

J1-1

J2-1

J1-1

J1-1

Mounting

Plate

VOM

1U53

ECEM

1U52

TCI MOD

1U54

J2-1

t

SCM

1U49

J1-1

RTM

1U48

Bracke

Control Module Locations for S_HF 30 Ton Units

J2-1

RTM

Bracke

1U48

t

1PCB MOD

1U55

J2-1

J1-1

TCI MOD

1U54

OR

LCI MOD

1U54

J1-1

Mounting

Plate

J1-1

ECEM

1U52

J1-1

VOM

1U53

1TB9

Heat MOD

1U50

Mounting

Plate

J1-1

J2-1

t

Bracke

t

Bracke

SCM

1U49

J1-1

Bracke

t

t

Bracke

t

Bracke

J2-1

J2-1

GBAS MOD

1U51

J2-1

J1-1

J2-1

t

12

General Information (Continued)

RTM

1U48

GBAS MOD

1U51

Bracke

VOM

1U53

Mounting

Plate

Heat MOD

1U50

LCI MOD

1U54

TCI MOD

1U54

OR

1PCB MOD

1U55

ECEM

1U52

1TB9

MCM

1U49

Bracke

Bracke

Bracke

Bracke

Bracke

Mounting

Plate

Mounting

Plate

J2-1

J1-1

J1-1

J2-1

J2-1

J1-1

J1-1

J2-1

J2-1

J1-1

J2-1

J1-1

J2-1

J1-1

GBAS MODGBAS MOD

1U511U51

BrackeBracket

VOMVOM

1U531U53

J1-1J1-1

J2-1J2-1

MountingMounting

PlatePlate

J2-1J2-1

J1-1J1-1

BrackeBracket

Bracke

Bracket

1PCB MOD1PCB MOD

1U551U55

ECEMECEM

1U521U52

1TB91TB9

J2-1J2-1

J1-1J1-1

J1-1J1-1

J2-1J2-1

MountingMounting

PlatePlate

MountingMounting

PlatePlate

J1-1J1-1

J2-1J2-1

J2-1J2-1

J1-1J1-1

Heat MODHeat MOD

1U501U50

LCI MODLCI MOD

1U541U54

TCI MODTCI MOD

1U541U54

OROR

BrackeBracket

Bracke

Bracket

J2-1J2-1

J1-1J1-1

RTMRTM

1U481U48

MCMMCM

1U491U49

J1-1J1-1

J2-1J2-1

J1-1J1-1

J2-1J2-1

GBAS MOD

1U51

Bracke

VOM

1U53

Mounting

Plate

1PCB MOD

1U55

ECEM

1U52

1TB9

Bracke

Mounting

Plate

Mounting

Plate

Heat MOD

1U50

LCI MOD

1U54

TCI MOD

1U54

OR

J1-1

J2-1

J1-1

J2-1

J2-1

J1-1

J2-1

J1-1

J2-1

J1-1

J1-1

J2-1

Bracke

Bracke

Bracke

Bracke

RTM

1U48

MCM

1U49

J1-1

J2-1

Control Module Locations for S_HF 40, 60, 70 &

75 Ton Units

MCM

1U49

Bracke

t

J1-1

TCI MOD

1U54

J2-1

J1-1

OR

J1-1

LCI MOD

1U54

J2-1

Mounting

Plate

1PCB MOD

1U55

Heat MOD

1U50

J2-1

J2-1

J1-1

Mounting

Plate

J2-1

J1-1

Bracke

J1-1

ECEM

1U52

VOM

1U53

1TB9

Bracke

t

J2-1

J1-1

t

Bracke

Mounting

Plate

Bracke

t

J2-1

GBAS MOD

1U51

t

Bracke

Control Module Locations for S_HF 50 & 55 Ton Units

RTM

1U48

t

Control Module Locations for S_HG 90 - 130 Ton Units

Bracke

Mounting

Plate

J1-1

J2-1

J2-1

TCI MOD

1U54

J1-1

t

ECEM

1U52

Bracke

OR

1TB9

t

J1-1

J2-1

LCI MOD

1U54

J1-1

J2-1

Bracke

Mounting

Plate

t

Heat MOD

1U50

J2-1

GBAS MOD

1U51

Mounting

Plate

VOM

1U53

J1-1

J2-1

1PCB MOD

1U55

J1-1

Bracke

J1-1

J2-1

Bracke

RTM

1U48

Bracke

t

t

MCM

1U49

t

13

Table of Contents

Section One

About The Manual ............................................................... 2

Literature Change History ................................................ 2

Overview of Manual ......................................................... 2

Section Two

General Information ............................................................. 4

Model Number Description .............................................. 4

Hazard Identification ........................................................ 6

Commonly Used Acronyms ............................................. 6

Unit Description ................................................................ 6

Input Devices & System Functions .................................. 8

Constant Volume & Variable Air Volume Units ................ 8

Constant Volume (CV) Units .......................................... 10

Variable Air Volume (VAV) Units .................................... 11

Space Temperature Averaging .......................................12

Unit Control Modules (UCM) ..........................................12

Section Three

Installation .......................................................................... 14

Unit Inspection ............................................................... 14

Storage ........................................................................... 14

Unit Clearances .............................................................14

Unit Dimensions & Weight Information .......................... 14

Roof Curb and Ductwork ............................................... 22

Pitch Pocket Location .................................................... 23

Unit Rigging & Placement .............................................. 23

General Unit Requirements ........................................... 25

Main Electrical Power Requirements............................. 25

Field Installed Control Wiring ......................................... 25

Requirements for Electric Heat Units ............................ 25

Requirements for Gas Heat ...........................................25

Requirements for Hot Water Heat (SLH_) ..................... 25

Requirements for Steam Heat (SSH_) .......................... 26

O/A Pressure Sensor and Tubing Installation ............... 26

Condensate Drain Connection....................................... 27

Shipping Fasteners ........................................................27

O/A Sensor & Tubing Installation ...................................31

Units with Statitrac™; .................................................... 31

Gas Heat Units (SFH_) ..................................................32

Connecting the Gas Supply Line to the Furnace

Gas Train ........................................................................32

Flue Assembly Installation ............................................. 34

Hot Water Heat Units (SLH_) ........................................ 34

Steam Heat Units (SSH_) ..............................................35

Disconnect Switch External Handle ............................... 38

Electric Heat Units (SEH_) ............................................ 38

Main Unit Power Wiring ................................................. 38

Disconnect Switch Sizing (DSS) ....................................44

Field Installed Control Wiring ......................................... 45

Controls using 24 VAC ................................................... 45

Controls using DC Analog Input/Outputs ....................... 45

Constant Volume System Controls ................................45

Variable Air Volume System Controls ............................ 46

Constant Volume or Variable Air Volume System

Controls ..........................................................................46

Section Four

Unit Start-Up ......................................................................55

Cooling Sequence of Operation .................................... 55

Gas Heating Sequence of Operation ............................. 56

Fenwal Ignition System .................................................. 56

Honeywell Ignition System ............................................. 56

Modulating Gas Sequence of Operation ....................... 57

Flame Failure ................................................................. 57

Electric Heat Sequence of Operation ............................ 58

Wet Heat Sequence of Operation.................................. 58

Electrical Phasing .......................................................... 59

Voltage Supply and Voltage Imbalance ......................... 60

Service Test Guide for Component Operation ............... 61

Verifying Proper Fan Rotation ....................................... 63

If all of the fans are rotating backwards;........................ 63

System Airflow Measurements ...................................... 63

Constant Volume Systems............................................. 63

Variable Air Volume Systems ......................................... 65

Exhaust Airflow Measurement ....................................... 66

TraqTM Sensor Airflow Measurement ........................... 66

Economizer Damper Adjustment ................................... 80

Compressor Start-Up .....................................................82

Compressor Operational Sounds .................................. 83

Thermostatic Expansion Valves..................................... 93

Charging by Subcooling ................................................. 93

Low Ambient Dampers ................................................... 93

Electric, Steam and Hot Water Start-Up ........................ 94

Gas Furnace Start-Up .................................................... 94

Two Stage Gas Furnace ................................................ 95

Full Modulating Gas Furnace......................................... 97

Limited Modulating Gas Furnace ................................... 98

Final Unit Checkout ........................................................ 99

Section Five

Service & Maintenance.................................................... 100

Fan Belt Adjustment ..................................................... 104

Scroll Compressor Replacement ................................. 105

VFD Programming Parameters ................................... 106

Monthly Maintenance ................................................... 107

Filters............................................................................ 107

Cooling Season ............................................................107

Heating Season............................................................ 108

Coil Cleaning ................................................................ 108

Final Process ............................................................... 109

Index ............................................................................... 111

UV ................................................................................... 114

Warranty ......................................................................... 114

Installation

Unit Inspection

As soon as the unit arrives at the job site

[ ] Verify that the nameplate data matches the data on the

sales order and bill of lading (including electrical data).

[ ] Verify that the power supply complies with the unit name-

plate specifications.

[ ] Verify that the power supply complies with the electric

heater specifications on the uit nameplate.

[ ] Visually inspect the exterior of the unit, including the roof,

for signs of shipping damage.

[ ] Check for material shortages. Refer to the Component

Layout and Shipwith Location illustration.

If the job site inspection of the unit reveals damage or material shortages, file a claim with the carrier immediately.

Specify the type and extent of the damage on the "bill of

lading" before signing.

[ ] Visually inspect the internal components for shipping

damage as soon as possible after delivery and before it

is stored. Do not walk on the sheet metal base pans.

Storage

Ta ke precautions to prevent condensate from forming inside

the unit’s electrical compartments and motors if:

a. the unit is stored before it is installed; or,

b. the unit is set on the roof curb, and temporary heat is

provided in the building. Isolate all side panel service

entrances and base pan openings (e.g., conduit

holes, S/A and R/A openings, and flue openings)

from the ambient air until the unit is ready for startup.

Note: Do not use the unit's heater for temporary

heat without first completing the startup procedure

detailed under "Starting the Unit".

Trane will not assume any responsibility for

equipment damage resulting from condensate accumulation

on the unit's electrical and/or mechanical components.

Unit Clearances

Figure 3-1 illustrates the minimum operating and service

clearances for either a single or multiple unit installation.

These clearances are the minimum distances necessary to

assure adequate serviceability, cataloged unit capacity, and

peak operating efficiency.

WARNING

No Step Surface!

FOR ACCESS TO COMPONENTS, THE BASE SHEET

METAL SURFACE MUST BE REINFORCED.

Bridging between the unit's main supports may consist

of multiple 2 by 12 boards or sheet metal grating.

Failure to comply could result in death or severe

personal injury from falling.

[ ] If concealed damage is discovered, notify the carrier's

terminal of damage immediately by phone and by mail.

Concealed damage must be reported within 15 days.

Request an immediate joint inspection of the damage by

the carrier and the consignee. Do not remove damaged

material from the receiving location. Take photos of the

damage, if possible. The owner must provide reasonable

evidence that the damage did not occur after delivery.

[ ] Remove the protective plastic coverings that shipped

over the compressors.

Providing less than the recommended clearances may result in condenser coil starvation, "short-circuiting" of exhaust and economizer airflows, or recirculation of hot condenser air.

Unit Dimensions & Weight Information

Overall unit dimensional data for a SAHF (20 thru 75 Ton)

cooling only unit is illustrated in Figure 3-2A. Tables 3-1A,

3-1B, and 3-1C list the dimensions. Dimensional data for

SEH_, SFH_, SLH_, SSH_, and SXH_ (20 thru 130 Ton)

units are illustrated in Figure 3-2B. Tables 3-2A, 3-2B, and

3-2C list the dimensions for the 20 thru 75 Ton units. Dimensions for 90 through 130 Ton units are listed on the illustration in Figure 3-2C.

A Center-of-Gravity illustration and the dimensional data is

shown in Figure 3-3.

Table 3-3 list the typical unit and curb operating weights.

Weights shown represent approximate operating weights.

Actual weights are stamped on the unit nameplate.

14

Figure 3-1

Minimum Operation and Service Clearances for Single & Multiple Unit Installation

15

Figure 3-2A

SAHF Cooling-Only Units (20 thru 75 Ton)

16

Installation (Continued)

Table 3-1A

Unit Dimensional Data

Unit Dimensions

Size ABCDEFGHJ

20 & 25 Ton 21'-9 3/4" 5'-3 1/8" 7'-6 1/2" 5'-8 15/16" 3'-9 5/16" 12'-6" 1" 7' 1'-3 1/2"

30 Ton 21'-9 3/4" 5'-8 5/8" 7'-6 1/2" 6'-2 7/16" 4'-9 5/16" 12'-6" 1" 7' 1'-3 1/2"

40 Ton 27'-0" 6'-1 5/8" 7'-6 1/2" 6'-7 3/8" 5'-9 5/16" 15'-11 1/8" 1" 8' 2'-5"

50 & 55 Ton 29'-8" 5'-3 1/8" 7'-6 1/2" 5'-8 7/8" 6'-9 5/16" 15'-11 1/8" 1" 8' 2'-5"

60 Ton 27'-0" 6'-1 5/8" 9'-8" 6'-7 3/8" 5'-9 5/16" 15'-11 1/8" 1" 8' 2'-5"

70 & 75 Ton 27'-0" 6'-1 5/8" 9'-8" 6'-7 3/8" 5'-9 5/16" 15'-11 1/8" 1" 8' 1'-4"

Table 3-1B

Unit Base Dimensional Data

Unit Dimensions

Size A BCDEFG

20 - 30 Ton

40 - 55 Ton

60 Ton 16'-7 13/16" 2'-5" 1'-4 9/16" 6'-10 7/8" 4'-5 3/8" 5 13/16" 7'-8 3/16"

70 - 75 Ton

14'-0 1/4" 2'-2 1/2" 11 3/4" 5'-7" 3'-4 3/8" 5 13/16" 6'-6 15/16"

16'-7 13/16" 2'-5" 11 3/4" 5'-7" 3'-4 3/8" 5 13/16" 7'-8 3/16"

16'-7 13/16" 2'-5" 1'-4 9/16" 6'-10 7/8" 4'-5 3/8" 5 13/16" 7'-8 3/16"

Table 3-1C

Electrical Entrance Data

Unit Dimens ions

Size F G H J K L M N

20, 25, & 30 8 7/32" 6 31/32" 15 21/32" 13 21/32" 9 17/32" 8 1/2" 18 1/16" 19 9/16"

50 & 55 Ton

40, 60, 70 8 3/4" 7 3/4" 17 7/8" 15 7/8" 9 29/32" 10 1/16" 20 13/32" 22 5/32"

& 75 Ton

17

Figure 3-2B

SEHF, SFHF, SLHF, SSHF, SXHF Units (20 thru 75 Ton)

18

Installation (Continued)

g

g

Table 3-2A

Unit Dimensional Data

Unit Dimensions

SizeABCDEFGHJ

20 & 25 Ton 24'-1 3/8" 5'-3 1/8" 7'-6 1/2" 5'-8 15/16" 3'-9 5/16" 13'-3" 1" 7' 1'-3 1/2"

30 Ton 24'-1 3/8" 5'-8 5/8" 7'-6 1/2" 6'-2 3/8" 4'-9 5/16" 13'-3" 1" 7' 1'-3 1/2"

40 Ton 30'-2 1/2" 6'-1 5/8" 7'-6 1/2" 6'-7 3/8" 5'-9 5/16" 15'-11 1/8" 1" 8' 2'-5"

50 & 55 Ton 32'-10 1/2" 5'-3 1/8" 7'-6 1/2" 5'-8 7/8" 6'-9 5/16" 15'-11 1/8" 1" 8' 2'-5"

60 Ton 30'-2 1/2" 6'-1 5/8" 9'-8" 6'-7 3/8" 5'-9 5/16" 15'-11 1/8" 1" 8' 2'-5"

70 & 75 Ton 30'-2 1/2" 6'-1 5/8" 9'-8" 6'-7 3/8" 5'-9 5/16" 15'-11 1/8" 1" 8' 1'-4"

Dimensions

KLMNO

16'-7" 16'-6" 8 1/8" 6 1/4" 9"

16'-7" 16'-6" 8 1/8" 6 1/4" 9"

19'-7" See Note 8 1/8" 6 1/4" 9"

19'-7" See Note 8 1/8" 6 1/4" 9"

19'-7" See Note 8 1/8" 6 1/4" 9"

Note: