Trane HUV Installation and Maintenance Manual

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and

servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific

knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could

result in death or serious injury. When working on the equipment, observe all precautions in the literature

and on the tags, stickers, and labels that are attached to the equipment.

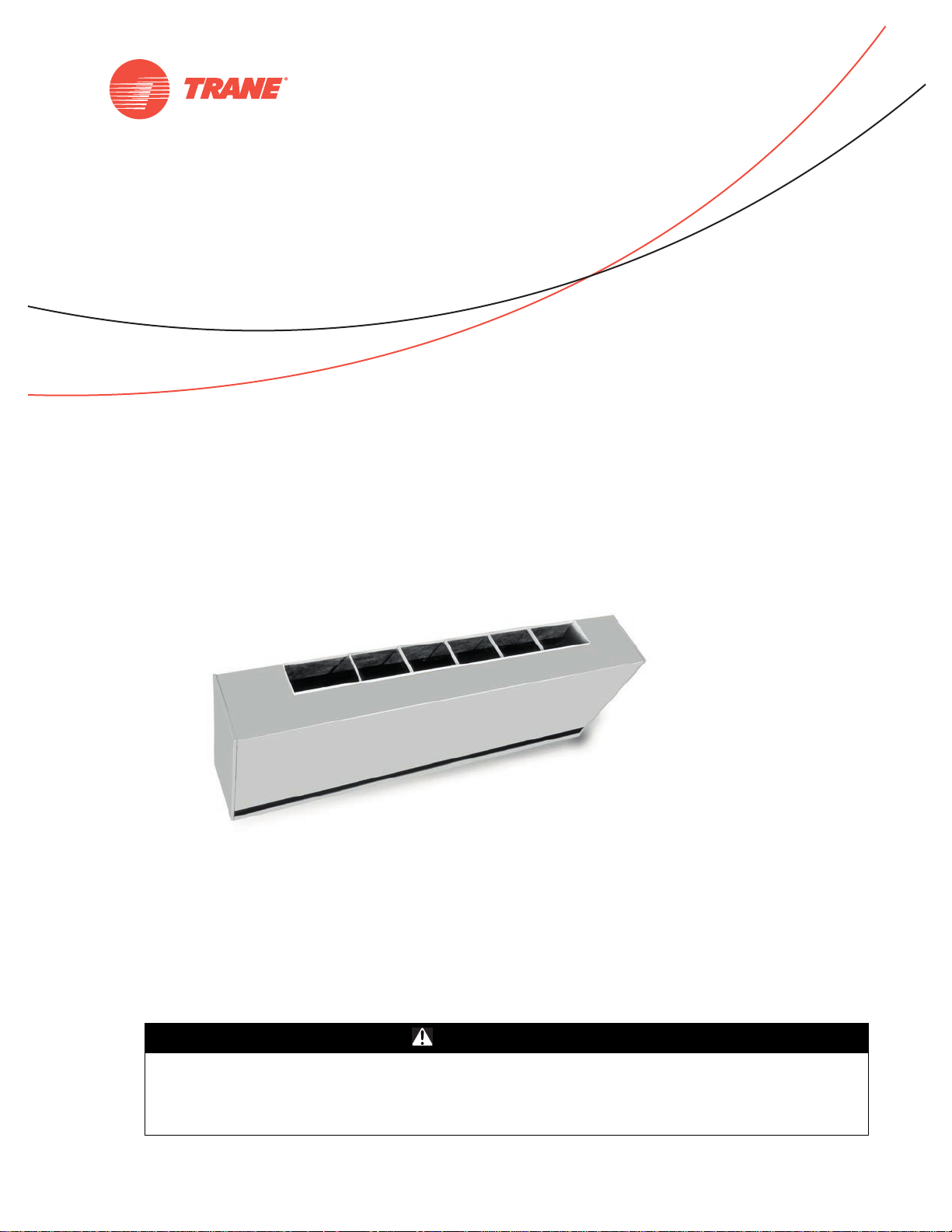

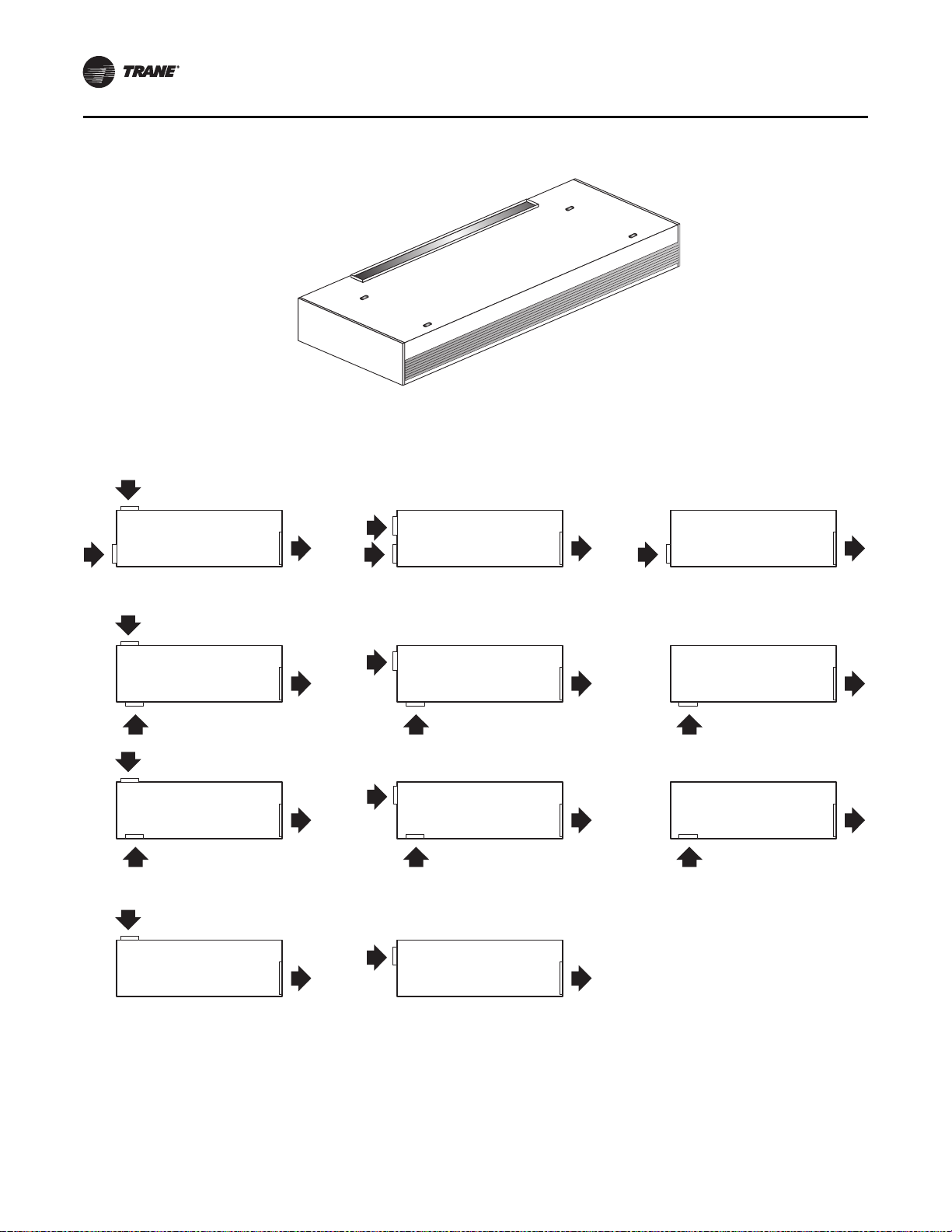

Horizontal Unit Ventilator

Classroom Unit Ventilator—Model HUV

January 2013 UV-SVN02C-EN

Installation, Operation,

and Maintenance

Models

“C” and later Design Sequence

HUVC

750 cfm—2000 cfm

© 2013 Trane All rights reserved UV-SVN02C-EN

Warnings, Cautions, and Notices

Warnings, Cautions, and Notices. Note that

warnings, cautions, and notices appear at appropriate

intervals throughout this manual. Warnings are provide to

alert installing contractors to potential hazards that could

result in personal injury or death. Cautions are designed to

alert personnel to hazardous situations that could result in

personal injury, while notices indicate a situation that

could result in equipment or property-damage-only

accidents.

Your personal safety and the proper operation of this

machine depend upon the strict observance of these

precautions.

Important

Environmental Concerns!

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment. Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified. The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

ATT EN TI ON : Warnings, Cautions, and Notices appear at

appropriate sections throughout this literature. Read

these carefully:

WARNING

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTIONs

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

NOTICE:

Indicates a situation that could result in

equipment or property-damage only

WARNI NG

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

WARNING

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken. ALWAYS refer to appropriate MSDS

sheets and OSHA guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS sheets and

OSHA guidelines for information on allowable

personal exposure levels, proper respiratory

protection and handling instructions.

• If there is a risk of arc or flash, technicians MUST put

on all PPE in accordance with NFPA 70E or other

country-specific requirements for arc flash

protection, PRIOR to servicing the unit.

Failure to follow instructions could result in death or

serious injury.

WARNI NG

Contains Refrigerant!

System contains oil and refrigerant under high

pressure. Recover refrigerant to relieve pressure before

opening the system. See unit nameplate for refrigerant

type. Do not use non-approved refrigerants, refrigerant

substitutes, or refrigerant additives.

Failure to follow proper procedures or the use of non-

approved refrigerants, refrigerant substitutes, or

refrigerant additives could result in death or serious

injury or equipment damage.

Warnings, Cautions, and Notices

UV-SVN02C-EN 3

Trademarks

ComfortLink, Rover, Tracer, Tracer Summit, Trane, and the

Trane logo are trademarks or registered trademarks of

Trane in the United States and other countries. All

trademarks referenced in this document are the

trademarks of their respective owners.

BACnet is a registered trademark of American Society of

Heating, Refrigerating and Air-Conditioning Engineers

(ASHRAE); Echelon, LonTalk, and L

ONWORKS are registered

trademarks of Echelon Corporation; Energizer is a

registered trademark of Eveready Battery Company, Inc.;

National Electrical Code, National Fire Protection

Association, and NEC are registered trademarks of the

National Fire Protection Association.

WARNING

R-410A Refrigerant under Higher Pressure

than R-22!

Some of the units described in this manual uses R-410A

refrigerant which operates at higher pressures than

R-22 refrigerant. Use ONLY R-410A rated service

equipment or components with this unit. For specific

handling concerns with R-410A, please contact your

local Trane representative.

Failure to use R-410A rated service equipment or

components could result in equipment or components

exploding under R-410A high pressures which could

result in death, serious injury, or equipment damage.

WARNING

Hazard of Explosion!

Use only dry nitrogen with a pressure regulator for

pressurizing unit. Do not use acetylene, oxygen or

compressed air or mixtures containing them for

pressure testing. Do not use mixtures of a hydrogen

containing refrigerant and air above atmospheric

pressure for pressure testing as they may become

flammable and could result in an explosion. Refrigerant,

when used as a trace gas should only be mixed with

dry nitrogen for pressurizing units. Failure to follow

these recommendations could result in death or serious

injury or equipment or property-only damage.

4 UV-SVN02C-EN

Table of Contents

Model Number Descriptions . . . . . . . . . . . . . . 6

General Information . . . . . . . . . . . . . . . . . . . . . 8

Unit Description . . . . . . . . . . . . . . . . . . . . . 8

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Unit Ventilator Controls . . . . . . . . . . . . . . 10

ECM Application Notes . . . . . . . . . . . . . . . . . . 12

Dimensions and Weights . . . . . . . . . . . . . . . . 13

Unit Location and Clearances . . . . . . . . . 13

Receiving and Handling . . . . . . . . . . . . . . . . . 19

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . 20

Jobsite Inspection . . . . . . . . . . . . . . . . . . 20

Jobsite Storage . . . . . . . . . . . . . . . . . . . . 20

Installation—Mechanical . . . . . . . . . . . . . . . . 21

Location Considerations . . . . . . . . . . . . . . . 21

Unit Mounting . . . . . . . . . . . . . . . . . . . . . . . 21

Horizontal Recessed Mounting . . . . . . . . 21

Installation—Piping . . . . . . . . . . . . . . . . . . . . . 23

Trane Piping Packages (Option) . . . . . . . 23

Split System Units . . . . . . . . . . . . . . . . . . 23

Refrigerant Piping . . . . . . . . . . . . . . . . . . 23

Steam Piping . . . . . . . . . . . . . . . . . . . . . . 24

Modulating Water Valves (Option) . . . . . 24

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Manual Opener . . . . . . . . . . . . . . . . . . . . . 26

Isolation Valves . . . . . . . . . . . . . . . . . . . . . . 26

Installation . . . . . . . . . . . . . . . . . . . . . . . . 26

Servicing/Removal of Valves . . . . . . . . . . 26

Heating Coils with Direct Expansion Cooling

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installation—Sensors . . . . . . . . . . . . . . . . . . . 28

Control Options . . . . . . . . . . . . . . . . . . . . . . 28

Installing Wall-Mounted Wired Sensors . 29

Location Considerations . . . . . . . . . . . . . 30

Location Considerations for Wireless Zone

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Fan Mode Switch Installation . . . . . . . . . 30

Zone Sensor Installation . . . . . . . . . . . . . 30

Wireless Sensors . . . . . . . . . . . . . . . . . . . . . 31

Address Setting . . . . . . . . . . . . . . . . . . . . 31

Observing the Receiver for Readiness to As-

sociate . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Associating the Sensor to the Receiver . .32

Testing Signal Strength and Battery Status

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Configuring the Wireless Display Sensor

(Model WDS only) . . . . . . . . . . . . . . . . . . .34

Sensor Operations . . . . . . . . . . . . . . . . . . .36

Wireless Sensor Specifications . . . . . . . . . 39

Installation—Electrical . . . . . . . . . . . . . . . . . . .41

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Electrical Wiring . . . . . . . . . . . . . . . . . . . . .41

Electric Heat Units . . . . . . . . . . . . . . . . . . . 41

Heating Coils with Direct Expansion Cooling

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

ECM Overview and Setup . . . . . . . . . . . . . . . . 43

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

General Information . . . . . . . . . . . . . . . . . . .43

Trane BLDC Motor . . . . . . . . . . . . . . . . . . .43

ECM Engine Controller . . . . . . . . . . . . . . .43

Standard Adapter Board . . . . . . . . . . . . . .44

CSTI Adapter Board . . . . . . . . . . . . . . . . . .44

Installation and Initial Setup . . . . . . . . . . . .45

Installation and Initial Setup . . . . . . . . . . .45

Adjustment and Configuration of the Engine

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Status Display . . . . . . . . . . . . . . . . . . . . . . .48

Initial Setup and Configuration . . . . . . . . .53

Configuration . . . . . . . . . . . . . . . . . . . . . . . . .53

Configuring the ECM Engine Controller . .53

Configuring the ECM Engine Board . . . . .58

Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Setting the Time Clock . . . . . . . . . . . . . . . .63

Wired Controllers—Communication Wiring 65

Wiring Installation (Tracer ZN520) . . . . . . .65

Device Addressing . . . . . . . . . . . . . . . . . . .65

Recommended Communication Wiring Prac-

tices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Wiring Installation (Tracer UC400) . . . . . . .65

Wiring Overview Outline . . . . . . . . . . . . . .66

UV-SVN02C-EN 5

General Instructions . . . . . . . . . . . . . . . . . 66

BACnet MS/TP Link . . . . . . . . . . . . . . . . . 66

Power Supply . . . . . . . . . . . . . . . . . . . . . . 67

Pre-Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Pre-Start-up Checklist . . . . . . . . . . . . . . . 69

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Tracer ZN520 Unit Startup . . . . . . . . . . . . 70

Tracer UC400 Unit Startup . . . . . . . . . . . 70

General Information . . . . . . . . . . . . . . . . . 70

Fan Mode Switch Operation . . . . . . . . . . 70

Tracer ZN520 Operation . . . . . . . . . . . . . 70

UC400 Controller Operation . . . . . . . . . . 71

Tracer ZN520 Sequence of Operation . . . 71

Cooling Operation (Tracer ZN520) . . . . . 72

Fan Mode Operation (Tracer ZN520) . . . 73

UC400 Sequence of Operation . . . . . . . . . 78

Power-up Sequence (UC400) . . . . . . . . . 78

Random Start (UC400) . . . . . . . . . . . . . . . 78

Occupancy Modes (UC400) . . . . . . . . . . . 78

Timed Override Control (UC400) . . . . . . 79

Zone Temperature Control (UC400) . . . . 79

Discharge Air Tempering (UC400) . . . . . 80

Heating or Cooling Mode (UC400) . . . . . 80

Entering Water Temperature Sampling Func-

tion (UC400) . . . . . . . . . . . . . . . . . . . . . . . 80

Fan Operation (UC400) . . . . . . . . . . . . . . 80

Exhaust Control (UC400) . . . . . . . . . . . . . 81

Valve Operation (UC400) . . . . . . . . . . . . . 81

Modulating Outdoor/Return Air Damper

(UC400) . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Two-position Control Of A Modulating Out-

door Air Damper (UC400) . . . . . . . . . . . . 83

Electric Heat Operation (UC400) . . . . . . . 83

Dehumidification Operation (UC400) . . . 83

Peer-to-peer Communication (UC400) . . 83

Unit Protection Strategies (UC400) . . . . . 83

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Service Access . . . . . . . . . . . . . . . . . . . . . 85

Periodic Maintenance . . . . . . . . . . . . . . . 85

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Removal of the Drain Pan . . . . . . . . . . . . .85

Removal of the Fanboard and Coil Cleaning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Lubrication: Fan Shaft . . . . . . . . . . . . . . . .86

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Modulating Valves (3-Wire Floating) . . . .87

Preventive Maintenance . . . . . . . . . . . . . . . .87

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Troubleshooting Checklist . . . . . . . . . . . . .88

Output Testing and Diagnostics (Tracer

ZN520)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Output Testing and Diagnostics (UC400) . .93

Output Testing (UC400) . . . . . . . . . . . . . . .93

Diagnostics (UC400) . . . . . . . . . . . . . . . . . 93

Troubleshooting (Wireless Controls) . . . . .94

Troubleshooting (Tracer ZN520) . . . . . . .100

Troubleshooting (UC400) . . . . . . . . . . . .101

Troubleshooting (ECM) . . . . . . . . . . . . . .103

General Information (ECM) . . . . . . . . . . .104

Troubleshooting Information (ECM) . . .104

Replacing ECM Components . . . . . . . . . . . .106

Circuit Modules Replacement Notes/Work In-

structions . . . . . . . . . . . . . . . . . . . . . . . . .107

Softsetting the IMC Address of an ECM En-

gine Module . . . . . . . . . . . . . . . . . . . . . . . 107

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Wallboxes . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

General Instructions . . . . . . . . . . . . . . . . .109

Installation in Masonry Walls . . . . . . . . .111

Installation in Curtain Walls . . . . . . . . . .111

6 UV-SVN02C-EN

Model Number Descriptions

Digit 1, 2, 3 — Unit

Configuration

HUV = Horizontal Unit Ventilator

Digit 4 — Development

Sequence

C = Third Generation

Digit 5, 6, 7 — Development

Sequence

075 = 750 CFM

100 = 1000 CFM

125 = 1250 CFM

150 = 150 0 CFM

200 = 2000 CFM

Digit 8 — Unit Incoming Power

Supply

1 = 120V/60/1

2 = 208V/60/1

3 = 208V/60/3

4 = 240V/60/1

5 = 240V/60/3

6 = 277V/60/1

8 = 480V/60/3-Phase 4-Wire Power

Supply

Digit 9 — Motor

0 = Free Discharge ECM

4 = Free Discharge ECM, Low

Acoustics

7 = Free Discharge ECM, Low FLA

Option

N = Free Discharge, Low Acoustics,

Low FLA

A = High Static ECM

E = High Static ECM, Low Acoustics

H = High Static ECM, Low FLA

Option

K = High Static ECM, Low Acoustics,

Low FLA

Digit 10, 11 — Design Sequence

** = Design Sequence

Digit 12, 13 — Coil Letter

Designation

(Single Coil Options)

AA = 2 R, 12 FPI CW/HW Changeover

AB = 2 R, 16 FPI CW/HW Changeover

AC = 3 R, 12 FPI CW/HW Changeover

AD = 4 R, 12 FPI CW/HW Changeover

AE = 4 R, 16 FPI CW/HW Changeover

H1 = 1 R, 12 FPI Heating Coil

H2 = 1 R, 14 FPI Heating Coil

H3 = 1 R, 16 FPI Heating Coil

H4 = 2 R, 12 FPI Heating Coil

H5 = 2 R, 14 FPI Heating Coil

H6 = 2 R, 16 FPI Heating Coil

K1 = 1 R Low Capacity Steam Coil

K2 = 1 R High Capacity Steam Coil

E4 = 4 Element Heating Only Coil

E6 = 6 Element Heating Only Coil

E8 = 8 Element Heating Only Coil

G0 = 2 R, 12 FPI DX Coil

(Coupled Coil Options)

DA = 1 R, 12 FPI HW Coil with 2 R,

12 FPI CW Coil

DC = 1 R, 12 FPI HW Coil with 2 R,

14 FPI CW Coil

DD = 1 R, 12 FPI HW Coil with 3 R,

12 FPI CW Coil

DE = 1 R, 14 FPI HW Coil with 3 R,

14 FPI CW Coil

DK = 1 R Steam with 3 R CW Coil

X3 = 3 Element Elec Coil with

3 R CW Coil (2 R on Sz 125)

X4 = 4 Element Elec Coil with

3 R CW Coil (2 R on Sz 125)

X6 = 6 Element Elec Coil with

3 R CW Coil (2 R on Sz 125)

GK = 1 R Steam Coil with 2 R DX Coil

GA = 1 R Heating coil with 2 R DX Coil

G3 = 3 Element Elec Heat Coil with

2 R DX Coil

G4 = 4 Element Elec Heat Coil with

2 R DX Coil

G6 = 6 Element Elec Heat Coil with

2 R DX Coil

R1 = 3 R, 12 FPI CW Coil with 1 R,

12 FPI HW Coil

R2 = 3 R, 14 FPI CW Coil with 1 R,

12 FPI HW Coil

Digit 14 — Coil Connections

A = Right Hand Supply

B = Left Hand Supply

C = Left Hand Cool/Right Hand Heat

D = Right Hand Cool/Left Hand Heat

Digit 15 — Control Types

0 = Unit-Mounted Speed Switch

Q = Tracer™ ZN520

R = Tracer ZN520 w/Low Temp

T = Tracer ZN520 w/Time Clock

U = Tracer ZN520 w/Low Temp &

Time Clock

X = Tracer ZN520 ICS w/Fan Status

Y = Tracer ZN520 ICS w/Low Temp &

Fan Status

8=CSTI

9 = CSTI w/Low Temp

L = Tracer UC400

M = Tracer UC400 w/Time Clock

Digit 16 — Heating/Change Over

Coil Control

0=None

1 = Face & Bypass Damper Actuator

2 = 2-Pipe Face & Bypass Damper

Control

3 = 4-Pipe Face & Bypass Damper

Control & Isolation Valve

4 = Single Stage Electric Heat

Control

5 = Dual Stage Electric Heat

7 = Face & Bypass Damper w/2-Pipe

Control & Isolation Valve

9 = 2-Way 1/2-in. 3.3 CV; 3-Wire Mod

W = 2-Way 1/2-in. 1.9 CV; 3-Wire Mod

G = 2-Way 3/4-in. 4.7 CV; 3-Wire Mod

H = 2-Way 1-in. 6.6 CV; 3-Wire Mod

Z = 3-Way 1/2-in. 1.9 CV; 3-Wire Mod

Q = 3-Way 1/2-in. 3.8 CV; 3-Wire Mod

R = 3-Way 3/4-in. 6.6 CV; 3-Wire Mod

T = Steam: 3-Wire Mod 1/2-in. 1.9 CV

U = Steam: 3-Wire Mod 1/2-in. 4.7 CV

V = Steam: 3-Wire Mod 3/4-in. 8.6 CV

Digit 17 — Cooling Coil Control

0=None

1 = Single Stage DX Controls

A = Field-Supplied Analog Valves

W = 2-Way 1/2-in. 1.9 CV; 3-Wire Mod

G = 2-Way 3/4-in. 4.7 CV; 3-Wire Mod

H = 2-Way 1-in. 6.6 CV; 3-Wire Mod

Z = 3-Way 1/2-in. 1.5 CV; 3-Wire Mod

Q = 3-Way 1/2-in. 3.8 CV; 3-Wire Mod

R = 3-Way 3/4-in. 6.6 CV; 3-Wire Mod

Digit 18 — Damper

Configuration

0 = Field Installed Damper Actuator

1 = 100% Return Air/No Damper or

Actuator

(Modulating ASHRAE Cycle II)

F = RA/OA Damper and Actuator

(2–10 Vdc)

A = RA/OA Damper and Actuator

(3-Point Modulating)

E = RA/OA Damper and Actuator

with Exhaust (3-Point Mod)

(Two Position Control)

D = Damper w/Manual Quad Adjust

Model Number Descriptions

UV-SVN02C-EN 7

Digit 19 — Zone Sensor/Fan

Speed Switch

0 = No Sensor - Unit Mounted Fan

Speed Switch

J = Wall Mt Zone Sensor (OALMH;

Setpoint Dial; On/Cancel)

K = Wall Mt Zone Sensor (OALMH;

Setpoint Dial)

L = UNIT Mt Zone Sensor (OALMH;

Setpoint Dial)

M = Wall Mount Display Sensor

w/Setpoint Adjust

P = Wall Mt Sensor (Setpoint dial;

On/Cancel) w/Unit-Mt Speed

Switch

Q = Wall Mt Sensor (Setpoint Dial)

w/Unit Speed Switch

3 = Wireless Display Sensor

(H-L-A-O)

4 = Wireless Sensor - Ext Adjust

Digit 20 — Inlet Arrangement

A = FA Duct Top/RA Duct Lower Back

B = FA Duct Top/RA Duct Bottom

C = FA Duct Top/RA Bar Grille

Bottom

D = FA Duct Top/RA Open Bottom

E = 100% FA Duct Top

F = FA Duct Upper Back/RA Duct

Lower Back

G = FA Duct Upper Back/RA Duct

Bottom

H = FA Duct Upper Back/RA Bar

Grille Bottom

J = FA Duct Upper Back/RA Open

Bottom (no grille)

K = 100% FA Duct Upper Back

L = 100% RA Duct Lower Back

M = 100% RA Duct Bottom

N = 100% RA Bar Grille Bottom

P = 100% RA Open Bottom (no grille)

Digit 21 — Discharge

Arrangement

1 = Bar Grille Discharge

2 = Duct Collar Discharge 7-1/8 in.

from Top

3 = Duct Collar Discharge 3/4 in.

from Top

4 = Duct Collar Discharge 3-5/8 in.

from Top

5 = Front Double Deflection Grille

Discharge

6 = Front Double Deflection Opening

Only (no grille)

7 = Bottom w/Double Deflection

Grille

Digit 22 — Unit Access Panel

0 = Std. Horizontal Access Panel

1 = Safety Chain/Std. Access Panel

2 = Removable Access Panel

3 = Safety Chain/Removable

Access Panel

Digit 23 — Recessing Flange

0 = No Recessing Flange

1 = Standard Recessing Flange

Digit 24 — Piping Package

0 = No Factory Installed Piping

Package

A = Package 1; Standard Package

C = Package 2; Standard Package

w/Circuit Setter

D = Package 3; Standard Package

w/Strainer and Circuit Setter

Digit 25 — Filter

1 = Throwaway Filter

2 = MERV 8 Filter

3 = MERV 13 Filter

Digit 26 — Color Selection

1 = Deluxe Beige Cabinet

2 = Cameo White Cabinet

3 = Soft Dove Cabinet

4 = Stone Gray Cabinet

5 = Driftwood Gray Cabinet

Digit 27 — Motor Disconnect

0 = No Disconnect

A = Non-Fused Toggle

B = Circuit Breaker

Digit 28 — Control Accessories

0=None

A= C0

2

Sensor

B = Wall Mounted Relative Humidity

Sensor

8 UV-SVN02C-EN

General Information

Unit Description

Configuration. This classroom unit ventilator is

configured in a horizontal (ceiling mount) configuration.

The units range from 750 cfm to 2000 cfm for the

horizontal configuration.

Cabinet. The units are constructed of 14- and 16-gauge

zinc coated steel. All steel surfaces are cleaned,

phosphatized, rinsed and dried before application of final

finish paint. The paint is applied by an electrostatic powder

spray system, minimum thickness of 1.5 mil which results

in an appliance grade finish.

Front Panels. The front panels are retained by Allen

wrench operated locks which open with a 180-degree

rotation.

The bottom panel is constructed of heavy gauge material.

End Pockets. Unit Ventilators are equipped with end

pockets to provide field installation of valves, piping, and

controls. The units have a large pipe access opening in

both end pockets and large knockouts for piping and

electrical connections. All electrical connections are made

in the left-hand end pocket, with exception of units

equipped with the electric heating coil option.

Drain Pan. The drain pan is positively sloped in all planes

to assure proper drainage and help eliminate the risk of

microbial growth. To help ensure indoor air quality, the

drain pan is insulated on the bottom to help prevent

condensate formation. The drain pan can be easily

removed for cleaning purposes. The drain pan is drilled-

out and pitched toward the cooling coil connection during

assembly per model number selection.

Fanboard. The fanboard assembly is acoustically

designed in a single, rigid assembly that includes the fans,

fan housing, bearings, fan shaft and motor. The fan motor

is mounted on the fanboard. The fanboard is made from

14-gauge galvanized steel to resist corrosion and increase

strength.

Electrically Commutated Motor (ECM). All motors

are brushless DC (BLDC)/electronically commutated

motors (ECM) factory-programmed and run-tested in

assembled units. The motor controller is mounted in a

control box with a built-in integrated user interface and

LED tachometer. If adjustments are needed, motor

parameters can be adjusted through momentary contact

switches accessible without factory service personnel on

the motor control board.

Motors will soft-ramp between speeds to lessen the

acoustics due to sudden speed changes. Motors can be

operated at three speeds or with a field-supplied variable

speed controller. The motor will choose the highest speed

if there are simultaneous/conflicting speed requests.

All motors have integral thermal overload protection with

a maximum ambient operating temperature of 104°F and

are permanently lubricated. Motors are capable of starting

at 50 percent of rated voltage and operating at 90 percent

of rated voltage on all speed settings. Motors can operate

up to 10 percent over voltage.

Filter. Standard units are equipped with a single 1-inch

thick filter (MERV 8) that is accessible without removal of

the unit front panel. Filter options include throwaway,

MERV 8 and MERV 13 options.

OA/RA Damper. Trane unit ventilators are equipped

with dual blade type mixing damper to ensure proper

modulation and mixing of return and outdoor air designed

in accordance to ARI 840. A splitter is placed between the

damper blades to separate the fresh-air and return-air

compartments to prevent draft blow-through.

Options

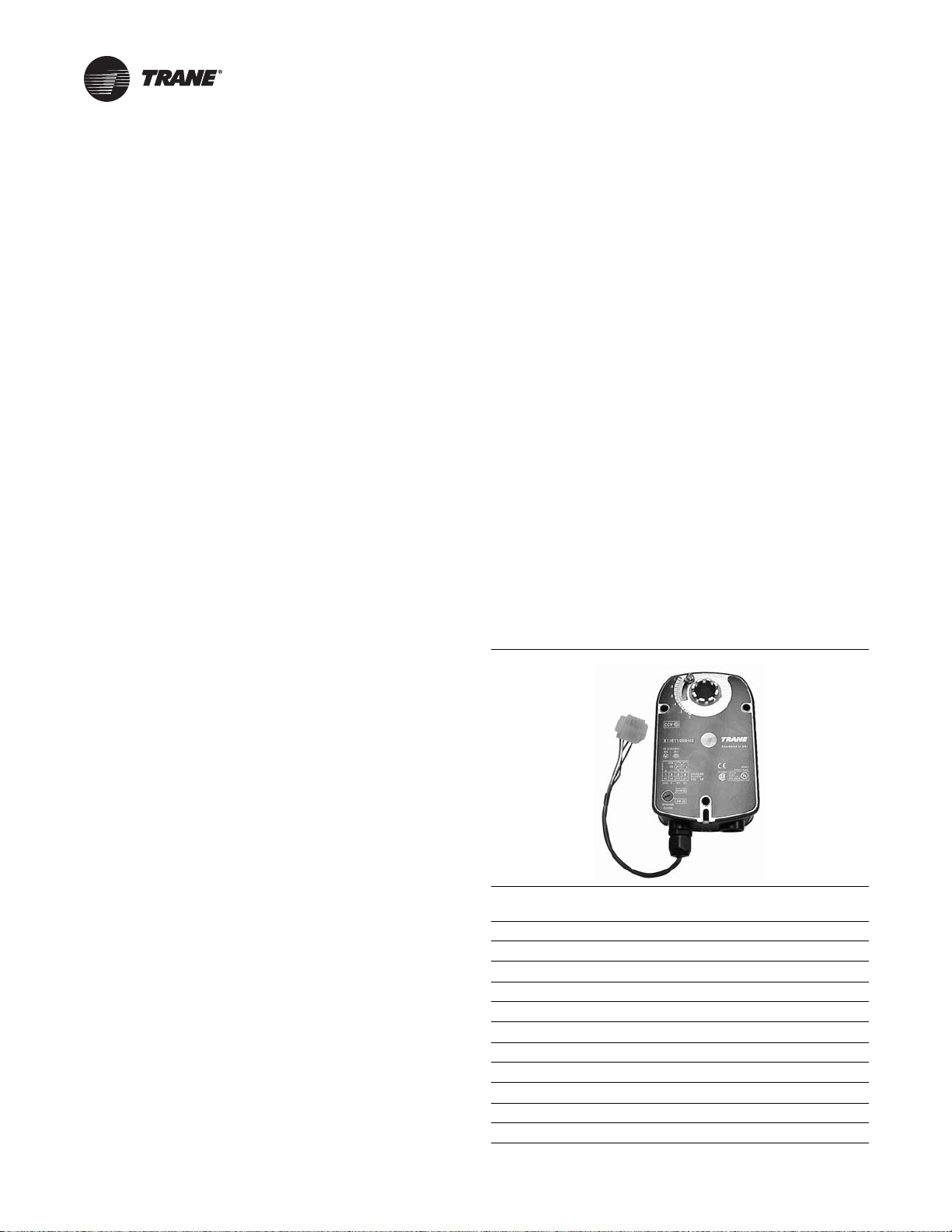

OA/RA Actuator (Option). The OA/RA actuator

provides true spring return operation for positive close-off

of the OA/RA damper. The spring return system of the

actuator closes the outside damper if power is lost to the

building. When ordered with factory mounted controls,

the actuator is 3-point floating. A 2 to 10 Vdc actuator is

also available when other than Trane controls is required.

See Ta b l e 1 , p . 8 for technical data of the OA/RA actuator.

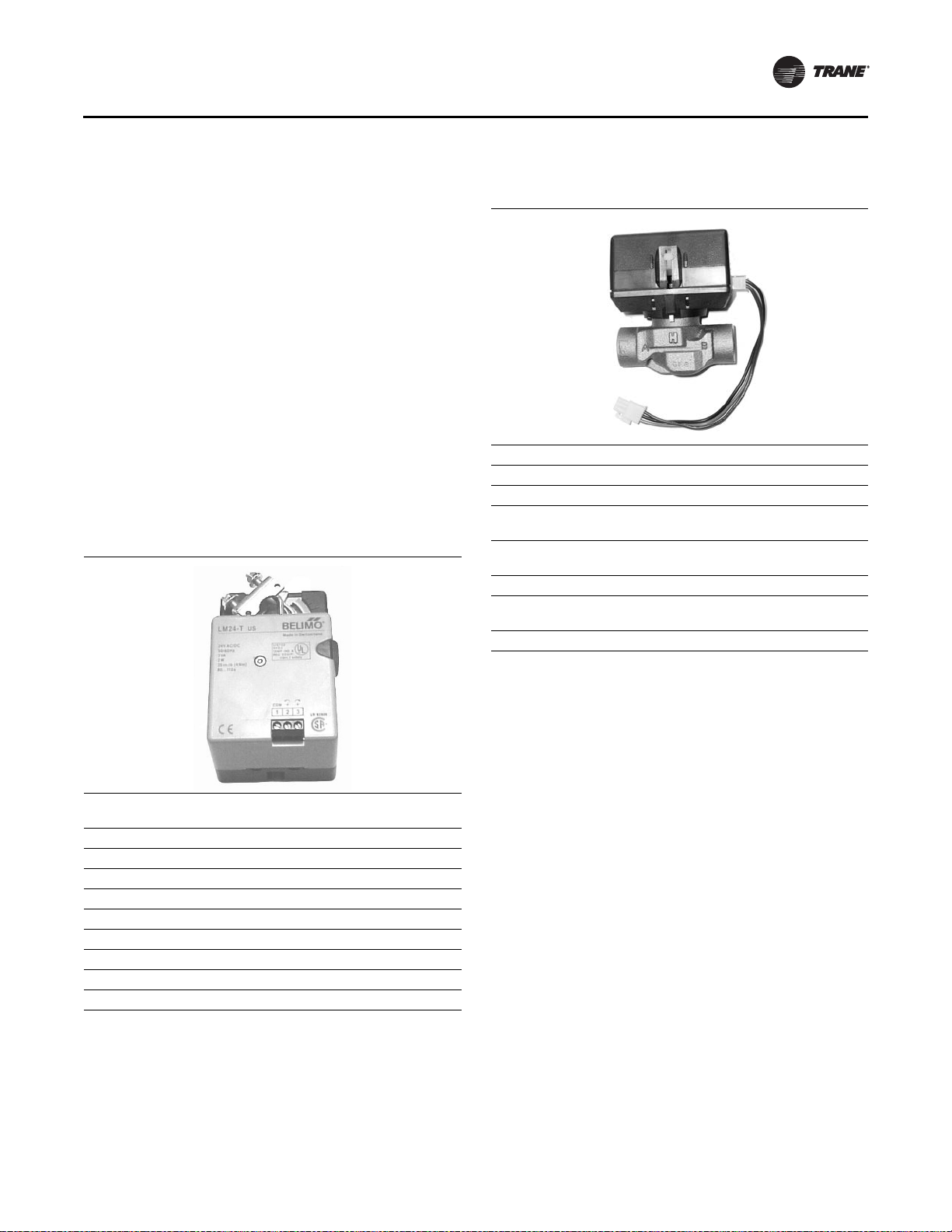

Table 1. Technical data for OA/RA actuator

Power Supply 24 Vac ±20% 50/60Hz

24 Vac ±10%

Power Running: 2.5W

Consumption Holding: 1W

Transformer Sizing 5VA (class 2 power source)

Overload Electronic throughout

Protection 0- to 95-degree rotation

Control Signal 2–10 Vdc 3 point floating w/ Trane controls

Rotation Angle 95-degree max. Adjustable w/mechanical stop

Torque 35-inch/lb

Rotation Direction Spring return reversible w/CW/CCW mounting

Position Indication Visual indicator, 0- to 95-degrees

Noise Level Running: 30dB

General Information

UV-SVN02C-EN 9

Face and Bypass (Option). The face and bypass option

consist of an actuator, damper blade and 2-position water

valve (option).

During bypass mode, the damper moves to prevent air

from traveling through the coil. The damper blade is

tightly sealed to eliminate heat pickup while in the full

bypass mode.

A two-position isolation valve control (option) further

enhances this system by closing off all water flow to the

coil during full bypass operation. Two-pipe main steam

systems utilize the face and bypass as part of the standard

operation and may incorporate the optional isolation

valve.

Face and Bypass Actuator (Option). The face and

bypass damper actuator incorporates a direct couple

design for the horizontal configurations. The actuator is

provided with electronic protection against overload. It

does not contain, nor require a limit switch. When reaching

the damper end position, the actuator automatically stops.

The gears can be manually disengaged with a button on

the actuator housing. See Tab l e 2 for technical data.

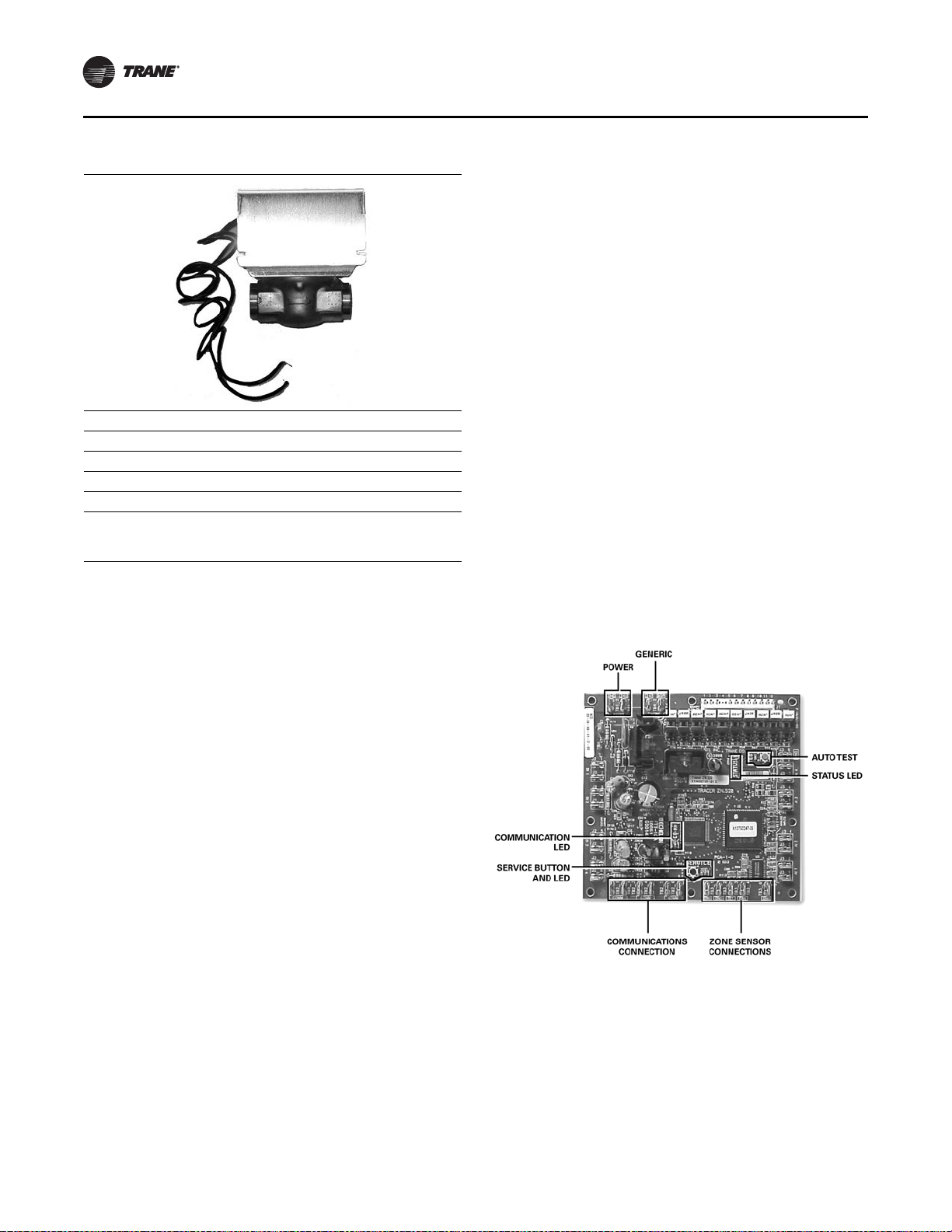

Modulating Water Valves (Option). The modulating

control valve option provides optimum control of hot and

chilled water flow in various heating and cooling

applications. They are designed to provide sinusoidal

valve actuator travel and operate silently, resisting water

hammer.

The actuator on the valve is a 24V, 3-point floating type.

See Ta b l e 3 , p . 9 for more technical data.

Isolation Valves (Option). The isolation valves are two

position 24V, spring return type. They provide added

control in heating and cooling applications when used in

conjunction with the face and bypass damper.

On heating coils and two-pipe change-over applications,

the valve is a normally open type to prevent the coil from

freezing in case of power loss.

For cooling, the valve is normally closed and opens when

there is a call for cooling. See Table 4, p. 10 for more

technical data.

Table 2. Technical data for face and bypass actuator

Power Supply 24 Vac ±20% 50/60Hz

24 Vac ±10%

Power Consumption 2W

Transformer Sizing 3VA (class 2 power source)

Manual Override External push button

Control Signal 3-point floating w/Trane controls

Rotation Angle 95-degree max. Adjustable w/mechanical stop

Torque 35-inch/lb

Rotation Direction Reversible with switch L/R

Position Indication Clip-on indicator

Noise Level Less than 35dB

Table 3. Technical data for modulating water valves

Power Supply 24V - 50/60 Hz

Power Consumption 4W

Maximum Duty Cycle 15%

Operating Ambient Temperature 0°C to 65°C

32°F to 150°F

Min./Max. Fluid Temperatures 1°C to 95°C

34°F to 203°F

Operating Pressure Differential Max. - 4 bar (60 psi)

Pressure Rating Static - 20 bar (300 psi)

Burst - 100 bar (1500 psi)

Flow Characteristics Linear

General Information

10 UV-SVN02C-EN

Unit Ventilator Controls

Options

Field-Installed Controls (Option). The unit comes

equipped with a fan speed switch, damper blade (only),

and an optional low temperature detection.

Customer Supplied Terminal Interface (CSTI)

(Option).

Units containing the end device control design

will incorporate a pre-wired, selected control components

to a terminal strip for wiring a field-provided controller and

temperature sensor.

Note: For controller operation malfunction of any non-

Trane, field installed controls, consult the literature

or technical support of the controls manufacturer.

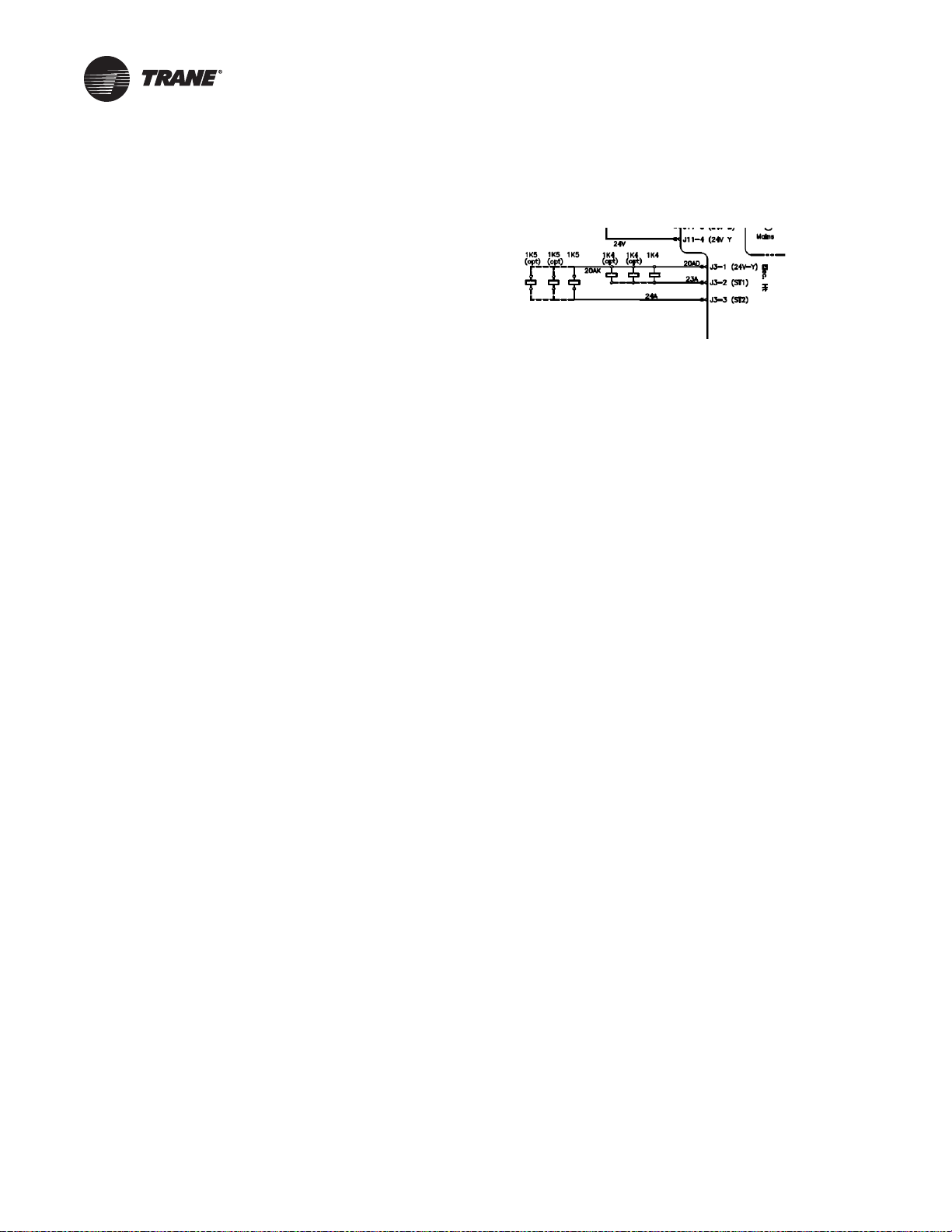

Tracer ZN520 Control Package (Option). The Tracer

ZN520 electronic digital controller is a factory installed,

tested and commissioned LonTalk

®

certified design. It

may be used in a stand-alone control scheme, or as part of

a building automation system. The controller is pre-wired

to Trane selected control components best suited for room

comfort. For more information on the Tracer ZN520 unit

controller operation and service issues, refer to

CNT-SVX04A-EN (Installation, Operation, and

Programming Guide: Tracer ZN520 Unit Controller), or the

most recent version.

Tracer UC400 Control Package (Option). The Tracer

UC400 electronic digital controller is a factory installed,

tested and commissioned BACnet

®

certified design. The

Tracer UC400 operates as a single zone VAV controller and

ramps fan speed based on space load. It may be used in a

stand-alone control scheme, or as part of a building

automation system. The controller is mounted, pre-wired,

and pre-programmed to selected control components

best suited for room comfort. For more information on the

Tracer UC400 unit controller operation and service issues,

refer to BAS-SVX48B-EN (Installation, Operation, and

Table 4. Technical data for isolation water valves

Power Supply 24V - 50/60 Hz

Power Consumption 5W

Max. Fluid Temp. 200°F / 94°C

Min. Fluid Temp. 34°F / 1°C

Max. Operating Pressure 300 psi

Max. Close-off Pressure 1/2 in.= 30 psi

3/4 = 20 psi

1 = 15 psi

Figure 1. Tracer ZN520 unit controller

General Information

UV-SVN02C-EN 11

Programming: Tracer UC400 Programmable Controller),

or the most recent version.

When Trane controls are ordered for an installation, the

controls are shipped already installed and factory-tested

to ensure proper operation at start-up.

Notes:

• For more details on the ZN520 unit controller option or

operation and service/replacement issues, please refer

to CNT-SVX04A-EN (Installation, Operation, and

Programming Guide: Tracer ZN520 Unit Controller), or

the most recent version.

• For more details on the UC400 unit controller option or

operation and service/replacement issues, refer to

BAS-SVX48B-EN (Installation, Operation, and

Programming: Tracer UC400 Programmable

Controller), or the most recent revision.

Automatic Controls

Regardless of type of controls, all systems provide a

sequence of operation designed to provide rapid warm-up

of the room and increase ventilation while offsetting

overheating.

In addition, air conditioning installations will usually

provide a means of system changeover from heating to

cooling as well as provisions for drawing a pr e-determined

amount of outside air into the room.

Unit Switch

The unit “On-Off” switch, provided by Trane, is typically

housed in the control box mounted in the left hand end

pocket immediately below the discharge grille.

When Tracer ZN520 or Tracer UC400 unit controllers are

used, the unit switch is located on the switch module in the

end pocket behind the front panel rather than below the

grille.

Figure 2. Tracer UC400 unit controller

12 UV-SVN02C-EN

ECM Application Notes

The new Trane BLDC system has some notable differences

to traditional designs.

RPM Mode

The motors are programmed from the factory to run in

rpm mode and will not change rpm based on external

static pressure, except at the performance limits of the

motor/controller. For ducted units, the units are shipped

with the rpm set for 0.2 in. ESP for High, Medium, and Low

speeds. The speeds can for high, medium, and low

operation, but should not be changed for the electric heat

actuation speeds.

Generally, the fans deliver less cfm for the same rpm, if the

static is increased and the power will decrease. The fan will

deliver more cfm for the same rpm, if the static is

decreased and the fan power will increase. A unit with high

static configuration should not be used to free-deliver air

(i.e., with no ducting attached).

Field Power Wiring

Note: This product uses an electronic variable speed

motor control, which includes a line reactor to

minimize power line harmonic currents. It is

recommended that good wiring practices be

followed to manage building electrical power

system harmonic voltages and currents to avoid

electrical system problems or other equipment

interaction.

Performance Boundaries

While the speeds of the fan motors can be adjusted, never

program a fan speed higher than 1700 rpm, or lower than

450 rpm. In many cases, units configured for high-static

operation will not achieve the desired rpm if the ESP of the

unit is too low, or the unit is allowed to “free-discharge.”

The ECM engine contains settings that will limit the output

power of the motor under these overload conditions. If the

motors cannot achieve rpm close to the target for a specific

period of time, the unit will disable electric heat and fan-

status indicators.

MCA/MFS and Power Draw

The Trane BLDC motors have variable output but are

shipped at specific settings to deliver proper performance

and reliability. The power draw indicated in the catalogue

indicates the power consumed when applied properly (as

shipped and with the nominal ESP applied). However, the

nameplate of the unit indicates the maximum input draw

of the motor, as the motor settings can be changed to draw

more power.

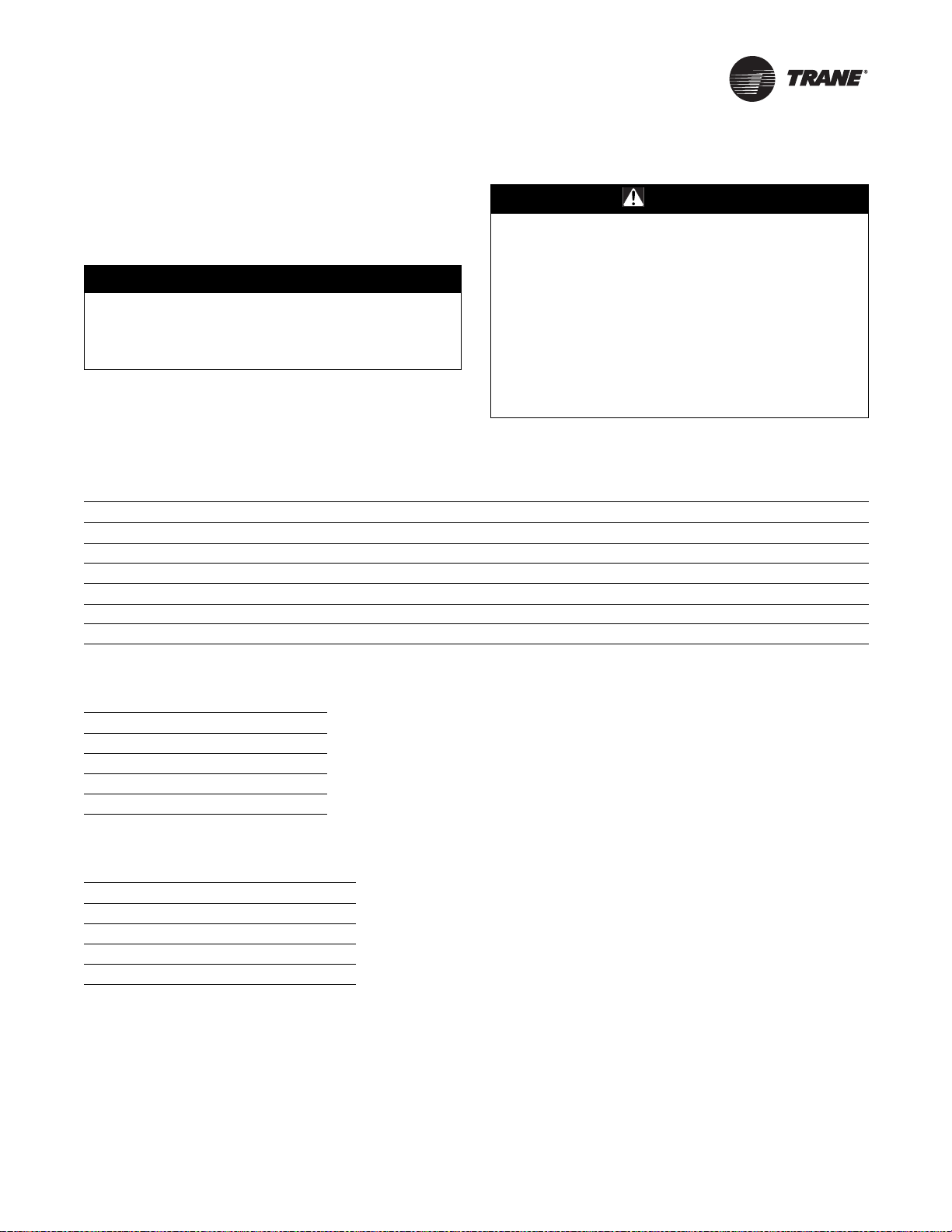

Electric Heat Relays

For quiet operation, the new BLDC units employ power

relays instead of definite purpose contactors for electric

heat actuation. The coils of multiple relays are hooked in

parallel to simulate a multi-pole contactor, as shown in

Figure 3. In Figure 3, two sets of three relays are used to

perform the function of a two 3-pole contactors.

Troubleshooting Other Unit Functions

In some cases, the normal or abnormal operation of the

BLDC system may interact with other components in the

system. Generally, verification of the engine and adapter

boards’ wiring and configuration should be checked if

there are unexplained abnormalities in other areas of the

unit:

1. Valve operation

2. Electric Heat operation

3. Changeover sensor operation

4. Damper operation

5. Condensate overflow switch

A high degree of protection is provided on electric heat

u

nits. If electric heat fails to actuate, it may be because of

one of the following events:

1. Fans are failing to meet target speed. If a second motor

is not present, all settings for speeds for Motor 2

should be set to 0000.

2. Hot water may be available in the changeover coil.

3. The connection to analogue input 1 on the Tracer ZN

controlle

r may be reversed in polarity.

4. Target speeds for motor

s may be set too high:

a. The parameter may be set incorrectly.

b. The

parameter may be set incorrectly.

Figure 3. Sample arrangement: electric heat relay

UV-SVN02C-EN 13

Dimensions and Weights

Unit Location and Clearances

Locate the unit in an indoor area. The ambient

temperature surrounding the unit must not be less than

45°F. Do not locate the unit in areas subject to freezing.

Attention should be given to service clearance and

technician safety. The unit should contain enough space

for service personnel to perform maintenance or repair.

Provide sufficient room to make water, and electrical

connection(s).

A 36-inch clearance at the unit front is sufficient for

maintenance and service of the equipment.

NOTICE:

Equipment Damage!

Do not locate the unit in areas subject to freezing. Pipes

could burst at lower temperature resulting in

equipment damage.

WARNING

Electrocution and Fire Hazards with

Improperly Installed and Grounded Field

Wiring!

Improperly installed and grounded field wiring poses

FIRE & ELECTROCUTION hazards. To avoid these

hazards, you MUST follow requirements for field wiring

installation and grounding as described in NEC and

your local/state electrical codes. All field wiring MUST

be performed by qualified personnel.

Failure to follow these requirements could result in

death or serious injury.

Table 5. Weights and measurements: horizontal unit ventilators

Unit Size 075 100 125 150 200

Unit Length (in.) 70-1/4 82-1/4 94-1/4 106-1/4 106-1/4

Unit Height (in.) 16-5/8 16-5/8 16-5/8 16-5/8 17-5/8

Unit Width (Front Discharge) (in.) 35-5/8 35-5/8 35-5/8 35-5/8 43-1/8

Unit Width (Bottom Discharge) (in.) 48-3/4 48-3/4 48-3/4 48-3/4 57-1/4

Shipping Weight (lb)

(a)

340* 375* 435* 500* 600*

Filter Size (inches-actual) 41-1/2 x 15-1/4 x 1 53-1/2 x 15-1/4 x 1 65-1/2 x 15-1/4 x 1 77-1/2 x 15-1/4 x 1 77-1/2 x 15-1/4 x 1

(a) Working weight is approximately 10% less than shipping weight. Trane recommends 1/4-inch rods for hanging suspension

Table 6. Control methodology

Fan Speed

FSS 3 or infinite

(a)

(a)With a field-supplied 2–10 Vdc controller.

CSTI 3 or infinite

(a)

Tracer ZN520 3

Tracer UC400 Infinite

Table 7. Control sequences

Fan Speeds

DX operation

(a)

(a) Fan speed during sequence operation.

1

Electric heat operation

(a)

1

Sidewall Exhaust

(b)

(b)Unit Ventilator when operating with option.

2

ERSA

(b)

2

Dimensions and Weights

14 UV-SVN02C-EN

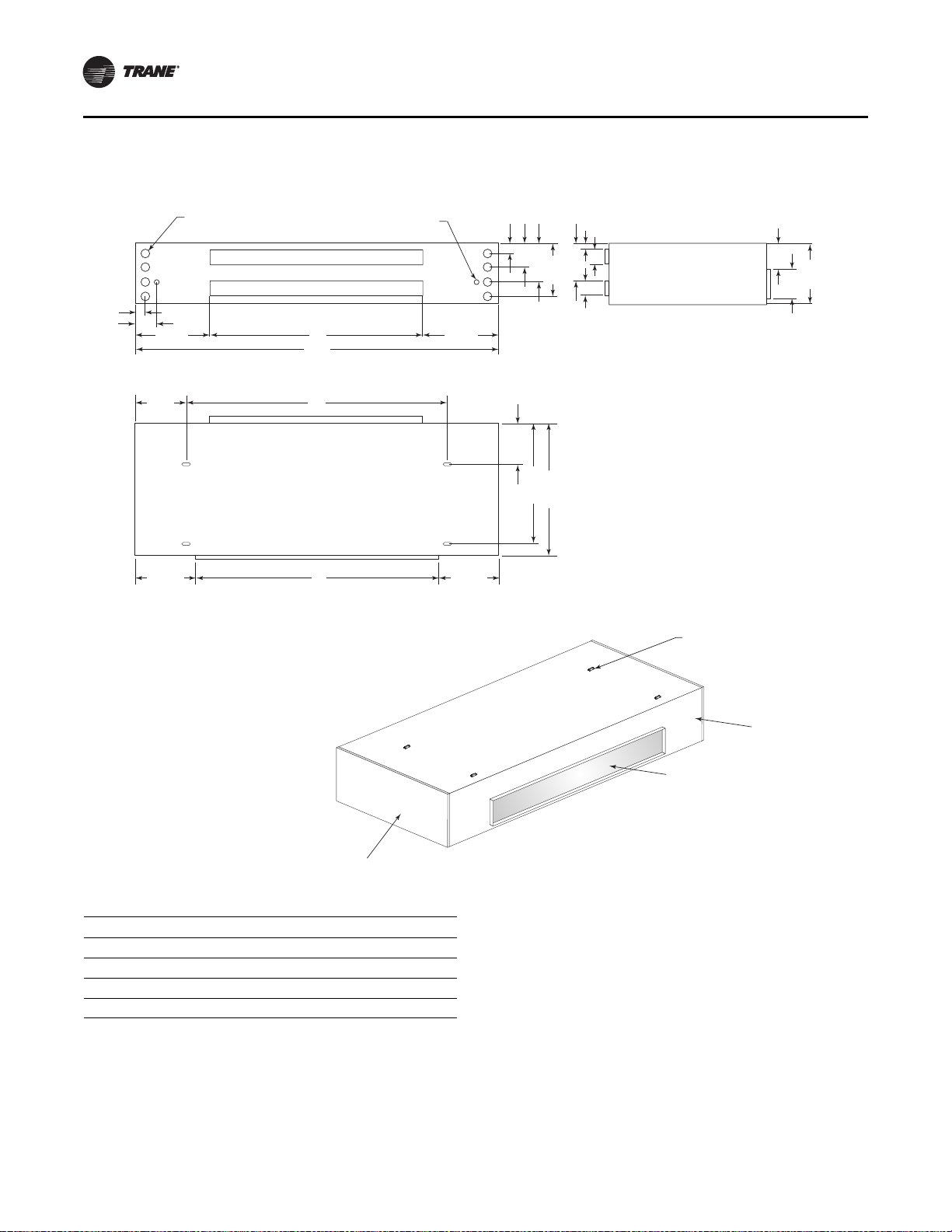

Figure 4. Horizontal unit ventilator with ducted front discharge dimensional data; sizes 075–150 (dimensions in

inches)

3"

4"

4"

1 3/4"

10 1/8"

6 1/2"

10 1/2"

32 1/2"

35 5/8"

11"

14 1/2"

16 5/8"

7 1/8"

7 7/8"

B17 1/8"

12 1/8"

13 1/2" 13 1/2"

4 7/8"

2 3/8"

2"-DIA K.O.

FOR PIPING

7/8"-DIA K.O.

FOR ELECTRICAL

17 1/8"

A

C

D

F.A. UPPER BACK

R.A. LOWER BACK

BACK VIEW SIDE VIEW

TOP VIEW

NOTE:

WHEN ELECTRIC HEAT IS PRESENT, ALL POWER

CONNECTIONS ARE MADE IN THE RIGHT HAND

END POCKET. ON ALL OTHER CONFIGURATIONS,

POWER CONNECTIONS ARE MADE IN THE LEFT

HAND END POCKET.

ISO VIEW

7/8" x 2" SLOTS

FOR HANGING BRACKETS

RIGHT HAND

END POCKET

LEFT HAND

END POCKET

DISCHARGE

Size A B C D

75 70-1/4 36 46 43-1/4

100 82-1/4 48 58 55-1/4

125 94-1/4 60 70 67-1/4

150 106-1/4 72 82 79-1/4

Dimensions and Weights

UV-SVN02C-EN 15

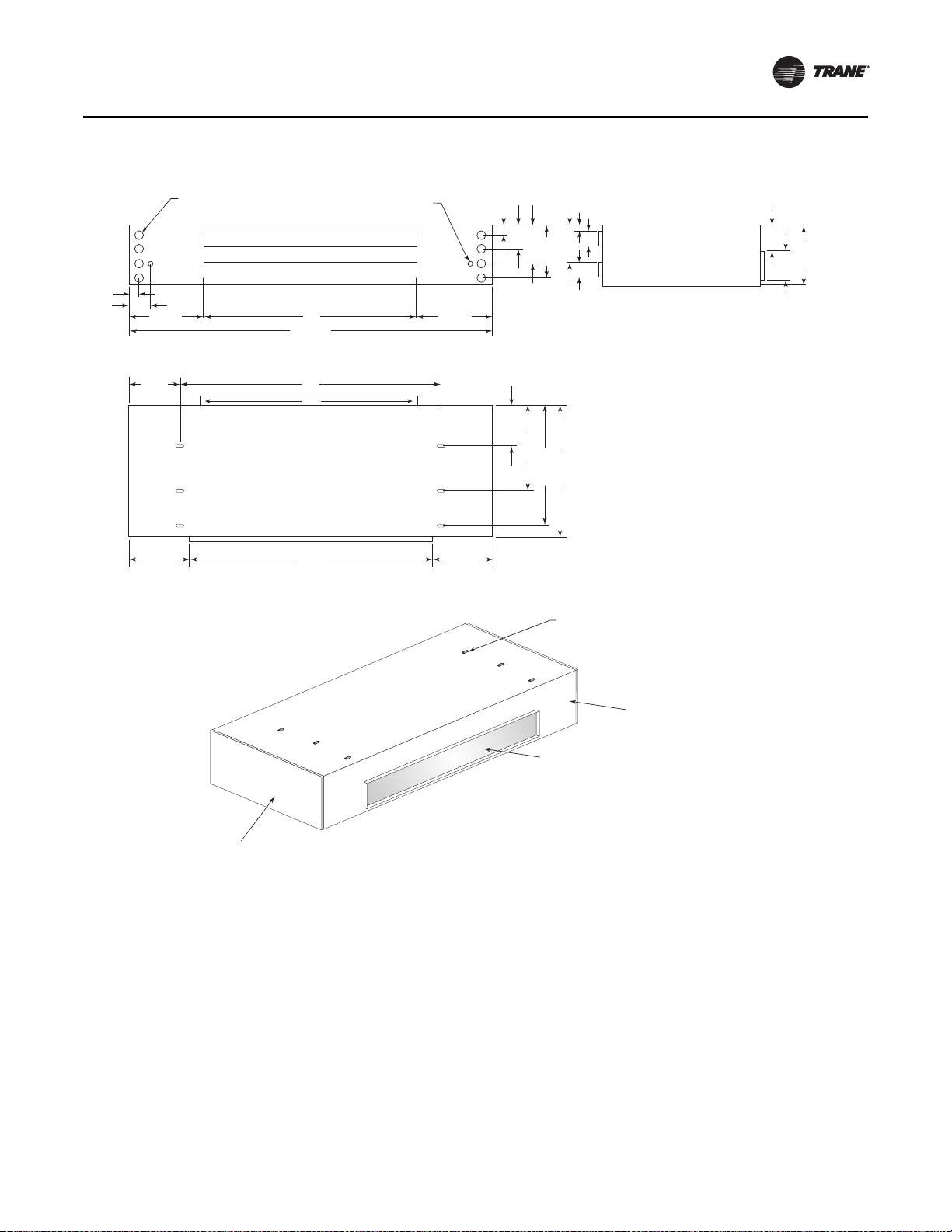

Figure 5. Horizontal unit ventilator with ducted front discharge dimensional data; size 200 (dimensions in inches)

4"

5"

5"

2 3/4"

10 1/8"

7 1/2"

11 1/2"

39 1/2"

26 1/2"

43 1/8"

13 1/2"

15 1/2"

17 5/8"

6 1/8"

9 7/8"

72"17 1/8"

12 1/8"

13 1/2" 13 1/2"

4 7/8"

2 3/8"

2"-DIA K.O.

FOR PIPING

7/8"-DIA K.O.

FOR ELECTRICAL

17 1/8"

106 1/4"

82"

79 1/4"

F.A. UPPER BACK

R.A. LOWER BACK

BACK VIEW SIDE VIEW

TOP VIEW

ISO VIEW

7/8" x 2" SLOTS

FOR HANGING BRACKETS

RIGHT HAND

END POCKET

LEFT HAND

END POCKET

DISCHARGE

NOTE:

WHEN ELECTRIC HEAT IS PRESENT, ALL POWER

CONNECTIONS ARE MADE IN THE RIGHT HAND

END POCKET. ON ALL OTHER CONFIGURATIONS,

POWER CONNECTIONS ARE MADE IN THE LEFT

HAND END POCKET.

72"

Dimensions and Weights

16 UV-SVN02C-EN

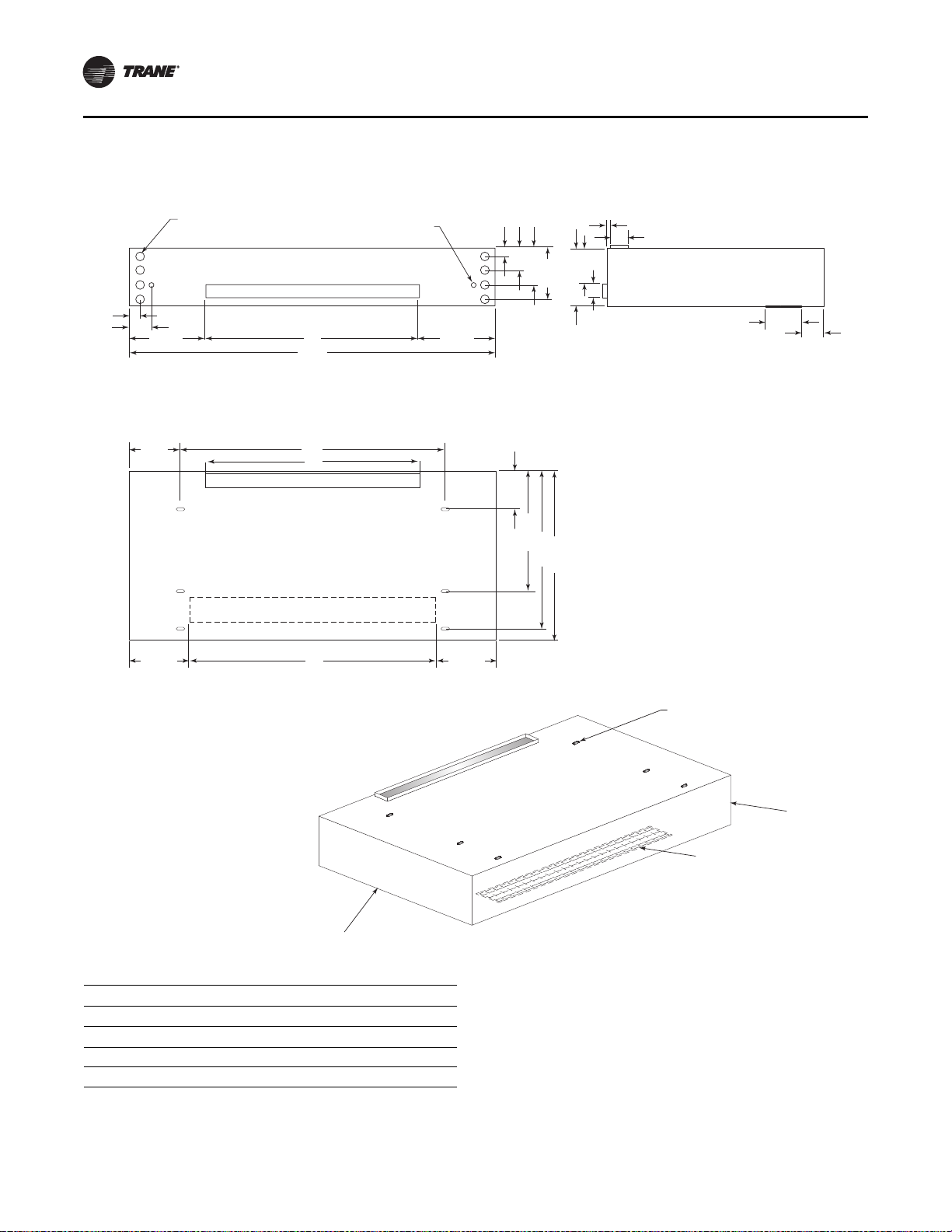

Figure 6. Horizontal unit ventilator with double deflection discharge dimensional data; sizes 075–150 (dimensions in

inches)

3"

6 1/2"

10 1/2"

14 1/2"

B

R.A. LOWER BACK

17 1/8"

4 7/8"

2 3/8"

2"-DIA K.O.

FOR PIPING

7/8"-DIA K.O.

FOR ELECTRICAL

17 1/8"

3/4"

7 1/4"

5 1/8"

4"

A

4"

16 5/8"

10 1/8"

32 3/4"

46"

48 3/4"

11"

12 1/8"

13 1/2" 13 1/2"

C

D

BACK VIEW SIDE VIEW

TOP VIEW

NOTE:

WHEN ELECTRIC HEAT IS PRESENT, ALL POWER

CONNECTIONS ARE MADE IN THE RIGHT HAND

END POCKET. ON ALL OTHER CONFIGURATIONS,

POWER CONNECTIONS ARE MADE IN THE LEFT

HAND END POCKET.

ISO VIEW

7/8" x 2" SLOTS

FOR HANGING BRACKETS

RIGHT HAND

END POCKET

LEFT HAND

END POCKET

BOTTOM DISCHARGE

B

Size A B C D

75 70-1/4 36 46 43-1/4

100 82-1/4 48 58 55-1/4

125 94-1/4 60 70 67-1/4

150 106-1/4 72 82 79-1/4

Dimensions and Weights

UV-SVN02C-EN 17

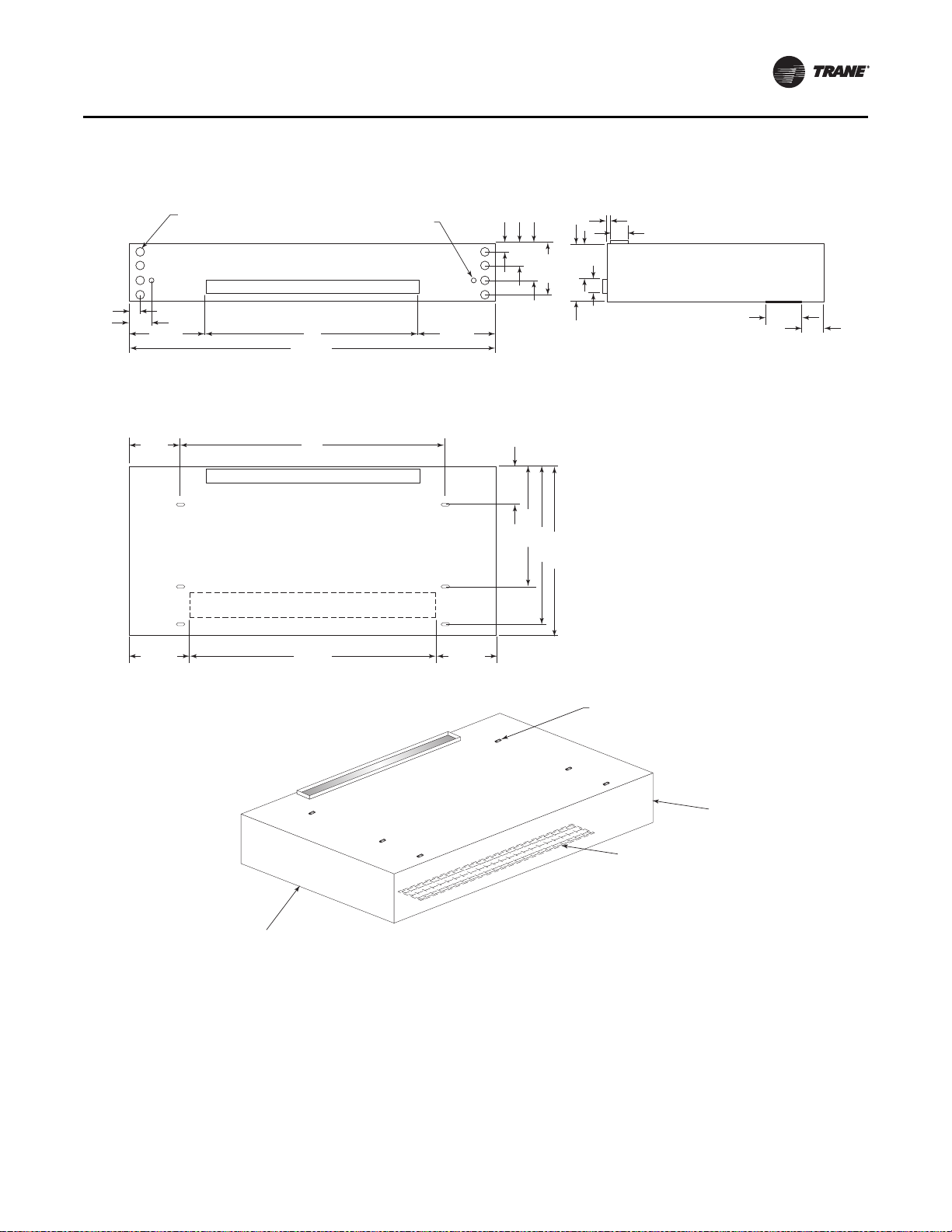

Figure 7. Horizontal unit ventilator with double deflection discharge dimensional data; size 200 (dimensions in

inches)

4"

7 1/2"

11 1/2"

15 1/2"

72"

R.A. LOWER BACK

17 1/8"

4 7/8"

2 3/8"

2"-DIA K.O.

FOR PIPING

7/8"-DIA K.O.

FOR ELECTRICAL

17 1/8"

3/4"

9 1/4"

5 1/8"

5"

106 1/4"

5"

17 5/8"

10 1/8"

26 1/2"

53 3/4"

57 1/4"

13 1/2"

12 1/8"

13 1/2" 13 1/2"

82"

79 1/4"

BACK VIEW SIDE VIEW

TOP VIEW

ISO VIEW

7/8" x 2" SLOTS

FOR HANGING BRACKETS

RIGHT HAND

END POCKET

LEFT HAND

END POCKET

NOTE:

WHEN ELECTRIC HEAT IS PRESENT, ALL POWER

CONNECTIONS ARE MADE IN THE RIGHT HAND

END POCKET. ON ALL OTHER CONFIGURATIONS,

POWER CONNECTIONS ARE MADE IN THE LEFT

HAND END POCKET.

BOTTOM DISCHARGE

Dimensions and Weights

18 UV-SVN02C-EN

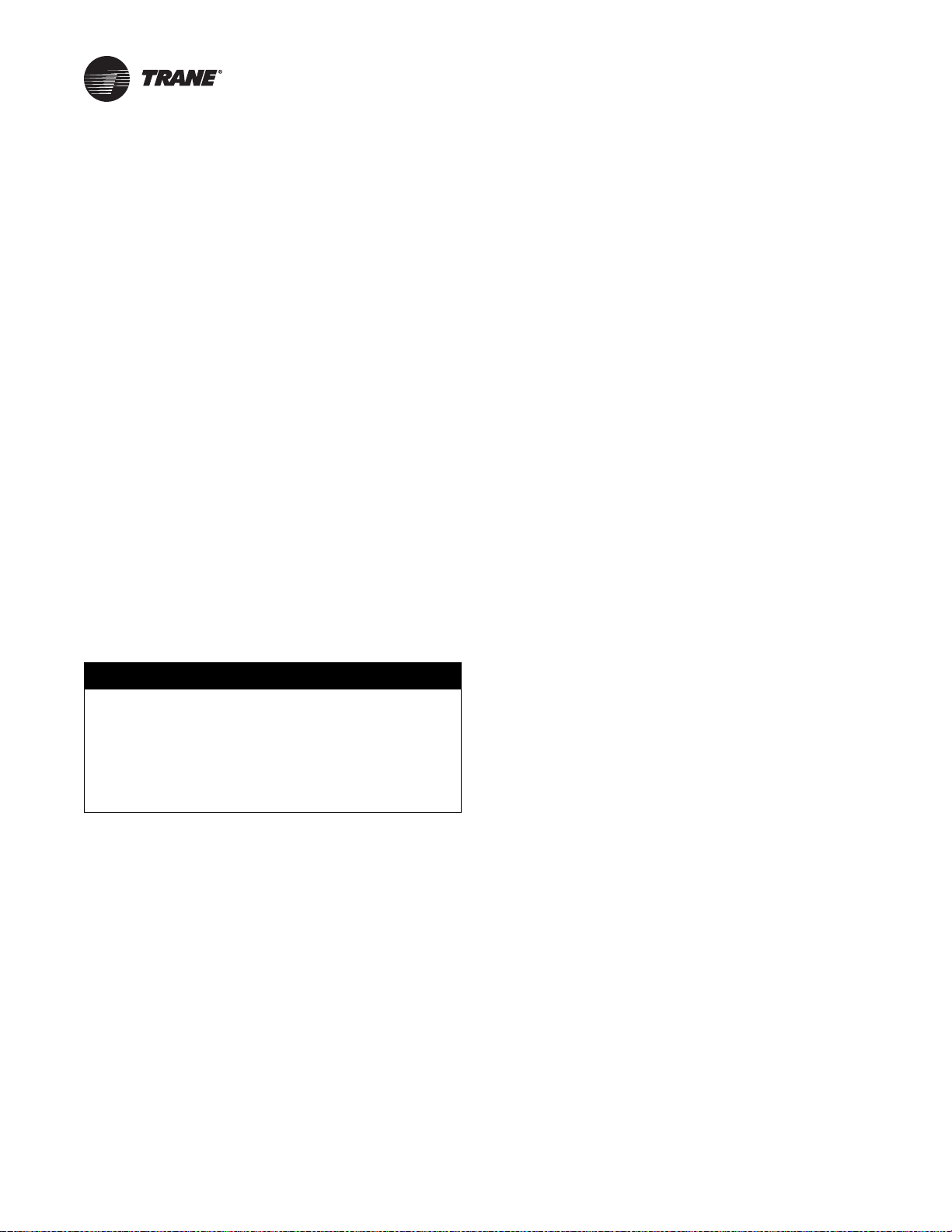

Figure 8. Supply/return air arrangements for the horizontal unit ventilator

DIGIT 20 = A

FA DUCT TOP

w/RA DUCT LOWER BACK

DIGIT 20 = B

FA DUCT TOP

w/RA DUCT BOTTOM

DIGIT 20 = G

FA DUCT UPPER BACK

w/RA DUCT BOTTOM

DIGIT 20 = F

FA DUCT UPPER BACK

w/RA DUCT LOWER BACK

DIGIT 20 = E

100% FA DUCT TOP

DIGIT 20 = K

100% FA DUCT UPPER BACK

DIGIT 20 = C & D

(C) FA DUCT TOP

w/RA BAR GRILLE BOTTOM

(D) FA DUCT TOP

w/RA OPEN BOTTOM

DIGIT 20 = H & J

(H) FA DUCT UPPER BACK

w/RA BAR GRILLE BOTTOM

(J) FA DUCT UPPER BACK

w/RA OPEN BOTTOM (no grille)

DIGIT 20 = M

100% RA DUCT BOTTOM

DIGIT 20 = L

100% RA DUCT LOWER BACK

DIGIT 20 = N & P

(N) 100% RA BAR GRILL BOTTOM

(P) 100% RA OPEN BOTTOM

(no grille)

UV-SVN02C-EN 19

Receiving and Handling

The unit ventilator is packaged in clear stretch wrap and

protective cardboard.

Note: Before unwrapping, make a visual inspection of the

unit for any damage that may have occurred during

shipping. All orders are shipped FOB (Freight on

Board) from the factory, therefore any claims must

be made with the delivering carrier.

Following visual inspection, carefully begin the following

procedures:

1. Carefully remove the stretch wrap and the top

cardboard cover.

2. Remove remaining cardboard blocking.

3. Remove the bottom access panel with a 7/32-in. Allen

wrenc

h.

4. Verify nameplate sales order number is correct.

5. Remove shipping bracket from the lower rear corners

of the unit and shipping skid. Access to the screws

holding unit to the skid is obtained inside the unit.

6. Rotate fan wheels manually. Wheels should move

freely and be in proper alignment. Visually inspect the

fan area for obstructions or shipping damage.

7. Remove all applicable knock-outs for coil piping and

electrical connections

(see Figure 5, p. 13 through

Figure 7, p . 17).

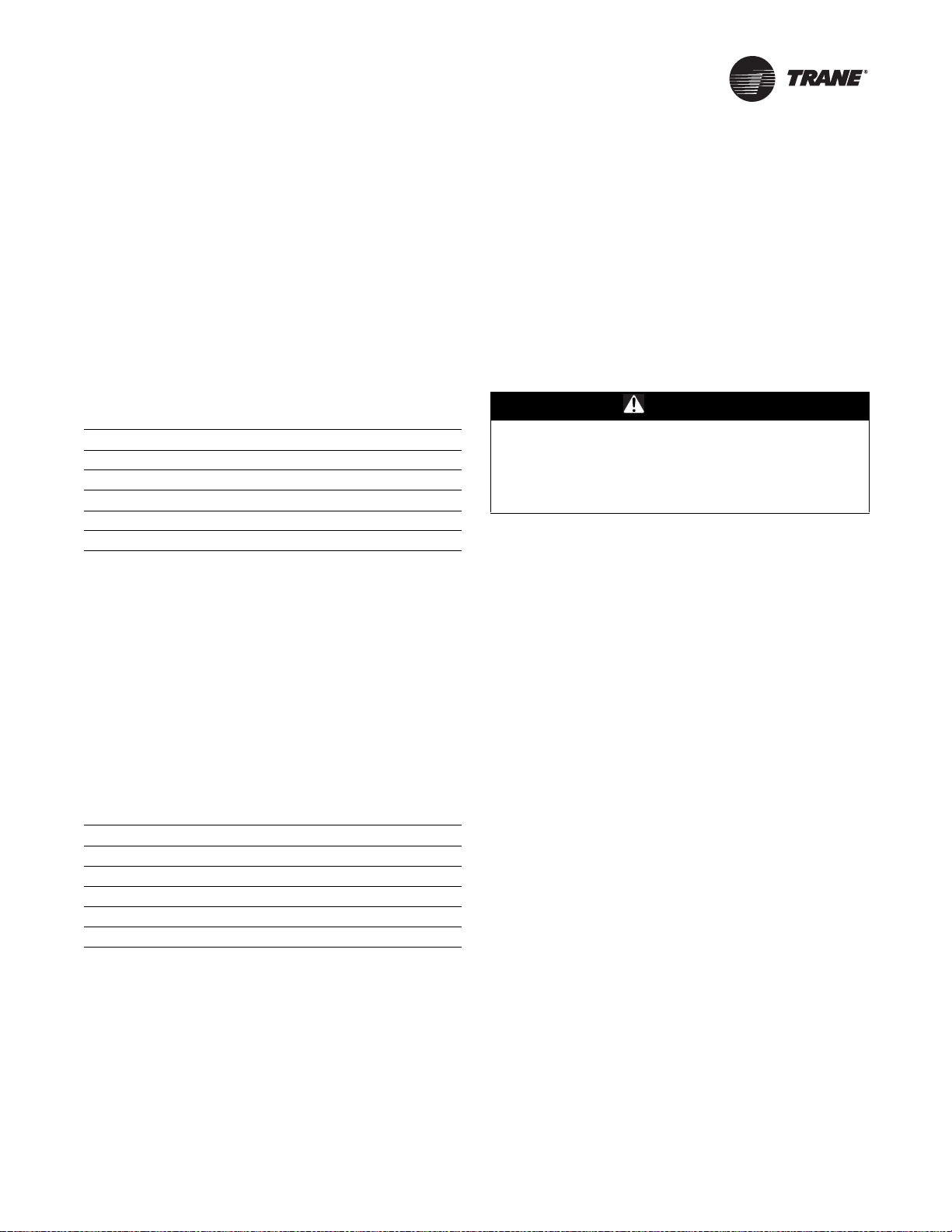

Figure 9. Horizontal unit ventilator as shipped

Figure 10. Shipping skid removal

20 UV-SVN02C-EN

Pre-Installation

Jobsite Inspection

Always perform the following checks before accepting a

unit:

1. Verify that the nameplate data matches the data on the

sales order and bill of lading (including electrical data).

2. Verify that the power supply complies with the unit

nameplate specifications.

3. Visually inspect the exterior

of the unit, for signs of

shipping damage. Do not sign the bill of lading

accepting the unit(s) until inspection has been

completed. Check for damage promptly after the

unit(s) are unloaded. Once the bill of lading is signed at

the jobsite, the unit(s) are now the property of the

SOLD TO party and future freight claims MAY NOT be

accepted by the freight company.

Jobsite Storage

This unit is intended for indoor use only. To protect the unit

from damage due to the elements, and to prevent possible

IAQ contaminant sources from growing.

1. Place the unit(s) on a dry surface or raise above the

ground to assure adequate air circulation beneath the

unit.

2. Cover the unit(s) with a water proof tarp to protect

them

from the elements.

3. Make provisions for continuous venting of the covered

units to prevent moisture from standing on the unit(s)

surfaces.

4. Do not stack units.

NOTICE:

Microbial Growth!

Wet interior unit insulation can become an

amplification site for microbial growth (mold), which

may cause odors and damage to the equipment and

building materials. If there is evidence of microbial

growth on the interior insulation, the insulation should

be removed and replaced prior to operating the system.

UV-SVN02C-EN 21

Installation—Mechanical

Location Considerations

Selecting the appropriate location for installing a unit is

very important. The following factors should be

considered:

1. Ceiling hung design must be of sufficient structure to

support the weight of the unit (see Ta bl e 8 for weight

data). Figure 5, p. 13 through Figure 9, p. 17 show

hanging rod location and placement.

Note: Isolator and suspension rods are to be provided

by the installer. For hanging suspension, Trane

recommends 3/8-in. rods.

2. Service access is gained through the access panels on

the bottom of the unit. Sufficient space should be

allowed for panel removal. If the hinged panel option

is ordered, allow for a swing radius of 14-in.

3. Sufficient free area around both the discharge and wall

b

ox should be maintained to ensure proper

ventilation. If any part of the discharge is blocked off,

unit performance may be affected. If the wall box is too

small on the inlet, water or debris could be pulled into

the unit (see Ta bl e 9) for minimum wall box free area

requirements).

4. Use the shortest and most efficient ductwork possible

when ducting the discharge and/or return air grille.

Units ordered with a duct collar discharge

arrangement are equipped with a 1-in. duct flange.

Note: Ductwork

for ducted units will be provided by

the installer.

5. If installing a split system, refe

r to the condenser

installation instructions provided with that unit for

special location considerations.

Note: M

easurements in Figure 5, p. 13 through

Figure 9, p. 17 do not include adjusted leveling

legs. Adjustment of Leveling legs should be

done first. New measurements from the floor

should be retaken before installation.

Unit Mounting

The horizontal unit ventilator may be attached directly to

the ceiling or suspended from the ceiling by hangers.

Hanger rods should be at least 3/8 in. diameter steel to

support unit weight, as given in Table 8, p. 21.

Install the hanging devices before hoisting the unit. A fork

lift or other special lifting device is required to hoist the

unit into mounting position.

Protect the unit finish by covering the lifting platform.

To hoist the unit into place, follow the instructions below:

1. Secure 2 x 4s to the lift forks. These two supports must

be long enough and spaced properly on the forks to

support the unit while it is being lifted and clear the

duct flanges on the unit.

2. Tip the unit onto the supports and slide it toward the lift

un

til the unit weight balances.

3. Lift the unit. Once in position, temporarily secure the

u

nit to the hanger rods or mounting studs with nuts

and washers.

4. Align the unit with the du

ct work. When in proper

alignment, tighten the mounting nuts securely.

5. Recheck the unit alignment and make sure the unit is

level

.

6. Replace all covers, panels and filters

before starting

the unit.

Note: Un

it must be mounted level. Coils and drain pans

inside unit are pitched properly for drainage before

shipment.

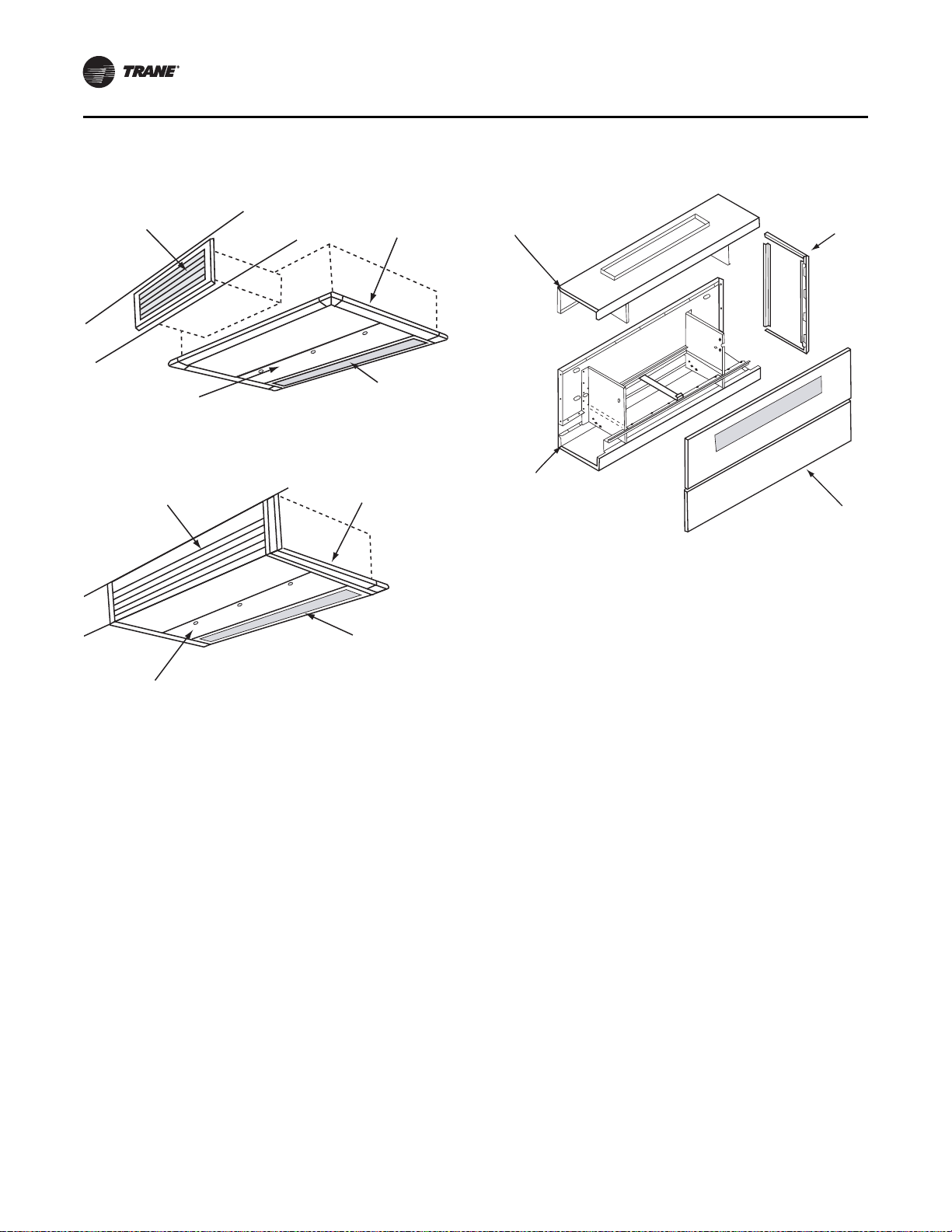

Horizontal Recessed Mounting

The recessing flange assembly ships in a box separate

from the unit. The assembly includes pre-cut flanges,

corner transition pieces, mounting screws, filler pieces,

and pressure sensitive gaskets. Refer to Figure 11 and

Figure 12, p. 22 for typical horizontal installation.

Ta b l e 8. Typical unit weights

(a)

(a) Weight at time of shipping. Subtract approximately 10% for actual

hanging weight.

Unit Size lb kg

075 340 154

100 375 170

120 435 197

150 500 227

200 600 272

Table 9. Wall box free area requirements

Unit Size Discharge (in

2

)Inlet (in

2

)

075 232 169

100 296 217

120 364 265

150 430 313

200 576 391

WARNI NG

Heavy Objects!

Always lift unit with fork trucks or other special lifting

device following the recommended procedures. Failure

to properly lift the unit as instructed, could result in

death or serious injury.

Installation—Mechanical

22 UV-SVN02C-EN

1. Measure and cut the pressure sensitive gaskets to the

correct lengths and attach to the flanges.

2. Starting at a corner, attach the top flange with the

mounting screws provided.

3. Press the corner transition pieces

onto the end of the

flange and attach the adjoining flanges and filler

pieces at the bottom of the unit. Work around the unit

in this manner until all flanges and corners are

installed.

4. Mounting holes are pre-drilled in

the flanges. Use the

assembled flanges as a template to drill all 7/32-in.

mounting holes in the cabinet.

5. Attach the flange section to

the unit cabinet with the

mounting screws provided.

6. Open and remove the front access panel.

7. Tighten the mounting fastener

, making sure that the

unit is level.

8. Open the unit access panel and remove the bottom

front panel

(see Figure 13, p. 22).

9. Hoist the unit onto a forklift and mount in place as

described in “Unit Mounting,” p. 21, ensuring the unit

is secured and aligned in place, and that the mounting

nuts

are tightly fastened.

Note: Un

it must be mounted level. Coils and drain

pans inside the unit are pitched internally for

proper drainage.

10. Replace all covers, panels and filters before starting the

un

it.

Figure 11. Recess flange installation around horizontal

unit ventilator access panel and inlet

Figure 12. Recess flange installation around bottom

and front of horizontal unit

Supply

Air

G

rille

Access Panel

Recessing Flange

Return Air

Inlet Grille

Supply Air

Grille

Access Panel

Recessing Flange

Return Air

Inlet Grille

Figure 13. Horizontal unit ventilator with front panel

removed

Intake Panel

Bottom Front Panel

Discharge Panel

End Cover

UV-SVN02C-EN 23

Installation—Piping

Note: Before installation of piping package, the shipping

bracket holding the piping in place, must be

removed.

Proper installation of piping is necessary to provide

efficient coil operation and to prevent damage during

operation. Follow standard piping practices and include all

accessories as necessary.

Piping connection knockouts are shown in Figure 5, p. 13

through Figure 9, p. 17. Field connection types and sizes

for units without piping packages are listed in Tab l e 10 ,

p. 23.

A 3/4-in. OD condensate drain connection is provided on

the chilled water supply end of the unit. Attach a flexible

condensate drain hose over the drain pan connection and

secure with a hose clamp.

The drain pan on the horizontal unit is internally pitched.

To field reverse, remove the screws and drain pan, rotate

the pan and reinstall.

After the condensate drain piping has been completed,

check water flow to be sure the system properly carries and

away all condensate accumulation.

A P-trap is recommended for installations that drain

directly into a sewer system. A P-trap is not necessary for

operation but will eliminate sewer gas odor.

Trane Piping Packages (Option)

Trane Standard Piping Package includes a two- or three-

way valve with bypass balance valve, ball valves, Pete’s

plugs, and unions. A strainer and circuit balancing valve

are optional.

All union connections should be tightened in the field.

Units are shipped with union connections hand-tightened

only in the factory.

Notes:

• All connections made in the field should be sweat

connections.

• Piping packages are not shipped insulated. Any

insulation should be provided in the field by the

installing contractor.

Split System Units

The following refrigerant piping and interconnecting

wiring instructions apply to unit ventilators with direct

expansion type cooling coils used in conjunction with air-

cooled condensing units. Reference must also be made to

the condensing unit installation and wiring manuals which

are shipped with the condensing unit.

Note: A UL listing mark applied to a unit ventilator does

not apply to any associated refrigerant condensing

unit.

Refrigerant Piping

Unit ventilators with direct expansion cooling are

dehydrated and shipped with a dry air holding charge.

Connections are “pinched off” at the factory.

To connect the condensing unit lines, cut off the stubouts

and swage. The condensing unit lines can then be brought

into the swage and brazed. Trane recommends the use of

nitrogen purge when brazing refrigerant lines to prevent

formation of oxides in the lines.

Table 10. Coil data for field piping

Coil Type Connection Location Field Connection Size

4-pipe chilled water /

hot water

Left or right (opposite

ends)

7/8 in. OD / 5/8 in. OD

2-pipe changeover coil Left or right 7/8 in. OD

Hot water only Left or right 7/8 in. OD

Steam Left or right 1 in. MPT

Chilled water / electric

heat

Left cooling 7/8 in. OD

Chilled water / steam Left or right 7/8 in. OD / 1 in. MPT

DX Left 7/8 in. suction, 3/8 in.

DX / hot water Left cooling / right

heating

7/8 in. suction,

3/8 in. / 5/8 in. OD

DX / steam Left cooling / right

heating

7/8 in. suction,

3/8 in. / 1 in. MPT

DX / electric heat Left cooling / right

heating

7/8 in. suction,

3/8 in. / NA

Figure 14. Condensate drain pan location

13-5/8"

3"

Horizontal Unit

WARNING

Hazard of Explosion and Deadly Gases!

Never solder, braze or weld on refrigerant lines or any

unit components that are above atmospheric pressure

or where refrigerant may be present. Always remove

refrigerant by following the guidelines established by

the EPA Federal Clean Air Act or other state or local

codes as appropriate. After refrigerant removal, use dry

nitrogen to bring system back to atmospheric pressure

before opening system for repairs. Mixtures of

refrigerants and air under pressure may become

combustible in the presence of an ignition source

leading to an explosion. Excessive heat from soldering,

brazing or welding with refrigerant vapors present can

form highly toxic gases and extremely corrosive acids.

Failure to follow all proper safe refrigerant handling

practices could result in death or serious injury.

Installation—Piping

24 UV-SVN02C-EN

Install the refrigerant suction and liquid lines as described

in the condensing unit installation instructions. The

thermal expansion valve (TXV) is factory-installed on the

Unit Ventilator.

Note: The R-410A direct expansion (DX) refrigerant coil

includes a factory-mounted adjustable thermal

expansion valve (TXV) set to 90 psig superheat and

an equalizing tube.

Piping should be run straight out through the back of the

unit. Access piping knockouts are located in the rear

panels of the unit, as shown in Figure 5, p. 13 through

Figure 9, p. 17.

Recommended refrigerant line connections for various

unit combinations are given in Table 9, p. 21. Typical

Superheat Charging Charts are shown in the Trane Service

Facts found in the condensing unit section manual.

Refrigerant charge weights can also be determined with

your local Trane account manager using a valid Trane

Selection Program.

Steam Piping

When air, water or another product is heated, the

temperature or heat transfer rate can be regulated by a

modulating steam pressure control valve. Since pressure

and temperature do not vary at the same rate as load, the

steam trap capacity, which is determined by the pressure

differential between the trap inlet and outlet, may be

adequate at full load, but not some lesser load.

There are detailed methods for determining condensate

load under various operating conditions. However, in

most cases this is not necessary if the coils are piped as

shown in Figure 15. Follow the procedure documented in

the ASHRAE Systems Handbook, Steam Systems.

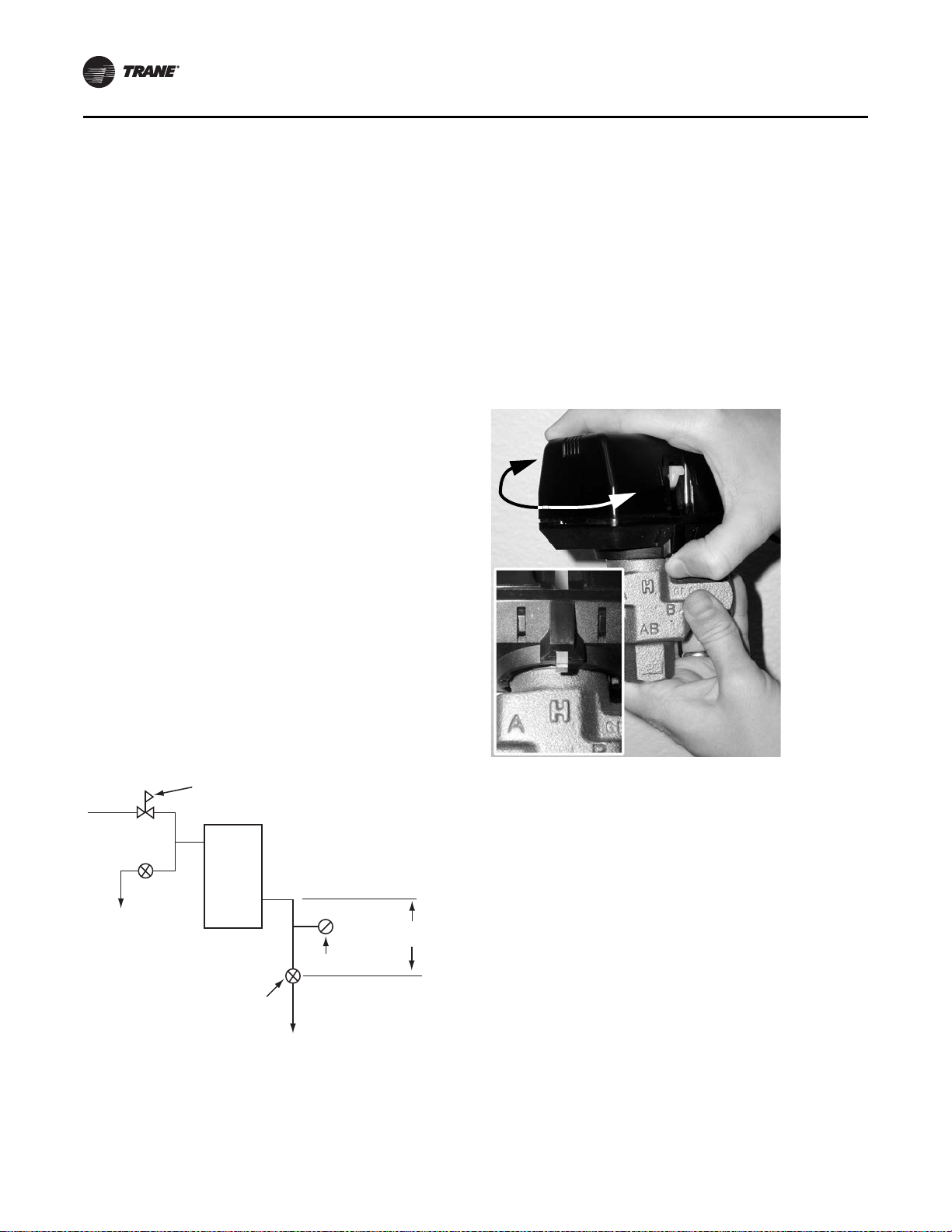

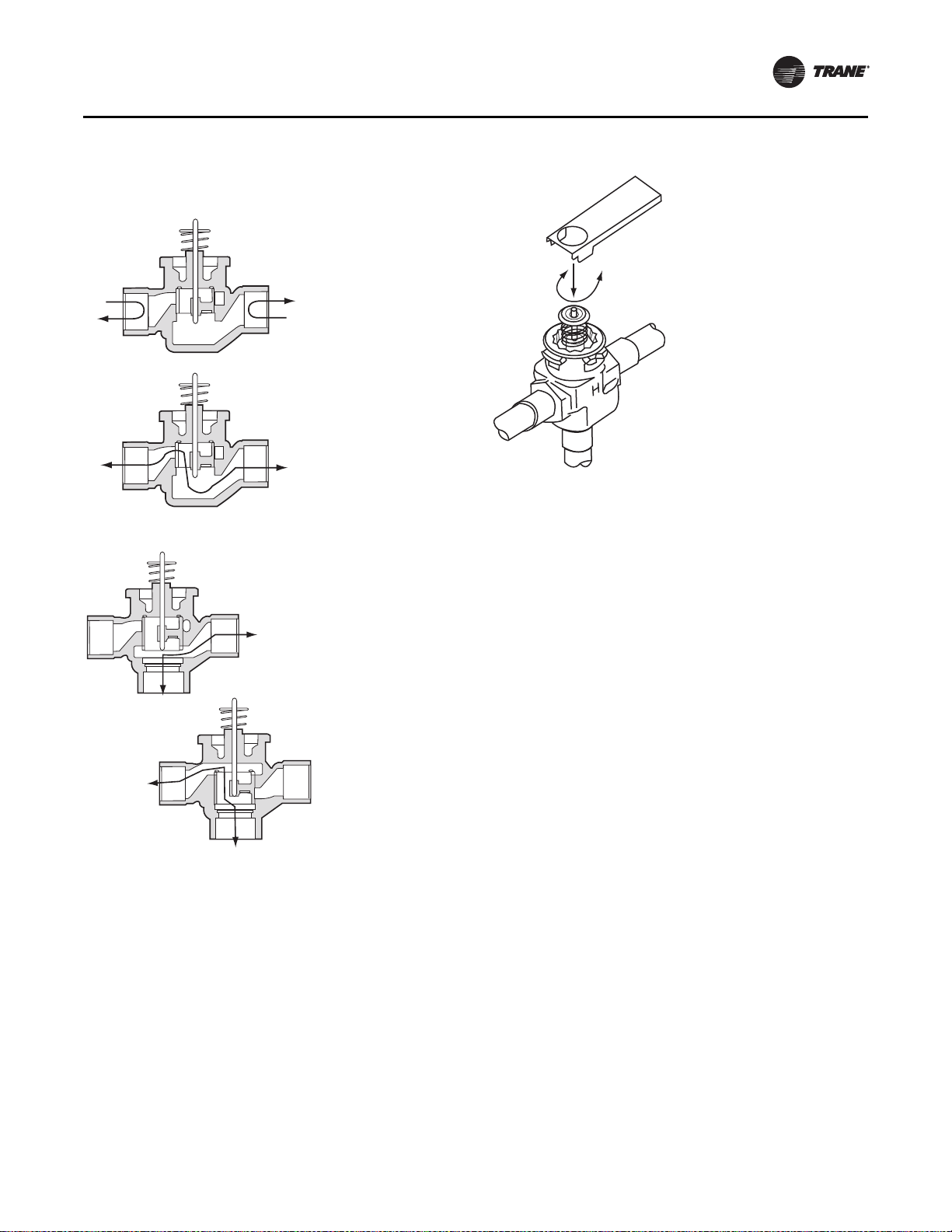

Modulating Water Valves (Option)

The actuator on the valve is a 24 V, three-point floating

valve. The actuator can be easily removed from the valve

body by pressing in on the locking tab and rotating the

actuator 45° counter-clockwise (see Figure 16). The two-

way valves are bi-directional flow. The three-way valves

can be mixing or diverting (see Figure 17).

Note: The actuator must be removed if soldering is being

conducted near the valve. High heat may cause

damage to the actuator’s plastic body/

mechanisms.

On applications without factory-installed piping packages

(option), it is important to remove the cartridge assembly

from the valve body with the provided tool (see Figure 18,

p. 25).

Figure 15. Steam piping

Vacuum Equalizer

H= 12"

minimum

F&T Trap

See text for sizing

Gravity flow to

vented receiver

Coil

To Condensate

return

Temp. Regulating Valve

Figure 16. Remove modulating valve actuator by

pressing in tab (inset) and turning actuator

45° clockwise

Installation—Piping

UV-SVN02C-EN 25

Use the following steps to complete cartridge assembly

removal:

1. Remove valve actuator.

2. Remove the cartridge assembly from the valve body

with the enclosed tool.

3. Solder the valve in accordance with normal soldering

practices.

4. Re-install the cartridge after soldering by tightening

un

til it bottoms out. The top surface of the cartridge

will be flush with the top edge of the body casting.

Note: D

o not over-tighten. Maximum torque is 40

in·lb.

5. Replace valve actuator and wire in accordance with

instructions

.

Plumbing

The valve may be plumbed in any angle but preferably not

with the actuator below horizontal level of the body. Make

sure there is enough room around the actuator for

servicing or replacement.

For use in diverting applications, the valve is installed with

the flow water entering through the bottom AB port and

diverting through end ports A or B. In mixing applications

the valve is installed with inlet to A or B and outlet through

AB.

Mount directly to the tube or pipe. Do not grip the actuator

while making or tightening plumbing connections. Either

hold valve body by hand or attach an adjustable spanner

(38 mm/1-1/2”) across the hexagonal or flat faces on the

valve body (see Figure 19, p. 26).

Figure 17. Steam piping: two-way valve (top) and three-

way valve (bottom)

Closed

Open

A

B

A

B

Two-way valve

AB<->B

AB

B

AB<->A

A

AB

Three-way valve

Figure 18. Cartridge removal tool

Installation—Piping

26 UV-SVN02C-EN

Manual Opener

The manual opener can be manipulated only when in the

up position. The A port can be manually opened by firmly

pushing the white manual lever down to the midway

position and pushing the lever in. In this position, both A

and B ports are open. This “manual open” position may be

used for filling, venting and draining the system or

opening the valve during power failure.

The valve can be closed by depressing the white lever

lightly and then pulling the lever outward. The valve and

actuator will return to the automatic position when power

is restored.

Note: If the valve is powered open, it cannot be manually

closed, unless the actuator is removed.

Typical floating controller is an SPDT controller with a

center-off position. On a change in temperature from the

set point, the controller will close the NO or NC contacts,

driving the valve to an intermediate position until a further

change at the controller.

The valve is set between the limits of the controller to

satisfy various load requirements. In the event of power

failure, the valve will stay in the position it was in before

loss of power. When power is restored, the valve will again

respond to controller demand.

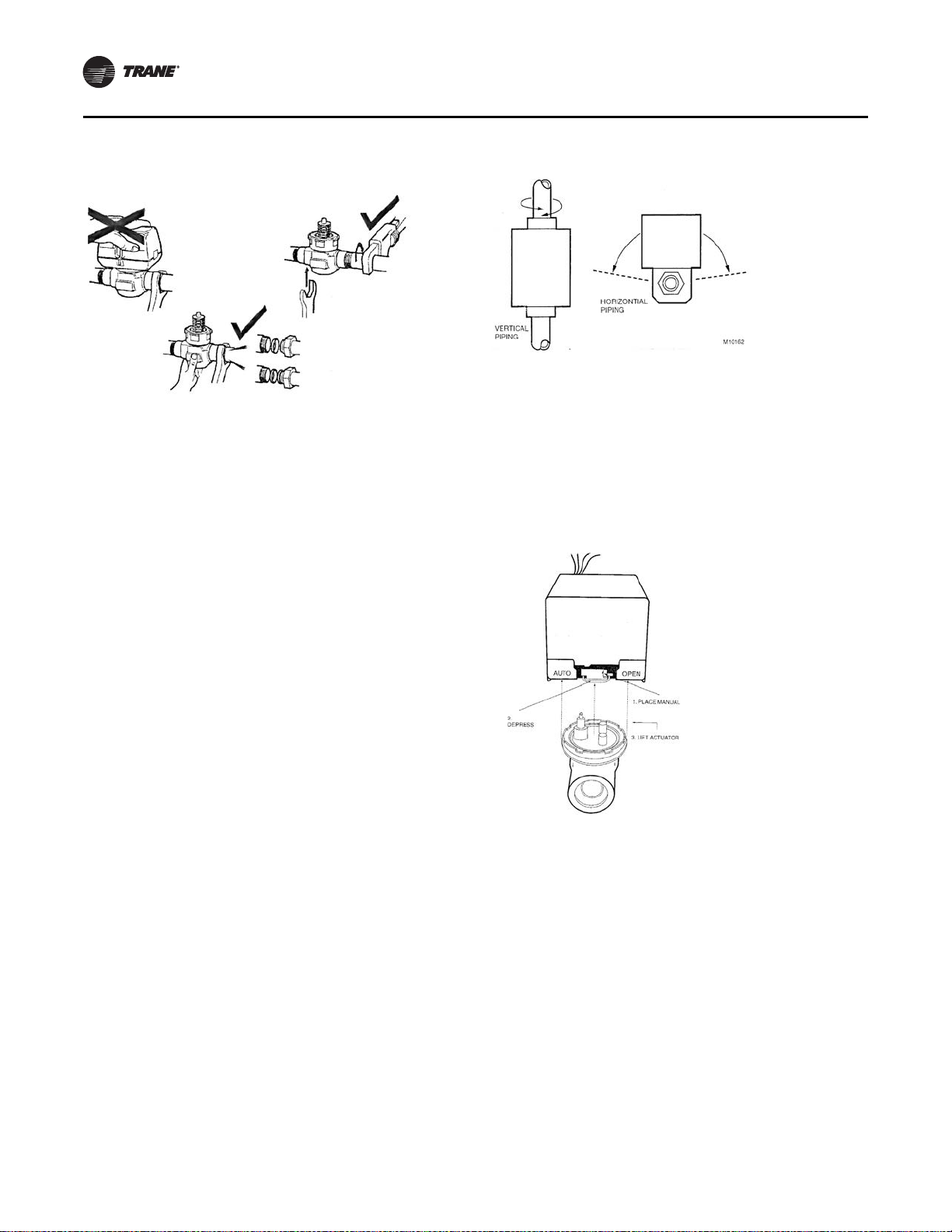

Isolation Valves

Installation

The valve can be mounted in any position on a vertical line.

If the valve is mounted horizontally, the actuator must be

even with or above the center line. Make sure there is

enough room to remove actuator cover for servicing.

Mount the valve on the tube or pipe.

Note: Make sure the flow through the valve is in the

direction indicated by the arrow stamped on the

valve body.

Servicing/Removal of Valves

The actuator can be removed from the valve body.

Removing the actuator is recommended of soldering is

being conducted near the valve.

To remove the actuator:

1. Place the manual operating lever in the Open position

(see Figure 21, p. 26).

2. Depress the locking button and lift actuator until it

separates from the valve body.

To install the actuator to the valve body:

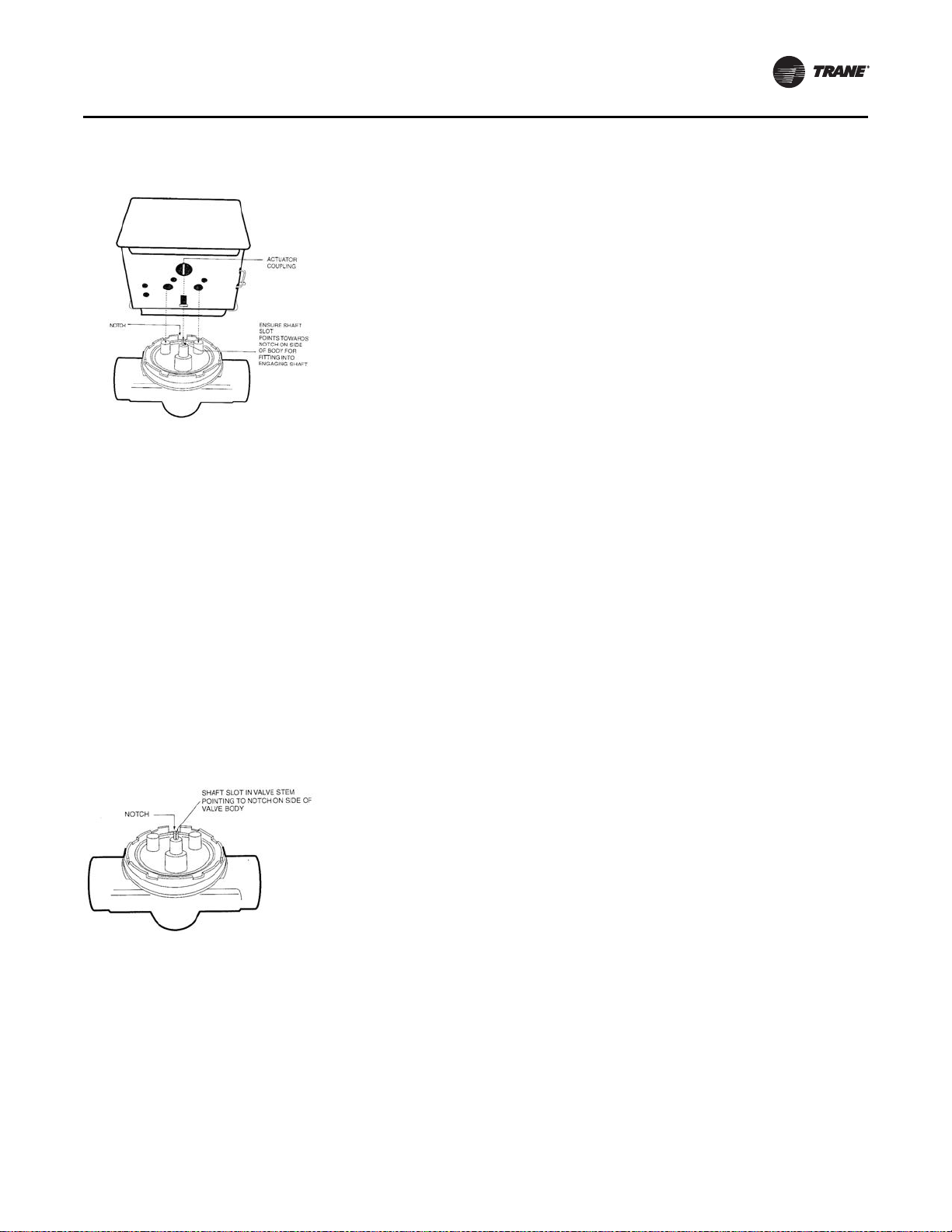

1. Align the slot on the shaft of the valve with the valve

body notch on side of body (see Figure 22, p. 27).

Figure 19. Proper plumbing technique for modulating

valves

Figure 20. Proper mounting for isolation valves

Figure 21. Removing isolation valve actuator

Installation—Piping

UV-SVN02C-EN 27

2. Install body valve into pipe.

3. Wiring connections may be made either before or after

actua

tor installed on body.

4. Place the manual operating leve

r on the actuator in the

OPEN position.

5. Align actuator coupling to slot on the shaf

t of the valve

body and fit the head onto the valve body to ensure the

shaft seats correctly (see Figure 22).

6. Press the actuator and valve body until it secures

together

.

Soldering procedures are as follows:

1

. Remove actuator as stated earlier.

2. Place valves on the pipe. Rotate valve stem so the shaf

t

slot points at the notch in the side of the body (90O to

flow direction). This protects the plug inside the valve

by removing it from the seat (see Figure 23).

3. Sweat the joints, keeping outer surface free from

solder.

Note: Do not use silver solder due to high

temperature requirements.

Heating Coils with Direct

Expansion Cooling

Heating options for direct expansion cooling in the unit

ventilator are hot water, steam or electric heat.

These coils facilitate direct expansion cooling with

standard capacities. The supply and return connections

are located in the right hand end pocket. Hot water field

connections are made with a 5/8 in.\[15.9\] OD male

sweated joint, while steam coils have a 1 in.\[25.4\] male

pipe thread (MPT) connection (see Tab l e 10 , p . 2 3 ).

Electric heat coils provide a third way to supply heating to

the direct expansion cooling. The coil utilizes three to six

preheat elements which are factory-wired.

Figure 22. Installing isolation valve actuator

Figure 23. Preparation for soldering

28 UV-SVN02C-EN

Installation—Sensors

Control Options

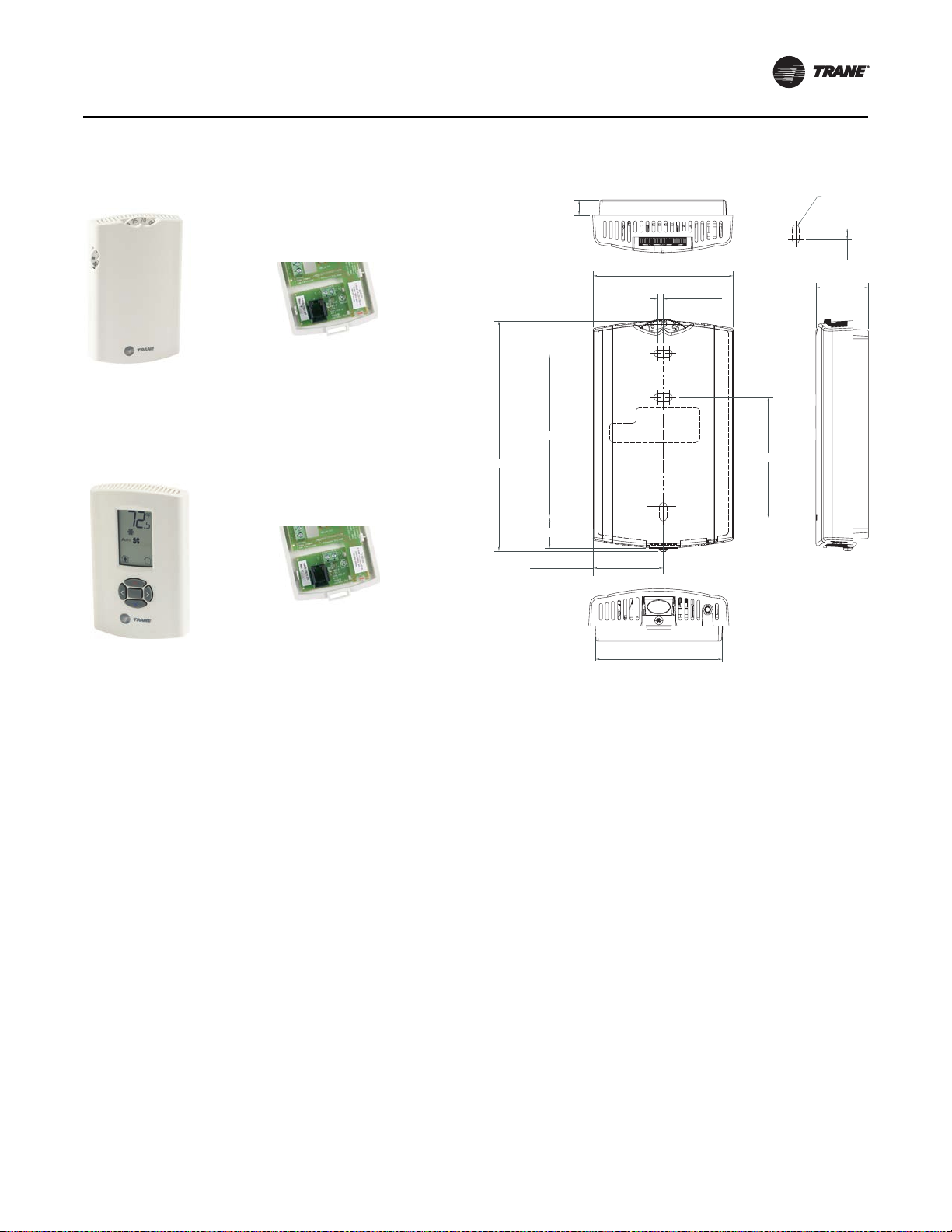

Figure 24. Wireless temp sensor with display

(SP, OALH, COMM)

Digit 19 = 3

Figure 25. Wireless temp sensor

(SP, OALMH, COMM)

Digit 19 = 4

Figure 26. Wall mtd temp sensor

(SP, OCC/UNOCC, OA, LMH, COMM)

Digit 19 = J

X13790822-04 (wall)

X13790855-01 (unit)

X13790492-01 (wall)

X13790855-01 (unit)

X13790842-01 (wall)

X13651467-02 (comm)

Figure 27. Unit mtd temp sensor

(SP, OALH, COMM)

Digit 19 = L

Figure 28. Split mtd zone sensor, unit mtd fan speed

switch, and wall mtd setpoint dial

with On/Cancel

Digit 19 = P

Figure 29. Split mtd zone sensor,

unit mtd fan speed switch, and

wall mtd setpoint dial

Digit 19 = Q

X13790843-01 (unit)

X13511527-01 (wall)

X13790849-01 (unit)

X13651467-02 (comm)

X13511529-01 (wall)

X13790849-01 (unit)

X13651467-02 (comm)

Installation—Sensors

UV-SVN02C-EN 29

Installing Wall-Mounted Wired

Sensors

Reference the wall-mounted zone sensor dimensions in

Figure 32, p. 29. Position the sensor on an inside wall three

to five feet above the floor and at least 18 inches from the

nearest outside wall. Installing the sensor at a lower height

may give the advantage of monitoring the temperature

closer to the zone, but it also exposes the sensor to airflow

obstructions. Ensure that air flows freely over the sensor.

Sensor

When selecting a sensor location, avoid the following:

• Areas of direct sunlight

• Areas in the direct airstream of air diffusers

• Exterior walls and other walls that have a

temperature

differential between the two sides

• Areas that are close to heat sources

such as sunlight,

appliances, concealed pipes, chimneys, or other heat-

generating equipment

• Drafty areas

• Dead spots behind doors, projection screens, or

corner

s

• Walls that are subject to high vibration

• Areas with high humidity

• High traffic areas (to reduce acci

dental damage or

tampering)

Figure 30. Wall mtd temp sensor

(SP, OALMH, COMM)

Digit 19 = K

Figure 31. Wall mtd display temp sensor

(SP, OCC/UNOCC, OALMH, COMM)

Digit 19 = M

X13790841-01 (wall)

X13651467-02 (comm)

X13790886-04 (wall)

X13651467-02 (comm)

Figure 32. Wall-mounted wired and wireless zone

sensor dimensions

1. 0.31 in

2. TYP R.07 in (R1.9)

3. TYP 0.24 in)

4. 2.9 in

5. 1.08 in

6. 0.12 in

7. 3.39 in

8. 4.68 in

9. 2.48 in

10. 0.6 3 i n

11. 1.45 in

12. 2.62 in

1

2

3

4

5

6

7

8

9

0

-

=

Installation—Sensors

30 UV-SVN02C-EN

• Metal barriers between the receiver and the sensor (for

example, plastered walls with metal lathe or metal roof

decks)

• Thick, solid concrete walls between the receiver and

the sensor

• Placing the sensor inside metal enclosures

Height Requirements

It is recommended that you mount the back plate a

maximum distance of 54 inches above the floor. If a

parallel approach by a person in a wheelchair is required,

reduce the maximum height to 48 inches.

Note: Consult section 4.27.3 of the 2002 ADA (Americans

with Disability Act) guideline, and local building

codes, for further details regarding wheelchair

requirements.

Mounting Surfaces

Using the hardware provided, mount the back plate of the

sensor to a flat surface such as sheetrock or plaster, or an

electrical junction box. The sensor must be mounted

plumb for accurate temperature control and to ensure

proper air movement through the sensor.

• If mounting onto sheetrock or plaster

, use the plastic

threaded anchors (pre-drilling holes is not usually

necessary) and the two M3.5 x 20 mm mounting

screws.

• For mounting onto an electrical junction box, use the

two 6-32 x 3/4 in. screws.

Before beginning installation, consider the location

co

nsiderations below. Also, refer to the unit wiring

schematic for specific wiring details and point

connections.

Location Considerations

Avoid mounting the sensor in an area subject to the

following conditions:

• Dead spots, such as behind do

ors or in corners that do

not allow free air circulation.

• Air drafts from stairwells, outside doors, or

un

sectioned hollow walls.

• Radiant heat from the sun, fireplaces, appliances, etc.

• Airflow from adjacent z

ones or other units.

• Unheated or uncooled spaces behind the controller,

su

ch as outside walls or unoccupied spaces.

• Concealed pipes, air ducts, or chimneys in partition

sp

aces behind the controller.

Location Considerations for Wireless Zone

Sensors

Placement of the sensor is critical to proper operation (the

receiver is factory mounted on fan-coil units). For most

installations, barriers limit proper radio signal strength

more than distance. For best radio transmission range and

reliability, mount the receiver and sensor in line of sight.

Where this is not possible, try to minimize the number of

barriers between the pair of devices. In general, sheetrock

walls and ceiling tiles offer little restriction to the

transmission range for the sensor is as follows:

• Open range: 2,500 ft (packet error rate = 2%)

• Usable range: 200 ft

• Typical range: 75 ft

Fan Mode Switch Installation

The fan mode switch ships loose inside the unit accessory

bag. Follow the steps below to install the fan mode switch.

Items needed:

2 x 4 electrical junction box

1. Remove the brown wire if not using a field-supplied

damper.

2. Remove the terminals, cut and strip wires as required

fo

r installation.

3. Level and position a 2 x 4 electrical

junction box.

4. Follow the instructions given in “Wall-Mounted

Control Interconnection Wiring,” p. 41 and route the

wires as shown in the wiring diagram. R

efer to the