Siemens SINAMICS S210 Users guide

© Siemens 2020

|

|

|

|

|

|

Motion Control Drives |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SINAMICS |

S210 |

|

|

|

|

|

|

Servo Drive System |

|

|

|

Edition |

|

|

|

|

|

Catalog |

|

January |

|

|

|

|

|

|

|

|

|||||

D 32 |

|

2020 |

|

|

|

|

siemens.com/drives |

|

|

|

|

|

|

|

|

Related catalogs

Motion Control Drives |

D 31.1 |

SINAMICS Inverters for Single-Axis Drives |

|

Built-In Units |

|

E86060-K5531-A111-A1-7600 |

|

Motion Control Drives |

D 31.2 |

SINAMICS Inverters for Single-Axis Drives |

|

Distributed Inverters |

|

E86060-K5531-A121-A1-7600 |

|

Motion Control Drives |

D 31.5 |

SINAMICS Converters for Single-Axis Drives |

|

SINAMICS G120X infrastructure converters |

|

for HVAC/Water/Wastewater |

|

PDF (E86060-K5531-A151-A3-7600) |

|

SINAMICS S120 |

D 21.3 |

Chassis Format Converter Units |

|

Chassis-2 Format Converter Units |

|

Cabinet Modules, Cabinet Modules-2 |

|

SINAMICS S150 |

|

Converter Cabinet Units |

|

E86060-K5521-A131-A7-7600 |

|

Motion Control Drives |

D 21.4 |

SINAMICS S120 and SIMOTICS |

|

E86060-K5521-A141-A1-7600 |

|

SIMOTICS S-1FG1 |

D 41 |

Servo geared motors |

|

Helical, Parallel shaft, Bevel and |

|

Helical worm geared motors |

|

PDF (E86060-K5541-A101-A4-7600) |

|

SIMOTICS GP, SD, XP, DP |

D 81.1 |

Low-Voltage Motors

Type series 1FP1, 1LE1, 1LE5, 1MB1, 1MB5, 1PC1 Frame sizes 63 to 450

Power range 0.09 to 1000 kW

PDF (E86060-K5581-A111-B4-7600)

FLENDER Couplings |

MD 10.1 |

Standard Couplings |

|

E86060-K5710-A111-A5-7600 |

|

SIMOGEAR |

D 50.1 |

Geared Motors |

|

Helical, parallel shaft, bevel, helical worm and worm geared motors

E86060-K5250-A111-A6-7600

© Siemens 2020

|

|

Motion Control System |

PM 21 |

SIMOTION |

|

Equipment for Production Machines |

|

E86060-K4921-A101-A4-7600 |

|

|

|

|

|

Industrial Controls |

IC 10 |

SIRIUS |

|

E86060-K1010-A101-B1-7600 |

|

|

|

|

|

Industrial Controls |

IC 10 AO |

SIRIUS Classic |

|

PDF (E86060-K1010-A191-A5-7600) |

|

|

|

|

|

Low-Voltage Power Distribution and |

LV 10 |

Electrical Installation Technology |

|

SENTRON • SIVACON • ALPHA

Protection, Switching, Measuring and Monitoring

Devices, Switchboards and Distribution Systems

PDF (E86060-K8280-A101-B1-7600)

Print (E86060-K8280-A101-A6-7600)

|

|

|

SIMATIC |

|

ST 70 |

Products for |

|

|

Totally Integrated Automation |

|

|

PDF (E86060-K4670-A101-B7-7600) |

|

|

|

|

|

|

|

|

SIMATIC HMI / |

ST 80/ST PC |

|

PC-based Automation |

|

|

Human Machine Interface Systems |

|

|

PC-based Automation |

|

|

PDF (E86060-K4680-A101-C7-7600) |

|

|

|

|

|

|

|

|

Industrial Communication |

|

IK PI |

SIMATIC NET |

|

|

E86060-K6710-A101-B8-7600 |

|

|

|

|

|

|

|

|

Products for Automation and Drives |

CA 01 |

|

Interactive Catalog |

|

|

Download |

|

|

www.siemens.com/automation/ca01

Industry Mall

Information and Ordering Platform on the Internet:

www.siemens.com/industrymall

Change 07/2020

© Siemens 2020

SINAMICS S210

Servo Drive System

Motion Control Drives

Catalog D 32 · January 2020

Dear Customer,

We are pleased to present you with the new Catalog D 32 · January 2020. This edition replaces Catalog D 32 · April 2019. The catalog provides a comprehensive overview of the new SINAMICS S210 servo drive system consisting of a SINAMICS S210 servo converter, a SIMOTICS S-1FK2 servomotor and a matching One Cable Connection (OCC).

The single-axis AC/AC servo converter system stands out due to its high performance and dynamic response for mid-range Motion Control applications. In addition to details of updates and technical modifications, the latest edition of the catalog has also been supplemented with the 400 V versions.

The products listed in this catalog are also included in the Industry Mall. Please contact your local Siemens office for additional information.

NEW: By clicking on the Article No. in the web PDF you can jump directly to the Industry Mall where you can obtain additional information and order products online.

Up-to-date information about SINAMICS S210 is available on the Internet at: www.siemens.com/sinamics-s210

You can access our Interactive Catalog and Industry Mall online at: www.siemens.com/industrymall

Your personal contact will be happy to receive your suggestions and recommendations for improvement. You can find your representative in our Personal Contact database at: www.siemens.com/automation-contact

We hope that you will often enjoy using Catalog D 32 · January 2020 as a selection and ordering reference document and wish you every success with our products and solutions.

With kind regards,

Achim Peltz

Vice President

General Motion Control

Siemens AG, Digital Industries, Motion Control

siemens.com/drives

© Siemens 2020

© Siemens 2020

SINAMICS S210 Servo Drive System

Motion Control Drives

Catalog D 32 · January 2020

Supersedes:

Catalog D 32 · April 2019

Refer to the Industry Mall for current updates of this catalog:

www.siemens.com/industrymall

The products contained in this catalog can also be found in the Interactive Catalog CA 01.

The Catalog CA 01 can be downloaded at: www.siemens.com/automation/ca01

Please contact your local Siemens branch.

© Siemens 2020

Click on an Article No. in the catalog PDF to call it up in the Industry Mall and to obtain all the information.

Article No.

6SL3070-0AA00-0AG0 6SL3072-0AA00-0AG0

Or directly on the Internet, e.g. www.siemens.com/product?6SL3070-0AA00-0AG0

The products and systems described in this catalog are manufactured/distributed under application of a certified quality management system in accordance with DIN EN ISO 9001. The certificate is recognized by all IQNet countries.

System overview

SINAMICS S210 servo drive

SIMOTICS S-1FK2 servomotors

MOTION-CONNECT connection systems

Engineering tools

Services and documentation

Appendix

1 |

2 |

3 |

4 |

5 |

6 |

7 |

© Siemens 2020

Digital Enterprise

The building blocks that ensure everything works together perfectly in the digital enterprise

Digitalization is already changing all areas of life and existing business models. It is placing greater pressure on industry while at the same time creating new business opportunities. Today, thanks to scalable solutions from Siemens, companies can already become a digital enterprise and ensure their competitiveness.

Industry faces tremendous challenges

Reduce time-to-market

Today manufacturers have to bring products to market at an ever-increas- ing pace despite the growing complexity of these products. In the past, a major manufacturer would push aside a small one, but now it is a fast manufacturer that overtakes a slow one.

Boost |

Improve |

Boost |

Increase |

flexibility |

quality |

efficiency |

security |

Consumers want cus- |

To ensure a high level of |

Today the product itself |

Increasing networking |

tomized products, but at |

quality while meeting |

needs to be sustainable |

escalates the threat to |

a price they would pay |

legal requirements, |

and environmentally |

production facilities |

for a mass-produced |

companies have to |

friendly, while energy |

of cyberattacks. Today |

item. That only works |

establish closed quality |

efficiency in production |

more than ever, com- |

if production is more |

loops and enable the |

has become a competi- |

panies need suitable |

flexible than ever |

traceability of products. |

tive advantage. |

security measures. |

before. |

|

|

|

|

|

|

|

2 |

|

Siemens D 32 · January 2020 |

|

|

|

© Siemens 2020

The digital enterprise has already become a reality

To fully benefit from all the advantages of digitalization, companies first have to achieve complete consistency of their data. Fully digitally integrated business processes, including those of suppliers, can help to create a digital representation of the entire value chain. This requires

•the integration of industrial software and automation,

•expansion of the communication net- works,

•security in automation,

•and the use of business-specific industrial services.

MindSphere

The cloud-based open IoT operating system from Siemens

With MindSphere, Siemens offers a costeffective and scalable cloud platform as a service (PaaS) for the development of appli- cations. The platform, designed as an open operating system for the Internet of Things, makes it possible to improve the efficiency of plants by collecting and analyzing large volumes of production data.

Totally Integrated Automation (TIA)

Where digitalization becomes reality

Totally Integrated Automation (TIA) ensures the seamless transition from the virtual to the real world. It already encompasses all the necessary conditions for transforming the benefits of digitalization into true added value. The data that will form the digital twin for actual production is generated from a common base.

Digital Plant

Learn more about the digital enterprise for the process industry www.siemens.com/ digitalplant

Digital Enterprise Suite

Learn more about the digital enterprise for the discrete industry www.siemens.com/ digital-enterprise-suite

IA/DT Digital Enterprise En 05.03.18

Siemens D 32 · January 2020 |

|

3 |

|

|

|

© Siemens 2020

Integrated Drive Systems

Faster on the market and in the black with Integrated Drive Systems

Integrated Drive Systems are Siemens’ trendsetting answer to the high degree of complexity that characterizes drive and automation technology today. The world’s only true one-stop solution for entire drive systems is characterized in particular by its threefold integration: Horizontal, vertical, and lifecycle integration ensure that every drive system component fits seamlessly into the whole system, into any automation environment, and even into the entire lifecycle of a plant.

The outcome is an optimal workflow – from engineering all the way to service that entails more productivity, increased efficiency, and better availability. That’s how Integrated Drive Systems reduce time to market and time to profit.

Horizontal integration

Integrated drive portfolio: The core elements of a fully integrated drive portfolio are frequency converters, motors, couplings, and gear units.

At Siemens, they‘re all available from a single source. Perfectly integrated, perfectly interacting. For all power and performance classes. As standard solutions or fully customized. No other player in the market can offer a comparable portfolio. Moreover, all Siemens drive components are perfectly matched, so they are optimally interacting.

You can boost the availability of your application or plant to up to

99%*

*e.g., conveyor application

Vertical integration

Thanks to vertical integration, the complete drive train is seamlessly integrated in the entire automation environment – an important prerequisite for production with maximum value added. Integrated Drive Systems are part of Totally Integrated Automation (TIA), which means that they

are perfectly embedded into the system architecture of the entire industrial production process. This enables optimal processes through maximum communication and control.

With TIA Portal you can cut your engineering time by up to

30%

30%

Lifecycle integration

Lifecycle integration adds the factor of time: Software and service are available for the entire lifecycle of an Integrated Drive System. That way, important optimization potential for maximum productivity, increased efficiency, and highest availability

can be leveraged throughout the system’s lifecycle – from planning, design, and engineering to operation, maintenance, and all the way even to modernization.

With Integrated Drive Systems, assets become important success factors. They ensure shorter time to market, maximum productivity and efficiency in operation, and shorter time to profit.

With Integrated Drive Systems you can reduce your maintenance costs by up to

15%

15%

www.siemens.com/ids

4 |

|

Siemens D 32 · January 2020 |

|

|

|

|

© Siemens 2020 |

1 |

||

|

|

|||

System overview |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/2 |

|

The SINAMICS converter family |

|

|

|

|

|

|

|

1/6 |

|

Drive selection |

|

|

|

|

|

|

|

1/7 |

|

SINAMICS S210 servo drive system |

|

|

1/13 |

|

Order overview |

|

|

|

|

|

|

|

1/20 |

|

SINAMICS S210 starter kit |

|

|

|

|

|

|

Siemens D 32 · January 2020

© Siemens 2020

System overview

1 |

|

|

The SINAMICS converter family |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

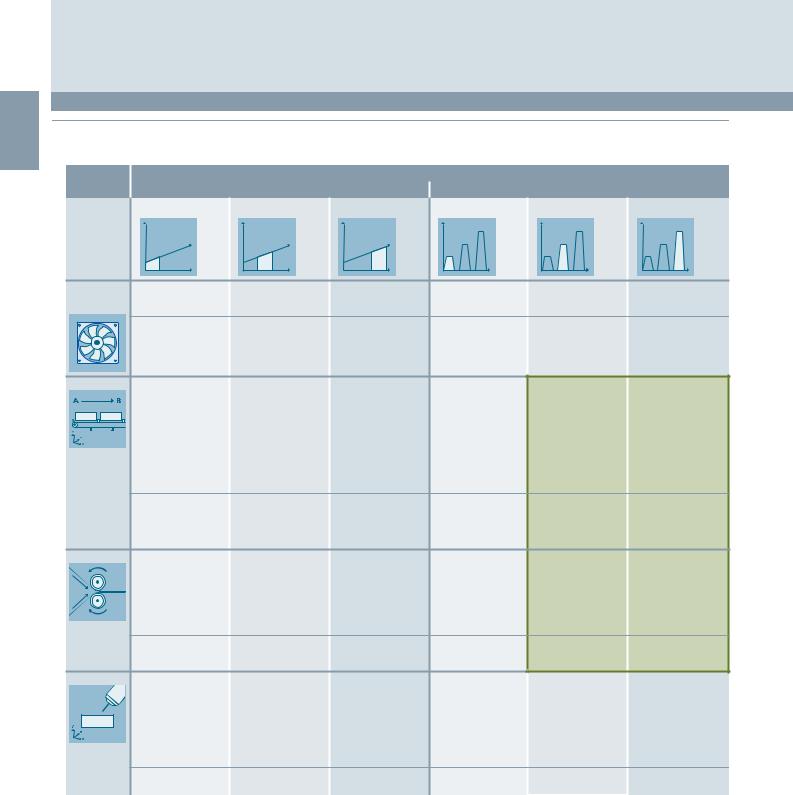

■ Overview |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Integration in automation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

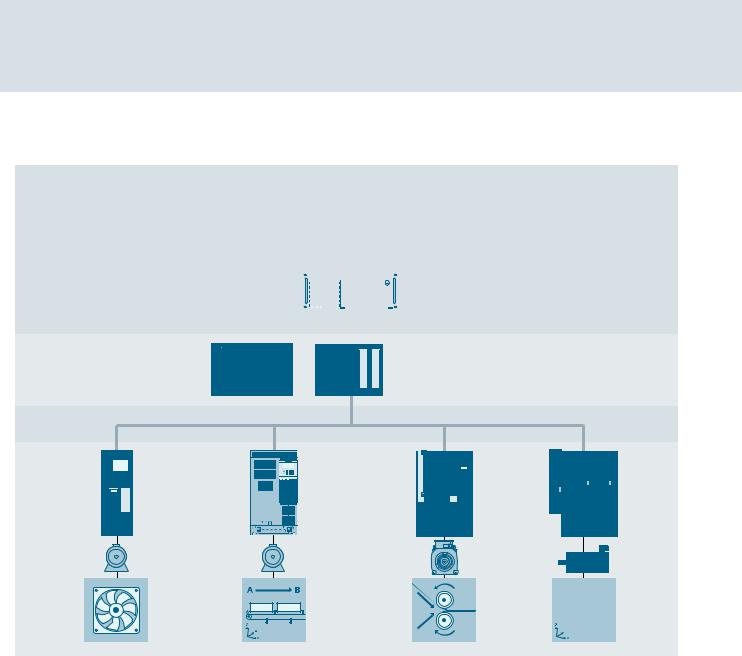

Management level |

Office environment: SIMATIC IT / COMOS... |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Process control level |

|

|

|

|

|

|

|

|

Control center / control system: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

SIMATIC PCS 7 / WINCC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Control level |

|

|

|

|

|

|

|

|

|

Automation systems / HMI: |

|

|

|

|

|

|

|

|

|

|

SIMATIC / SIMOTION / SINUMERIK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fieldbus |

|

|

|

SINAMICS V |

SINAMICS V |

SINAMICS V |

|

SINAMICS G |

SINAMICS G |

|

|

SINAMICS G |

SINAMICS S |

SINAMICS S |

SINAMICS S |

pumping |

|

|

|

ventilating |

moving |

processing |

machining |

compressing |

<![endif]>

G_D011_EN_00337d

G_D011_EN_00337d

Totally Integrated Automation and communication

SINAMICS is an integral component of the Siemens "Totally Integrated Automation" concept. Integrated SINAMICS systems covering configuration, data storage, and communication at automation level ensure low-maintenance solutions with the SIMATIC, SIMOTION and SINUMERIK control systems.

Depending on the application, the appropriate variable frequency drives can be selected and incorporated in the automation concept. With this in mind, the drives are clearly subdivided into their different applications. A wide range of communication options (depending on the drive type) are available for establishing a communication link to the automation system:

•PROFINET

•PROFIBUS

•EtherNet/IP

•Modbus TCP

•Modbus RTU

•AS-Interface

•BACnet MS/TP

Applications

SINAMICS is the comprehensive converter family from Siemens designed for machine and plant engineering applications. SINAMICS offers solutions for all drive tasks:

•Simple pump and fan applications in the process industry

•Demanding single drives in centrifuges, presses, extruders, elevators, as well as conveyor and transport systems

•Drive line-ups in textile, plastic film, and paper machines as well as in rolling mill plants

•Highly dynamic servo drives for machine tools, as well as packaging and printing machines

1/2 |

|

Siemens D 32 · January 2020 |

|

|

|

© Siemens 2020

|

|

|

System overview |

|

||

|

|

|

|

|

|

|

|

|

|

The SINAMICS converter family |

|

1 |

|

|

|

|

|

|

|

|

■ Overview |

|

|

|

|

||

|

|

|

|

|

||

|

SINAMICS as part of the Siemens modular automation system |

|

|

|

|

|

|

SIMOTION |

SINUMERIK |

SIMATIC |

|

||

|

|

|||||

SINAMICS

SIMOGEAR |

SIMOTICS |

<![endif]>G_D011_XX_00515b

Innovative, energy-efficient and reliable drive systems and applications as well as services for the entire drive train

The solutions for drive technology place great emphasis on the highest productivity, energy efficiency and reliability for all torque ranges, performance and voltage classes.

Siemens offers not only the right innovative variable frequency drive for every drive application, but also a wide range of energy-efficient low-voltage motors, geared motors, explosionprotected motors and high-voltage motors for combination with SINAMICS.

Furthermore, Siemens supports its customers with global pre-sales and after-sales services, with over 295 service points in 130 countries – and with special services e.g. application consulting or motion control solutions.

Energy efficiency

Energy management process

Efficient energy management consultancy identifies the energy flows, determines the potential for making savings and implements them with focused activities.

Almost two thirds of the industrial power requirement is from electric motors. This makes it all the more important to use drive technology permitting energy consumption to be reduced effectively even in the configuration phase, and consequently to optimize plant availability and process stability. With SINAMICS, Siemens offers powerful energy efficient solutions which, depending on the application, enable a significant reduction in electricity costs.

Siemens D 32 · January 2020 |

|

1/3 |

|

|

|

© Siemens 2020

System overview

1 |

|

The SINAMICS converter family |

|

|

|

|

|

|

|

|

■ Overview |

|

|

|

|

|

Up to 70 % potential for savings using variable-speed operation |

Regenerative feedback of braking energy |

|

|

|

SINAMICS enables great potential for savings to be realized by |

In conventional drive systems, the energy produced during |

|

|

||||

|

|

controlling the motor speed. In particular, huge potential savings |

braking is converted to heat using braking resistors. Energy |

|

|

|

can be recovered from pumps, fans and compressors which are |

produced during braking is efficiently recovered to the supply |

|

|

|

operated with mechanical throttle and valves. Here, changing to |

system by versions of SINAMICS G and SINAMICS S drives with |

|

|

|

variable-speed drives brings enormous economic advantages. |

regenerative feedback capability and these devices do not |

|

|

|

In contrast to mechanical control systems, the power consump- |

therefore need a braking resistor. This permits up to 60 % of the |

|

|

|

tion at partial load operation is always immediately adjusted to |

energy requirement to be saved, e.g. in lifting applications. |

|

|

|

the demand at that time. So energy is no longer wasted, |

Energy which can be reused at other locations on a machine. |

|

|

|

permitting savings of up to 60 % – in exceptional cases even up |

Furthermore, this reduced power loss simplifies the cooling of |

|

|

|

to 70 %. Variable-speed drives also offer clear advantages over |

the system, enabling a more compact design. |

|

|

|

mechanical control systems when it comes to maintenance and |

Energy transparency in all configuration phases |

|

|

|

repair. Current spikes when starting up the motor and strong |

||

|

|

|

|

|

|

|

torque surges become things of the past – and the same goes |

Early on, in the configuration phase, the SIZER for Siemens |

|

|

|

for pressure waves in pipelines, cavitation or vibrations which |

Drives engineering tool provides information on the specific |

|

|

|

cause sustainable damage to the plant. Smooth starting and |

energy requirement. The energy consumption across the entire |

|

|

|

ramp-down relieve the load on the mechanical system, ensuring |

drive train is visualized and compared with different plant |

|

|

|

a significantly longer service life of the entire drive train. |

concepts. |

|

SINAMICS in combination with energy-saving motors

Engineering integration stretches beyond the SINAMICS converter family to higher-level automation systems, and to a broad spectrum of energy-efficient motors with a wide range of performance classes, which, compared to previous motors, are able to demonstrate up to 10 % greater efficiency.

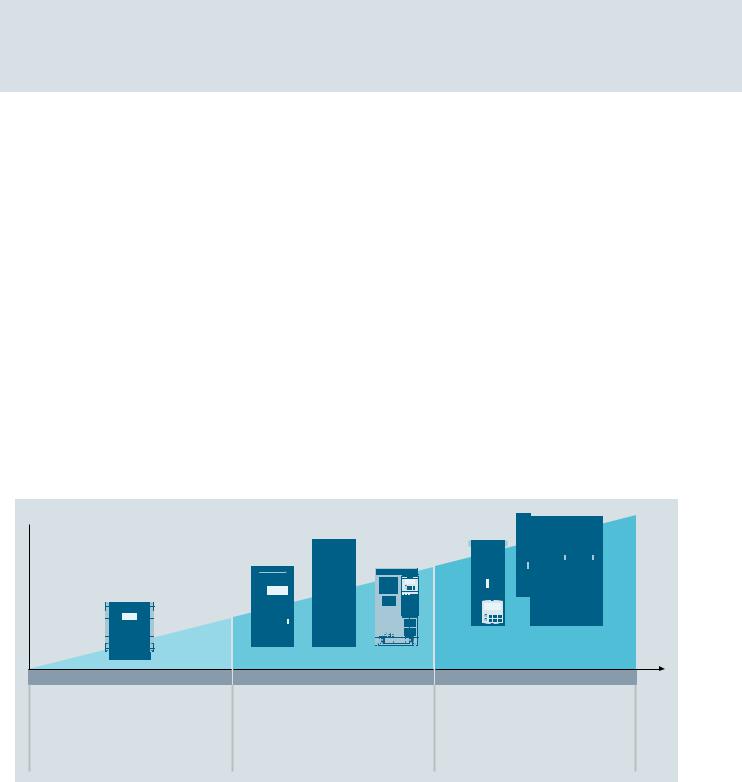

Variants

Depending on the application, the SINAMICS converter family offers the ideal variant for any drive task.

Performance

Performance

SINAMICS V

SINAMICS V drives focus on

the essentials both in terms of hardware and functionality.

This results in a high degree of ruggedness combined with lower investment costs.

SINAMICS G

SINAMICS G drives function perfectly for low and medium demands on the dynamic response of the control system.

SINAMICS S

SINAMICS S drives are predestined for demanding single - and multi-axis

applications in machine and plant engineering as well as for numerous motion control tasks.

Price

<![if ! IE]><![endif]>G_D011_EN_00449b

1/4 |

|

Siemens D 32 · January 2020 |

|

|

|

|

|

© Siemens 2020 |

|

|

|

|

System overview |

|

|

|

|

|

|

|

|

|

The SINAMICS converter family |

1 |

|

|

|

|

|

|

■ Overview |

|

|

||

|

|

|

||

|

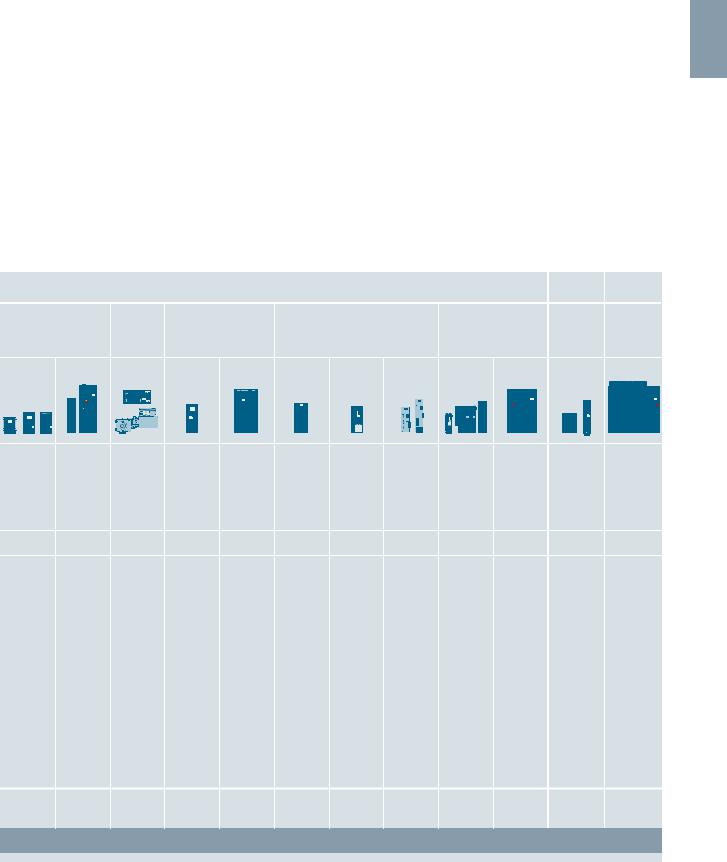

Platform concept |

IDS – Integration at its very best |

|

|

All SINAMICS variants are based on a platform concept. Joint hardware and software components, as well as standardized tools for dimensioning, configuration, and commissioning tasks ensure high-level integration across all components. SINAMICS handles a wide variety of drive tasks with no system gaps. The different SINAMICS variants can be easily combined with each other.

Quality management according to EN ISO 9001

SINAMICS conforms to the most exacting quality requirements. Comprehensive quality assurance measures in all development and production processes ensure a consistently high level of quality.

Of course, our quality management system is certified by an independent authority in accordance with EN ISO 9001.

The Siemens Integrated Drive Systems (IDS) solution offers perfectly matched drive components with which you can meet your requirements. The drive components reveal their true strengths as an Integrated Drive System over the full range from engineering and commissioning through to operation: Integrated system configuration is performed using the Drive Technology Configurator: Just select a motor and a converter and design them with the SIZER for Siemens Drives engineering tool. The STARTER and SINAMICS Startdrive commissioning tools integrate the motor data and at the same time simplify efficient commissioning. Integrated Drive Systems are incorporated in the TIA Portal – this simplifies engineering, commissioning and diagnostics.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Low voltage |

|

|

|

|

|

Direct |

|

Medium |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

voltage |

|

voltage |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Standard performance |

Distributed |

Industry-specific frequency |

|

|

Servo drives |

High performance |

|

DC |

|

Converters for |

||||||||||||||||||||||||||||

|

|

frequency converters |

frequency |

|

|

converters |

|

|

|

|

|

|

|

|

|

|

frequency converters |

converters |

|

applications |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

converters |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

with high |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

outputs |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SINAMICS |

SINAMICS |

SINAMICS |

SINAMICS |

SINAMICS |

SINAMICS |

SINAMICS |

SINAMICS |

SINAMICS |

SINAMICS |

SINAMICS |

SINAMICS |

V20 |

G130 |

G110D |

G120X |

G180 |

V90 |

S110 |

S210 |

S120 |

S150 |

DCM |

GH150 |

G120C |

G150 |

G120D |

|

|

|

|

|

S120M |

|

DCP * |

GH180 |

G120 |

|

G110M |

|

|

|

|

|

|

|

|

GM150 |

|

|

SIMATIC |

|

|

|

|

|

|

|

|

SM150 |

|

|

|

|

|

|

|

|

|

|

GL150 |

|

|

|

ET 200pro FC-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SL150 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM120CM |

|

|

|

|

|

|

|

|

|

|

|

|

0.12 kW to |

75 kW to |

0.37 kW to |

0.75 kW to |

2.2 kW to |

0.05 kW to |

0.55 kW to |

0.05 kW to |

0.55 kW to |

75 kW to |

6 kW to |

0.15 MW to |

250 kW |

2700 kW |

7.5 kW |

630 kW |

6600 kW |

7 kW |

132 kW |

7 kW |

5700 kW |

1200 kW |

30 MW |

85 MW |

Pumps, fans, |

Pumps, |

Conveyor |

Pumps, |

Pumps, |

Handling |

Single-axis |

Packaging |

Production |

Test bays, |

Rolling mill |

Pumps, |

compressors, |

fans, |

technology, |

fans, |

fans, |

machines, |

positioning |

machines, |

machines |

cross cutters, |

drives, |

fans, |

conveyor compressors, single-axis |

compressors, |

compressors, |

packaging |

applications in |

handling |

(packaging, |

centrifuges |

wire-drawing |

compressors, |

||

belts, mixers, |

conveyor |

positioning |

building |

conveyor |

machines, |

machine and |

equipment, |

textile and |

|

machines, |

mixers, |

mills, spinning |

belts, mixers, |

applications |

management |

belts, |

automatic |

plant |

feed and |

printing |

|

extruders and |

extruders, |

machines, |

mills, |

(G120D) |

systems, |

extruders, |

assembly |

engineering |

withdrawal |

machines, |

|

kneaders, |

mills, |

textile |

extruders |

|

process |

mixers, mills, |

machines, |

|

devices, |

paper |

|

cableways |

crushers, |

machines, |

|

|

industry, |

kneaders, |

metal forming |

|

stacking units, |

machines, |

|

and lifts, |

rolling mills, |

refrigerated |

|

|

HVAC, |

centrifuges, |

machines, |

|

automatic |

plastic |

|

test bay drives |

conveyor |

display |

|

|

water/waste |

separators |

printing |

|

assembly |

processing |

|

|

technology, |

counters, |

|

|

water |

|

machines, |

|

machines, |

machines), |

|

* DC/DC |

excavators, |

fitness |

|

|

industries |

|

winding and |

|

laboratory |

machine |

|

test bays, |

|

|

|

|

|

|

controllers |

||||||

equipment, |

|

|

|

|

unwinding |

|

automation, |

tools, plants, |

|

marine drives, |

|

|

|

|

|

|

|

|

|||||

ventilation |

|

|

|

|

units |

|

wood, glass |

process lines |

|

|

blast furnace |

systems, |

|

|

|

|

|

|

and ceramics |

and rolling |

|

|

fans, retrofit |

single-axis |

|

|

|

|

|

|

industry, |

mills, marine |

|

|

|

positioning |

|

|

|

|

|

|

digital printing |

drives, test |

|

|

|

applications in |

|

|

|

|

|

|

machines |

bays |

|

|

|

machine and |

|

|

|

|

|

|

|

|

|

|

|

plant |

|

|

|

|

|

|

|

|

|

|

|

engineering |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Catalog |

Catalog |

Catalog |

Catalog |

Catalog |

Catalog |

Catalog |

Catalog |

Catalogs |

Catalog |

Catalog |

Catalogs |

D 31.1 |

D 11 |

D 31.2 |

D 31.5 |

D 18.1 |

D 33 |

D 31.1 |

D 32 |

D 21.3, D 21.4 |

D 21.3 |

D 23.1 |

D 15.1, D 12 |

|

|

|

|

|

|

|

|

NC 62 |

|

* Industry Mall |

|

|

|

|

|

|

|

|

|

|

|

|

|

Engineering tools (e.g. Drive Technology Configurator, SIZER for Siemens Drives, STARTER and SINAMICS Startdrive)

G_D011_EN_00450o

Siemens D 32 · January 2020 |

|

1/5 |

|

|

|

© Siemens 2020

System overview

1 |

Drive selection |

■ Overview |

SINAMICS selection guide – typical applications

Use |

Requirements for torque accuracy/speed accuracy/position accuracy/coordination of axes/functionality |

|

||||

|

Continuous motion |

|

|

Non-continuous motion |

|

|

|

Basic |

Medium |

High |

Basic |

Medium |

High |

Pumping, |

Centrifugal pumps |

Centrifugal pumps |

Eccentric screw |

Hydraulic pumps |

Hydraulic pumps |

Descaling pumps |

ventilating, |

Radial / axial fans |

Radial / axial fans |

pumps |

Metering pumps |

Metering pumps |

Hydraulic pumps |

compressing |

Compressors |

Compressors |

|

|

|

|

|

V20 |

G120X |

S120 |

G120 |

S110 |

S120 |

|

G120C |

G130/G150 |

|

|

|

|

|

G120X |

G180 1) |

|

|

|

|

Moving |

Conveyor belts |

Conveyor belts |

Elevators |

Acceleration |

Acceleration |

Storage and retrieval |

|

Roller conveyors |

Roller conveyors |

Container cranes |

conveyors |

conveyors |

machines |

|

Chain conveyors |

Chain conveyors |

Mining hoists |

Storage and retrieval |

Storage and retrieval |

Robotics |

|

|

Lifting/lowering |

Excavators for |

machines |

machines |

Pick & place |

|

|

devices |

open-cast mining |

|

Cross cutters |

Rotary indexing tables |

|

|

Elevators |

Test bays |

|

Reel changers |

Cross cutters |

|

|

Escalators/moving |

|

|

|

Roll feeds |

|

|

walkways |

|

|

|

Engagers/disengagers |

|

|

Indoor cranes |

|

|

|

|

|

|

Marine drives |

|

|

|

|

|

|

Cable railways |

|

|

|

|

|

V20 |

G120 |

S120 |

V90 |

S110 |

S120 |

|

G110D |

G120D |

S150 |

G120 |

S210 |

S210 |

|

G110M |

G130/G150 |

DCM |

G120D |

DCM |

DCM |

|

G120C |

G180 1) |

|

|

|

|

|

ET 200pro FC-2 2) |

|

|

|

|

|

Processing |

Mills |

Mills |

Extruders |

Tubular bagging |

Tubular bagging |

Servo presses |

|

Mixers |

Mixers |

Winders/unwinders |

machines |

machines |

Rolling mill drives |

|

Kneaders |

Kneaders |

Lead/follower drives |

Single-axis motion |

Single-axis motion |

Multi-axis motion |

|

Crushers |

Crushers |

Calenders |

control |

control |

control |

|

Agitators |

Agitators |

Main press drives |

such as |

such as |

such as |

|

Centrifuges |

Centrifuges |

Printing machines |

• Position profiles |

• Position profiles |

• Multi-axis positioning |

|

|

Extruders |

|

• Path profiles |

• Path profiles |

• Cams |

|

|

Rotary furnaces |

|

|

|

• Interpolations |

|

V20 |

G120 |

S120 |

V90 |

S110 |

S120 |

|

G120C |

G130/G150 |

S150 |

G120 |

S210 |

S210 |

|

|

G180 1) |

DCM |

|

|

DCM |

Machining |

Main drives for |

Main drives for |

Main drives for |

Axis drives for |

Axis drives for |

Axis drives for |

|

• Turning |

• Drilling |

• Turning |

• Turning |

• Drilling |

• Turning |

|

• Milling |

• Sawing |

• Milling |

• Milling |

• Sawing |

• Milling |

|

• Drilling |

|

• Drilling |

• Drilling |

|

• Drilling |

|

|

|

• Gear cutting |

|

|

• Lasering |

|

|

|

• Grinding |

|

|

• Gear cutting |

|

|

|

|

|

|

• Grinding |

|

|

|

|

|

|

• Nibbling and |

|

|

|

|

|

|

punching |

|

S110 |

S110 |

S120 |

S110 |

S110 |

S120 |

|

|

S120 |

|

|

S120 |

|

|

Using the SINAMICS selection guide |

• The application type is selected from the vertical column |

|

The varying range of demands on modern variable frequency |

- Pumping, ventilating, compressing |

|

- Moving |

|

|

drives requires a large number of different types. Selecting the |

|

|

- Processing |

|

|

optimum drive has become a significantly more complex pro- |

|

|

- Machining |

|

|

cess. The application matrix shown simplifies this selection pro- |

|

|

• The quality of the motion type is selected from the horizontal row |

|

|

cess considerably, by suggesting the ideal SINAMICS drive for |

|

|

examples of typical applications and requirements. |

- Basic |

|

|

- Medium |

|

|

- High |

|

|

|

■ More Information |

|

Further information about SINAMICS is available on the Internet at

www.siemens.com/sinamics

1) Industry-specific converters.

Practical application examples and descriptions are available on the Internet at

www.siemens.com/sinamics-applications

2)Information on the SIMATIC ET 200pro FC-2 frequency converter is available in Catalog D 31.2 and at: www.siemens.com/et200pro-fc

1/6 |

|

Siemens D 32 · January 2020 |

|

|

|

© Siemens 2020

System overview

SINAMICS S210 servo drive system

■ Overview

1

The SINAMICS S210 can be used in numerous applications.

Typical applications are:

•Packaging machines

•Handling equipment

•Feed and withdrawal devices

•Stacking units

•Automatic assembly machines

•Laboratory automation

•Woodworking, glass and ceramic industries

•Digital printing machines

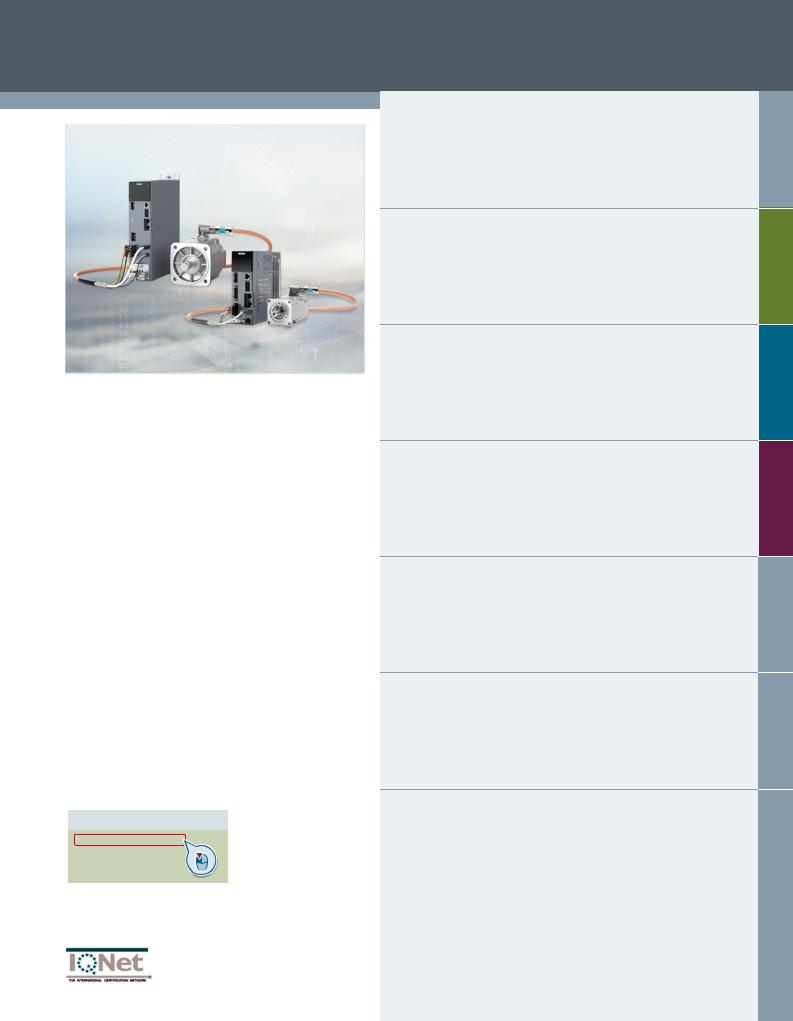

Flexible in application

Example: SINAMICS S210 converter frame size FSB, 200 V 1 AC, with SIMOTICS S-1FK2 servomotor shaft height 30

Example: SINAMICS S210 converter frame size FSB, 400 V 3 AC, with SIMOTICS S-1FK2 servomotor shaft height 63

The new servo drive system comprises a SINAMICS S210 servo converter, a SIMOTICS S-1FK2 servomotor and a matching One Cable Connection (OCC) for connecting the motor to the converter. The SINAMICS S210 is a single-axis AC/AC servo converter system with high performance and dynamic response for mid-range Motion Control applications.

SINAMICS S210 servo converters are available for the following line voltages:

•200 V to 240 V 1 AC (1 AC series)

•200 V to 480 V 3 AC (3 AC series)

Depending on the converter voltage, the SIMOTICS S-1FK2 servomotors are available in the following frame sizes and torque ranges:

•1 AC series

-Up to 240 V: Shaft heights 20 to 48 with 0.16 to 3.6 Nm

•3 AC series

-Up to 240 V: Shaft heights 20 to 100 with 0.16 to 40 Nm

-Up to 480 V: Shaft heights 40 to 100 with 1.27 to 40 Nm

The motors are available in the High Dynamic (HD) and Compact (CT) designs.

The SINAMICS S210 is a flexible, versatile system.

SIMOTICS S-1FK2 series synchronous servomotors are installed in rotary and linear axes. The integrated One Cable Connection (OCC) interface allows user-friendly connection of a SIMOTICS S-1FK2 motor with just one cable. The electronic motor type plate data can be read out, which eliminates the need to parameterize the converter with the motor data. This significantly simplifies and shortens commissioning.

In conjunction with the technological functions of the higher-level controller, there are many possibilities of motion – from continuous operation through positioning and synchronous operation, to coordinated motion of multiple axes via cyclic cams or interpolation – everything is possible.

The SINAMICS S210 converter has an integrated PROFINET communications interface for connecting to a control system.

The data exchange with the higher-level controllers takes place via standardized protocols – the PROFIdrive profile for positioning mode and the PROFIsafe profile for safety-related communication.

Thus, operation is optimally ensured with the SIMATIC S7 automation system. The drive axis is connected via technology objects and Motion Control blocks in the SIMATIC S7 or a SIMOTION controller.

High performance for fast and precise control

The high performance of the SINAMICS S210 servo drive system in conjunction with the SIMOTICS S-1FK2 servomotor derives from the following features:

•Low moment of inertia and high overload capability of the motor

•High-resolution encoder with fast scanning

•Current controller clock cycle of 62.5 μs and a pulse frequency of 8 kHz of the servo converter

This enables short cycle times on the machine even with complex motion control.

DC link coupling (only 3 AC series)

For devices of the 3 AC series, the DC links of up to six converters can be coupled. Thus, energy balancing between the axes is possible and energy produced during braking can be used by other axes for accelerating. This is not only efficient but also reduces the dissipated heat in the control cabinet, because the energy that is produced no longer has to be converted to heat in the braking resistor.

Siemens D 32 · January 2020 |

|

1/7 |

|

|

|

|

|

|

|

© Siemens 2020 |

||

|

|

|

System overview |

|

|

|

|

|

|

|

|

|

|

1 |

|

|

SINAMICS S210 servo drive system |

|

|

|

|

|

|

|

|

|

|

|

■ Overview |

|

|

|

||

|

|

|

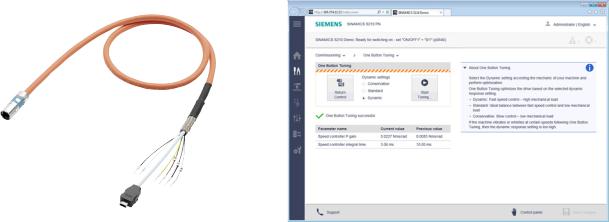

Optimized connection technology with |

|

Easy commissioning via web server, One Button Tuning and |

|

|

|

|

One Cable Connection (OCC) |

|

SINAMICS Startdrive/TIA Portal (V15.1 or higher) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Example: SINAMICS S210 M12 OCC connecting cable

Motor and converter are simply connected to one another by one instead of the usual two or three cables. With this One Cable Technology, energy supply, encoder signals and braking signal are brought together in a single cable. This results in the following advantages:

•Time-saving by laying only one cable

•Smaller installation space and space requirement in cable collars, tight bending radii

•Only one cable has to be cleaned. This is advantageous, e.g. in the pharmaceutical industry and where higher requirements are placed upon hygiene

•Can be ordered to the decimeter

•Compact connection system

•Rotatable connector on the motor side

•Motor with very low interfering contour for restricted installation space.

Cables are available in two different qualities:

•MOTION-CONNECT 500

•MOTION-CONNECT 800PLUS

In addition to the pre-assembled cable, individual components (connectors and products sold by the meter) can be ordered for self-assembly (available soon).

One Button Tuning

The web server of the converter offers a simple means of parameter assignment. The web server allows commissioning purely oriented on the functionality of the drive. With the web server, the SINAMICS S210 servo drive system can be brought into operation with a few clicks.

As a result of reading the electronic type plate of the connected SIMOTICS S-1FK2 servomotor, only a few operator actions, such as automatic controller optimization with One Button Tuning, are necessary, as the motor and encoder are automatically detected. The controller parameters are automatically optimized. The three selectable dynamic levels of the controller can optimally take into account the desired behavior of the connected mechanics.

A motion of the axis can take place directly via the control panel during commissioning.

The customer benefits from the web server in many ways:

•Commissioning can also be easily done in places difficult to access, as the web server in the converter can also be accessed directly via PROFINET from the controller.

•The web server provides full diagnostic capability without the need for additional software.

•Commissioning and diagnostics can also be done without a cable via mobile devices, such as laptops, smart phones and tablets (an additional WLAN access point is necessary).

•Intuitive user interface

In addition to easy commissioning directly via the web server of the converter, engineering is also possible with SINAMICS Startdrive and TIA Portal (V15.1 or higher). The tool for configuration, commissioning and diagnostics has been optimized with regard to the consistent utilization of the TIA Portal advantages – one shared work environment for PLC, HMI and drives. SINAMICS firmware V5.2 or higher is required for

SINAMICS S210 devices.

For more information, see the Engineering tools section.

1/8 |

|

Siemens D 32 · January 2020 |

|

|

|

© Siemens 2020

System overview

SINAMICS S210 servo drive system

■ Overview

1

Diagnostics

Faults and warnings are shown on the display located under the front cover, and they can be acknowledged with the Acknowledge button. Extensive diagnostics with plain text messages for cause and remedy information is possible via the web server.

Safety Integrated

The integrated safety functions provide highly effective, applica- tion-oriented protection for personnel and machinery (terms as defined in IEC 61800-5-2).

The following Safety Integrated Basic Functions are included as standard:

•Safe Torque Off (STO)

•Safe Brake Control (SBC)

•Safe Stop 1 (SS1)

The following Safety Integrated Extended Functions 1) are available as options:

•Safe Stop 2 (SS2)

•Safe Operating Stop (SOS)

•Safely-Limited Speed (SLS)

•Safe Speed Monitor (SSM)

•Safe Direction (SDI)

•Safely-Limited Acceleration (SLA)

•Safe Brake Test (SBT) diagnostic function

The Safety Integrated Functions are fully integrated into the drive system. They can be activated via fail-safe digital inputs on the converter (only STO and SS1) or via PROFINET with PROFIsafe.

The Safety Integrated Functions are implemented electronically and therefore require no additional installation effort or space in the control cabinet. Furthermore, the costs are considerably lower than for externally implemented monitoring functions.

The Safety Integrated Functions can be easily commissioned using the web server of the converter or SINAMICS Startdrive/ TIA Portal V15.1 or higher.

Perfect combination with

SIMATIC S7-1500, SIMATIC S7-1500 T-CPU, SIMATIC ET 200SP Open Controller, and PROFINET

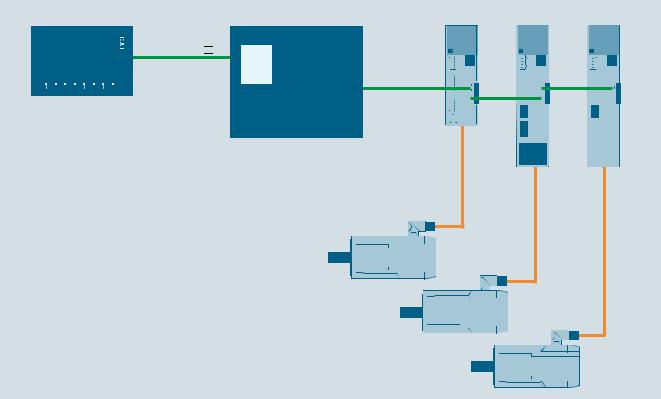

It communicates with the higher-level control via PROFINET IRT. For optimal interaction between the controller and the SINAMICS S210 servo drive system, SIMATIC S7-1500, SIMATIC S7-1500 T-CPU, SIMATIC ET 200SP Open Controller, and SIMOTION can be used as the control system.

The SINAMICS S210 servo converter has an integrated PROFINET communications interface with a cycle of up to 250 μs for connecting to a control system.

Standardized protocols for linking to a higher-level control with RT and IRT are supported – the PROFIdrive profile with DSC for positioning mode and the PROFIsafe profile for safety-related communication. Functions, such as Shared Device, ring redundancy and PROFIenergy, are also possible.

Everything from one source: Through the use of Motion Control functionalities in the controller, the combination of converter and SIMATIC S7 automation system or a SIMOTION controller allows ideally harmonized engineering. As a result, commissioning times are shortened.

Via technology objects and Motion Control blocks of the higherlevel controller, there are many possibilities of motion, such as continuous operation, positioning and synchronous operation, and coordinated motion of multiple axes via cyclic cams or interpolation.

Siemens offers tested SIMATIC PLC/HMI application examples for connection of the servo drive system to a SIMATIC controller: www.siemens.com/sinamics-applications

Further information on the SIMATIC S7-1500,

SIMATIC S7-1500 T-CPU and SIMATIC ET 200SP Open Controller is available in the ST 70 Catalog and on the Internet under www.siemens.com/simatic-s7-1500

1)Available in SINAMICS V5.1 SP1 and higher. The Extended Functions require a Safety license.

Change 07/2020 |

Siemens D 32 · January 2020 |

|

1/9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

© Siemens 2020 |

|

|

|

|

|

|

|

|

|

|

System overview |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

SINAMICS S210 servo drive system |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

■ Overview |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

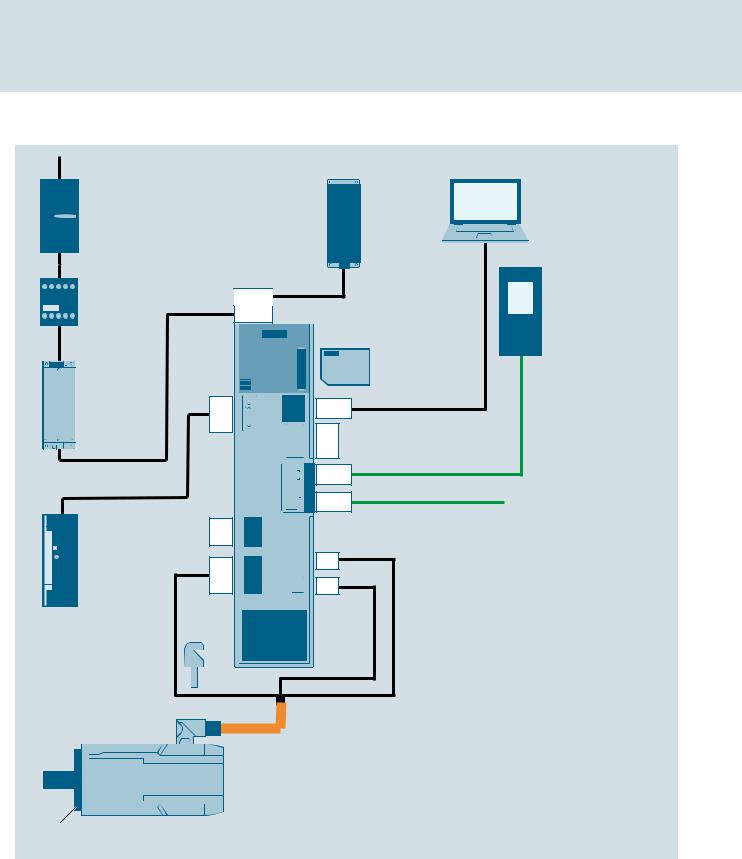

SIMATIC Basic Panel |

SIMATIC S7-1515T PN |

SINAMICS S210 servo drive |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROFINET

PROFINET IRT

<![if ! IE]><![endif]> G_D211_EN_00392

G_D211_EN_00392

OCC (One Cable Connection for motor, motor holding brake and encoder)

SIMOTICS S-1FK2 servomotors

Example: Communication via PROFINET

Ruggedness

The SINAMICS S210 is equipped as standard with varnished or partially varnished modules. The painting on the modules protects the sensitive SMD components against corrosive gases, chemically active dust and moisture.

Can be used worldwide

In addition to the usual approvals, the SINAMICS S210 drive system also has UL approval for the North American market. This means that the drive system, comprising SINAMICS S210 and SIMOTICS S-1FK2, including the One Cable Connection (OCC), can be used worldwide.

More information

A Quick Installation Guide is supplied in hard copy form in English with every SINAMICS S210. Further documentation, such as the operating instructions, is available free on the Internet at: www.siemens.com/sinamics-s210/documentation

Detailed information on the SINAMICS S210 drive system, including the latest technical documentation (brochures, tutorials, dimensional drawings, certificates, manuals and operating instructions), is available on the Internet at: www.siemens.com/sinamics-s210

and is also available via the Drive Technology Configurator (DT Configurator) on the Internet.

The DT Configurator can be found in the Siemens Industry Mall at the following address:

www.siemens.com/dt-configurator

1/10 |

|

Siemens D 32 · January 2020 |

|

|

|

© Siemens 2020

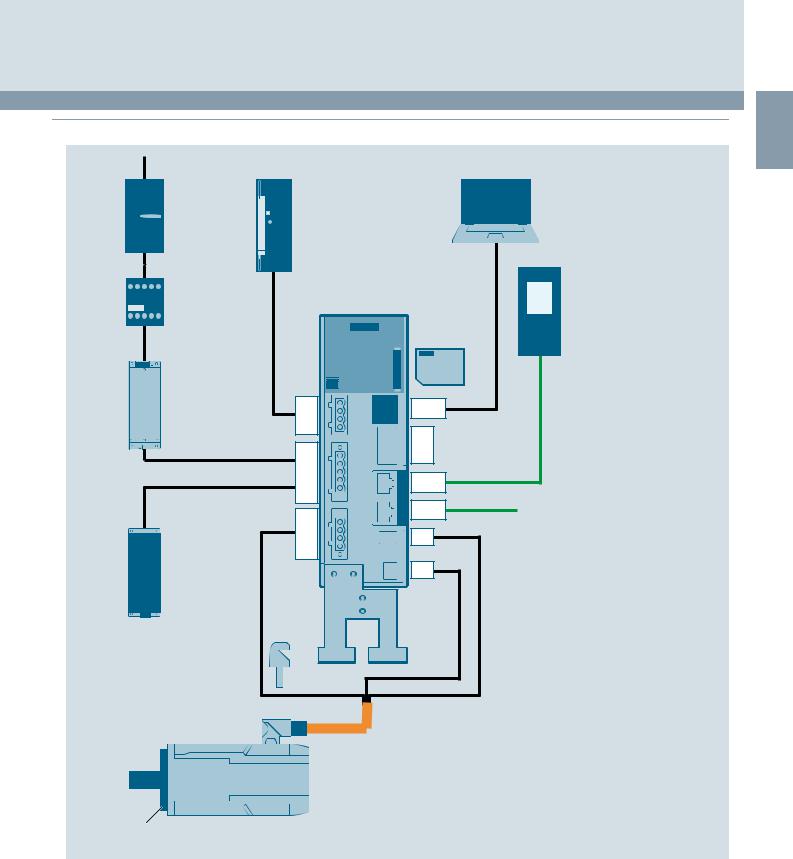

System overview

SINAMICS S210 servo drive system

■ Overview

1

|

|

|

Fuse or |

|

|

Power supply |

|

|

|

|

|

|

Commissioning device |

||

|

|

|

circuit-breaker |

|

|

|

24 V DC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Line contactor |

|

|

|

Controller |

SINAMICS S210 |

|

|

(e.g. SIMATIC S7-1500) |

|

(optional) |

converter |

|

|

|

|

1 AC series |

|

|

|

|

|

SD memory card |

|

|

|

|

(optional) |

|

|

Line filter |

|

|

|

|

(optional) |

|

|

|

|

|

X124 |

X127 |

|

|

|

|

|

|

|

|

|

X130 |

F-DI |

|

|

|

measuring probe |

|

|

|

X1 |

|

|

|

|

|

X150 P1 |

|

|

|

|

X150 P2 |

To further PROFINET devices |

|

|

|

(e.g. further SINAMICS S210) |

||

|

|

|

|

|

External |

X2 |

X100 |

|

|

braking resistor |

|

|

|

|

|

|

|

|

|

(optional) |

|

|

|

|

|

|

X107 |

|

|

|

|

Shield plate |

|

|

|

Shield |

|

|

|

|

connection clamp |

|

|

|

SIMOTICS S-1FK2

OCC (One Cable Connection for motor,

servomotor

motor holding brake and encoder)

<![if ! IE]><![endif]>G_D211_EN_00368a

Shaft sealing ring (optional)

Example for the 1 AC series

Siemens D 32 · January 2020 |

|

1/11 |

|

|

|

© Siemens 2020

|

|

System overview |

|

|

|

|

|

1 |

|

SINAMICS S210 servo drive system |

|

|

|

|

|

|

■ Overview |

||

|

|

|

|

|

|

|

Fuse or |

External |

|

|

|

|

circuit-breaker |

braking resistor |

|

|

|

|

|

(optional) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SINAMICS S210 |

|

converter |

Line contactor |

3 AC series |

(optional) |

X4 |

|

|

|

X1 |

SD memory card (optional)

Line filter (optional)

X127

X124

F-DI

X130 measuring probe

Power supply 24 V DC

X150 P1

X150 P2

DC link

coupling X3 (optional)

X100

X2

X107

Shield connection clamp

SIMOTICS S-1FK2

OCC (One Cable Connection for motor,

servomotor

motor holding brake and encoder)

<![if ! IE]><![endif]>G_D211_EN_00391

Shaft sealing ring (optional)

Commissioning device

Controller

(e.g. SIMATIC S7-1500)

To further PROFINET devices (e.g. further SINAMICS S210)

Example for the 3 AC series

1/12 |

|

Siemens D 32 · January 2020 |

|

|

|

© Siemens 2020

Clicking to the Industry Mall

6SL3255-0AA00-5AA0

System overview

|

|

|

|

|

|

|

|

|

|

|

SINAMICS S210 servo drive system |

|

1 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

■ Order overview |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

SINAMICS S210 drive system for line connection 200 ... 240 V 1 AC |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

SIMOTICS S-1FK2 servomotor |

|

|

|

SINAMICS S210 servo converter |

MOTION-CONNECT |

|

|

||||||

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

(1 AC series) |

|

motor connection cable |

|

|

||

|

|

|

|

|

|

|

|

|

Supply voltage 200 ... 240 V 1 AC |

|

|

|

|

||

|

|

Static |

Maxi- |

Maxi- |

Rated |

Rated |

Rotor |

|

Rated |

Frame |

|

|

|

|

|

|

|

torque |

mum |

mum |

power |

torque |

moment |

|

power |

size |

|

|

|

|

|

|

|

|

torque |

speed |

230 V |

|

of inertia |

|

230 V |

|

|

|

|

|

|

|

|

M0 |

Mmax |

nmax |

Prated |

Mrated |

JMot |

|

Prated |

|

|

|

|

|

|

|

|

Nm |

Nm |

|

kW |

Nm |

kg cm2 |

|

kW |

|

|

|

|

|

|

|

|

(lbf-ft) |

(lbf-ft) |

rpm |

(hp) |

(lbf-ft) |

(lbf-in2) |

Article No. |

|

|

Article No. |

Article No. |

|

|

|

|

|

High Dynamic for highly dynamic applications |

|

|

SINAMICS S210 servo converter |

One Cable Connection |

|

|

|||||||

|

|

Shaft height 20 – rated speed nrated 3000 rpm |

|

|

|

|

|

|

|

|

|

||||

|

0.16 |

0.56 |

8000 |

0.05 |

0.16 |

0.025 |

1FK2102-0AG■■-■■A0 |

0.1 |

FSA |

6SL3210-5HB10-1UF0 |

6FX■002-8QN04-1■■■ |

|

|

||

(0.12) |

(0.41) |

|

(0.07) |

(0.12) |

(0.009) |

|

|

|

|

|

|

|

|

||

|

0.32 |

1.11 |

8000 |

0.1 |

0.32 |

0.036 |

1FK2102-1AG■■-■■A0 |

0.1 |

FSA |

6SL3210-5HB10-1UF0 |

6FX■002-8QN04-1■■■ |

|

|

|

|

(0.24) |

(0.82) |

|

(0.13) |

(0.24) |

(0.012) |

|

|

|

|

|

|

|

|

||

|

|

Shaft height 30 – rated speed nrated 3000 rpm |

|

|

|

|

|

|

|

|

|

||||

|

0.64 |

1.95 |

8000 |

0.2 |

0.64 |

0.093 |

1FK2103-2AG■■-■■A0 |

0.2 |

FSA |

6SL3210-5HB10-2UF0 |

6FX■002-8QN04-1■■■ |

|

|

||

(0.47) |

(1.44) |

|

(0.27) |

(0.47) |

(0.032) |

|

|

|

|

|

|

|

|

||

|

1.27 |

4.05 |

7300 |

0.4 |

1.27 |

0.14 |

1FK2103-4AG■■-■■A0 |

0.4 |

FSB |

6SL3210-5HB10-4UF0 |

6FX■002-8QN04-1■■■ |

|

|

|

|

(0.94) |

(2.99) |

|

(0.54) |

(0.94) |

(0.048) |

|

|

|

|

|

|

|

|

||

|

|

Shaft height 40 – rated speed nrated 1500 rpm |

|

|

|

|

|

|

|

|

|

||||

|

1.27 |

3.75 |

3600 |

0.2 |

1.27 |

0.35 |

1FK2104-4AF■■-■■A0 |

0.2 |

FSA |

6SL3210-5HB10-2UF0 |

6FX■002-8QN08-1■■■ |

|

|

||

(0.94) |

(2.77) |

|

(0.27) |

(0.94) |

(0.120) |

|

|

|

|

|

|

|

|

||

|

2.4 |

7.5 |

3300 |

0.38 |

2.4 |

0.56 |

1FK2104-5AF■■-■■A0 |

0.4 |

FSB |

6SL3210-5HB10-4UF0 |

6FX■002-8QN08-1■■■ |

|

|

|

|

(1.77) |

(5.53) |

|

(0.51) |

(1.77) |

(0.191) |

|

|

|

|

|

|

|

|

||

|

3.2 |

10 |

3600 |

0.5 |

3.2 |

0.76 |

1FK2104-6AF■■-■■A0 |

0.75 |

FSC |

6SL3210-5HB10-8UF0 |

6FX■002-8QN08-1■■■ |

|

|

|

|

(2.36) |

(7.38) |

|

(0.67) |

(2.36) |

(0.260) |

|

|

|

|

|

|

|

|

||

|

|

Shaft height 40 – rated speed nrated 3000 rpm |

|

|

|

|

|

|

|

|

|

||||

|

1.27 |

3.85 |

7500 |

0.4 |

1.27 |

0.35 |

1FK2104-4AK■■-■■A0 |

0.4 |

FSB |

6SL3210-5HB10-4UF0 |

6FX■002-8QN08-1■■■ |

|

|

||

(0.94) |

(2.84) |

|

(0.54) |

(0.94) |

(0.120) |

|

|

|

|

|

|

|

|

||

|

2.4 |

7.6 |

7100 |

0.75 |

2.4 |

0.56 |

1FK2104-5AK■■-■■A0 |

0.75 |

FSC |

6SL3210-5HB10-8UF0 |

6FX■002-8QN08-1■■■ |

|

|

|

|

(1.77) |

(5.61) |

|

(1.01) |

(1.77) |

(0.191) |

|

|

|

|

|

|

|

|

||

|

|

Compact for high precision applications |

|

|

SINAMICS S210 servo converter |

One Cable Connection |

|

|

|||||||

|

|

Shaft height 30 – rated speed nrated 3000 rpm |

|

|

|

|

|

|

|

|

|

||||

|

0.64 |

1.85 |

8000 |

0.2 |

0.64 |

0.20 |

1FK2203-2AG■■-■■A0 |

0.2 |

FSA |

6SL3210-5HB10-2UF0 |

6FX■002-8QN04-1■■■ |

|

|

||

(0.47) |

(1.36) |

|

(0.27) |

(0.47) |

(0.068) |

|

|

|

|

|

|

|

|

||

|

1.27 |

3.75 |

7800 |

0.4 |

1.27 |

0.35 |

1FK2203-4AG■■-■■A0 |

0.4 |

FSB |

6SL3210-5HB10-4UF0 |

6FX■002-8QN04-1■■■ |

|

|

|

|

(0.94) |

(2.77) |

|

(0.54) |

(0.94) |

(0.120) |

|

|

|

|

|

|

|

|

||

|

|

Shaft height 40 – rated speed nrated 1500 rpm |

|

|

|

|

|

|

|

|

|

||||

|

2.4 |

7.1 |

3700 |

0.38 |

2.4 |

1.2 |

1FK2204-5AF■■-■■A0 |

0.4 |

FSB |

6SL3210-5HB10-4UF0 |

6FX■002-8QN08-1■■■ |

|

|

||

(1.77) |

(5.24) |

|

(0.51) |

(1.77) |

(0.410) |

|

|

|

|

|

|

|

|

||

|

3.2 |

9.5 |

3800 |

0.5 |

3.2 |

1.6 |

1FK2204-6AF■■-■■A0 |

0.75 |

FSC |

6SL3210-5HB10-8UF0 |

6FX■002-8QN08-1■■■ |

|

|

|

|

(2.36) |

(7.01) |

|

(0.67) |

(2.36) |

(0.547) |

|

|

|

|

|

|

|

|

||

|

|

Shaft height 40 – rated speed nrated 3000 rpm |

|

|

|

|

|

|

|

|

|

||||

|

2.4 |

7.1 |

7500 |

0.75 |

2.4 |

1.2 |

1FK2204-5AK■■-■■A0 |

0.75 |

FSC |

6SL3210-5HB10-8UF0 |

6FX■002-8QN08-1■■■ |

|

|

||

(1.77) |

(5.24) |

|

(1.01) |

(1.77) |

(0.410) |

|

|

|

|

|

|

|

|

||

|

|

Shaft height 48 – rated speed nrated 1500 rpm |

|

|

|

|

|

|

|

|

|

||||

|

3.6 |

10.8 |

3200 |

0.53 |

3.4 |

3.2 |

1FK2205-2AF■■-■■A0 |

0.75 |

FSC |

6SL3210-5HB10-8UF0 |

6FX■002-8QN08-1■■■ |

|

|||

(2.66) |

(7.97) |

|

(0.71) |

(2.51) |

(1.093) |

|

|

|

|

|

|

|

|

||

Article No. supplements |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Holding brake |

|

|

|

|

|

|

Pre-assembled MOTION-CONNECT cable |

|

|

|

|

|

|

|

Without brake |

0 |

|

|

|

|

|

MOTION-CONNECT 500 |

5 |

|

|

|

|

|

|

With brake |

1 |

|

|

|

|

|

MOTION-CONNECT 800PLUS |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Degree of protection |

|

|

|

|

|

|

Length code (max. 50 m (164 ft)) |

|

|

|

|

|

|

|

IP64 (without shaft sealing ring) |

|

0 |

|

|

|

|

0 m (0 ft) |

|

|

A |

|

|

|

|

IP65 (with shaft sealing ring) |

|

1 |

|

|

|

|

10 m (32.8 ft) |

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

... |

|

|

... |

|

|

|

|

Shaft extension / feather key |

|

|

|

|

|

|

50 m (164 ft) |

|

|

F |

|

|