Siemens SINUMERIK 808 Users guide

© Siemens Industry, Inc. 2018

Motion Control

SINUMERIK 808

Equipment for Machine Tools

|

|

US |

|

|

Catalog |

|

Edition |

|

|

|

||||

NC 81.1 |

|

2019 |

|

siemens.com/sinumerik |

|

|

|

|

|

© Siemens Industry, Inc. 2018

Related catalogs

|

|

Motion Control |

NC 62 |

SINUMERIK 840 |

|

Equipment for Machine Tools |

|

E86060-K4462-A101-A2-7600 |

|

|

|

|

|

Motion Control |

NC 82 |

SINUMERIK 828 |

|

Equipment for Machine Tools |

|

E86060-K4482-A101-A6-7600 |

|

|

|

|

|

Motion Control Drives |

D 31.1 |

SINAMICS Inverters for Single-Axis Drives |

|

Built-In Units |

|

E86060-K5531-A111-A1-7600 |

|

|

|

|

|

Motion Control Drives |

D 31.2 |

SINAMICS Inverters for Single-Axis Drives

Distributed Inverters

E86060-K5531-A121-A1-7600

SITRAIN

Training for Industry

www.siemens.com/sitrain

Products for Automation and Drives CA 01

Interactive Catalog

Download

www.siemens.com/ca01download

Industry Mall

Information and Ordering Platform

in the Internet:

www.siemens.com/industrymall

© Siemens Industry, Inc. 2018

SINUMERIK 808

Equipment for Machine Tools

Motion Control

Catalog NC 81.1 · 2019

Supersedes:

Catalog NC 81.1 · 2018

Refer to the Industry Mall for current updates of this catalog:

www.siemens.com/industrymall

The products contained in this catalog can also be found in the Interactive Catalog CA 01.

Article No.: E86060-D4001-A510-D8-7500

Please contact your local Siemens branch.

Click on an Article No. in the catalog PDF to call it up in the Industry Mall and to obtain all the information.

Article No.

6SL3070-0AA00-0AG0 6SL3072-0AA00-0AG0

Or directly on the Internet, e.g. www.siemens.com/product?6SL3070-0AA00-0AG0

The products and systems described in

this catalog are distributed under application of a certified quality management system in accordance with DIN EN ISO 9001 (Certified Registration No. 001258 UM). The certificate is recognized by all IQNet countries.

Introduction

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

SINUMERIK 808D ADVANCED system

SINUMERIK 808D ADVANCED PPU 15x.3/PPU 16x.3 Operator components

Feed axis solutions Spindle solutions

MOTION-CONNECT connection systems Example packages

Accessories

Operator components

Supplementary components

Direct spindle encoder

Services and training

Services

Training

Documentation

Appendix

Certificates of suitability

Subject index

Conversion tables

Metal surcharges

Conditions of sale and delivery

Export regulations

1

2

3

4

5

6

© Siemens Industry, Inc. 2018

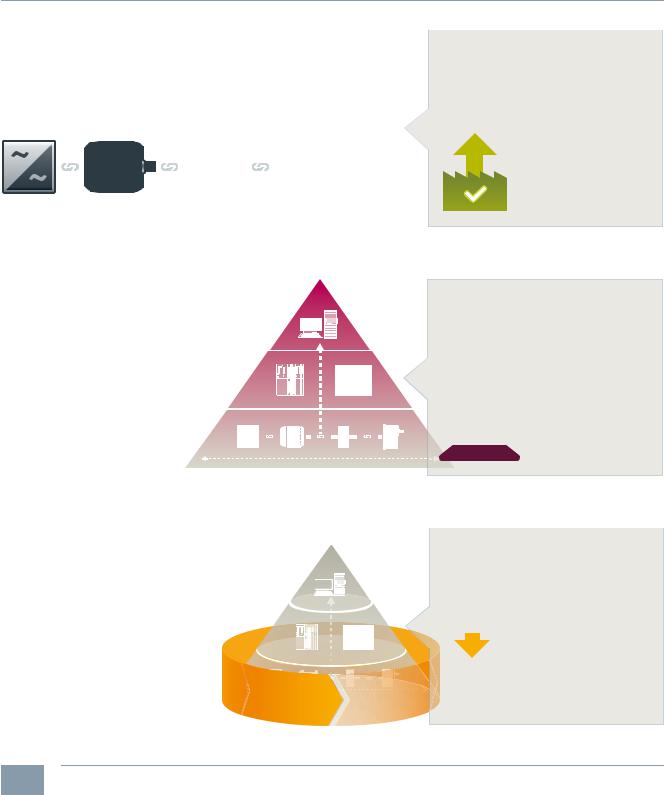

Digital Enterprise

The building blocks that ensure everything works together perfectly in the digital enterprise

Digitalization is already changing all areas of life and existing business models. It is placing greater pressure on industry while at the same time creating new business opportunities. Today, thanks to scalable solutions from Siemens, companies can already become a digital enterprise and ensure their competitiveness.

Industry faces tremendous challenges

Reduce time-to-market

Today manufacturers have to bring products to market at an ever-increas- ing pace despite the growing complexity of these products. In the past, a major manufacturer would push aside a small one, but now it is a fast manufacturer that overtakes a slow one.

Boost |

Improve |

Boost |

Increase |

flexibility |

quality |

efficiency |

security |

Consumers want cus- |

To ensure a high level of |

Today the product itself |

Increasing networking |

tomized products, but at |

quality while meeting |

needs to be sustainable |

escalates the threat to |

a price they would pay |

legal requirements, |

and environmentally |

production facilities |

for a mass-produced |

companies have to |

friendly, while energy |

of cyberattacks. Today |

item. That only works |

establish closed quality |

efficiency in production |

more than ever, com- |

if production is more |

loops and enable the |

has become a competi- |

panies need suitable |

flexible than ever |

traceability of products. |

tive advantage. |

security measures. |

before. |

|

|

|

|

|

|

|

2Siemens NC 81.1 · 2019

© Siemens Industry, Inc. 2018

The digital enterprise has already become a reality

To fully benefit from all the advantages of digitalization, companies first have to achieve complete consistency of their data. Fully digitally integrated business processes, including those of suppliers, can help to create a digital representation of the entire value chain. This requires

•the integration of industrial software and automation,

•expansion of the communication net- works,

•security in automation,

•and the use of business-specific industrial services.

MindSphere

The cloud-based open IoT operating system from Siemens

With MindSphere, Siemens offers a costeffective and scalable cloud platform as a service (PaaS) for the development of appli- cations. The platform, designed as an open operating system for the Internet of Things, makes it possible to improve the efficiency of plants by collecting and analyzing large volumes of production data.

Totally Integrated Automation (TIA)

Where digitalization becomes reality

Totally Integrated Automation (TIA) ensures the seamless transition from the virtual to the real world. It already encompasses all the necessary conditions for transforming the benefits of digitalization into true added value. The data that will form the digital twin for actual production is generated from a common base.

Digital Plant

Learn more about the digital enterprise for the process industry www.siemens.com/ digitalplant

Digital Enterprise Suite

Learn more about the digital enterprise for the discrete industry www.siemens.com/ digital-enterprise-suite

Siemens NC 81.1 · 2019 |

|

3 |

|

|

|

© Siemens Industry, Inc. 2018

Integrated Drive Systems

Faster on the market and in the black with Integrated Drive Systems

Integrated Drive Systems are Siemens’ trendsetting answer to the high degree of complexity that characterizes drive and automation technology today. The world’s only true one-stop solution for entire drive systems is characterized in particular by its threefold integration: Horizontal, vertical, and lifecycle integration ensure that every drive system component fits seamlessly into the whole system, into any automation environment, and even into the entire lifecycle of a plant.

The outcome is an optimal workflow – from engineering all the way to service that entails more productivity, increased efficiency, and better availability. That’s how Integrated Drive Systems reduce time to market and time to profit.

Horizontal integration

Integrated drive portfolio: The core elements of a fully integrated drive portfolio are frequency converters, motors, couplings, and gear units.

At Siemens, they‘re all available from a single source. Perfectly integrated, perfectly interacting. For all power and performance classes. As standard solutions or fully customized. No other player in the market can offer a comparable portfolio. Moreover, all Siemens drive components are perfectly matched, so they are optimally interacting.

You can boost the availability of your application or plant to up to

99%*

*e.g., conveyor application

Vertical integration

Thanks to vertical integration, the complete drive train is seamlessly integrated in the entire automation environment – an important prerequisite for production with maximum value added. Integrated Drive Systems are part of Totally Integrated Automation (TIA), which means that they

are perfectly embedded into the system architecture of the entire industrial production process. This enables optimal processes through maximum communication and control.

With TIA Portal you can cut your engineering time by up to

30%

30%

Lifecycle integration

Lifecycle integration adds the factor of time: Software and service are available for the entire lifecycle of an Integrated Drive System. That way, important optimization potential for maximum productivity, increased efficiency, and highest availability

can be leveraged throughout the system’s lifecycle – from planning, design, and engineering to operation, maintenance, and all the way even to modernization.

With Integrated Drive Systems, assets become important success factors. They ensure shorter time to market, maximum productivity and efficiency in operation, and shorter time to profit.

With Integrated Drive Systems you can reduce your maintenance costs by up to

15%

15%

www.siemens.com/ids

4Siemens NC 81.1 · 2019

|

© Siemens Industry, Inc. 2018 |

1 |

||

|

|

|||

Introduction |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/2 |

|

How to use this catalog |

|

|

|

|

|

|

|

1/3 |

|

The system |

|

|

|

|

|

|

|

1/4 |

|

SINUMERIK 808D ADVANCED |

|

|

|

|

|

|

|

1/5 |

|

Feed and spindle drive solutions |

|

|

|

|

|

|

|

1/6 |

|

MOTION-CONNECT |

|

|

|

|

|

connection systems |

|

|

|

|

|

Siemens NC 81.1 · 2019

© Siemens Industry, Inc. 2018

Introduction

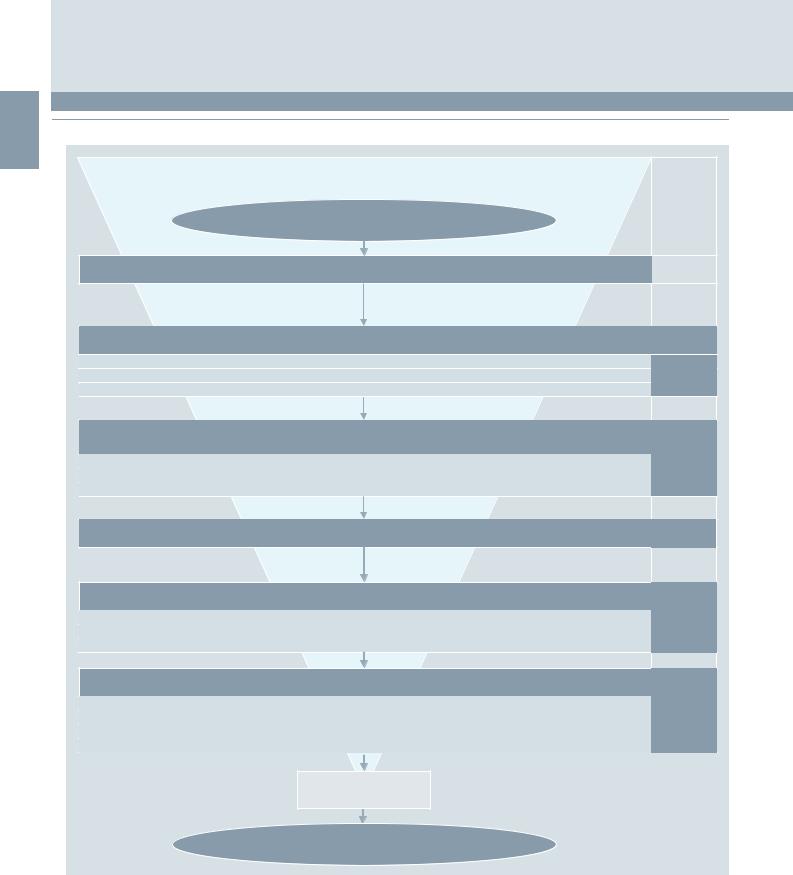

How to use this catalog

1 ■ Overview

See chapter

my CNC/drive/motor order list ?

Quick overview of the CNC/drive/motor system |

1 |

|

|

SINUMERIK 808D ADVANCED |

|

|

Overview of CNC functions |

2 |

|

Technical specifications of CNC |

3 |

|

Selection and ordering data of CNC |

||

|

Feed and spindle drive solution SINAMICS V70/ |

|

SIMOTICS S-1FL6/SIMOTICS M-1PH1 |

|

Technical specifications of drive modules, motors and cables |

3 |

Selection and ordering data of drive modules, motors and cables |

|

Dimensional drawings of drive modules, motors and cables |

|

Example packages to cross-check my order list |

3 |

CNC accessories (MCP, handwheels, PLC I/O, power supply, direct spindle encoder)

Technical specifications of CNC accessories |

4 |

Selection and ordering data of CNC accessories |

|

Dimensional drawings of CNC accessories |

|

Services and training

Material warranty and on-site service

5

System documentation

Training portfolio

SINUMERIK 808D on PC (training and offline programming system for PC)

G_NC01_EN_00796

Spindle solution

my CNC/drive/motor order list !

1/2 |

|

Siemens NC 81.1 · 2019 |

|

|

|

© Siemens Industry, Inc. 2018

Introduction

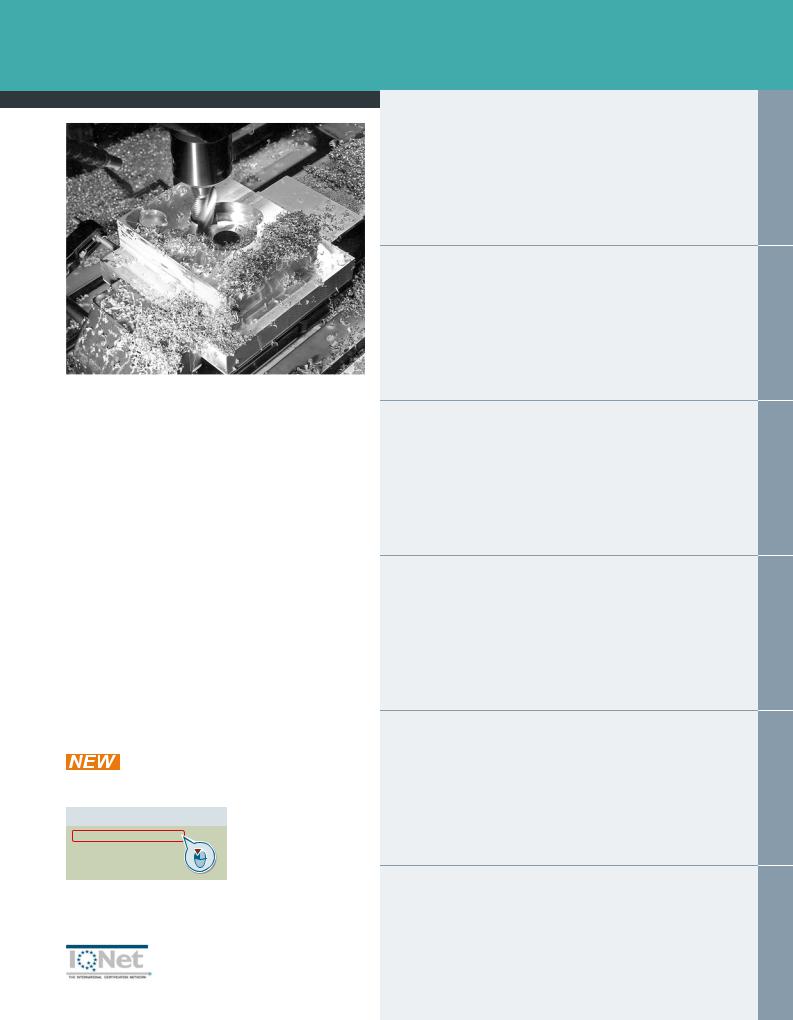

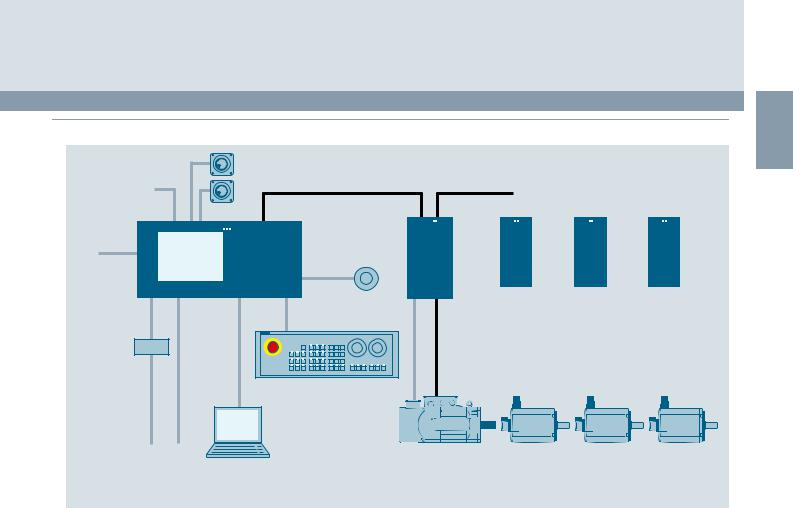

The system

1

■ Overview

|

|

Handwheels |

|

|

|

|

|

SINAMICS V70 |

|

Digital tool probe1) |

|

Drive bus |

|

spindle drive |

|

|

|

||

|

|

SINUMERIK 808D |

|

|

USB stick |

|

ADVANCED |

|

|

|

|

|

|

|

|

|

TTL |

|

|

|

|

|

Spindle |

|

Ribbon cable |

Ethernet/ |

USB |

encoder |

|

|

|

|||

|

factory |

|

|

|

Terminal strip |

network |

|

|

|

converter |

|

|

|

|

|

|

SINUMERIK 808D MCP |

PLC |

|

SIMOTICS |

process signals |

Notebook |

M-1PH1 |

1) Only used for milling version |

|

asynchronous |

|

main spindle motor |

SINAMICS V70 |

|

SINAMICS V70 |

SINAMICS V70 |

||||||||||||

|

servo drive |

|

servo drive |

|

servo drive |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>G NC01 EN 00548b |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SIMOTICS |

SIMOTICS |

SIMOTICS |

S-1FL6 |

S-1FL6 |

S-1FL6 |

synchronous |

synchronous |

synchronous |

feed motor |

feed motor |

feed motor |

SINUMERIK 808D ADVANCED system

Siemens NC 81.1 · 2019 |

|

1/3 |

|

|

|

© Siemens Industry, Inc. 2018

Introduction

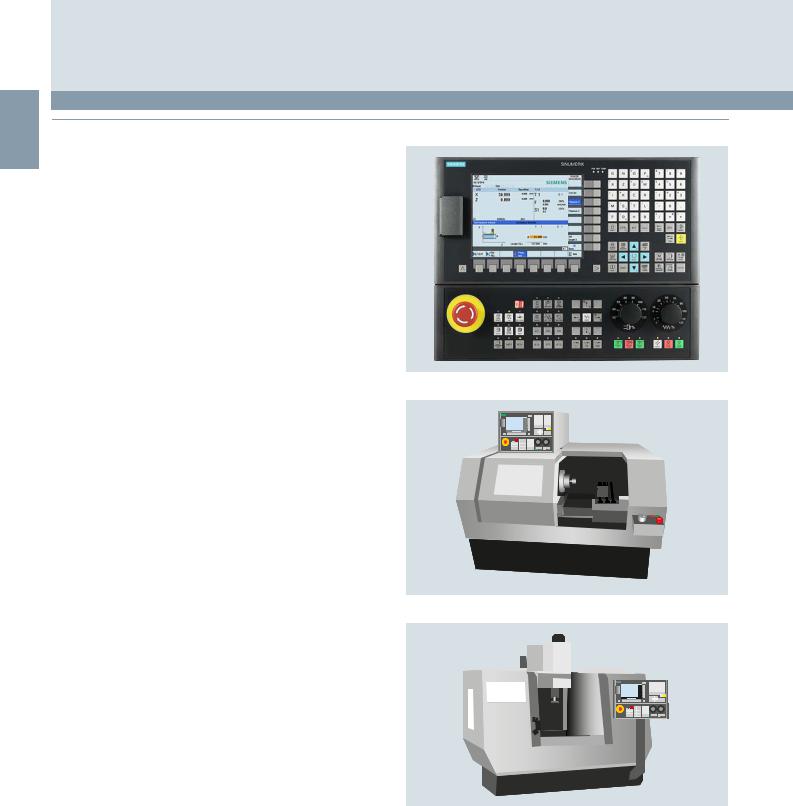

SINUMERIK 808D ADVANCED

1 ■ Overview

Small, robust, easy, simply smart

The operator-panel-based CNC SINUMERIK 808D ADVANCED is extremely compact, rugged and very easy to maintain.

With variable software options and high-dynamic servo drive systems, the SINUMERIK 808D ADVANCED system is offering the latest CNC solution for high-performance basic machines.

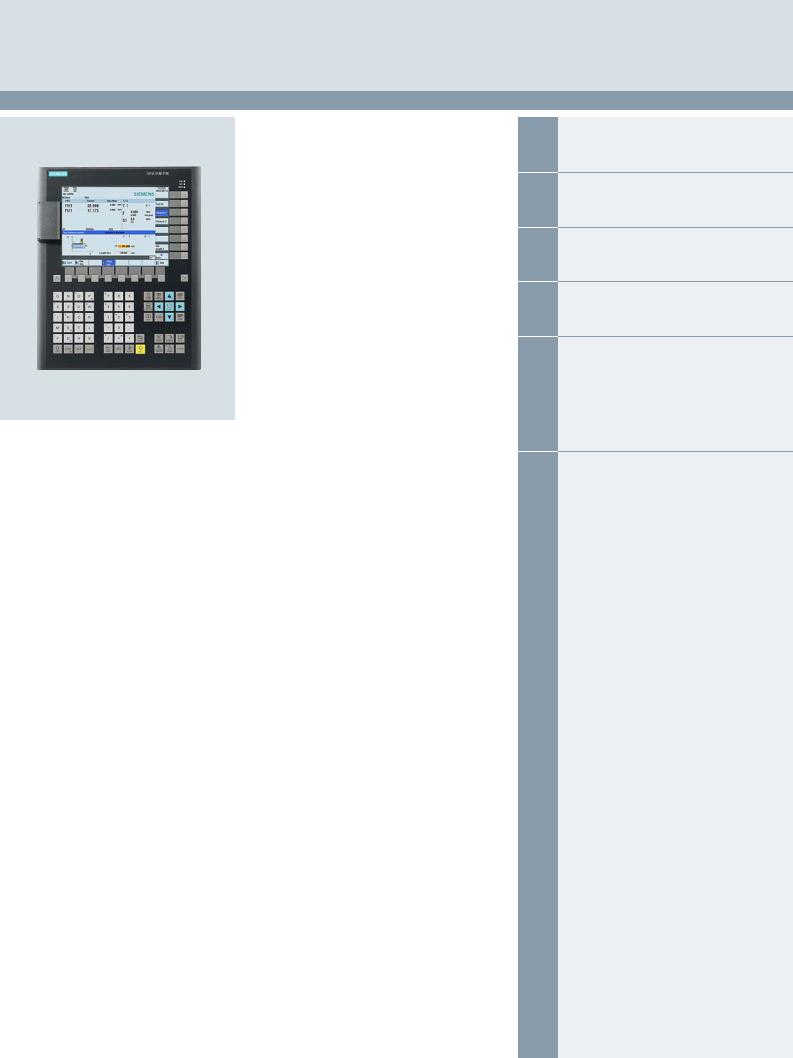

Preconfigured for basic standard turning machines …

The SINUMERIK 808D ADVANCED T CNC is perfectly preconfigured to meet the requirements of modern standard turning machines. Intelligent CNC features such as full servo controlled rigid tapping or the flying switchover between spindle and C axis enable most precise and fastest turning operation.

Perfectly preconfigured for:

7SINUMERIK 808D ADVANCED T:

Up to 6 axes/spindles in one machining channel with/without driven tool

7Preconfigured system software for inclined bed fully automated lathes and flat bed semi-automatic lathes

| <![if ! IE]> <![endif]>G NC01 XX 00493 |

... and basic standard milling machines

The SINUMERIK 808D ADVANCED M CNC is perfectly preconfigured to meet the requirements of modern standard milling machines.

7 SINUMERIK 808D ADVANCED M:

Up to 6 axes/spindles in one machining channel

7 Preconfigured system software for vertical machining centers

<![if ! IE]><![endif]>G_NC01_XX_00494

1/4 |

|

Siemens NC 81.1 · 2019 |

|

|

|

© Siemens Industry, Inc. 2018

Introduction

Feed and spindle drive solutions

1

■ Overview

SINAMICS V70, SIMOTICS S-1FL6 and SIMOTICS M-1PH1

SINAMICS V70 servo drives, SIMOTICS S-1FL6 feed motors and SIMOTICS M-1PH1 main spindle motors are designed for the maximum cutting performance for the basic turning and milling machine tool applications. The bus communication with the SINUMERIK 808D ADVANCED CNC system, threefold overload capacity and the 20 bit high-resolution absolute encoder installed in SIMOTICS S-1FL6 feed motors and SIMOTICS M-1PH1 main spindle motors allow to increase the precision and efficiency of the machines.

With a robust design, SINAMICS V70 together with SIMOTICS S-1FL6 feed motors and SIMOTICS M-1PH1 main

spindle motors are perfectly prepared for maximum availability even in harsh environments.

Up to 36 months material warranty and on-site service

Siemens offers a standard material warranty and free on-site service period of 24 months for the

SINUMERIK 808D ADVANCED and the associated components. Warranty can be easily extended up to 36 months by end user registration.

Moreover, Siemens ensures elimination of any defects on the components free of cost on site during the warranty period.

Further information about the conditions and the scope of the warranty and the on-site service can be found at:

www.siemens.com/automation/oss

Siemens NC 81.1 · 2019 |

|

1/5 |

|

|

|

© Siemens Industry, Inc. 2018

Introduction

MOTION-CONNECT connection systems

1 ■

Overview

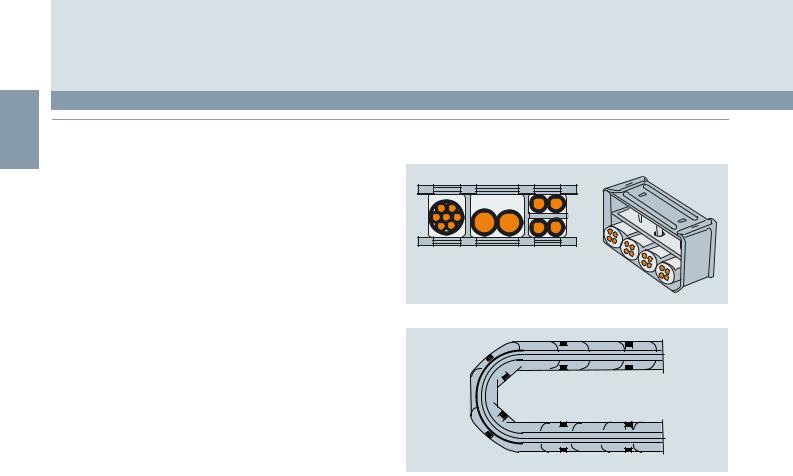

MOTION-CONNECTION 300 connection system

The MOTION-CONNECT 300 cables in this catalog are suitable for use with standard turning and milling machines.

The use of pre-assembled MOTION-CONNECT 300 cables ensures high quality and system-tested, problem-free operation.

Degree of protection of pre-assembled power and signal cables and their extensions is IP65 when closed and connected unless otherwise stated.

MOTION-CONNECT 300 cables are not suitable for outdoor use.

MOTION-CONNECT cables are approved for a maximum horizontal traverse path of 5 m.

To maximize the service life of the cable carrier and cables, cables in the carrier made from different materials must be separated in the cable carrier using spacers. The spacers must be filled evenly to ensure that the position of the cables does not change during operation. The cables should be distributed as symmetrically as possible according to their weights and dimensions. Cables with different outer diameters should be separated by spacers as well.

When inserting pre-assembled cables into the cable carrier, do not pull at the connector, as this may damage the strain relief or cable clamping.

The cables must not be fixed in the cable carrier. They must be freely movable.

The cables must be able to be moved without applying force, specifically in the bending radii of the carrier. The specified minimum bending radii must be adhered to.

The cable fixings must be attached at both ends at an appropriate distance from the end points of the moving parts in a dead zone.

Cables must be installed in accordance with the instructions supplied by the cable carrier manufacturer.

In case of vibration load and with horizontal or vertical cable entries, we recommend that the cable is additionally fixed if between the cable strain relief on the cable carrier and the terminal at the motor part of the cable is hanging loose or is not routed. To prevent machine vibrations being transmitted to the connectors, the cable should be fixed at the moving part where the motor is mounted.

The cables must be unwound without twisting.

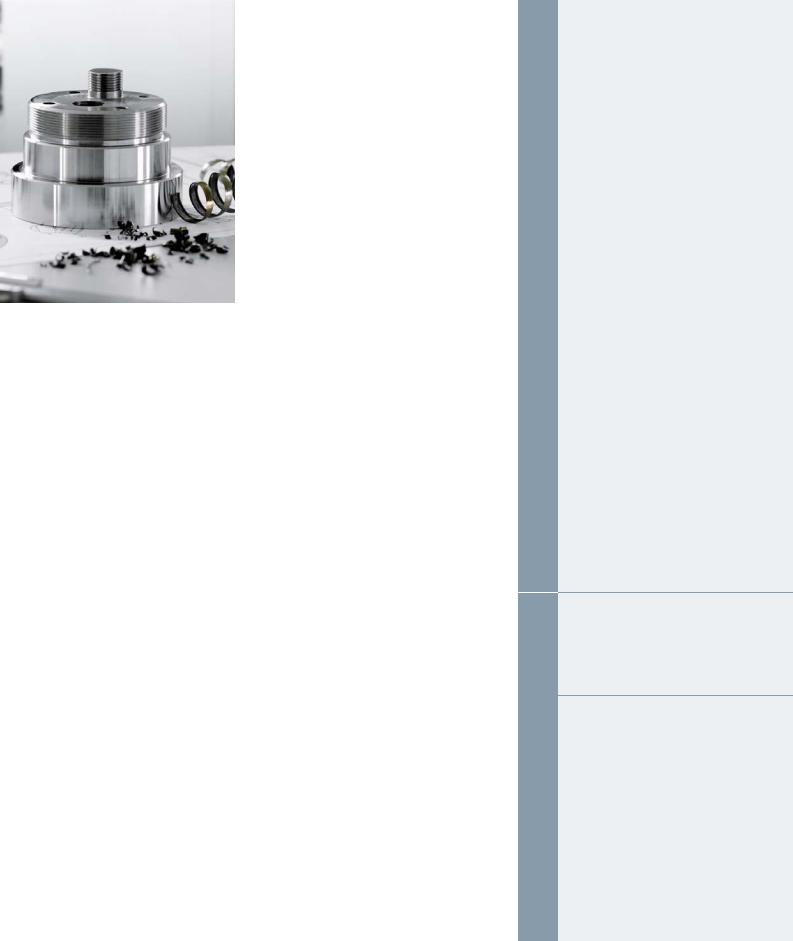

G_NC01_XX_00455

G_NC01_XX_00290

Derating factors for power and signal cables

Ambient air temperature |

Derating factor |

|

°C (°F) |

according to EN 60204-1 Table D.1 |

|

|

|

|

30 |

(86) |

1.15 |

35 |

(95) |

1.08 |

40 |

(104) |

1.00 |

45 |

(113) |

0.91 |

50 |

(122) |

0.82 |

55 |

(131) |

0.71 |

60 |

(140) |

0.58 |

|

|

|

1/6 |

|

Siemens NC 81.1 · 2019 |

|

|

|

|

© Siemens Industry, Inc. 2018 |

2 |

|

|

|

||

Overview of functions |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

2/2 |

SINUMERIK 808D ADVANCED |

|

|

|

|

CNC controls |

|

2/2 |

Control structure and configuration |

|

|

2/2 |

Connectable drives |

|

|

2/2 |

Connectable measuring systems |

|

|

2/3 |

Operation |

|

|

2/3 |

Axis functions |

|

|

2/4 |

Spindle functions |

|

|

2/4 |

Interpolations |

|

|

2/4 |

Measuring functions |

|

|

2/4 |

Motion-synchronous actions |

|

|

2/5 |

Open Architecture |

|

|

2/5 |

CNC programming language |

|

|

2/6 |

Technology cycles |

|

|

2/6 |

Canned cycles |

|

|

2/7 |

Program and workpiece management |

|

|

2/7 |

Programming support |

|

|

2/7 |

Simulations |

|

|

2/8 |

Operating modes |

|

|

2/8 |

Tools |

|

2/9 |

Communication and data management |

||

2/10 |

HMI functions |

||

2/10 |

Monitoring functions |

||

2/10 |

Compensations |

||

2/11 |

PLC area |

||

2/12 |

Commissioning and serial production |

||

2/12 |

Diagnostic functions |

||

2/12 |

Service and maintenance |

||

2/12 |

Training and offline programming |

||

The functionality of the SINUMERIK 808D ADVANCED CNCs PPU 15x and PPU 16x complies with the export list restrictions. Accordingly, these CNC controls do not require official approval as a result of their type in accordance with EU or German law.

The following overview lists all the functions that are available with SINUMERIK 808D ADVANCED controls. The information in the overview of SINUMERIK 808D ADVANCED functions is based on the following software version:

CNC |

Software |

|

version |

SINUMERIK 808D |

4.90 |

ADVANCED |

|

PPU 15x.3/PPU 16x.3 |

|

Siemens NC 81.1 · 2019

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Control structure and configuration/Connectable drives/Connectable measuring systems

|

|

Basic version |

Article No. |

SINUMERIK 808D ADVANCED |

|

|

||

|

|

O |

Option |

|

|

|

|

|

|

|

|

PPU 15x.3 |

|

PPU 16x.3 |

|

||

|

|

– |

Not available |

|

|

|

||

|

|

|

|

Note |

Turning |

Milling |

Turning |

Milling |

|

|

Control structure and configuration |

|

|

|

|

|

|

|

|

Panel-based control system comprising: |

|

|

|

|

|

|

|

|

• Compact operator panel |

|

|

|

|

|

|

|

|

• CNC/PLC Control Unit |

|

|

|

|

|

|

|

|

• Onboard digital PLC inputs/outputs |

|

|

|

|

|

|

2 |

|

• CF card with system software Export version |

|

Turning |

Milling |

Turning |

Milling |

|

|

|

|

|

|

|

|

||

|

SINUMERIK operator panel CNC: |

|

|

|

|

|

||

|

|

• Operator panel layout |

|

/ |

/ |

/ |

/ |

|

|

|

horizontal/vertical |

|

|

|

|

|

|

|

|

• Color display |

|

8.4" |

8.4" |

8.4" |

8.4" |

|

|

|

|||||||

|

|

• Display resolution |

|

800 × 600 |

800 × 600 |

800 × 600 |

800 × 600 |

|

|

|

• Integrated CNC keyboard with hard keys |

|

|

|

|

|

|

|

|

• Specific CNC keyboard layout for |

|

Turning |

Milling |

Turning |

Milling |

|

|

|

• Operator panel with Simplified Chinese layout |

|

|

|

|

|

|

|

|

• Operator panel with English layout |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SINUMERIK Operate BASIC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Quantity of bus interfaces for axis converter |

|

1 |

1 |

1 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

Quantity of analog ±10 V interfaces for |

|

1 |

1 |

1 |

1 |

|

|

|

spindle converter |

|

|

|

|

|

|

|

|

Channels/mode groups MG: |

|

|

|

|

|

|

|

|

• Maximum configuration |

|

1 |

1 |

1 |

1 |

|

|

|

CNC user memory (buffered) for |

The 1.25 MB memory is for |

1.25 MB |

1.25 MB |

1.25 MB |

1.25 MB |

|

|

|

CNC part programs |

storing and editing the user |

|

|

|

|

|

|

|

|

|

program. There is another |

|

|

|

|

|

|

|

|

500 MB memory for NC |

|

|

|

|

|

|

|

|

program storage. |

|

|

|

|

|

|

Axes/spindles: |

|

|

|

|

|

|

|

|

• Basic quantity of axes/spindles |

|

3 |

4 |

3 |

4 |

|

|

|

• Maximum configuration axes/spindles |

|

4 |

4 |

6 |

6 |

|

|

|

• Axis/spindle, each additional |

|

O |

– |

O |

O |

|

|

|

6FC5800-0AK70-0YB0 |

||||||

|

|

• Additional 1 positioning axis/auxiliary spindle |

6FC5800-0AK80-0YB0 |

O |

– |

O |

O |

|

|

|

Connectable drives |

|

|

|

|

|

|

|

|

Feed drives: |

|

|

|

|

|

|

|

|

• SINAMICS V70 via bus interface |

|

O |

O |

O |

O |

|

|

|

Spindles: |

|

|

|

|

|

|

|

|

• Analog Drive Interface |

|

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

|

|

|

SINAMICS V70 spindle via bus interface |

|

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

|

|

|

Connectable measuring systems |

|

|

|

|

|

|

|

|

Number of measuring systems per axis, max. |

|

1 |

1 |

1 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

Encoder installed in |

|

|

|

|

|

|

|

|

SIMOTICS S-1FL6 feed motors |

|

|

|

|

|

|

|

|

Encoder installed in |

|

|

|

|

|

|

|

|

SIMOTICS M-1PH1 main spindle motors |

|

|

|

|

|

|

|

|

RS422 (TTL) direct incremental spindle encoder |

6FX2001-2E... |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

|

2/2 |

|

Siemens NC 81.1 · 2019 |

|

|

|

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Operation/Axis functions

Basic version |

Article No. |

SINUMERIK 808D ADVANCED |

|

|

|

|

||

O |

Option |

|

|

|

|

|

|

|

|

PPU 15x.3 |

|

PPU 16x.3 |

|

|

|

||

– |

Not available |

|

|

|

|

|

||

|

|

Note |

Turning |

Milling |

Turning |

Milling |

|

|

Operation |

|

|

|

|

|

|

|

|

Machine Control Panel: |

|

|

|

|

|

|

|

|

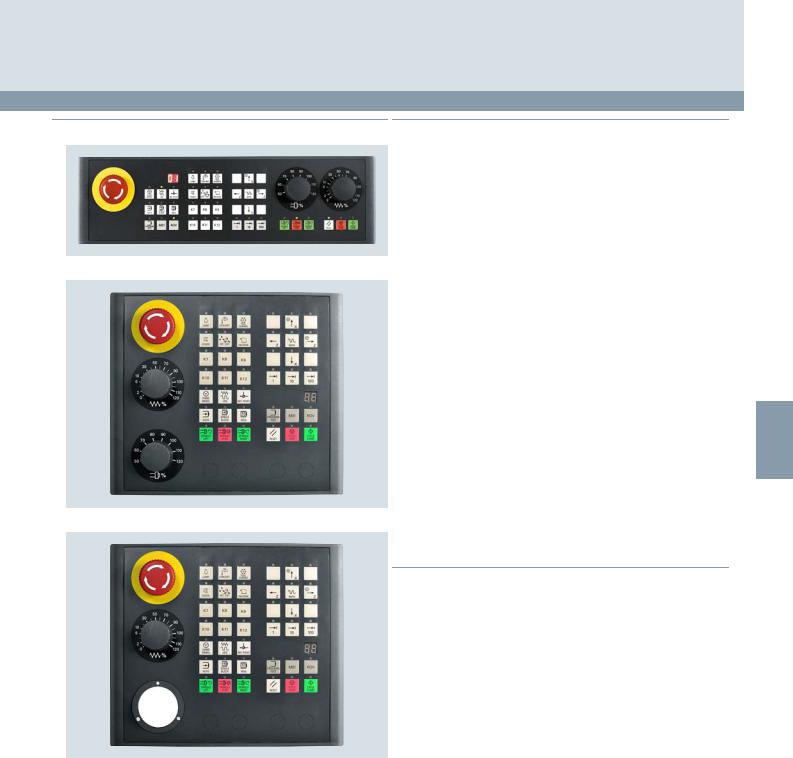

• SINUMERIK 808D MCP horizontal: |

|

|

|

|

|

|

|

|

- English layout |

|

O |

O |

O |

O |

|

|

|

6FC5303-0AF35-0AA0 |

|

|

||||||

- Simplified Chinese layout |

6FC5303-0AF35-0CA0 |

O |

O |

O |

O |

|

|

|

• SINUMERIK 808D MCP vertical: |

|

|

|

|

|

|

2 |

|

- English layout |

|

O |

O |

O |

O |

|

||

6FC5303-0AF35-2AA0 |

|

|||||||

- Simplified Chinese layout |

6FC5303-0AF35-2CA0 |

O |

O |

O |

O |

|

|

|

• SINUMERIK 808D MCP vertical: |

|

|

|

|

|

|

|

|

with handwheel slot |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

- English layout |

|

O |

O |

O |

O |

|

|

|

6FC5303-0AF35-3AA0 |

|

|

||||||

- Simplified Chinese layout |

6FC5303-0AF35-3CA0 |

O |

O |

O |

O |

|

|

|

• 3rd-party MCP via onboard digital |

|

O |

O |

O |

O |

|

|

|

PLC inputs/outputs |

|

|

|

|

|

|

|

|

Number of digital tool probes, max. |

|

– |

1 |

– |

1 |

|

|

|

Number of electronic handwheels |

|

2 |

2 |

2 |

2 |

|

|

|

RS422 5 V DC, max. |

|

|

|

|

|

|

|

|

Electronic handwheels 5 V DC: |

|

|

|

|

|

|

|

|

• With 120 mm × 120 mm front panel |

|

O |

O |

O |

O |

|

|

|

6FC9320-5DB01 |

|

|

||||||

• With 76.2 mm × 76.2 mm front panel |

6FC9320-5DC01 |

O |

O |

O |

O |

|

|

|

• Without front panel, without setting wheel |

6FC9320-5DF01 |

O |

O |

O |

O |

|

|

|

• Without front panel, with setting wheel |

6FC9320-5DM00 |

O |

O |

O |

O |

|

|

|

Axis functions |

|

|

|

|

|

|

|

|

Feedrate override |

|

0 ... 200 % |

0 ... 200 % |

0 ... 200 % |

0 ... 200 % |

|

|

|

Feedrate override axis-specific |

|

0 ... 200 % |

0 ... 200 % |

0 ... 200 % |

0 ... 200 % |

|

|

|

Traversing range decades |

|

± 9 |

± 9 |

± 9 |

± 9 |

|

|

|

Rotary axis, turning endlessly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Velocity, max. |

|

300 m/s |

300 m/s |

300 m/s |

300 m/s |

|

|

|

|

|

|

|

|

|

|

|

|

Acceleration with jerk limitation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Programmable acceleration |

|

|

|

|

|

|

|

|

Feedrate interpolation |

|

|

|

|

|

|

|

|

Separate path feed for corners and chamfers |

|

|

|

|

|

|

|

|

Velocity-dependent feed forwad control |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Friction compensation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Auto Servo Tuning AST |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Direct Servo Control DSC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TRANSMIT/TRACYL Transformation without Y axis |

6FC5800-0AS50-0YB0 |

– |

– |

O |

O |

|

|

|

Pair of synchronized axes (gantry axes), basic |

6FC5800-0AS51-0YB0 |

– |

– |

O |

O |

|

|

|

Contour handwheel |

6FC5800-0AM08-0YB0 |

O |

O |

O |

O |

|

|

|

Generic coupling, CP-Basic, e.g. multi-edge |

6FC5800-0AM72-0YB0 |

– |

– |

O |

– |

|

|

|

turning |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Siemens NC 81.1 · 2019 |

|

2/3 |

|

|

|

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Spindle functions/Interpolations/Measuring functions/Motion-synchronous actions

|

|

Basic version |

Article No. |

SINUMERIK 808D ADVANCED |

|

|

||

|

|

O |

Option |

|

|

|

|

|

|

|

|

PPU 15x.3 |

|

PPU 16x.3 |

|

||

|

|

– |

Not available |

|

|

|

||

|

|

|

|

Note |

Turning |

Milling |

Turning |

Milling |

|

|

Spindle functions |

|

|

|

|

|

|

|

|

Spindle speed, analog |

|

|

|

|

|

|

|

|

Spindle speed, max. programmable value range |

|

106 ... 10-4 |

106 ... 10-4 |

106 ... 10-4 |

106 ... 10-4 |

|

|

|

(display ± 999999999.9999) |

|

|

|

|

|

|

|

|

Spindle override |

|

0 ... 200 % |

0 ... 200 % |

0 ... 200 % |

0 ... 200 % |

|

2 |

|

Gear stages |

|

5 |

5 |

5 |

5 |

|

|

Intermediate gear |

|

|

|

|

|

||

|

|

|

||||||

|

|

Automatic gear stage selection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oriented spindle stop |

Requires direct spindle |

|

|

|

|

|

|

|

|

|

encoder. |

|

|

|

|

|

|

Spindle speed limitation min./max. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Constant cutting rate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spindle control via PLC (positioning, oscillation) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Changeover to axis mode |

Requires servo spindle and |

|

|

|

|

|

|

|

|

|

direct encoder. |

|

|

|

|

|

|

Axis synchronization on-the-fly |

Requires servo spindle and |

|

|

|

|

|

|

|

|

|

direct encoder. |

|

|

|

|

|

|

Thread run-in and run-out programmable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Thread cutting with constant or variable pitch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tapping with compensating chuck/rigid tapping |

Requires servo spindle and |

|

|

|

|

|

|

|

|

|

direct encoder. |

|

|

|

|

|

|

Interpolations |

|

|

|

|

|

|

|

|

Linear interpolation axes, max. |

|

3 |

3 |

3 |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

Circle via center point and end point |

|

|

|

|

|

|

|

|

Circle via interpolation point |

|

|

|

|

|

|

|

|

Helical interpolation |

|

|

|

|

|

|

|

|

Continuous-path mode with programmable |

|

|

|

|

|

|

|

|

rounding clearance |

|

|

|

|

|

|

|

|

Advanced Surface look ahead, velocity control |

|

– |

– |

– |

|

|

|

|

and CNC block compression |

|

|

|

|

|

|

|

|

High-speed setting cycle CYCLE832 |

|

– |

– |

– |

|

|

|

|

Look ahead (number of blocks) |

|

1 |

50 |

1 |

150 |

|

|

|

|

|

|

|

|

|

|

|

|

Measuring functions |

|

|

|

|

|

|

|

|

Measuring in JOG: |

|

|

|

|

|

|

|

|

• Number of probes (switching) |

|

– |

1 |

– |

1 |

|

|

|

with/without deletion of distance-to-go |

|

|

|

|

|

|

|

|

Motion-synchronous actions |

|

|

|

|

|

|

|

|

CNC inputs/outputs, high-speed: |

|

|

|

|

|

|

|

|

• Digital inputs CNC onboard |

|

3 |

3 |

3 |

3 |

|

|

|

- Digital inputs cycle time |

|

0.2 ms |

0.2 ms |

0.2 ms |

0.2 ms |

|

|

|

• Digital outputs CNC onboard |

|

1 |

1 |

1 |

1 |

|

|

|

- Digital outputs cycle time |

|

0.3 ms |

0.3 ms |

0.3 ms |

0.3 ms |

|

|

|

Synchronized actions and high-speed auxiliary |

|

|

|

|

|

|

|

|

function output incl. 3 synchronous functions |

|

|

|

|

|

|

|

|

Positioning axes and spindles via |

|

|

|

|

|

|

|

|

synchronized actions (command axes) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2/4 |

|

Siemens NC 81.1 · 2019 |

|

|

|

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Open Architecture/CNC programming language

Basic version |

Article No. |

SINUMERIK 808D ADVANCED |

|

|

|

|

||

O |

Option |

|

|

|

|

|

|

|

|

PPU 15x.3 |

|

PPU 16x.3 |

|

|

|

||

– |

Not available |

|

|

|

|

|

||

|

|

Note |

Turning |

Milling |

Turning |

Milling |

|

|

Open Architecture |

|

|

|

|

|

|

|

|

Customizable HMI: |

|

|

|

|

|

|

|

|

• Customizable screens in the HMI |

|

|

|

|

|

|

|

|

• Input screens for customized user cycles |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CNC programming language |

|

|

|

|

|

|

|

|

Programming methods: |

|

|

|

|

|

|

2 |

|

• SINUMERIK style programming language |

|

|

|

|

|

|

||

(DIN 66025 and high-level language expansion) |

|

|

|

|

|

|

|

|

• ISO code |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Main program call from main program and |

|

|

|

|

|

|

|

|

|

|

|||||||

subroutine |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Subprogram levels, max. |

|

11 |

11 |

11 |

11 |

|

|

|

|

|

|

|

|

|

|

|

|

Number of subprogram passes |

|

9999 |

9999 |

9999 |

9999 |

|

|

|

|

|

|

|

|

|

|

|

|

Number of levels for skip blocks |

|

1 |

1 |

1 |

1 |

|

|

|

Polar coordinates |

|

|

|

|

|

|

|

|

Dimensions metric/inch, changeover: |

|

|

|

|

|

|

|

|

• Manually |

|

|

|

|

|

|

|

|

• Via program |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inverse-time feedrate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Auxiliary function output: |

|

|

|

|

|

|

|

|

• Via M word, max. programmable value range |

|

INT 231-1 |

INT 231-1 |

INT 231-1 |

INT 231-1 |

|

|

|

• Via H word, max. programmable value range |

|

INT -231 ... |

INT -231 ... |

INT -231 ... |

INT -231 ... |

|

|

|

REAL ± 3.4028 ex 38 |

|

231-1 |

231-1 |

231-1 |

231-1 |

|

|

|

(display ± 999999999.9999) |

|

|

|

|

|

|

|

|

Basic frames, max. number |

|

1 |

1 |

1 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

Settable offsets, max. number |

|

6 |

6 |

32 |

32 |

|

|

|

|

|

|

|

|

|

|

|

|

Work offsets, programmable (frames) |

|

|

|

|

|

|

|

|

Global and local user data |

|

|

|

|

|

|

|

|

Global program user data |

|

|

|

|

|

|

|

|

SINUMERIK high-level CNC language with: |

|

|

|

|

|

|

|

|

• Frame concept |

|

|

|

|

|

|

|

|

TRANS/ROT/SCALE/MIRROR |

|

|

|

|

|

|

|

|

• User variables, configurable |

|

|

|

|

|

|

|

|

• Predefined user variables |

|

|

|

|

|

|

|

|

(arithmetic parameters) |

|

|

|

|

|

|

|

|

• Predefined user variables |

|

|

|

|

|

|

|

|

(arithmetic parameters), configurable |

|

|

|

|

|

|

|

|

• Read/write system variables |

|

|

|

|

|

|

|

|

• Indirect programming |

|

|

|

|

|

|

|

|

• Program jumps and branches |

|

|

|

|

|

|

|

|

• Arithmetic and trigonometric functions |

|

|

|

|

|

|

|

|

• Compare operations and logic combinations |

|

|

|

|

|

|

|

|

• Macro techniques |

|

|

|

|

|

|

|

|

• Control structures IF-ELSE-ENDIF |

|

|

|

|

|

|

|

|

• Control structures WHILE, FOR, REPEAT, LOOP |

|

|

|

|

|

|

|

|

• STRING functions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Siemens NC 81.1 · 2019 |

|

2/5 |

|

|

|

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Technology cycles/Canned cycles

|

|

Basic version |

Article No. |

SINUMERIK 808D ADVANCED |

|

|

||

|

|

O |

Option |

|

|

|

|

|

|

|

|

PPU 15x.3 |

|

PPU 16x.3 |

|

||

|

|

– |

Not available |

|

|

|

||

|

|

|

|

Note |

Turning |

Milling |

Turning |

Milling |

|

|

Technology cycles |

|

|

|

|

|

|

|

|

Technology cycles for SINUMERIK style |

|

|

|

|

|

|

|

|

programming language: |

|

|

|

|

|

|

|

|

• Drilling, centering – CYCLE81 |

|

|

|

|

|

|

|

|

• Drilling, counterboring – CYCLE82 |

|

|

|

|

|

|

|

|

• Deep-hole drilling – CYCLE83 |

|

|

|

|

|

|

2 |

|

|

||||||

|

• Rigid tapping – CYCLE84 |

|

|

|

|

|

||

|

|

|

||||||

|

|

• Tapping with compensating chuck – CYCLE840 |

|

|

|

|

|

|

|

|

• Reaming 1 – CYCLE85 |

|

|

|

|

|

|

|

|

• Boring – CYCLE86 |

|

|

|

|

|

|

|

|

|||||||

|

|

• Position pattern: Row of holes – HOLES1 |

|

– |

|

– |

|

|

|

|

• Position pattern: Circle of holes – HOLES2 |

|

– |

|

– |

|

|

|

|

• Cutoff - CYCLE92 |

|

|

– |

|

– |

|

|

|

• Groove – CYCLE93 |

|

|

– |

|

– |

|

|

|

• Undercut (forms E and F according to DIN) – |

|

|

– |

|

– |

|

|

|

CYCLE94 |

|

|

|

|

|

|

|

|

• Contour cutting with relief cut – CYCLE95 |

|

|

– |

|

– |

|

|

|

• Thread undercut – CYCLE96 |

|

|

– |

|

– |

|

|

|

• Thread chaining – CYCLE98 |

|

|

– |

|

– |

|

|

|

• Thread cutting – CYCLE99 |

|

|

– |

|

– |

|

|

|

• Face milling – CYCLE71 |

|

– |

|

– |

|

|

|

|

• Contour milling – CYCLE72 |

|

– |

|

– |

|

|

|

|

• Milling a rectangular spigot – CYCLE76 |

|

– |

|

– |

|

|

|

|

• Milling a circular spigot – CYCLE77 |

|

– |

|

– |

|

|

|

|

• Long holes located on a circle – LONGHOLE |

|

– |

|

– |

|

|

|

|

• Slots on a circle – SLOT1 |

|

– |

|

– |

|

|

|

|

• Circumferential slot – SLOT2 |

|

– |

|

– |

|

|

|

|

• Milling a rectangular pocket – POCKET3 |

|

– |

|

– |

|

|

|

|

• Milling a circular pocket – POCKET4 |

|

– |

|

– |

|

|

|

|

• Thread milling – CYCLE90 |

|

– |

|

– |

|

|

|

|

• High-speed settings – CYCLE832 |

|

– |

|

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

Canned cycles |

|

|

|

|

|

|

|

|

Canned cycles for ISO code milling: |

|

|

|

|

|

|

|

|

• High-speed deep hole drilling cycle with chip |

|

– |

|

– |

|

|

|

|

breakage (G73) |

|

|

|

|

|

|

|

|

• Drilling a left-hand thread without any |

|

– |

|

– |

|

|

|

|

compensating chuck cycle (G74) |

|

|

|

|

|

|

|

|

• Fine drilling cycle (G76) |

|

– |

|

– |

|

|

|

|

• Deselection of a fixed cycle (G80) |

|

– |

|

– |

|

|

|

|

• Drilling cycle, counterboring (G81) |

|

– |

|

– |

|

|

|

|

• Countersink drilling cycle (G82) |

|

– |

|

– |

|

|

|

|

• Deep hole drilling cycle with chip removal (G83) |

|

– |

|

– |

|

|

|

|

• Drilling a right-hand thread without any |

|

– |

|

– |

|

|

|

|

compensating chuck cycle (G84) |

|

|

|

|

|

|

|

|

• Boring cycle (G85) |

|

– |

|

– |

|

|

|

|

• Boring cycle, retraction with G00 (G86) |

|

– |

|

– |

|

|

|

|

• Boring cycle, reverse countersinking (G87) |

|

– |

|

– |

|

|

|

|

• Boring cycle, retraction with machining feedrate |

|

– |

|

– |

|

|

|

|

(G89) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2/6 |

|

Siemens NC 81.1 · 2019 |

|

|

|

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Canned cycles/Program and workpiece management/Programming support/Simulations

Basic version |

Article No. |

SINUMERIK 808D ADVANCED |

|

|

|

|

||

O |

Option |

|

|

|

|

|

|

|

|

PPU 15x.3 |

|

PPU 16x.3 |

|

|

|

||

– |

Not available |

|

|

|

|

|

||

|

|

Note |

Turning |

Milling |

Turning |

Milling |

|

|

Canned cycles (continued) |

|

|

|

|

|

|

|

|

Canned cycles for ISO code turning |

|

|

|

|

|

|

|

|

(G code system A): |

|

|

|

|

|

|

|

|

• Thread cutting with constant lead (G32) |

|

|

– |

|

– |

|

|

|

• Thread cutting with variable lead (G34) |

|

|

– |

|

– |

|

|

|

• Finishing cycle (G70) |

|

|

– |

|

– |

|

|

|

|

|

2 |

||||||

• Stock removal cycle longitudinal axis (G71) |

|

|

– |

|

– |

|

||

|

|

|

||||||

• Stock removal cycle transverse axis (G72) |

|

|

– |

|

– |

|

|

|

• Closed cutting cycle (G73) |

|

|

– |

|

– |

|

|

|

• Multiple repetitive grooving cycles in the |

|

|

– |

|

– |

|

|

|

|

|

|||||||

longitudinal axis (G74) |

|

|

|

|

|

|

|

|

• Deep hole drilling and recessing in |

|

|

– |

|

– |

|

|

|

facing axis (G75) |

|

|

|

|

|

|

|

|

• Multiple thread cutting (G76) |

|

|

– |

|

– |

|

|

|

• Axial cutting (G90) |

|

|

– |

|

– |

|

|

|

• Thread cutting (G92) |

|

|

– |

|

– |

|

|

|

• Radial cutting (G94) |

|

|

– |

|

– |

|

|

|

|

|

|

|

|

|

|

|

|

Program and workpiece management |

|

|

|

|

|

|

|

|

Part programs on PPU, max. number |

|

255 |

255 |

255 |

255 |

|

|

|

Readable part program names |

|

|

|

|

|

|

|

|

Sub-folders for part programs with |

|

|

|

|

|

|

|

|

readable names |

|

|

|

|

|

|

|

|

Programming support |

|

|

|

|

|

|

|

|

Background editing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Program editor: |

|

|

|

|

|

|

|

|

• Full screen CNC editor with cut, copy and |

|

|

|

|

|

|

|

|

paste functionality |

|

|

|

|

|

|

|

|

• Programming support programGUIDE BASIC |

|

|

|

|

|

|

|

|

for SINUMERIK technology cycles |

|

|

|

|

|

|

|

|

• Contour computer with programming |

|

|

|

|

|

|

|

|

graphics/free contour input (contour calculator) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Simulations |

|

|

|

|

|

|

|

|

2D simulation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Real-time simulation of current machining |

|

|

|

|

|

|

|

|

operation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Siemens NC 81.1 · 2019 |

|

2/7 |

|

|

|

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Operating modes/Tools

|

|

Basic version |

Article No. |

SINUMERIK 808D ADVANCED |

|

|

||

|

|

O |

Option |

|

|

|

|

|

|

|

|

PPU 15x.3 |

|

PPU 16x.3 |

|

||

|

|

– |

Not available |

|

|

|

||

|

|

|

|

Note |

Turning |

Milling |

Turning |

Milling |

|

|

Operating modes |

|

|

|

|

|

|

|

|

Manual Machine plus for manual controlled |

6FC5800-0AP07-0YB0 |

O |

– |

O |

– |

|

|

|

semi-CNC lathes |

|

|

|

|

|

|

|

|

JOG: |

|

|

|

|

|

|

|

|

• T, S, M screen for quick activation of machine |

|

|

|

|

|

|

|

|

functions |

|

|

|

|

|

|

2 |

|

|

|

|

|

|||

|

• Face milling cycle for workpiece preparation |

|

– |

|

– |

|

||

|

|

|

||||||

|

|

• Handwheel selection |

|

|

|

|

|

|

|

|

• Switchover: inch/metric |

|

|

|

|

|

|

|

|

• Manual measurement of work offset |

|

|

|

|

|

|

|

|

• Manual measurement of tool offset |

|

|

|

|

|

|

|

|

• Semi-automatic tool measurement with |

|

– |

|

– |

|

|

|

|

tool probe |

|

|

|

|

|

|

|

|

MDI: |

|

|

|

|

|

|

|

|

• Input in text editor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Automatic: |

|

|

|

|

|

|

|

|

• Execution from memory stick connected to |

|

|

|

|

|

|

|

|

USB interface on operator panel front |

|

|

|

|

|

|

|

|

• Program control |

|

|

|

|

|

|

|

|

(dry-run feed, block skip etc.) |

|

|

|

|

|

|

|

|

• Program editing |

|

|

|

|

|

|

|

|

• Block search with/without calculation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Repos (repositioning on the contour): |

|

|

|

|

|

|

|

|

• With operator command/semi-automatically |

|

|

|

|

|

|

|

|

• Program-controlled |

|

|

|

|

|

|

|

|

Preset: |

|

|

|

|

|

|

|

|

• Set actual value |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tools |

|

|

|

|

|

|

|

|

Tools/cutting edges, max. |

|

64/128 |

64/128 |

64/128 |

64/128 |

|

|

|

|

|

|

|

|

|

|

|

|

Tool types: |

|

|

|

|

|

|

|

|

• Turning |

|

|

– |

|

– |

|

|

|

• Drilling |

|

|

|

|

|

|

|

|

• Milling |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tool radius compensations in plane: |

|

|

|

|

|

|

|

|

• With approach and retract strategies |

|

|

|

|

|

|

|

|

• With transition circle/ellipse on outer edges |

|

|

|

|

|

|

|

|

Tool offset selection via T and D numbers |

|

|

|

|

|

|

|

|

Look-ahead detection of contour violations |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2/8 |

|

Siemens NC 81.1 · 2019 |

|

|

|

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Communication and data management

Basic version |

Article No. |

SINUMERIK 808D ADVANCED |

|

|

|

|

||

O |

Option |

|

|

|

|

|

|

|

|

PPU 15x.3 |

|

PPU 16x.3 |

|

|

|

||

– |

Not available |

|

|

|

|

|

||

|

|

Note |

Turning |

Milling |

Turning |

Milling |

|

|

Communication and data management |

|

|

|

|

|

|

|

|

USB interface on panel front for memory stick |

|

|

|

|

|

|

|

|

and USB PC keyboard: |

|

|

|

|

|

|

|

|

• Transfer of: |

|

|

|

|

|

|

|

|

- Machine and setting data |

|

|

|

|

|

|

|

|

- PLC data |

|

|

|

|

|

|

|

|

|

|

2 |

||||||

- Compensation data |

|

|

|

|

|

|

||

|

|

|

||||||

- Tool and work offset data |

|

|

|

|

|

|

|

|

- R parameter |

|

|

|

|

|

|

|

|

- HMI data |

|

|

|

|

|

|

|

|

|

|

|||||||

- User cycles |

|

|

|

|

|

|

|

|

- Part programs |

|

|

|

|

|

|

|

|

- PLC program (*.pte) |

|

|

|

|

|

|

|

|

• Execute part program |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ethernet interface: |

|

|

|

|

|

|

|

|

• Transfer of: |

|

|

|

|

|

|

|

|

- Machine and setting data |

|

|

|

|

|

|

|

|

- PLC data |

|

|

|

|

|

|

|

|

- Compensation data |

|

|

|

|

|

|

|

|

- Tool and work offset data |

|

|

|

|

|

|

|

|

- R parameter |

|

|

|

|

|

|

|

|

- HMI data |

|

|

|

|

|

|

|

|

- User cycles |

|

|

|

|

|

|

|

|

- Part programs |

|

|

|

|

|

|

|

|

• Execute part program |

|

|

|

|

|

|

|

|

• Part program send/receive |

|

|

|

|

|

|

|

|

• PLC program upload/download |

|

|

|

|

|

|

|

|

• PLC status monitoring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Siemens NC 81.1 · 2019 |

|

2/9 |

|

|

|

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

HMI functions/Monitoring functions/Compensations

|

|

Basic version |

Article No. |

SINUMERIK 808D ADVANCED |

|

|

||

|

|

O Option |

|

|

|

|

|

|

|

|

|

PPU 15x.3 |

|

PPU 16x.3 |

|

||

|

|

– |

Not available |

|

|

|

||

|

|

|

|

Note |

Turning |

Milling |

Turning |

Milling |

|

|

HMI functions |

|

|

|

|

|

|

|

|

CNC lock function |

6FC5800-0AS71-0YB0 |

O |

O |

O |

O |

|

|

|

Lock MyCycles |

6FC5800-0AP54-0YB0 |

O |

O |

O |

O |

|

|

|

SINUMERIK 808D startGUIDE: |

|

|

|

|

|

|

|

|

• Startup assistant |

|

|

|

|

|

|

2 |

|

|

Built-in graphical interactive assistant for |

|

|

|

|

|

|

|

1st commissioning of machines with |

|

|

|

|

|

|

|

|

SINUMERIK 808D |

|

|

|

|

|

|

|

|

• Series startup assistant |

|

|

|

|

|

|

|

|

|

Built-in graphical interactive assistant for |

|

|

|

|

|

|

|

|

the series production of machines with |

|

|

|

|

|

|

|

|

SINUMERIK 808D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Sales assistant |

|

|

|

|

|

|

|

|

|

Built-in viewer for bitmaps with sales arguments |

|

|

|

|

|

|

|

|

for SINUMERIK 808D, extendable by customer- |

|

|

|

|

|

|

|

|

specific sales arguments for the machine |

|

|

|

|

|

|

|

Online help for programming, alarms and |

|

|

|

|

|

|

|

|

machine data |

|

|

|

|

|

|

|

|

CNC program messages |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screen saver |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Access protection level support |

|

|

|

|

|

|

|

|

Chinese input method editor for part program |

|

|

|

|

|

|

|

|

names, sub-directory names and CNC comments |

|

|

|

|

|

|

|

|

Operating software languages: |

|

|

|

|

|

|

|

|

• Chinese Simplified, Czech, English, French, |

|

|

|

|

|

|

|

|

|

German, Italian, Korean, Polish, Portuguese, |

|

|

|

|

|

|

|

|

Russian, Spanish, Turkish, Hungarian |

|

|

|

|

|

|

|

• Language switchover online |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Monitoring functions |

|

|

|

|

|

|

|

|

Working area limitation |

|

|

|

|

|

|

|

|

Limit switch monitoring |

|

|

|

|

|

|

|

|

Software and hardware limit switches |

|

|

|

|

|

|

|

|

Position monitoring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Standstill (zero-speed) monitoring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clamping monitoring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Contour monitoring |

|

|

|

|

|

|

|

|

Axis limitation from the PLC |

|

|

|

|

|

|

|

|

Spindle speed limitation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Compensations |

|

|

|

|

|

|

|

|

Backlash compensation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Leadscrew error compensation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bidirectional leadscrew error compensation |

6FC5800-0AM54-0YB0 |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

|

2/10 |

|

Siemens NC 81.1 · 2019 |

|

|

|

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

PLC area

Basic version |

Article No. |

SINUMERIK 808D ADVANCED |

|

|

|

|

||

O |

Option |

|

|

|

|

|

|

|

|

PPU 15x.3 |

|

PPU 16x.3 |

|

|

|

||

– |

Not available |

|

|

|

|

|

||

|

|

Note |

Turning |

Milling |

Turning |

Milling |

|

|

PLC area |

|

|

|

|

|

|

|

|

Integrated PLC |

|

|

|

|

|

|

|

|

Style of PLC program: |

|

|

|

|

|

|

|

|

• Prepared and ready to run PLC program |

|

|

|

|

|

|

|

|

on board |

|

|

|

|

|

|

|

|

• Fully customized PLC programs by |

|

|

|

|

|

|

|

|

|

|

2 |

||||||

offline PLC programming tool |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Fixed cycle time for PLC |

|

12 ms |

12 ms |

12 ms |

12 ms |

|

|

|

Maximum number of ladder steps |

|