Ricoh coretech CORE TECHNOLOGY MANUAL

C

ONTENTS

• Introduction

• Handling Paper

• Photocopying Processes

• Digital Processes

• Facsimile Processes

• Process Control

• Color Processes

• Standard Components

©Ricoh CO., LTD., 1999. All rights reserved.

C

C

C

O

O

O

R

R

R

E

E

E

T

T

T

E

E

E

C

C

C

H

H

H

N

N

N

O

O

O

L

L

L

O

O

O

G

G

G

Y

Y

Y

M

M

M

A

A

A

N

N

N

U

U

U

A

A

A

L

L

L

I

I

n

n

t

t

r

r

o

o

d

d

u

u

c

c

t

t

i

i

o

o

n

n

Purpose and Scope

What is it for?

The Core Technology Manual is a reference source for standard technologies used in Ricoh office

products. It has three main intended uses.

1. Support for Service Manuals

Instead of repeating a common technical description, a service manual can refer to the description

of the process in the Core Technology Manual. Or the service manual can refer the reader to the

Core Technology Manual for additional information. Thus service manuals can be made more

compact and more focused on the target machine.

2. General Technical Reference

Technical staff and field service personnel can use this manual as a standard technical reference

about Ricoh office machines. It may be especially useful as a memory refresher concerning the

technical aspects of the various products that are often encountered in the field.

3. Source for Training Material

This manual can be used as a source of background material when preparing technical training

courses.

Purpose and Scope

How to use this manual

7 October 1999 Page 2

Introduction How to use this manual

Scope

While the Core Technology Manual can be studied, it is intended primarily for use as a reference. It

doesn’t cover all technical aspects of Ricoh office products. Instead, it concentrates on the common

technologies used in many products. Generally, leading edge technology and machine specific

technology will not be covered.

This manual will be updated from time to time as technology evolves and field needs change.

How to use this manual

The Portable Document Format

This manual is a PDF (portable document format) file, and you must use Acrobat Reader or Acrobat

Explorer to view it. We assume that you are familiar with the features of Adobe Acrobat. If not,

please take a few minutes to familiarize yourself with Acrobat’s navigation features. To make best

use of this and other electronic documents, you need to know how to use the navigation buttons,

bookmarks, thumbnails, and searching functions. (Acrobat comes with several reference and tutorial

documents that you can use to “book up” on Acrobat.)

7 October 1999 Page 3

Introduction How to use this manual

Navigating

This manual has numerous links that allow you to quickly jump to related information. The links are

indicated by green italic text. Also, this manual is heavily bookmarked. You can get almost anywhere

you need to by “drilling down” through the bookmarks. In addition the manual is fully indexed; so, you

can use Acrobat’s full text search function to locate items by keyword searches.

Printing this manual

This manual is formatted for screen viewing. The actual formatted size is A5; however, if you print to

A5 paper, some of the image may be cut at the margins depending on the capabilities of the printer.

If this happens, print to a slightly larger size paper. ISO B5 and JIS B5 work well. As colors are used

in this manual you will get better results by using a color printer.

7 October 1999 Page 4

H

H

a

a

n

n

d

d

l

l

i

i

n

n

g

g

P

P

a

a

p

p

e

e

r

r

There are several key factors involved with handling paper in office machines (copiers, printers,

faxes, whatever). First, there has to be a stock of paper from which to feed, which implies some kind

of holder—a tray, a cassette, or a roll—which positions the paper properly for feeding. Second, there

has to be a method of separating a single sheet from the source; this is referred to as paper feed.

Finally, most machines use sensors to detect paper size and detect the presence or absence of

paper.

After paper is fed into a machine, it must be transported to a registration mechanism, then to an

imaging section where the image is transferred to the paper. Finally the paper passes through an

image fusing section and exits the machine.

Paper Feed

Paper feed is the separation of a single sheet of paper from a paper source—usually a stack of

paper in a cassette or tray—and moving it into the machine.

Paper Feed

Registration

Paper Transport

Duplexing

Misfeed Detection

7 October 1999 Page 5

Handling Paper Paper Feed

Paper Feed Methods

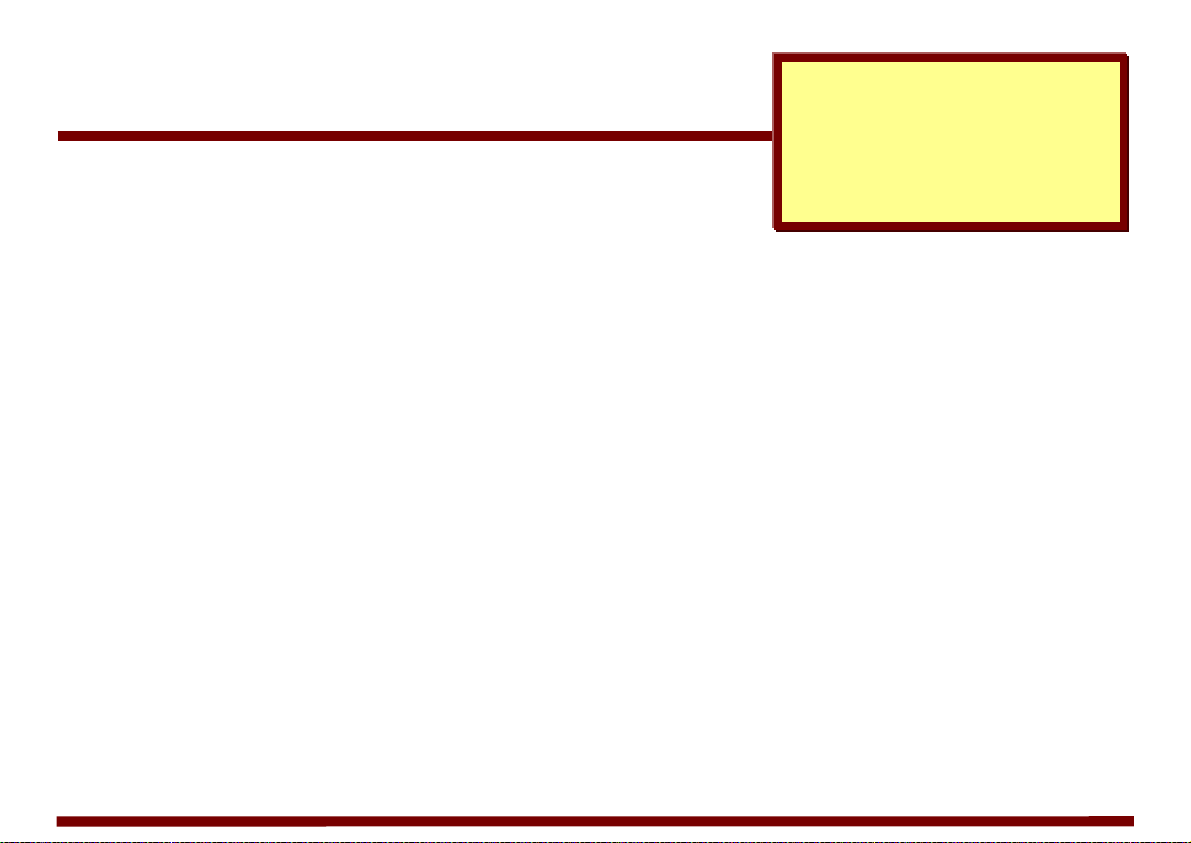

Feed and Reverse Roller (FRR)

The FRR feed mechanism consists of a pick-up

roller, a feed roller, and a reverse roller.

The pick-up roller [A] is not in contact with the

paper stack before it starts feeding paper. Shortly

after the start key is pressed, the pick-up roller

drops down and feeds the top sheet between the

feed roller [B] and the reverse roller [C]. At almost

the same time that the paper’s leading edge

arrives at the feed roller, the pick-up roller lifts off

the paper stack so that it does not interfere with

the operation of the feed and reverse rollers. The

feed and reverse rollers then take over the paper feed process.

There is a one-way bearing inside the feed roller so it can turn

only in one direction. The reverse roller turns in the opposite

direction as the feed roller. A slip clutch (torque limiter clutch)

drives the reverse roller, however, allowing it to turn in either

direction depending on the friction between the rollers. A spring

keeps the reverse roller in contact with the feed roller.

frr1.jpg

frr2.tif

7 October 1999 Page 6

Handling Paper Paper Feed

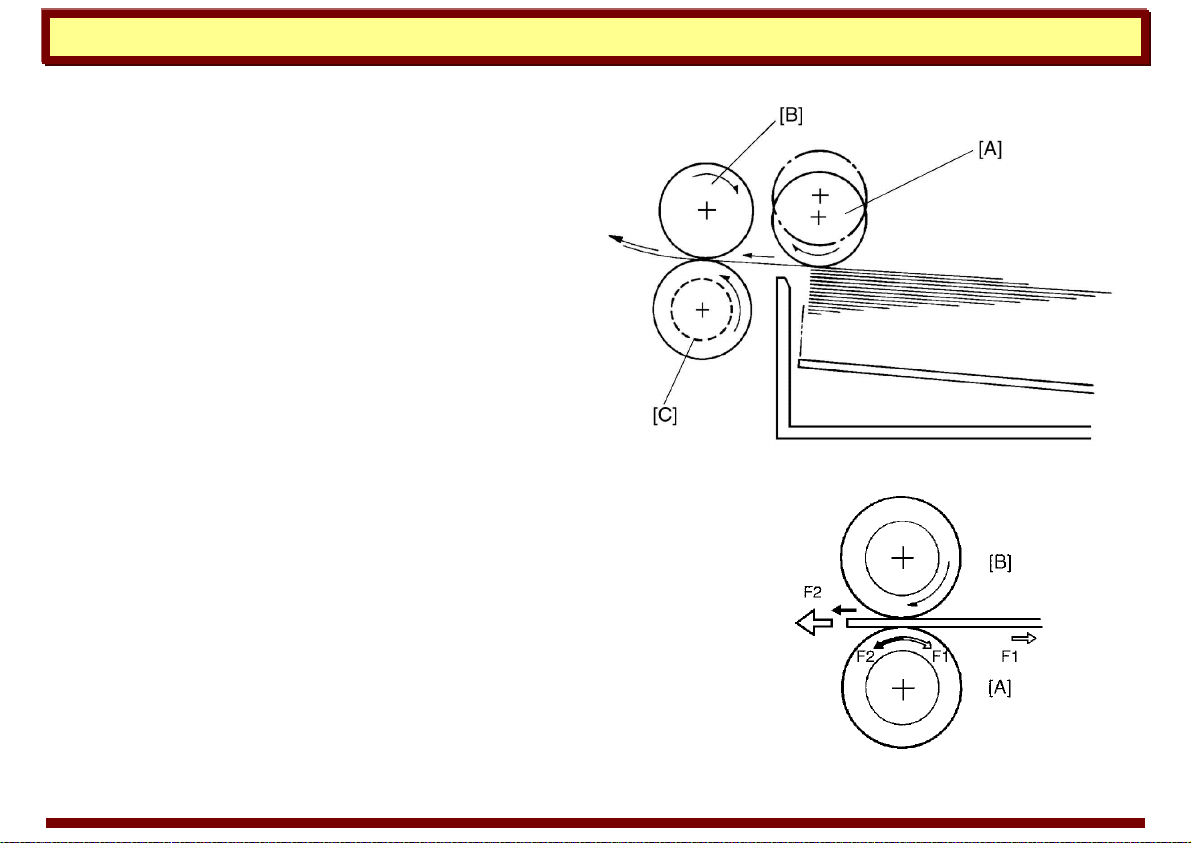

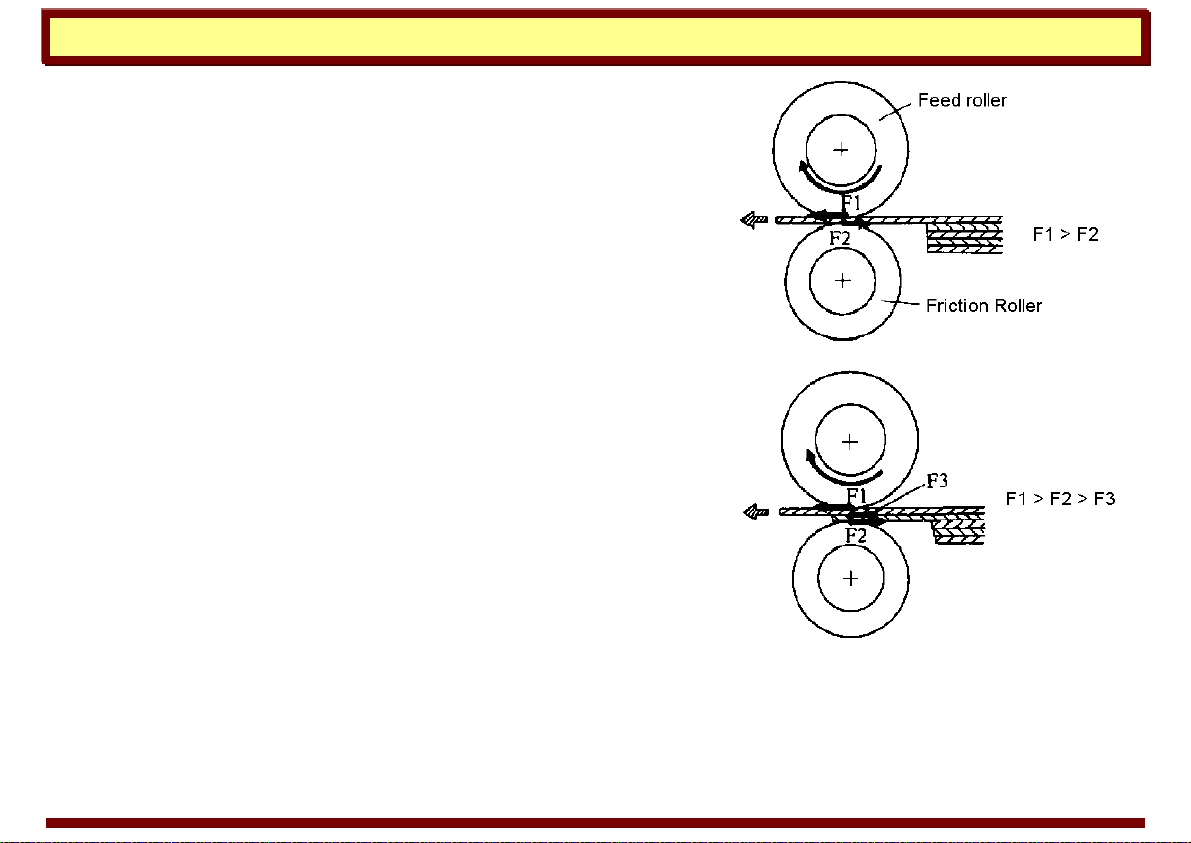

The direction that the reverse roller [A] turns depends on the

frictional forces acting on it. The slip clutch applies a constant

clockwise force (F1). When there is a single sheet of paper being

driven between the rollers, the force of friction between the feed

roller [B] and the paper (F2) is greater than F1. So, the reverse

roller turns counterclockwise.

If two or more sheets are fed between the rollers, the forward

force on the second sheet (F3), becomes less than F1 because

the low coefficient of friction between the two sheets. So, the

reverse roller starts turning clockwise and drives the second

sheet back to the cassette.

frr3.tif

7 October 1999 Page 7

Handling Paper Paper Feed

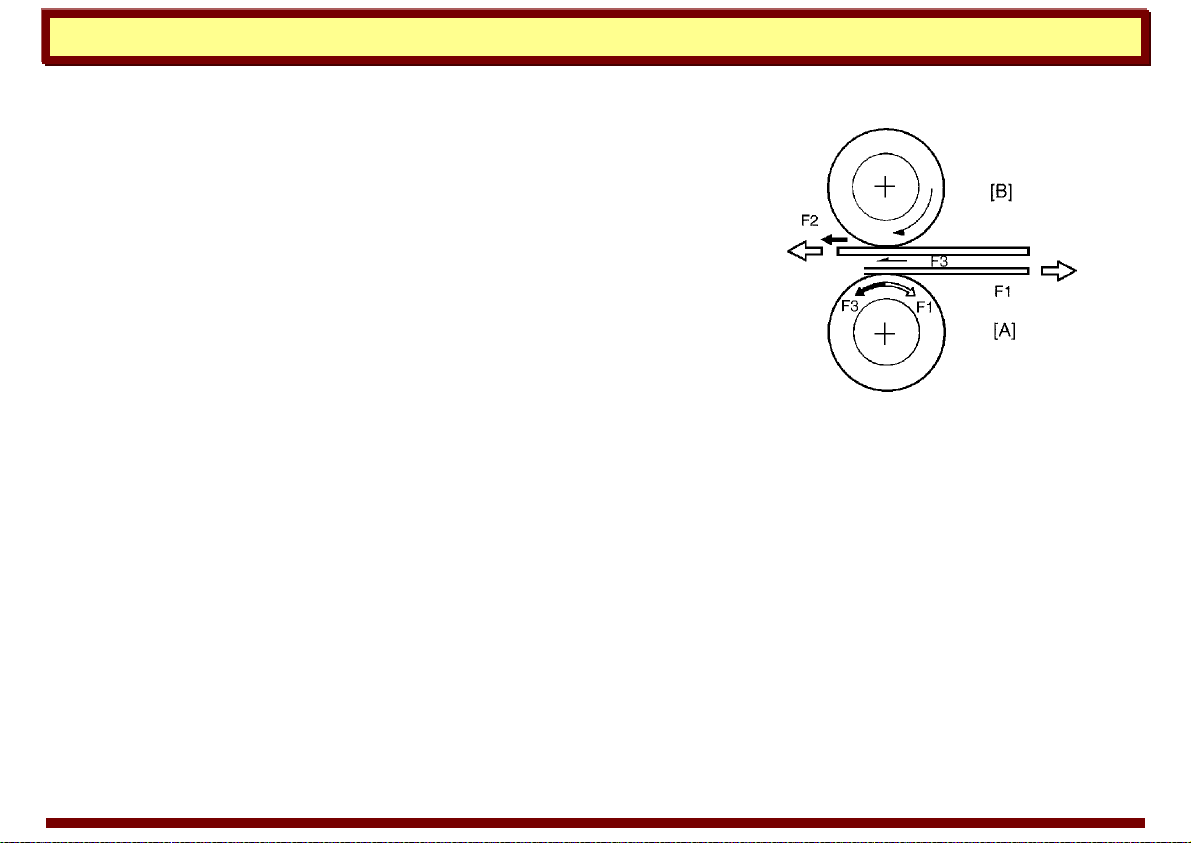

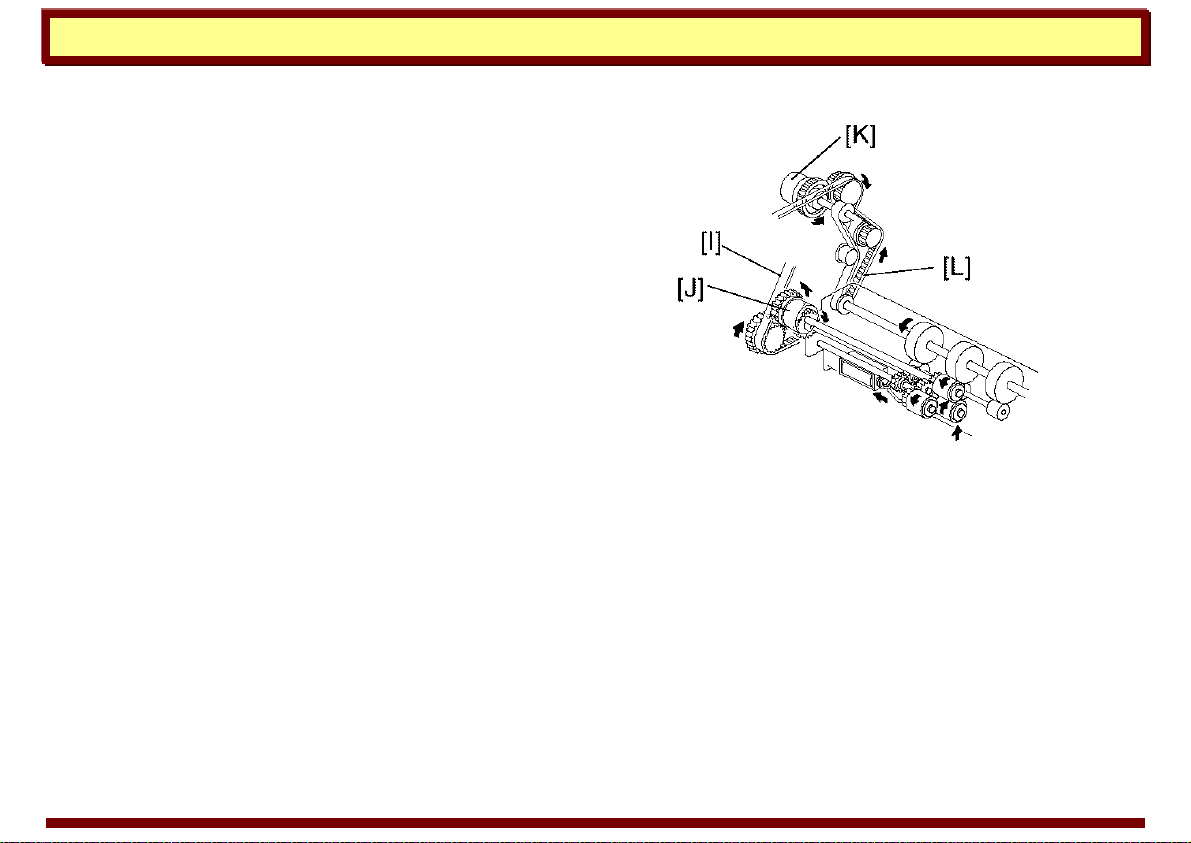

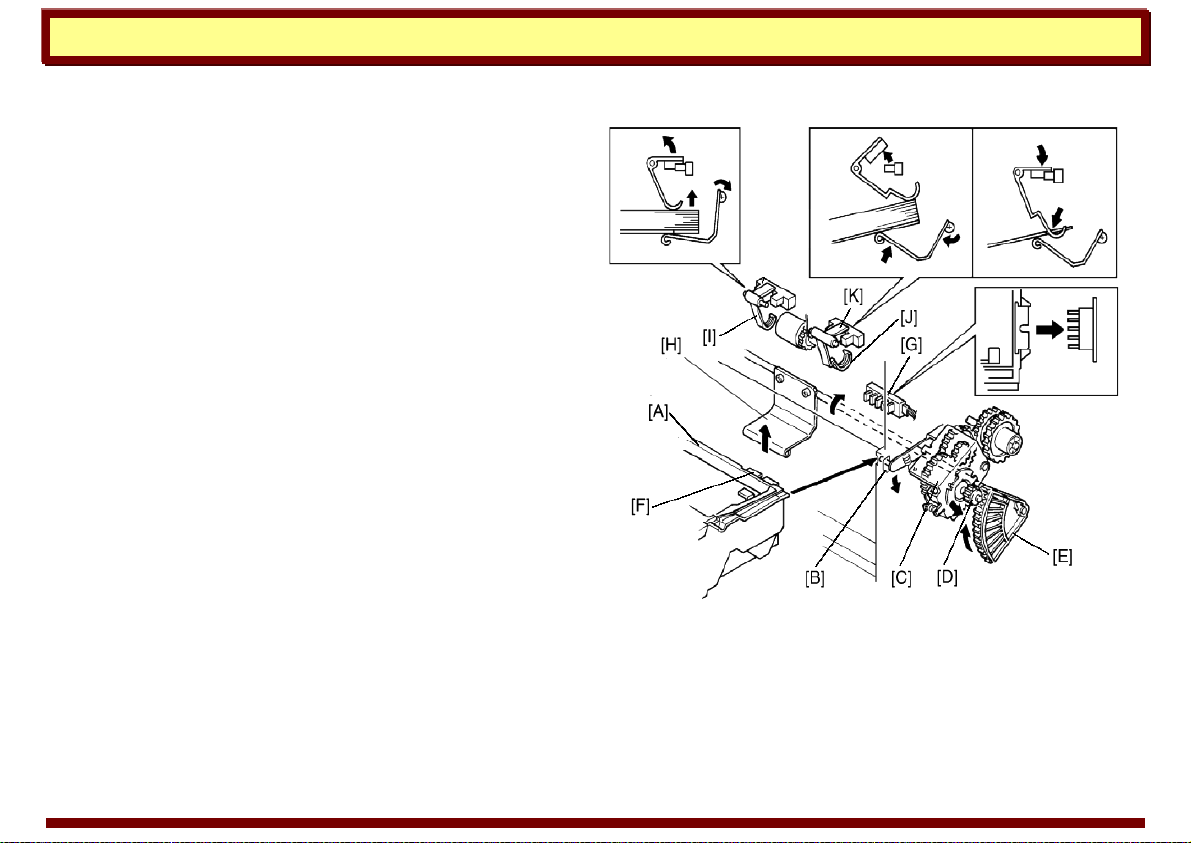

Example: Model A113

Drive Mechanism

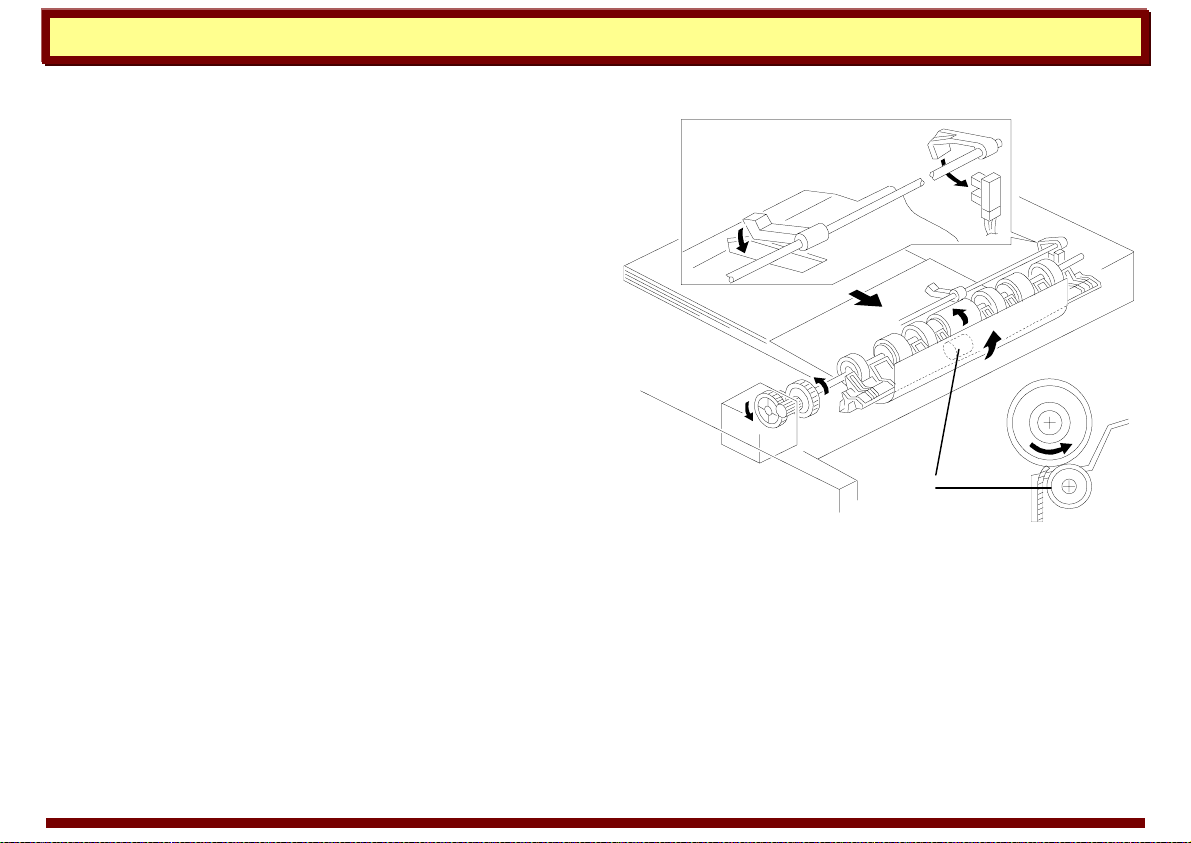

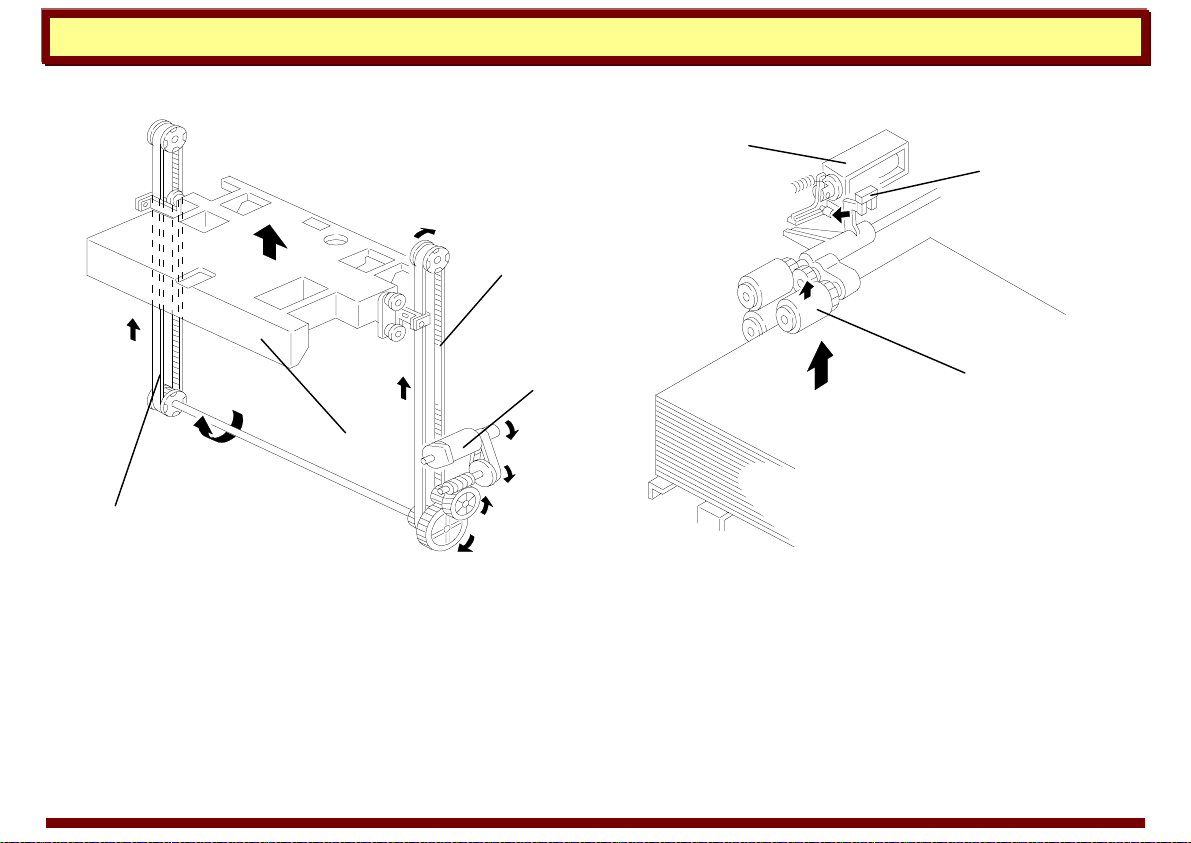

The paper feed unit consists of a pick-up roller [A],

feed roller [B], separation roller [C], relay roller [D],

pick-up solenoid [E], separation solenoid [F],

paper upper limit sensor [G], and paper end

sensor [H].

The main motor drives the pick-up, feed, and

separation rollers via the timing belt [I] and the

paper feed clutch [J]. The main motor also drives

the relay roller. However, drive is transmitted to

the relay roller via the relay clutch [K] and the

timing belt [L].

In stand-by mode, the separation roller is away

from the feed roller. 50 ms after pressing the start

key, the main motor and the separation solenoid

turn on. Then the separation roller comes in

contact with the feed roller. 100 ms after the main

motor starts to rotate, the pick-up solenoid turns

on. The pick-up roller lowers to make contact with

the top of the paper stack. The pick-up solenoid

stays on for 550 ms.

frr4.tif

7 October 1999 Page 8

Handling Paper Paper Feed

200 ms after the main motor starts to rotate, the

paper feed clutch and the relay clutch turn on. The

feed roller and relay rollers feed the top sheet of

the paper stack to the registration rollers. When

the leading edge of the paper passes through the

upper relay sensor, the paper feed clutch is de-

energized.

frr5.tif

7 October 1999 Page 9

Handling Paper Paper Feed

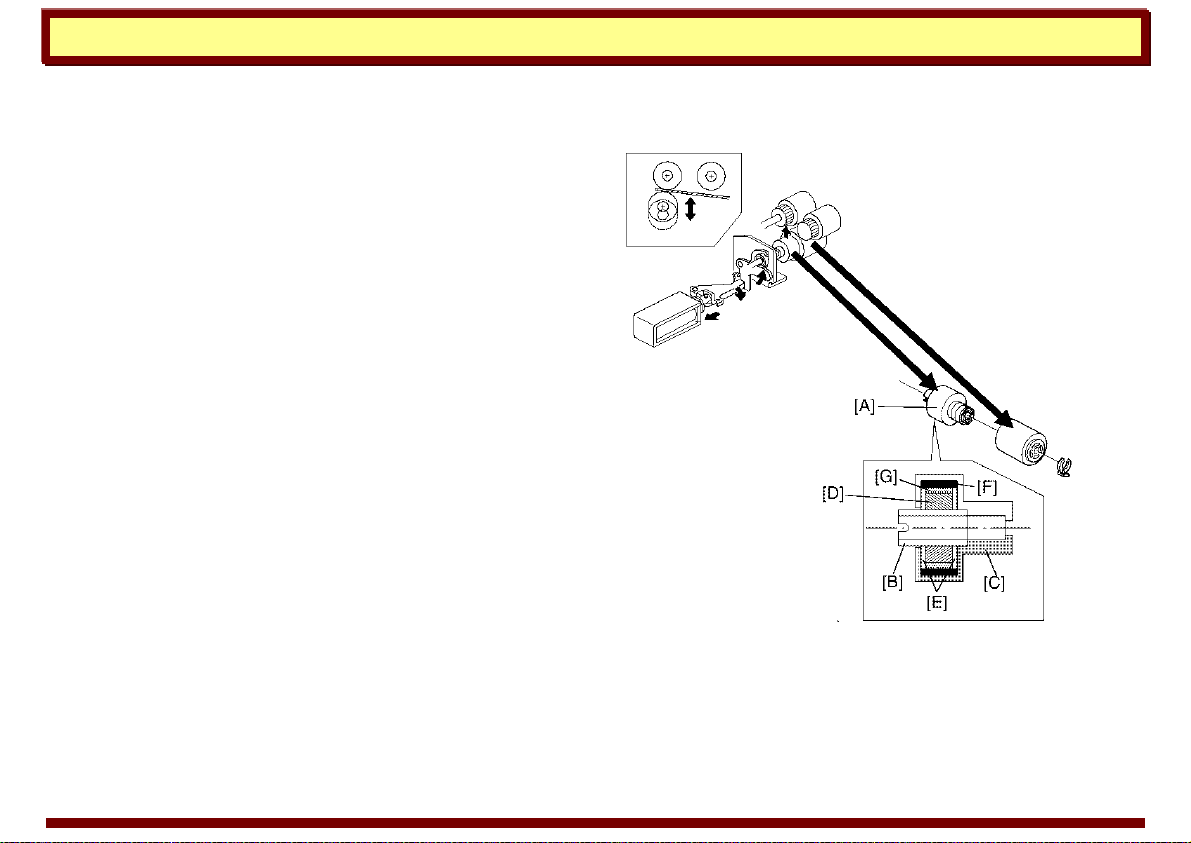

Slip-clutch Mechanism

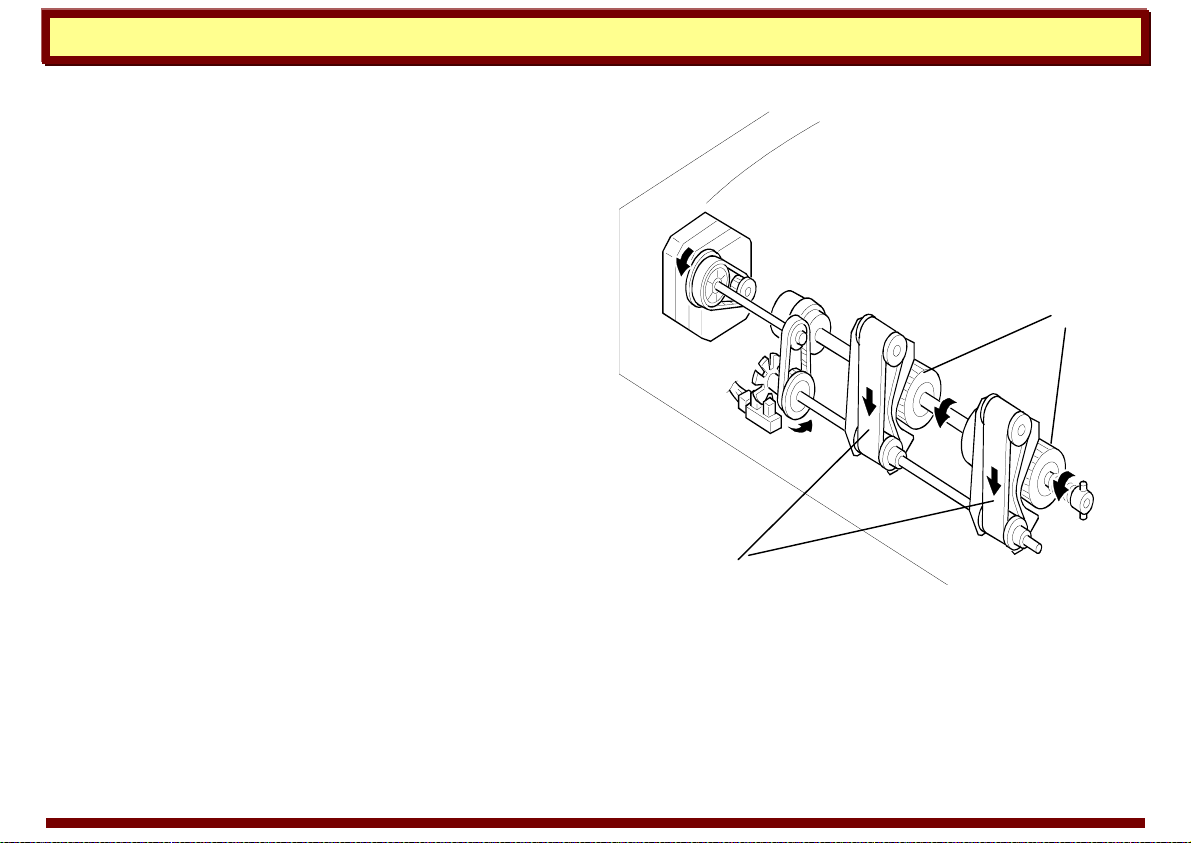

The separation roller is mounted on a slip clutch.

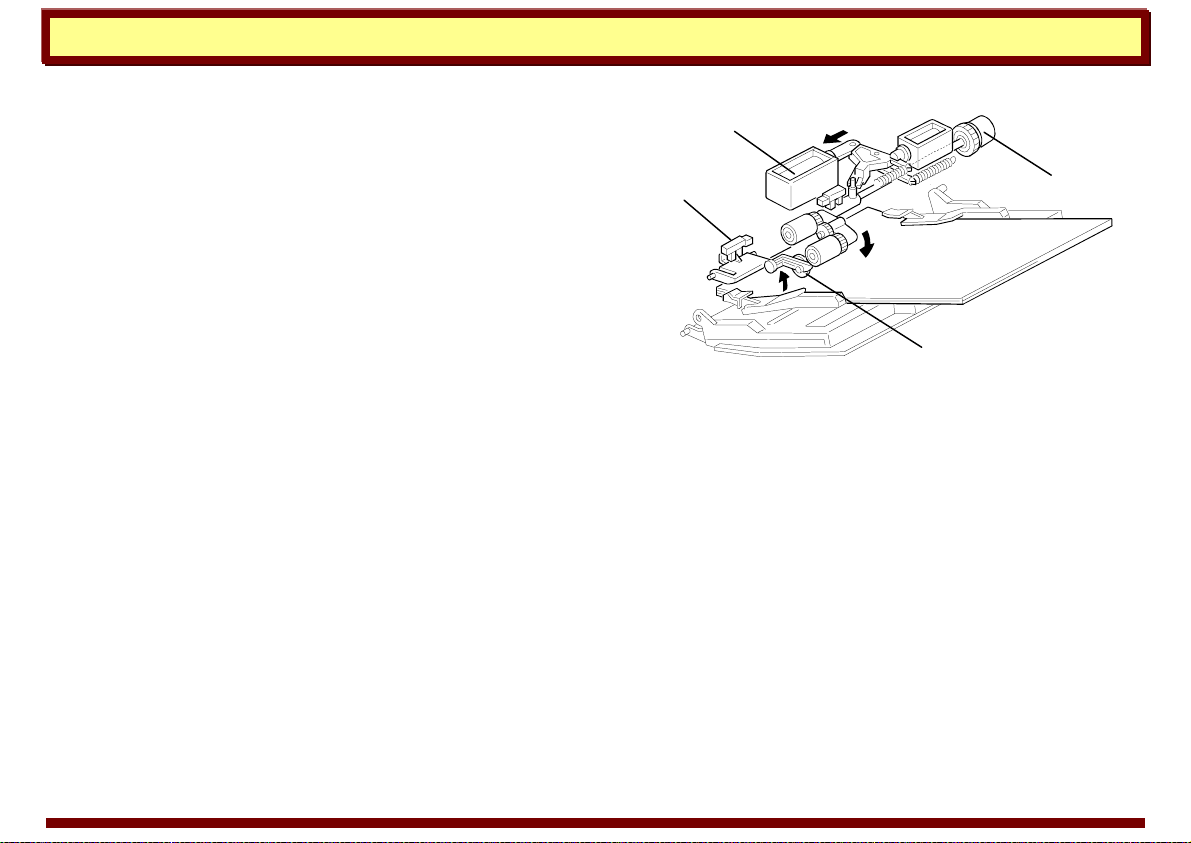

The slip clutch [A] consists of an input hub [B] and

an output hub [C], which also acts as the case of

the clutch. A magnetic ring [D] and steel spacers

[E] are fitted onto the input hub. A ferrite ring [F] is

fitted into the output hub. Ferrite powder [G]

packed between the magnetic ring and the ferrite

ring generates a constant torque due to magnetic

force. The input hub and the output hub slip when

the rotational force exceeds this constant torque.

The constant torque prevents double feeding,

because it exceeds the coefficient of friction

between sheets of paper. This type of slip clutch

does not require lubrication.

frr6.tif

7 October 1999 Page 10

Handling Paper Paper Feed

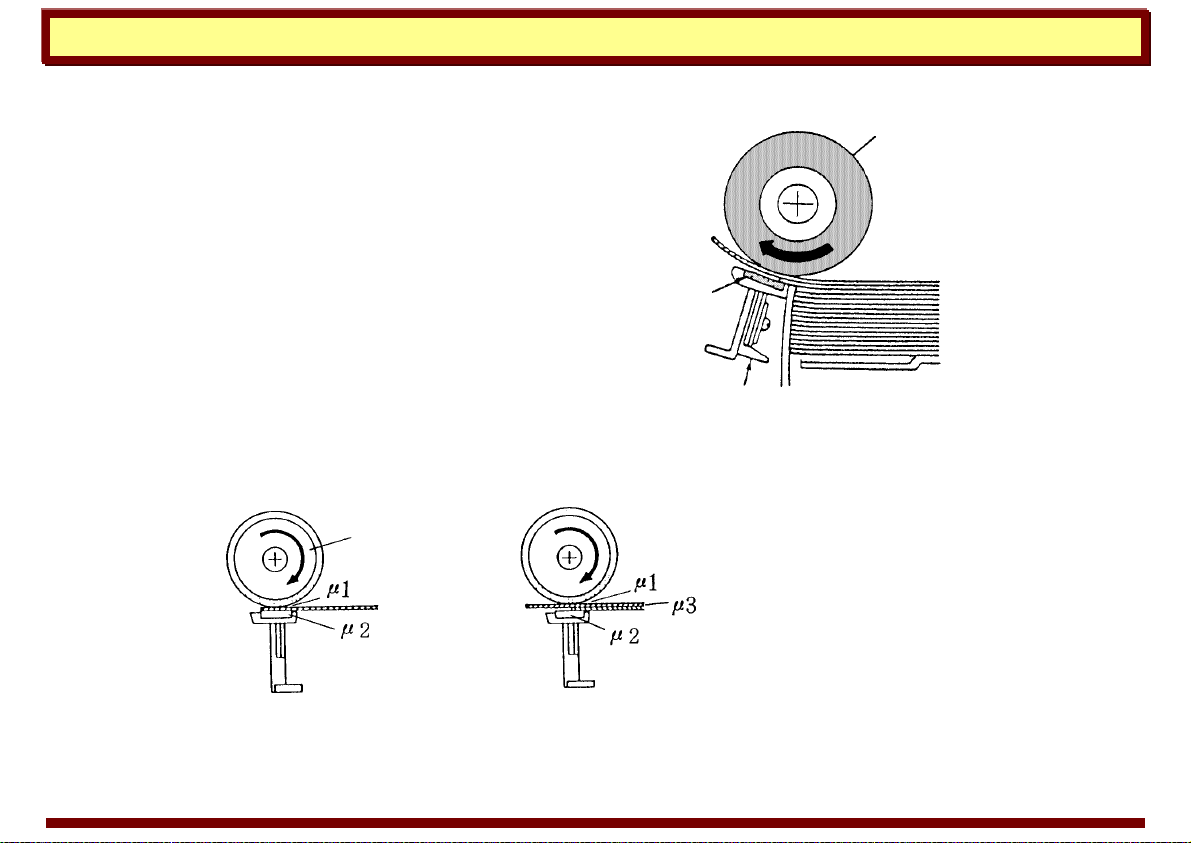

Friction Pad

The friction pad mechanism has two principle

components—the paper feed roller [A] and a friction

pad [B].

When the paper feed roller rotates, it feeds the top

sheet of paper. The second sheet also tries to feed,

but because the friction force between the friction pad

and the second sheet is greater than that between the

first and second sheets, the first sheet of paper is the

only one that feeds.

The friction coefficient applied to the surface of each

sheet of paper is shown below.

020117.tif

[A]

[B]

0201 18. tif

µ1>µ2>µ3

7 October 1999 Page 11

Handling Paper Paper Feed

Example: Model A074

When the paper tray is placed in the copier, it

pushes the pressure release lever [A], causing it

to turn clockwise. This then causes the friction

pad holder [B], holding the friction pad, to press

up against the paper feed roller [C]. The friction

pad pressure against the paper feed roller is

determined by the friction pad pressure spring

[D]. This pressure is applied evenly to the paper

feed roller because the friction pad holder is

mounted on the mounting bracket [E] with a

swivel bushing.

fricpad.tif

7 October 1999 Page 12

Handling Paper Paper Feed

Friction roller

The paper separation mechanism for the friction roller uses

the same principles as the paper separation method for the

friction pad.

The two main components are the paper feed roller and the

friction roller. When the paper feed roller rotates, the top

sheet of paper is fed. The second sheet also tries to feed, but

as the friction force between the friction roller and the second

sheet is greater than that between the first and second

sheets, only the first sheet of paper is fed.

fricroll1.tif

7 October 1999 Page 13

Handling Paper Paper Feed

Example: Model

A133

Duplex

The duplex paper feed system consists of three

sets of duplex feed rollers and a friction roller [A].

The friction roller has a one-way bearing inside;

therefore, it rotates freely during paper stacking

and locks during paper feeding. The duplex feed

rollers can only feed the top sheet of the stack

because the friction roller functions in the same

way as a friction pad does.

a133d587.wmf

[A]

7 October 1999 Page 14

Handling Paper Paper Feed

Separation Belt

The separation belt system (also called the

“friction belt” system) primarily feeds sheets from

the bottom of a stack. It is commonly employed in

automatic document feeders (ADFs) and in

duplexing systems.

The separation belt feed mechanism is similar to

the friction pad and friction roller systems; it

exploits the difference in friction resistance to

separate a single sheet of paper. However, unlike

these two systems, the separation belt does not

passively resist the passage of extra sheets of

paper; it turns against the movement of the paper

to feed back all but the bottom sheet.

The mechanism shown to the right is from the

DF62.

[A] Separation belts

[B] Feed rollers

A610d506.wmf

[B]

[A]

7 October 1999 Page 15

Handling Paper Paper Feed

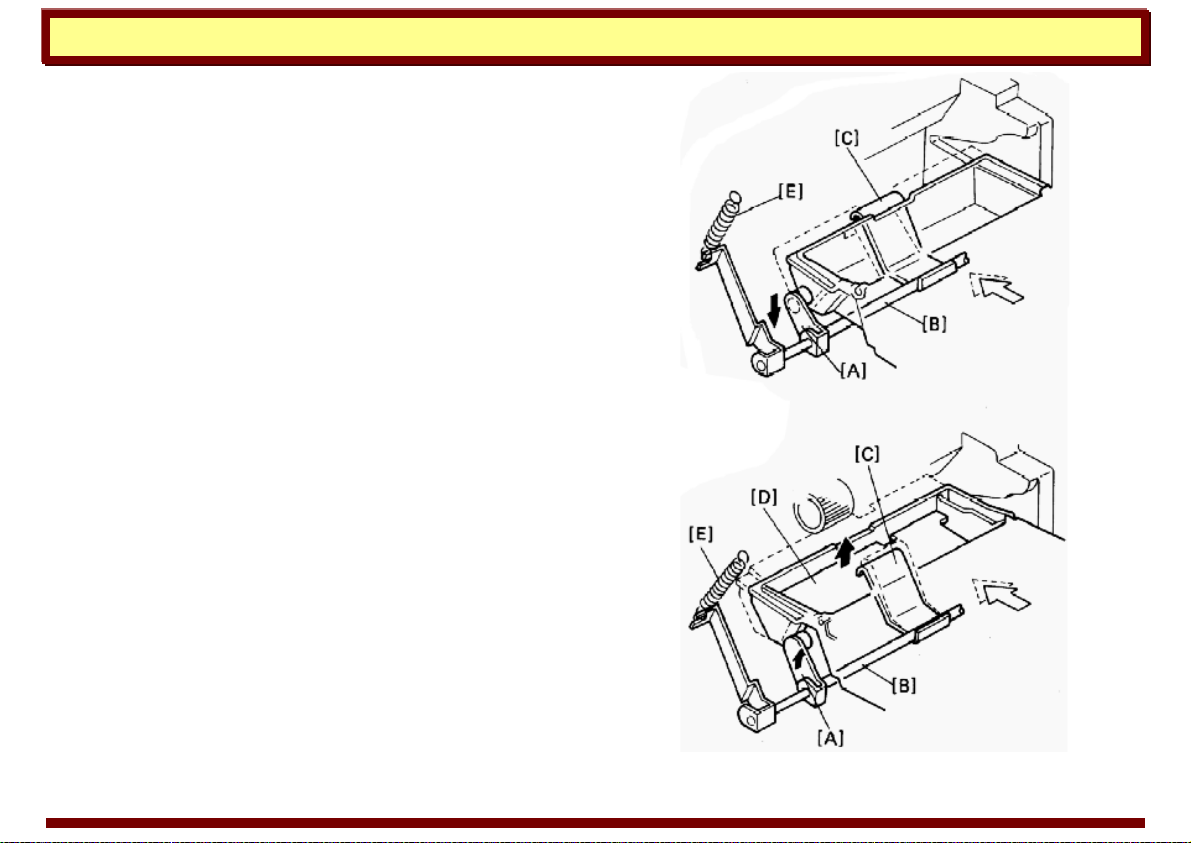

Example: Model A095 Duplex

The illustrations to the right show the model A095

duplex paper feed mechanism.

The paper on the duplex tray feeds in order from

the bottom to the top sheet. After all copies are

stacked on the duplex tray, the duplex pressure

solenoid [A] turns on to lower the pressure arm [B]

causing the pressure arm to press the paper

against the pick-up roller [C].

Then, the paper feed clutch [D] turns on to rotate

the pick-up roller, separation belts [E] and the

feed roller [F]. The separation belts and the feed

roller rotate in opposite directions.

Only the bottom sheet is fed because the

separation belt prevents any other sheets from

feeding.

sepbelt1.wmf

[B]

[

E

]

[A]

sepbelt2.wmf

[C]

[D]

[

F

]

[B]

[

E

]

7 October 1999 Page 16

Handling Paper Paper Feed

Separation Tab

The separation tab separation system is a

variation of the separation belt system. It is used

in slower feeding ADF units.

The illustration shows a document feeder using a

separation tab. The pick-up roller [A] and feed

roller [B] feed the document into the ADF unit.

Only the bottom sheet is fed because the

separation tab [C] prevents any other sheets from

feeding. The document feed-in roller [D], feeds the

document through the ADF unit.

g025d504.wmf

[B]

[C]

[D]

[A]

7 October 1999 Page 17

Handling Paper Paper Feed

Corner Separator

Corner separators provide a simple and reliable

method of separating off the top sheet during

paper feed. Commonly, they are used along with

semicircular feed rollers in low and medium speed

copiers.

A spring [A] holds the paper stack up against the

underside of the corner separators [B]. As the

feed rollers [C] start forcing the paper forward, the

corner separators retard the movement of the

paper causing the top sheet to bow up at the

edges and thus separate from the lower sheets.

With further feeding, the corners of the top sheet

release from the corner separators. The top sheet

then feeds into the paper path while the corner

separators stop the lower sheets from feeding.

cor_sep.tif

[B]

[C]

[A]

7 October 1999 Page 18

Handling Paper Paper Feed

Example: Model A219

This copier has one paper feed station and a by-

pass feed table. The paper feed station uses a

paper tray [A] that can hold 500 sheets. The by-

pass feed table [B] can hold 80 sheets.

The paper tray uses two semicircular feed rollers

[C] and corner separators. The semicircular feed

rollers make one rotation to drive the top sheet of

the paper stack to the relay rollers [D]. The two

corner separators allow only one sheet to feed.

They also hold the paper stack. When the paper

tray is drawn out of the machine, the spring

pressure is released, and the tray bottom plate

drops. In addition, there is no need to press the

bottom plate down when putting the tray back in.

The by-pass feed table uses a feed roller and

friction pad system to feed the top sheet of paper

to the registratio n rollers.

cor_sep2.tif

7 October 1999 Page 19

Handling Paper Paper Feed

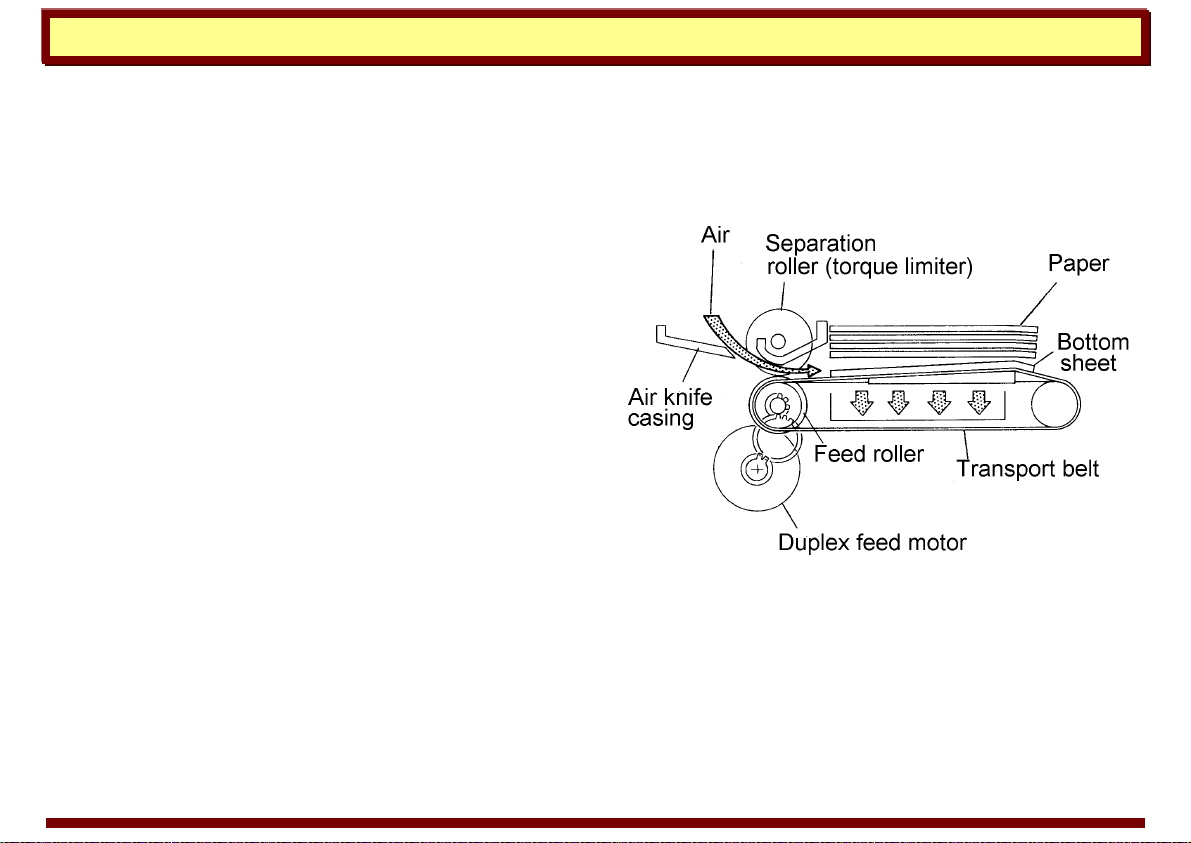

Air Knife

The air knife paper feed process uses jets of air to

separate sheets of paper for paper feed. The air

knife method (also called “air separation” method)

is suitable for high speed copying and printing

systems because it reduces the feed roller marks

and paper deformation that can occur in high

speed feeding.

The duplex paper feed mechanism of model A112

(right) uses a combination of air knife and FRR

feed mechanisms. The air knife directs jets of air

at the bottom of the paper stack to separate the

sheets of paper. A vacuum fan holds the bottom

sheet against the transport belt. The separation

roller allows only the bottom sheet to feed.

airknife.tif

7 October 1999 Page 20

Handling Paper Paper Feed

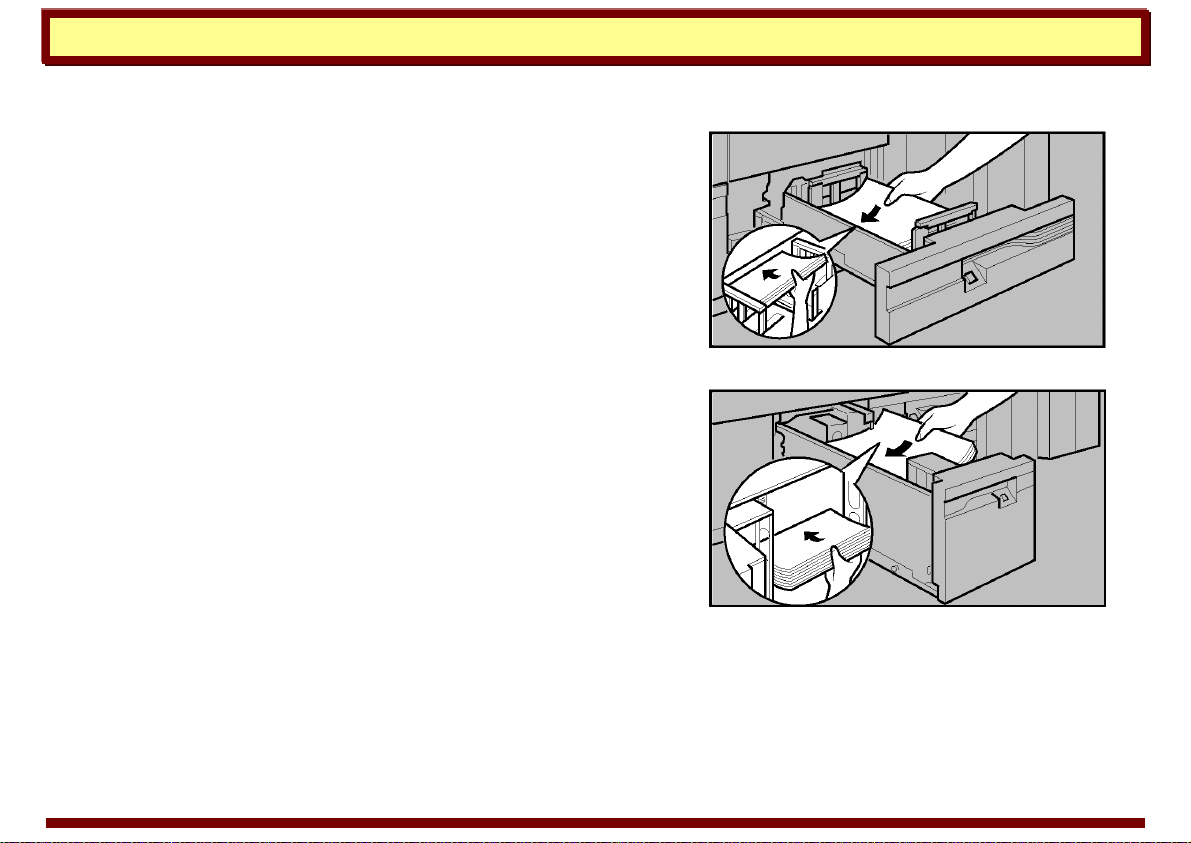

Paper Cassette

A paper cassette is a removable paper tray. A

cassette is taken out of the machine to load paper

and then reinserted in a cassette holder or

cassette entrance.

Paper Lift Mechanism

Cassettes all have a moveable bottom plate on

which the paper rests. The bottom plate must be

raised to place the paper in position to be fed.

Generally, this is accomplished by raising a

cassette arm under the bottom plate. (Refer to the

following examples.)

cassett1.tif

cassett2.tif

7 October 1999 Page 21

Handling Paper Paper Feed

Example 1: Model A111

This is an example of the cassette arm being

raised by a gear.

When inserting the cassette [A] into the copier,

the cassette pushes down the cassette actuator

pin [B]. The paper lift clutch unit [C] moves down

and then the paper lift gear [D] engages with the

sector gear [E] causing the cassette arm [H] to

raise the cassette bottom plate.

Simultaneously, the paper size actuator [F]

actuates the paper size switch [G] and the paper

raises the paper end feeler [I].

cassett3.tif

7 October 1999 Page 22

Handling Paper Paper Feed

Example 2: Model A006

This is an example of the cassette arm being

raised by a spring.

When a cassette is inserted into the copier, the

curved release guides on the sides of the cassette

press against the rollers on the release levers [A]

and force the release levers down. The release

levers rotate the cassette arm shaft [B], moving

the cassette arm down and out of the way. When

the cassette is fully seated, the release guides

allow the release levers to move back up. The

cassette arm [C] levers up the cassette bottom

plate [D] until the paper contacts the paper feed

roller.

To prevent copy paper from multi-feeding or

jamming, the spring [E] pressure is adjustable.

cassett4.tif

7 October 1999 Page 23

Handling Paper Paper Feed

Paper Tray

A paper tray is a non-removable drawer or bin that

is permanently built into or attached to the

machine. The capacity of paper trays varies

considerably; smaller trays typically hold 250 to

500 sheets of paper, but large capacity trays hold

a paper stock of 1000 or more sheets.

Paper Lift Mechanism

Smaller paper trays resemble paper cassettes and

have similar paper lift mechanisms employing

springs or a bottom plate lift arm.

However, large capacity trays have more

complicated mechanisms to raise the bottom plate

and place the paper in position to be fed.

Generally, this is accomplished using a wire- or

belt-lift mechanism. (Refer to the following

examples.)

500_sheet_tray.tif

1700_sheet_tray.tif

7 October 1999 Page 24

Handling Paper Paper Feed

Example 1: Model A609 (belt lift)

The bottom plate [A] of the LCT is raised and lowered by the LCT motor [B] and the drive belts [C].

When the main switch is on and the LCT cover is closed, the pick-up solenoid [D] activates and the

LCT motor [B] rotates clockwise to raise the bottom plate until the top sheet pushes up the pick-up

roller [E]. When the lift sensor [F] is de-actuated, the copier CPU de-activates the LCT motor [B] and

the pick-up solenoid [D].

a609d502.wmf

[D]

[

E

]

[

F

]

a609d501.wmf

[B]

[C]

[A]

[C]

7 October 1999 Page 25

Handling Paper Paper Feed

Example 2: Model A171 (wire lift)

Drive from a reversible motor [A] is transmitted trough a

worm gear [B] to the drive pulley [C] shaft. The tray wires

have metal beads on them. These beads are inserted in

the slots at the ends of the tray support bracket [D] of the

bottom plate; so, when the wire pulley turns

(counterclockwise rear view), the beads on the wires drive

the tray support bracket and the tray moves upward. The

tray goes up until the top sheet pushing up the pick-up

roller [E] actuates the upper limit sensor [F]. To lower the

tray, the pulley turns clockwise until the lower limit sensor

[G] is actuated by the of the bottom plate [H] actuator.

a171d620.pcx

[

F

]

E

]

a171d629.pcx

[G]

[H]

a171d628.pcx

[B]

[C]

[D]

[A]

7 October 1999 Page 26

Handling Paper Paper Feed

By-pass Feed Tray

Most copiers and multifunction machines

incorporate a fold-out by-pass feed table. By-pass

feed is useful for casual copying on odd paper

sizes. Also, on most machines, the by-pass feed

tray provides a straight paper path that is suitable

for stiff feed stock such as post cards or OHP

transparencies.

Example: A195

The by-pass feed table switch [A] detects when

the by-pass feed table is opened. Then the CPU

turns on the by-pass feed indicator on the

operation panel.

The by-pass feed table uses an FRR feed system,

using the same rollers as the LCT, and one of the

solenoids. Only the by-pass pick-up solenoid [B] is

used, because the pick-up roller does not have to

drop so far as it does when feeding from the LCT.

The user can put up to 40 sheets of paper on the

by-pass feed table. Note that the paper can be

pushed right into the machine, causing jams. The

[C]

a195d602.wmf

[

A

]

a195d569.wmf

7 October 1999 Page 27

Handling Paper Paper Feed

user must stop pushing the paper in when the by-

pass feed indicator goes out.

When the Start key is pressed, the by-pass feed

clutch [C] and the pick-up solenoid turn on to feed

the top sheet of paper.

When there is no paper on the by-pass feed table,

the paper end feeler [D] drops into the cutout in

the lower guide plate and the by-pass feed paper

end sensor [E] is deactivated.

[B]

a195d604.wmf

[D]

[

E

]

[C]

7 October 1999 Page 28

Handling Paper Paper Feed

Paper Roll

Wide format copiers and machines that use a

thermal printing process commonly feed paper

from a roll.

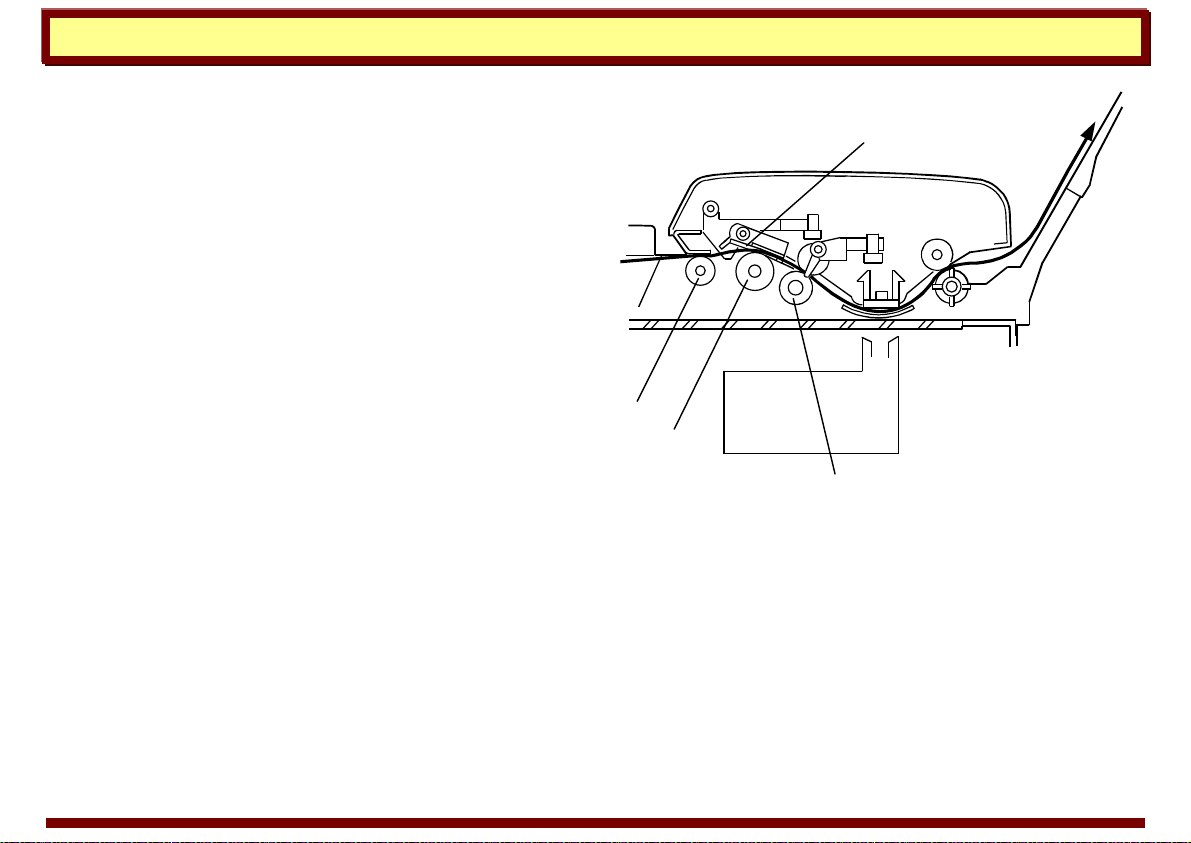

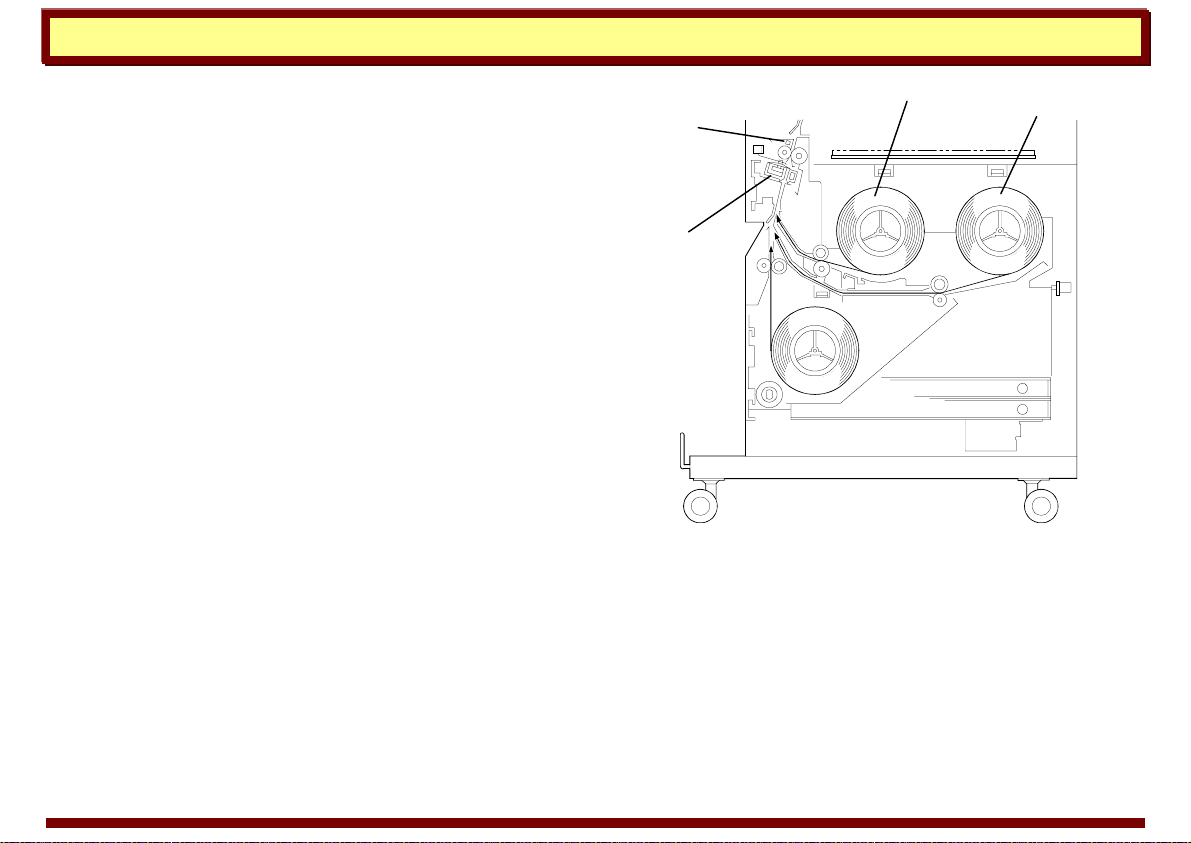

The illustration to the right shows the main

components of a roll feeding system—the paper

feed rollers [A], the paper roll [B], the cutter unit

[C], and the paper leading edge sensor [D].

sr740-4.pcx

7 October 1999 Page 29

Handling Paper Paper Feed

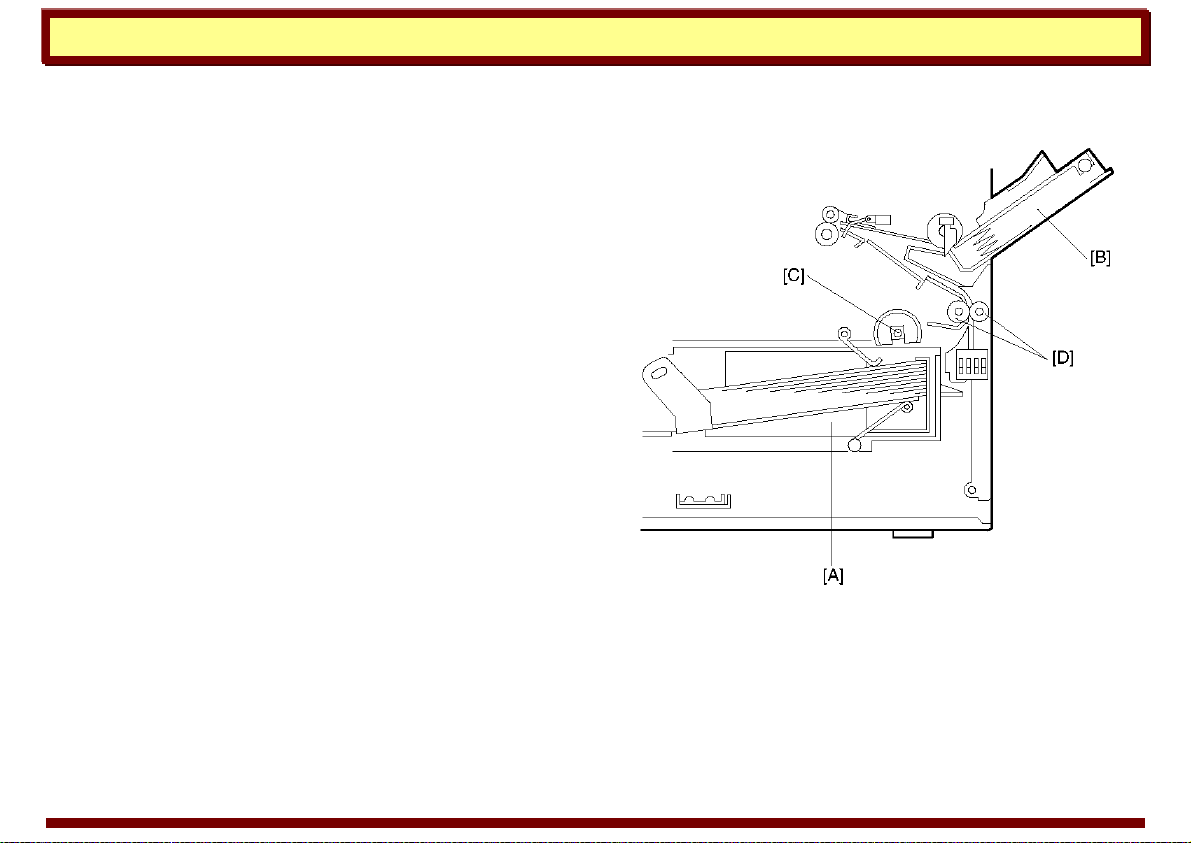

Example: A175

This machine has two standard roll feed units (1st

[A] and 2nd [B]), one manual feed unit, and one

optional roll feed unit (3rd [C]). The cutter unit [D]

uses a sliding rotary cutting blade.

When the main switch is turned on or when roll

paper is replenished, the roll feed motor rotates

and the leading edge of the roll paper is fed until

the roll lead edge sensor [E] is activated. Then,

the leading edge of the roll paper is returned to

the paper feed start position (120 mm before the

cutter unit).

When the original lead edge sensor detects the

leading edge of the original, the roll feed motor

and the roll feed clutch turn on, and paper feed

starts

a174d507.wmf

[B]

[D]

[

E

]

[A]

7 October 1999 Page 30

Loading...

Loading...