Ricoh iris Service Manual iris

Aficio Color 3006/4006/4106

(Iris/Lilac, A258/A259/A260)

Service Manual

Issued February 24, 1999, Ricoh CO., LTD.

øIMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1.Before disassembling or assembling parts of the copier and peripherals, make sure that the copier power cord is unplugged.

2.The wall outlet should be near the copier and easily accessible.

3.Note that some components of the copier and the paper tray unit are supplied with electrical voltage even if the main power switch is turned off.

4.If any adjustment or operation check has to be made with exterior covers off or open while the main switch is turned on, keep hands away from electrified or mechanically driven components.

5.If the Start key is pressed before the copier completes the warm-up period

(the Start key starts blinking red and green alternatively), keep hands away from the mechanical and the electrical components as the copier starts making copies as soon as the warm-up period is completed.

6.The inside and the metal parts of the fusing unit become extremely hot while the copier is operating. Be careful to avoid touching those components with your bare hands.

HEALTH SAFETY CONDITIONS

1.Never operate the copier without the ozone filters installed.

2.Always replace the ozone filters with the specified ones at the specified intervals.

3.Toner and developer are non-toxic, but if you get either of them in your eyes by accident, it may cause temporary eye discomfort. Try to remove with eye drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1.The copier and its peripherals must be installed and maintained by a customer service representative who has completed the training course on those models.

2.The NVRAM on the system control board has a lithium battery which can explode if replaced incorrectly. Replace the NVRAM only with an identical one. The manufacturer recommends replacing the entire NVRAM. Do not recharge or burn this battery. Used NVRAM must be handled in accordance with local regulations.

1

1.SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when exposed to an open flame.

2.Dispose of used toner, developer, and organic photoconductors in accordance with local regulations. (These are non-toxic supplies.)

3.Dispose of replaced parts in accordance with local regulations.

4.When keeping used lithium batteries in order to dispose of them later, do not put more than 100 batteries per sealed box. Storing larger numbers or not sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based optical units in the field. The optical housing unit can only be repaired in a factory or at a location with the requisite equipment. The laser subsystem is replaceable in the field by a qualified Customer Engineer. The laser chassis is not repairable in the field. Customer engineers are therefore directed to return all chassis and laser subsystems to the factory or service depot when replacement of the optical subsystem is required.

øWARNING

Use of controls, or adjustment, or performance of procedures other than those specified in this manual may result in hazardous radiation exposure.

øWARNING

Turn off the main switch before attempting any of the procedures in the Laser Unit section. Laser beams can seriously damage your eyes. CAUTION MARKING:

2

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION ........................................ |

1-1 |

1.1 SPECIFICATIONS.................................................................................... |

1-1 |

1.1.1 MACHINE CONFIGURATION ......................................................... |

1-1 |

1.1.2 GENERAL SPECIFICATIONS ......................................................... |

1-2 |

1.1.3 PLATEN/ARDF ORIGINAL SIZE DETECTION................................ |

1-6 |

1.1.4 COPY PAPER SIZE......................................................................... |

1-7 |

1.1.5 APS PAPER SIZES AVAILABLE ..................................................... |

1-8 |

1.1.6 NOISE EMISSION ........................................................................... |

1-9 |

1.1.7 POWER CONSUMPTION.............................................................. |

1-10 |

1.1.8 DISPLAY EDITOR SPECIFICATIONS .......................................... |

1-10 |

1.2 MECHANISM OVERVIEW ..................................................................... |

1-11 |

1.2.1 IMAGE GENERATION PROCESS ................................................ |

1-11 |

1.3 MAJOR UNIT LAYOUT AND PAPER FEED PATH................................ |

1-14 |

1.4 PARTS LAYOUT .................................................................................... |

1-17 |

1.4.1 MECHANICAL COMPONENT LAYOUT ........................................ |

1-17 |

1.4.2 ELECTRICAL COMPONENT LAYOUT ......................................... |

1-18 |

1.4.3 DRIVE LAYOUT............................................................................. |

1-25 |

1.4.5 AIR FLOW ..................................................................................... |

1-26 |

1.4.5 ELECTRICAL COMPONENT DESCRIPTIONS............................. |

1-27 |

Printed Circuit Boards ........................................................................ |

1-27 |

Motors ................................................................................................ |

1-28 |

Fan Motors ......................................................................................... |

1-28 |

Sensors.............................................................................................. |

1-29 |

Switches............................................................................................. |

1-30 |

Clutches ............................................................................................. |

1-30 |

Solenoids ........................................................................................... |

1-31 |

Lamps ................................................................................................ |

1-31 |

Heaters .............................................................................................. |

1-31 |

Thermistors ........................................................................................ |

1-31 |

Thermofuses ...................................................................................... |

1-31 |

Thermostat......................................................................................... |

1-31 |

Counter .............................................................................................. |

1-32 |

2. DETAILED DESCRIPTIONS ....................................................... |

2-1 |

2.1 PROCESS CONTROL.............................................................................. |

2-1 |

2.1.1 OVERVIEW ..................................................................................... |

2-1 |

2.1.2 POTENTIAL CONTROL .................................................................. |

2-2 |

Overview .............................................................................................. |

2-2 |

Potential Control Timing....................................................................... |

2-2 |

2.1.3 PROCESS CONTROL SELF CHECK ............................................. |

2-4 |

Flow Chart............................................................................................ |

2-4 |

Step 1: VSG Adjustment ...................................................................... |

2-5 |

Step 2: ID Sensor Pattern Generation.................................................. |

2-5 |

I

Step 3: Sensor Pattern Potential Detection.......................................... |

2-6 |

Step 4: Sensor Pattern Density Detection............................................ |

2-7 |

Step 5: Toner Amount Calculation ....................................................... |

2-8 |

Step 6: Development Potential Calculation .......................................... |

2-9 |

Step 7: Selecting the Optimum VD, VB, VL ....................................... |

2-10 |

2.1.4 PROCESS CONTROL γ CORRECTION ....................................... |

2-11 |

What is process control γ? ................................................................. |

2-11 |

How is it done?................................................................................... |

2-11 |

Process control gamma correction timing .......................................... |

2-12 |

2.2 TONER SUPPLY CONTROL.................................................................. |

2-13 |

2.2.1 TONER SUPPLY CONTROL METHOD ........................................ |

2-13 |

2.2.2 FUZZY CONTROL MODE ............................................................. |

2-13 |

2.2.3 VSP DETECTION FOR TONER SUPPLY CONTROL .................. |

2-14 |

2.2.4 CALCULATING THE AMOUNT OF TONER ON THE DRUM....... |

2-14 |

Fuzzy Logic Algorithm........................................................................ |

2-14 |

Image Area Ratio ............................................................................... |

2-15 |

2.2.5 FIXED SUPPLY MODE ................................................................. |

2-15 |

2.2.6 TONER SUPPLY IN ABNORMAL SENSOR CONDITIONS .......... |

2-15 |

2.2.7 DETECTING TONER NEAR END/END......................................... |

2-16 |

Toner Near-end.................................................................................. |

2-16 |

Toner End .......................................................................................... |

2-16 |

Toner near end detection ................................................................... |

2-17 |

Toner end detection ........................................................................... |

2-17 |

Toner end recovery ............................................................................ |

2-18 |

Toner replenishment confirmation mode............................................ |

2-18 |

2.3 DRUM UNIT............................................................................................ |

2-19 |

2.3.1 OVERVIEW ................................................................................... |

2-19 |

2.3.2 DRIVE MECHANISM ..................................................................... |

2-20 |

2.3.3 DRUM CHARGE............................................................................ |

2-21 |

2.3.4 DRUM CLEANING......................................................................... |

2-22 |

2.3.5 PCC ............................................................................................... |

2-22 |

2.3.6 QUENCHING ................................................................................. |

2-23 |

2.3.7 CARRIER CATCHER .................................................................... |

2-23 |

2.4 SCANNER UNIT..................................................................................... |

2-24 |

2.4.1 OVERVIEW ................................................................................... |

2-24 |

2.4.2 SCANNER ..................................................................................... |

2-25 |

2.4.3 SCANNER DRIVE ......................................................................... |

2-26 |

2.4.4 COLOR CCD ................................................................................. |

2-27 |

2.4.5 WHITE PLATE SCANNING ........................................................... |

2-28 |

2.4.6 SCANNER IPU BOARD................................................................. |

2-28 |

2.4.7 ORIGINAL SIZE DETECTION ....................................................... |

2-29 |

2.4.8 OTHERS........................................................................................ |

2-31 |

Anti-condensation Heater................................................................... |

2-31 |

Fans ................................................................................................... |

2-31 |

2.5 IMAGE PROCESSING ........................................................................... |

2-32 |

2.5.1 OVERVIEW ................................................................................... |

2-32 |

2.5.2 SCANNER SECTION BLOCK DIAGRAM...................................... |

2-33 |

2.5.3 SCANNER SECTION .................................................................... |

2-34 |

Photoelectric Conversion (by the CCD) ............................................. |

2-34 |

II

Signal Processing (in the Analog ASIC)............................................. |

2-34 |

A/D Conversion .................................................................................. |

2-34 |

Shading Circuit................................................................................... |

2-35 |

D/A Conversion .................................................................................. |

2-37 |

Scan Line Correction.......................................................................... |

2-37 |

2.5.4 IPU SECTION BLOCK DIAGRAM ................................................. |

2-38 |

2.5.5 IPU SECTION ................................................................................ |

2-39 |

Picture Element Correction and Scanner Gamma Correction............ |

2-39 |

ACS (Auto Color Selection)................................................................ |

2-41 |

Auto Letter/Photo Separation............................................................. |

2-42 |

Filtering and Color Conversion........................................................... |

2-44 |

Changes in UCR Ratio with Image Density and Copy Mode ............. |

2-50 |

UCA (Under Color Addition)............................................................... |

2-50 |

Main Scan Magnification .................................................................... |

2-51 |

Mirror Image....................................................................................... |

2-51 |

Gamma (γ) Correction (Printer Gamma) ............................................ |

2-52 |

Area Editing........................................................................................ |

2-55 |

CPU ................................................................................................... |

2-55 |

IPU Board Test................................................................................... |

2-55 |

2.6 LASER EXPOSURE ............................................................................... |

2-56 |

2.6.1 OVERVIEW ................................................................................... |

2-56 |

2.6.2 OPTICAL PATH ............................................................................. |

2-57 |

Overview ............................................................................................ |

2-57 |

F-theta Lenses and the BTL............................................................... |

2-59 |

Laser Synchronizing Detector Boards................................................ |

2-60 |

Gradation Control (Laser Pulse Width and Laser Power Modulation) 2-61 |

|

600 DPI Writing .................................................................................. |

2-62 |

Auto Power Control (APC) ................................................................. |

2-63 |

LD Safety Switches ............................................................................ |

2-64 |

2.6 DEVELOPMENT UNIT ........................................................................... |

2-65 |

2.6.1 OVERVIEW ................................................................................... |

2-65 |

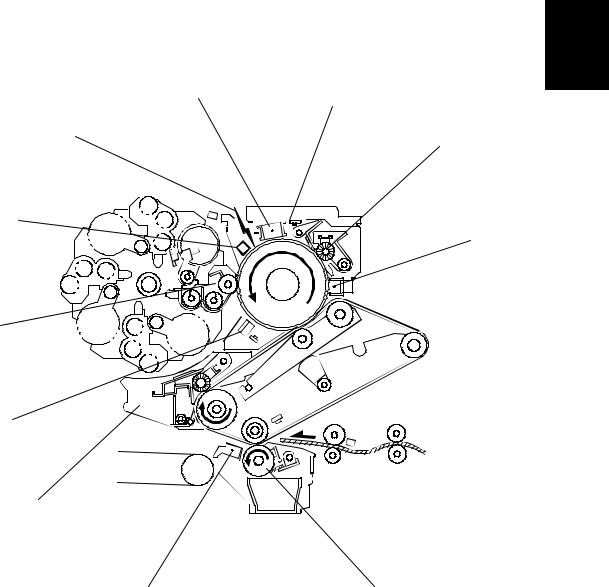

2.6.2 REVOLVER MECHANISM............................................................. |

2-66 |

Overview ............................................................................................ |

2-66 |

Revolver Drive.................................................................................... |

2-67 |

Revolver Home Position Detection..................................................... |

2-68 |

2.6.3 DEVELOPMENT MECHANISMS................................................... |

2-69 |

Overview ............................................................................................ |

2-69 |

Development Drive............................................................................. |

2-70 |

Developer Agitation............................................................................ |

2-70 |

Toner Agitation................................................................................... |

2-71 |

Development Bias .............................................................................. |

2-72 |

Toner Supply Mechanism .................................................................. |

2-73 |

Toner Cartridge Detection.................................................................. |

2-74 |

Incorrect Toner Installation Prevention............................................... |

2-74 |

Toner End Detection .......................................................................... |

2-75 |

2.7 TRANSFER BELT UNIT ......................................................................... |

2-76 |

2.7.1 OVERVIEW ................................................................................... |

2-76 |

2.7.2 BELT TRANSFER MECHANISMS ................................................ |

2-77 |

Transfer Belt Drive ............................................................................. |

2-77 |

III

Transfer Belt Release Lever............................................................... |

2-78 |

Belt Transfer Bias............................................................................... |

2-79 |

Belt Mark Detection............................................................................ |

2-80 |

Transfer Belt Cleaning Mechanism .................................................... |

2-81 |

2.7.3 PAPER TRANSFER MECHANISM................................................ |

2-85 |

Paper Transfer Unit Contact/Release Mechanism ............................. |

2-85 |

Paper Transfer Bias Roller Drive........................................................ |

2-86 |

Paper Transfer Bias Roller Cleaning.................................................. |

2-87 |

Paper Transfer Bias ........................................................................... |

2-88 |

2.7.4 PAPER SEPARATION MECHANISM............................................ |

2-90 |

2.8 PAPER FEED AND REGISTRATION..................................................... |

2-91 |

2.8.1 OVERVIEW ................................................................................... |

2-91 |

2.8.2 PAPER TRAY ................................................................................ |

2-92 |

Paper Feed/Separation ...................................................................... |

2-92 |

Separation and Pick-Up Roller Release............................................. |

2-92 |

Paper Lift............................................................................................ |

2-93 |

Paper End Detection .......................................................................... |

2-94 |

Paper Size Setting ............................................................................. |

2-94 |

Tray Paper Height Sensor.................................................................. |

2-95 |

2.8.3 BY-PASS TRAY............................................................................. |

2-96 |

By-pass Table Mechanism................................................................. |

2-96 |

Paper Feed/Separation ...................................................................... |

2-96 |

Paper End Detection .......................................................................... |

2-97 |

Paper Size Detection ......................................................................... |

2-98 |

Pick-up Roller..................................................................................... |

2-99 |

2.8.4 REGISTRATION MECHANISM AND PAPER FEED DRIVE ......... |

2-99 |

2.9 PAPER TRANSPORT, FUSING, AND PAPER EXIT ........................... |

2-100 |

2.9.1 MAJOR COMPONENTS.............................................................. |

2-100 |

2.9.2 DRIVE MECHANISM ................................................................... |

2-101 |

2.9.3 FUSING UNIT .............................................................................. |

2-102 |

Fusing Mechanism ........................................................................... |

2-102 |

Fusing Temperature Control ............................................................ |

2-102 |

Fusing/Pressurization Mechanism ................................................... |

2-103 |

Oil Supply Mechanism ..................................................................... |

2-104 |

Cleaning Mechanism........................................................................ |

2-105 |

2.9.4 INVERTER AND PAPER EXIT MECHANISMS ........................... |

2-106 |

Paper Exit......................................................................................... |

2-106 |

Junction Gate Mechanism (A259/A260 Only) .................................. |

2-106 |

Paper Exit Door Mechanism (A259/A260 Only) ............................... |

2-107 |

2.10 DUPLEX TRAY (A259/A260 COPIERS ONLY) .................................. |

2-108 |

2.10.1 OVERVIEW ............................................................................... |

2-108 |

2.10.2 DRIVE MECHANISM ................................................................. |

2-109 |

2.10.3 PAPER FEED INTO THE DUPLEX TRAY................................. |

2-110 |

1. Duplex Stacking ........................................................................... |

2-110 |

2. Paper Feed from the Duplex Tray ................................................ |

2-110 |

3. Duplex Entrance To Duplex Tray ................................................. |

2-111 |

2.10.4 JOGGER MECHANISM............................................................. |

2-112 |

2.10.5 PAPER FEED FROM THE DUPLEX TRAY............................... |

2-113 |

Bottom Plate Lift Mechanism ........................................................... |

2-113 |

IV

Paper Feed-out mechanism............................................................. |

2-114 |

2.11 OTHERS............................................................................................. |

2-115 |

2.11.1 SYSTEM CONFIGURATION ..................................................... |

2-115 |

2.11.2 POWER STATES ...................................................................... |

2-116 |

Energy Saver Mode ......................................................................... |

2-116 |

Power-off (Sleep) State.................................................................... |

2-116 |

Main Power Switch Off State ........................................................... |

2-117 |

Power State Transition Diagram ...................................................... |

2-117 |

2.11.3 TOUCH PANEL (A259/A260 MACHINES ONLY)...................... |

2-118 |

2.11.4 BUS SWITCH BOARD (OPTIONAL) ......................................... |

2-119 |

3. INSTALLATION PROCEDURE ................................................... |

3-1 |

|

3.1 |

INSTALLATION REQUIREMENTS .......................................................... |

3-1 |

|

3.1.1 DIMENSIONS .................................................................................. |

3-2 |

|

3.1.2 ENVIRONMENTAL REQUIREMENTS ............................................ |

3-3 |

|

3.1.3 MINIMUM SPACE REQUIREMENTS.............................................. |

3-5 |

|

3.1.4 POWER REQUIREMENTS.............................................................. |

3-6 |

3.2 |

COPIER INSTALLATION.......................................................................... |

3-7 |

|

3.2.1 ACCESSORY CHECK..................................................................... |

3-7 |

|

3.2.2 COPIER INSTALLATION PROCEDURE......................................... |

3-8 |

|

Tape Removal...................................................................................... |

3-8 |

|

Removing the Inner Transfer Cover and Paper Transfer |

|

|

Locking Screw.................................................................................. |

3-10 |

|

Developer Installation......................................................................... |

3-12 |

|

Pressure Release Lever Set-up ......................................................... |

3-17 |

|

Installing Fusing Silicone Oil .............................................................. |

3-18 |

|

Initialization and Function Checks...................................................... |

3-19 |

|

Setting the Tray Paper Size ............................................................... |

3-20 |

|

Setting the Language and Unit of Measurement................................ |

3-21 |

|

Resetting the Counter ........................................................................ |

3-21 |

|

3.2.2 RELOCATION PROCEDURE........................................................ |

3-22 |

3.3 |

PAPER TRAY UNIT (A832/A833)........................................................... |

3-23 |

|

3.3.1 ACCESORY CHECK ..................................................................... |

3-23 |

|

3.3.2 INSTALLATION ............................................................................. |

3-24 |

|

TRAY HEATER (OPTION)................................................................. |

3-27 |

3.4 |

PLATEN COVER (A749-01) ................................................................... |

3-28 |

3.5 |

ARDF (A663) .......................................................................................... |

3-29 |

|

3.5.1 ACCESSORY CHECK................................................................... |

3-29 |

|

3.5.2 INSTALLATION ............................................................................. |

3-30 |

3.6 |

20-BIN SORTER STAPLER (A834)........................................................ |

3-31 |

|

3.6.1 ACCESSORY CHECK................................................................... |

3-31 |

|

3.6.2 INSTALLATION ............................................................................. |

3-32 |

3.7 |

10-BIN SORTER STAPLER (A555)........................................................ |

3-36 |

|

3.7.1 ACCESSORY CHECK................................................................... |

3-36 |

|

3.7.2 INSTALLATION ............................................................................. |

3-37 |

3.8 |

3-BIN SORTER (A849) ........................................................................... |

3-42 |

V

3.8.1 ACCESSORY CHECK................................................................... |

3-42 |

|

3.8.2 INSTALLATION ............................................................................. |

3-43 |

|

3.9 FILM PROJECTOR TABLE (A702-19) ................................................... |

3-45 |

|

3.10 |

FILM PROJECTOR UNIT (A846) ......................................................... |

3-47 |

3.10.1 ACCESSORY CHECK................................................................. |

3-47 |

|

3.10.2 INSTALLATION ............................................................................ |

3-48 |

|

3.11 |

CONTROLLER INTERFACE TYPE E (A848)....................................... |

3-55 |

3.12 |

OTHERS............................................................................................... |

3-59 |

3.12.1 ORIGINAL TABLE INSTALLATION PROCEDURE ..................... |

3-59 |

|

3.12.2 KEY COUNTER HOLDER INSTALLATION PROCEDURE ......... |

3-60 |

|

4. SERVICE TABLES ...................................................................... |

4-1 |

4.1 SERVICE PROGRAM (SP) MODES ........................................................ |

4-1 |

4.1.1 HOW TO ENTER SP MODE............................................................ |

4-1 |

4.2 SP MODE TYPES .................................................................................... |

4-1 |

4.3 SP MODE TABLE..................................................................................... |

4-2 |

4.4 SP MODE ADDITIONAL NOTES ............................................................. |

4-3 |

4.4.1 SP5-804 OUTPUT CHECK............................................................ |

4-3 |

4.4.2 SP5-803 INPUT CHECK.................................................................. |

4-5 |

Printer .................................................................................................. |

4-5 |

Sorter ................................................................................................... |

4-7 |

ARDF ................................................................................................... |

4-8 |

4.4.3 SP5-955-018 TEST PATTERN SELECTION................................... |

4-8 |

4.4.4 5-955-001 LD_PWM (DOT, LINE) ................................................... |

4-8 |

4.4.5 5-955-002 TO 5-955-016 LD_PWM (16-GRADATION) ................... |

4-9 |

4.4.6 5-995-017 LD_PWM (COLOR PATCHES) ...................................... |

4-9 |

4.5 USER TOOL ........................................................................................... |

4-10 |

4.5.1 USER TOOL MENU....................................................................... |

4-10 |

System settings.................................................................................. |

4-10 |

COPY FEATURES............................................................................. |

4-11 |

4.5.2 SYSTEM SETTINGS ..................................................................... |

4-12 |

4.5.3 COPY FEATURES......................................................................... |

4-16 |

General Features ............................................................................... |

4-16 |

Image Adjustment .............................................................................. |

4-19 |

Set Favorite Keys............................................................................... |

4-21 |

Special Modes.................................................................................... |

4-21 |

4.6 TP/SW/LED/FUSE.................................................................................. |

4-22 |

4.6.1 MAIN CONTROL BOARD TEST POINTS ..................................... |

4-22 |

4.6.2 SCANNER IPU BOARD TEST POINTS ........................................ |

4-23 |

4.6.3 LD MAIN CONTROL BOARD TEST POINTS................................ |

4-24 |

4.6.4 I/O CONTROL BOARD TEST POINTS ......................................... |

4-25 |

4.6.5 SWITCH SPECIFICATIONS .......................................................... |

4-28 |

Scanner IPU Board ............................................................................ |

4-28 |

4.6.6 LED SPECIFICATIONS ................................................................. |

4-28 |

4.6.7 FUSE SPECIFICATIONS .............................................................. |

4-29 |

PSU (US model)................................................................................. |

4-29 |

PSU (European/Asian Model) ............................................................ |

4-30 |

VI

5. PREVENTIVE MAINTENANCE ................................................... |

5-1 |

|

5.1 |

PM PROCEDURES .................................................................................. |

5-1 |

|

5.1.1 PM-RELATED COUNTERS............................................................. |

5-1 |

|

5.1.2 REGULAR PREVENTIVE MAINTENANCE FLOW DIAGRAM ........ |

5-3 |

5.2 |

REGULAR PM ITEMS .............................................................................. |

5-7 |

|

Regular PM Table ................................................................................ |

5-7 |

6. REPLACEMENT AND ADJUSTMENT........................................ |

6-1 |

6.1 COVERS, FANS, AND FILTERS.............................................................. |

6-1 |

6.1.1 FRONT, INNER, AND INNER TRANSFER COVERS ..................... |

6-1 |

6.1.2 REAR COVERS............................................................................... |

6-2 |

6.1.3 RIGHT COVERS.............................................................................. |

6-3 |

6.1.4 LEFT COVERS ................................................................................ |

6-3 |

6.1.5 EXPOSURE GLASS ........................................................................ |

6-4 |

6.1.6 OPERATION PANEL ....................................................................... |

6-4 |

6.1.7 UPPER COVERS ............................................................................ |

6-4 |

6.1.8 USED TONER TANK....................................................................... |

6-5 |

6.1.9 CHARGE CORONA FAN FILTER ................................................... |

6-5 |

6.1.10 MAIN EXHAUST FAN FILTER....................................................... |

6-6 |

6.1.11 SCANNER EXHAUST FAN FILTER .............................................. |

6-6 |

6.1.12 MAIN EXHAUST FAN.................................................................... |

6-7 |

6.2 DRUM UNIT.............................................................................................. |

6-8 |

6.2.1 PULLING OUT THE REVOLVER/DRUM DRAWER...................... |

6-10 |

6.2.2 DRUM REPLACEMENT ................................................................ |

6-12 |

6.2.3 CLEANING BLADE AND PCC WIRE REPLACEMENT................. |

6-14 |

6.2.4 CLEANING BRUSH REPLACEMENT ........................................... |

6-15 |

6.2.5 LUBRICANT BAR REPLACEMENT .............................................. |

6-16 |

6.2.6 CHARGE CORONA GRID AND WIRE REPLACEMENT .............. |

6-17 |

6.2.7 POTENTIAL SENSOR REPLACEMENT ....................................... |

6-18 |

6.3 SCANNER UNIT..................................................................................... |

6-19 |

6.3.1 EXPOSURE LAMP REPLACEMENT ............................................ |

6-19 |

6.3.2 SBU REPLACEMENT.................................................................... |

6-20 |

6.3.3 SCANNER IPU BOARD REPLACEMENT..................................... |

6-21 |

6.3.4 SCANNER WIRE/SCANNER MOTOR REPLACEMENT .............. |

6-22 |

6.3.5 APS SENSORS ............................................................................. |

6-26 |

6.3.6 SCANNER HP SENSOR ............................................................... |

6-27 |

6.4 COPY IMAGE ADJUSTMENT ................................................................ |

6-28 |

6.4.1 PRINTER GAMMA ADJUSTMENT................................................ |

6-28 |

Setting the KCMY standard values .................................................... |

6-28 |

Gamma Data Print Out....................................................................... |

6-28 |

KCMY color balance adjustment ........................................................ |

6-28 |

Adjustment procedure ........................................................................ |

6-29 |

Standard Copy Quality ....................................................................... |

6-30 |

6.4.2 ACC TARGET ADJUSTMENT....................................................... |

6-31 |

6.4.3 MAIN SCAN DOT POSITION CORRECTION ............................... |

6-32 |

VII

6.5 LASER OPTICS SECTION..................................................................... |

6-34 |

6.5.1 POLYGON MIRROR MOTOR REPLACEMENT............................ |

6-35 |

6.5.2 LASER SYNCHRONIZING DETECTOR BOARD AND LD UNIT |

|

REPLACEMENT ...................................................................................... |

6-37 |

6.5.3 SQUARENESS ADJUSTMENT ..................................................... |

6-38 |

6.6 DEVELOPMENT UNIT ........................................................................... |

6-40 |

6.6.1 REPLACING THE DEVELOPER ................................................... |

6-40 |

Developer Collection Procedure......................................................... |

6-40 |

Installing New Developer ................................................................... |

6-43 |

6.6.2 POST DEVELOPER COLLECTION PROCEDURE....................... |

6-46 |

6.6.3 DEVELOPMENT UNIT REPLACEMENT....................................... |

6-47 |

6.6.4 TONER COLLECTION TRAY CLEANING..................................... |

6-48 |

6.7 TRANSFER BELT UNIT ......................................................................... |

6-49 |

6.7.1 TRANSFER BELT SECTION......................................................... |

6-49 |

Transfer Belt and Cleaning Unit ......................................................... |

6-49 |

Cleaning Blade Replacement............................................................. |

6-52 |

Lubricant Bar and Lubricant Brush Replacement............................... |

6-53 |

6.7.2 PAPER TRANSFER UNIT ............................................................. |

6-54 |

Lubricant Bar And Blade Replacement .............................................. |

6-54 |

Paper Separation Corona Wire Replacement .................................... |

6-54 |

Transfer Roller Replacement ............................................................. |

6-55 |

6.8 PAPER FEED AND REGISTRATION SECTION.................................... |

6-56 |

6.8.1 BY-PASS FEED TABLE REMOVAL .............................................. |

6-56 |

6.8.2BY-PASS PAPER WIDTH DETECTION BOARD REPLACEMENT6-56

6.8.3BY-PASS FEED, PICK-UP AND SEPARATION ROLLERS,

AND TORQUE LIMITER REPLACEMENT .................................... |

6-57 |

6.8.4 BY-PASS FEED UNIT REPLACEMENT........................................ |

6-58 |

6.8.5 REGISTRATION SENSOR REPLACEMENT ................................ |

6-58 |

6.8.6 VERTICAL TRANSPORT DOOR REPLACEMENT....................... |

6-59 |

6.8.7 PAPER TRAY PICK-UP, PAPER FEED, AND SEPARATION |

|

ROLLER REPLACEMENT............................................................. |

6-59 |

6.8.8 PAPER FEED UNIT AND CLUTCH REPLACEMENT ................... |

6-60 |

6.8.9 COPY IMAGE AREA ADJUSTMENT ............................................ |

6-61 |

Preparation ........................................................................................ |

6-61 |

Leading Edge Registration................................................................. |

6-62 |

Side-to-side Registration.................................................................... |

6-63 |

6.9 PAPER TRANSPORT, FUSING, AND PAPER EXIT SECTIONS .......... |

6-64 |

6.9.1 FUSING UNIT REMOVAL ............................................................. |

6-64 |

6.9.2 TRANSPORT UNIT REMOVAL ..................................................... |

6-65 |

6.9.3 FUSING UNIT TOP COVER REMOVAL ....................................... |

6-66 |

6.9.4 OIL SUPPLY PAD AND OIL BLADE REPLACEMENT.................. |

6-67 |

6.9.5 HOT ROLLER THERMOFUSE REPLACEMENT .......................... |

6-68 |

6.9.6 FUSING UNIT DISASSEMBLY...................................................... |

6-68 |

6.9.7 CLEANING ROLLER SCRAPER CLEANING................................ |

6-69 |

6.9.8 HOT ROLLER THERMISTOR REPLACEMENT............................ |

6-70 |

6.9.9 HOT ROLLER FUSING LAMP REPLACEMENT ........................... |

6-71 |

6.9.10 HOT ROLLER AND CLEANING ROLLER REPLACEMENT |

|

AND CLEANING........................................................................... |

6-72 |

VIII

6.9.11 PRESSURE ROLLER AND PRESSURE ROLLER FUSING |

|

LAMP........................................................................................... |

6-73 |

6.9.12 PRESSURE ROLLER THERMOFUSE AND THERMISTOR |

|

REPLACEMENT .......................................................................... |

6-74 |

6.9.13 NIP BAND WIDTH ADJUSTMENT .............................................. |

6-75 |

6.9.14 CAUTIONS TO BE TAKEN WHEN USING A FUSING UNIT |

|

THAT HAS BEEN IN STOCK FOR A LONG PERIOD.................. |

6-76 |

6.10 DUPLEX UNIT ...................................................................................... |

6-77 |

6.10.1 DUPLEX UNIT REMOVAL........................................................... |

6-77 |

6.10.2 SEPARATION ROLLER REPLACEMENT................................... |

6-77 |

6.10.3 FEED ROLLER REPLACEMENT ................................................ |

6-78 |

6.10.4 DUPLEX FEED MOTOR REPLACEMENT .................................. |

6-79 |

6.11 SYSTEM AND ELECTRONICS ............................................................ |

6-81 |

6.11.1 IPU PROGRAM DOWNLOADING ............................................... |

6-81 |

6.11.2 MAIN PROGRAM DOWNLOADING ............................................ |

6-82 |

6.11.3 NV-RAM UPLOADING AND DOWNLOADING............................ |

6-83 |

Upload/Download Procedure ............................................................. |

6-83 |

6.11.4 RAM CLEAR ................................................................................ |

6-84 |

RAM Clear Procedure ........................................................................ |

6-84 |

Precautions when replacing the NV-RAM .......................................... |

6-85 |

6.11.5 TOUCH PANEL CALIBRATION (A259/A260 ONLY)................... |

6-86 |

7. TROUBLESHOOTING................................................................. |

7-1 |

|

7.1 |

SERVICE CALL (SC) ERRORS ............................................................... |

7-1 |

|

7.1.1 SC TYPES AND RESETTING PROCEDURES ............................... |

7-1 |

7.2 |

SC CODE TABLE ..................................................................................... |

7-2 |

7.3 |

PROCESS CONTROL ERROR CONDITIONS ........................................ |

7-3 |

|

7.3.1 PROCESS CONTROL SELF-CHECK RESULTS (SP3-975-00) ..... |

7-3 |

|

7.3.2 DEVELOPER SETUP RESULTS (SP3-964-00) .............................. |

7-4 |

|

7.3.3 SELF-CHECK PROCESS CONTROL RELATED SCS ................... |

7-5 |

7.4 |

DRUM LIGHT FATIGUE ........................................................................... |

7-6 |

IX

OPTIONS

ARDF (A663)

1. |

SPECIFICATIONS................................................................. |

A663-1 |

|

2. |

COMPONENT LAYOUT ........................................................ |

A663-2 |

|

|

2.1 |

MECHANICAL COMPONENTS.......................................................... |

A663-2 |

|

2.2 |

ELECTRICAL COMPONENTS ........................................................... |

A663-3 |

3. |

ELECTRICAL COMPONENT DESCRIPTION ....................... |

A663-4 |

|

4. |

DETAILED DESCRIPTIONS ................................................. |

A663-5 |

|

|

4.1 |

ORIGINAL PICK-UP MECHANISM .................................................... |

A663-5 |

|

4.2 |

SEPARATION AND PAPER FEED MECHANISM.............................. |

A663-6 |

|

4.3 |

FRICTION BELT DRIVE MECHANISM .............................................. |

A663-7 |

|

4.4 |

ORIGINAL SIZE DETECTION ............................................................ |

A663-8 |

|

4.5 |

PAPER TRANSPORT MECHANISM.................................................. |

A663-9 |

|

4.6 |

THICK/THIN ORIGINAL MODES ..................................................... |

A663-10 |

|

4.7 |

ORIGINAL FEED-OUT MECHANISM............................................... |

A663-11 |

|

4.8 |

TWO-SIDED ORIGINAL FEED MECHANISM.................................. |

A663-12 |

5. |

TIMING CHARTS ................................................................ |

A663-13 |

|

|

5.1 |

A4 SIDEWAYS: 1 SIDED ORIGINAL ............................................... |

A663-13 |

|

5.2 |

COMBINE 2 ORIGINAL MODE ........................................................ |

A663-14 |

|

5.3 |

A4 SIDEWAYS: DUPLEX ................................................................. |

A663-15 |

6. |

SERVICE TABLES .............................................................. |

A663-16 |

|

|

6.1 |

DIP SWITCHES................................................................................ |

A663-16 |

|

6.2 |

VARIABLE RESISTORS................................................................... |

A663-17 |

|

6.3 |

LED................................................................................................... |

A663-17 |

|

6.4 |

FUSE ................................................................................................ |

A663-17 |

7. |

REPLACEMENT AND ADJUSTMENT................................ |

A663-18 |

|

|

7.1 |

TRANSPORT BELT REPLACEMENT .............................................. |

A663-18 |

|

7.2 |

FEED ROLLER REPLACEMENT ..................................................... |

A663-19 |

|

7.3 |

FRICTION BELT REPLACEMENT ................................................... |

A663-20 |

|

7.4 |

ORIGINAL SET AND WIDTH SENSOR REPLACEMENT................ |

A663-21 |

|

7.5 |

VERTICAL REGISTRATION ADJUSTMENT ................................... |

A663-22 |

|

|

7.5.1 ONE SIDED THIN ORIGINAL MODE ...................................... |

A663-22 |

|

|

7.5.2 TWO SIDED ORIGINAL MODE............................................... |

A663-23 |

|

7.6 |

SIDE-TO-SIDE REGISTRATION (DF POSITIONING) |

|

|

|

ADJUSTMENT.................................................................................. |

A663-24 |

X

PAPER TRAY UNIT (A832/A833)

1. PRODUCT OVERVIEW .......................................................... |

A833-1 |

||

1.1 |

SPECIFICATIONS.............................................................................. |

A833-1 |

|

1.2 |

COMPONENT DESCRIPTION ........................................................... |

A833-1 |

|

|

1.2.1 PAPER FEED MECHANISM ..................................................... |

A833-1 |

|

1.3 |

COMPONENT LAYOUTS................................................................... |

A833-2 |

|

|

1.3.1 ELECTRICAL COMPONENT LAYOUT ..................................... |

A833-2 |

|

|

1.3.2 DRIVE LAYOUT......................................................................... |

A833-3 |

|

|

1.3.3 DISASSEMBLY AND ADJUSTMENT PROCEDURES.............. |

A833-4 |

|

|

(1) |

Pick-up, paper feed, and separation rollers .............................. |

A833-4 |

|

(2) |

Bank paper feed and tray lift motors ......................................... |

A833-4 |

|

(3) |

Paper feed clutch...................................................................... |

A833-5 |

|

(3) |

Relay clutch .............................................................................. |

A833-5 |

|

(4) |

Paper feed unit ......................................................................... |

A833-6 |

20-BIN SORTER (A834)

1. OVERALL MACHINE INFORMATION ................................... |

A834-1 |

1.1 SPECIFICATIONS.............................................................................. |

A834-1 |

1.2 COMPONENT LAYOUT ..................................................................... |

A834-3 |

1.2.1 MECHANICAL COMPONENT LAYOUT.................................... |

A834-3 |

1.2.2 DRIVE LAYOUT......................................................................... |

A834-4 |

1.2.3 ELECTRICAL COMPONENT DESCRIPTION ........................... |

A834-5 |

2. DETAILED DESCRIPTIONS .................................................. |

A834-6 |

2.1 BASIC OPERATION........................................................................... |

A834-6 |

2.1.1 NORMAL MODE AND SORT/STACK MODE............................ |

A834-6 |

Normal (Proof) Mode...................................................................... |

A834-6 |

Sort Mode ...................................................................................... |

A834-6 |

Stack Mode .................................................................................... |

A834-7 |

2.1.2 STAPLE MODE ......................................................................... |

A834-8 |

Mechanism..................................................................................... |

A834-8 |

Automatic Stapling ......................................................................... |

A834-8 |

Manual Stapling ............................................................................. |

A834-8 |

2.1.3 BIN DRIVE MECHANISM .......................................................... |

A834-9 |

2.1.4 BIN HOME POSITION ............................................................. |

A834-10 |

2.1.5 JOGGER MECHANISM........................................................... |

A834-11 |

2.1.6 GRIP ASSEMBLY.................................................................... |

A834-12 |

2.1.7 STAPLER UNIT ....................................................................... |

A834-13 |

2.1.8 STAPLER SWITCH ................................................................. |

A834-14 |

Staple Mode Disabling Conditions ............................................... |

A834-14 |

2.1.9 PAPER FEED AND MISFEED DETECTION TIMING.............. |

A834-15 |

Proof ModeA4 sideways, five copies, 150 mm/s .......................... |

A834-15 |

Sorter ModeA4 sideways, two copies a of two-page original, |

|

150 mm/s ..................................................................................... |

A834-15 |

XI

|

Staple ModeA4 sideways, two copies of a two-page original, after |

|

|

sorting, 150 mm/s......................................................................... |

A834-16 |

|

2.1.10 JAM DETECTION .................................................................. |

A834-17 |

|

Paper JamA4 sideways................................................................ |

A834-17 |

|

Staple Jam ................................................................................... |

A834-17 |

3. REPLACEMENT AND ADJUSTEMENT .............................. |

A834-18 |

|

3.1 |

EXTERIOR COVER REMOVAL ....................................................... |

A834-18 |

|

3.1.1 FRONT COVER....................................................................... |

A834-18 |

|

3.1.2 REAR COVER ......................................................................... |

A834-18 |

|

3.1.3 TOP COVER............................................................................ |

A834-18 |

|

3.1.4 LOWER COVER ...................................................................... |

A834-18 |

3.2 |

STAPLER UNIT REMOVAL.............................................................. |

A834-19 |

3.3 |

GRIP ARM REPLACEMENT ............................................................ |

A834-20 |

3.4 |

BIN REMOVAL ................................................................................. |

A834-21 |

3.5 |

TRANSPORT MOTOR REMOVAL................................................... |

A834-22 |

10-BIN SORTER (A555) |

|

|

1. SPECIFICATIONS................................................................. |

A555-1 |

|

2. COMPONENT LAYOUT ........................................................ |

A555-3 |

|

2.1 |

MECHANICAL COMPONENT LAYOUT............................................. |

A555-3 |

2.2 |

DRIVE LAYOUT ................................................................................. |

A555-4 |

2.3 |

ELECTRICAL COMPONENT DESCRIPTION .................................... |

A555-5 |

3. BASIC OPERATION............................................................... |

A555-6 |

|

3.1 |

NORMAL MODE AND SORT/STACK MODE..................................... |

A555-6 |

3.2 |

STAPLE MODE .................................................................................. |

A555-8 |

3.3 |

BIN DRIVE MECHANISM ................................................................. |

A555-10 |

3.4 |

BIN HOME POSITION...................................................................... |

A555-11 |

3.5 |

JOGGER MECHANISM.................................................................... |

A555-12 |

3.6 |

GRIP ASSEMBLY............................................................................. |

A555-13 |

3.7 |

STAPLER UNIT ................................................................................ |

A555-14 |

3.8 |

STAPLER SWITCH .......................................................................... |

A555-15 |

3.9 |

PAPER FEED AND MISFEED DETECTION TIMING ...................... |

A555-16 |

3.10 JAM DETECTION........................................................................... |

A555-18 |

|

4. SERVICE TABLES ............................................................... |

A555-19 |

|

4.1 |

DIP SWITCHES................................................................................ |

A555-19 |

4.2 |

TEST POINTS .................................................................................. |

A555-20 |

4.3 |

LED................................................................................................... |

A555-20 |

4.4 |

VARIABLE RESISTOR..................................................................... |

A555-20 |

5. REPLACEMENT AND ADJUSTMENT................................. |

A555-21 |

|

5.1 |

EXTERIOR COVER REMOVAL ....................................................... |

A555-21 |

5.2 |

STAPLE UNIT REMOVAL ................................................................ |

A555-21 |

5.3 |

GRIP ARM REPLACEMENT ............................................................ |

A555-22 |

XII

5.4 |

BIN REPLACEMENT ........................................................................ |

A555-23 |

5.5 |

TRANSPORT MOTOR REPLACEMENT.......................................... |

A555-24 |

5.6 |

BIN JAM SENSOR ADJUSTMENT .................................................. |

A555-25 |

3-BIN SORTER (A849) |

|

||

1. |

SPECIFICATIONS.................................................................. |

A849-1 |

|

2. |

COMPONENT LAYOUT ......................................................... |

A849-2 |

|

|

2.1 |

MECHANICAL COMPONENT LAYOUT............................................. |

A849-2 |

|

2.2 |

DRIVE LAYOUT ................................................................................. |

A849-3 |

|

2.3 |

ELECTRICAL COMPONENT DESCRIPTION .................................... |

A849-4 |

3. |

DETAILED SECTION DESCRIPTIONS.................................. |

A849-5 |

|

|

3.1 |

BASIC OPERATION........................................................................... |

A849-5 |

|

|

3.1.1 FACE-UP MODE ....................................................................... |

A849-5 |

|

|

3.1.2 FACE-DOWN MODE ................................................................. |

A849-6 |

|

3.2 |

1ST BIN UP/DOWN MECHANISM ..................................................... |

A849-7 |

|

3.3 |

1ST BIN SIDE-TO-SIDE SHIFT MECHANISM ................................... |

A849-8 |

|

3.4 |

PAPER FEED AND MISFEED DETECTION TIMING ........................ |

A849-9 |

|

3.5 |

JAM DETECTION............................................................................. |

A849-11 |

4. |

REPLACEMENT AND ADJUSTMENT................................. |

A849-12 |

|

|

4.1 |

EXTERIOR COVER AND BIN REMOVAL........................................ |

A849-12 |

|

4.2 |

TRAY LIFT/SHIFT MOTOR ASSEMBLY REMOVAL ....................... |

A849-13 |

|

4.3 |

ENTRANCE MOTOR REPLACEMENT ............................................ |

A849-14 |

|

4.4 |

EXIT MOTOR REPLACEMENT........................................................ |

A849-15 |

|

4.5 |

STACK HEIGHT SENSOR AND 1ST EXIT |

|

|

|

SENSOR REPLACEMENT............................................................... |

A849-16 |

|

4.6 |

2ND / 3RD EXIT SENSOR AND INVERTER |

|

|

|

SENSOR REPLACEMENT............................................................... |

A849-18 |

FPU (A846) |

|

||

1. |

SPECIFICATIONS.................................................................. |

A846-1 |

|

2. |

ELECTRICAL COMPONENT LAYOUT |

A846-2 |

|

|

AND DESCRIPTIONS ........................................................... |

||

3. |

SECTIONAL DESCRIPTIONS................................................ |

A846-3 |

|

|

3.1 |

OVERVIEW ........................................................................................ |

A846-3 |

|

3.2 |

SHADING ........................................................................................... |

A846-4 |

|

3.3 |

MIRROR UNIT.................................................................................... |

A846-5 |

XIII

APPENDIX |

|

1. TIMMING CHART |

|

A4 SIZE B/W MODE ...................................................................................... |

1 |

A4 SIZE FULL COLOR MODE ...................................................................... |

2 |

A3 SIZE B/W MODE ...................................................................................... |

3 |

A3 SIZE FULL COLOR MODE ...................................................................... |

4 |

2. SP MODE TABLE |

|

3. SC CODE TABLE |

|

XIV

24 February, 1999 |

SPECIFICATIONS |

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

1.1.1 MACHINE CONFIGURATION

|

|

A258 |

A259 |

|

|

A260 |

Operation Panel |

40-digit 4-line LCD |

144 mm x 192 mm (10.4 inch) |

||||

Hard Key Type |

Color Touch Panel Display |

|

||||

|

|

|||||

Paper Tray Unit |

|

500 sheets |

Duplex |

|

||

Edit Function |

|

No |

No |

|

|

Yes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overall Information

Platen Cover |

ARDF |

A749-00 |

A663 |

Sorter/Stapler

A555

FPU A846

Copier

A834

FPU Table

FPU Table

A702-19

A702-19

I/F A848 A849

I/F A848 A849

Paper Tray Unit (500 sheets per tray)

|

|

|

|

|

|

|

|

|

|

|

A833 |

|

|

|

A832 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A259V501.WMF

1-1

SPECIFICATIONS 24 February, 1999

1.1.2 GENERAL SPECIFICATIONS

Configuration: |

Desktop |

Copy Process: |

Dry electrostatic transfer system |

Resolution: 400 dpi; Printer mode 600 dpi |

|

Gradations: |

256 gradations |

Originals: |

Sheet/Book/Object |

Original Size: |

Maximum 11" x 17" /A3 |

Copy Paper Size:

|

Maximum |

Minimum |

Paper Tray Feed |

11" x 17" /A3 |

51/2 x 81/2 /A5(L) |

(A258 only) |

|

|

Bypass Feed |

12" x 18"/305 mm x 457 mm |

A6(L) |

|

|

|

Copy Paper Weight:

Paper Tray Feed |

17 to 28 lbs. |

64 to 105 g/m2 |

Bypass Feed |

14 to 43 lbs. |

52 to 160 g/m2 |

Auto Duplex Tray |

17 to 28 lbs. |

64 to 105 g/m2 |

|

|

|

Reproduction Ratios:

|

81/2" x 11"LT/11" x 17"DLT |

A4/A3 version |

|

version |

|

Enlargement |

121, 129, 155, 200, 400% |

115, 122, 141, 200, 400% |

Full size |

100% |

100% |

Reduction |

25, 50, 65, 73, 78, 85, 93% |

25, 50, 65, 71, 75, 82, 93% |

Programmable |

2 user ratios |

2 user ratios |

|

|

|

Zoom: From 25% to 400 % in 1% steps.

1-2

24 February, 1999 SPECIFICATIONS

Copying Speed:

|

81/2" x 11" (S) /A4 |

11" x 17"/A3 |

Normal Mode |

|

|

Full Color (4 scans) |

6 cpm |

3 cpm |

Single Color (C, M Y, K) |

A258: 21 cpm |

A258: 11 cpm |

|

A259/260: 28 cpm |

A259/260: 14 cpm |

Single Color (B, G) |

9 cpm |

4.5 cpm |

Single Color (R) |

7 cpm |

3.5 cpm |

OHP/Thick Paper Mode |

|

|

Full Color (4 scans) |

3 cpm |

1.5 cpm |

Single Color (C, M Y, K) |

5 cpm |

2.5 cpm |

Single Color (G, B) |

4 cpm |

2 cpm |

Single Color (R) |

3.5 cpm |

1.5 cpm |

|

|

|

Duplexing: Same as Normal Mode speed in the above table

Printer Speed: 2/3 the speeds shown in the above table

First Copy Time (A258/259/260):

|

81/2" x 11" (S) /A4 |

Normal Mode |

|

Full Color (4 scans) |

22.4 seconds |

Single Color (K) |

8 seconds |

Single Color (C, M, Y) |

10 seconds |

Single Color (B, G, R) |

16 seconds |

OHP/Thick Paper Mode |

|

Full Color (4 scans) |

35 seconds |

|

|

Single Color (K) |

23 seconds |

Single Color (C, M, Y) |

25 seconds |

Single Color (B, G, R) |

27 seconds |

|

|

Warm-up Time: Approx. 7 minutes (at 68°F / 20°C)

Overall Information

1-3

SPECIFICATIONS |

24 February, 1999 |

Duplexing: |

|

Basic Manual Duplex |

Manual duplexing in full color and single |

Model (A258): |

color modes |

Basic Auto Duplex |

Manual & auto duplexing in full color and |

Model (A259): |

single color modes |

Edit Auto Duplex Model |

Manual & auto duplexing in full color and |

(A260): |

single color modes |

|

Duplexing can be done on 64-105 g/m2 paper. |

|

Manual duplexing can be done through the |

|

bypass table only, and the user should press |

|

the Duplex Side 2 key before copying the reverse |

|

side. |

Non-Reproduction Area:

Leading Edge:

Side:

Trailing Edge:

Copy Number Input:

Copy Number Input

(Auto Duplex):

Image Density:

Automatic Reset:

Paper Capacity:

0.2" ± 0.08" (5 mm ± 2 mm)

0.08" ± 0.08" (2 mm ± 2 mm)/

Total less than 0.16" (4 mm)

2.0 mm + 2.0/-1.5 mm

Number keys, 1 to 99

Number keys |

|

Single Color - |

1 to 50: smaller than A3, 11" x 17" |

|

1 to 30: A3, 11" x17" |

Full Color |

1 to 20: all sizes |

Auto/Manual (9 steps)

Yes (10 to 990 seconds or Off)

Tray:

500 sheets x 1 tray

(Basic Manual Duplex Model: A258)

Bypass: |

|

Normal paper (80 g/m2/20 lb) |

50 sheets |

OHP |

20 sheets |

Adhesive paper |

1 sheet |

Toner Replenishment: |

Toner Addition (K, Y, C, M) (220 g/cartridge) |

Copy Tray Capacity: |

100 sheets (11" x 17"/A3 and smaller) |

Power Source: |

US: 120V/12A/60Hz, |

|

Europe/Asia: 220-240V/8A/50,60 Hz |

|

Taiwan: 110 V/12A/60Hz |

Maximum Power |

1.5 kVA |

Consumption: |

|

1-4

24 February, 1999 SPECIFICATIONS

Dimensions (without Platen Cover):

|

|

Width |

|

Depth |

Height |

|

A258 |

620 mm |

|

680 mm |

602 mm |

|

24.4" |

|

26.8" |

23.7" |

|

|

|

|

|||

|

A259 |

620 mm |

|

757 mm |

602 mm |

|

24.4" |

|

29.8" |

23.7" |

|

|

|

|

|||

|

A260 |

620 mm |

|

757 mm |

602 mm |

|

24.4" |

|

29.8" |

23.7" |

|

|

|

|

|||

|

|

|

|

|

|

Height: 1,018 mm with optional paper tray unit |

|

|

|||

Weight: |

Manual Duplex: 105 kg (231.3 lbs.) |

|

|||

|

|

Auto Duplex: 108 kg (237.9 lbs.) |

|

||

Optional Equipment: |

Automatic Document Feeder (ARDF): A663 |

||||

|

|

Sorter Stapler: A555 (10 bins), A834 (20 bins), |

|||

|

|

Sorter: A849 (3 bins) |

|

|

|

Film Projector: A846

Holder for Film Projector Unit: A702-19

Paper Tray Unit: A832 (2 trays), A833 (3 trays)

Key Counter

Platen Cover: A749-00

Original Tray: A430-07 (Type F)

Overall Information

1-5

SPECIFICATIONS 24 February, 1999

1.1.3 PLATEN/ARDF ORIGINAL SIZE DETECTION

Size (width x length) |

Platen |

|

|

ARDF |

||||

|

[mm] |

|

Inches |

|

Metric |

Inches |

|

Metric |

A3 |

(297 x 420) |

L |

No |

|

Yes |

No |

|

Yes |

B4 |

(257 x 364) |

L |

No |

|

Yes |

No |

|

Yes |

|

|

|

|

|

|

|

|

|

A4 |

(210 x 297) |

L |

No |

|

Yes |

Yes |

|

Yes |

A4 |

(297 x 210) |

S |

No |

|

Yes |

Yes |

|

Yes |

B5 |

(182 x 257) |

L |

No |

|

Yes |

No |

|

Yes |

B5 |

(257 x 182) |

S |

No |

|

Yes |

No |

|

Yes |

A5 |

(148 x 210) |

L |

No |

|

No* |

No |

|

Yes |

A5 |

(210 x 148) |

S |

No |

|

No |

No |

|

Yes |

B6 |

(128 x 182) |

L |

No |

|

No |

No |

|

Yes |

B6 |

(182 x 128) |

S |

No |

|

No |

No |

|

Yes |

11" x 17" (DLT) |

|

Yes |

|

No |

Yes |

|

Yes |

|

11" x 15" |

|

No |

|

No |

Yes |

|

No |

|

10" x 14" |

|

No |

|

No |

Yes |

|

Yes |

|

8.5" x 14" (LG) |

|

Yes |

|

No |

Yes |

|

No |

|

8.5" x 13" (F4) |

|

No |

|

No |

Yes |

|

Yes |

|

8.25" x 13" |

|

No |

|

No |

No |

|

No |

|

8" x 13"(F) |

|

No |

|

Yes |

Yes |

|

No |

|

8.5" x 11" (LT) |

|

Yes |

|

No |

Yes |

|

Yes |

|

11" x 8.5" (LT) |

|

Yes |

|

No |

Yes |

|

Yes |

|

|

|

|

|

|

|

|

|

|

8" x 10.5" |

|

No |

|

No |

No |

|

No |

|

8" x 10" |

|

No |

|

No |

Yes |

|

No |

|

5.5" x 8.5" (HLT) |

No* |

|

No |

Yes |

|

No |

||

8.5" x 5.5" (HLT) |

No |

|

No |

Yes |

|

No |

||

A6 |

(105 x 148) L |

No |

|

No |

No |

|

No |

|

|

|

|

|

|

|

|

|

|

*: For A5 lengthwise/HLT, SP4-303 can be used to select “Cannot detect original size” or “A5 lengthwise/5.5" x 8.5"(HLT)”.

1-6

24 February, 1999 SPECIFICATIONS

1.1.4 COPY PAPER SIZE

|

|

|

|

|

Trays in the main body |

|

Bypass |

Optional |

|||

|

|

|

|

|

|

S.Stapler |

|||||

|

Size |

|

|

|

|

|

|

|

|

||

|

|

Paper Tray (A258) |

Duplex Tray |

All |

|

||||||

(width x length) |

|

||||||||||

(A259/A260) |

|

||||||||||

|

[mm] |

|

|

|

|

versions |

|

||||

|

|

Inches |

|

Metric |

Inches |

|

Metric |

(A258/ |

|

||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

259/260) |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A3 |

(297 x |

420) |

L |

No |

|

Yes |

Yes |

|

Yes |

Yes |

Yes |

|

|

|

|

|

|

|

|

|

|

|

|

B4 |

(257 x |

364) |

L |

No |

|

Yes |

Yes |

|

Yes |

Yes |

Yes |

A4 |

(210 x |

297) |

L |

Yes |

|

Yes |

Yes |

|

Yes |

Yes |

Yes |

A4 |

(297 x |

210) |

S |

Yes |

|

Yes |

Yes |

|

Yes |

Yes |

Yes |

B5 |

(182 x |

257) |

L |

No |

|

Yes |

No |

|

Yes |

Yes |

Yes |

B5 |

(257 x |

182) |

S |

No |

|

Yes |

No |

|

Yes |

Yes |

Yes |

A5 |

(148 x |

210) |

L |

No |

|

Yes |

No |

|

No |

Yes |

Yes (1) |

A5 |

(210 x |

148) |

S |

No |

|

No |

Yes |

|

Yes |

Yes |

Yes (2) |

B6 |

(128 x |

182) |

L |

No |

|

No |

No |

|

No |

Yes |

Yes (1) |

B6 |

(182 x |

128) S |

No |

|

No |

No |

|

No |

No |

No |

|

12” x 18” |

|