Omron SJDE-ANA-OY User Manual

Manual No.

TOEP-C71080603-01-OY

OMRON YASKAWA Motion Control B.V.

JUNMA SERIES SERVO DRIVE

Mechatrolink-II communications type

Model: SJDE- ANA-OY

USER´ S MANUAL

Copyright © 2006 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of Yaskawa. No

patent liability is assumed with respect to the use of the information contained herein.

Moreover, because Yaskawa is constantly striving to improve its high-quality products,

the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, Yaskawa

assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained in this publication.

Introduction

This instruction manual describes the JUNMA series AC SERVOPACKs. To properly use the JUNMA

series AC SERVOPACKs, read these instructions thoroughly and retain for easy reference for inspections,

maintenance, and so on. Make sure that the end user receives this manual.

Related Manuals

Refer to the following manuals as required.

Manual Name Manual Number

JUNMA series AC SERVOMOTOR

INSTRUCTIONS

TOMPC23026100

or

TOEPC23026101

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed these precautions can result in serious or possibly even fatal injury or damage to the products or to related equipment

and systems.

WARNING

CAUTION

PROHIBITED

MANDATORY

Indicates precautions that, if not heeded, could possibly result in loss of life or serious injury.

Indicates precautions that, if not heeded, could result in relatively serious or minor

injury, damage to the product, or faulty operation.

In some situations, the precautions indicated could have serious consequences if

not heeded.

Indicates prohibited actions that must not be performed. For example, this symbol

would be used as follows to indicate that fire is prohibited: .

Indicates compulsory actions that must be performed. For example, this symbol

would be used as follows to indicate that grounding is compulsory: .

Visual Aids

The following aids are used to indicate certain types of information for easier reference.

• Indicates important information that should be memorized, including precautions

IMPORTANT

INFOINFO

such as alarm displays to avoid damaging the devices.

• Indicates supplemental information.

Trademarks

MECHATROLINK is a trademark of the MECHATROLINK Members Association.

1

Notes for Safe Operation

Read these instructions thoroughly before checking products on delivery, storage and transportation,

installation, wiring, operation and inspection, and disposal of the AC SERVOPACK.

WARNING

• Be sure to correctly connect the SERVOPACK connectors.

Incorrect wiring may result in electric shock, fire, or damage to the equipment. For the wir-

ing method, refer to 3.4 Main Circuit Wiring.

• Use the emergency stop signal input E-STP to forcibly turn OFF the servo from an external

sequence, such as host controller, at occurrence of servo alarm or system emergency stop.

The residual voltage rotates the servomotor for a few seconds after the power supply has

been turned OFF, and may result in injury or damage to the equipment. Be sure to completely stop the motor by turning OFF the servo using the emergency stop.

• Configure the circuit’s power supply to be automatically cut off if E-STP signal is OFF at

occurrence of emergency stop

The residual voltage rotates the servomotor for a few seconds after the power supply has

been turned OFF, and may result in injury or damage to the equipment. Be sure to completely stop the motor by turning OFF the servo using the emergency stop.

Position information is not stored in the SERVOPACK, so this information will be lost if the

power supply is turned OFF. This information cannot be read again if the power supply is

turned OFF.

• Never touch any rotating motor parts while the motor is running.

Failure to observe this warning may result in injury.

• Before starting operation with a machine connected, make sure that an emergency stop can

be applied at any time. Also, configure the circuit’s power supply to be automatically cut off if

E-STP signal is OFF at occurrence of emergency stop.

Failure to observe this warning may result in injury.

• Never touch the inside of the SERVOPACK.

Failure to observe this warning may result in electric shock.

• Do not touch terminals for five minutes after the power is turned OFF.

Residual voltage may cause electric shock.

• Follow the procedures and instructions for trial operation precisely as described in this man-

ual.

Malfunctions that occur after the servomotor is connected to the equipment not only damage the equipment, but may also cause an accident resulting in death or injury.

• Do not remove cables, connectors, or optional items while the power is ON.

Failure to observe this warning may result in electric shock.

• Installation, wiring, advice on inspection and malfunction must be performed only by autho-

rized personnel.

Failure to observe this warning may result in fire, electric shock, or injury.

• Do not damage, press, exert excessive force or place heavy objects on the cables or the

cables between other objects where they might be pinched.

Failure to observe this warning may result in electric shock, stopping operation of the product, or burning.

2

WARNING

• Provide an appropriate stopping device on the machine side to ensure safety.

A holding brake for a servomotor with brake is not a stopping device for ensuring safety.

Failure to observe this warning may result in injury.

• Do not come close to the machine immediately after resetting momentary power loss to

avoid an unexpected restart.

Take appropriate measures to ensure safety against an unexpected restart. Failure to

observe this warning may result in injury.

• Never modify the product.

Failure to observe this warning may result in injury or damage to the product.

• Be sure to correctly ground the SERVOPACK and the servomotor.

• Connect the SERVOPACK’s ground terminal to electrical codes (ground resistance: 100 Ω

or less).

Improper grounding may result in electric shock.

Checking on Delivery

CAUTION

• Always use the servomotor and SERVOPACK in one of the specified combinations.

Failure to observe this caution may result in fire or malfunction.

Storage and Transportation

CAUTION

• Do not store or install the product in the following places.

Failure to observe this caution may result in damage to the product.

• Locations subject to direct sunlight.

• Locations subject to temperatures outside the range specified in the storage or installation temperature conditions.

• Locations subject to humidity outside the range specified in the storage or installation

humidity conditions.

• Locations subject to condensation as the result of extreme changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust, salts, or iron dust.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

• Do not hold the product by the cables or motor shaft while transporting it.

Failure to observe this caution may result in injury or malfunction.

• Do not place any load exceeding the limit specified on the packing box.

Failure to observe this caution may result in injury or malfunction.

3

Installation

CAUTION

• Make sure to follow the conditions on 2.1 Installation Conditions.

Failure to observe this caution may result in electric shock, fire, or SERVOPACK’s malfunc-

tion.

• Do not step on or place a heavy object on the product.

Failure to observe this caution may result in injury.

• Do not cover the inlet or outlet parts of the SERVOPACK and prevent any foreign objects,

such as metallic fragment, or combustibles from entering the product.

Failure to observe this caution may cause internal elements to deteriorate resulting in malfunction or fire.

• Be sure to install the product in the correct direction.

Failure to observe this caution may result in malfunction.

• Provide the specified clearances between the SERVOPACK and the control panel or with

other devices.

Failure to observe this caution may result in fire or malfunction.

• SERVOPACK and servomotor are precision equipment. Do not apply any strong impact.

Failure to observe this caution may result in malfunction.

4

Wiring

WARNING

• Be sure to correctly ground the SERVOPACK and the servomotor.

• Wiring must be performed by an authorized person qualified in electrical work.

• When using the servomotor for a vertical axis, install safety devices to prevent workpieces

from falling off because of alarms. Workpiece’s falling off may result in injury or malfunction.

• Configure the interlock circuit so that the system is interlocked to avoid injury whenever the

protective cover on the machine is opened or closed.

• Use the emergency stop signal input E-STP to forcibly turn OFF the servo from an external

sequence, such as host controller, at occurrence of servo alarm or system emergency stop.

The residual voltage rotates the servomotor for a few seconds after the power supply has

been turned OFF, and may result in injury or damage to the equipment. Be sure to completely stop the motor by turning OFF the servo using the emergency stop.

• When executing the JOG operation and the home position search operation using CX-Drive,

the E-STP signal will be ignored. Alternative measures must be taken in case an emergency stop is needed.

• Configure the circuit’s power supply to be automatically cut off if E-STP signal is OFF at

occurrence of emergency stop.

The residual voltage rotates the servomotor for a few seconds after the power supply has

been turned OFF, and may result in injury or damage to the equipment.

Position information is not stored in the SERVOPACK, so this information will be lost if the

power supply is turned OFF. This information cannot be read again if the power supply is

turned OFF.

• When executing JOG operation and the home position search operation using CX-Drive, the

P-OT and N-OT signals will be ignored. Alternative measures must be taken in case of

overtravel.

5

CAUTION

• Do not connect a three-phase power supply to the U, V, or W output terminals.

Failure to observe this caution may result in injury or fire.

• Securely connect the power supply terminals, regenerative unit connection terminal, and

motor main circuit cable terminals.

Failure to observe this caution may result in fire.

• Do not bundle or run power and signal lines together in the same duct. Keep power and sig-

nal lines separated by at least 300 mm. (11.81 in).

Failure to observe this caution may result in malfunction.

• Use twisted-pair shielded wires or multi-core twisted pair shielded wires for I/O signal cable

and encoder cable.

The maximum length is 3 m (118.11 in) for I/O signal cable and is 20 m (787.40 in) for

encoder cable.

• Do not touch the power terminals for five minutes after turning the power supply LED (PWR)

are OFF because high voltage may still remain in the SERVOPACK.

• Avoid frequently turning power ON and OFF. Do not turn power ON or OFF more than once

per minute.

Since the SERVOPACK has a capacitor in the power supply, a high charging current flows

when power is turned ON. Frequently turning power ON and OFF causes main power

devices such as capacitors and fuses to deteriorate, resulting in unexpected problems.

• Observe the following precautions when wiring connector for power supply/regenerative

unit.

• Remove the connector for power supply/regenerative unit from the SERVOPACK prior to

wiring.

• Insert only one wire per terminal on the connector for power supply/regenerative unit.

• Make sure that the core wire is not electrically shorted to adjacent core wires.

• Be sure to wire correctly and securely.

Failure to observe this caution may result in motor overrun, injury, or malfunction.

• Always use the specified power supply voltage of single-phase 200 V to 230 V without con-

necting directly to the power supply of 400 V.

The SERVOPACK will be destroyed.

• Take appropriate measures to ensure that the input power supply is supplied within the

specified voltage fluctuation range.

An incorrect power supply may result in damage to the product.

• Install external breakers or other safety devices against short-circuit in external wiring.

Failure to observe this caution may result in fire.

• Take appropriate and sufficient countermeasures for each when installing systems in the fol-

lowing locations.

Failure to observe this caution may result in damage to the product.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies, including power supply lines.

• Do not reverse the polarity of the battery when wiring with regenerative unit.

Failure to observe this caution may result in damage to the product.

6

Operation

CAUTION

• Conduct trial operation on the servomotor alone with the motor shaft disconnected from

machine to avoid any unexpected accidents.

Failure to observe this caution may result in injury.

• During the JOG operation and the home position search operation using CX-Drive, the forward run prohibited (P-OT), reverse run prohibited (N-OT), and emergency stop (E-STP)

signals will be ignored. Alternative measures must be taken in case of overtravel and emergency stop.

• When using the servomotor for a vertical axis, install safety devices to prevent workpieces

from falling off because of alarms.

Workpiece’s falling off may result in injury or malfunction.

• Do not touch the SERVOPACK heat sinks, regenerative unit, or servomotor while power is

ON or soon after the power is turned OFF.

Failure to observe this caution may result in burns due to high temperatures.

• When an alarm occurs, remove the cause, turn OFF the power and ON again after confirming safety, and then resume operation.

Failure to observe this caution may result in injury.

• Do not use the holding brake of the servomotor for ordinary braking.

Failure to observe this caution may result in malfunction.

Maintenance and Inspection

CAUTION

• Do not open the SERVOPACK case for 5 minutes after the power supply indicator (PWR

LED) goes out. High voltage may remain in the SERVOPACK after the power supply has

been turned OFF.

• After turning OFF the power supply, wait 15 minutes before replacing the cooling fan.

Failure to observe this caution may result in burns because the heat sink is hot.

• Mount the cooling fan in the correct way explained in 9.3 Replacement of Cooling Fan.

Improper mounting may result in the breakdown of the SERVOPACK.

• Do not attempt to change wiring while the power is ON.

Failure to observe this caution may result in electric shock or injury.

• Do not touch the SERVOPACK heat sinks, regenerative unit, or servomotor while power is

ON or soon after the power is turned OFF.

Disposal

CAUTION

• When disposing of the products, treat them as general industrial waste.

7

General Precautions

Note the following to ensure safe application.

• The drawings presented in this manual are sometimes shown without covers or protective guards.

Always replace the cover or protective guard as specified first, and then operate the products in

accordance with the manual.

• The drawings presented in this manual are typical examples and may not match the product you

received.

• This manual is subject to change due to product improvement, specification modification, and manual improvement. When this manual is revised, the manual code is updated and the new manual is

published as a next edition.

• If the manual must be ordered due to loss or damage, inform your nearest Omron Yaskawa representative or one of the offices listed on the back of this manual.

• Omron Yaskawa will not take responsibility for the results of unauthorized modifications of this

product. Omron Yaskawa shall not be liable for any damages or troubles resulting from unauthorized modification.

8

CONTENTS

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Related Manuals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Safety Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Visual Aids- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Trademarks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Notes for Safe Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2

1 Before Use- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

1.1 Checking Products - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

1.2 Warning Label- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

1.3 Model Designation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

1.4 SERVOPACKs and Applicable Servomotors- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

1.5 Part Names and Functions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

1.6 Applicable Standards- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

1.6.1 North American Safety Standards (UL, CSA) - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

1.6.2 European Directives - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

2 Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -17

2.1 Installation Conditions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

2.2 Installation Method - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

3 Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

3.1 System Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

3.2 Standard Connection- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

3.3 Precautions on Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

3.3.1 Protection for Power Supply Line - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

3.3.2 Caution for Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

3.3.3 Caution for Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

3.3.4 Power Loss- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

3.3.5 SERVOPACKs and Applicable Peripheral Devices - - - - - - - - - - - - - - - - - - - - - - - 22

3.3.6 Noise Prevention- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

3.3.7 Installation and Wiring Conditions on CE Marking - - - - - - - - - - - - - - - - - - - - - - - 26

3.3.8 Other Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

3.4 Main Circuit Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

3.4.1 SERVOPACK Main Circuit Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

3.4.2 Wiring Connector for the Power Supply/Regenerative Unit (CNA) - - - - - - - - - - - - 32

3.4.3 Wiring Connector for the Servomotor Main Circuit Cable (CNB)- - - - - - - - - - - - - - 34

3.4.4 Wiring the Encoder Connector (CN2) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

3.4.5 Wiring the I/O Signal Connector (CN1) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

3.4.6 Wiring the MECHATROLINK-II Communication Connectors (CN6A and CN6B) - - 41

9

3.4.7 Wiring the Personal Computer Connector (CN9)- - - - - - - - - - - - - - - - - - - - - - - - - 43

3.5 Connection Examples of Input Signal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 44

3.6 Connection Example of Output Signal- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

3.7 I/O Signals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

3.7.1 Homing Deceleration Signal Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

3.7.2 External Latch Signal Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

3.7.3 Emergency Stop Signal Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

3.7.4 Forward/Reverse Run Prohibited Inputs (Overtravel Inputs) - - - - - - - - - - - - - - - - - 49

3.7.5 Servo Alarm Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

3.7.6 Brake Interlock Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

3.8 Setting MECHATROLINK-II Communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

3.8.1 MECHATROLINK-II Communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

3.8.2 Wiring Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

3.8.3 Setting Communications Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

3.8.4 Transmission Cycle and Number of Stations- - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

3.8.5 MECHATROLINK-II Communications Status Indicator COM LED- - - - - - - - - - - - - 54

4 MECHATROLINK-II Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

4.1 Lists of Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

4.1.1 Main Commands List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

4.1.2 Subcommands List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 57

4.2 Main Commands- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

4.2.1 Communication Phases- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

4.2.2 No Operation (NOP: 00H)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60

4.2.3 Read Parameter (PRM_RD: 01H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

4.2.4 Write Parameter (PRM_WR: 02H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

4.2.5 Read ID (ID_RD: 03H)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 63

4.2.6 Setup Device (CONFIG: 04H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64

4.2.7 Read Alarm or Warning (ALM_RD: 05H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

4.2.8 Clear Alarm or Warning (ALM_CLR: 06H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 66

4.2.9 Start Synchronous Communication (SYNC_SET: 0DH) - - - - - - - - - - - - - - - - - - - 67

4.2.10 Establish Connection (CONNECT: 0EH) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 68

4.2.11 Release Connection (DISCONNECT: 0FH) - - - - - - - - - - - - - - - - - - - - - - - - - - - 69

4.2.12 Write Stored Parameter (PPRM_WR: 1CH) - - - - - - - - - - - - - - - - - - - - - - - - - - - 69

4.2.13 Set Coordinates (POS_SET: 20H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 70

4.2.14 Apply Brake (BRK_ON: 21H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 70

4.2.15 Release Brake (BRK_OFF: 22H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 72

4.2.16 Turn Sensor ON (SENS_ON: 23H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 73

4.2.17 Turn Sensor OFF (SENS_OFF: 24H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 73

4.2.18 Stop Motion (HOLD: 25H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 74

4.2.19 Request Latch Mode (LTMOD_ON: 28H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 75

4.2.20 Release Latch Mode (LTMOD_OFF: 29H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - 76

4.2.21 Status Monitoring (SMON: 30H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 77

4.2.22 Servo ON (SV_ON: 31H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 78

4.2.23 Servo OFF (SV_OFF: 32H)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 79

4.2.24 Interpolation Feed (INTERPOLATE: 34H)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 80

4.2.25 Positioning (POSING: 35H)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

10

4.2.26 Constant Speed Feed (FEED: 36H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 82

4.2.27 Interpolation Feeding with Position Detection (LATCH: 38H)- - - - - - - - - - - - - - - - 83

4.2.28 External Input Positioning (EX_POSING: 39H) - - - - - - - - - - - - - - - - - - - - - - - - - 84

4.2.29 Homing (ZRET: 3AH) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 85

4.2.30 Adjusting (ADJ: 3EH) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 87

4.3 Subcommands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 90

4.3.1 No Operation (NOP: 00H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 90

4.3.2 Read Parameter (PRM_RD: 01H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 90

4.3.3 Write Parameter (PRM_WR: 02H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 91

4.3.4 Read Alarm or Warning (ALM_RD: 05H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 91

4.3.5 Write Stored Parameter (PPRM_WR: 1CH) - - - - - - - - - - - - - - - - - - - - - - - - - - - - 92

4.3.6 Request Latch Mode (LTMOD_ON: 28H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 92

4.3.7 Release Latch Mode (LTMOD_OFF: 29H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 93

4.3.8 Status Monitoring (SMON: 30H) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 93

4.4 Combination of MECHATROLINK-II Main Commands and Subcommands - - - - - - - - - 94

4.5 Command Data Field- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 95

4.5.1 Latch Signal Field Specifications: LT_SGN - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 95

4.5.2 Option Field Specifications: OPTION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 95

4.5.3 Status Field Specifications: STATUS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 96

4.5.4 Monitor Selection and Monitor Information Field Specifications:

SEL_MON1/2/3/4, MONITOR1/2/3/4- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 101

4.5.5 IO Monitor Field Specifications: IO_MON - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

4.5.6 Substatus Field Specifications: SUBSTATUS - - - - - - - - - - - - - - - - - - - - - - - - - - 104

4.5.7 Alarm/Warning Field Specifications: ALARM- - - - - - - - - - - - - - - - - - - - - - - - - - - 105

4.6 Command and Response Timing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 108

4.6.1 Command Data Execution Timing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 108

4.6.2 Monitor Data Input Timing- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 108

4.7 Operation Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 109

4.7.1 Operation Sequence for Managing Parameters Using a

Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 109

4.7.2 Operation Sequence for Managing Parameters

Using SERVOPACK- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 110

4.7.3 Operation Sequence to Turn the Servo ON- - - - - - - - - - - - - - - - - - - - - - - - - - - - 111

4.7.4 Operation Sequence When OT (Overtravel Limit Switch) Signal is Input - - - - - - - 111

4.7.5 Operation Sequence When E-STP Signal is Input - - - - - - - - - - - - - - - - - - - - - - - 111

5 Trial Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 113

6 Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 118

6.1 Filter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 118

6.2 Switching Servomotor Rotation Direction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 119

6.3 Electronic Gear - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 120

6.3.1 Setting the Electronic Gear - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 120

6.4 Position Management - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 123

6.5 Motion Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 124

11

6.5.1 INTERPOLATE Related Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -124

6.5.2 POSING Related Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -124

6.6 Software Limit Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -125

6.6.1 Conditions Needed to Enable the Software Limit Function - - - - - - - - - - - - - - - - - -125

6.6.2 Parameters Related Software Limit Function - - - - - - - - - - - - - - - - - - - - - - - - - - -125

6.6.3 Monitoring Software Limit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -126

6.7 Latching Area - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -127

7 Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 128

7.1 Parameter Editor- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -128

7.2 List of Parameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -129

8 Troubleshooting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 134

8.1 Alarm Displays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -136

8.2 Warning Displays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -138

8.3 Alarm/Warning Display and Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -139

8.3.1 Alarm Display and Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -139

8.3.2 Warning Display and Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -149

8.4 Troubleshooting for Malfunction without Alarm Display - - - - - - - - - - - - - - - - - - - - - - -151

9 Inspections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 156

9.1 Regular Inspections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -156

9.2 Part’s Life Expectancy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -156

9.3 Replacement of Cooling Fan - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -157

10 Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 163

10.1 Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -163

10.2 Allowable Moment of Inertia - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -165

10.3 Overload Characteristics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -166

Revision History

12

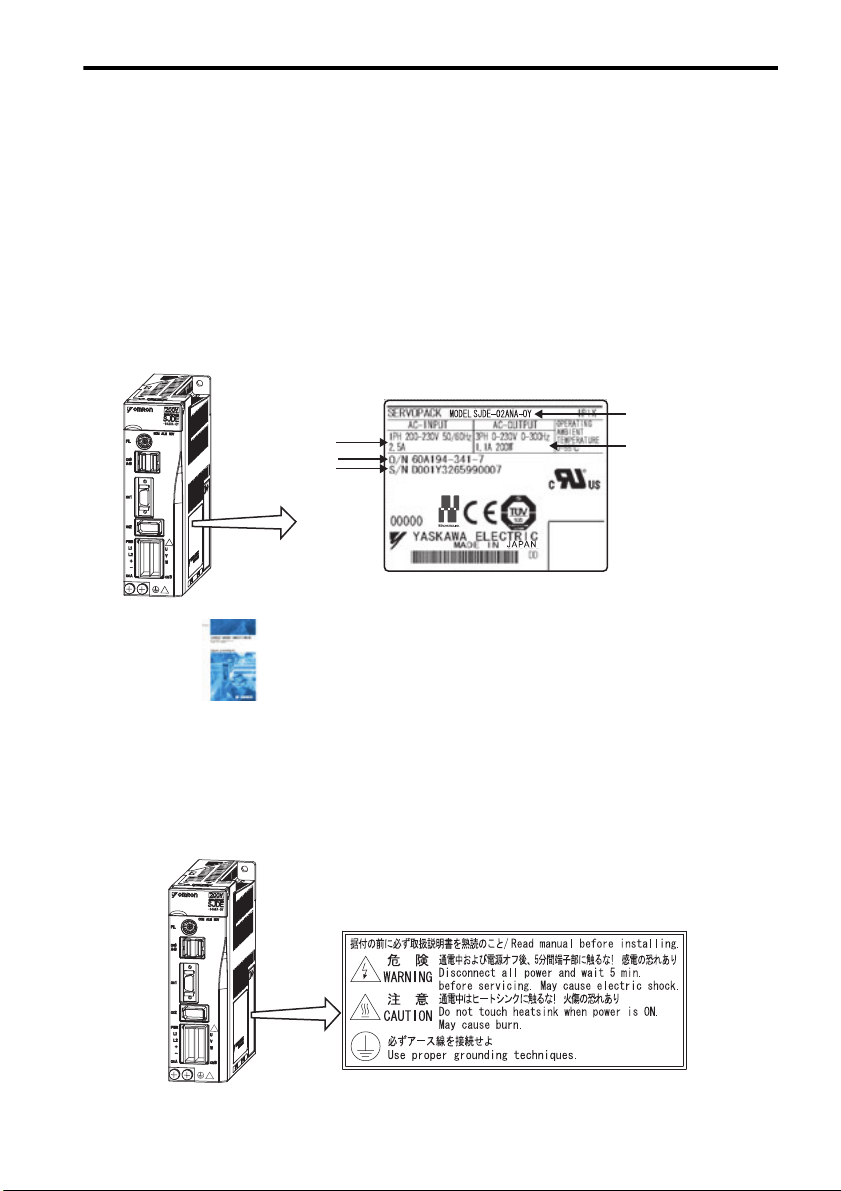

1.1 Checking Products

1 Before Use

1.1 Checking Products

Confirm that the following items have been delivered together with the SERVOPACK. Verify that the

ordered product as received by the model number marked on the nameplate on the SERVOPACK.

If you find any irregularities such as incorrect SERVOPACK model, damages, and missing parts or

items, contact your Omron Yaskawa representative or the dealer from whom you purchased the products.

SJDE

SERVOPACK

Nameplate

Applicable

power supply

Order number

Serial number

One copy of this Instruction Manual 1 Connector Part Number JZSP-CHG9-1

SERVOPACK

model

Applicable motor

capacity

1.2 Warning Label

A warning label is located on the side of the SERVOPACK.

SJDE

SERVOPACK

13

SERVOPACK's Warning Label

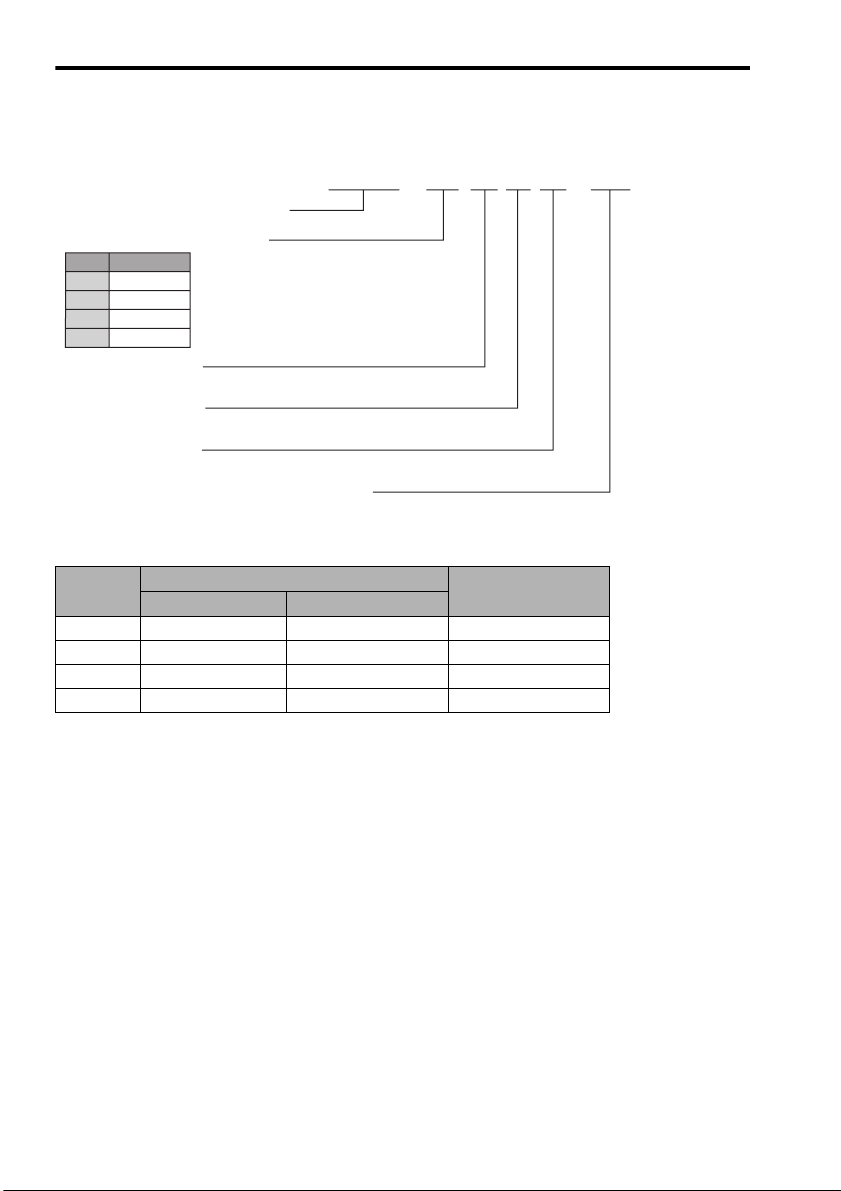

1.3 Model Designation

1.3 Model Designation

SJDE—02 A N A - OY

JUNMA series SJDE SERVOPACK

Applicable servomotor capacity

Code

Output (W)

100

01

200

02

400

04

750

08

Power supply voltage

A: 200 VAC

Interface specification

N: MECHATROLINK-II

Design revision order

A

Sold by OMRON YASKAWA Motion Control B.V.

1.4 SERVOPACKs and Applicable Servomotors

Rated

Output

100 W SJME-01AM41-OY SJME-01AM4C-OY SJDE-01ANA-OY

200 W SJME-02AM41-OY SJME-02AM4C-OY SJDE-02ANA-OY

400 W SJME-04AM41-OY SJME-04AM4C-OY SJDE-04ANA-OY

750 W SJME-08AM41-OY SJME-08AM4C-OY SJDE-08ANA-OY

Without Brakes With Brakes

Servomotors SERVOPACKs

14

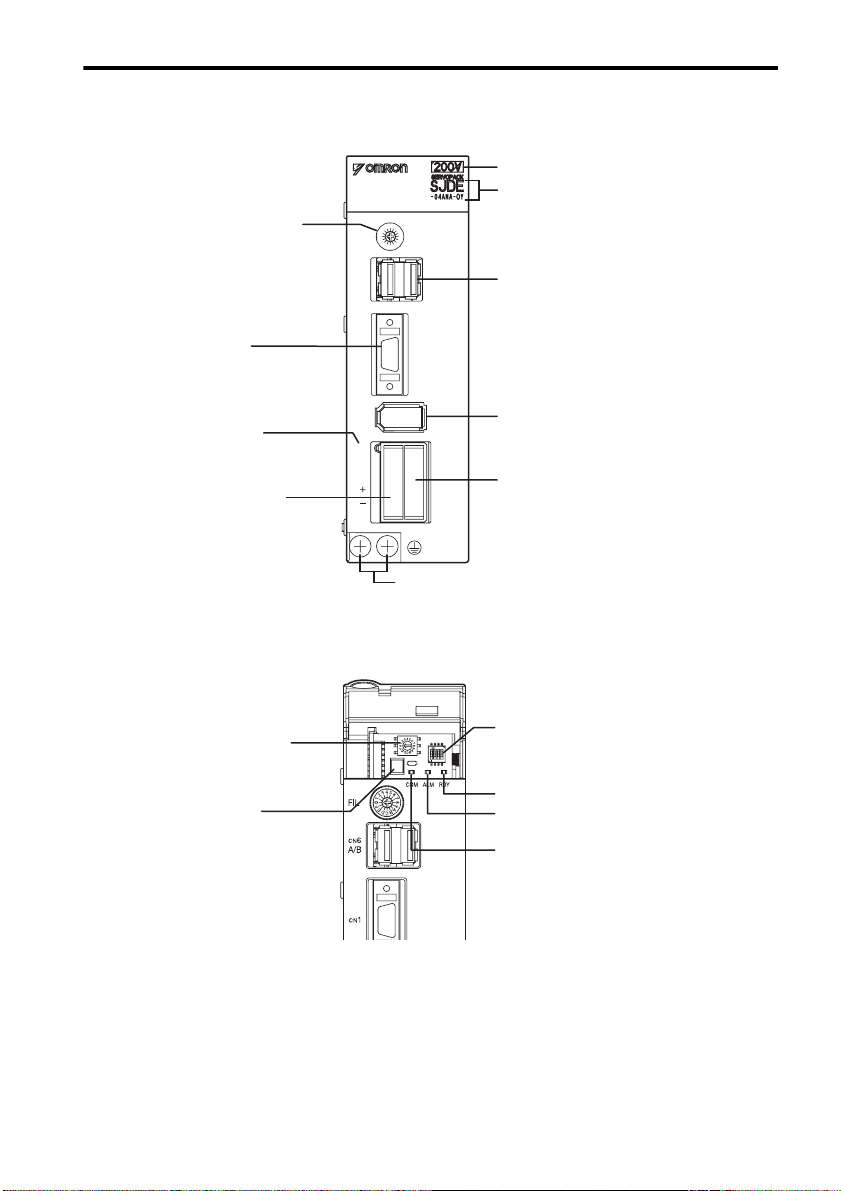

1.5 Part Names and Functions

Rotary switch for reference filter

setting(FIL)

Refer to 6.1 Filter Setting.

I/O signal connector (CN1)

Refer to 3.4 Main Circuit Wiring.

4

5

3

6

2

7

1

8

0

9

FIL

F

A

E

B

D

C

CN6

A/B

CN1

1.5 Part Names and Functions

Input voltage

Model

COM

ALM

RDY

Connector for MECHATROLINK-II

communications (CN6)

Refer to 3.4.6 Wiring the MECHATROLINK-

II Communication Connectors (CN6A and

CN6B).

Power supply indicator (PWR)

Connector for power supply/

regenerative unit (CNA)

Refer to 3.4.2 Wiring Connector for the

Power Supply/Regenerative Unit

(CNA).

CN2

PWR

L1

L2

U

V

W

CNBCNA

Encoder connector (CN2)

Refer to 3.4.4 Wiring the Encoder Connec-

tor (CN2).

Connector for servomotor main circuit

cable (CNB)

Refer to 3.4.3 Wiring Connector for the Ser-

vomotor Main Circuit Cable (CNB).

Ground terminal

MECHATROLINK-II Communications Settings

The SW1 and the SW2 switches set the MECHATROLINK-II communications settings. Settings that

have been changed are enabled when the power is turned OFF and then ON again.

DIP switch for MECHATROLINK-II

Rotary switch for MECHATROLINK-II

station address setting (SW1)

Refer to 3.8 Setting for

MECHATROLINK-II Communications.

Connector for personal

computer (CN9)

communications setting (SW2)

Refer to 3.8 Setting MECHATROLINK-II

Communications.

Servo status indicator (RDY)

Alarm indicator (ALM)

Refer to 8 Troubleshooting.

Indicator for MECHATROLINK-II

communications status (COM)

Refer to 3.8.5 MECHATROLINK-II

Communications Status Indicator COM LED

and 8 Troubleshooting.

15

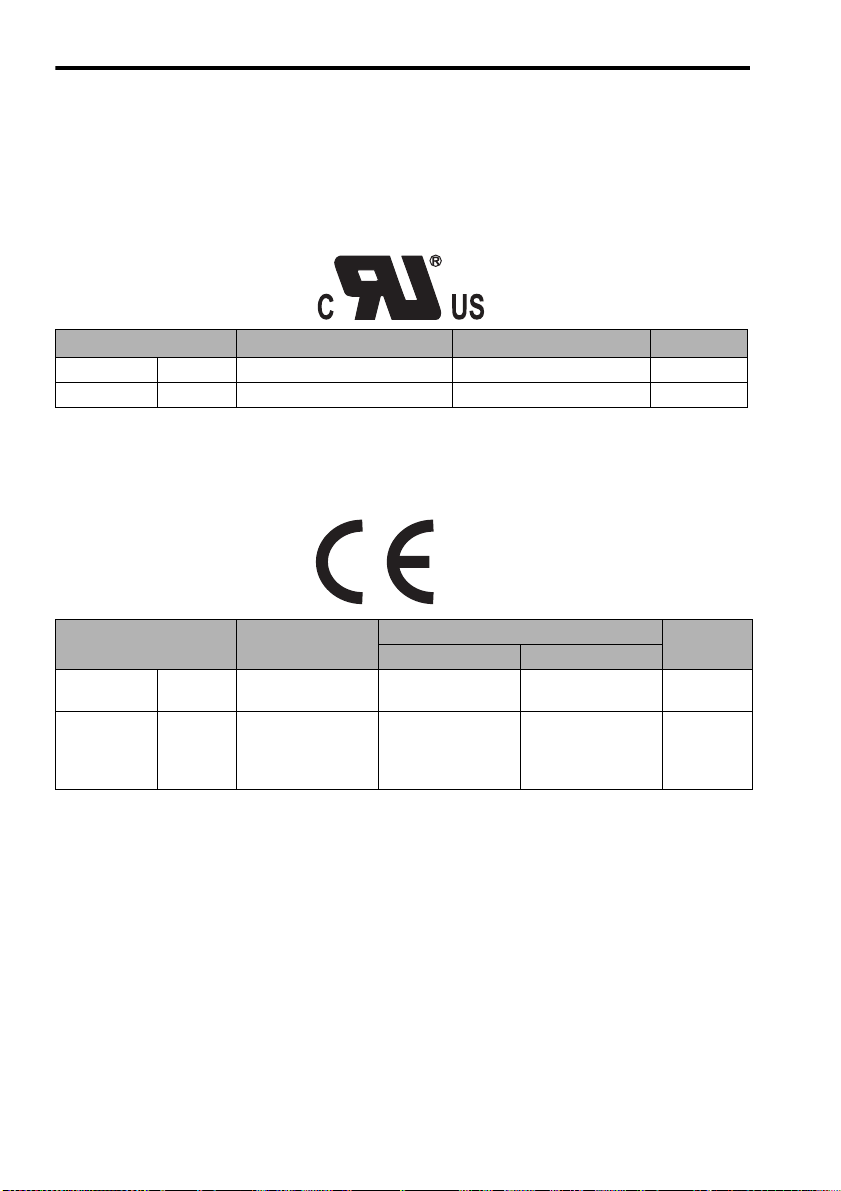

1.6 Applicable Standards

1.6 Applicable Standards

JUNMA series SERVOPACKs comply with the following standards.

1.6.1 North American Safety Standards (UL, CSA)

Model

SERVOPACK SJDE

Servomotor SJME

* 1. Underwriters Laboratories Inc.

* 2. Canadian Standards Association.

UL∗1 Standards (UL File No.) CSA∗2 Standards

UL508C (E147823) CSA C22.2 No.14 UL

UL1004 (E165827) CSA C22.2 No.100 UL

1.6.2 European Directives

Model Low Voltage

SERVOPACK

Servomotor

* TÜV Product Services GmbH

Note: 1. Because SERVOPACKs and servomotors are built-in type, reconfirmation is

required after being installed in the final product.

SJDE EN50178 EN55011

SJME IEC60034-1

Directive

IEC60034-5

IEC60034-8

IEC60034-9

class A, group 1

class A, group 1

EMC Directive Certification

EMI EMS

EN61000-6-2 TUV PS*

EN55011

EN61000-6-2 TUV PS*

Certification

16

2 Installation

The following shows the installation location and method of the SERVOPACK.

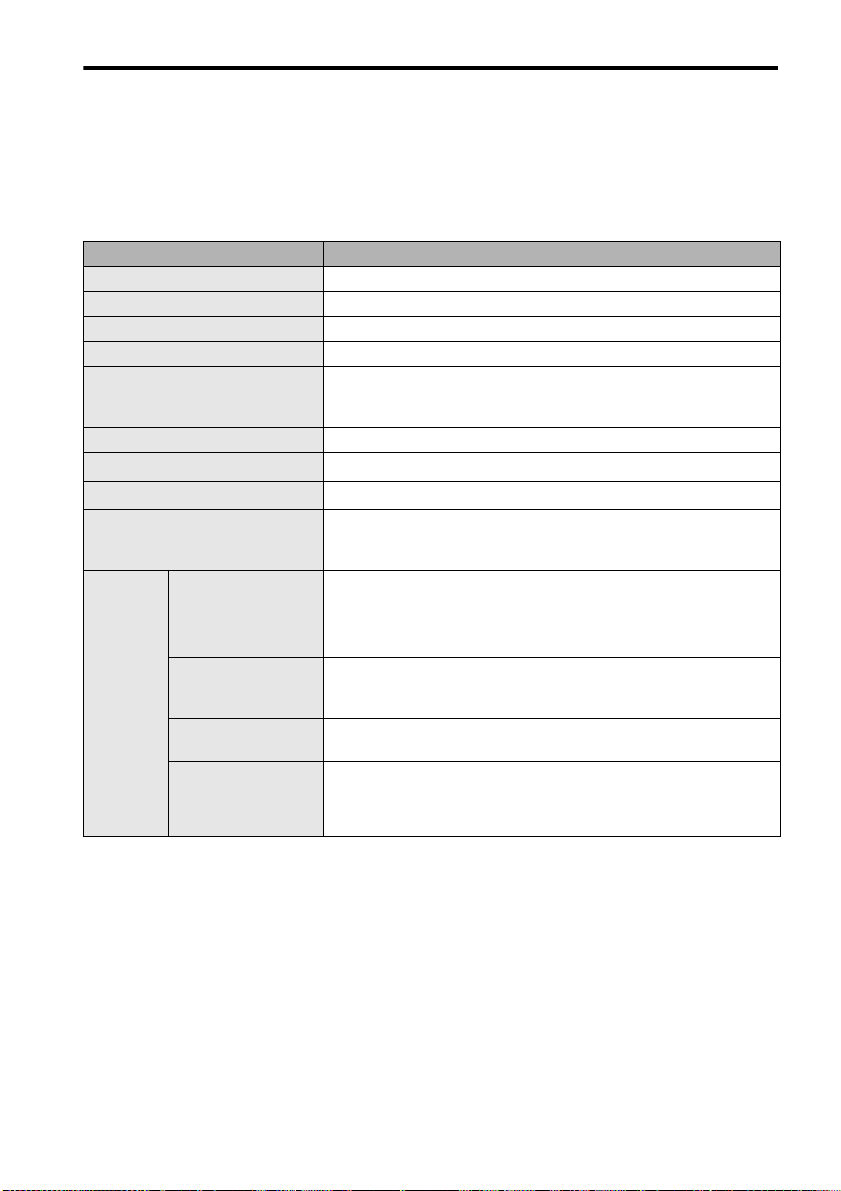

2.1 Installation Conditions

Item Specifications

Operating temperature 0 ° C to +55 °C

Operating humidity 90% RH or less (with no condensation)

Storage temperature -20 ° C to +70 °C

Storage humidity 90% RH or less (with no condensation)

Installation site Free of corrosive gases

Altitude 1000 m or below

Vibration resistance

Shock resistance

Operating conditions Installation category (overvoltage category): II

Installation in a control

panel

Installation near a

Installation

Site

heating unit

Installation near a

source of vibration

Installation at a site exposed to corrosive gas

Free of dust and iron powder

Not subjected to moisture or lubrication oil such as cutting oil.

2

4.9m/s

2

19.6m/s

Pollution degree: 2

Protection class: IP1X (EN50178)

Design the control panel size, unit layout, and cooling method so that

the temperature around the SERVOPACK does not exceed 55 °C.

Note: To extend product life and maintain reli-

ability, keep the temperature inside the

control panel under 45 ° C.

Minimize the heat radiating from the heating unit as well as any

temperature rise caused by natural convection so that the temperature

around the SERVOPACK does not exceed 55 ° C.

Install a vibration isolator beneath the SERVOPACK to avoid subjecting

it to vibration.

Corrosive gas does not have an immediate effect on the SERVOPACK

but will eventually cause the electronic components and contactor-

related devices to malfunction. Take appropriate action to avoid corrosive gas.

2.1 Installation Conditions

17

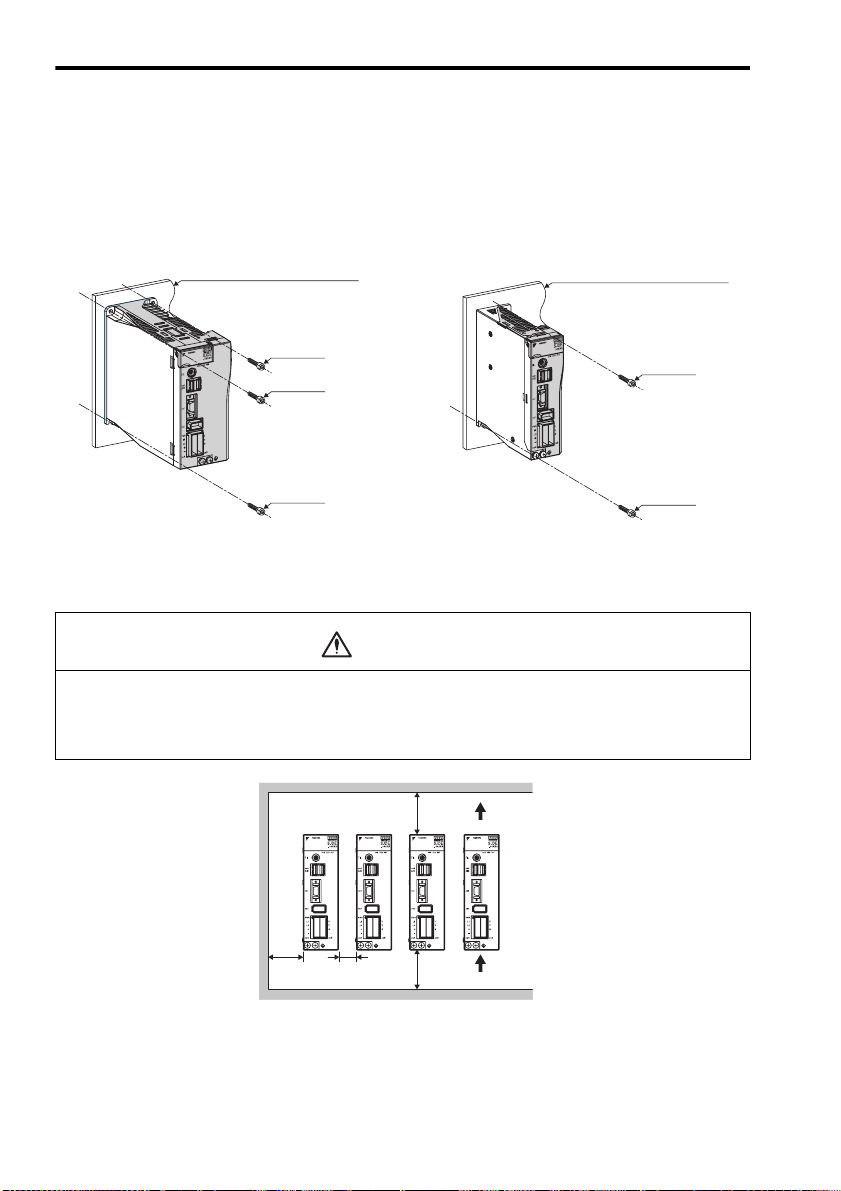

2.2 Installation Method

2.2 Installation Method

Installation Method and Direction

• Install the SERVOPACK perpendicular to the wall.

• Connect the mounting holes securely to the mounting surface with M4 screws.

SJDE-08ANA-OY: Three mounting holes SJDE-01 to 04ANA-OY: Two mounting holes

SERVOPACK installation plate

M4 screw

M4 screw

M4 screw

SERVOPACK installation plate

M4 screw

M4 screw

Space between SERVOPACK Units

• Be sure to keep a space between adjacent SERVOPACK units as shown the following figure if they

are mounted inside the control panel. This allows the units to cool.

CAUTION

• Do not cover the inlet or outlet parts of the SERVOPACK and prevent any foreign objects, such as

metallic fragment, or combustibles from entering the product.

Failure to observe this caution may cause internal elements to deteriorate resulting in malfunction

or fire.

50 mm

min.

Air outlet

direction

30 mm

min.

10 mm

min.

18

50 mm

min.

Air inlet

direction

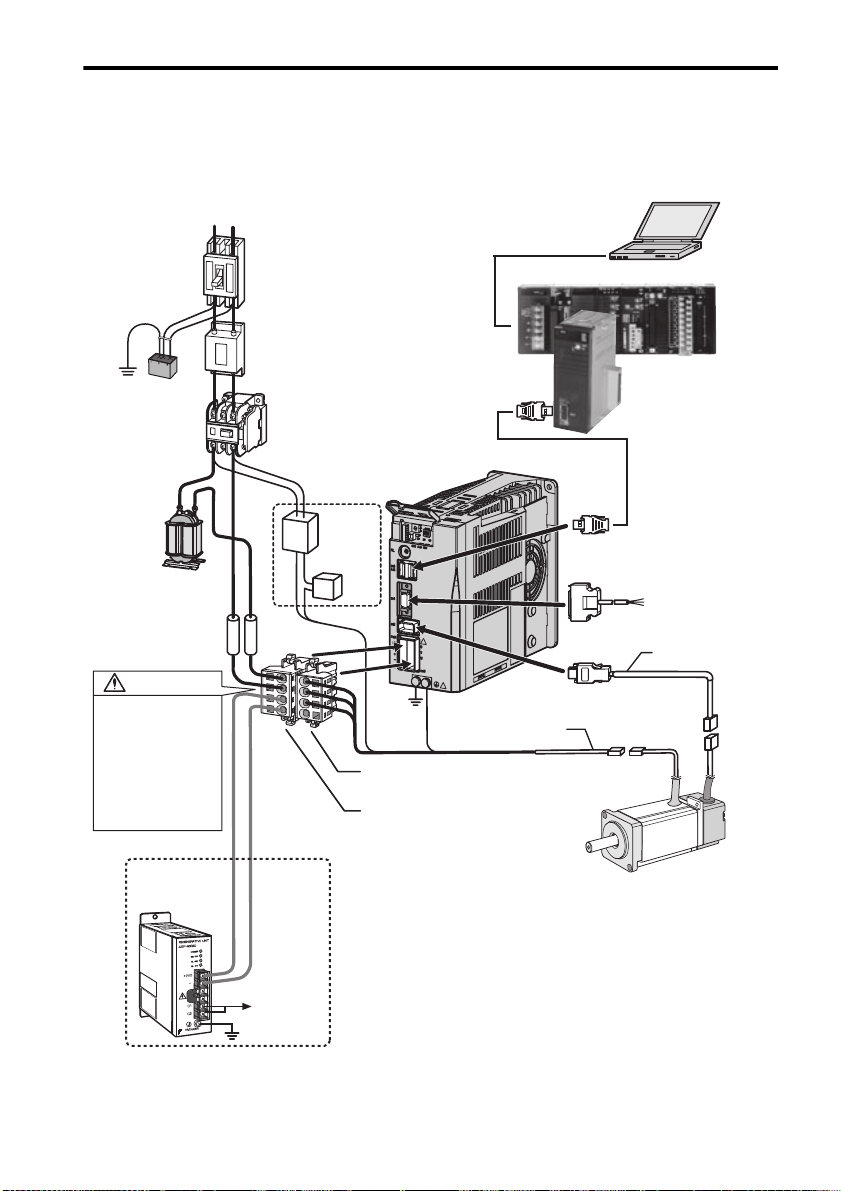

3 Wiring

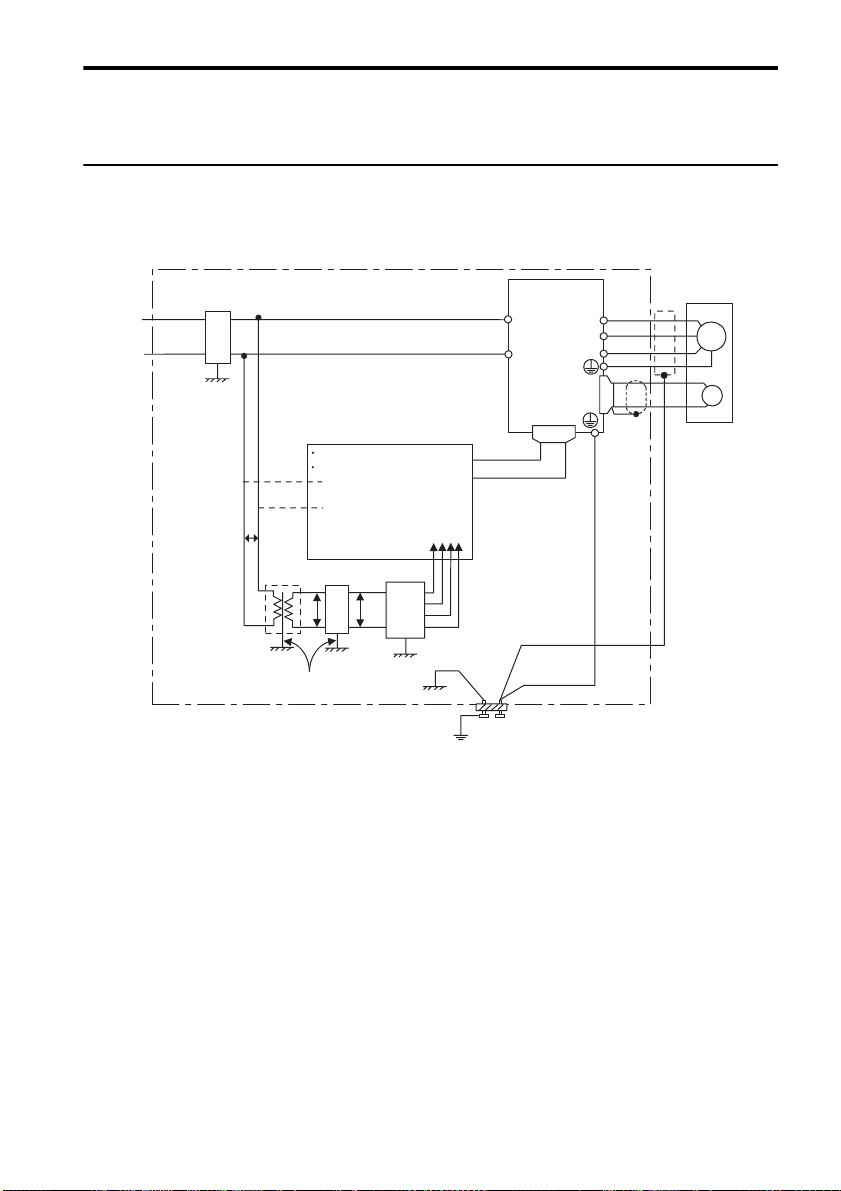

3.1 System Configuration

Power supply

Single-phase 200 VAC

L1 L2

Molded-case circuit breaker

To protect the equipment and wiring,

always connect a molded-case circuit

breaker.

Noise filter

Used to eliminate suppress noise

from power lines.

Surge protector

Protects the

system from

lightening surge.

AC reactor

Used for a power

supply harmonic

suppression.

Fuse

To protect the

equipment, always

install fuses.

WARNING

Correctly connect the

connectors CNA and CNB.

Incorrect wiring may result in

electric shock, injury, or

damage to the equipment.

After wiring, install the

connectors as explained in

3.8 Wiring the Power

Supply/Regenerative Unit

Connector (CNA) and 3.9

Wiring the Servomotor Main

Circuit Cable Connector

(CNB).

Used for a

regenerative unit.

Regenerative unit

Used if regenerative

energy is high.

Magnetic contactor

Used to turn OFF the servo

power supply when using a

regenerative unit or a

emergency stop.

Used for a

servomotor

with a brake.

24-VDC

power

supply

Brake relay

n

SJDE

SERVOPACKs

*1

*

Servomotor main circuit

cable (for relay)

Connectors for servomotor

main circuit cable (CNB

Connectors for power

supply/regenerative unit

(

)

CNA

Personal computer

software: CX-One

)

SJME

Servomotors

3.1 System Configuration

CJ-series PLC

CJ1 series

Position control unit

CJ1W-NCF71

MECHATROLINK-II

connection

I/O Signal cable

Connects to

CJ-Series PLC

To the control

circuits of

magnetic

contactor

* 1. Prepare a 24-VDC power supply for the brake separately from the sequence power supply.

19

3.2 Standard Connection

3.2 Standard Connection

Power supply

Single-phase 200 VAC to 230 VAC

50/60Hz

L1 L2

Molded-case circuit breaker

Surge protector

AVR 2

24 VDC power

supply

Noise

filter

200 VAC

to

230 VAC

+24V 0V

MC1

SW1 SW2

MC1

Regenerative unit

Controller

130Ω

MC1

Spark

killer

C1 C2

JUSP-

RG08D

MECHATROLINK-II

cable

Shielded wire

MC1

Ry1

Flywheel

diode

Shielded wire

AVR 1*

24 VDC

power supply

200 VAC to

230 VAC

CNA CNB

Fuse

1

L1

Reactor

Fuse

L2

2

3

/TXD

/RXD

GND

/S

Ter m i nator

130Ω

24VIN

/EXT1

/DEC

N-OT

P-OT

E-STP

ALM

/BK

SG_COM

+

4

-

CN9

1

2

3,4

CN6A

A2

S

A3

Shell

CN6B

B2

B3

CN1

5

1

2

3

4

6

12

13

7

+

Y4

Y5

+

24V

0V

SERVOPACK

3.3kΩ

3.3kΩ

3.3kΩ

3.3kΩ

3.3kΩ

Ry1

CN2

Shell

1

2

3

1

2

3

4

5

6

7

8

9

10

Varistor

PG5V

PG0V

U

V

W

Shielded wire

A+

A-

B+

B-

/Z

U

V

W

Shielded wire

5

6

1

2

V

3

4

1

2

3

4

5

6

7

8

9

10

12

Brake

U

Servomotor

W

FG

Encoder

Note: 1. AVR1:24 VDC

power supply for

brake

AVR2:24 VDC power supply for sequence

PB1:Power OFF switch

PB2:Power ON switch

MC1:Magnetic contactor

Ry1:Brake relay

• Parts example

Spark killer Okaya Electric Industries

Flywheel

diode

Co., Ltd.

Toshiba Corporation 1NH42

CRE-50500

Brake relay OMRON Corporation MY series

Varistor NIPPON CHEMI-CON

CORPORATION

TNR7V121K

20

3.3 Precautions on Wiring

2. The ground protection circuit is designed for ground fault inside the motor

windings while the motor is running. Therefore, it may not protect the system

under the following conditions.

• A low-resistance ground fault occurs between the main circuit cable and connector for the servomotor.

• The power supply is turned ON during a ground fault.

To configure a safer system, install an earth leakage breaker for protection

against overloads and short-circuit, or install an earth leakage breaker for

ground protection combined with a wiring circuit breaker.

3. Position information is not stored in the SERVOPACK, so this information will be

lost if the power supply is turned OFF. If this information is required for the

operation of the host controller, make sure that the system has an emergency

stop signal (E-STP) that will stop operations without turning OFF the power

supply.

* 1. Prepare a 24 VDC power supply for sequence separately from the 24 VDC power supply for brake.

3.3 Precautions on Wiring

WARNING

• Be sure to correctly ground the SERVOPACK and the servomotor.

• Wiring must be performed by an authorized person qualified in electrical work.

• Configure the circuit’s power supply to be automatically cut off if E-STP signal is OFF at occurrence of emergency stop. (Refer to 3.7.3 Emergency Stop Signal Input.)

The residual voltage rotates the servomotor for a few seconds after the power supply has been

turned OFF, and may result in injury or damage to the equipment. Be sure to completely stop the

motor by turning OFF the servo using the emergency stop.

Position information is not stored in the SERVOPACK, so this information will be lost if the power

supply is turned OFF. This information cannot be read again if the power supply is turned OFF.

• When using the servomotor for a vertical axis, install safety devices to prevent workpieces from falling off because of alarms. Workpiece’s falling off may result in injury or malfunction.

• Configure the interlock circuit so that the system is interlocked to avoid injury whenever the protective cover on the machine is opened or closed.

3.3.1 Protection for Power Supply Line

• Use a molded-case circuit breaker and fuse to protect the power supply line. The SERVOPACK connects directly to a commercial power supply without a transformer, so always use a circuit breaker

and fuse to protect the servo system from accidental high voltage.

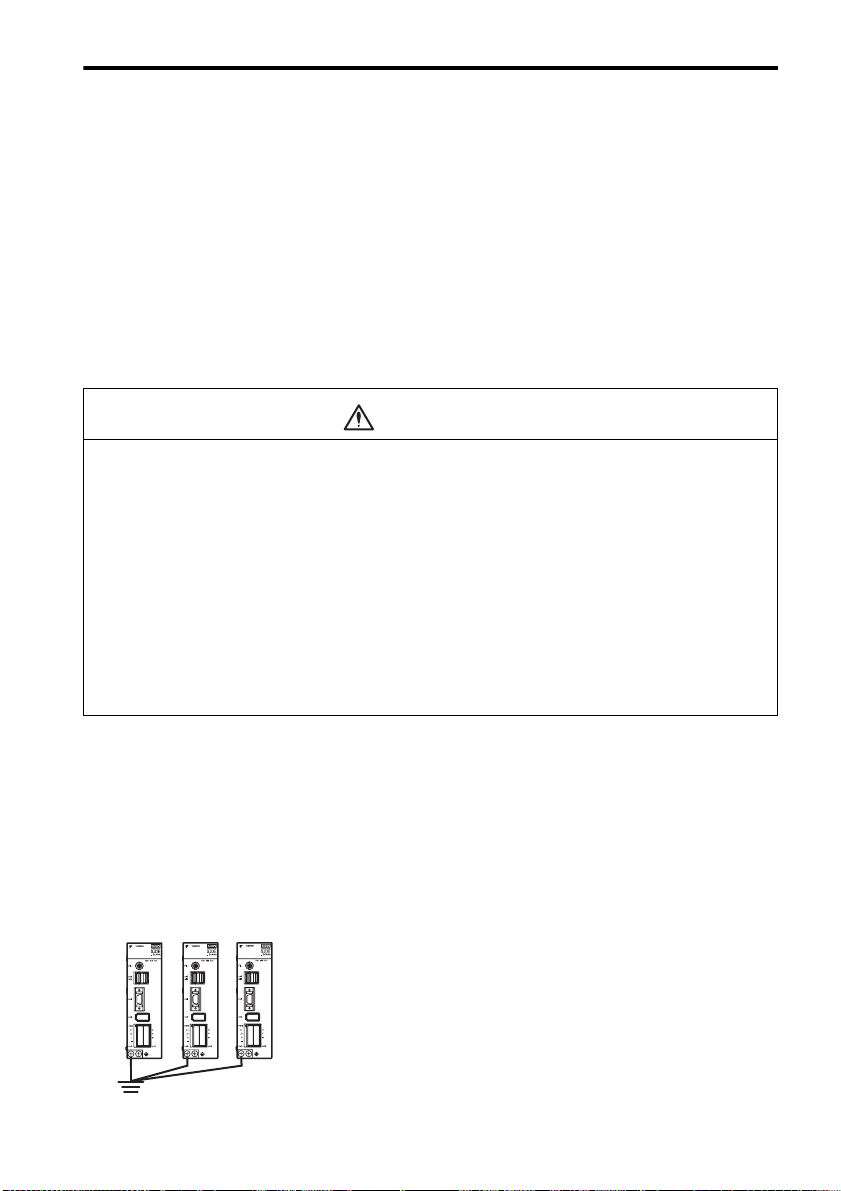

3.3.2 Caution for Grounding

Consider the following conditions when grounding the SERVOPACK.

• For a ground wire, use as thick a cable as possible (2.0 mm2 or thicker).

• A ground resistance of 100 (Ω) or less is recommended.

• Ground to one point only.

21

3.3 Precautions on Wiring

3.3.3 Caution for Cable

• For wiring, use the specified cables. Use cables that are as short as possible.

• Do not bend or apply tension to cables. The conductor of a signal cable is thin (0.08 to 0.12 mm

so handle the cables carefully.

2

),

3.3.4 Power Loss

Power Loss with SERVOPACK Rated Output

Main

Circuit

Powe r

Supply

Single-

phase

200 V

Note: Values obtained with the servomotor rated output.

SERVOPACK Output Current

Model Capacity

SJDE-01ANA-OY 100 W 0.84 6 9 15

SJDE-02ANA-OY 200 W 1.1 8 17

SJDE-04ANA-OY 400 W 2.0 16 25

SJDE-08ANA-OY 750 W 3.7 27 36

(Effective

Val ue)

A

Main Circuit

Power Loss

W

Control Circuit

Power Loss

W

Tot a l Powe r

Loss

W

3.3.5 SERVOPACKs and Applicable Peripheral Devices

SERVOPACK Power

Ty pe Capa-

SJDE01ANA-OY

SJDE02ANA-OY

SJDE04ANA-OY

SJDE08ANA-OY

Manufacturer

Note: It is recommended to use a general-purpose circuit breaker of the sensed current 200 mA or more, or a cir-

* 1. Nominal value at the rated load. The specified derating is required to select the appropriate molded-case

circuit breaker.

* 2. Cut-off characteristics (25 °C): 200 % two seconds min. and 700 % 0.01 seconds min.

100 W

200 W

400 W

750 W

cuit breaker for inverters (for high-frequency).

city

Supply

Capacity

SERVO-

PAC K

Power sup-

ply

Capacity of

per

kVA

0.40 4 0KLK

0.75 X5053

1.2 8 X5054

2.2 16 0KLK

Molded-

case

Circuit

Breaker

Arms

--Littelfuse

*1 *2

Power

supply

Capacity

and

Model of

External

Fuse

015.T

(15 Arms)

030.T

(30 Arms)

Inc.

Inrus

Mag-

h

netic

Cur-

Contac-

rent

A0-p

tor

30 HI-11J R7A-

60 HI-15J R7A-

-Yaskawa

Controls

Co., Ltd.

Noise

Filter

FIZN105

-BE

FIZN109

-BE

Block

Elek-

tronik

Surge

Protector

xCxM-

R

601BQZ-4

Okaya

Electric

Industries

Co., Ltd.

AC

Reactor

X5052

X5056

Yaskawa

Controls

Co., Ltd.

IMPORTANT

Ground Fault

The ground protection circuit is designed for ground fault inside the motor windings while the

motor is running. Therefore, it may not protect the system under the following conditions.

• A ground fault occurs between the main circuit cable and connector for the servomotor.

• The power supply is turned ON during a ground fault.

To configure a safer system, install an ground fault detector for protection against overloads

22

and short-circuit, or install an ground fault detector combined with a wiring circuit breaker for

ground protection.

3.3.6 Noise Prevention

Example of Wiring for Noise Prevention

3.3 Precautions on Wiring

Noise filter

Min. wire

size

: 3.5 mm

*

1.

2LF

Casing

2

P

Operation relay sequence

User signal generating circuit

1LF

P

Casing

Casing

Min. wire size: 3.5 mm

*2.

P

2

*1.

AVR

(Grounding)

Casing

2 mm2 or larger

Min. wire size:

3.5 mm

Casing

200 VAC

* 1. For the wires connected to the casings for installation purposes, use wires with a diameter of 3.5 mm2 or

larger. Flat braided copper wires are recommended.

* 2. Use twisted pair wires for section P.

SJDE

SERVOPACK

L1

L2

2

*1.

Grounding plate

Groudning: Ground to one point only.

Min. grounding resistance: 100 Ω

CN1

CN2

U

V

W

Min. wire

size

: 3.5 mm

Min. wire

size

: 3.5 mm

2

2

Servomotor

M

(FG)

PG

Correct Grounding

• Servomotor frame grounding:

Be sure to connect the FG grounding terminal on the frame of the servomotor to the grounding terminal on the SERVOPACK.

• Be sure to ground the grounding terminal of the SERVOPACK.

• If the wires of the servomotor’s main circuit are laid in a metal conduit, ground the conduit and the

grounding box.

One-point grounding must be used.

23

3.3 Precautions on Wiring

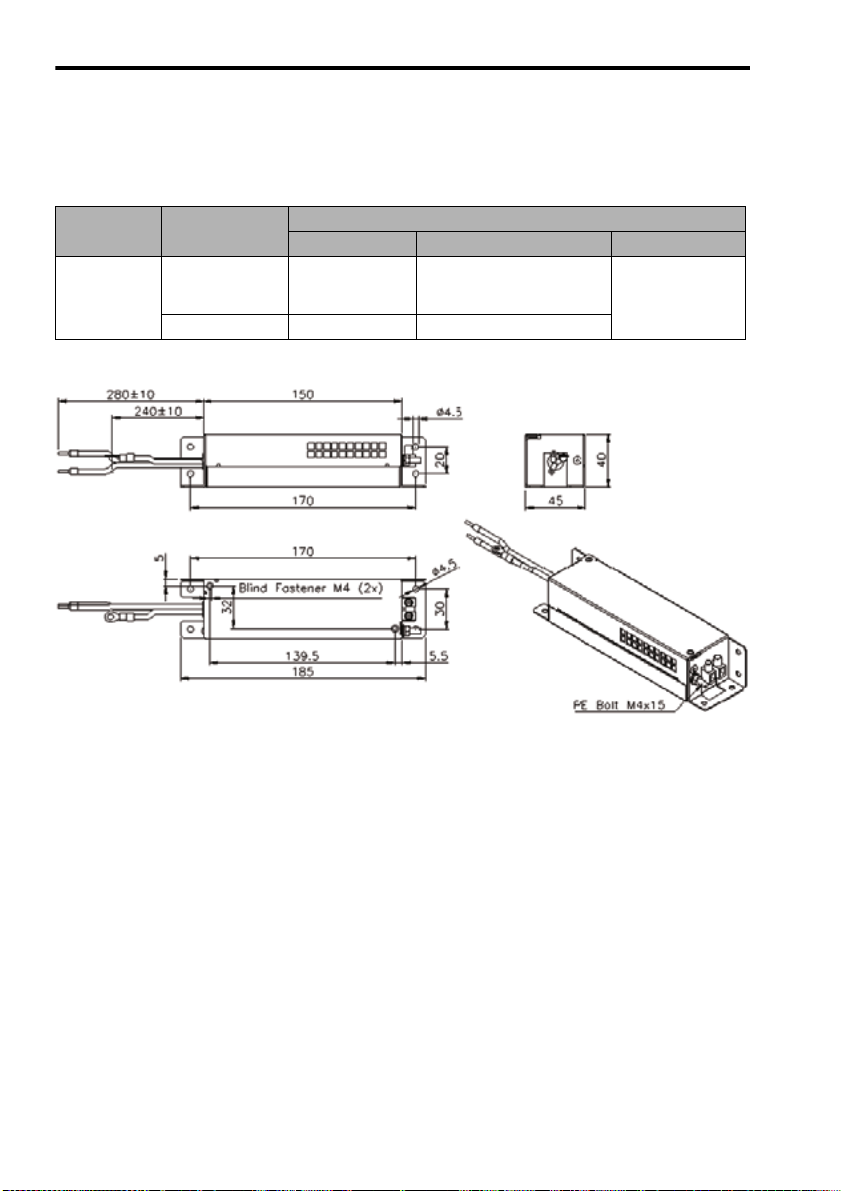

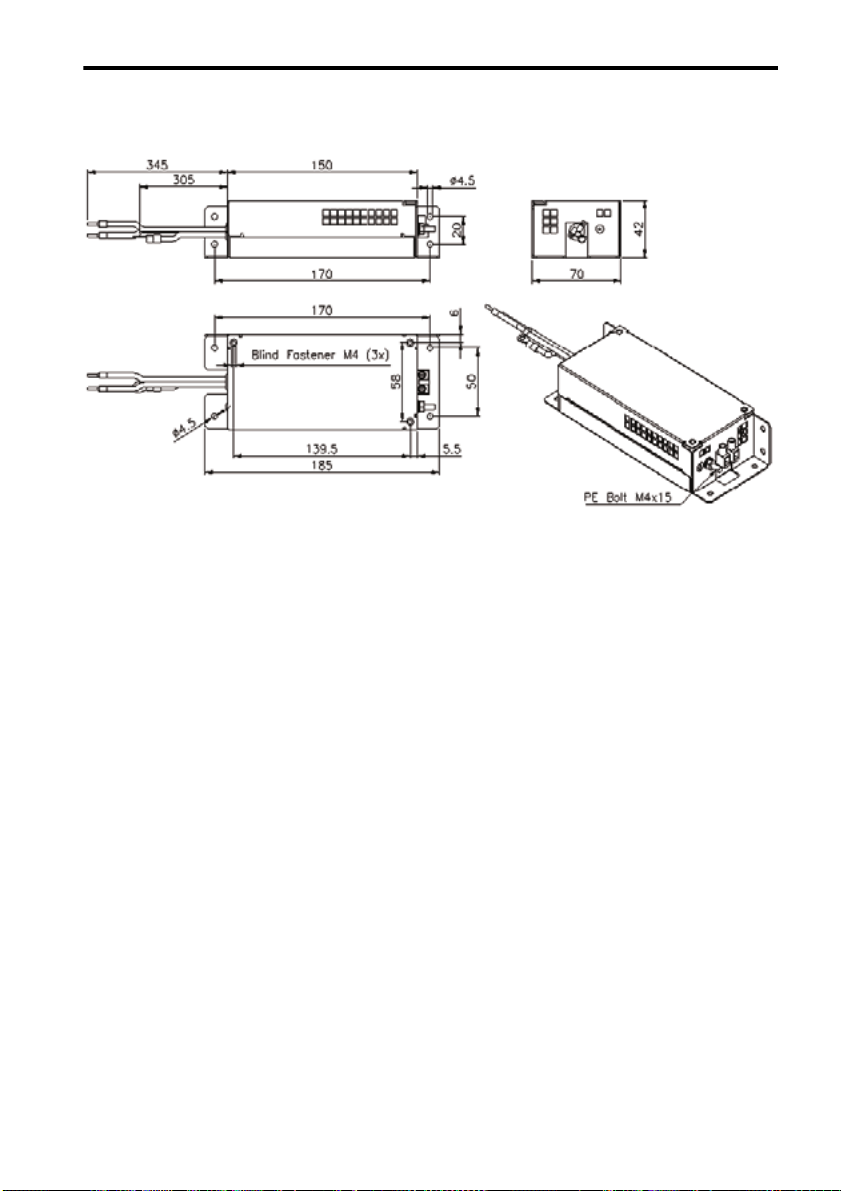

Noise Filters

Use a block type noise filters to prevent any noise interference from the power-supply line.

The following table lists the recommended noise filters for several SERVOPACK models.

Application of Noise Filters

Power-Supply

Voltage

Single-

phase

230 V +10%

50-60 Hz

Filter dimensions for model R7A-FIZN105-BE

SERVOPACK

Model

SJDE-01ANA-OY

SJDE-02ANA-OY

SJDE-04ANA-OY

SJDE-08ANA-OY

Recommended Noise Filters

Model Specifications Manufacturer

R7A-FIZN105-BE Single-phase 250 VAC, 5A

R7A-FIZN109-BE Single-phase 250 VAC, 9A

Block

Transformatoren

Elektronik

GmbH & Co. KG.

24

Filter dimensions for model R7A-FIZN109-BE

3.3 Precautions on Wiring

25

3.3 Precautions on Wiring

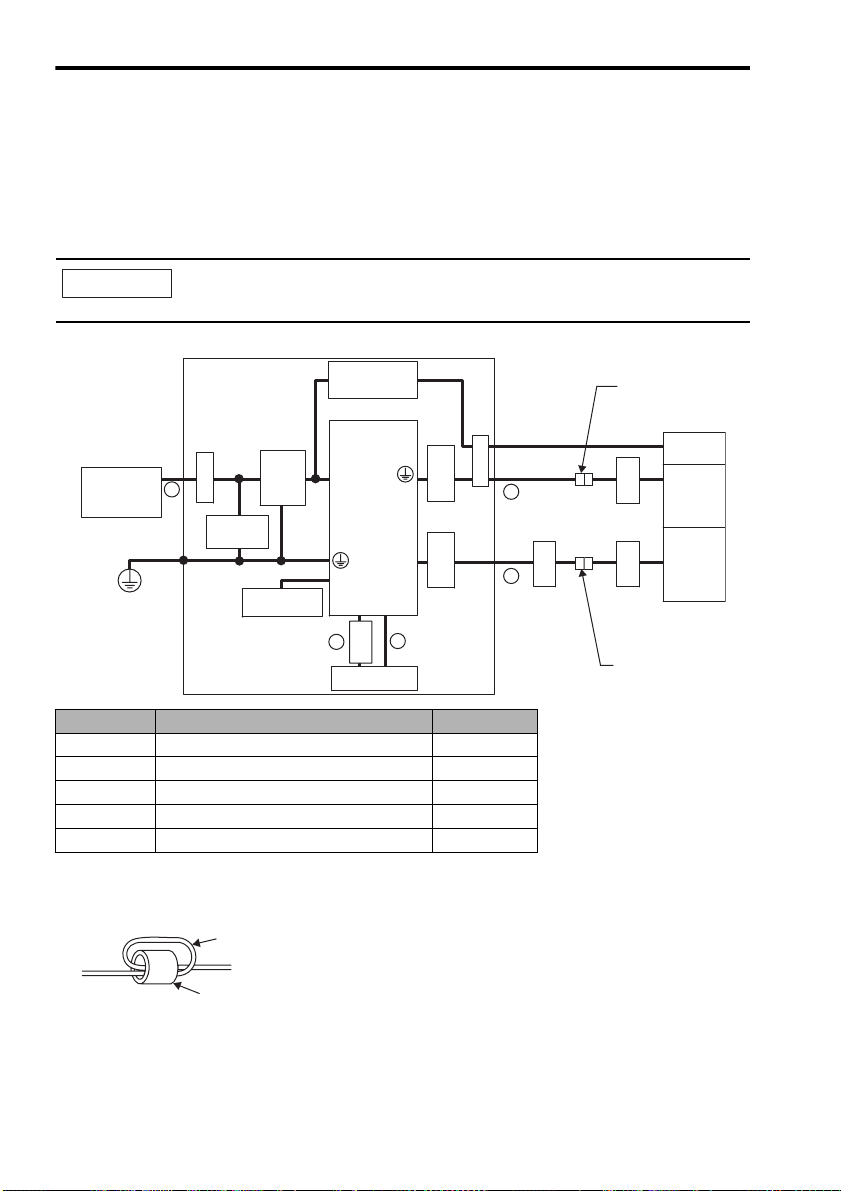

3.3.7 Installation and Wiring Conditions on CE Marking

Installation Conditions of EMC Directives

To adapt a combination of a SJME servomotor and a SJDE SERVOPACK to EMC Directives

(EN55011, group 1, class A and EN61000-6-2), the following conditions must be satisfied.

Because SERVOPACKs are built-in type, reconfirmation is required after being installed in the final

product.

IMPORTANT

Power supply

Single-phase

200 VAC

PE

The actual EMC level may differ depending on the actual system’s configuration, wiring, and

other conditions.

Ground Plate

Brake power

supply

SERVOPACK

Noise

Surge

protector

filter

Regenerative

unit

5

Clamp

U, V, W

L1, L2

CN2

+,–

CN1CN6

2

1

core

Ferrite

Host controller

Clamp

core

Ferrite

Ferrite

core

3

core

4

Ferrite

Cable joint

core

Ferrite

core

Ferrite

Cable joint

Servomotor

Encoder

Symbol Cable Name Specifications

A I/O Signals cable Shielded wire

B MECHATROLINK-II Communication cable Shielded wire

C Servomotor Main circuit cable Shielded wire

D Encoder cable Shielded wire

E AC Line cable Shielded wire

Attaching the Ferrite Core

Coil the servomotor main circuit cable (as a connection) around the ferrite core with two turns, then

attach them by the SERVOPACK. Refer to the diagram in the previous page.

Cable (two turns)

Brake

Ferrite core

Note: Recommended Ferrite-core

Model: ESD-SR-25 (Tokin. Corp.)

26

Fixing the Cable

Fix and ground the cable shield using a piece of conductive metal (cable clamp).

• Example of Cable Clamp

3.4 Main Circuit Wiring

Host

controller

side

Ground plate

Cable

Cable

clamp

Shield (cable sheath stripped)

Fix and ground the cable shield

using a piece of conductive metal.

Remove paint on mounting surface.

Shield Box

A shield box, which is a closed metallic enclosure, should be used for shielding magnetic interference

(EMI). The structure of the box should allow the main body, door, and cooling unit to be attached to the

ground. The box opening should be as small as possible.

3.3.8 Other Precautions

• Whether the electricity is served or not to the motor, do not use the motor being rotated from the

outside.

• When restarting the power supply soon after turning OFF, alarm may occur to the SERVOPACK.

Refer to the power supply holding time in the following table to restart the power supply correctly.

SERVOPACK Min. Waiting Time

Model Capacity

SJDE-01ANA-OY 100 W

SJDE-02ANA-OY 200 W

SJDE-04ANA-OY 400 W

SJDE-08ANA-OY 750 W

before Restarting

(s)

20

30

3.4 Main Circuit Wiring

• SJDE SERVOPACKs are suitable where the power supply is less than 5000 Arms (230 V max.).

• SERVOPACKs must be used with UL-listed fuses or molded-case circuit breakers, in accordance

with the National Electrical Code (NEC).

•Use 75 ° C heat-resistant copper wires or an equivalent.

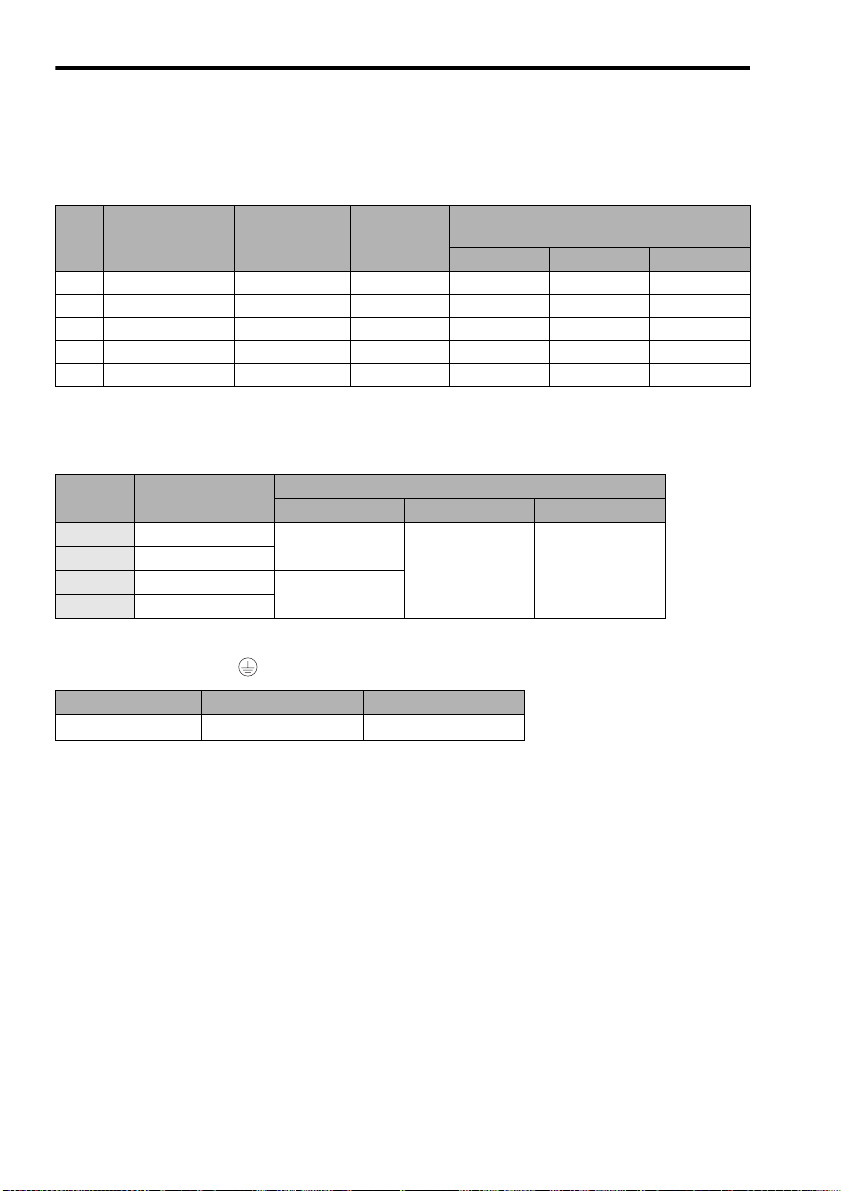

3.4.1 SERVOPACK Main Circuit Cables

Cable Types

Symbol Name Allowable Conductor Temperature

PVC Normal vinyl cable

IV 600 V vinyl cable

HIV Temperature-resistant vinyl cable

• Wire sizes are selected for three cables per bundle at 40 ° C ambient temperature with the rated

current.

• Use cables with a minimum withstand voltage of 600 V for main circuits.

• If cables are bundled in PVC or metal ducts, consider the reduction ratio of the allowable current.

• Use heat-resistant cables under high ambient or panel temperatures where normal vinyl cables will

rapidly deteriorate and will not be able to use in a short period of time.

• Do not use cables under continuous regenerative state.

27

−

60 ° C

75 ° C

3.4 Main Circuit Wiring

Wire Size and Allowable Current

The following table shows the wire size and allowable current for three cables. Use a cable whose

specifications meet or are less than allowable current in the table.

• 600 V Heat-resistant Vinyl Cables (HIV)

AWG

Note: The values in the table are only for reference.

Nominal Cross

Size

Section Diameter

20 0.5 19/0.18 39.5 6.6 5.6 4.5

- 0.75 30/0.18 26.0 8.8 7.0 5.5

18 0.9 37/0.18 24.4 9.0 7.7 6.0

16 1.25 50/0.18 15.6 12.0 11.0 8.5

14 2.0 7/0.6 9.53 23 20 16

mm

2

Configuration

Number of

2

wires/mm

Conductive

Resistance

2

Ω/mm

Allowable Current at Ambient Temperature

A

30 ° C 40 ° C 50 ° C

Power Supply Input Terminals (L1, L2), Motor Connection Terminals (U, V,

W), and Regenerative Unit Connection Terminals (+, -)

CapacityWSERVOPACK Type Terminal Symbol

L1, L2 U, V, W +, 100

200

400

750

Note: Connectors are used for all wiring.

SJDE-01ANA-OY

SJDE-02ANA-OY

SJDE-04ANA-OY

SJDE-08ANA-OY

HIV1.25 mm

HIV2.0 mm

2

2

HIV1.25mm

Wiring length:

20 m max.

2

HIV1.25mm

Wiring length:

0.5 m max.

2

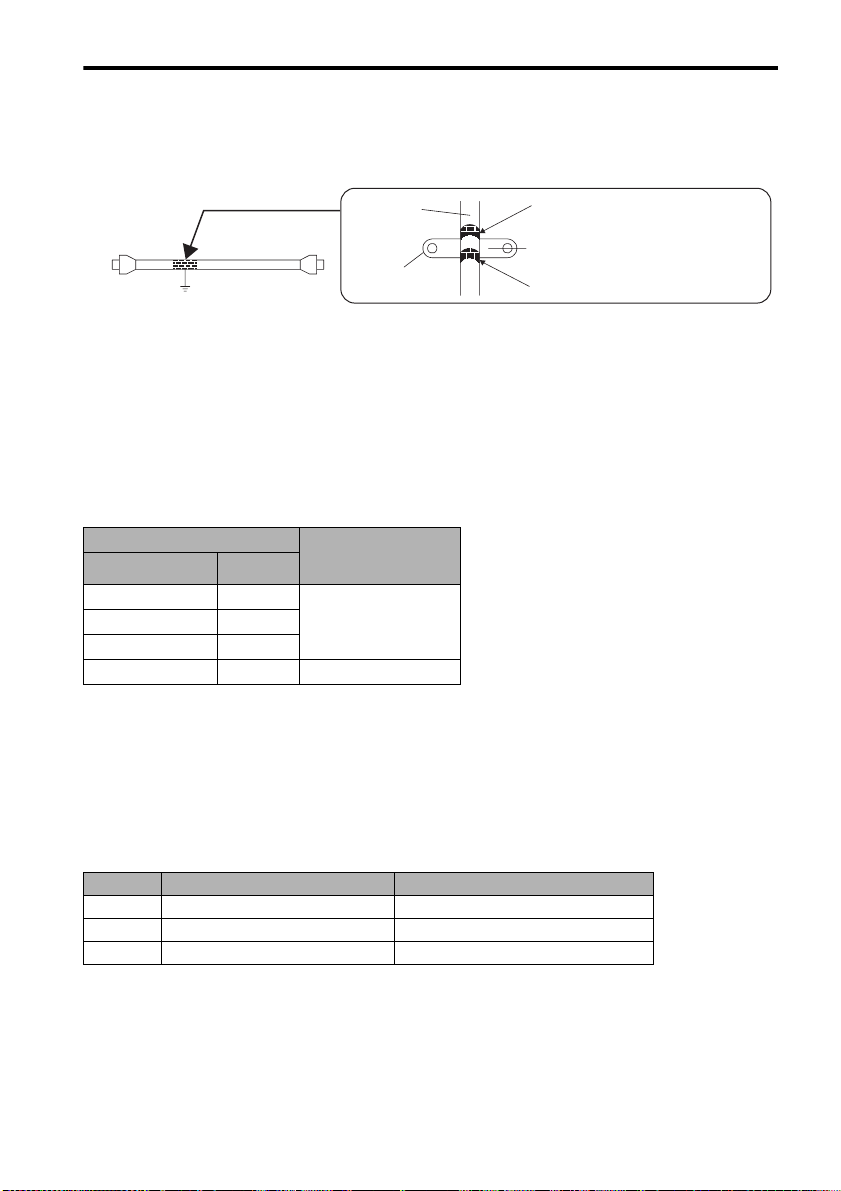

Ground Terminal ( )

Wire Size Terminal Screw Size Tightening Torque

HIV 2.0 mm

2

min.

M4 1.2 to 1.4 Nxm

28

Loading...

Loading...