Omron NSH5-SQR00B-V2, NSH5-SQG00B-V2, NSH5-SQR10B-V2, NSH5-SQG10B-V2 Operation Manual

Cat. No. V090-E1-07

NSH5 Series

NSH5-SQR00B-V2

NSH5-SQG00B-V2

NSH5-SQR10B-V2

NSH5-SQG10B-V2

Hand-held

Programmable Terminal

OPERATION MANUAL

NSH5 Series NSH5-SQR00B-V2 NSH5-SQG00B-V2 NSH5-SQR10B-V2 NSH5-SQG10B-V2

Hand-held Programmable Terminal

Operation Manual

Revised June 2008

iv

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means “word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Important

The LCD panel is created using extremely advanced technology, but there may still be some defective pixels, such as pixels that will not light or that are lit continuously. These are characteristic of LCDs and do not indicate a fault. Although manufacturing processes are managed to eliminate defective pixels as much as possible, eliminating all of them is not possible using currently available technology.

The display device may be changed to make improvements without prior notice.

Trademarks

Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

Other brand and product names are trademarks or registered trademarks of their respective owners.

v

OMRON, 2005

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

vi

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xvii |

|

1 |

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xviii |

2 |

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xviii |

3 |

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xviii |

4 Precautions for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xix |

|

5 |

Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xxi |

6 |

EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xxii |

SECTION 1 |

|

|

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

1-1 |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

1-2 |

Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

1-3 |

Special Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

SECTION 2 |

|

|

Grounding and Connections . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

|

2-1 |

Installation Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

2-2 Power Supply and FG Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

|

2-3 Connecting the Special Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

|

2-4 Attaching the Hand Strap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

|

2-5 Installing the Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

|

SECTION 3 |

|

|

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

|

3-1 |

Creating Screen Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

3-2 |

Emergency Stop Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

3-3 |

Enabling Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

3-4 |

Function Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

3-5 |

Memory Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

3-6 |

USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

44 |

3-7 Usable Host Connection Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

44 |

|

3-8 |

Station Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

SECTION 4 |

|

|

Connecting to the Removable Box . . . . . . . . . . . . . . . . . . . . |

47 |

|

4-1 Overview of Removable Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

|

4-2 |

Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

4-3 |

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

4-4 |

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

4-5 |

Connection Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

55 |

vii

TABLE OF CONTENTS

SECTION 5 |

|

|

Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

|

5-1 |

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

5-2 |

Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

5-3 |

Error Message Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

65 |

5-4 |

Precautions When Replacing the PT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

65 |

Appendices |

|

|

A |

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

67 |

B |

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

73 |

C |

Types of Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

75 |

D |

Comparison of Functions with NS-Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

77 |

E |

Recommended Enabling Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

81 |

F |

Removable Box Application Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

87 |

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

97 |

|

viii

About this Manual:

This manual describes the installation and operation of the NSH5 Programmable Terminal and includes the sections described below.

The NSH5 Programmable Terminal is a Hand-held Programmable Terminal manufactured by OMRON that provides a touch panel and safety switches.

Please read this manual carefully and be sure you understand the information provided before attempting to install or operate the NSH5 Programmable Terminal.

Use this manual together with the NS-series PT manual, and be sure to read the precautions provided in the following section.

Precautions provides general precautions for using the NSH5 Programmable Terminal and related devices.

Section 1 describes the features, nomenclature, and functions of the NSH5 Programmable Terminal for first-time users.

Section 2 describes wiring and grounding the power supply and how to connect the NSH5 Programmable Terminal using the Special Cable.

Section 3 describes the functions that have been expanded or newly added to the NSH5 Programmable Terminal.

Section 4 describes the Removable Box, which is connected to the NSH5.

Section 5 describes inspection and maintenance and the contents of error messages for the NSH5 Programmable Terminal.

The Appendices provide specifications, dimensions, memory reference tables, and recommended enabling circuits

!WARNING Failure to read and understand the information provided in this manual may result in personal injury or death, damage to the product, or product failure. Please read each section in its entirety and be sure you understand the information provided in the section and related sections before attempting any of the procedures or operations given.

ix

Related Manuals

Related manuals are listed below.

The @ symbol at the end of the catalog number is the revision code.

Operating the CX-Designer

• CX-Designer Operation Manual (V088-E1-@)

This manual describes the installation method, basic operating procedures, and the user interface of the CX-Designer. Typical features and applications methods are also described. Operating methods, procedures, and settings for the CX-Designer can be displayed on the screen using online help. Online help can be referred to for normal operations.

Refer to the following manuals for detailed information of the operation of NSseries PTs.

Checking NS-series PT Functions, Applications, and Troubleshooting

• NS-series Programmable Terminal Programming Manual (V073-E1-@)

This manual describes functions and applications of NS-series PTs. Also included are descriptions of remedies for faults that occur in NS-series PTs.

Checking NS-series PT Functions, Operation, and Restrictions

•NS-series Programmable Terminal Programming Manual (V083-E1-@) This manual is for NS V1/V2-series PTs (NS12-V1, NS10-V1, NS8-

V1, NS5-V1, NS5-V2).

The manual describes installation, connections, general specifications, and hardware for NS-series PTs.

•NS-series Programmable Terminal Setup Manual (V072-E1-@)

This manual is for NS-series PTs (NS12, NS10, NS7).

Checking PLC Functions and Operation

• Relevant PLC User’s Manual

When information on PLC operation and functions is required, refer to the user’s manuals for the relevant PLC, Special I/O Unit, CPU Bus Unit, or Communications Unit.

x

Terminology

|

The following terminology is used in this manual. |

Terminology |

|

NSH5 |

Indicates products in the OMRON NSH5 Series of Programmable |

|

Terminals. |

PLC |

Indicates an OMRON Programmable Controller. |

Host |

Indicates the PLC or IBM PC/AT or compatible computer functioning |

|

as the control device and interfaced with the NS-series PT. |

CX-Designer |

Indicates the OMRON CX-Designer (NS-CXDC1-V@). The CX- |

|

Designer is a Support Software application used to create screen |

|

data for NS-series PTs. |

CS1G-CPU@@-V1 |

Boxes in model numbers indicate variable characters. |

|

For example, “CS1G-CPU@@-EV1” indicates the following models: |

|

CS1G-CPU42-EV1, CS1G-CPU43-EV1, CS1G-CPU44-EV1, |

|

and CS1G-CPU45-EV1. |

xi

xii

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xiii

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying ratings and limitations of use that apply to the products. This information by itself is not sufficient for a complete determination of the suitability of the products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses listed may be suitable for the products:

•Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this manual.

•Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines, vehicles, safety equipment, and installations subject to separate industry or government regulations.

•Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

xiv

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction changes are made. However, some specifications of the products may be changed without any notice. When in doubt, special model numbers may be assigned to fix or establish key specifications for your application on your request. Please consult with your OMRON representative at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xv

xvi

PRECAUTIONS

This section provides general precautions for using the NSH5-series Programmable Terminal (PT).

The information contained in this section is important for the safe and reliable application of the PT. You must read this section and understand the information contained before attempting to set up or operate an NSH5-series PT.

1 |

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xviii |

2 |

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xviii |

3 |

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xviii |

4 |

Precautions for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xix |

5 |

Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xxi |

6 |

EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xxii |

xvii

Intended Audience |

1 |

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

•Personnel in charge of introducing FA systems into production facilities.

•Personnel in charge of designing FA systems.

•Personnel in charge of installing and connecting FA systems.

•Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the manual or applying the product to nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines and equipment that may have a serious influence on lives and property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are sufficient for the systems, machines, and equipment, and be sure to provide the systems, machines, and equipment with double safety mechanisms.

This manual provides information for using the PT. Be sure to read this manual before attempting to use the software and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that PTs and related devices be used for the specified purpose and under the specified conditions, especially in applications that can directly or indirectly affect human life. You must consult with your OMRON representative before applying PTs to the above-mentioned applications.

3 Safety Precautions

Read these safety precautions carefully and make sure you understand them before using the PT so that you can use it safely and correctly.

! WARNING

Do not attempt to take the PT apart and do not touch any internal parts while the power is being supplied. Doing either of these may result in electrical shock.

xviii

Precautions for Safe Use |

4 |

! WARNING

•Always ensure that personnel in charge properly perform installation, inspection, and maintenance for the PT. “Personnel in charge” refers to individuals qualified and responsible for ensuring safety during machine design, installation, operation, maintenance, and disposal.

•Ensure that installation and post-installation checks are performed by personnel in charge who possess a thorough understanding of the machinery to be installed.

•Do not attempt to disassemble, repair, or modify the PT. Doing so may impair the safety functions.

•Always connect the stop/emergency stop switch and enabling switch to safety circuits. Serious accidents may occur if connection is made to a PLC and there is a malfunction. When using the function switches or switches on the touch panel, do not create switches that may cause injury or damage property. Install a monitoring circuit or other device in output signals that may result in serious accidents. Construct the system so that switching of important operations is performed in devices outside the PT.

•For devices and components connected to the PT that affect safety, use appropriate products meeting the required safety level and safety category. System safety and the appropriate safety category must be evaluated for the entire system. Consult a certified third-party organization to determine the appropriate safety category.

•It is the user’s responsibility to ensure that system safety adheres to relevant standards.

•Connect the emergency stop switch, and enabling switch on the PT so that they function according to stop category 0 or 1 described in IEC/EN 60204-1.

•Do not operate the PT on the floor or on a tabletop.

•There are two types of switches on the PT, a red one for use as an emergency stop switch, and a gray one for use as a stop switch. Use each of these for its intended purpose. When using a PT with a red emergency stop switch, attach the cable from the system securely so it cannot be easily disconnected. When using a PT with a gray stop switch in an application where the PT is detached from the system, make sure that the emergency stop switch and the stop switch can be clearly distinguished.

4Precautions for Safe Use

•When unpacking the PT and peripheral devices, check that they are not damaged. Lightly shake the products to confirm that no abnormal sound is made.

•Use a power supply with the following specifications for the PT, and for supplying power to the emergency stop switch, enabling switch, function switches, and station detection.

•For compliance with the EC Directives (Low Voltage Directive), use a power supply with reinforced insulation. Reinforced insulation refers to a single insulation method that is capable of providing the same level of protection against electric shock as double insulation.

•Do not connect the power supply terminals to an AC power source.

•Do not perform a dielectric strength test.

•Insert a 3-A fuse immediately after the secondary output from the power supply.

•Use a DC power supply with minimal voltage fluctuation.

Rated power supply voltage: 24 VDC (Allowable range: 20.4 to 27.6 VDC), Capacity: 10 W min.

xix

Precautions for Safe Use |

4 |

•Always use a Class 2 power supply for compliance with UL standards. A Class 2 power supply refers to one in which the current and voltage levels of the product’s secondary output are both limited (100 VA max.), and which has undergone and passed the necessary tests for UL certification.

•Properly ground the PT to prevent malfunction due to noise.

•Never touch the electronic components or patterns on product boards with your bare hands. Touch grounded metal to discharge any static electricity before handling the PT.

•When connecting the cable to the PT, make sure to secure the cable and the PT. Do not pull on the cable with a force greater than 60 N.

•Thoroughly check the wiring before supplying power.

•Turn OFF the power supply to the PT before connecting or disconnecting the cable.

•Be sure to tighten the connector screws after connecting the cable.

•The entire system may fail to operate depending on how the power supply is turned ON or OFF. Follow specified procedures for turning the power supply ON and OFF.

•Thoroughly confirm operation of screen data, macros, and host programming before starting actual use.

•Do not perform the following operations while the Memory Card is being accessed.

Turning OFF the power supply to the PT Removing the Memory Card

Always follow specified procedures for removing the Memory Card.

•To ensure system safety, incorporate programming at the host to periodically accesses a RUN signal to confirm that the PT is operating properly.

•Press touch switches with a force of 30 N max.

•Confirm system safety before pressing touch switches.

•Use caution when pressing touch switches if there is no display shown or if the touch switch backlight is not lit.

•The inputs may not be read properly if touch switches are pressed in rapid succession. Confirm one input before proceeding with the next.

•Confirm that the created screen data is backed up in the CX-Designer before initializing the screen data.

•When changing the password in the System Menu, do not reset the PT or turn OFF the power supply until the write operation has been performed (i.e., until the Write Button returns to normal). The screen may not function if the password is not properly saved.

•When using the device monitor function, thoroughly confirm system safety before performing the following operations.

•Changing present values for monitor data, timers, or counters

•Changing the operating mode

•Force-setting/resetting bits

•Changing settings for timers or counters

•Never use volatile solvents, such as paint thinner or benzene, or chemical wipes for cleaning.

•Do not attempt to disassemble, repair, or modify the PT.

xx

Operating Environment Precautions |

5 |

•When disposing of batteries, comply with all local ordinances that apply to disposal.

•Do not connect a USB connector to any device that is not applicable.

•Before connecting a USB connector to a device, check the external appearance of the device and make sure that the device is free from damage.

•When mounting the battery, be sure to use the correct battery and mount it correctly.

•Dispose of the product and batteries according to local ordinances as they apply. Have qualified specialists properly dispose of used batteries as industrial waste.

•The backlight in the PT contains mercury. Do not dispose of the PT together with other waste to be sent to a disposal site. Dispose of the PT according to local ordinances as they apply.

•Do not turn OFF the power supply to the PT while downloading or uploading screen data or system programming. The screen data and system programming may become corrupted.

•Secure the PT’s cable at the control panel when connecting it to the control panel.

•Be sure not to trip over the cable when moving around while holding the PT.

•This is a class A product. In residential areas it may cause radio interference, in which case the user may be required to take adequate measures to reduce interference.

5 Operating Environment Precautions

!Caution Do not install the control system in the following locations.

•Locations subject to severe changes in temperature

•Locations subject to temperatures or humidity outside the range specified in the specifications

•Locations subject to condensation as a result of severe changes in temperature

•Locations subject water, oil, or chemical spray

•Locations subject to corrosive or flammable gases

•Locations subject to shock or vibration

•Locations outdoors directly subject to wind or rain

•Locations subject to strong ultraviolet light

xxi

EC Directives |

6 |

!Caution Take appropriate and sufficient countermeasures when using systems in the following locations:

•Locations subject to static electricity or other forms of noise

•Locations subject to strong electromagnetic fields

•Locations close to power lines

•Locations subject to possible exposure to radioactivity

6 EC Directives

Conforming Directive

The NSH5-series PTs conform to the EMC Directive.

EMC Directive Conformance

OMRON products are designed as electrical devices for use built into other devices or the overall machine. As individual devices, they comply with the related EMC standards (see note) so that they can more easily be built into other devices or the overall machine. The actual products have been checked for conformity to EMC standards. Whether they conform to the standards in the system used by the customer, however, must be checked by the customer.

EMC-related performance of the OMRON devices will vary depending on the configuration, wiring, and other conditions of the equipment or control panel on which the OMRON devices are installed. The customer must, therefore, perform the final check to confirm that devices and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): |

EN 61131-2 |

EMI (Electromagnetic Interference): |

EN 61131-2 (Radiated emission: |

|

10-m regulations) |

Complying with EC Directives

NSH5-series PTs comply with EC Directives. Observe the following precautions to ensure that the customer’s device and the overall machine also comply with EC Directives.

1,2,3... 1. Use reinforced insulation or double insulation for the DC power supply to the PT. Ensure that a stable power output can be provided even if a 10-ms interruption occurs at the input.

2.The PT conforms to the EN 61131-2, but the radiated emission characteristics (10-m regulations) may vary depending on the configuration of the control panel used, other devices connected to the control panel, wiring, and other conditions. You must therefore confirm that the overall machine or equipment complies with EC Directives.

xxii

SECTION 1

Introduction

This section describes the features, nomenclature, and functions of the NSH5 Programmable Terminal for first-time users.

1-1 |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

|

1-1-1 What Is the NSH5 Programmable Terminal? . . . . . . . . . . . . . . . . . . |

2 |

|

|

1-1-2 |

NSH5 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

1-1-3 |

NSH5 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

|

1-1-4 |

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

1-1-5 |

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

1-1-6 |

Switch Output Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

1-1-7 |

External Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

1-1-8 |

Safety Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

1-2 |

Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

|

1-2-1 |

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

1-2-2 |

Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

1-2-3 |

Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

1-3 |

Special Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

|

|

1-3-1 |

Special Cable Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

|

1-3-2 |

UL-standard Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

|

1-3-3 |

Loose-wire/D-Sub Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

1-3-4 |

Removable Box Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

|

1-3-5 |

External Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

|

1-3-6 |

Interface Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

1

Overview |

Section 1-1 |

1-1 Overview

1-1-1 What Is the NSH5 Programmable Terminal?

The NSH5 is an NSH5-series Hand-held Programmable Terminal that provides both a touch panel and safety switches.

RUN

F6

F7

F8

F9

F10

|

|

RE |

|

E |

T |

|

SE |

|

T |

||

ES |

|

|

|

R |

|

|

|

|

|

TESE |

R |

|

|

|

|

F1 |

Touch panel |

F2 |

F3 NSH5

F4

Safety switches

F5

Touch Panel |

The touch panel is the same as the one for NS5-series Programmable Termi- |

|

nals with touch panels. Connecting to an OMRON PLC by RS-232C or RS- |

|

422A does not require a program. Function switches are also provided. |

Safety Switches |

An emergency stop switch and an enabling switch are provided. Be sure to |

|

externally connect them to safety circuits. |

|

Use safety circuits that are capable of detecting shorts in the emergency stop |

|

switch and enable switch. |

1-1-2 NSH5 Models

There are two NSH5 models, one equipped with a red switch and the other with a gray switch. The switching function is the same for both.

•NSH5-SQR@0B-V2 (equipped with a red switch for use as an emergency stop switch)

This switch functions as the emergency stop switch so the PT must be mounted and used on a control panel in a way that it cannot be detached.

•NSH5-SQG@0B-V2 (equipped with a gray switch for use as a stop switch) This functions as the stop switch and can be used in either the hand-held

or mounted condition.

2

Overview |

Section 1-1 |

1-1-3 NSH5 Features

Computer running CX-Designer

Memory Card (Compact Flash)

USB port |

Screen |

|

transfer |

||

|

Memory Card slot

RUN

F6

F7

F8

F9

|

|

R |

|

T |

ES |

|

T |

|

E |

|

E |

S |

|

|

E |

|

|

R |

|

|

|

|

ER |

|

|

TES |

F1

F2

F3

F4

Function switches (10)

F10 |

F5 |

Color STN LCD

Enabling switch (on back)

|

Serial connection |

CS/CJ-series PLC |

|||||||||||

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(RS-422A/RS-232C) |

|

|

|

|

|

|

|

|

|

Safety circuits |

||

|

|

|

|

|

|

|

|

|

|

||||

|

1:N NT Link |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24-VDC power supply

External switch outputs

Function switches (F1, F2, F6, and F7) Stop/emergency stop switch

Enabling switch

•Equipped with both a stop/emergency stop switch and an enabling switch There are two switches provided for stopping machine operation while using the touch panel. The stop/emergency stop switch is for stopping operation intentionally, and the enabling switch is for stopping machine operation without taking conscious action.

The emergency stop switch (DPST-NC contact + NO bit) is allocated one bit in the internal memory or in the host (PLC) memory and is hard-wired to two external outputs. It has a direct opening mechanism.

The enabling switch (3-position DPST-NO) is hard-wired to an output. It has a direct opening mechanism, an easily confirmed click, and a rubber cover.

•Ten function switches (SPST-NO) are provided. They can be used for operations such as inching. Six of the function switches can be allocated bits in internal memory or host (PLC) memory, and four of the function switches can be output via hard-wired external outputs.

•Program-free connection is possible to an OMRON PLC via RS-232C or RS-422A.

•A 5.7-inch STN display with 256 colors (bit maps: 4,096 colors) is provided.

3

Overview |

Section 1-1 |

•The external end of the Special Cable (3 m, 10 m) has both a 9-pin D-Sub male connector, and loose wires for the stop/emergency stop switch, enabling switch, and function switches.

•Screen transfers are enabled by connecting a computer running CXDesigner to the USB port (standard feature).

•Project data can be shared with panel-mounted NS-series Programmable Terminals.

•The Smart Active Parts library for NS-series PTs can be used.

•A Memory Card can be mounted to save screen data, data logs, operation logs, error logs, and recipes.

•The PT is waterproof to a IP65 degree of protection. (See note 1.)

•The PT withstands shock from dropping it from one meter (JIS B 3502 and IEC 61131-2). (See note 2.)

•The PT features a lightweight 1-kg hand-held design.

•The removable box is automatically detected when it’s connected.

The box number is set using the DIP switch on the removable box. When the PT is connected, the box number is automatically detected and the screens corresponding to the box number are automatically displayed on the PT. At the same time, the PLC can be notified of the box number.

Note (1) Conformance is evaluated under applicable test conditions, and it may not be possible to use the PT in every environment. When used over a long period of time, the drip-proof packing may become damaged or dirty and lose its effectiveness.

(2)Conformance is evaluated under applicable test conditions, and it may not be possible to use the PT in every environment.

1-1-4 |

Product Specifications |

|

|

|

|

|

|

|

|

Model |

Specifications |

|

|

|

|

|

|

NSH5-SQR00B-V2 |

5.7-inch color STN LCD |

|

|

NSH5-SQG00B-V2 |

• Dots: 320 x 240 |

|

|

NSH5-SQR10B-V2 |

|

|

|

• Colors: 256 (bit maps: 4,096) |

|

|

|

NSH5-SQG10B-V2 |

|

|

|

• Screen capacity |

|

|

|

|

|

|

|

|

NSH5-SQ@10B-V2: 60 MB |

|

|

|

NSH5-SQ@00B-V2: 20 MB |

|

|

|

• 1 USB port (for transferring screen from the CX-Designer) |

|

|

|

Commercially available USB cable can be connected. |

|

|

|

• Memory Card: Can be mounted. |

|

|

|

• Serial communications: Either RS-232C or RS-422A, |

|

|

|

depending on the Special Cable used. The serial communi- |

|

|

|

cations mode is 1:N NT Link. |

|

|

|

• 1 stop/emergency stop switch (DPST-NC contact + NO |

|

|

|

bit) |

|

|

|

• 1 enabling output (DPST-NO) |

|

|

|

• 10 function outputs |

|

|

|

|

1-1-5 |

Applications |

|

|

•Setting parameters and monitoring operation when starting up equipment or switching processes

•Setting parameters and monitoring operation when an error occurs

4

Overview |

Section 1-1 |

•Setting parameters and monitoring operation anywhere in expansive facilities

1-1-6 Switch Output Configuration

The stop/emergency stop switch uses DPST-NC contact + NO bit. Of these, DPST-NC contacts are used for external hardware outputs. The remaining NO bit can be allocated any bit in the internal memory or in the host (PLC) memory.

Six function switches can be allocated any bits in the internal memory or in the host (PLC) memory. Four of the function switches can be output to external contact outputs.

The enabling switch (DPST-NO) can also be output to external contact outputs.

|

|

NSH5 |

|

|

|

|

Stop/emergency stop switch |

|

Allocation |

|

Host (PLC) memory |

||

|

|

Stop/emergency stop switch |

||||

(DPST-NC contact + NO bit) |

|

|

||||

|

|

|

||||

|

|

Internal memory |

|

|

||

|

|

Stop/emergency stop switch |

|

|

||

|

F1 |

|

|

|

|

|

|

F2 |

|

|

F5 |

F4 |

F3 |

|

|

|

or |

|

|

|

|

F3 |

Allocation |

|

|

|

|

|

|

F9 |

F10 |

F8 |

||

|

|

F5 |

F4 |

F3 |

|

|

|

F4 |

|

|

|

|

|

|

F5 |

F9 |

F10 |

F8 |

|

|

10 function switches |

F6 |

|

|

|

|

|

|

|

|

RS-232C |

|

|

|

|

|

|

|

|

|

|

|

F7 |

|

|

or RS-422A |

|

|

|

|

|

|

|

|

|

|

F8 |

|

|

|

|

|

|

F9 |

|

|

|

|

|

|

F10 |

|

|

|

|

|

Enabling switch |

|

|

|

|

|

|

(DPST-NO) |

|

|

|

|

|

|

External |

|

|

|

Color STN LCD |

|

|

output |

|

|

|

|

|

|

|

|

24-VDC power supply |

|

|

||

Enabling switch outputs |

4 function |

Stop/emergency stop |

(DPST-NO) |

switch outputs |

switch outputs (DPST-NC) |

The hard-wired outputs operate even when the PT power supply is OFF.

1-1-7 External Connections

Use a Special Cable (NSH5-232/422-CW-@@M, UL type: NSH5-232/422UL- @@M), loose-wires and D-Sub connector on one end) to connect the signals as follows:

•Emergency stop switch/stop switch

When using as a safety system, connect to safety components. (Do not connect to the PLC.)

•Enabling switch

When using as a safety system, connect to safety components. (Do not connect to the PLC.)

•Serial communications (RS-232C or RS-422A) Connect to the serial port of the PLC.

•Function switches

Connect to an DC Input Unit of the PLC.

5

Overview |

Section 1-1 |

RUN

F6

F7

F8

F9

F10

|

T |

RES |

SE |

ET |

|

|

|

|

RE |

|

|

|

|

R |

|

|

TESE |

F1

F2

F3

F4

F5

Special Cable (3 or 10 m)

•RS-232C: NSH5-232@@-@@M

•RS-422A: NSH5-422@@-@@M

CS/CJ-series PLC |

Safety circuits |

|

9-pin D-sub (male) |

|

|

Function |

Safety switch |

|

switch outputs |

||

outputs |

||

|

||

Loose wires (21) |

|

|

24-VDC power supply |

|

Note (1) When used in a safety control system, the stop/emergency stop switch and enabling switch must be connected to a safety circuit.

(2)Do not use the function switches or the touch switches on the touch panel as emergency stop switches in situations involving potential risk to human life or serious damage.

(3)Use safety circuits that are capable of detecting shorts in the stop/emergency stop switch and enable switch.

1-1-8 Safety Standards

Overview of Standards |

General Standards |

EN 954-1

Safety-related Parts of Control Systems

Part 1: General Principles for Design

ISO Standards: ISO 13849-1; JIS Standards: JIS B 9705-1

Summary

This standard applies to design procedures for parts in control systems that involve safety.

Main Point

The levels for machines are determined by taking into consideration the degree of anticipated damage (from light to heavy) and the rate of occurrence (from rare to frequent). The danger level is classified into five categories, and for each category the safety functions that should be provided for control parts are specified.

EN 60204-1

Electrical Equipment of Machines

Part 1: Specification for General Requirements

IEC Standards: IEC 60204-1; JIS Standards: JIS B 9960-1

Summary

This standard applies to electrical devices in which the power supply nominal voltage between lines is less than 1,000 V (for AC) or 1,500 V (for DC), and the nominal frequency is less than 200 Hz.

6

Overview |

Section 1-1 |

Standards Applicable to the NSH5

Main Point

The standard covers all of the elements required in electrical devices, such as control circuits, functions, and devices for electrical and electronic equipment, safety measures, and technical materials related for installation, operation, and maintenance.

Standard Related to Safety Switches

EN 60947-5-1

Low-voltage Switching Gear and Control Gear

Part 5: Control Circuit Devices and Switching Elements

Section 1: Electromechanical Control Circuit Devices

IEC Standards: IEC 60947-5-1; JIS Standards: JIS C 8201-5-1

Summary

This standard applies to switching elements and control circuit devices created for purposes such as control of switching control equipment, signals, and interlock.

Main Points

Section 1: General Requirements

Section 2: Special Requirements for Indicator Lights

Section 3: Special Requirements for Direct Opening Operations

The standards cover topics such as switching capacity, temperature rise, terminal strength, protective construction, and direct opening operations.

Standard Regarding Emergency Stop Equipment

EN 418

Emergency Stop Equipment

Functional Aspects: Principles for Design

ISO Standards: ISO 13850; JIS Standards: JIS B 9703

Summary

This standard prescribes the design principles for emergency stop equipment.

Main Points

A direct opening mechanism must be provided.

A self-holding mechanism must be provided.

The stopping device must be in a form that is easy to operate, such as a protruding pushbutton, a wire, or a rope.

The stopping device must be red with a yellow background.

The following safety standards apply to the NSH5 PT.

•Based on EN 60204-1

•Complies with EN 954-1

EN 60204-1 Safety Standard

IEC204-1 (EN60204-1: Electrical Safety Standard for Machinery) stipulates that an emergency stop switch must be red, and a stop switch must be gray or black. When detaching and using the PT separate from the system, always use a PT with a gray switch.

In the EN60204-1safety standard, emergency stop and emergency shutdown are defined as emergency switches.

Emergency stop |

Stop category 0 or 1 |

|

|

Emergency shutdown |

Stop category 0 only |

|

|

7

Nomenclature and Functions |

Section 1-2 |

It is stipulated in EN 60204-1 that the pushbutton for an emergency stop must be red and the background yellow. In SEMI-S2 as well, the background for an emergency shutdown pushbutton must be yellow.

To comply with these standards, a yellow seal is included with the product to affix around the emergency stop switch.

EN 954-1 General Design Principles

Redundant conformity is provided with an enabling switch and an emergency stop switch. The emergency stop switch is a three-pole switch (3PST-NC), with a DPST-NC contact structure and a SPST-NC contact structure for an emergency stop notification signal.

1-2 Nomenclature and Functions

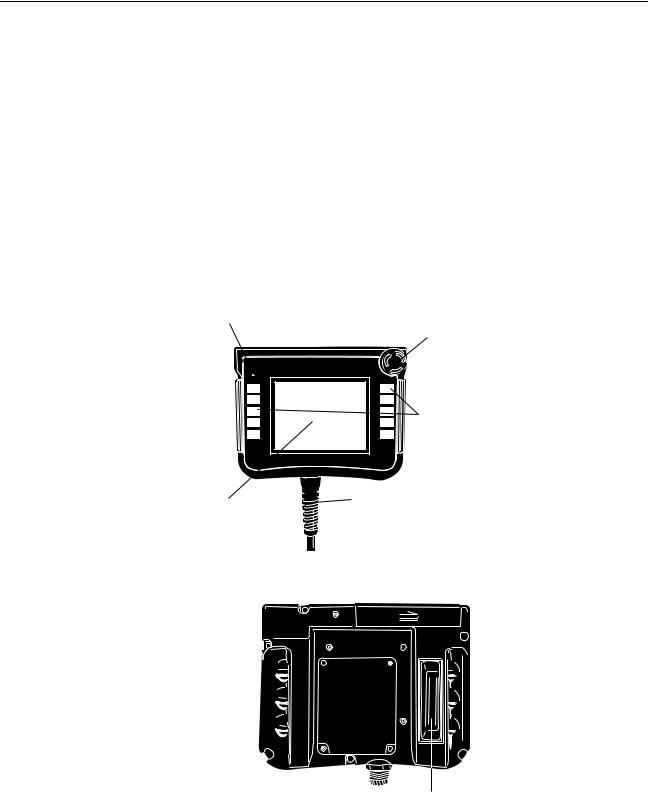

1-2-1 Front

LED indicator

RUN

F6

F7

F8

F9

F10

5.7-in. STN

Stop/emergency stop switch

|

|

RE |

E |

T |

SE |

T |

||

ES |

|

|

R |

|

|

|

|

ER |

|

|

TES |

F1

F2

F3

F4

F5

Cable Loose wires Loose wires

Function switches

F1, F2, F6, and F7 are hard-wired outputs. F3, F4, F5, F8, F9, and F10 are software (communications) outputs.

and RS-232C cable (3 or 10 m) and RS-422A cable (10 m)

1-2-2 Back

Hand holds |

|

|

|

Hand holds |

|

|

|

|

|

Enabling switch

8

Nomenclature and Functions Section 1-2

1-2-3 Top

Memory Card slot USB port

Display Section |

Effective display area: 5.7 inches |

|

|

|

|

Liquid crystal: Color STN LCD with backlight |

|

||

|

Number of dots: 320 × 240 |

|

|

|

|

Number of display colors: 256 (BMP/JPG images: 4,096) |

|

||

RUN Indicator |

The NSH5 status indicator is described in the following table. |

|||

|

|

|

|

|

|

Color |

Green |

Orange |

Red |

|

RUN |

|

|

|

|

Indicator |

|

|

|

|

|

|

|

|

|

Lit |

Normal operation |

• Checking file system |

Error occurred at |

|

|

|

at startup. |

startup. |

|

|

|

• Normal operation |

|

|

|

|

with battery voltage |

|

|

|

|

low or battery discon- |

|

|

|

|

nected. |

|

|

|

|

|

|

|

Flashing |

• Memory Card transfer |

Memory Card transfer |

Error occurred dur- |

|

|

completed normally. |

in progress. |

ing Memory Card |

|

|

• Backlight error discov- |

|

transfer. |

|

|

ered after startup. |

|

|

|

|

|

|

|

|

Not lit |

• Power is not being supplied. |

|

|

•A fuse is burned out.

•A system program is damaged and cannot boot.

Switch Section |

OMRON A165E-S-03U Stop/Emergency Stop Switch |

|

DPST-NC contact: External output |

|

Rated voltage: 24 V |

|

Maximum rated current: 100 mA (minimum applicable load: 1 mA at 5 VDC) |

|

NO bit: Allocated in internal memory or host (PLC) |

OMRON A4E-B200VA Enabling Switch

DPST-NO contact: External output

Rated voltage: 24 V

Maximum rated current: 100 mA (minimum applicable load: 4 mA at 24 VDC) 3-position switch

Operating patterns:

Operation: OFF to ON to OFF

Reset: OFF to ON, momentary 3-position operation

9

Loading...

Loading...