Omron XWT-ID08, DRT2-ID16, XWT-ID16 BROCHURE

Available Models |

|

|

|

Remote I/O Terminal Basic Units |

Remote I/O Terminal Expansion Unit |

||

Model number |

Specification |

Model number |

Specification |

DRT2-ID16 |

16 inputs, NPN |

XWT-ID08 |

8 expansion inputs, NPN |

DRT2-ID16-1 |

16 inputs, PNP |

XWT-ID08-1 |

8 expansion inputs, PNP |

DRT2-OD16 |

16 outputs, NPN |

XWT-OD08 |

8 expansion outputs, NPN |

DRT2-OD16-1 |

16 outputs, PNP |

XWT-OD08-1 |

8 expansion outputs, PNP |

One Basic Unit and one Expansion Unit can be combined freely. |

XWT-ID16 |

16 expansion inputs, NPN |

|

|

|

||

XWT-ID16-1 |

16 expansion inputs, PNP |

||||

|

|

|

|

|

16 expansion outputs, NPN |

|

XWT-OD16 |

||||

|

|

|

|

16 expansion outputs, PNP |

|

|

XWT-OD16-1 |

||||

Dimensions

Dimensions

Remote I/O Terminal Basic Units

43.9

MS NS NODE ADDRESS |

|

|

50 |

115 |

3.1 |

Remote I/O Terminal Expansion Units |

43.9 |

|

|

|

50 |

|

|

13 |

16-point models: 94 |

3.1 |

29.9 |

|

49.7 |

||||

|

8-point models: 66 |

|

||

|

|

|

Smart Slaves

Smart Slaves

Adding a new dimension to

with remote maintenance.

Model number DRT2-ID16 -1 DRT2-ID16 DRT2-OD16 -1 DRT2-OD16

Remote I/O Terminnaallss

DRT2-ID16(-1)/O D16(-1)

XWT-ID16(-1)/O D16(-1)

XWT-ID08(-1)/O D08(-1)

Model number

XWT-ID16 -1

XWT-ID16

XWT-OD16 -1

XWT-OD16

XWT-ID08 -1

XWT-ID08

XWT-OD08 -1

XWT-OD08

Note: Do not use this document to operate the Unit.

OM RON Corporation |

Regional Headquarters |

|

FA Systems Division H.Q. |

OM RON EUROPE B.V. |

|

66 Matsumoto |

Wegalaan 67-69, NL-2132 JD Hoofddorp |

|

Mishima-city, Shizuoka 411-8511 |

The Netherlands |

|

Japan |

Tel:(31)2356-81-300/Fax:(31)2356-81-388 |

|

Tel:(81)55-977-9181 |

OM RON ELECTRONICS LLC |

|

Fax:(81)55-977-9045 |

||

1 East Commerce Drive, Schaumburg, IL 60173 |

||

|

||

|

U.S.A. |

|

|

Tel:(1)847-843-7900/Fax:(1)847-843-8568 |

|

|

OM RON ASIA PACIFIC PTE. LTD. |

|

|

83 Clemenceau Avenue, |

|

|

#11-01, UE Square, |

|

|

Singapore 239920 |

|

|

Tel:(65)6835-3011/Fax:(65)6835-2711 |

Authorized Distributor:

Note: Specifications subject to change without notice. |

Cat. No. R097-E1-01 |

|

Printed in Japan |

|

0502-2M |

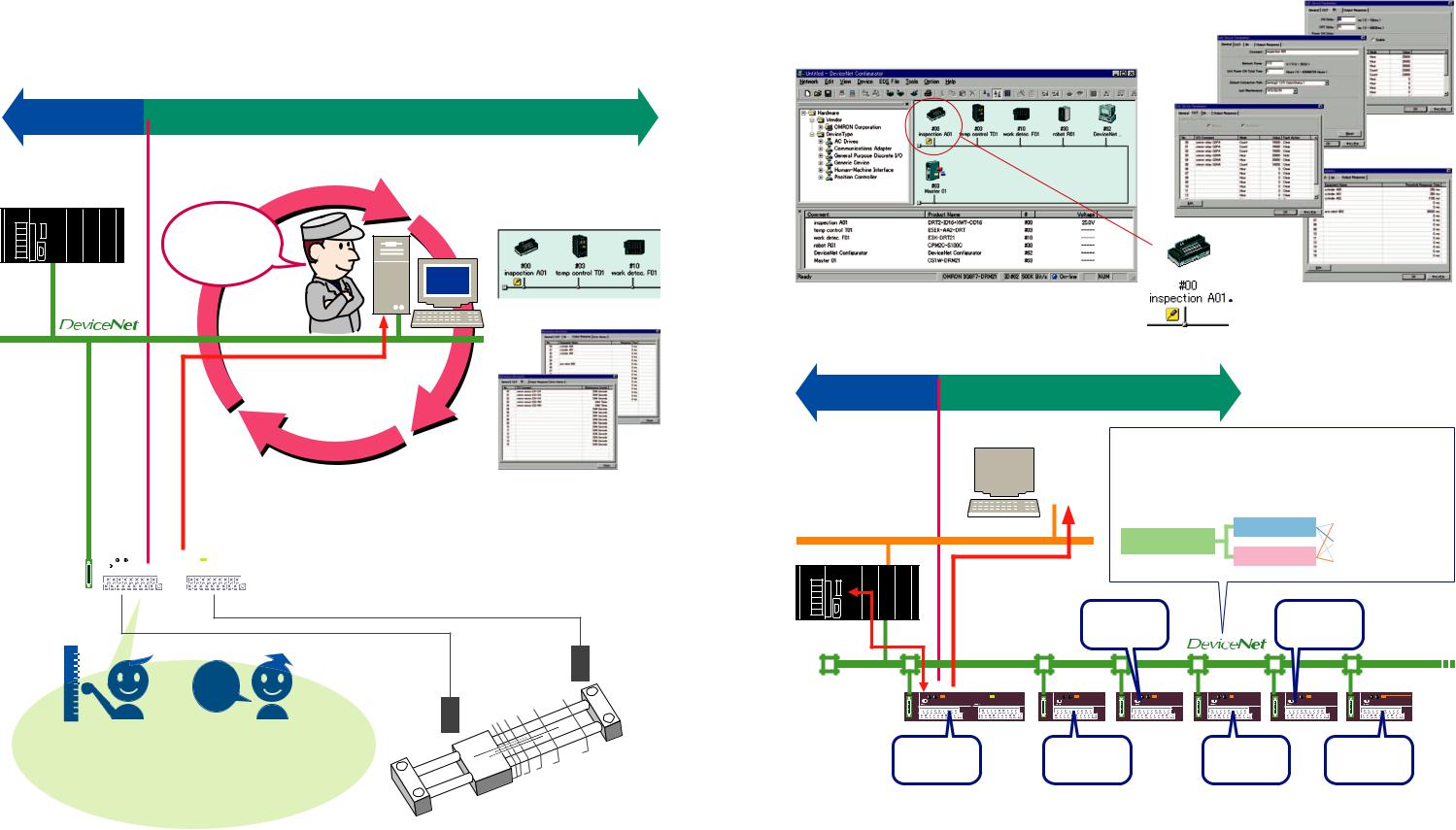

Use production site information in a variety of applications, such as maintenance and quality control.

OMRON's DRT2-series Smart Slaves do not just input and output ON/OFF signals. They collect a variety of value-added information to help increase the rate of operation without changing the wiring for existing DeviceNet networks. In particular, they allow the separation of control systems and maintenance systems so that maintenance systems can be created independently of control systems.

Control System |

Maintenance System |

|

Easy-to-view |

PLC |

Display |

Maintenance is |

2 Configurator |

required for |

|

cylinder 23A in |

|

inspection line A! |

|

Control I/O |

|

|

Operating time, contact operation |

|

counter |

|

Maintenance information |

|

|

|

|

|

|

|

Machine Operation |

Faster Maintenance |

||

|

|

|

|

|

|

|

Monitored by Slave |

Work |

||

1 |

|

|

3 The Slave can hold comments, |

|||||||

DRT2-series |

|

|

|

|

|

|

|

|

|

allowing quick identification of |

|

|

|

|

|

|

|

|

|

fault locations and faulty |

|

|

||||||||||

Smart Slave |

|

|

|

|

|

|

|

|

|

devices. |

|

|

|

|

|

|

|

|

|

||

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Smart Measuring

The Slave Unit represents machine operating time and operational changes as data, enabling monitoring without increasing the load between controllers.

1 2 3

4 5..

Smart Counting

By counting the number of ON/OFF operations and the total operating time, the Slave Unit can provide notification when maintenance is required.

Pneumatic valve

Sensor

Cylinder

Collect a variety of data from maintenance systems without influencing control systems and productivity.

All data can be converted to electronic format and, |

Information monitoring for |

by combining with an OMRON PLC (CS/CJ Series), |

each Slave |

checked directly from Ethernet or the Internet to |

|

allow remote maintenance. |

|

Configurator's maintenance mode screen |

|

Slave comment |

|

The Configurator's screen images may be changed without notice.

Status confirmation using the status icon

Status confirmation using the status icon

Control System |

|

|

Maintteennaannccee SSyysstteemm |

|

|

|

|||||

|

DeviceNet |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|||||

|

Configurator |

|

|

|

|

Operating time monitor |

|||||

|

|

|

|

|

|

|

|

|

|

|

Contact operation counter |

|

|

|

|

|

|

|

|

Preventive maintenance |

|

|

|

|

|

|

|

|

|

|

|

of equipment |

|

|

Unit conduction time monitor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Slave and connected component comments |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ethernet |

|

Reduced startup time |

I/O power status monitor |

||

|

Reliable equipment |

|

|

|||

|

|

|

Network power voltage monitor |

|||

|

|

startup |

|

|||

|

|

|

|

|

||

PLC |

|

|

Reduced downtime |

Communication error history |

||

|

Maintenance information |

|

|

monitor |

|

|

|

|

|

|

|

||

|

Unit conduction |

It's time for |

What is the |

Netw ork pow er |

||

|

present |

|

||||

|

motor |

|

||||

Control |

time mon itor |

comm unications |

voltage monitor |

|||

maintenance! |

||||||

(See note.) |

voltage? |

|

||||

information |

|

|

||||

|

|

|

|

|

||

MS NS NODE ADDRESS |

|

|

|

MS NS NODE ADDRESS |

|

MS NS NODE ADDRESS |

|

MS NS NODE ADDRESS |

|

MS NS NODE ADDRESS |

|

MS NS NODE ADDRESS |

DRT2-series |

DRT2-ID16 |

ET-OD16 |

DRT2-ID16 |

DRT2-ID16 |

DRT2-ID16 |

DRT2-ID16 |

DRT2-ID16 |

Smart Slave |

|

|

|

|

|

|

|

The cylinder's |

It m ight be time |

Is the I/ O |

What w as the |

speed is |

for a sw itch |

pow er supply |

cause |

incorrect! |

inspection! |

turned ON? |

of the error? |

Operating time |

Contact operation |

I/ O pow er status |

Comm unication error |

monitor |

counter (See note.) |

monitor |

history mon itor |

Note: The contact operation counter function and the unit conduction time monitor function cannot be used simultaneously.

2 |

3 |

Loading...

Loading...