Omron NT2S-SF121B-E, NT2S-SF122B-E QUICK START

NT2S-SF121B-E

&

NT2S-SF122B-E

QUICK START GUIDE - V1.03

Version 1.03 |

|

Page 1 |

|

NT2ST QUICK START GUIDE |

|

1. |

INTRODUCTION ............................................................................................................................................ |

3 |

2. |

NT2S OPERATION OVERVIEW ................................................................................................................... |

3 |

3. |

NT2ST SOFTWARE OVERVIEW .................................................................................................................. |

4 |

4. |

ADD/REMOVE DRIVERS .............................................................................................................................. |

5 |

5. |

CREATE NEW PROJECT ............................................................................................................................... |

6 |

6. |

PROJECT SETUP............................................................................................................................................. |

7 |

7. |

TAG DATABASE ............................................................................................................................................ |

8 |

8. |

EDIT – SCREENS .......................................................................................................................................... |

10 |

9. |

NORMAL SCREEN ....................................................................................................................................... |

11 |

10. |

LINK SCREEN............................................................................................................................................... |

15 |

11. |

SPECIAL SCREEN ........................................................................................................................................ |

16 |

12. |

FUNCTION SCREEN .................................................................................................................................... |

18 |

13. |

SPECIAL PROGRAMMING NOTES ........................................................................................................... |

20 |

STR Control from a Function Key ...................................................................................................................... |

20 |

|

STR Control from the PLC.................................................................................................................................. |

20 |

|

Function Key Control Definitions....................................................................................................................... |

20 |

|

Entering Text on Second Line of Display............................................................................................................ |

21 |

|

14. |

COMMUNICATION CABLES SPECIFICATIONS ..................................................................................... |

22 |

Omron Cables .................................................................................................................................................... |

22 |

|

Allen-Bradley Cables .......................................................................................................................................... |

24 |

|

GE Micro Cables ................................................................................................................................................ |

25 |

|

Modicon Cables .................................................................................................................................................. |

26 |

|

Keyence Cables................................................................................................................................................... |

27 |

|

Toshiba Cables.................................................................................................................................................... |

28 |

|

Koyo Cables ........................................................................................................................................................ |

29 |

|

15. |

NT2S SPECIFICATIONS .............................................................................................................................. |

30 |

Version 1.03 |

|

Page 2 |

1. INTRODUCTION

NT2ST is used with NT2S-SF121B-E and NT2S-SF122B-E products. These products are compact but highly functional operator interfaces and NT2ST is designed to be extremely flexible to take advantage of this functionality.

The bright LED back light and 2 x 16 character screen provide a highly visible display for showing fixed or scrolling text messages, bit controlled text, and numerical data.

Special screen types exist for simplifying data entry. Navigation can be achieved using programmed function keys, configuring a LINK screen, or chaining message screens that change on a timer. Six function keys provide many options for operator control and data entry. Function keys can be programmed locally for each screen, or globally for the project, to perform tasks which include momentary, set on, set off, and toggle bit control, as well as numerous numeric value control tasks.

The Windows based program, NT2ST, provides many tools to achieve flexible solutions. Follow this quick start guide to gain an overall understanding of the layout of this software tool.

This document assumes the user is familiar with the operation of programs within Windows and basic PLC concepts. Consult a technical resource for answers to basic PLC questions.

2. NT2S OPERATION OVERVIEW

The screens displayed on the NT2S are stored in the program memory of the unit. The NT2S displays the screen number currently stored in the Screen Trigger Register (STR), which is a PLC memory location. The NT2S remembers the last three STR values and will display them in order when the current screen is finished displaying.

Numeric data is displayed by placing fields on a screen that reference PLC memory locations. Up to six numeric fields can be placed on a single screen. Bit status can be displayed on the screen using bit controlled text.

Navigation from screen to screen can be handled in several ways:

•Function keys can be programmed to change the STR. F1 can increment the STR by one, and F2 can decrement the STR by 1. Function keys can also change the STR to a specified number.

•Link screens can be created to navigate a series of screens specified by the user. A link screen is a parent screen which displays a series of child screens. Link screens save programming time because it automatically defaults to F1 being a NEXT key, and F2 being a PREV key. Programmer does not have to set these functions up on each screen. Call the link screen number in the STR to activate the link screen.

•Chained screens can be used to automatically cycle through a list of screens. When creating a screen, specify to what screen number it is linked. During operation, the NT2S will continue to change screens at the rate specified in the MIN TIME field of each screen. The screens will loop until a STR number is called for a screen not in the chain.

Version 1.03 |

|

Page 3 |

3. NT2ST SOFTWARE OVERVIEW

It is recommended that programming steps be performed by accessing the Windows menu items at the top of the program window. Deactivate the Tool Station (the Desktop cartoon image) by selecting Options menu, Tool Station. The tool station should disappear.

Select Help at any point within NT2ST to view context sensitive help information. The help document will provide a more thorough explanation than this document will for most functions.

The sections below are roughly in the order in which a project will be created.

Version 1.03 |

|

Page 4 |

4. ADD/REMOVE DRIVERS

Before beginning the first project, select Project and Add/Remove Drivers. This menu item is not available once a project has been created.

A dialog will appear that allows additional PLC models to be added to the PLC selection menu. Make sure that the PLC needed for the project is included in the list on the right.

Select OK to complete addition of drivers to the project.

Version 1.03 |

|

Page 5 |

5. CREATE NEW PROJECT

1.Select New from the Project menu.

2.In the dialog presented, select the PLC and PLC Model from the New project dialog and select OK.

The PLC model can be changed at any time during the project. From the Project menu, select, PLC Model, and select a new PLC model from the list. Accept the change by clicking on OK. Care must be taken to verify that the tag addresses are valid for the new PLC model.

(If the brand of PLC required for the project does not appear, refer to the ADD/REMOVE DRIVERS section above.)

3.Select the NT2S hardware model that will be used for this project. Choose either NT2S- SF121B-E or NT2S-SF122B-E and click the CLOSE button.

(If the incorrect NT2S model is selected, the project can be converted at anytime using the file conversion utility located on the Project menu, and select Model type. Just open the project and select this menu item and select OK.)

Version 1.03 |

|

Page 6 |

6. PROJECT SETUP

The Setup dialog is used to configure the NT2S operation parameters. Specify the LED register, screen trigger register, power up screen, serial port settings, function key password, and real time clock download time. The project setup dialog is accessed from the Edit menu, Setup menu item.

Generally, there is no need to change the default settings. The only parameters that need to be set by the user are Power up screen number and the function key password settings.

LED Register – This setting tells the NT2S which TAG to reference for the LED Register. Any TAG of the proper type can be referenced for this setting. The default TAG is labeled “LED Register”.

STR – This setting tells the NT2S which TAG to reference for the Screen Trigger Register. Any TAG of the proper type can be referenced for this setting. The default TAG is labeled “Screen Trigger Reg”.

Power Up Screen – Enter the screen number for the screen that should appear at system start-up. This screen number is only referenced internally from the NT2S and is not written down to the STR in the PLC.

Serial Port settings: Set the serial port parameters for serial printer connection. The communication is Serial RS232, Selectable 7 or 8 bit, Odd, Even or No Parity, No handshake, 300, 600, 1200, 2400, 4800, 9600 or 19200 Baud.

NOTE: Serial Communications specifications apply to the Unit - printer setup and do not affect PC to Unit communications.

Function Key Password – This password will be applied to any function key that has the password activated. The password will be used throughout the project.

RTC Download Time (NT2S-SF121B-E only) – Enter the time interval for downloading the RTC tags to the PLC here. The values range from 0 to 600 ( seconds ). 0 means the values will be downloaded as fast as possible. Any other interval will mean that NT2S will wait for the specific time interval before downloading the value into the PLC.

Version 1.03 |

|

Page 7 |

7. TAG DATABASE

Once the project has been created, the very first step should be to define the TAG DATABASE. The tag database is a list of names (tags) that reference PLC registers or coils (bits). When programming screens, reference is made to this tag database. Users can choose to reference the tags either by name or PLC address.

Tags will be referenced while creating the NT2S screens are created. Tags can always be edited or modified later in the project.

New projects are created a set of default TAGS. For instance, NT2S-SF122B-E has the following tags:

0001 |

LED Register |

|DM00001| |

0002 |

Screen Trigger Reg |

|DM00000| |

NT2S-SF121B-E projects are created with 8 tags. Tags 0003 through 0008 are associated with the RTC and cannot be directly addressed in NT2ST. Their addresses are offset from the LED Register address. The tags are defined as follows:

0001 |

LED Register |

|DM00001| |

|

|

0002 |

Screen Trigger Reg |

|DM00000| |

|

|

0003 |

Date |

LED Register + 2 (Lower byte) ---- |

Date (DD) |

|

0004 |

Month |

LED Register + 3 (Higher byte) ---- |

Month (MO) |

|

0005 |

Year |

LED Register + 3 |

(Lower byte) ---- |

Year (YY) |

0006 |

Hours |

LED Register + 1 |

(Higher byte) ---- |

Hours (HH) |

0007 |

Minutes |

LED Register + 1 |

(Lower byte) ---- |

Minutes (MI) |

0008 |

Seconds |

LED Register + 2 |

(Higher byte) ---- |

Minutes (MI) |

Version 1.03 |

|

Page 8 |

CREATE A REGISTER

A tag can reference an entire word in PLC memory, called a register. Use the following steps to create a tag for a register:

1.Select Tag Database from the Edit menu.

2.From the Tag Database editor dialog (shown above), choose NEW.

3.Select the Register button.

4.Choose the PLC memory location from the provided list box.

5.Select the specific register number in the address box provided.

6.Enter a tag name in the lower text box.

7.Select ADD button to complete the creation of the register tag.

CREATE A COIL

A tag can reference a bit in PLC memory, called a coil. Use the following steps to create a tag for a coil:

1.Select Tag Database from the Edit menu.

2.From the Tag Database editor dialog, choose NEW.

3.Select the Coil button.

4.Choose the PLC memory location from the provided list box.

5.Select the specific register and bit number in the address box provided.

6.Enter a tag name in the lower text box.

7.Select ADD button to complete the creation of the coil tag.

Version 1.03 |

|

Page 9 |

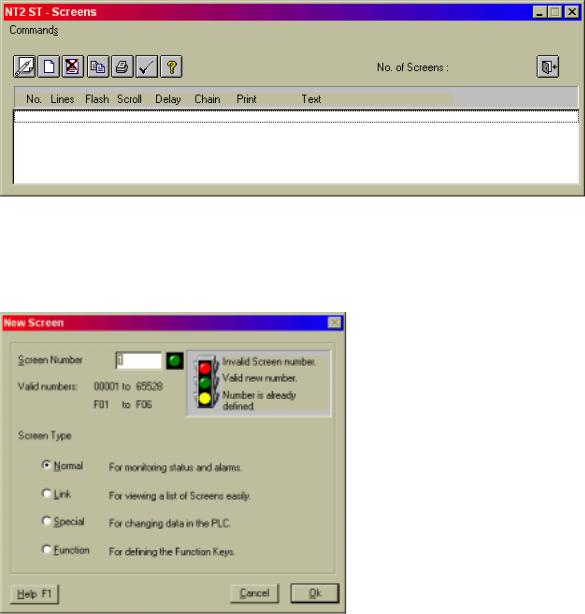

8. EDIT – SCREENS

Launch Screen Editor from EDIT menu. Select SCREENS menu item.

1.From the Edit menu, select the Screens item.

2.Click on the new screen button !  to launch the screen type selection dialog, New Screen.

to launch the screen type selection dialog, New Screen.

3.Four different types of screens can be selected from the New Screen dialog: Normal, Link, Special, and Function. The following sections will discuss each type of screen. Choose a screen type, enter a screen number, and select OK to launch the Editing Screen dialog.

Version 1.03 |

|

Page 10 |

Loading...

Loading...