Mitsubishi MSC-C07SV, MUH-C07SV, MSC-C09SV, MUH-C09SV, MSC-C12SV SERVICE MANUAL

...

Revision

•Set temperature change of Operating Temperature of Defrosting in MUH-C09SV- E1 .

•Change of refrigeration oil amount of MUH-C07/C09SV- E1 .

• Installed place change of defrost thermistor RT61 in

MUH-C07/C09/C12SV- E1 .

• Please void OB250.

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

|

HFC |

No. OB250 |

|

REVISED EDITION-A |

|

SERVICE MANUAL |

utilized |

|

R-407C |

|

|

|

|

Wireless type

Models

MSC-C07SV MSC-C09SV MSC-C12SV MSH-C18SV

-

-

-

-

E1 (WH)

E1 (WH)

E1 (WH)

E1 (WH)

·MUH-C07SV - E1

·MUH-C09SV - E1

·MUH-C12SV - E1

·MUH-C18SV - E1

CONTENTS

MSC-C07SV - E1 MSC-C09SV - E1 MSC-C12SV - E1

1.TECHNICAL CHANGES ···································2

2.SPECIFICATION················································5

3.NOISE CRITERIA CURVES ······························7

4.WIRING DIAGRAM ···········································8

5.REFRIGERANT SYSTEM DIAGRAM ·············10

6.PERFORMANCE CURVES ·····························11

7.SERVICE FUNCTIONS ···································23

8.TROUBLESHOOTING ····································23

9.PARTS LIST ····················································24

NOTE: This service Manual covers only change points.

•MSC-07/09/12RV - E1 , MUH-07/09/12RV - E1 MSC-C07/C09/C12SV - E1 , MUH-C07/C09/C12SV - E1 Please refer to the Service Manual OB227 REVISED EDITION-B for unchanged contents.

•MSH-18NV - E4 , MUH-18NV - E4 MSH-C18SV - E1 , MUH-C18SV - E1

Please refer to the Service Manual OB229 REVISED EDITION-A for unchanged contents.

1

TECHNICAL CHANGES

TECHNICAL CHANGES

The following are in common details.

1.Refrigerant type has changed from R-22(HCFC) to R-407C(HFC).

2.Rated voltage has changed from 220-240V to 220-230V.

3.Compressor has changed from one for R-22 to one for R-407C.

4.Jumper wire JPE for defrosting temperature change in deicer P.C.board is cut at factory shipping.

5.Refrigerant circuit has changed. (Accumulator has been removed.)

MSH-18NV - E4 MSH-C18SV - E1

1. It has become impossible that MSH-C18SV- E1 is connected to MXZ series as multi system units.

MUH-07RV - E1 MUH-C07SV - E1

1.Path of heat exchanger has changed.

2.Operating Temperature of Defrosting has changed.

Starting of defrost |

: -3: or less 0: or less |

Releasing of defrost |

: 3.1: or more 10.1: or more |

3. Refrigerant oil has changed from MS56 to NEO22.

MUH-09RV - E1 MUH-C09SV - E1

1.Path of heat exchanger has changed.

2.Operating Temperature of Defrosting has changed.

Starting of defrost |

: -3: or less 4.3: or less |

Releasing of defrost |

: 3.1: or more 14.7: or more |

3. Refrigerant oil has changed from MS56 to NEO22.

MUH-12RV - E1 MUH-C12SV - E1

1.Capillary tube has changed. {3.0X{1.8X300 {3.0X{1.8X250, {3.0X{1.6X700 {3.0X{1.6X800)

2.Operating temperature of High Pressure Protection has changed.

|

Outdoor fan motor ON : 48: 56: |

|

|

Outdoor fan motor OFF: 52: 60: |

|

3. |

Operating temperature of Defrosting has changed. |

|

|

Starting of defrost |

: -3: or less 0: or less |

|

Releasing of defrost |

: 3.1: or more 10.1: or more |

4. |

Refrigerant oil has changed from MS56 to NEO22. |

|

MUH-18NV - E4 MUH-C18SV - E1

1. |

Operating temperature of High Pressure Protection has changed. |

|

|

Outdoor fan motor ON : 56: 52: |

|

|

Outdoor fan motor OFF: 60: 56: |

|

2. |

Operating temperature of Defrosting has changed. |

|

|

Starting of defrost |

: -3: or less 0: or less |

|

Releasing of defrost |

: 3.1: or more 10.1: or more |

3. |

Refrigerant oil has changed from MS32N1 to NEO22. |

|

2

INFORMATION FOR THE AIR CONDITIONER WITH R-407C REFRIGERANT

This room air conditioner adopts HFC refrigerant (R-407C) which is never destroy the ozone layer. Pay attention following points.

1Take sufficient care not to allow water and other contaminations to enter the R-407C refrigerant during storage and installation, since it is more susceptible to contaminations than HCFC refrigerant.

2Clean refrigerant pipings should be used.

3Composition change may occur in R-407C since it is a mixed refrigerant. When charging, charge liquid refrigerant to prevent composition change.

4Be especially careful when managing the tools.

If dust, dirt, or water mixes in the refrigerant cycle, it may cause decrease of performance.

|

|

|

New refrigerant |

Previous refrigerant |

|

Refrigerant |

|

R-407C |

R-22 |

|

Composition (Ratio) |

|

R-32: R-125: R-134a (23%:25%:52%) |

R-22 (100%) |

|

Refrigerant handling |

|

Non-azeotropic refrigerant |

Single refrigerant |

|

Chlorine |

|

Not included |

Included |

Refrigerant |

Safety group (ASHRAE) |

|

A1/A1 |

A1 |

Saturated steam density [25:](Kg/K) |

42.5 |

44.4 |

||

|

Molecular weight |

|

86.2 |

86.5 |

|

Boiling point (:) |

|

-43.6 |

-40.8 |

|

Steam pressure [25:](Mpa [Gauge]) |

0.9177 |

0.94 |

|

|

|

|

|

|

|

Combustibility |

|

Non combustible |

Non combustible |

|

ODP w1 |

|

0 |

0.055 |

|

GWP w2 |

|

1530 |

1700 |

|

Refrigerant charge method |

|

From liquid phase in cylinder |

Gas phase |

|

Additional charge on leakage |

|

Impossible |

Possible |

Lubricant |

Kind |

|

Incompatible oil |

Compatible oil |

|

|

|||

|

Color |

|

Non |

Light yellow |

|

Smell |

|

Non |

Non |

w1 :Ozone Destruction Parameter |

: based on CFC-11 |

|

||

w2 :Global Warmth Parameter |

: based on CO2 |

|

||

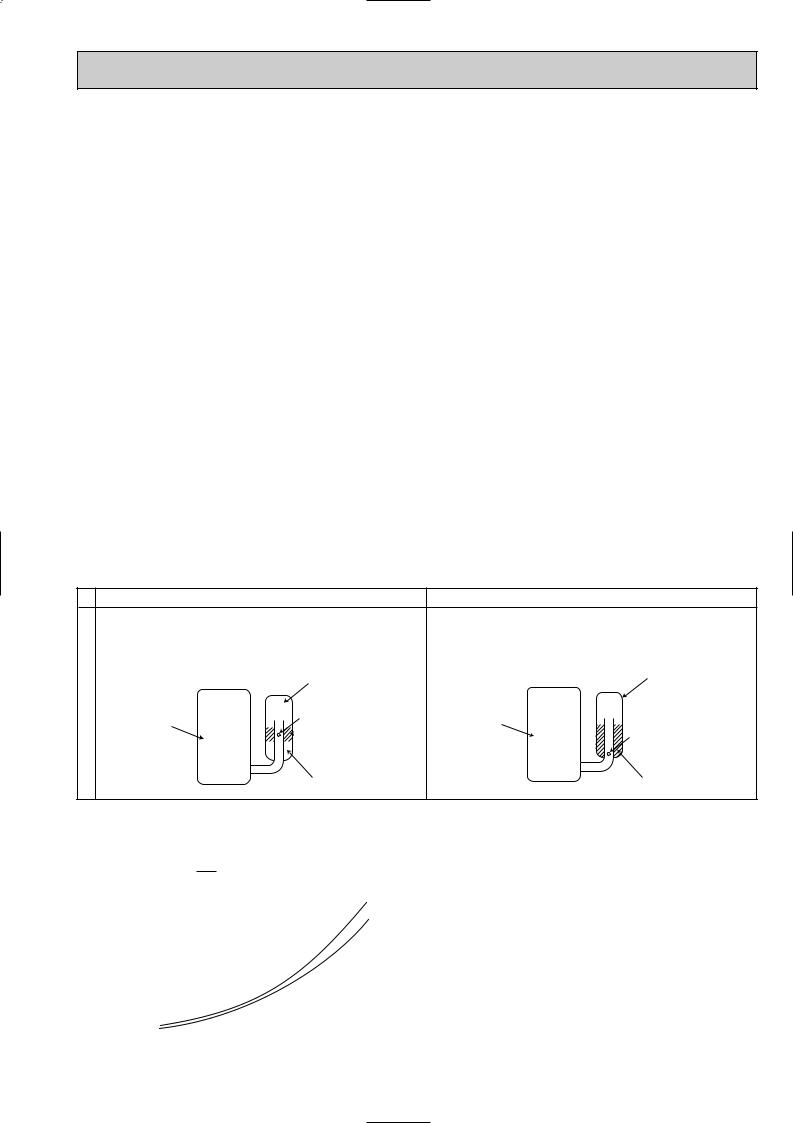

Compressor

|

New Specification |

Previous Specification |

|||||||||||||

The incompatible lubricant easily separates from refrigerant |

Since refrigerant and lubricant are compatible each other, |

||||||||||||||

and makes the layer in the upper inside the suction muffler. |

lubricant returns to the compressor through the lower |

||||||||||||||

The higher position of the returning oil hole enables to return |

position returning oil hole. |

||||||||||||||

the lubricant of the upper layer to the compressor. |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

Suction muffler |

|

|

|

|

|

|

Suction muffler |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

Returning oil hole |

|

|

|

|

|

|

|

|

Compressor |

|

|

|

|

|

|

Compressor |

|

|

||||||

|

|

|

|

|

|

|

|

Lubricant |

|

|

|

|

|

|

Returning oil hole |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||||||||

Refrigerant |

Lubricant and Refrigerant |

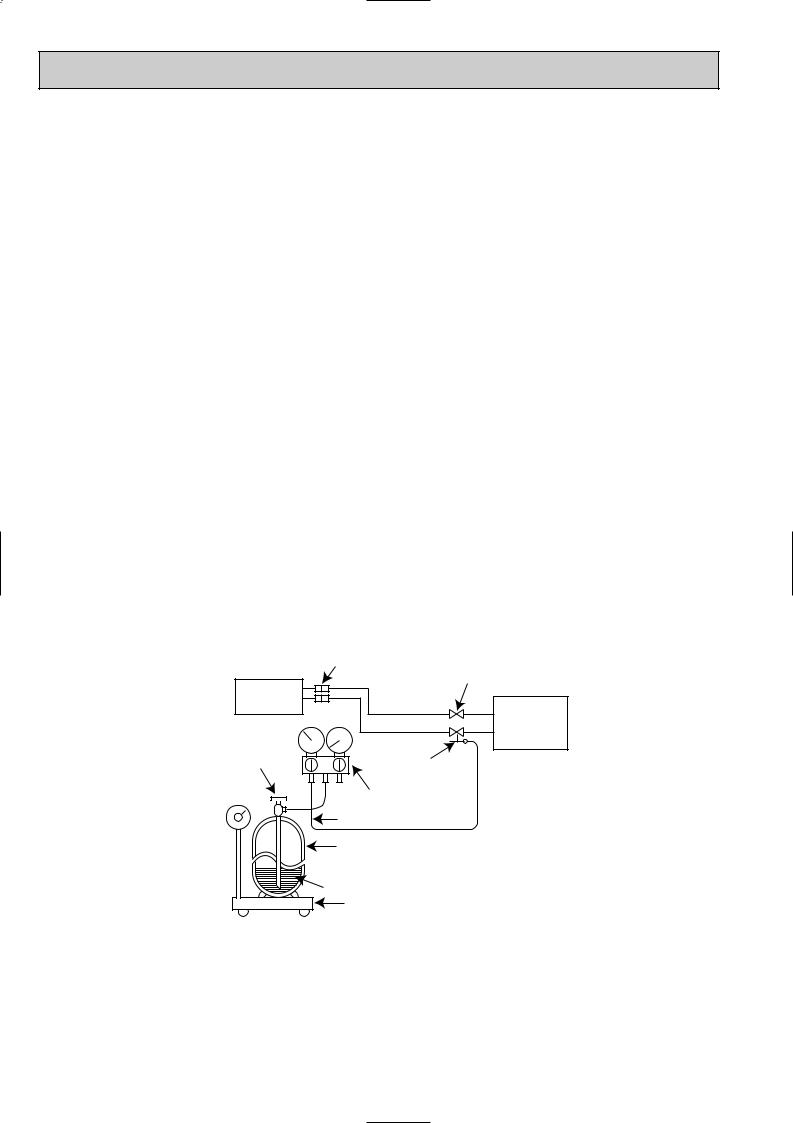

Conversion chart of refrigerant temperature and pressure

(MPa [Gauge])

|

4.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

pressure |

3.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R-407C |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

2.5 |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

liquid |

3.0 |

|

|

|

|

|

|

R-22 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

2.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE : The unit of pressure has been changed to MPa on the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Saturated |

1.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

international system of units(SI unit system). |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The conversion factor is: 1(MPa [Gauge]) =10.2(kgf/f [Gauge]) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

0.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-0.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-30 |

-20 -10 0 10 20 30 40 50 60 (:) |

||||||||||||||

3

1.Tools dedicated for the air conditioner with R-407C refrigerant

The following tools are required for R-407C refrigerant. Some R-22 tools can be substituted for R-407C tools. Do not use tools that are used with R-22 refrigerant in order to avoid mixing oils.

R-407C tools |

Can R-22 tools be used? |

|

Description |

||

Gauge manifold |

No |

A gauge manifold with a sight glass is recommended for charging the |

|||

liquid refregerant. |

|||||

|

|

||||

Charge hose |

No |

Hose material have been changed to improve the pressure |

|||

resistance. |

|||||

|

|

||||

Gas leak detector |

No |

Dedicated for HFC refrigerant. |

|||

|

|

|

|

|

|

Torque wrench |

Yes |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Flare tool |

Yes |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Vacuum pump |

New |

Provided to prevent the back flow of oil. This adapter enables you to use |

|||

adapter |

existing vacuum pumps. |

||||

|

|||||

Electronic scale for |

New |

It is difficult to measure R-407C with a charging cylinder because of |

|||

refrigerant charging |

refrigerant bubbles due to high pressure and high-speed vaporization. |

||||

|

|||||

|

|

|

|

|

|

2.Refrigerant piping

Do not use copper pipes which are broken, deformed or discoloured.

In addition, be sure that the inner surfaces of the pipes are clean, free of hazardous sulfur and oxides, or have no dust/ dirt, shaving particles, oil, moisture or any other contamination.

•If there is a large amount of residual oil inside the piping and joints, deterioration of the refrigerant oil will result.

3.Refrigerant oil

Apply the specific refrigeration oil (accessories) to the flare and the union seat surfaces.

4.Air purge

Use the vacuum pump for air purge to protect environments, and to avoid changing the composition of refrigerant.

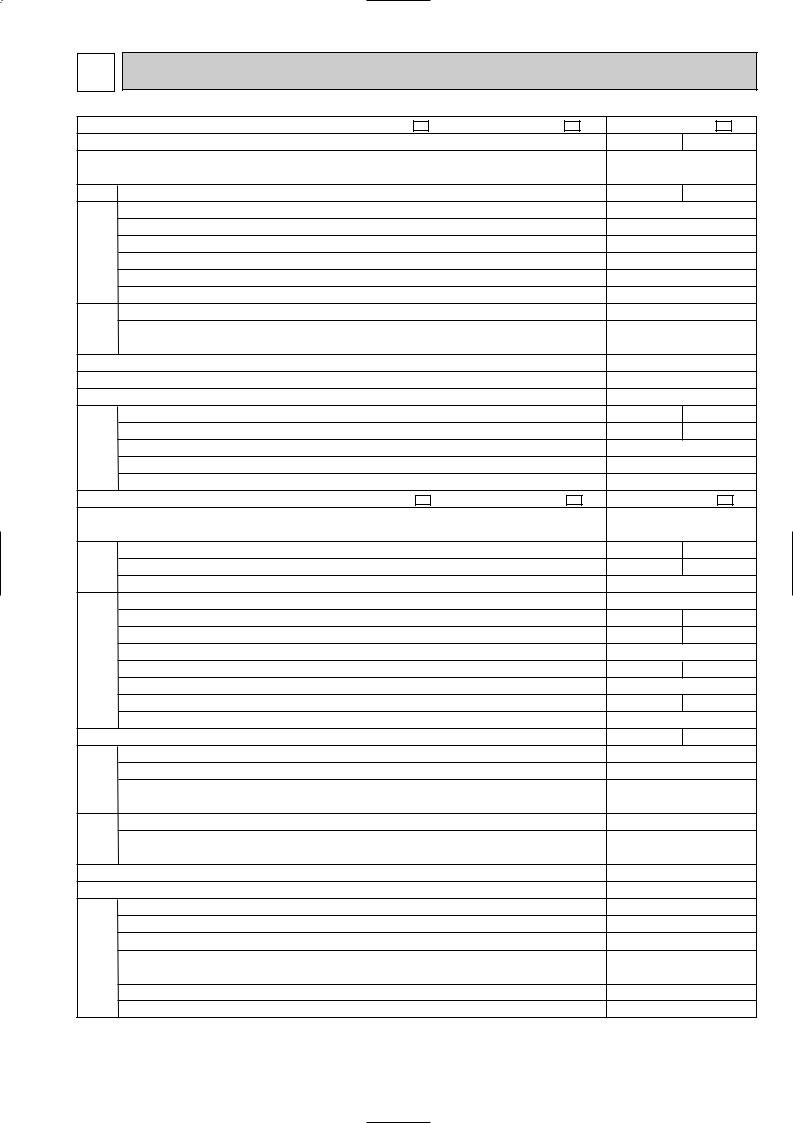

5.Additional charge

For additional charging, charge the refrigerant with liquid phase slowly using a gas cylinder. If the refrigerant is charged with gas phase, the composition of refrigerant will change.

If liquid refrigerant is rapidly charged at once, the compressor may be locked.

|

Union |

|

|

|

Stop valve |

Indoor unit |

Liquid pipe |

|

|

|

|

Refrigerant |

Gas pipe |

Outdoor unit |

|

|

|

gas cylinder |

|

|

operating |

Service port |

|

valve |

|

|

|

|

|

|

Gage manifold |

|

|

Charge hose |

|

|

Refrigerant gas cylinder |

|

|

for R-407C with siphon |

|

|

Refrigerant (liquid) |

|

|

Electronic scale for |

|

|

refrigerant charging |

|

4

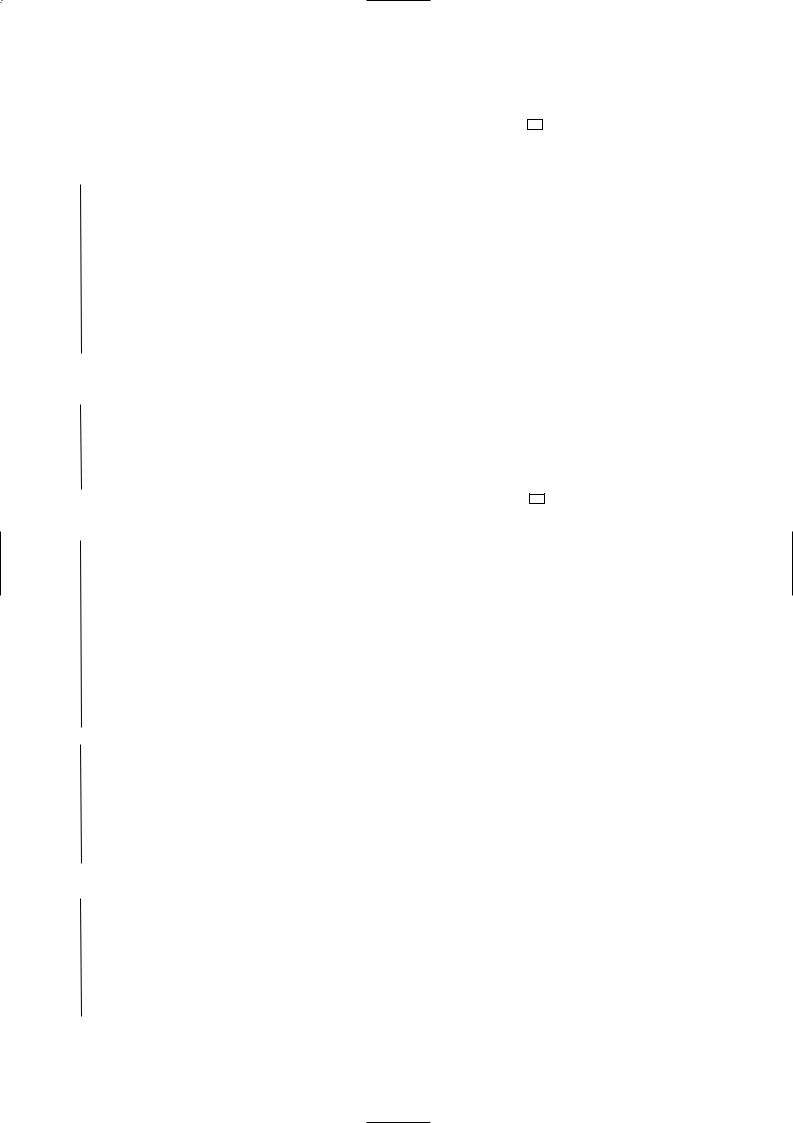

2 SPECIFICATION

|

Indoor model |

|

MSC-C07SV - E1 |

MSC-C09SV - E1 |

|||||

|

Function |

|

Cooling |

|

Heating |

Cooling |

|

Heating |

|

|

Indoor unit power supply |

|

Single phase |

Single phase |

|||||

|

|

220-230V,50Hz |

220-230V,50Hz |

||||||

|

|

|

|

||||||

Capacity |

Air flow(Hi) |

|

K /h |

474 |

|

504 |

474 |

|

504 |

|

Power outlet |

|

A |

10 |

|

|

10 |

||

Electrical data |

Running current |

|

A |

0.17 |

0.17 |

||||

Power factor |

|

% |

93.6-89.5 |

93.6-89.5 |

|||||

|

Power input |

|

W |

35 |

|

|

35 |

||

|

Starting current |

|

A |

— |

|

|

— |

||

|

Fan motor current |

|

A |

0.17 |

0.17 |

||||

Fan motor |

Model |

|

RC4V19-BA |

RC4V19-BA |

|||||

Winding |

|

" |

WHT-BLK 292 |

WHT-BLK 292 |

|||||

|

|

|

|||||||

|

resistance(at20:) |

|

|

BLK-RED 325 |

BLK-RED 325 |

||||

|

Dimensions WOHOD |

|

mm |

850O278O191 |

850O278O191 |

||||

|

Weight |

|

kg |

9 |

|

|

9 |

||

|

Air direction |

|

5 |

|

|

5 |

|||

|

Sound level (Hi) |

|

dB |

36 |

|

35 |

36 |

|

35 |

Special remarks |

Fan speed (Hi) |

|

rpm |

950 |

|

1000 |

950 |

|

1000 |

Fan speed regulator |

|

3 |

|

|

3 |

||||

|

|

|

|

||||||

|

Thermistor RT11(at25:) |

|

k" |

10 |

|

|

10 |

||

|

Thermistor RT12(at25:) |

|

k" |

10 |

|

|

10 |

||

|

Outdoor model |

|

MUH-C07SV - E1 |

MUH-C09SV - E1 |

|||||

|

Outdoor unit power supply |

|

Single phase |

Single phase |

|||||

|

|

220-230V,50Hz |

220-230V,50Hz |

||||||

Capacity |

|

|

|

||||||

Outdoor air flow |

|

K /h |

1,620- |

1,668 |

1,620- |

1,668 |

|||

|

Capacity |

|

kW |

2.2 |

|

2.4 |

2.5 |

|

3.0 |

|

Dehumidification |

|

R/h |

0.8 |

|

— |

1.1 |

|

— |

|

Power outlet |

|

A |

10 |

|

|

10 |

||

|

Running current |

|

A |

3.27-3.17 |

2.95-2.89 |

|

4.05-3.96 |

||

|

Power input |

|

W |

715-725 |

|

645-655 |

935-955 |

|

885-905 |

Electrical data |

Auxiliary heater |

|

A(kW) |

— |

|

|

— |

||

Power factor |

|

% |

99.4-99.4 |

|

99.4-98.5 |

98.2-99.3 |

|

99.3-99.4 |

|

|

Starting current |

|

A |

18 |

|

|

22 |

||

|

Compressor motor current |

|

A |

2.99-2.88 |

2.67-2.60 |

4.05-3.89 |

3.77-3.67 |

||

|

Fan motor current |

|

A |

0.28-0.29 |

0.28-0.29 |

||||

|

|

|

|

|

|

|

|

|

|

Coefficient of performance(C.O.P) |

2.93-2.89 |

3.53-3.48 |

|

3.26-3.19 |

|||||

Compressor |

Model |

|

RE-135VGSHT |

RE-174VGSHT |

|||||

Output |

|

W |

650 |

|

800 |

||||

|

|

|

|||||||

|

Winding |

|

" |

C-R 4.21 |

C-R 3.31 |

||||

|

resistance(at20:) |

|

C-S 5.93 |

C-S 6.01 |

|||||

|

|

|

|||||||

Fan motor |

Model |

|

RA6V23-EA |

RA6V23-EA |

|||||

Winding |

|

" |

WHT-BLK 258 |

WHT-BLK 258 |

|||||

|

|

|

|||||||

|

resistance(at20:) |

|

|

BLK-RED 385 |

BLK-RED 385 |

||||

|

Dimensions WOHOD |

|

mm |

780o540o255 |

780o540o255 |

||||

|

Weight |

|

kg |

33 |

|

|

33 |

||

|

Sound level |

|

dB |

47 |

|

|

47 |

||

|

Fan speed |

|

rpm |

620-645 |

620-645 |

||||

Special remarks |

Fan speed regulator |

|

1 |

|

|

1 |

|||

Refrigerant filling |

|

kg |

0.85 |

0.80 |

|||||

|

|

|

|

|

|

|

|

|

|

|

capacity(R-407C) |

|

|

|

|

|

|

|

|

|

Refrigerating oil (Model) |

|

cc |

350 |

(NEO22) |

350 |

(NEO22) |

||

|

Thermistor RT61(at0:) |

|

k" |

33.18 |

33.18 |

||||

NOTE: Test conditions are based on ISO 5151 (Refrigerant piping length (one way): 5m)

Cooling : Indoor |

DB27°C / WB19°C |

Heating : Indoor |

DB20°C |

: Outdoor |

DB35°C / WB24°C |

: Outdoor |

DB 7°C / WB 6°C |

|

|

5 |

|

MSC-C12SV - E1

Cooling Heating

Single phase 220-230V,50Hz

588 642

10

0.19

40

95.7-91.5

—

0.19

RC4V19-BA

WHT-BLK 292

BLK-RED 325

850O278O191

10

5

39 |

39 |

1020 |

1100 |

3

10

10

MUH-C12SV - E1

Single phase 220-230V,50Hz

3.44.0

1.6 —

1,656-1,704

10

5.78-5.73 5.87-5.87

1220-1240 1240-1270

—

95.9-94.1 96.0-94.1

34

5.42-5.36 5.51-5.50

0.36-0.37

2.70-2.66 3.13-3.05

RE-231VHSHT

1100

C-R 2.26

C-S 4.07

RA6V33-CA

WHT-BLK 176

BLK-RED 413

780o540o255

38

49

700-720

1

1.20

620 (NEO22)

33.18

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indoor model |

|

|

MSH-C18SV - E1 |

||

|

Function |

|

Cooling |

|

Heating |

|

|

Indoor unit power supply |

|

|

Single phase |

||

|

|

|

220-230V,50Hz |

|||

|

|

|

|

|

||

Capacity |

Air flow(Hi) |

|

K /h |

|

756 |

|

|

Power outlet |

|

A |

|

15 |

|

Electrical data |

Running current |

|

A |

|

0.25 |

|

Power input |

|

W |

|

55 |

||

Power factor |

|

% |

|

100.0-95.7 |

||

|

Starting current |

|

A |

|

— |

|

|

Fan motor current |

|

A |

|

0.25 |

|

Fan motor |

Model |

|

|

RA4V27-EF |

||

Winding |

|

" |

|

WHT-BLK 184 |

||

resistance(at20:) |

|

|

BLK-RED 250 |

|||

|

|

|

|

|||

|

Dimensions WOHOD |

|

mm |

|

1,015O320O190 |

|

|

Weight |

|

kg |

|

14 |

|

|

Air direction |

|

|

5 |

||

|

Sound level (Hi) |

|

dB |

|

42 |

|

Special remarks |

Fan speed (Hi) |

|

rpm |

|

1,180 |

|

Fan speed regulator |

|

|

4 |

|||

Thermistor RT11(at25:) |

|

k" |

|

10 |

||

|

|

|

||||

|

Thermistor RT12(at25:) |

|

k" |

|

10 |

|

|

Outdoor model |

|

|

MUH-C18SV - E1 |

||

|

Outdoor unit power supply |

|

|

— |

||

|

|

|

|

|

|

|

Capacity |

Capacity |

|

kW |

5.1 |

|

5.4 |

Dehumidification |

|

R/h |

2.5 |

|

— |

|

Outdoor air flow |

|

K /h |

|

2,142-2,196 |

||

|

Power outlet |

|

A |

|

15 |

|

|

Running current |

|

A |

9.44-9.34 |

|

9.17-9.12 |

|

Power input |

|

W |

2,035-2,085 |

|

1,975-2,035 |

Electrical data |

Auxiliary heater |

|

A(kW) |

|

— |

|

Power factor |

|

% |

98.0-97.1 |

|

97.9-97.0 |

|

Starting current |

|

A |

|

55 |

||

|

|

|

||||

|

Compressor motor current |

|

A |

9.05-8.95 |

|

8.78-8.73 |

|

Fan motor current |

|

A |

|

0.39 |

|

Coefficient of performance(C.O.P) |

2.44-2.38 |

|

2.66-2.58 |

|||

Compressor |

Model |

|

|

PE-36VPEHT |

||

Output |

|

W |

|

1,600 |

||

Winding |

|

" |

|

C-R 1.06 |

||

resistance(at20:) |

|

|

C-S 2.03 |

|||

|

|

|

||||

|

|

|

|

|||

Fan motor |

Model |

|

|

RA6V50-OG |

||

Winding |

|

" |

|

WHT-BLK 116 |

||

resistance(at20:) |

|

|

BLK-RED 111 |

|||

|

|

|

|

|||

|

Dimensions WOHOD |

|

mm |

|

850o605o290 |

|

|

Weight |

|

kg |

|

54 |

|

|

Sound level |

|

dB |

|

52 |

|

|

Fan speed |

|

rpm |

|

810-828 |

|

Special remarks |

Fan speed regulator |

|

|

1 |

||

Refrigerant filling |

|

kg |

|

1.70 |

||

capacity(R-407C) |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Refrigerating oil (Model) |

|

cc |

|

1100 (NEO22) |

|

|

Thermistor RT61(at0:) |

|

k" |

|

33.18 |

|

NOTE: Test conditions are based on ISO 5151 (Refrigerant piping length (one way): 5m)

Cooling : Indoor |

DB27°C / WB19°C |

Heating : Indoor |

DB20°C |

: Outdoor |

DB35°C / WB24°C |

: Outdoor |

DB 7°C / WB 6°C |

6

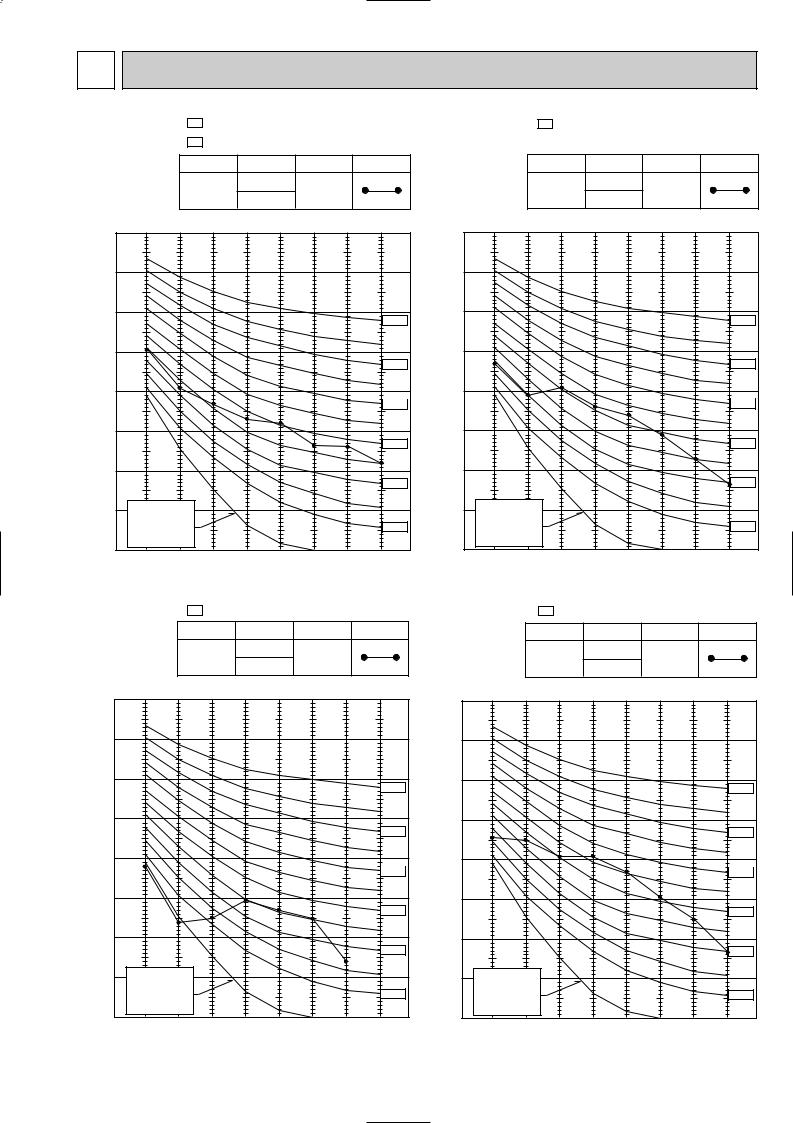

3 NOISE CRITERIA CURVES

MUH-C07SV - E1

MUH-C09SV - E1

NOTCH FUNCTION SPL(dB(A)) LINE

|

|

|

|

Hi |

COOLING |

47 |

|

|

|

|

|

|

|

HEATING |

|

|

|||

|

|

|

|

|

|

|

|

||

|

|

|

|

Test conditions, Cooling : DB 35: WB 24: |

|||||

|

90 |

|

|

|

|

Heating : DB 7: WB 6: |

|||

|

|

|

|

|

|

|

|

|

|

BAR |

|

|

|

|

|

|

|

|

|

MICRO |

80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.002 |

70 |

|

|

|

|

|

|

|

NC-70 |

|

|

|

|

|

|

|

|

||

dB re |

|

|

|

|

|

|

|

|

|

60 |

|

|

|

|

|

|

|

|

|

LEVEL, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NC-60 |

|

|

|

|

|

|

|

|

|

|

|

PRESSURE |

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NC-50 |

|

40 |

|

|

|

|

|

|

|

|

|

SOUND |

|

|

|

|

|

|

|

|

NC-40 |

30 |

|

|

|

|

|

|

|

|

|

BAND |

|

|

|

|

|

|

|

|

NC-30 |

|

APPROXIMATE |

|

|

|

|

|

|

||

OCTAVE |

20 |

|

|

|

|

|

|

||

THRESHOLD OF |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||

|

HEARING FOR |

|

|

|

|

|

NC-20 |

||

|

CONTINUOUS |

|

|

|

|

|

|

||

10 |

NOISE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

63 |

125 |

250 |

500 |

1000 |

2000 |

4000 |

8000 |

|

|

|

||||||||

BAND CENTER FREQUENCIES, Hz

MUH-C12SV - E1

NOTCH FUNCTION SPL(dB(A)) LINE

|

|

|

|

Hi |

COOLING |

49 |

|

|

|

|

|

|

|

HEATING |

|

|

|||

|

|

|

|

|

|

|

|

||

|

|

|

|

Test conditions, Cooling : DB 35: WB 24: |

|||||

|

90 |

|

|

|

|

Heating : DB 7: WB 6: |

|||

|

|

|

|

|

|

|

|

|

|

BAR |

|

|

|

|

|

|

|

|

|

MICRO |

80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.002 |

70 |

|

|

|

|

|

|

|

NC-70 |

|

|

|

|

|

|

|

|

||

dB re |

|

|

|

|

|

|

|

|

|

60 |

|

|

|

|

|

|

|

|

|

LEVEL, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NC-60 |

|

|

|

|

|

|

|

|

|

|

|

PRESSURE |

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NC-50 |

|

40 |

|

|

|

|

|

|

|

|

|

SOUND |

|

|

|

|

|

|

|

|

NC-40 |

30 |

|

|

|

|

|

|

|

|

|

BAND |

|

|

|

|

|

|

|

|

NC-30 |

|

APPROXIMATE |

|

|

|

|

|

|

||

OCTAVE |

20 |

|

|

|

|

|

|

||

THRESHOLD OF |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||

|

HEARING FOR |

|

|

|

|

|

NC-20 |

||

|

CONTINUOUS |

|

|

|

|

|

|

||

10 |

NOISE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

63 |

125 |

250 |

500 |

1000 |

2000 |

4000 |

8000 |

|

|

|

||||||||

BAND CENTER FREQUENCIES, Hz

MSH-C18SV - E1 |

MUH-C18SV - E1 |

NOTCH FUNCTION SPL(dB(A)) LINE

|

|

|

|

Hi |

COOLING |

42 |

|

|

|

|

|

|

|

|

|

HEATING |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

Test conditions, Cooling : DB 27: WB 19: |

|

|

|||||

|

90 |

|

|

|

|

Heating : DB 20: WB - : |

|

90 |

|||

|

|

|

|

|

|

|

|

|

|

||

BAR |

|

|

|

|

|

|

|

|

|

BAR |

|

MICRO |

80 |

|

|

|

|

|

|

|

|

MICRO |

80 |

|

|

|

|

|

|

|

|

|

|

||

0.002 |

70 |

|

|

|

|

|

|

|

NC-70 |

0.002 |

70 |

|

|

|

|

|

|

|

|

|

|||

dB re |

|

|

|

|

|

|

|

|

dB re |

|

|

60 |

|

|

|

|

|

|

|

|

60 |

||

LEVEL, |

|

|

|

|

|

|

|

|

LEVEL, |

||

|

|

|

|

|

|

|

|

NC-60 |

|

||

|

|

|

|

|

|

|

|

|

|

||

PRESSURE |

50 |

|

|

|

|

|

|

|

|

PRESSURE |

50 |

|

|

|

|

|

|

|

|

NC-50 |

|

||

40 |

|

|

|

|

|

|

|

|

40 |

||

SOUND |

|

|

|

|

|

|

|

|

NC-40 |

SOUND |

|

30 |

|

|

|

|

|

|

|

|

30 |

||

BAND |

|

|

|

|

|

|

|

|

NC-30 |

BAND |

|

|

APPROXIMATE |

|

|

|

|

|

|

|

|||

OCTAVE |

20 |

|

|

|

|

|

|

OCTAVE |

20 |

||

THRESHOLD OF |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||||

|

HEARING FOR |

|

|

|

|

|

NC-20 |

|

|||

|

CONTINUOUS |

|

|

|

|

|

|

|

|||

10 |

NOISE |

|

|

|

|

|

|

|

10 |

||

|

63 |

125 |

250 |

500 |

1000 |

2000 |

4000 |

8000 |

|

||

|

|

|

|

||||||||

NOTCH FUNCTION SPL(dB(A)) LINE

|

|

Hi |

COOLING |

45 |

|

|

|

|

|

HEATING |

|

|

|||

|

|

|

|

|

|

||

|

|

Test conditions, Cooling : DB 35: WB 24: |

|||||

|

|

|

|

Heating : DB 7: WB 6: |

|||

|

|

|

|

|

|

|

NC-70 |

|

|

|

|

|

|

|

NC-60 |

|

|

|

|

|

|

|

NC-50 |

|

|

|

|

|

|

|

NC-40 |

|

|

|

|

|

|

|

NC-30 |

APPROXIMATE |

|

|

|

|

|

|

|

THRESHOLD OF |

|

|

|

|

|

|

|

HEARING FOR |

|

|

|

|

|

NC-20 |

|

CONTINUOUS |

|

|

|

|

|

|

|

NOISE |

|

|

|

|

|

|

|

63 |

125 |

250 |

500 |

1000 |

2000 |

4000 |

8000 |

BAND CENTER FREQUENCIES, Hz |

BAND CENTER FREQUENCIES, Hz |

7

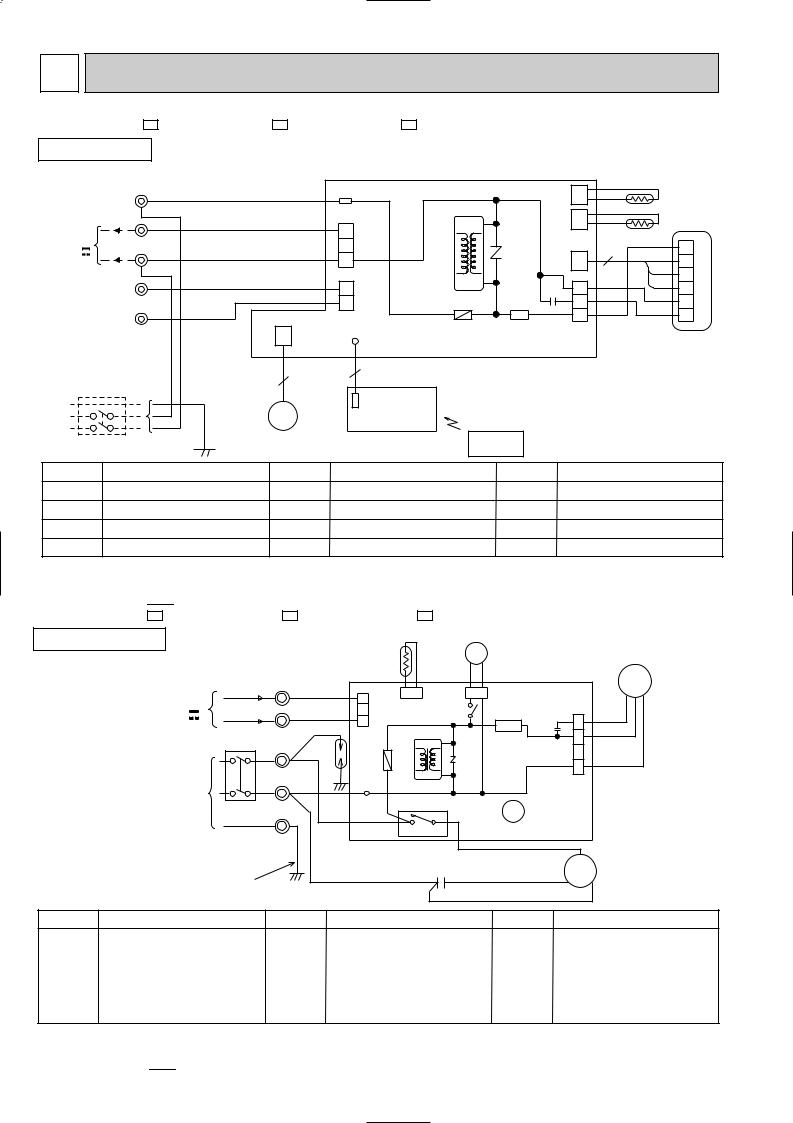

4 WIRING DIAGRAM

MSC-C07SV - E1 MSC-C09SV - E1 MSC-C12SV - E1 |

MODELS WIRING DIAGRAM |

INDOOR UNIT

TO OUTDOOR |

TB |

|

||

UNIT |

|

BRN |

||

CONNECTING |

L |

|||

BRN |

|

|||

|

|

|

||

|

|

3 |

RED |

|

12V |

|

N |

BLU |

|

|

|

BLU |

|

|

|

|

2 |

WHT |

|

|

|

1 |

BLK |

|

POWER |

|

|

||

SUPPLY |

|

|

||

CORD |

|

|

||

~/N 220-230V |

|

|||

50Hz |

|

|

|

|

PE |

|

|

GRN/YLW |

|

CIRCUIT BREAKER |

||||

|

||||

SYMBOL |

|

NAME |

||

C11 |

INDOOR FAN CAPACITOR |

|||

F11 |

FUSE(3.15A) |

|

||

HIC1 |

DC/DC CONVERTER |

|||

MF |

INDOOR FAN MOTOR(INNER FUSE) |

|||

|

TAB12 |

|

|

CN |

|

RT12 |

|

|

|

|

|

|

112 |

|

|

|

|

|

CN201 |

HIC1 |

CN |

|

RT11 |

|

||

|

|

|

111 |

|

|

|||

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

NR11 |

|

3 |

BLK |

1 |

|

|

|

CN |

GRY |

|

||||

|

1 |

|

2 |

|

||||

|

|

|

121 |

|

YLW |

|

||

|

CN202 |

|

|

|

3 |

|

||

|

|

|

|

|

MF |

|||

|

TRANS |

1 |

|

BRN |

||||

|

2 |

|

C11 |

|

WHT |

4 |

|

|

|

1 |

F11 |

SR141 |

2 |

|

5 |

|

|

|

|

|

|

3 |

|

RED |

6 |

|

|

|

|

|

|

|

|

||

CN |

LD101T |

|

CN211 |

|

|

|

|

|

151 |

ELECTRONIC CONTROL P.C. BOARD |

|

|

|

|

|

||

|

|

|

|

|

|

|||

5 |

5 |

|

|

|

|

|

|

|

POWER MONITOR, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MV |

RECEIVER |

|

|

|

|

|

|

|

P.C.BOARD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

REMOTE |

|

|

|

|

|

|

|

|

CONTROLLER |

|

|

|

|

|

SYMBOL |

NAME |

|

SYMBOL |

|

|

NAME |

|

|

MV |

VANE MOTOR |

SR141 |

SOLID STATE RELAY |

NR11 |

VARISTOR |

TB |

TERMINAL BLOCK |

RT11 |

ROOM TEMPERATURE THERMISTOR |

|

|

RT12 |

INDOOR COIL THERMISTOR |

|

|

NOTE:1. About the outdoor side electric wiring refer to the outdoor unit electric wiring diagram for servicing.

2.Use copper conductors only. (For field wiring)

3.Symbols below indicate.

/: Terminal block,

: Connector

: Connector

MUH-C07SV - E1 MUH-C09SV - E1 MUH-C12SV - E1 MODELS WIRING DIAGRAM

OUTDOOR UNIT

|

|

|

|

|

|

RT61 |

|

21S4 |

|

|

|

|

|

FROM |

|

|

|

|

|

BLK BLK |

|

|

|

||

|

TB2 |

|

|

|

|

|

|

|

MF |

|||

|

INDOOR UNIT |

|

|

|

|

|

|

|

||||

|

RED |

|

|

CN661 |

|

CN721 |

|

|

||||

|

CONNECTING |

3 |

|

1 |

CN730 |

|

|

|

|

|||

|

|

|

|

|

X62 |

|

|

|

||||

|

12V |

N |

|

BLK |

2 |

|

C65 |

|

RED |

|||

|

|

3 |

|

|

SR61 |

1 |

||||||

|

|

|

|

BRN |

|

|

WHT |

|||||

|

CIRCUIT BREAKER |

|

|

|

|

|

|

2 |

||||

|

TB1 |

|

|

|

|

|

|

|

|

|||

|

BRN |

|

F61 |

IC881 |

|

NR61 |

|

3 |

|

|||

|

|

L |

|

|

|

|

|

|||||

POWER SUPPLY |

|

|

DSAR |

|

|

|

4 |

BLK |

||||

|

|

|

|

|

TRANS |

|

|

CN711 |

|

|||

N |

BLU |

|

|

|

|

|

|

|||||

~/N |

|

|

|

|

|

|

||||||

TAB20 |

52C |

|

|

|

|

|

||||||

220-230V |

|

|

|

|

X62 |

|

|

|

||||

50Hz |

PE |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

4 3 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

DEICER P.C. BOARD |

|

||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

WHT |

C |

|

|

|

|

|

|

|

|

C1 |

|

MC R |

|||

|

GRN/YLW |

|

|

|

BLU |

|

RED |

S |

||||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

SYMBOL |

NAME |

SYMBOL |

|

|

NAME |

|

SYMBOL |

|

NAME |

|||

C1 |

COMPRESSOR CAPACITOR |

MC |

COMPRESSOR(INNER PROTECTOR) |

TB1,TB2 |

TERMINAL BLOCK |

C65 |

OUTDOOR FAN CAPACITOR |

MF |

OUTDOOR FAN MOTOR(INNER PROTECTOR) |

X62 |

REVERSING VALVE COIL RELAY |

|

|

|

|

|

|

DSAR |

SURGE ABSORBER |

NR61 |

VARISTOR |

21S4 |

REVERSING VALVE COIL |

|

|

|

|

|

|

F61 |

FUSE(2A) |

RT61 |

DEFROST THERMISTOR |

52C |

CONTACTOR |

IC881 |

DC/DC CONVERTER |

SR61 |

SOLID STATE RELAY |

|

|

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing. 2.Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block,

: Connector

: Connector

8

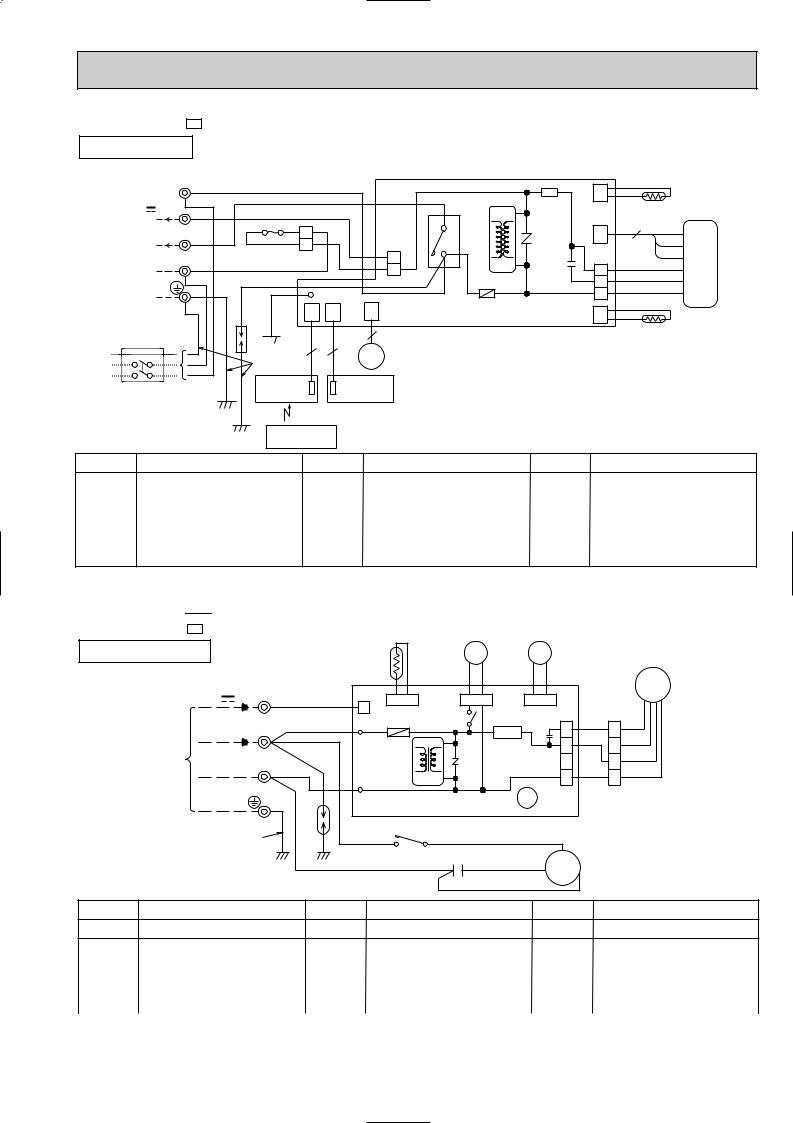

MSH-C18SV - E1 MODEL WIRING DIAGRAM

INDOOR UNIT

TO OUTDOOR |

L TB |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UNIT |

BRN |

|

|

|

|

|

|

|

|

|

|

CN |

|

RT12 |

|

CONNECTING |

BRN |

|

|

|

|

|

|

|

|

HIC1 |

IC141 |

112 |

|

||

12V |

|

|

|

|

|

|

|

|

|

|

|

||||

3 |

|

|

RED |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

F12 |

|

|

|

|

|

|

|

|

|

|

|

||

220-230V~ |

2 |

BLU |

2 |

|

|

|

|

4 |

|

NR11 |

CN |

3 |

BRN |

||

WHT |

|

BLU |

|

|

|

CN201 |

52C |

121 |

|

YLW |

|||||

|

|

|

|

1 |

|

|

|

3 |

|

|

|||||

|

|

|

|

|

|

|

|

|

3 |

|

|

|

CN211 |

|

GRY |

|

N |

BLU |

|

|

|

BLU |

|

TRANS |

C11 |

|

WHT MF |

||||

|

|

|

|

|

4 |

|

|||||||||

|

|

|

|

|

1 |

|

|

|

|||||||

|

BLU |

BRN |

|

|

|

|

|

|

F11 |

|

2 |

|

RED |

||

|

|

|

|

|

|

|

|

|

BLK |

||||||

POWER |

|

|

|

GRN/YLW |

LD1 |

|

|

|

|

|

|

1 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|||||

SUPPLY |

|

|

|

CN |

CN |

|

|

CN |

|

|

|

CN |

|

RT11 |

|

CORD |

|

|

|

101 |

102 |

|

|

151 ELECTRONIC CONTROL P.C BOARD |

111 |

|

|||||

~/N 220-230V |

|

|

DSAR |

|

|

|

|

5 |

|

|

|

|

|

|

|

50Hz |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

PE |

|

|

|

3 |

3 |

MV |

|

|

|

|

|

|

|||

|

|

GRN/YLW |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

CIRCUIT BREAKER |

|

|

RECEIVER |

|

DISPLAY |

|

|

|

|

|

|

||||

|

|

P.C.BOARD |

|

P.C.BOARD |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

REMOTE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONTROLLER |

|

|

|

|

|

|

|

|

|

||

SYMBOL |

|

NAME |

|

|

SYMBOL |

|

|

NAME |

SYMBOL |

|

|

NAME |

|||

C11 |

INDOOR FAN CAPACITOR |

IC141 |

HYBRID IC |

RT12 |

INDOOR COIL THERMISTOR |

DSAR |

SURGE ABSORBER |

MF |

INDOOR FAN MOTOR(INNER FUSE) |

TB |

TERMINAL BLOCK |

F11 |

FUSE(3.15A) |

MV |

VANE MOTOR |

52C |

CONTACTOR |

F12 |

THERMAL FUSE(93:) |

NR11 |

VARISTOR |

|

|

HIC1 |

DC/DC CONVERTER |

RT11 |

ROOM TEMPERATURE THERMISTOR |

|

|

NOTE:1. About the outdoor side electric wiring refer to the outdoor unit electric wiring diagram for servicing.

2.Use copper conductors only. (For field wiring)

3.Symbols below indicate.

/: Terminal block,  : Connector

: Connector

MUH-C18SV - E1 |

MODEL WIRING DIAGRAM |

|

|

|

|

|

|

|

|||||||

OUTDOOR UNIT |

|

|

|

|

RT61 |

|

21S4 |

52C |

|

|

|

||||

|

|

|

|

|

|

|

|

BLK |

BLK |

VLT |

VLT |

|

|

|

|

|

|

|

TB |

|

|

|

|

|

|

|

MF |

||||

|

|

|

|

|

|

CN730 CN661 |

|

|

|

|

|

|

|||

|

|

12V |

3 |

|

RED |

|

CN721 |

CN720 |

|

|

|||||

|

|

|

|

|

|

|

1 |

|

X62 |

|

|

|

|

|

|

|

|

|

|

|

WHT |

|

F61 |

|

|

|

C65 |

1 |

RED |

1 RED |

|

|

FROM INDOORUNIT CONNECTING |

220-230V~ 2 |

|

|

|

|

|

|

SR61 |

||||||

|

|

|

|

TAB21 |

|

|

|

2 |

WHT |

2 ORN |

|||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

N |

WHT |

|

IC881 |

|

|

|

|

|

3 |

|

3 WHT |

||

|

|

BLU |

|

TRANS |

|

|

|

4 |

BLK |

4 BLK |

|||||

|

|

|

|

|

|

|

NR61 |

|

X62 CN711 |

|

|

||||

|

|

|

|

|

|

|

TAB20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

DSAR |

|

DEICER P.C.BOARD |

|

|

|

|

||||

|

|

GRN/YLW |

|

WHT NO 52C |

COM |

|

WHT |

|

C |

|

|

||||

|

|

|

|

|

|

|

|

|

C1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

BLU |

|

RED |

|

MC |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

S |

R |

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

SYMBOL |

|

NAME |

|

SYMBOL |

|

NAME |

|

|

SYMBOL |

NAME |

|||||

C1 |

COMPRESSOR CAPACITOR |

MC |

COMPRESSOR(INNER PROTECTOR) |

|

TB |

TERMINAL BLOCK |

|||||||||

C65 |

OUTDOOR FAN CAPACITOR |

MF |

OUTDOOR FAN MOTOR(INNER PROTECTOR) |

X62 |

REVERSING VALVE COIL RELAY |

|||||

DSAR |

SURGE ABSORBER |

NR61 |

VARISTOR |

21S4 |

REVERSING VALVE COIL |

|||||

|

|

|

|

|

|

|

|

|

|

|

F61 |

FUSE(2A) |

|

RT61 |

DEFROST THERMISTOR |

52C |

CONTACTOR |

||||

|

|

|

|

|

|

|

|

|

|

|

IC881 |

DC/DC CONVERTER |

SR61 |

SOLID STATE RELAY |

|

|

|||||

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing. |

|

|

||||||||

2.Use copper conductors only. (For field wiring) |

|

|

|

|

||||||

3. Symbols below indicate. |

|

|

|

|

||||||

/: Terminal block, |

|

|

|

|

: Connector |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

9

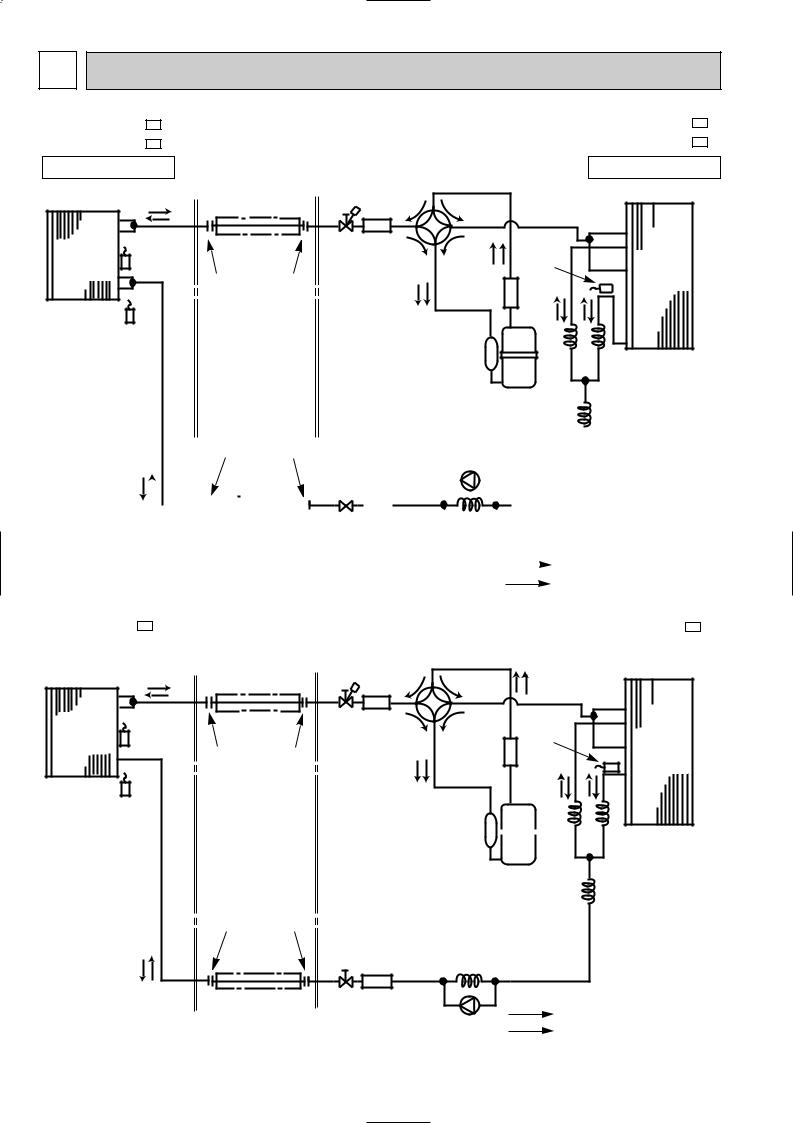

5 |

REFRIGERANT SYSTEM DIAGRAM |

|

|||||

|

|

|

|

|

|

Unit:mm |

|

MSC-C07SV - E1 |

|

|

|

MUH-C07SV - E1 |

|||

MSC-C09SV - E1 |

|

|

|

MUH-C09SV - E1 |

|||

INDOOR UNIT |

Refrigerant pipe [ 9.52 |

|

|

OUTDOOR UNIT |

|||

|

|

|

(Option) |

|

Reversing valve |

|

|

|

|

|

(with heat insulator) |

Muffler |

|

|

|

|

|

|

|

|

|

||

Indoor |

|

Indoor coil |

|

Stop valve |

Defrost |

Outdoor |

|

|

thermistor |

|

thermistor |

||||

heat |

|

|

(with service |

||||

exchanger |

RT12 |

|

RT61 |

heat |

|||

Flared connection |

port) |

||||||

|

|

|

Strainer |

exchanger |

|||

Room temperature |

|

|

|

|

|||

thermistor |

|

|

|

|

|

Capillary tube |

|

RT11 |

|

|

|

|

|

||

|

|

|

|

|

[3.0x[1.4x800 |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

(2 pcs) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Compressor |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Capillary tube |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[3.0x[1.6x600(MUH-C07SV) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

Flared connection |

|

|

|

|

|

|

|

|

[3.0x[1.6x400(MUH-C09SV) |

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check valve |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Strainer |

|

|

|

|

|

|

|

|

Reversing valve coil |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

heating ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stop valve |

Capillary tube |

cooling OFF |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[3.0x[1.4x600(MUH-C07SV) |

|

|||||||||||||

|

|

|

|

Refrigerant pipe [6.35 |

|

|

|

|

|

|

|

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

[3.0x[1.4x550(MUH-C09SV) |

|

|||||||||||||||||||||||||

|

|

|

|

(Option) |

|

|

|

|

|

|

|

|

|

|

|

Refrigerant flow in cooling |

||||||||||||||||||||

|

|

|

|

(with heat insulator) |

|

|

|

|

|

|

|

|

|

|

|

Refrigerant flow in heating |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unit:mm |

MSC-C12SV - E1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MUH-C12SV - E1 |

||

INDOOR UNIT |

Refrigerant pipe [12.7 |

|

|

|

|

|

|

Reversing valve |

OUTDOOR UNIT |

|||||||||||||||||||||||||||

|

|

|

(Option) |

|

|

|

|

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

(with heat insulator) |

Muffler |

|

|

|

|

|

|

|

|

|

|

Indoor |

Indoor coil |

|

Stop valve |

|

Defrost |

|

heat |

thermistor |

|

|

thermistor |

|

|

|

(with service port) |

|

Outdoor |

|||

exchanger |

RT12 |

|

Strainer |

RT61 |

||

Flared connection |

|

heat |

||||

|

|

|

|

|

||

|

|

|

|

|

|

exchanger |

Room temperature

thermistor

RT11  Capillary tube [3.0x[1.4x500(2pcs)

Capillary tube [3.0x[1.4x500(2pcs)

|

|

Compressor |

Capillary tube |

|

|

|

[3.0x[1.8x250 |

Flared connection |

|

|

|

|

|

Capillary tube |

Reversing valve coil |

|

Strainer |

[3.0x[1.6x800 |

|

|

heating ON |

||

|

|

||

|

|

|

|

|

|

|

cooling OFF |

|

Stop valve |

|

Refrigerant flow in cooling |

Refrigerant pipe [6.35 |

|

|

|

|

Check |

|

(Option) |

Refrigerant flow in heating |

|

valve |

||

(with heat insulator) |

||

|

||

|

10 |

Loading...

Loading...