Page 1

OPERATORS & SAFETY

Model

1932E2

2032E2

2632E2

2646E2

3246E2

3120854

June 25, 2004

CORPORATE OFFICE

JLG INDUSTRIES, INC.

1 JLG Drive

McConnellsburg, PA.

17233-9533

USA

Telephone: (717) 485-5161

Fax: (717) 485-6417

Page 2

JLG Industries (Australia)

P.O. Box 5119

11 Bolwarra Road

Port Macquarie

N.S.W. 2444

Australia

Phone: (61) 2 65 811111

Fax: (61) 2 65 810122

JLG Industries (UK)

Unit 12, Southside

Bredbury Park Industrial Estate

Bredbury

Stockport

SK6 2sP

England

Phone: (44) 870 200 7700

Fax: (44) 870 200 7711

JLG Deutschland GmbH

Max Planck Strasse 21

D-27721 Ritterhude/lhlpohl

Bei Bremen

Germany

Phone: (49) 421 693 500

Fax: (49) 421 693 5035

JLG Industries (Italia)

Via Po. 22

20010 Pregnana Milanese - MI

Italy

Phone: (39) 02 9359 5210

Fax: (39) 02 9359 5845

JLG Latino Americana Ltda.

Rua Eng. Carlos Stevenson,

80-Suite 71

13092-310 Campinas-SP

Brazil

Phone: (55) 19 3295 0407

Fax: (55) 19 3295 1025

JLG Industries (Europe)

Kilmartin Place,

Tannochside Park

Uddingston G71 5PH

Scotland

Phone: (44) 1 698 811005

Fax: (44) 1 698 811055

JLG Europe B.V.

Jupiterstraat 234

2132 HJ Foofddorp

The Netherlands

Phone: (31) 23 565 5665

Fax: (31) 23 557 2493

JLG Industries (Pty) Ltd.

Unit 1, 24 Industrial Complex

Herman Street

Meadowdale

Germiston

South Africa

Phone: (27) 11 453 1334

Fax: (27) 11 453 1342

JLG Industries (Norge AS)

Sofeimyrveien 12

N-1412 Sofienyr

Norway

Phone: (47) 6682 2000

Fax: (47) 6682 2001

Plataformas Elevadoras

JLG Iberica, S.L .

Trap a d e lla, 2

P. I . C a s t e l l b i s b a l S u r

08755Castellbisbal

Spain

Phone: (34) 93 77 24700

Fax: (34) 93 77 11762

JLG Polska

UI. Krolewska

00-060 Warsawa

Poland

Phone: (48) 91 4320 245

Fax: (48) 91 4358 200

JLG Industries (Sweden)

Enkopingsvagen 150

Box 704

SE - 175 27 Jarfalla

Sweden

Phone: (46) 8 506 59500

Fax: (46) 8 506 59534

Page 3

FOREWORD

FOREWORD

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions

and operating procedures essential for the safe and proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes

without prior notification. Contact JLG Industries, Inc. for updated information.

3120854 – JLG Lift – a

Page 4

FOREWORD

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

This is the Safety Alert Symbol. It is used to alert you to the

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death

INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF

NOT AVOIDED, WILL

THE MACHINE THIS WILL HAVE A RED BACKGROUND.

INDICATES A POTENTIALITY HAZARDOUS SITUATION WHICH, IF

NOT AVOIDED, COULD

ON THE MACHINE THIS WILL HAVE AN ORANGE BACKGROUND.

RESULT IN SERIOUS INJURY OR DEATH. ON

RESULT IN SERIOUS INJURY OR DEATH.

INDICATES A POTENTIALITY HAZARDOUS SITUATION WHICH IF

NOT AVOIDED, MAY

MAY ALSO BE USED TO ALERT AGAINST UNSAFE PRACTICES. ON

THE MACHINE THIS WILL HAVE A YELLOW BACKGROUND.

RESULT IN MINOR OR MODERATE INJURY. IT

IMPORTANT

INDICATES PROCEDURES ESSENTIAL FOR SAFE OPERATION AND

WHICH, IF NOT FOLLOWED, MAY RESULT IN A MACHINE MALFUNCTIONED DAMAGE. ON THE MACHINE THIS WILL HAVE A

GREEN BACKGROUND.

b – JLG Lift – 3120854

Page 5

FOREWORD

THIS PRODUCT MUST COMPLY WITH ALL SAFETY RELATED BULLETINS. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED JLG REPRESENTATIVE FOR INFORMATION REGARDING SAFETY-RELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR

THIS PRODUCT.

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM SHALL BE MADE ONLY WITH WRITTEN PERMISSION FROM THE

MANUFACTURER

IMPORTANT

JLG INDUSTRIES, INC. SENDS SAFETY RELATED BULLETINS TO THE OWNER OF RECORD OF THIS MACHINE. CONTACT JLG INDUSTRIES, INC. TO ENSURE THAT THE CURRENT OWNER RECORDS ARE UPDATED AND ACCURATE.

IMPORTANT

JLG INDUSTRIES, INC. MUST BE NOTIFIED IMMEDIATELY IN ALL INSTANCES WHERE JLG PRODUCTS HAVE BEEN INVOLVED IN AN

ACCIDENT INVOLVING BODILY INJURY OR DEATH OF PERSONNEL OR WHEN SUBSTANTIAL DAMAGE HAS OCCURRED TO PERSONAL

FOR :

•Accident Reporting

•Product Safety Publications

•Current Owner Updates

•Questions Regarding Product Safety

•Standards and Regulations Compliance Information

•Questions Regarding Special Product Applications

•Questions Regarding Product Modifications

CONTACT :

Product Safety and Reliability Department

JLG Industries, Inc.

1 JLG Drive

McConnellsburg, PA 17233

In USA:

Toll Free: 877-JLG-SAFE

877-554-7233

Outside USA:

717-485-5161

E-mail: ProductSafety@JLG.com

3120854 – JLG Lift – c

Page 6

FOREWORD

REVISION LOG

Original Issue - February, 1998

Revised - May, 1998

Revised - February, 1999

Revised - November 2, 1999

Revised - July 21, 2000

Revised - November 16, 2001

Revised - January 15, 2002

Revised - June 16, 2003

Revised - June 25, 2004

d – JLG Lift – 3120854

Page 7

TABLE OF CONTENTS

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION - FOREWORD

SECTION 1 - SAFETY PRECAUTIONS

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Pre-operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.4 Towing, Lifting, and Hauling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.5 Additional Hazards / Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.1 Personnel Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Preparation, Inspection, and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Personnel Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3 Operating Characteristics and Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.4 Controls and Indicators for Non Proportional Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.5 Controls and Indicators for Proportional Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

SECTION 4 - MACHINE OPERATION

4.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.3 Motor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.4 Raising and Lowering (Lifting) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.5 Platform Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.6 Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.7 Traveling (Driving) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.8 Parking and Stowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.9 Platform Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.10 Safety Prop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.11 Tie Down and Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

SECTION 5 - EMERGENCY PROCEDURES

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Emergency Towing Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.3 Emergency Controls and Their Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.4 Emergency Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.5 Incident Notification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

SECTION 6 - INSPECTION AND REPAIR LOG

3120854 – JLG Lift – i

Page 8

TABLE OF CONTENTS (Continued)

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

2-1. Daily Walk-Around Inspection - 2032E2/2632E2/2646E2/3246E2 (Sheet 1 of 2). . . . . . . . . . . . . .2-4

2-1. Daily Walk-Around Inspection - 2032E2/2632E2/2646E2/3246E2 (Sheet 2 of 2). . . . . . . . . . . . . .2-5

2-2. Daily Walk-Around Inspection - 1932E2 (Sheet 1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2-2. Daily Walk-Around Inspection - 1932E2 (Sheet 2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

3-1. Ground Control Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2. Platform Control Station - Non Proportional Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3-3. Platform Control Station - Proportional Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3-4. Decal Location (1932E2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3-5. Decal Location - 2032E2/2632E2/2646E2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3-6. Decal Location - 3246E2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

4-1. Grade and Sideslope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4-2. Lift and Tie Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4-3. Lifting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 Minimum Safe Approach Distances (M.S.A.D.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2-1 Inspection and Maintenance Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-2 Maximum Cutout Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

3-1 Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-2 Decal Location Legend - 1932E2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3-3 Decal Location Legend - 1932E2 (Continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3-4 Decal Location Legend - 2032E2/2632E2/2646E2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3-5 Decal Location Legend - 2032E2/2632E22646E2 (Continued) . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

3-6 Decal Location Legend - 3246E2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

3-7 Decal Location Legend - 3246E2 (Continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

4-1 Operating Specifications (CE and Australian) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4-2 High Drive Cutout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4-3 Platform Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

6-1 Inspection and Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

ii – JLG Lift – 3120854

Page 9

SECTION 1 - SAFETY PRECAUTIONS

SECTION 1. SAFETY PRECAUTIONS

1.1 GENERAL

This section outlines the necessary precautions for proper

and safe machine usage and maintenance. In order to

promote proper machine usage, it is mandatory that a

daily routine is established based on the content of this

manual. A maintenance program, using the information

provided in this manual and the Service and Maintenance

Manual, must also be established by a qualified person

and must be followed to ensure that the machine is safe to

operate.

The owner/user/operator/lessor/lessee of the machine

should not accept operating responsibility until this manual has been read, training is accomplished, and operation of the machine has been completed under the

supervision of an experienced and qualified operator.

These sections contain the responsibilities of the owner,

user, operator, lessor, and lessee concerning safety, training, inspection, maintenance, application, and operation.

If there are any questions with regard to safety, training,

inspection, maintenance, application, and operation,

please contact JLG Industries, Inc. (“JLG”).

FAILURE TO COMPLY WITH THE SAFETY PRECAUTIONS LISTED

IN THIS MANUAL COULD RESULT IN MACHINE DAMAGE, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

1.2 PRE-OPERATION

Operator Training and Knowledge

• The Operators and Safety Manual must be read in its

entirety before operating the machine. For clarification,

questions, or additional information regarding any portions of this manual, contact JLG Industries, Inc.

• Allow only those authorized and qualified personnel to

operate the machine who have demonstrated that they

understand the safe and proper operation and maintenance of the unit.

• Read, understand, and obey all DANGERS, WARNINGS, CAUTIONS, and operating instructions on the

machine and in this manual.

• Ensure that the machine is to be used in a manner

which is within the scope of its intended application as

determined by JLG.

• All operating personnel must be familiar with the emergency controls and emergency operation of the

machine as specified in this manual.

• Read, understand, and obey all applicable employer,

local, and governmental regulations as they pertain to

your utilization and application of the machine.

Workplace Inspection

• Precautions to avoid all hazards in the work area must

be taken by the user before operation of the machine.

• Do not operate or raise the platform from a position on

trucks, trailers, railway cars, floating vessels, scaffolds

or other equipment unless the application is approved

in writing by JLG.

• Before operation, check work area for overhead hazards such as electric lines, bridge cranes, and other

potential overhead obstructions.

• Check floor surfaces for holes, bumps, drop-offs,

obstructions, debris, concealed holes, and other

potential hazards.

• Check the work area for hazardous locations. Do not

operate the machine in hazardous environments

unless approved for that purpose by JLG.

• Ensure that the ground conditions are adequate to

support the maximum tire load indicated on the tire

load decals located on the chassis adjacent to each

wheel.

• Do not operate the machine when wind conditions

exceed 28 mph (12.5 m/s).

• This machine can be operated in nominal ambient tem-

peratures of 0

JLG to optimize operation outside of this temperature

range.

o

F to 104o F (-20o C to 40o C). Consult

• An operator must not accept operating responsibilities

until adequate training has been given by competent

and authorized persons.

Machine Inspection

• Do not operate this machine until the inspections and

functional checks have been performed as specified in

Section 2 of this manual.

3120854 – JLG Lift – 1-1

Page 10

SECTION 1 - SAFETY PRECAUTIONS

• Do not operate this machine until it has been serviced

and maintained according to the maintenance and

inspection requirements as specified in the machine’s

Service and Maintenance Manual.

• Ensure all safety devices are operating properly. Modification of these devices is a safety violation.

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM SHALL BE MADE ONLY WITH PRIOR WRITTEN PERMISSION FROM THE MANUFACTURER

• Do not operate any machine on which the safety or

instruction placards or decals are missing or illegible.

• Check the machine for modifications to original components. Ensure that any modifications have been

approved by JLG.

• Avoid accumulation of debris on platform deck. Keep

mud, oil, grease, and other slippery substances from

footwear and platform deck.

1.3 OPERATION

General

• Do not use the machine for any purpose other than

positioning personnel, their tools, and equipment.

• Before operation, the user must be familiar with the

machine capabilities and operating characteristics of

all functions.

• Never operate a malfunctioning machine. If a malfunction occurs, shut down the machine. Remove the unit

from service and notify the proper authorities.

• Do not remove, modify, or disable any safety devices.

• Never slam a control switch or lever through neutral to

an opposite direction. Always return switch to neutral

and stop before moving the switch to the next function.

Operate controls with slow and even pressure.

• Hydraulic cylinders should never be left at end of travel

(fully extended or fully retracted) before shutdown or

for long periods of time. Always “bump” control in

opposite direction slightly when function reaches end

of travel. This applies both to machines in operation or

in the stowed position.

• Do not allow personnel to tamper with or operate the

machine from the ground with personnel in the platform, except in an emergency.

• Do not carry materials directly on platform railing

unless approved by JLG.

• When two or more persons are in the platform, the

operator shall be responsible for all machine operations.

• Always ensure that power tools are properly stowed

and never left hanging by their cord from the platform

work area.

• Do not assist a stuck or disabled machine by pushing

or pulling except by pulling at the chassis tie-down

lugs.

• Stow scissor arm assembly and shut off all power

before leaving machine.

Trip and Fall Hazards

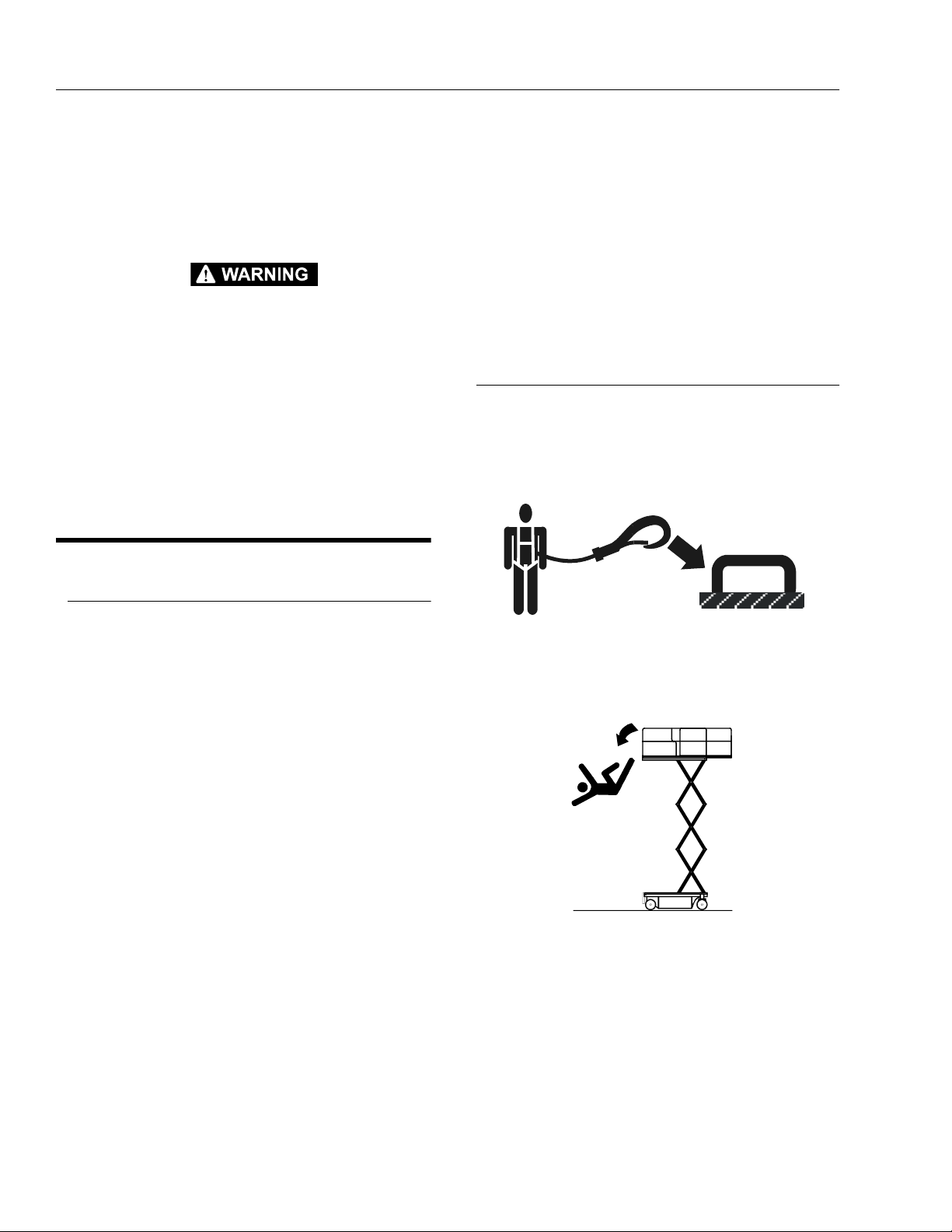

• JLG Industries, Inc. recommends that all persons in the

platform wear a full body harness with a lanyard

attached to an authorized lanyard anchorage point

while operating this machine. For further information

regarding fall protection requirements on JLG products, contact JLG Industries, Inc.

• Prior to operation, ensure all gates are fastened and

secured in their proper position. Identify the designated lanyard anchorage point(s) at the platform and

securely attach the lanyard. Attach only one (1) lanyard

per lanyard anchorage point.

• Keep both feet firmly positioned on the platform floor at

all times. Never position ladders, boxes, steps, planks,

or similar items on unit to provide additional reach for

any purpose.

• Never use the scissor arm assembly to gain access to

or leave the platform.

1-2 – JLG Lift – 3120854

Page 11

SECTION 1 - SAFETY PRECAUTIONS

• Use extreme caution when entering or leaving platform. Ensure that the scissor arm assembly is fully lowered. Face the machine when entering or leaving the

platform. Always maintain “three point contact” with

the machine, using two hands and one foot or two feet

and one hand at all times during entry and exit.

• Platform-to-structure transfers at elevated positions are

discouraged. Where transfer is necessary, enter/exit

through the gate only with the platform within 1 foot

(0.3m) of a safe and secure structure. 100% tie-off is

also required in this situation utilizing two lanyards.

One lanyard must be attached to the platform with the

second lanyard attached to the structure. The lanyard

connected to the platform must not be disconnected

until such time the transfer to the structure is safe and

complete.

• Keep oil, mud, and slippery substances cleaned from

footwear and the platform floor.

Electrocution Hazards

• This machine is not insulated and does not provide

protection from contact with an electrically charged

conductor.

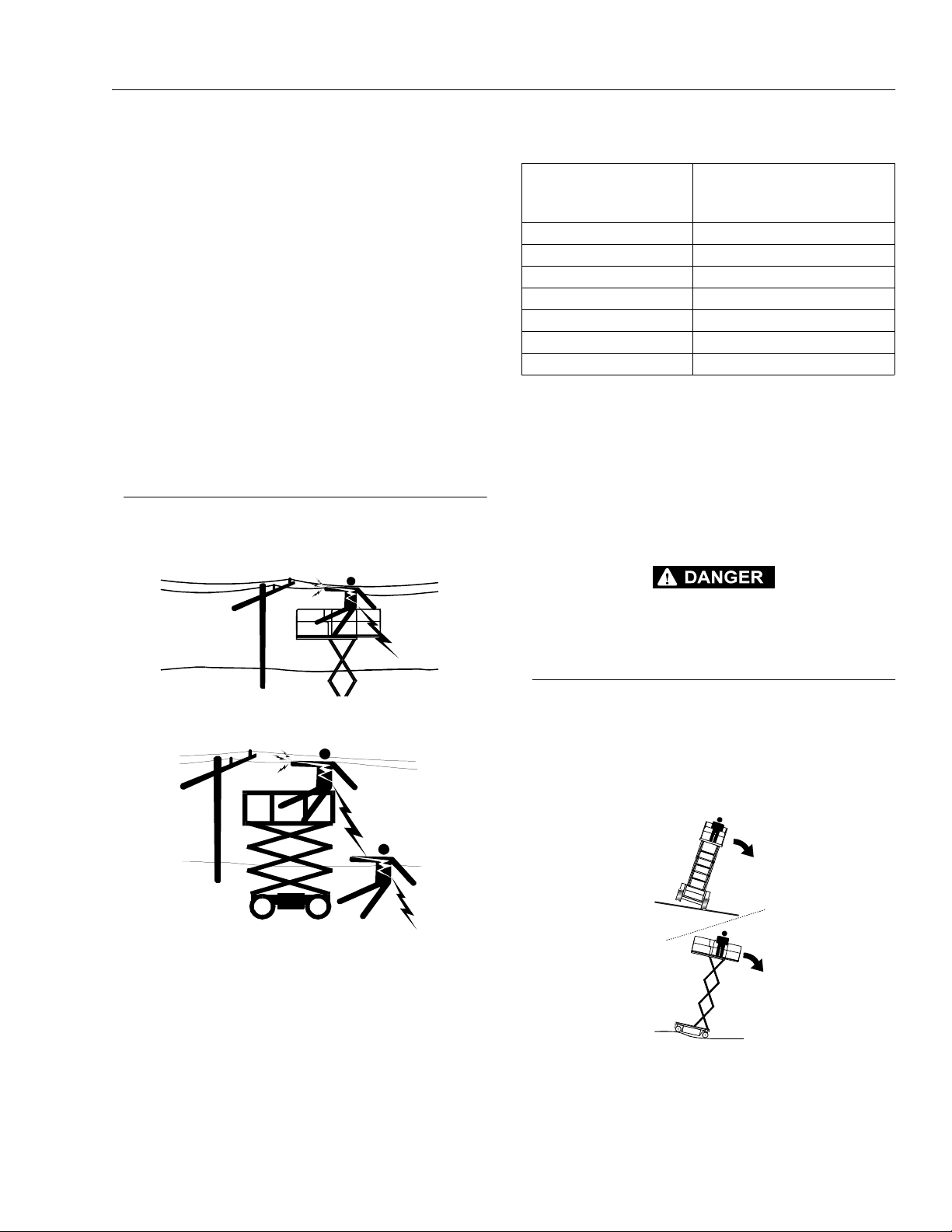

Table 1-1.Minimum Safe Approach Distances (M.S.A.D.)

Voltage Range

(Phase to Phase)

0 to 300V AVOID CONTACT

Over 300V to 50 KV 10 (3)

Over 50KV to 200 KV 15 (5)

Over 200 KV to 350 KV 20 (6)

Over 350 KV to 500 KV 25 (8)

Over 500 KV to 750 KV 35 (11)

Over 750 KV to 1000 KV 45 (14)

NOTE: This requirement shall apply except where

employer, local or governmental regulations

are more stringent.

• Maintain a clearance of at least 10 ft. (3m) between any

part of the machine and its occupants, their tools, and

their equipment from any electrical line or apparatus

carrying up to 50,000 volts. One foot additional clearance is required for every additional 30,000 volts or

less.

MINIMUM SAFE APPROACH

DISTANCE

in Feet (Meters)

• Maintain safe clearance from electrical lines, apparatus, or any energized (exposed or insulated) parts in

accordance with the Minimum Safe Approach Distance

(MSAD) as specified in Table 1-1. Allow for machine

movement and electrical line swaying.

DO NOT MANEUVER MACHINE OR PERSONNEL INSIDE PROHIBITED ZONE (MSAD). ASSUME ALL ELECTRICAL PARTS AND WIRING ARE ENERGIZED UNLESS KNOWN OTHERWISE.

Tipping Hazards

• Ensure that the ground conditions are adequate to

support the maximum tire load indicated on the tire

load decals located on the chassis adjacent to each

wheel. Do not travel on unsupported surfaces.

• The user should be familiar with the driving surface

before driving. Do not exceed the allowable sideslope

and grade while driving.

Do not elevate platform or drive with platform elevated

while on or near a sloping, uneven, or soft surface.

Ensure machine is positioned on a firm, level and uniformly supported surface before elevating platform or

driving with the platform in the elevated position.

3120854 – JLG Lift – 1-3

Page 12

SECTION 1 - SAFETY PRECAUTIONS

• Before driving on floors, bridges, trucks, and other surfaces, check allowable capacity of the surfaces.

• Never exceed the maximum work load as specified on

the platform. Distribute loads evenly on platform floor.

Keep all loads within the confines of the platform,

unless authorized by JLG.

• Keep the chassis of the machine a minimum of 2 ft.

(0.6m) from holes, bumps, drop-offs, obstructions,

debris, concealed holes, and other potential hazards at

the ground level.

• Never attempt to use the machine as a crane. Do not

tie-off machine to any adjacent structure. Never attach

wire, cable, or any similar items to platform.

• Do not operate the machine when wind conditions

exceed 28 mph (12.5 m/s).Unless otherwise specified

on machine or accessory.

• Do not cover the platform sides or carry large surfacearea items in the platform when operating outdoors.

The addition of such items increases the exposed wind

area of the machine.

• Do not increase the platform size with unauthorized

deck extensions or attachments.

• If scissor arm assembly or platform is caught so that

one or more wheels are off the ground, all persons

must be removed before attempting to free the

machine. Use cranes, forklift trucks, or other appropriate equipment to stabilize machine and remove personnel.

Crushing and Collision Hazards

• Approved head gear must be worn by all operating

and ground personnel.

• Keep hands and limbs out of the scissor arm assembly

during operation.

• Watch for obstructions around machine and overhead

when driving. Check clearances above, on sides, and

bottom of platform when lifting or lowering platform..

• Keep non-operating personnel at least 6 ft. (1.8m)

away from machine during all driving operations.

• Under all travel conditions, the operator must limit

travel speed according to conditions of ground surface, congestion, visibility, slope, location of personnel,

and other factors causing hazards of collision or injury

to personnel.

• Be aware of stopping distances in all drive speeds.

When driving in high speed, switch to low speed

before stopping. Travel grades in low speed only.

• Do not use high speed drive in restricted or close quarters or when driving in reverse.

• Exercise extreme caution at all times to prevent obstacles from striking or interfering with operating controls

and persons in the platform.

• Ensure that operators of other overhead and floor level

machines are aware of the aerial work platform’s presence. Disconnect power to overhead cranes. Barricade

floor area if necessary.

• Avoid operating over ground personnel. Warn personnel not to work, stand, or walk under a raised platform.

Position barricades on floor as necessary.

1.4 TOWING, LIFTING, AND HAULING

• Never allow personnel in platform while towing, lifting,

or hauling.

• This machine should not be towed, except in the event

of emergency, malfunction, power failure, or loading/

unloading. Refer to Section 6 for emergency towing

procedures.

• Ensure platform is fully retracted and completely

empty of tools prior to towing, lifting or hauling.

• When lifting machine with a forklift, position forks only

at designated areas of the machine. Lift with a forklift of

adequate capacity.

• Refer to Section 4 for lifting information.

1.5 ADDITIONAL HAZARDS / SAFETY

• Do not use machine as a ground for welding.

• When performing welding or metal cutting operations,

precautions must be taken to protect the chassis from

direct exposure to weld and metal cutting spatter.

• Do not refuel the machine with the engine running

(where applicable).

• During operation, keep all body parts inside platform

railing.

• Always post a lookout when driving in areas where

vision is obstructed.

1-4 – JLG Lift – 3120854

• Battery fluid is highly corrosive. Avoid contact with skin

and clothing at all times.

Charge batteries only in a well ventilated area.

Page 13

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

SECTION 2. USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.1 PERSONNEL TRAINING

The aerial platform is a personnel handling device; so it is

necessary that it be operated and maintained only by

trained personnel.

Persons under the influence of drugs or alcohol or who

are subject to seizures, dizziness or loss of physical control must not operate this machine.

Operator Training

Operator training must cover:

1. Use and limitations of the controls in the platform

and at the ground, emergency controls and safety

systems.

2. Control labels, instructions, and warnings on the

machine.

3. Rules of the employer and government regulations.

4. Use of approved fall protection device.

5. Enough knowledge of the mechanical operation of

the machine to recognize a malfunction or potential

malfunction.

6. The safest means to operate the machine where

overhead obstructions, other moving equipment,

and obstacles, depressions, holes, drop-offs.

7. Means to avoid the hazards of unprotected electrical

conductors.

8. Specific job requirements or machine application.

Tra i nin g Sup er vis i on

Training must be done under the supervision of a qualified

person in an open area free of obstructions until the

trainee has developed the ability to safely control and

operate the machine.

Operator Responsibility

The operator must be instructed that he/she has the

responsibility and authority to shut down the machine in

case of a malfunction or other unsafe condition of either

the machine or the job site.

NOTE: The Manufacturer or Distributor will provide qualified

people for training assistance with the first unit(s)

delivered and from tha t time forwa rd as r equested b y

the user or his/her personnel.

3120854 – JLG Lift – 2-1

Page 14

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.2 PREPARATION, INSPECTION, AND MAINTENANCE

The following table covers the periodic machine inspec-

maintenance must be increased as necessary when the

machine is used in a harsh or hostile environment, if the

machine is used with increased frequency, or if the

machine is used in a severe manner.

tions and maintenance recommended by JLG Industries,

Inc. Consult local regulations for further requirements for

aerial work platforms. The frequency of inspections and

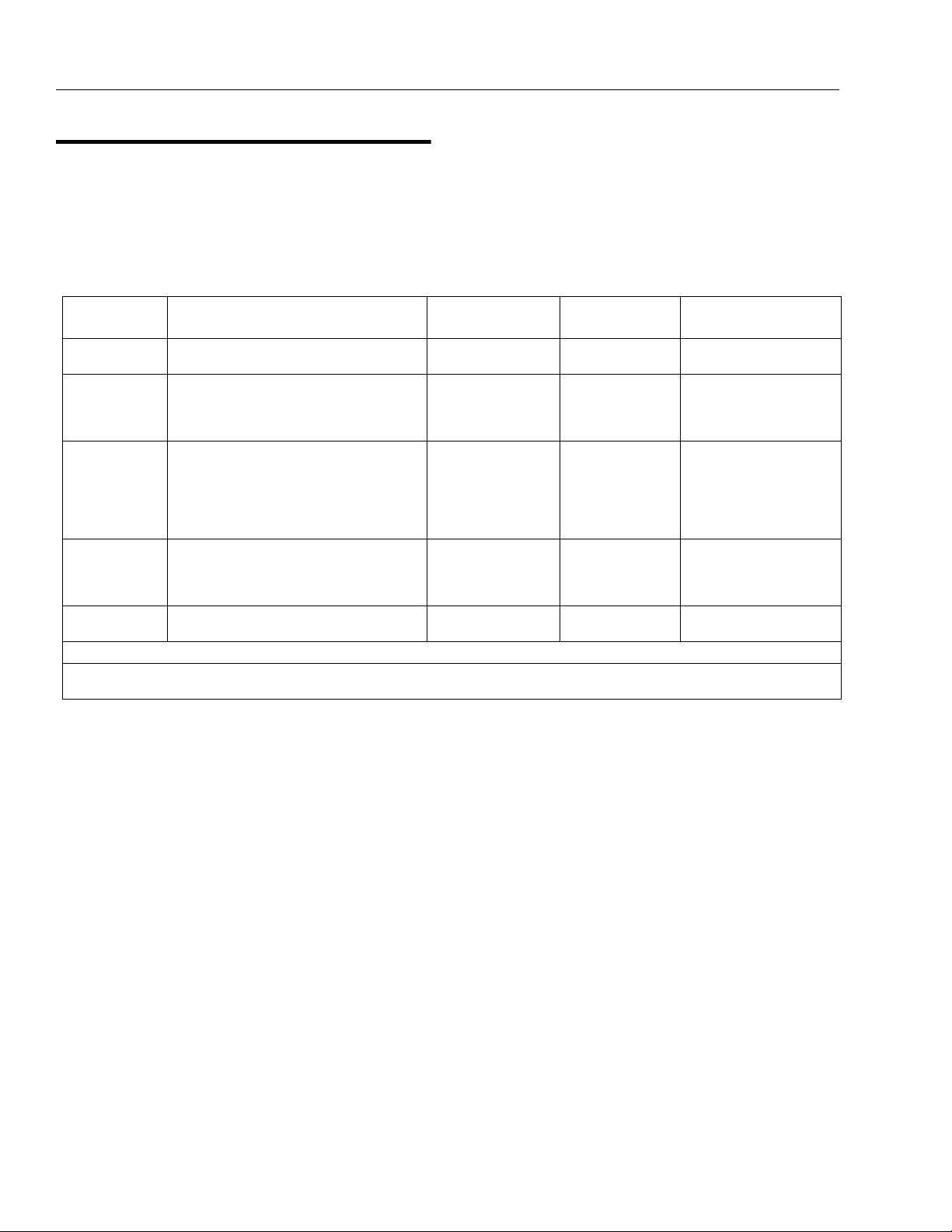

Table 2-1.Inspection and Maintenance Table

Type Frequency

Pre-Start

Inspection

Pre-Delivery

Inspection

(See Note)

Frequent

Inspection

Annual

Machine

Inspection

Preventative

Maintenance

Before using each day; or

whenever there’s an Operator change.

Before each sale, lease, or rental delivery. Owner, Deale r, or

In service for 3 months or 150 hours,

whichever comes first; or

Out of service for a period of more than 3

months; or

Purchased used.

Annually, no later than 13 months from the

date of prior inspection.

At intervals as specified in the Service and

Maintenance Manual.

Primary

Responsibility

User or Operator User or Operator Op e r a t o r an d Sa f e t y

User

Owner, Dealer, or

User

Owner, Dealer, or

User

Owner, Dealer, or

User

Service

Qualification

Qualified JLG

Mechanic

Qualified JLG

Mechanic

Factory-Certified

Service Technician*

Qualified JLG

Mechanic

Reference

Manual

Service and Maintenance Manual and applicable JLG inspection

form

Service and Maintenance Manual and applicable JLG inspection

form

Service and Maintenance Manual and applicable JLG inspection

form

Service and Maintenance Manual

NOTE: Inspection forms are available from JLG. Use the Service and Maintenance Manual to perform inspections.

* JLG Industries, Inc. recognizes a Factory-Certified Service Technician as a person who has successfully completed the JLG Service

Training School for the specific JLG product model.

2-2 – JLG Lift – 3120854

Page 15

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

Pre-Start Inspection

The Pre-Start Inspection should include each of the following:

1. Cleanliness – Check all surfaces for leakage (oil,

fuel, or battery fluid) or foreign objects. Report any

leakage to the proper maintenance personnel.

2. Decals and Placards – Check all for cleanliness

and legibility. Make sure none of the decals and

placards are missing. Make sure all illegible decals

and placards are cleaned or replaced.

3. Operators and Safety Manuals – Make sure a copy

of the Operator and Safety Manual, EMI Safety Manual (Domestic only), and ANSI Manual of Responsibilities (Domestic only) is enclosed in the weather

resistant storage container.

4. “Walk-Around” Inspection – Refer to Figures 1 and

2.

5. Battery – Charge as required.

6. Fuel (Combustion Engine Powered Machines) –

Add the proper fuel as necessary.

7. Hydraulic Oil – Check the hydraulic oil level. Ensure

hydraulic oil is added as required.

8. Function Check – Once the “Walk-Around” Inspec-

tion is complete, perform a functional check of all

systems in an area free of overhead and ground

level obstructions. Refer to Section 4 for more specific instructions.

Function Check

Perform the Function Check as follows:

1. From the ground control panel with no load in the

platform:

a. Check that all guards protecting the switches or

locks are in place;

b. Operate all functions and check all limiting and

cut-out switches; See Table 2-2, Maximum Cutout Height

c. Check auxiliary power (or manual descent);

d. Ensure that all machine functions are disabled

when the Emergency Stop Button is activated.

Table 2-2. Maximum Cutout Height

Model

1932E2 2.6 m N/A

2032E2 2.1 m N/A

2632E2

(Australian Only)

2632E2/2646E2 2.6 m N/A

3246E2 2.8 m N/A

High Drive Cutout

(Maximum Height)

2.9 m N/A

Drive Cutout

IF THE MACHINE DOES NOT OPERATE PROPERLY, TURN OFF

THE MACHINE IMMEDIATELY! REPORT THE PROBLEM TO THE

PROPER MAINTENANCE PERSONNEL. DO NOT OPERATE THE

MACHINE UNTIL IT IS DECLARED SAFE FOR OPERATION.

2. From the platform control console:

a. Ensure that the control console is firmly secured

in the proper location;

b. Check that all guards protecting the switches or

locks are in place;

c. Operate all functions and check all limiting and

cut-out switches;

d. Ensure that all machine functions are disabled

when the Emergency Stop Button is pushed in.

3. With the platform in the transport (stowed) position:

a. Drive the machine on a grade, not to exceed the

rated gradeability, and stop to ensure the brakes

hold;

Check the tilt sensor alarm to ensure proper operation.

3120854 – JLG Lift – 2-3

Page 16

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

192120

2425262728

29 3031

32

333435

10

11

12

4

3

2

1

5

6

7

8

9

13

14

15

16

17

18

22

Figure 2-1. Daily Walk-Around Inspection - 2032E2/2632E2/2646E2/3246E2 (Sheet 1 of 2).

23

2-4 – JLG Lift – 3120854

Page 17

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

GENERAL

Begin the “Walk-Around Inspection” at Item 1, as noted

on the diagram. Continue Left (counterclockwise viewed

from top) checking each item in sequence for the conditions listed in the following checklist.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS

“OFF” DURING “WALK-AROUND INSPECTION”.

DO NOT OVERLOOK VISUAL INSPECTION OF CHASSIS UNDERSIDE. CHECKING THIS AREA OFTEN RESULTS IN DISCOVERY

OF CONDITIONS WHICH COULD CAUSE EXTENSIVE MACHINE

DAMAGE.

NOTE: On each item, make sure there are no loose or

missing parts, that they are securely fastened, and

that no visible damage exists in addition to any

other criteria mentioned.

1. Platform Control Console - Placard secure and

legible, control lever and switches return to neutral, control lever lock and emergency stop switch

function properly, manual in storage box.

2. Spindle, Tie Rod and Steer Linkage (left front) See Note

3. Safety Prop - See Note

4. Sizzor Arms and Sliding Wear Pads - See Note

5. Wheel and Tire Assembly, Left Front - See Note

6. Drive Cutout Switch - See Note

7. Compartment Cover and Latches - See Note

8. Ground Controls - Placard secure and legible,

control switches return to neutral position, emergency stop switch functions properly. Control

markings legible.

9. Hydraulic Reservoir - Recommended hydraulic

fluid level on level indicator on tank. Breather cap

secure and working.

10. Hydraulic Filter - See Note

11. Hydraulic Pump/Motor - See Note

12. Pothole Protection System - See Note

13. Hourmeter - See Note

14. Wire Installation - See Note

15. Control Valve Installation - No unsupported wires

or hoses; no damaged or broken wires.

16. Wheel and Tire Assembly, Left Rear - See Note

17. Drive Motor, Left Rear - See Note

18. Sizzor Arms and Sliding Wear Pads - See Note

19. Handle for Manual Descent (2646E2/3246E2) See Note

20. Manual Descent Pump (2632E2/2646E2/3246E2) See Note

21. Manual Descent (2032E2) - See Note

22. Brake Cylinder - See Note

23. Ladder - See Note

24. Sizzor Arms and Sliding Wear Pads - See Note

25. Drive Motor, Right Rear - See Note

26. Wheel and Tire Assembly, Right Rear - See Note

27. Lift Cylinder - See Note

28. Tilt Switch - See Note

29. Battery Compartment - Proper electrolyte level.

30. Pothole Protection System - See Note

31. Battery Charger - See Note

32. Compartment Cover and Latches - See Note

33. Wheel and Tire Assembly, Right Front - See Note

34. Platform/Handrail Installation (Not Shown) - See

Note

35. Sizzor Arms and Sliding Wear Pads - See Note

Figure 2-1. Daily Walk-Around Inspection - 2032E2/2632E2/2646E2/3246E2 (Sheet 2 of 2).

3120854 – JLG Lift – 2-5

Page 18

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

21

22

33

32

11

12

13

14

6

7

8

9

10

4

3

2

1

5

31

30

29

28

27

26

15

25

24

23

16

17

Figure 2-2. Daily Walk-Around Inspection - 1932E2 (Sheet 1 of 2).

2-6 – JLG Lift – 3120854

18 19

20

Page 19

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

GENERAL

Begin the “Walk-Around Inspection” at Item 1, as noted

on the diagram. Continue Left (counterclockwise viewed

from top) checking each item in sequence for the conditions listed in the following checklist.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS

“OFF” DURING “WALK-AROUND INSPECTION”.

DO NOT OVERLOOK VISUAL INSPECTION OF CHASSIS UNDERSIDE. CHECKING THIS AREA OFTEN RESULTS IN DISCOVERY

OF CONDITIONS WHICH COULD CAUSE EXTENSIVE MACHINE

DAMAGE.

NOTE: On each item, make sure there are no loose or

missing parts, that they are securely fastened, and

that no visible damage exists in addition to any

other criteria mentioned.

1. Platform Control Console - Placard secure and legible, control lever and switches return to neutral,

control lever lock and emergency stop switch function properly, manual in storage box.

2. Spindle, Tie Rod and Steer Linkage (left front) - See

Note

3. Safety Prop - See Note

4. Sizzor Arms and Sliding Wear Pads - See Note

5. Drive Motor, Left Front - See Note

6. Wheel and Tire Assembly, Left Front - See Note

7. Drive Cutout Switch - See Note

8. Compartment Cover and Latches - See Note

9. Ground Controls - Placard secure and legible, control switches return to neutral position, emergency

stop switch functions properly. Control markings

legible.

10. Hydraulic Reservoir - Recommended hydraulic

fluid level on level indicator on tank. Breather cap

secure and working.

11. Hydraulic Filter - See Note

12. Hydraulic Pump/Motor - See Note

13. Pothole Protection System - See Note

14. Hourmeter - See Note

15. Wire Installation - See Note

16. Wheel and Tire Assembly, Left Rear - See Note

17. Sizzor Arms and Sliding Wear Pads - See Note

18. Manual Descent - See Note

19. Brake Cylinder - See Note

20. Ladder - See Note

21. Control Valve Installation - No unsupported wires or

hoses; no damaged or broken wires.

22. Sizzor Arms and Sliding Wear Pads - See Note

23. Wheel and Tire Assembly, Right Rear - See Note

24. Lift Cylinder - See Note

25. Tilt Switch - See Note

26. Battery Compartment - Proper electrolyte level

27. Pothole Protection System - See Note

28. Battery Charger - See Note

29. Compartment Cover and Latches - See Note

30. Wheel and Tire Assembly, Right Front - See Note

31. Drive Motor, Right Rear - See Note

32. Platform/Handrail Installation (Not Shown) - See

Note

33. Sizzor Arms and Sliding Wear Pads - See Note

Figure 2-2. Daily Walk-Around Inspection - 1932E2 (Sheet 2 of 2).

3120854 – JLG Lift – 2-7

Page 20

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

This page left blank intentionally.

2-8 – JLG Lift – 3120854

Page 21

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

SECTION 3. USER RESPONSIBILITIES AND MACHINE CONTROL

3.1 GENERAL

SINCE THE MANUFACTURER HAS NO DIRECT CONTROL OVER

MACHINE APPLICATION AND OPERATION, CONFORMANCE WITH

GOOD SAFETY PRACTICES IN THESE AREAS IS THE RESPONSIBILITY OF THE USER AND HIS OPERATING PERSONNEL.

This section provides the necessary information needed

to understand control functions. Included in this section

are the operating characteristics and limitations, and functions and purposes of controls and indicators. It is important that the user read and understand the proper

procedures before operating the machine. These procedures will aid in obtaining optimum service life and safe

operation.

3.2 PERSONNEL TRAINING

The scissor lift is a personnel handling device; therefore, it

is essential that it be operated and maintained only by

authorized and qualified personnel who have demonstrated that they understand the proper use and maintenance of the machine. It is important that all personnel

who are assigned to and responsible for the operation

and maintenance of the machine undergo a thorough

training program and check out period in order to become

familiar with the characteristics prior to operating the

machine.

Persons under the influence of drugs or alcohol or who

are subject to seizures, dizziness or loss of physical control must not be permitted to operate the machine.

Operator Training

Operator training must include instruction in the following:

1. Use and limitations of the platform controls, ground

controls, emergency controls and safety systems.

2. Knowledge and understanding of this manual and of

the control markings, instructions and warnings on

the machine itself.

3. Knowledge and understanding of all safety work

rules of the employer and of Federal, State and

Local Statutes, including training in the recognition

and avoidance of potential hazards in the work

place; with particular attention to the work to be performed.

4. Proper use of all required personnel safety equipment.

5. Sufficient knowledge of the mechanical operation of

the machine to recognize a malfunction or potential

malfunction.

6. The safest means to operate near overhead obstructions, other moving equipment, obstacles, depressions, holes, dropoffs, etc. on the supporting

surface.

7. Means to avoid the hazards of unprotected electrical

conductors.

8. Any other requirements of a specific job or machine

application.

Tra i nin g Sup er vis i on

Training must be done under the supervision of a qualified

operator or supervisor in an open area free of obstructions

until the trainee has developed the ability to safely control

a scissor lift in congested work locations.

Operator Responsibility

The operator must be instructed that he has the responsibility and authority to shut down the machine in case of a

malfunction or other unsafe condition of either the

machine or the job site and to request further information

from his supervisor or JLG Distributor before proceeding.

NOTE: Manufacturer or Distributor will provide qualified per-

sons for training assistan ce with first uni t(s) delivered

and thereafter as requested by user or his personnel.

3.3 OPERATING CHARACTERISTICS AND LIMITATIONS

General

A thorough knowledge of the operating characteristics

and limitations of the machine is always the first requirement for any user, regardless of user’s experience with

similar types of equipment.

Placards

Important points to remember during operation are provided at the control stations by DANGER, WARNING,

CAUTION, IMPORTANT and INSTRUCTION placards. This

information is placed at various locations for the express

purpose of alerting personnel of potential hazards constituted by the operating characteristics and load limitations

of the machine. See foreword for definitions of the above

placards.

3120854 – JLG Lift – 3-1

Page 22

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

Capacities

Raising platform with or without any load in platform,

is based on the following criteria:

1. Machine is positioned on a smooth, firm and level

surface.

2. Load is within manufacturer’s rated capacity.

3. All machine systems are functioning properly.

Stability

This machine, as originally manufactured by JLG and

operated within its rated capacity on a smooth, firm and

level supporting surface, provides a stable aerial platform

for all platform positions.

3.4 CONTROLS AND INDICATORS FOR NON PROPORTIONAL CONTROL

Battery Charger

NOTE: If batteries are run down to under 6 volts, the sup-

plied battery charger will not pick up the charge.

The battery charger is located in the right side battery

door. The charger is a 20 Amp, SCR-style charger

equipped with a manual switch that allows the operator to

select 110-125 Volt input or 220-250 Volt input. A rocker

switch circuit breaker is included to reset the charger in

the event of a loss of power. LED’s on the front panel of

the charger indicate the status of charger operation

(Charge Complete, 80% Charge, Incomplete Charge,

Charger On, Abnormal Cycle)

Ground Control Station

DO NOT OPERATE FROM GROUND CONTROL STATION WITH

PERSONNEL IN THE PLATFORM EXCEPT IN AN EMERGENCY.

PERFORM AS MANY PRE-OPERATIONAL CHECKS AND INSPECTIONS FROM THE GROUND CONTROL STATION AS POSSIBLE.

REFER TO SECTION 2 FOR PRE-OPERATIONAL CHECKS AND

INSPECTIONS.

.

Figure 3-1. Ground Control Station

3-2 – JLG Lift – 3120854

Page 23

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

1. Power Selector Switch

A three position, key-operated power selector switch

supplies operating power to the platform or ground

controls, as selected. When positioned to platform,

the switch provides power to the emergency stop

switch at the platform controls. When positioned to

ground, the switch provides power to the emergency stop switch at the ground controls. With the

power selector switch in the center off position,

power is shut off to both platform and ground controls.

NOTE: With the power selector switch in the off position, the

key can be removed in order to avoid unauthorized

use of the machine.

Low speed is the de fault s peed fo r all fun ction s when

the platform is fully lowered. When the platform is

elevated, all functions operate in creep speed only.

2. Emergency Stop Switch

A two-position, red, mushroom-shaped emergency

stop switch, when positioned to on (pulled out) with

the power selector switch positioned to ground, furnishes operating power to the ground control station. In addition, the switch can be used to turn off

power to the function controls in the event of an

emergency. Power is turned on by pulling the switch

out (on), and is turned off by pushing the switch in

(off).

3. Lift Switch

A three-position, momentary-contact switch provides raising and lowering of the platform when

positioned to up or down.

2. Enable Switch

The enable switch is located on the left side

of the platform control box. This switch must be

depressed and held before and during actuation of

the lift function and for the duration of lift. The enable

switch works in conjunction with the lift switch.

3. Drive

The joystick is used to drive the machine forward

and reverse. To drive, the red trigger on the front of

the joystick must be depressed and held. Then the

joystick must be pushed forward for forward travel or

pulled backward for reverse travel. The adjustment

between low and high speed is determined by the

joystick travel. When motor is first activated you are

in low speed, high speed is achieved by moving the

joystick to the complete forward position.

NOTE: When the machine is raised, and a door is opened,

the machine will not drive.

The drive system may make an occ asion al cav itatio n

noise when driving with steer wheels turned all the

way in one direction or while going down hill. This

noise is a byproduct of the drive system.

4. Lift

The lift switch, when used in conjunction with the

enable switch, will raise or lower the machine. Lift is

activated by pressing and holding the enable and

moving the lift switch forward (lift up) or backward

(lift down).

4. Circuit Breaker

A push button reset 15 Amp circuit breaker, located

behind the pump/motor in the left side door, returns

interrupted power to the machine functions when

depressed.

5. Hourmeter

The machine may be equipped with an hourmeter to

indicate the number of hours the machine has been

operated. The hourmeter operates when a machine

function is operating or when key switch and emergency stop switch are on.

Platform Control Station

1. Emergency Stop Switch

A two-position, red, mushroom-shaped emergency

stop switch functions to provide power to the platform control station and also to turn off power to the

platform function controls in the event of an emergency. With the power selector switch positioned to

platform, power is turned on by pulling the switch

out (on), and is turned off by pushing the switch in

(off).

DO NOT “LIFT DOWN” WITHOUT COMPLETELY RETRACTING

THE PLATFORM EXTENSION.

5. Steer Switch

The thumb-operated steer switch, located on top of

the joystick controller, activates the steer wheels in

the direction the switch is moved (left or right).

DO NOT USE HIGH DRIVE SPEED WHEN DRIVING IN CLOSE

QUARTERS OR WHEN DRIVING IN REVERSE.

6. Drive Speed Select Switch

The speed select switch is a toggle switch which

allows you to select high or low speed.

NOTE: The High Drive Speed switch will cut-out when the

platform is raised above the stowed position, returning drive speed to low until the platform is lowered

completely.

3120854 – JLG Lift – 3-3

Page 24

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

Figure 3-2. Platform Control Station - Non Proportional Control

DO NOT OPERATE MACHINE IF HIGH DRIVE SPEED OPERATES

WHEN PLATFORM IS RAISED ABOVE THE STOWED POSITION.

NOTE: The machine is equipped with a Pothole Protection

System which lowers automatically when the platform is raised. The Pothole Protection System will

also lower when either of the door s are opene d, but

only on the side of the opened door and this will not

provide tip over protect ion. If the Poth ole Protect ion

System does not fully lower, the DRIVE function is

cut out until the platform is completely lowered.

7. Tilt Alarm Warning Horn.(If Equipped)

The Tilt Alarm Warning is activated by the Tilt Alarm

Switch when the chassis is on a slope. See Figure 31, Tilt, for degree of tilt per model.

Ta b le 3 - 1 . T i lt

1932E2/2032E2 2632E2/2646E2/3246E2

IF TILT ALARM IS ON WHEN PLATFORM IS RAISED, LOWER

PLATFORM COMPLETELY, THEN REPOSITION MACHINE SO

THAT IT IS LEVEL BEFORE RAISING PLATFORM.

8. Tilt Alarm Warning Light. (If Equipped)

A red warning light on the control box panel will illuminate when the chassis is on a slope. See Figure 31, Tilt, for degree of tilt per model

9. Horn. (If Equipped)

This push button switch, when activated, permits the

operator to warn jobsite personnel when the

machine is operating in the area.

10. Battery Discharge Indicator

The battery discharge indicator is a gauge that provides a visual indication of the condition of the batteries.

1.5 Degrees 2 Degrees

3-4 – JLG Lift – 3120854

Page 25

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

Figure 3-3. Platform Control Station - Proportional Control

3.5 CONTROLS AND INDICATORS FOR PROPORTIONAL CONTROL

The machine is equipped with control panels that use

symbols instead of words to indicate control functions.

Refer to Symbols figure for these symbols and their corresponding functions.

JLG SMART™ System

The machine is controlled by the JLG SMART™ System, a

24 volt, multiplex motor controller which works in conjunction with a joystick and several switches to operate all

machine functions.

Special operating characteristics of the JLG SMART™

System are noted where applicable. Special attention

should be paid to these operating characteristics, as they

may be somewhat different from those on previous JLG

machines.

IT IS A GOOD PRACTICE TO AVOID PRESSURE-WASHING ELECTRICAL/ELECTRONIC COMPONENTS. SHOULD PRESSUREWASHING BE UTILIZED TO WASH AREAS CONTAINING ELECTRICAL/ELECTRONIC COMPONENTS, JLG INDUSTRIES, INC. RECOMMENDS A MAXIMUM PRESSURE OF 750 PSI (52 BAR) AT A

MINIMUM DISTANCE OF 12 INCHES (30.5 CM) AWAY FROM THESE

COMPONENTS. IF ELECTRICAL/ELECTRONIC COMPONENTS

ARE SPRAYED, SPRAYING MUST NOT BE DIRECT AND BE FOR

BRIEF TIME PERIODS TO AVOID HEAVY SATURATION.

Ground Control Station

NOTE: Refer to the Ground Control Station for Non Propor-

tional Control machines.

3120854 – JLG Lift – 3-5

Page 26

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

Platform Control Station

1. Emergency Stop Switch - A two-position, red,

mushroom-shaped emergency stop switch functions to provide power to the platform control station

and also to turn off power to the platform function

controls in the event of an emergency. With the

power selector switch positioned to platform, power

is turned on by pulling the switch out (on), and is

turned off by pushing the switch in (off). Turning the

emergency stop switch off and then on again will

reset the smart system if a system fault has occurred

and the machine has shut down.

2. Membrane Switch Panel - The function switches at

the platform control station are an integral part of a

membrane switch panel, which contains switches

for drive, high drive, lift, powered deck extension (if

equipped), and posi-trac, plus a red tilt indicator

light (if equipped). The drive, lift and powered deck

extension function switches have a small green light

indicator beside them which is illuminated when that

function is active. The function switch light indicators

will flash once or twice, then go out, when the platform emergency stop switch is turned on. If the light

indicators fail to flash or if they fail to stop flashing,

re-cycle the emergency stop switch. To activate the

drive, lift, and powered deck functions, press the

applicable function switch, then activate the joystick

within three seconds to operate the function. If the

joystick is not activated within three seconds, power

is turned off to the function switch and the switch

must be pressed again. The posi-trac and high drive

functions are used in conjunction with the drive function. Do not try to operate the drive, lift, and powered

deck extension functions simultaneously. If the drive,

lift, and powered deck extension functions are

selected simultaneously, no function will operate. If

this occurs, pause, then press only one of the function switches to activate the function. Refer to the following paragraphs for more information about the

function switches.

3. Controller (Joystick) - The joystick controls three

functions: speed, direction, and powered deck

extension (if equipped). The joystick is used in conjunction with the trigger switch and controls the

drive, high drive, lift, and powered deck extension

switches to control speed and direction for the

selected function. The drive, high drive and posi-trac

functions may be operated simultaneously, but the

drive, lift, and powered deck extension functions

must be operated independently of each other. If the

drive, lift, and powered deck extension functions are

selected simultaneously, no function will operate. If

this occurs, pause, then press only one of the function switches to activate the function. To operate the

joystick, squeeze the red trigger switch, then position the joystick to forward or reverse, as desired

5. Steer Switch - The thumb-operated steer switch,

located on top of the joystick, works in conjunction

with the trigger switch and activates the steer wheels

in the direction the switch is moved (left or right).

6. Drive Switch - The drive switch, when used in con-

junction with the joystick, provides for driving the

machine in forward or reverse. Drive is activated by

pressing the drive switch, in conjunction with the

trigger switch, and moving the joystick forward (forward) or backward (reverse). Drive speed is determined by the distance the joystick is moved forward

or backward. Increased drive speed is possible

when the high drive speed switch is pressed either

simultaneously with the drive switch or while operating the drive function. The drive switch is part of the

enable circuit, which provides power to the joystick

and the drive function for 3 seconds when the drive

switch is pressed. If the joystick is not activated

within 3 seconds, the drive switch must be pressed

again before activating the joystick. When the joystick is returned to the center off position, the operator has 3 seconds to re-activate the joystick or select

another function before power is removed by the

enable circuit. In addition, the posi-trac switch can

be engaged while operating the drive function to

give a more evenly distributed oil flow to each drive

motor. Do not try to operate the drive, lift, and powered deck extension functions simultaneously. If the

drive, lift, and powered deck extension functions are

selected simultaneously, no function will operate. If

this occurs, pause, then press only one of the function switches to activate the function

NOTE: The machine is equipped with a Pothole Protection

System which lowers automatically when the platform is raised. If the Pothole Prot ect ion S ystem doe s

not fully lower, the DRIVE function is cut out until the

platform is completely lowered.

3-6 – JLG Lift – 3120854

Page 27

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

7. High Drive Speed Switch - The high drive speed

switch, when used in conjunction with the joystick

being operated in the drive mode, provides additional oil flow to the drive circuit for increased travel

speed. To operate high drive, depress the high drive

speed switch either simultaneously with the drive

switch or while operating the drive function.

DO NOT USE HIGH DRIVE SPEED WHEN DRIVING IN

CLOSE QUARTERS OR WHEN DRIVING IN REVERSE.

IF HIGH DRIVE IS SELECTED WHEN OIL TEMPERATURE IS VERY COLD (BELOW 4°C 40° F.) HIGH DRIVE

WILL NOT ENGAGE IMMEDIATELY. AS OIL WARMS

(ABOVE 4°C 40° F.) IF HIGH DRIVE IS SELECTED, IT

WILL ENGAGE AUTOMATICALLY WHILE DRIVING.

NOTE: The High Drive Speed switch will cut-out when the

platform is raised above the stowed position, returning drive speed to low until the platform is lowered

completely.

DO NOT ATTEMPT TO OPERATE THE LIFT AND DRIVE FUNCTIONS AT THE SAME TIME; NO FUNCTION WILL OPERATE AND IT

WILL BE NECESSARY TO RE-SELECT A SINGLE FUNCTION.

WHEN OPERATING LIFT DOWN MOVE THE JOYSTICK TO THE

FULL DOWN (FULLY BACKWARD) POSITION.

9. Positive Traction (Posi-Trac) Switch - This switch,

when pressed, activates a solenoid on the main control valve, forcing oil through a flow divider in the

drive circuit, maintaining hydraulic oil flow to both

drive motors for improved traction. The positive traction (Posi-trac) switch activates the positive traction

solenoid for a preset time when the positive traction

(Posi-trac) switch is pressed. Positive traction is

automatically de-activated after the preset time is

out. This function will only operate when the drive

function is activated.

10. Tilt Alarm Warning Horn (If Equipped) - The Tilt

Alarm Warning Horn is activated by the Tilt Alarm

Switch when the chassis is on a slope. (See Figure

3-1, Tilt for the appropriate degree of tilt). When the

machine is equipped with a powered deck extension, the horn is activated when the deck extension

is being extended or retracted.

DO NOT OPERATE MACHINE IF HIGH DRIVE SPEED OPERATES

WHEN PLATFORM IS RAISED ABOVE THE STOWED POSITION.

8. Lift Switch - The lift switch, when used in conjunc-

tion with the joystick, provides for raising and lowering the platform. Lift is activated by pressing the lift

switch and moving the joystick forward (lift up) or

backward (lift down). Lift up speed is determined by

the distance the joystick is moved forward. Lift down

speed is non-adjustable, and lift down is attained by

moving the joystick fully backward. The lift switch is

part of the enable circuit, which provides power to

the joystick and the lift function for 3 seconds when

the lift switch is pressed. If the joystick is not activated within 3 seconds, the lift switch must be

pressed again before activating the joystick. When

the joystick is returned to the center off position, the

operator has 3 seconds to re-activate the joystick or

select another function before power is removed by

the enable circuit. Do not try to operate the drive, lift,

and powered deck extension functions simultaneously. If the drive, lift, and powered deck extension functions are selected simultaneously, no

function will operate. If this occurs, pause, then

press only one of the function switches to activate

the function.

IF TILT ALARM IS ON WHEN PLATFORM IS RAISED, LOWER

PLATFORM COMPLETELY, THEN REPOSITION MACHINE SO

THAT IT IS LEVEL BEFORE RAISING PLATFORM.

11. Tilt Alarm Warning Light (Red) (If Equipped) - A

warning light on the membrane switch panel that

illuminates when the chassis is on a severe slope

(See Figure 3-1, Tilt for the appropriate degree of

tilt).

12. Horn (If Equipped) - This push-button switch, when

activated, permits the operator to warn jobsite personnel when the machine is operating in the area.

13. Battery Discharge Indicator (If Equipped) - The

battery discharge indicator is a gauge that provides

a visual indication of the condition of the batteries.

DO NOT LIFT DOWN WITHOUT COMPLETELY RETRACTING THE

PLATFORM EXTENSION.

3120854 – JLG Lift – 3-7

Page 28

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

1

1

3

2

3

2

Figure 3-4. Decal Location (1932E2)

3-8 – JLG Lift – 3120854

Page 29

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

Table 3-2. Decal Location Legend - 1932E2

Item #

1532E2/

1932E2

Ansi Australian

China/

English

Dutch French

French/

English

German Italian Japan

1 1702773 1702773 1702773 1702773 1702773 1702773 1702773 1702773 1702773

2 1703817 1703817 1703817 1703817 1703817 1703817 1703817 1703817 1703817

3 1703823 1703823 1704609 1703895 1703866 1703866 1703883 1703888 1703850

4 1703811 1703811 1703811 1703811 1703811 1703811 1703811 1703811 1703811

5 1704399 1704399 1704399 1704399 1704399 1704399 1704399 1704399 1704399

6 1703814 1703814 1703814 1703814 1703814 1703814 1703814 1703814 1703814

7 1703819 1703819 1703819 1703819 1703819 1703819 1703819 1703819 1703819

8 1703813 1703813 1704613 1703893 1703864 1703864 1703881 1703886 1703848

9 N/A N/A N/A 1702928 1702928 N/A 1702928 1702928 N/A

10 3252747

(1532E2)

3252598

(1932E2)

N/A

(1532E2)

3252598

(1932E2)

3252747

(1532E2)

3252598

(1932E2)

N/A

(1532E2)

3252598

(1932E2)

3252747

(1532E2)

3252598

(1932E2)

3252747

(1532E2)

3252598

(1932E2)

N/A

(1532E2)

3252598

(1932E2)

N/A

(1532E2)

3252598

(1932E2)

3252747

(1532E2)

3252598

(1932E2)

11 3251813 N/A N/A 3251813 N/A 3251813 N/A N/A N/A

12 N/A 1703969 N/A 1703973 1703970 1703868 1703971 1703972 N/A

13 1703818 1703818 1704611 1703894 1703865 1703865 1703882 1703887 1704282

14 1703869 1703869 1703869 1703869 1703869 1703869 1703869 1703869 1703869

15 1702153 1704123 1704607 N/A N/A 1703074 N/A N/A 1701621

16 1703868 N/A 1703868 N/A N/A 1703868 N/A 1703886 1703868

17 1703706 1703706 1703706 1703706 1703706 1703706 1703706 1703706 1703706

18 1703816 3252616 1704616 1704173 1704173 1703867 1704173 1704173 1704278

(1532E2)

1703868

(1932E2)

19 N/A 1703877 N/A 1703896 1703878 N/A 1703884 1703889 1704807

20 1701509 1701509 1701509 1701509 1701509 1701509 1701509 1701509 1701509

21 1704017 1704017 1704608 1704149 1704146 1704146 1704147 1704148 1704144

22 1703822 1703822 1703822 1703822 1703822 1703822 1703822 1703822 1703822

23 3252645 3252534 3252699 3252533 3252645

(1532E2)

3252533

(1932E2)

3252645 3252533 3252533 3252644

(1532E2)

3252749

(1932E2)

3120854 – JLG Lift – 3-9

Page 30

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

Table 3-3. Decal Location Legend - 1932E2 (continued)

Item #

1532E2/

1932E2

1 1702773 1702773 1702773 1702773 1702773

2 1703817 1703817 1703817 1703817 1703817

3 1703858 1703834 1703842 1703842 1703823

4 1703811 1703811 1703811 1703811 1703811

5 1704399 1704399 1704399 1704399 1704399

6 1703814 1703814 1703814 1703814 1703814

7 1703819 1703819 1703819 1703819 1703819

8 1703856 1703832 1703840 1703840 1703813

9 N/A N/A 1702928 N/A 1702928

10 3252747

11 N/A 3251813 N/A 3251813 N/A

12 N/A 1703829 1703974 1703837 1703969

13 1703857 1703865 1703841 1703841 1703818

14 1703869 1703869 1703869 1703869 1703869

15 1703962 1703961 N/A 1702552 N/A

16 1703868 1703868 N/A 1703868 N/A

17 1703706 1703706 1703706 1703706 1703706

18 1703859 1703835 1704173 1703843 1704173

19 1703868 1703868 1703897 1703868 1703877

20 1701509 1701509 1701509 1701509 1701509

21 1704145 1704142 1704143 1704143 1704017

22 1703822 1703822 1703822 1703822 1703822

23 3252645 3252645 3252533 3252645 3252533

Korean Brazil Spanish Latin CE/English

(1532E2)

3252598

(1932E2)

3252747

(1532E2)

3252598

(1932E2)

N/A

(1532E2)

3252598

(1932E2)

3252747

(1532E2)

3252598

(1932E2)

3252747

(1532E2)

3252598

(1932E2)

3-10 – JLG Lift – 3120854

Page 31

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

2

4

5

4

1

2

3

2

4

6

5

13

9

8

7

14

5

6

11

10

15

2

2

3

17

18

16

14

19

Figure 3-5. Decal Location - 2032E2/2632E2/2646E2

3120854 – JLG Lift – 3-11

Page 32

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

Table 3-4. Decal Location Legend - 2032E2/2632E2/2646E2

Item #

2032E2

2632E2

2646E2

1 1702773 1702773 1702773 1702773 1702773 1702773 1702773 1702773 1702773

2 1703817 1703817 1703817 1703817 1703817 1703817 1703817 1703817 1703817

3 1703823 1703823 1704069 1703895 1703866 1703842 1703883 1703888 1703850

4 1703811 1703811 1703811 1703811 1703811 1703811 1703811 1703811 1703811

5 1703814 1703814 1703814 1703814 1703814 1703814 1703814 1703814 1703814

6 1704400

7 1703812 1703812 1703812 1703812 1703812 1703812 1703812 1703812 1703812

8 1703706 1703706 1703706 1703706 1703706 1703706 1703706 1703706 1703706

9 1703818 1703818 1704611 1703894 1703865 1703841 1703882 1703887 1704282

10 3252567

11 N/A N/A N/A 1702928 N/A 1702928 1702928 1702928 N/A

12 1703813 1703813 1704613 1703893 1703864 1703840 1703881 1703886 1703848

13 1701509 1701509 1701509 1701509 1701509 1701509 1701509 1701509 1701509

14 1703816 1704115 1704616 1703898 1703867 1703898 1703898 1703898 1704807

15 1703821 1703969 1704610 1703973 1703861 1703874 1703971 1703972 1703845

16 1703694 1703877 1703694 1703896 1703694 1703897 1703884 1703889 1704283

17 1704420

18 1703698 1703698 1703614 1703892 N/A 1703839 1703880 1703885 1704281

19 1703822

20 1703621 1703621 1703621 1703621 1703621 1703621 1703621 1703621 1703621

21 1703697 1703697 1703697 1703697 1703697 1703697 1703697 1703697 1703697

22 3252645 3252534 3252699 3252565 3252564 3252565 3252565 3252565 3252749

23 N/A 1704123 1703694 N/A 1703694 N/A N/A N/A 1704283

24 N/A 1702153 1704607 N/A 1703074 N/A N/A N/A 1701621

Ansi Australian

(2032E2)

1704137

(2632E2)

1704402

(2646E2)

(2032E2)

1705013

(2632E2)

3252568

(2646E2)

(2632E2 only)

(2032E2 only)

(2632E2 only)

(2032E2 only)

1704400

(2032E2)

1704137

(2632E2)

1704402

(2646E2)

3252567

(2032E2)

1705013

(2632E2)

3252568

(2646E2)

1704420

1703822

China/

English

1704400

(2032E2)

N/A

(2632E2)

1704402

(2646E2)

3252567

(2032E2)

N/A

(2632E2)

3252568

(2646E2)

1704420

(2632E2 only)

1703822

(2032E2 only)

Dutch CSA/French Spanish German Italian Japan

1704400

(2032E2)

N/A

(2632E2)

1704402

(2646E2)

3252567

(2032E2)

N/A

(2632E2)

3252568

(2646E2)

1704420

(2632E2 only)

1703822

(2032E2 only)

1704400

(2032E2)

1704137

(2632E2)

1704402

(2646E2)

3252567

(2032E2)

1705013

(2632E2)

3252568

(2646E2)

1704420

(2632E2 only)

1703822

(2032E2 only)

1704400

(2032E2)

N/A

(2632E2)

1704402

(2646E2)

3252567

(2032E2)

N/A

(2632E2)

3252568

(2646E2)

1704420

(2632E2 only)

1703822

(2032E2 only)

1704400

(2032E2)

N/A

(2632E2)

1704402

(2646E2)

3252567

(2032E2)

N/A

(2632E2)

3252568

(2646E2)

1704420

(2632E2 only)

1703822

(2032E2 only)

1704400

(2032E2)

N/A

(2632E2)

1704402

(2646E2)

3252567

(2032E2)

N/A

(2632E2)

3252568

(2646E2)

1704420

(2632E2 only)

1703822

(2032E2 only)

(2632E2 only)

(2032E2 only)

1704400

(2032E2)

1704137

(2632E2)

1704402

(2646E2)

3252567

(2032E2)

1705013

(2632E2)

3252568

(2646E2)

(2032E2/

2646E2)

1703868

(2632E2)

1704420

1703822

3-12 – JLG Lift – 3120854

Page 33

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

Table 3-5. Decal Location Legend - 2032E2/2632E22646E2 (continued)

Item #

2032E2

2632E2

2646E2

1 1702773 1702773 1702773 1702773 1702773

2 1703817 1703817 1703817 1703817 1703817

3 1703842 170383 1703866 1703834 1703858

4 1703811 1703811 1703811 1703811 1703811

5 1703814 1703814 1703814 1703814 1703814

6 1704400

7 1703812 1703812 1703812 1703812 1703812

8 1703706 1703706 1703706 1703706 1703706

9 1703841 1703818 1703865 1703833 1703857

10 3252567

11 N/A 1702928 1702928 1702928 N/A

12 1703840 1703813 1703864 1703832 1703856

13 1701509 1701509 1701509 1701509 1701509

14 1703843 1703898 1703898 1703835 1703859

15 1703837 1703969 1703970 1703829 1703853

16 1703694 1703877 1703868 1703694 1703694

17 1704420

18 1703839 1703698 1703822 1703831 1703855

19 1703822

20 1702631 1702631 1702631 1703621 1703621

21 1703697 1703697 1703697 1703697 1703697

22 3252645 3252565 3252565 3252645 3252645

23 1703694 N/A N/A 1703694 1703694

24 1702552 N/A N/A 1703691 1703962

Latin CE/English CE/French Brazil Korean

(2032E2)

1704137

(2632E2)

1704402

(2646E2)

(2032E2)

1705013

(2632E2)

3252568

(2646E2)

(2632E2 only)

(2032E2 only)

1704400

(2032E2)

N/A

(2632E2)

1704402

(2646E2)

3252567

(2032E2)

N/A

(2632E2)

3252568

(2646E2)

1704420

(2632E2 only)

1703822

(2032E2 only)

1704400

(2032E2)

N/A

(2632E2)

1704402

(2646E2)

3252567

(2032E2)

N/A

(2632E2)

3252568

(2646E2)

1704420

(2632E2 only)

1703822