Page 1

Service Manual

iTNC 530

July 2010

Page 2

Page 3

1 How to Use this Service Manual........................................................................................ 11

1.1 Target Group.................................................................................................................. 11

1.2 About this Manual ......................................................................................................... 11

1.3 Other Service Manuals.................................................................................................. 12

1.4 Other Documentation.................................................................................................... 12

1.5 Support.......................................................................................................................... 12

1.6 Service Training ............................................................................................................. 12

1.7 Meaning of the Symbols Used in this Manual............................................................... 13

1.8 Safety ............................................................................................................................ 13

2 Safety Precautions............................................................................................................... 15

2.1 Overview ....................................................................................................................... 15

3 Code Numbers ..................................................................................................................... 17

3.1 Introduction ................................................................................................................... 17

3.2 Overview ....................................................................................................................... 17

3.3 Input of Code Numbers ................................................................................................ 18

4 Error Messages .................................................................................................................... 21

4.1 Introduction ................................................................................................................... 21

4.2 HELP Key....................................................................................................................... 25

4.3 ERR Key ........................................................................................................................ 26

4.4 CE Key .......................................................................................................................... 28

4.5 List of NC Error Messages ............................................................................................ 29

5 Errors Patterns ..................................................................................................................... 55

5.1 Introduction ................................................................................................................... 55

5.2 Overview of Possible Error Patterns ............................................................................. 55

6 Procedures and Tips for Error Diagnosis........................................................................... 59

6.1 Introduction ................................................................................................................... 59

6.2 Power Off and On ......................................................................................................... 59

6.3 Sequence for Finding Serious Electrical Errors.............................................................. 60

6.4 Sequence for Finding Errors in the Control Loop .......................................................... 62

6.5 Error Localization by Process of Interchange ................................................................ 65

6.6 Error Localization by Process of Exclusion .................................................................... 66

6.7 Finding Position Differences of Direct and Indirect Encoder......................................... 68

6.8 Error Localization by Switching from Direct to Indirect Position Measurement............ 70

6.9 Notes and Tips............................................................................................................... 72

7 Creating and Downloading of Service Files ...................................................................... 77

7.1 Introduction ................................................................................................................... 77

7.2 Automatic Generation of Service Files .......................................................................... 78

7.3 Automatic Generation of Service Files .......................................................................... 78

7.4 Downloading of Service Files ........................................................................................ 79

8 Log......................................................................................................................................... 81

8.1 Introduction ................................................................................................................... 81

8.2 Calling the Log............................................................................................................... 82

verview of Log En

8.3 O

8.4 Log Entries at Program Cancelation .............................................................................. 87

9 Integrated Diagnostic Functions and DriveDiag ............................................................... 89

9.1 Introduction ................................................................................................................... 89

9.2 Activation and Operation ............................................................................................... 90

9.3 For Error Diagnosis........................................................................................................ 98

10 Integrated Oscilloscope..................................................................................................... 99

10.1 Introduction ................................................................................................................. 99

10.2 Activation and Settings.............................................................................................. 100

10.3 Recording and Adjusting the Signals......................................................................... 105

10.4 Saving and Loading Recordings................................................................................. 110

tries................................................................................................ 83

July 2010 HEIDENHAIN Service Manual iTNC 530

Page 4

10.5 For Error Diagnosis.................................................................................................... 111

10.5.1 Triggering on error marker ............................................................................... 111

10.5.2 Circular interpolation test ................................................................................. 113

10.5.3 Descriptions in this manual ............................................................................. 114

11 PLC Diagnosis................................................................................................................... 115

11.1 Introduction ............................................................................................................... 115

11.2 Possible Causes of Errors ......................................................................................... 118

11.3 Diagnosis Tools in the PLC Mode ............................................................................. 119

11.3.1 The TABLE function ......................................................................................... 119

11.3.2 The LOGIC diagram ......................................................................................... 125

11.3.3 The TRACE function ....................................................................................... 128

11.3.4 The WATCH LIST function .............................................................................. 129

11.3.5 The I / O - FORCE LIST .................................................................................... 131

11.3.6 PROFIBUS diagnosis ....................................................................................... 133

11.4 Non-Volatile PLC Markers and Words ....................................................................... 136

11.5 Overviews ................................................................................................................. 138

11.6 Specifications ............................................................................................................ 147

11.6.1 PLC inputs ....................................................................................................... 147

11.6.2 Analog inputs ................................................................................................... 148

11.6.3 Inputs for thermistors ...................................................................................... 148

11.6.4 PLC outputs ..................................................................................................... 149

12 Hard Disk and File Manager of the iTNC 530 ................................................................ 151

12.1 Introduction ............................................................................................................... 151

12.2 Structure of the Hard Disk......................................................................................... 152

12.3 Possible Causes of Error ........................................................................................... 152

12.4 Test of Hard Disk ..................................................................................................... 153

12.5 Setting the System Time........................................................................................... 159

12.6 Setting the Program Manager .................................................................................. 162

12.7 File Management of TNC Partition ........................................................................... 163

12.8 File Management of PLC Partition ............................................................................ 165

13 Data Backup ..................................................................................................................... 169

13.1 Introduction ............................................................................................................... 169

13.2 Connection Setup...................................................................................................... 172

13.2.1 Via Ethernet ..................................................................................................... 172

13.2.2 Via serial interface RS-232-C or RS-422 ........................................................... 182

13.2.3 Via USB ............................................................................................................ 185

13.3 Reading In and Out of Individual Files or Directories ................................................ 186

13.4 Backup on an External Data Medium........................................................................ 192

13.5 Extracting Files from the Backup File........................................................................ 196

13.6 Restoring Data........................................................................................................... 197

13.7 Cable Overview ......................................................................................................... 200

13.7.1 Ethernet interface RJ45 connection ................................................................ 200

13.7.2 RS-232-C (V.24) ............................................................................................... 201

13.7.3 RS-422 (V.11) .................................................................................................. 204

13.8 Operating Modes of the Data Interfaces................................................................... 205

13.8.1 Overview of operating modes ......................................................................... 205

13.8.2 Interface configuration and assignment of

13.9 Drive Symbols

14 Reloading the NC Software Used .................................................................................. 209

14.1 Introduction ............................................................................................................... 209

14.2 Preparations .............................................................................................................. 209

14.3 Proceeding up to NC Software 34049x-02 (Single-Processor Version) ..................... 210

14.4 Proceeding as of NC Software 34049x-02 (Single-Processor Version)...................... 212

14.5 Proceeding for the Dual-Processor Version............................................................... 215

........................................................................................................... 207

mode ............................................ 206

HEIDENHAIN Service Manual iTNC 530

Page 5

15 Loading of Service Packs ................................................................................................ 219

15.1 Introduction ............................................................................................................... 219

15.2 Preparations............................................................................................................... 220

15.3 Execution up to NC Software 34049x-01 (Single and Dual Processor Version) ........ 221

15.4 Execution as of NC Software 34049x-02 (Single-Processor Version)........................ 223

15.5 Execution as of NC Software 34049x-02 (Dual-Processor Version) .......................... 226

16 Checking the Enables on the iTNC 530.......................................................................... 229

16.1 Introduction ............................................................................................................... 229

16.2 Examination............................................................................................................... 232

16.2.1 Checking the "Control is ready" output and input

(EMERGENCY STOP chain) ....................................................................................... 233

16.2.2 Checking the global drive enable I32, connector X42 / pin 33 ......................... 239

16.2.3 Checking the drive enabling for the axis groups via connector

X150 and X151 (if wired) ............................................................................................ 242

16.2.4 Checking the readiness of the inverter system ............................................... 243

16.2.5 Checking PLC modules, markers and words ................................................... 248

17 Power Supply ................................................................................................................... 251

17.1 Power Supply for the iTNC 530 ................................................................................. 251

17.1.1 Introduction ...................................................................................................... 251

17.1.2 UV 105, UV 105 B ............................................................................................ 256

17.1.3 UV 106, UV 106 B ............................................................................................ 260

17.2 Power Supply for "Control-Is-Ready Signal"............................................................... 262

17.3 Buffer Battery............................................................................................................ 264

17.4 Information Menu...................................................................................................... 267

17.5 Power Supply for PLC Outputs ................................................................................. 268

17.5.1 Introduction ...................................................................................................... 268

17.5.2 Supply voltage for PLC outputs on the MC ..................................................... 269

17.5.3 Supply voltage for PLC outputs on the PL 4xx B ............................................. 272

17.5.4 Supply voltage for PLC outputs on the PL 510 ................................................ 274

17.6 Power Supply for the Display Units........................................................................... 276

18 Encoder Interface ............................................................................................................. 277

18.1 Position Encoders...................................................................................................... 277

18.1.1 Introduction ...................................................................................................... 277

18.1.2 Possible causes of errors ................................................................................. 279

18.1.3 Troubleshooting ............................................................................................... 280

18.1.4 Possibilities with the integrated diagnosis or DriveDiag .................................. 282

18.1.5 Possibilities with the integrated oscilloscope .................................................. 283

18.1.6 Corrective action .............................................................................................. 286

18.1.7 Determining the field angle on linear motors, torque motors and

synchronous spindles ................................................................................................ 287

18.1.8 Resetting the machine datum ......................................................................... 288

18.1.9 Restoring the spindle orientation ..................................................................... 292

18.2 Speed Encoders ........................................................................................................ 293

18.2.1 Introduction ...

18.2.2 Possible causes of errors ................................................................................. 295

18.2.3 Trouble shooting on the CC 422 ...................................................................... 296

18.2.4 Trouble shooting on the CC 424 (B) ................................................................. 298

18.2.5 Possibilities with the integrated diagnosis or DriveDiag .................................. 300

18.2.6 Possibilities with the integrated oscilloscope .................................................. 301

18.2.7 Corrective action .............................................................................................. 304

18.2.8 Readjusting the trip dog for reference end position ........................................ 305

18.2.9 Resetting the machine datum ......................................................................... 306

18.2.10 Restoring the spindle orientation ................................................................... 306

18.3 Error Codes for Encoders with EnDat Interface ........................................................ 307

18.4 Further Examination of Position and Speed Encoders .............................................. 308

..............

.................................................................................... 293

July 2010 HEIDENHAIN Service Manual iTNC 530

Page 6

18.5 Position Measurement via Motor Encoder (Indirect Position Measurement) ........... 311

18.6 Switching over the Position Display for Servicing ..................................................... 315

19 Reference Run .................................................................................................................. 317

19.1 Definition................................................................................................................... 317

19.2 Traversing the Reference Marks............................................................................... 318

19.3 Possible Causes of Errors ......................................................................................... 318

19.4 Troubleshooting......................................................................................................... 319

19.5 Corrective Action....................................................................................................... 320

19.6 Deselecting the Reference Run for Axes .................................................................. 320

19.7 Retraction after an Error with Control Reset ............................................................. 321

20 Interface to the Drives..................................................................................................... 323

20.1 Digital PWM Interface............................................................................................... 323

20.1.1 Introduction ..................................................................................................... 323

20.1.2 Tables for power supply modules, power stages and motors ........................ 326

20.1.3 Possible causes of error .................................................................................. 332

20.1.4 Sequence for finding errors in the control loop ............................................... 332

20.1.5 Troubleshooting: Interchanging PWM outputs on the CC 422 ........................ 333

20.1.6 Troubleshooting: Interchanging PWM outputs on the CC 424 (B) .................. 336

20.1.7 Troubleshooting: Interchanging power modules or output stages of

the same type ............................................................................................................. 339

20.1.8 Troubleshooting: Interchanging the HEIDENHAIN interface boards

for the SIMODRIVE 611 system ............................................................................... 342

20.1.9 Corrective action .............................................................................................. 343

20.2 Analog Speed Command Interface ........................................................................... 344

20.2.1 Introduction ..................................................................................................... 344

20.2.2 Possible causes of error .................................................................................. 344

20.2.3 Sequence for finding errors in the control loop ............................................... 345

20.2.4 Checking the analog speed command interface ............................................. 346

20.2.5 Adjusting the electrical offset (drift adjustment) ............................................. 349

20.2.6 Speed adjustment at the servo amplifier (tachometer adjustment) ................ 352

20.2.7 Corrective action .............................................................................................. 354

21 Visual Display Unit .......................................................................................................... 355

21.1 Introduction ............................................................................................................... 355

21.2 Possible Causes of Errors ......................................................................................... 355

21.3 Troubleshooting......................................................................................................... 356

21.4 Corrective Action....................................................................................................... 358

22 Keyboard Unit .................................................................................................................. 359

22.1 Introduction ............................................................................................................... 359

22.2 Front View of the Keyboard Units ............................................................................ 360

22.3 Possible Causes of Error ........................................................................................... 362

22.4 Checking the Keys..................................................................................................... 363

22.5 Checking the Potentiometers.................................................................................... 367

22.6 Checking the Touchpads ........................................................................................... 370

22.7 Corrective Action....................................................................................................... 371

22.8 Key Matrix of the Keyboard Units ............................................................................. 372

22.9 Key Matrix of the Keyboard Units ............................................................................. 388

23 Machine Operating Panel................................................................................................ 389

23.1 Introduction ............................................................................................................... 389

23.2 Possible Causes of Errors ......................................................................................... 390

23.3 Checking the Power Supply ...................................................................................... 391

23.4 Checking the Keys..................................................................................................... 392

23.5 Checking the Outputs ............................................................................................... 397

23.6 Corrective Action....................................................................................................... 398

HEIDENHAIN Service Manual iTNC 530

Page 7

24 Handwheel........................................................................................................................ 399

24.1 Introduction ............................................................................................................... 399

24.2 Possible Causes of Errors.......................................................................................... 400

24.3 Error Location on Portable Handwheel with HR 420 Display .................................... 401

24.4 Error Diagnosis at HR 410 Portable Handwheel........................................................ 406

24.5 Deselecting and Disconnecting the Portable Handwheel ......................................... 409

24.6 Error Diagnosis at Panel-Mounted Handwheels........................................................ 410

24.7 Corrective Action....................................................................................................... 412

25 Touch Probe ..................................................................................................................... 413

25.1 Introduction ............................................................................................................... 413

25.2 Possible Causes of Errors.......................................................................................... 417

25.3 Error Diagnosis on TS Touch Probes......................................................................... 418

25.4 Error Diagnosis on TT Touch Probes ......................................................................... 422

25.5 Error Diagnosis on Laser Touch Probe...................................................................... 425

25.6 Deselecting and Disconnecting the Touch Probe...................................................... 426

25.7 Corrective Action....................................................................................................... 427

26 Important Features of HEIDENHAIN Components ....................................................... 429

26.1 HEIDENHAIN Components in a Machine Tool .......................................................... 429

26.2 Hardware Identification ............................................................................................. 430

26.3 Display of Important System Information.................................................................. 443

27 Connector Designation and Layout ............................................................................... 447

27.1 Important Note .......................................................................................................... 447

27.2 MC and CC ................................................................................................................ 447

27.2.1 Designation and position of connectors .......................................................... 447

27.2.2 Pin Layouts on the MC and CC ........................................................................457

27.3 Power Supply Units................................................................................................... 487

27.3.1 UV 105 power supply unit ............................................................................... 488

27.3.2 UV 105 B power supply unit ............................................................................ 490

27.3.3 UV 106 (B) power supply unit .......................................................................... 492

27.4 Monitors .................................................................................................................... 493

27.4.1 Designation and position of connectors ......................................................... 493

27.4.2 Pin layouts ...................................................................................................... 494

27.5 Keyboard Units .......................................................................................................... 495

27.5.1 Designation and position of connectors .......................................................... 495

27.5.2 Pin layouts ....................................................................................................... 497

27.6 BTS 1x0 Monitor/Keyboard Switch............................................................................ 498

27.7 Machine Operating Panel ....................................................................................... 499

27.7.1 Designation and position of connectors .......................................................... 499

27.7.2 Pin Layouts on MB 420 ................................................................................... 499

27.7.3 Pin layouts on MB 520 ..................................................................................... 500

27.8 Handwheels............................................................................................................... 503

27.8.1 HR 4xx portable handwheel ............................................................................. 503

27.8.2 HR 130 panel-mounted handwheel ................................................................. 504

27.8.3 HRA 110 handwheel adapter ........................................................................... 505

27.9 Touch Probes............................................................................................................. 507

27.10 PLC Input/Output Units........................................................................................ 507

27.10.1 Designation and position of connectors ........................................................ 507

27.10.2 PL 4xxB Pin Layouts ...................................................................................... 510

27.10.3 Pin layouts for PL 510 .................................................................................... 516

27.11 Encoders.................................................................................................................. 520

27.11.1 Position encoders .......................................................................................... 520

27.11.2 Speed encoders .............................................................................................

27.12 Inverters and Mo

27.13 Interface Boards for the SIMODRIVE System 611D............................................. 522

tors.............................................................................................. 522

522

July 2010 HEIDENHAIN Service Manual iTNC 530

Page 8

28 Exchange of HEIDENHAIN Components........................................................................ 523

28.1 Important Information ............................................................................................... 523

28.2 Exchange of the MC 422........................................................................................... 531

28.3 Exchange of the Drive Assembly .............................................................................. 537

28.4 Exchange of the MC 422 B, MC 422 C, MC 420 ...................................................... 542

28.5 Exchange of the HDR................................................................................................ 544

28.6 Exchange of the CC................................................................................................... 551

28.7 Exchange of the Buffer Battery................................................................................. 552

28.8 Exchange of Other HEIDENHAIN Components ........................................................ 553

28.9 Exchange of HEIDENHAIN Components in the SIMODRIVE System ...................... 554

29 Measuring, Testing and Inspection Equipment............................................................ 561

29.1 Important Notes ........................................................................................................ 561

29.2 Test Adapter.............................................................................................................. 562

29.3 PWM 9 Encoder Diagnostic Set................................................................................ 566

29.4 PWT 10/17/18 Testing Unit ....................................................................................... 568

29.5 IK 215 Adjusting and Testing Package ...................................................................... 570

30 Machine Parameter ........................................................................................................ 571

30.1 Explanation................................................................................................................ 571

30.2 The Machine Parameter Editor.................................................................................. 572

30.3 Meaning of the Machine Parameters........................................................................ 579

30.4 List of Machine Parameters ...................................................................................... 580

30.4.1 Encoders and machines .................................................................................. 580

30.4.2 Positioning ....................................................................................................... 586

30.4.3 Operation with Velocity Feedforward Control ................................................. 592

30.4.4 Operation with following error (servo lag) ....................................................... 593

30.4.5 Integrated speed and current control .............................................................. 594

30.4.6 Spindle ............................................................................................................. 603

30.4.7 Integrated PLC ................................................................................................. 606

30.4.8 Configuration of the Data Interface ................................................................. 609

30.4.9 3-D touch probe ............................................................................................... 611

30.4.10 Tool Measurement with TT ........................................................................... 613

30.4.11 Tapping .......................................................................................................... 616

12 Display and operation ..

30.4.

30.4.13 Color .............................................................................................................. 624

30.4.14 Machining and Program Run ......................................................................... 627

30.4.15 Hardware ....................................................................................................... 634

30.4.16 Second spindle .............................................................................................. 643

.................................................................................. 617

1 Annex: Principle of Function of the iTNC 530 Control.................................................... 645

1.1 Introduction ................................................................................................................. 645

1.2 The Control Loop......................................................................................................... 645

1.3 PWM Signals............................................................................................................... 654

2 Annex: Principle of Function of the iTNC 530 Control.................................................... 657

3 Annex: Monitoring Functions........................................................................................... 661

3.1 Introduction ................................................................................................................. 661

3.2 During Start-Up............................................................................................................ 661

3.3 During Operation......................................................................................................... 663

3.3.1 Position or servo lag monitoring ........................................................................ 664

3.3.2 Nominal speed value monitoring ....................................................................... 666

3.3.3 Movement monitoring ....................................................................................... 667

3.3.4 Standstill monitoring .......................................................................................... 669

3.3.5 Positioning window ........................................................................................... 670

3.3.6 Monitoring of the power supply unit ................................................................. 672

3.3.7 Temperature monitoring .................................................................................... 674

3.3.8 Internal power supply and housing fan .............................................................. 675

HEIDENHAIN Service Manual iTNC 530

Page 9

3.3.9 I2t monitoring ..................................................................................................... 676

3.3.10 Actual utilization of drive motors .....................................................................681

3.3.11 Status of HEIDENHAIN inverters ..................................................................... 682

3.3.12 Controlling the motor brakes ...........................................................................684

3.3.13 EMERGENCY STOP monitoring during operation ........................................... 687

July 2010 HEIDENHAIN Service Manual iTNC 530

Page 10

HEIDENHAIN Service Manual iTNC 530

Page 11

1 How to Use this Service Manual

Note

1.1 Target Group

This Service Manual has been written for specialist electricians for service, maintenance and

commissioning.

Specialists who perform work on the electrical system of a machine tool and its components

must have the required technical knowledge and competence!

1.2 About this Manual

This Service Manual assists service personnel in the field in diagnosing and

correcting errors on machine tools controlled by iTNC 530.

It includes:

Error messages and types of errors that indicate technical defects

Information on possible error causes

Descriptions of error diagnosis

Application descriptions of the diagnosis tools

Information on corrective action

Data backup instructions

Theoretical explanations of functions and their correlations

The ”List of NC Error Messages” on page 4 – 29 and the ”Overview of Possible Error Patterns”

on page 5 – 55 include many references to the descriptions for error diagnosis. You will find

these descriptions in the chapters of this Service Manual sorted by topics.

The Service Manual does not provide any commissioning support!

It comprises the service possibilities with the current hardware and software at the editing date

of this manual. The service possibilities of your devices may differ from those described here.

The descriptions also provide information on any peculiarities of the hardware or software.

This manual is valid for:

iTNC 530, single-processor with NC software 340420 / 421

iTNC 530, single-processor with NC software 340422 / 423

iTNC 530, dual-processor with NC software 340480 / 481

iTNC 530, single-processor with NC software 340490 / 491

iTNC 530, dual-processor with NC software 340492 / 493

For the instructions for the field service it is assumed that ...

the machine had been working perfectly before the error occurred!

only original parts are used!

Basic knowledge in Windows is required for some descriptions in this Service Manual

concerning the handling of the dual-processor control iTNC 530 and the use of a service

laptop or PC.

July 2010 1 – 11

Page 12

Udpate service This Service Manual is updated at irregular intervals.

Note

Note

Caution

Note

You find the current printable version on our website -->

http://www.heidenhain.de/ ... /SHB iTNC 530

If you take part in a service training, you receive also a paper version of the Service Manual.

1.3 Other Service Manuals

Service Manual for Inverter Systems and Motors

1.4 Other Documentation

For more important information please refer to the following documentation:

Machine documentation by the manufacturer

(circuit diagrams, wiring diagrams, machine operating manual, etc.)

HEIDENHAIN User's Manual for iTNC 530

HEIDENHAIN TNCguide on DVD

Mounting instructions by HEIDENHAIN

Brochures of the respective HEIDENHAIN products

PWM 9 User's Manual

PWT Operating Instructions

IK 215 Operating Instructions

1.5 Support

However, support will also be provided by the Service Department of HEIDENHAIN Traunreut

or by the HEIDENHAIN agencies.

You will find telephone numbers as well as e-mail addresses on the back cover of this Service

Manual, or on the HEIDENHAIN website (www.heidenhain.de).

1.6 Service Training

HEIDENHAIN Traunreut offers service training courses in German language. We recommend

the HEIDENHAIN Service Training Seminars for iTNC 530 for the technician who works with this

Service Manual.

Please contact HEIDENHAIN Traunreut or visit our website (www.heidenhain.de).

You can find up-to-date issues of this and other HEIDENHAIN documents quickly on our

website --> www.heidenhain.de

HEIDENHAIN software tools (e.g. TNCremoNT) feature detailed on-line help.

The machine manufacturer must be contacted first for error diagnosis on your machine

tool!

If required, please inquire at the HEIDENHAIN subsidiary in your country whether Service

Training Seminars are offered in your language.

1 – 12 HEIDENHAIN Service Manual iTNC 530

Page 13

1.7 Meaning of the Symbols Used in this Manual

DANGER

Caution

Note

DANGER

Failure to comply with this information could result in most serious or fatal injuries, and/or

in substantial material damage.

Failure to comply with this information could result in injuries and interruptions of operation,

including material damage.

These boxes contain important and useful information.

1.8 Safety

It is extremely important that you read the safety precautions in chapter 2 before you start

servicing!

See “Safety Precautions” on page 2 – 15.

July 2010 1 – 13

Page 14

1 – 14 HEIDENHAIN Service Manual iTNC 530

Page 15

2 Safety Precautions

DANGER

DANGER

DANGER

DANGER

DANGER

Caution

DANGER

2.1 Overview

Ground

Ensure that the equipment grounding conductor is continuous!

Interruptions in the equipment grounding conductor may cause damage to persons or

property.

Zero potential

Ensure that the main switch of the control is switched off and that connected devices are

not under power when you engage or disengage any connectors or terminals.

Take precautions against restart!

Use an appropriate voltage test unit to ensure that the unit is not under voltage!

Fundamental knowledge

In order to be able to judge the behavior of an NC controlled machine, service engineers

need to have fundamental knowledge of controls, encoders, drives, electronics and

mechanics.

Improper use can result in serious injury to persons and damage to equipment.

Know-how and competence

Suitable tools

Safety precautions of the machine manufacturer

Regulations for

power installations

and instructions for

safety and prevention of accidents

Technicians who work on the electrical system of the machine must have the required

know-how and competence!

Use suitable tools, e.g. insulated screwdrivers and pincers!

Note the safety precautions on the machine (e.g. labels, signs) and the safety precautions

in the documentation of the machine manufacturer (e.g., operating instructions).

Observe the national regulations for power installations and the general instructions for

safety and prevention of accidents!

July 2010 2 – 15

Page 16

Basic insulation

DANGER

DANGER

DANGER

Caution

Vertical axes

Changes to entry values

The interfaces for the PLC inputs/outputs, machine operating panel and PL expansion cards

comply with the basic insulation in accordance with IEC 742 EN 50 178.

Only units that comply with the requirements of IEC 742 EN 50 178 for basic insulation may

be connected, otherwise damage to persons or property may be caused.

The maximum dc voltage mean value of the PLC inputs is 31 V.

Always secure vertical axes to prevent them from falling down before you perform tests on

these axes!

Incorrect or non-optimized input values can lead to faulty machine performance and

therefore to serious injury to persons and damage to equipment.

Machine parameters may only be changed by the machine manufacturer or after consulting

the machine manufacturer!

Uncontrolled axis and spindle movements must be expected.

Settings that have an effect on the control's feedback loops may only be altered when the

EMERGENCY STOP button of the machine is pressed.

Liability

HEIDENHAIN does not accept any responsibility for indirect or direct damage caused to

persons or property through incorrect use or operation of the machine!

2 – 16 HEIDENHAIN Service Manual iTNC 530

Page 17

3 Code Numbers

DANGER

Note

3.1 Introduction

With code numbers …

certain areas of the hard disk

certain file types

certain functions

... can be called.

Code numbers may only be passed on to and be used by trained service technicians.

Keep the code numbers confidential!

Inexpert handling may result in a loss of important data, in faulty machine performance and

thus lead to damage or injury to property or persons.

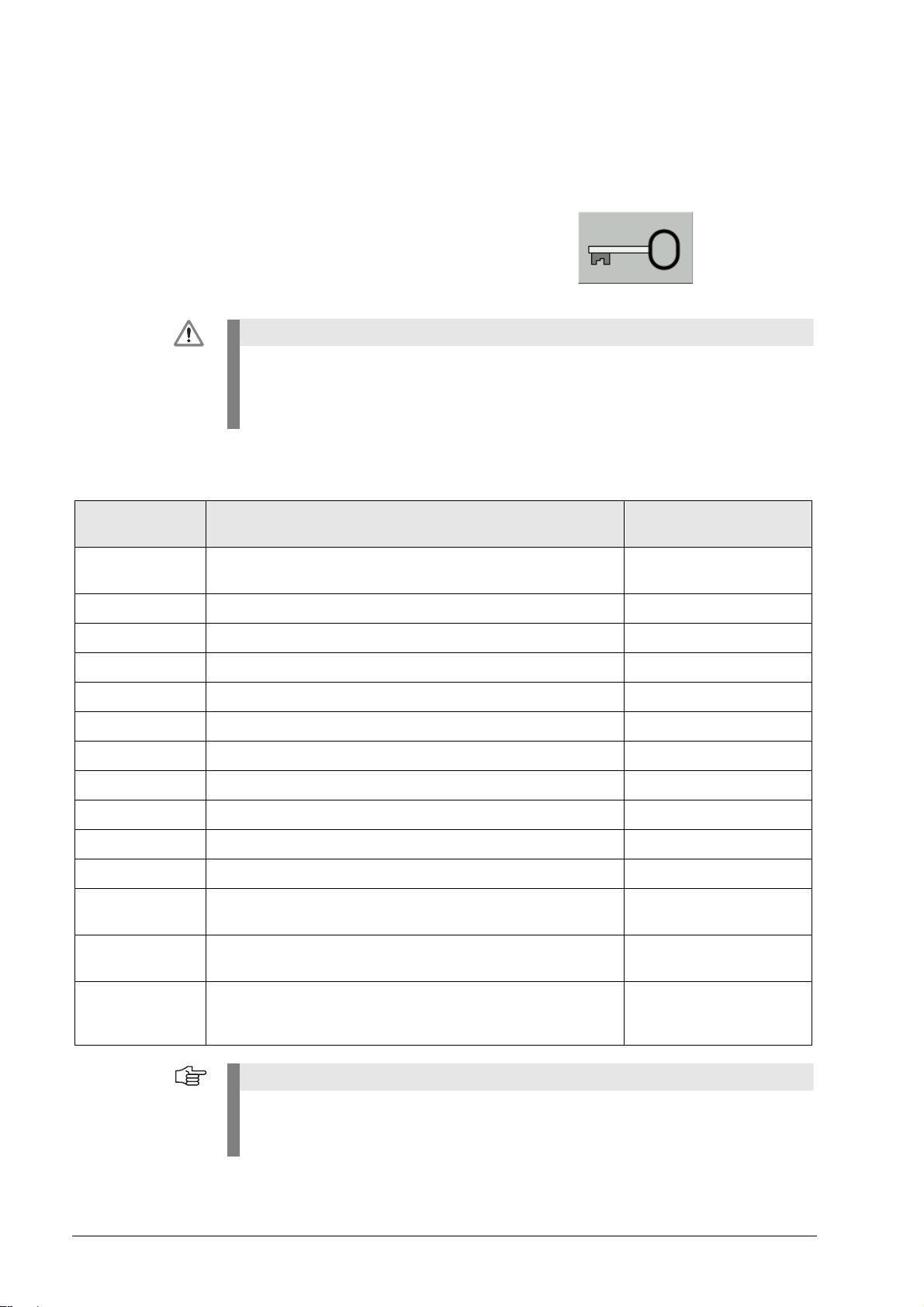

3.2 Overview

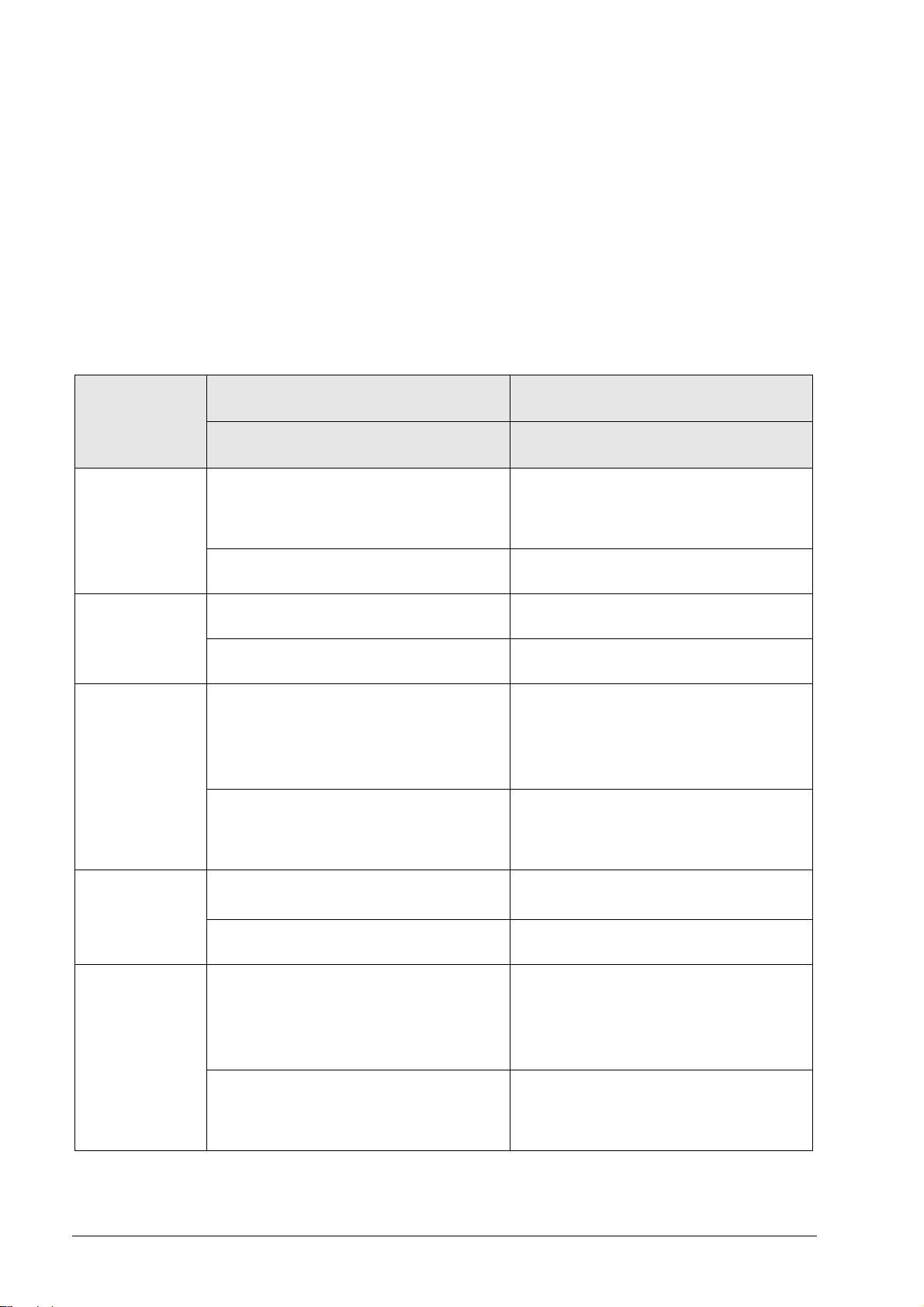

Code number Brief description Description in

this manual

0 Delete the code numbers entered so far --> Code-number

softkeys, such as MP EDIT or PLC EDIT are deleted.

123 Edit subset of machine parameters for the machine operator See page 30 - 571

75368 Offset adjustment for analog axes See page 20 – 349

79513 Info menu (U[BATT], U[ACCU], U[VCC], TEMP, T[CPU1]), See page 17 – 267

95148 Call the active machine parameter list See page 30 – 572

531210 Reset non-volatile PLC markers and PLC words in the RAM See page 11 – 133

688379 Integrated oscilloscope See page 10 – 99

807667 Call the PLC area See page 11 – 115

857282 Reset the operating times -

LOGBOOK Call and save the internal log of the TNC See page 8 – 81

NET123 Network settings for the single-processor control See page 13 – 172

SETUP Call for loading of service packs and NC software for the single-

processor control

SIK Display of the number of the system identification key and of the

enabled options

VERSION Create the file TNC:\Version.a

System data is saved in this file for diagnostic purposes. The file

can be read out for diagnosis.

In this chapter

See page 15 – 219

See page 28 – 525

-

The machine manufacturer can define own MP and PLC code numbers.

In this event the HEIDENHAIN code numbers do not function any longer, or only function to

a limited extent. --> Contact your machine manufacturer!

July 2010 3 – 17

Page 18

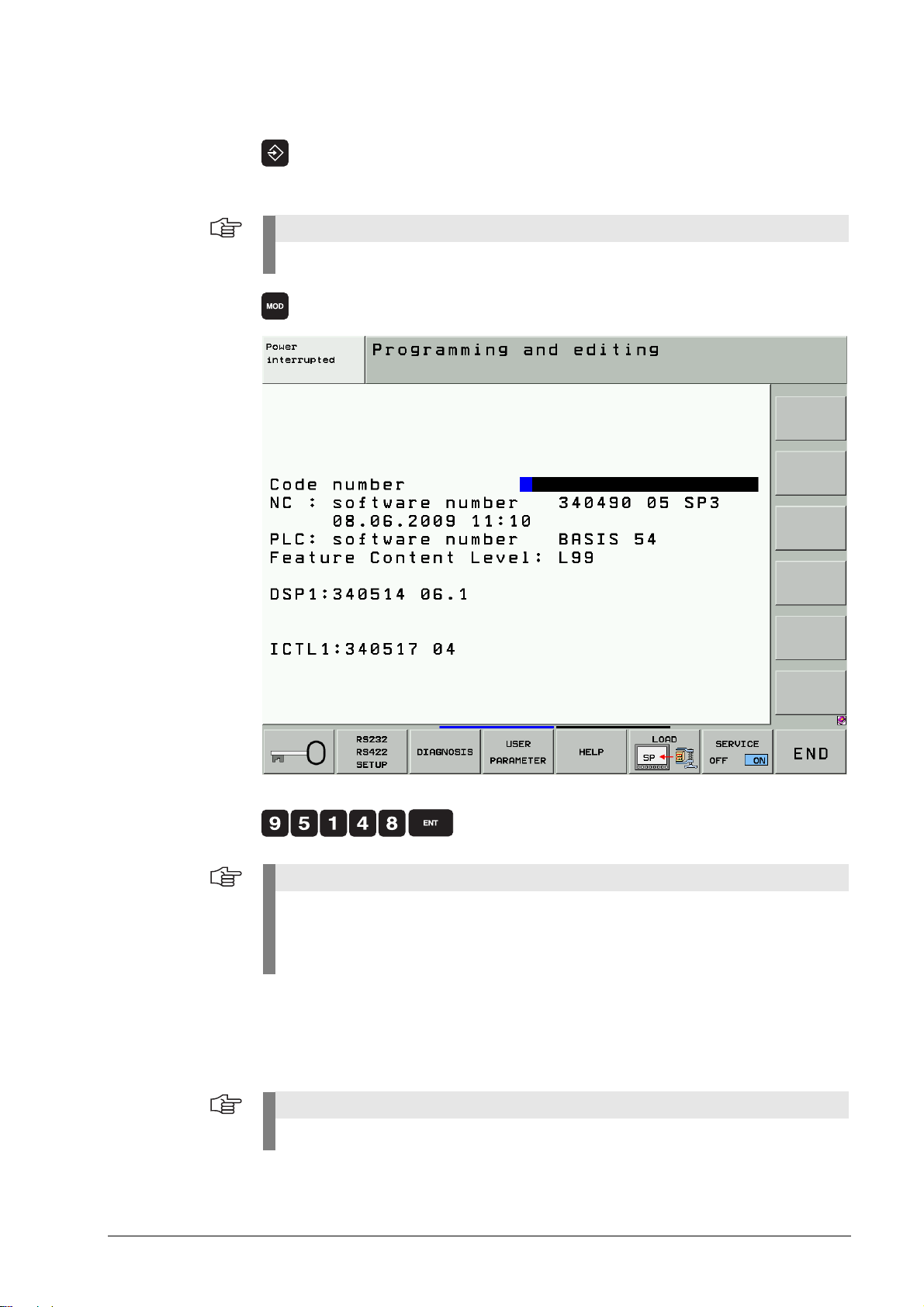

3.3 Input of Code Numbers

Note

Note

Note

8 If open: Close the program management by pressing the END button.

Pressing the MOD key while the program manager is open calls the interface settings.

8 Select the Programming and Editing operating mode.

8 Call the code number window.

8 Enter the code number and press ENT to confirm.

When certain code numbers are entered, new soft keys are displayed, MP EDIT,

PLC EDIT, OSCI.

With these soft keys you can also change to the corresponding areas without having to

enter the code number again.

When you have finished your work, reset all previously entered code numbers:

8 Enter the code number 0 and press ENT to confirm.

8 Press END to exit the code-number page.

All key codes are reset when the control is restarted.

3 – 18 HEIDENHAIN Service Manual iTNC 530

Page 19

Additional notes

As long as the machine parameter list is in the editor, no further code number can be

entered. First close the MP editor if you want to enter a new code number

After you have entered the code number for the machine parameters the PLC tree can be

seen in the program manager.

Only files with the extension .MP are displayed.

After entering the PLC code number all files in the PLC tree can be seen and loaded in the

editor.

However, to edit machine parameters, the soft key MP EDIT needs to be pressed first.

July 2010 3 – 19

Page 20

3 – 20 HEIDENHAIN Service Manual iTNC 530

Page 21

4Error Messages

Note

4.1 Introduction

iTNC features a comprehensive integral monitoring system for the prevention of input or

operation errors, as well as for identification and diagnosis of technical defects on the control

and the connected devices. The monitoring system is an integral component of the iTNC

hardware and software and is active as long as the control is switched on. The presence of a

technical fault or an operation error is made known through a plain-language message.

The effect of the monitoring functions is described in the annex -- .> See “Annex: Monitoring

Functions” on page 3 – 661.

Moreover, the machine manufacturer can define specific PLC error messages.

Type of error message

PLC error messages

Machine-specific error messages

Are defined by the machine manufacturer (e.g., coolant pump defective, protective door

open).

The machine manufacturer defines how the control reacts to a PLC error message (NC Stop,

EMERGENCY STOP, etc.).

The machine manufacturer defines whether the control can still be operated or has to be

rebooted after a PLC error message.

If you have any questions, please contact your machine manufacturer.

NC error messages

Are part of the HEIDENHAIN NC software.

Can be subdivided into error messages that result from operation, programming and machine

applications and those that indicate a technical defect (devices, electronic and mechanical

components, etc.)

HEIDENHAIN defines how the control reacts to an NC error message (NC Stop, EMERGENCY

STOP, etc.)

HEIDENHAIN defines whether the control can still be operated or has to be rebooted after an

NC error message.

If you have any questions, please contact your machine manufacturer and/or HEIDENHAIN.

Is the displayed error message an NC or PLC error message?

Display PLC error message NC error message

ERR window in the column

"Group".

Call -->

See “ERR Key” on page 4 – 26.

Log

Call -->

See “Log” on page 8 – 81.

There are no error numbers assigned to NC error messages that begin with N-1.

Operating-system error messages

Often contain the note CHILD PROCESS ERROR.

The control cannot be operated any more and has to be rebooted.

If you have any questions, please contact your machine manufacturer and/or HEIDENHAIN.

July 2010 4 – 21

PLC GENERAL

or

OPERATION

or

PROGRAMMING

P- (number and text of

error message)

N- (number and text of

error message)

Page 22

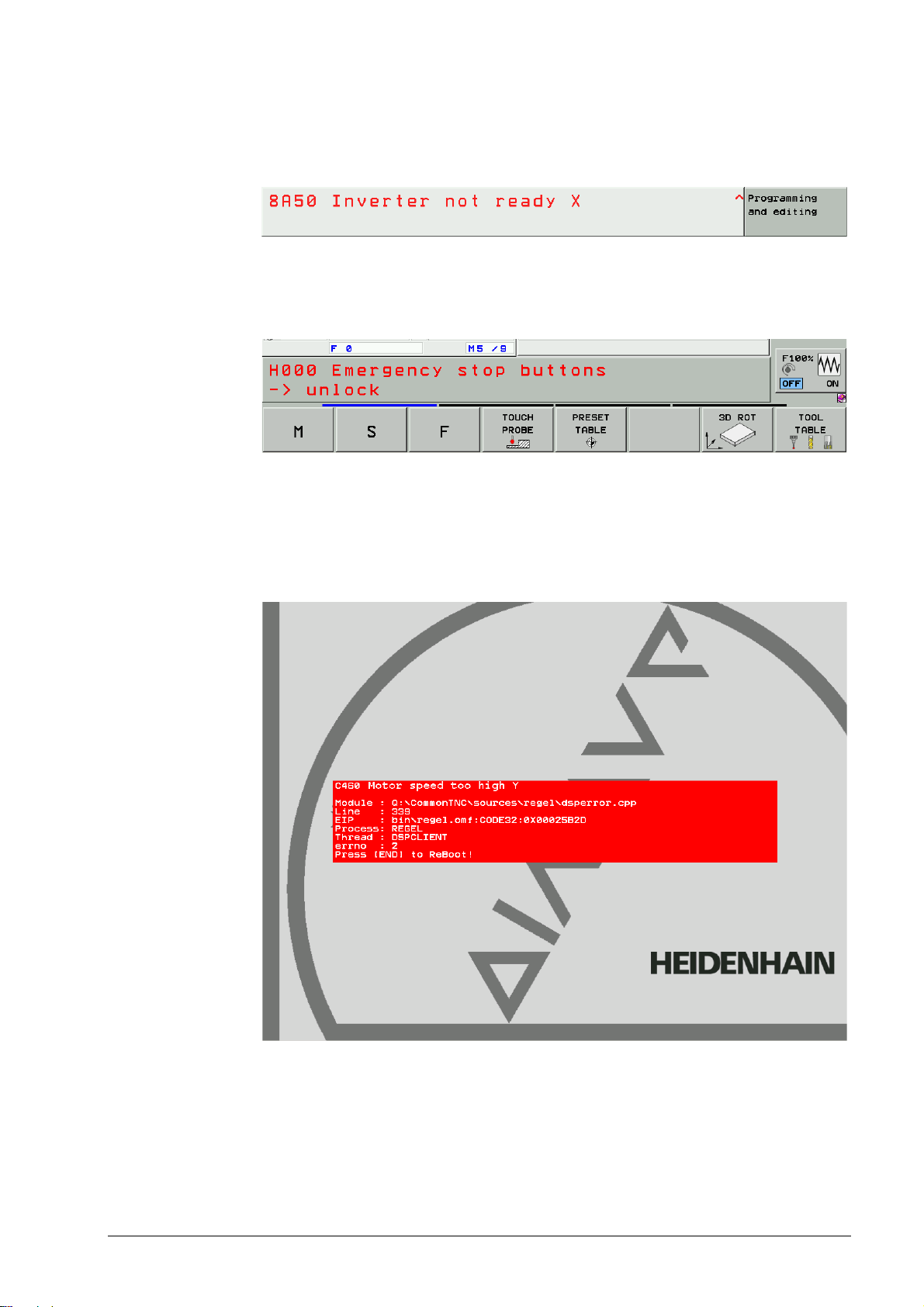

Display of the error message

All error messages that can be acknowledged with the CE key are …

Displayed in the screen header (at the top of the screen) usually in red color.

As a plain-language message.

Figure: Error message in the header

The machine manufacturer can display additional information on PLC error messages in the

small PLC window (above the soft-key row).

Figure: Additional information in the small PLC window

Error messages that require a rebooting of the control ...

are displayed in a red or gray window (depending on the NC software version) in the center

of the screen.

are made known through a plain-language message.

Figure: Red error window

4 – 22 HEIDENHAIN Service Manual iTNC 530

Page 23

Figure: Gray error window

July 2010 4 – 23

Page 24

Reaction of control and machine

Display only

A message (info, warning, error) is only displayed.

The machine does not react. Programs are not stopped.

The error message can be acknowledged anytime.

Feed stop

The feed-rate enable is reset. The "F"symbol for the feed rate is highlighted.

The axes are braked at the nominal-value characteristic.

The contour of the workpiece is usually not damaged.

Once the error message is acknowledged, the machine continues to operate at the set feed

rate.

Program cancellation

The running NC progam is canceled.

The axes are braked at the nominal-value characteristic.

The contour of the workpiece is usually not damaged.

After the error message was acknowledged, the NC program needs to be restarted

(GOTO 0, NC-START).

NC stop

The running NC progam is stopped. The star "*" (STIB) flashes.

The axes are braked at the nominal-value characteristic.

The contour of the workpiece is usually not damaged.

After the error message was acknowledged, the NC program can be restarted at the position

where it was interrupted (NC-START key).

EMERGENCY STOP

Automatic generation of service files

An EMERGENCY STOP is triggered at the machine.

Axes and spindles decelerate at the current limit; the machine must be brought to a standstill

as quickly as possible.

The contour of the workpiece is not taken into account and may be damaged.

After the error message was acknowledged, the machine must be switched on completely.

Now, the PLC program can be restarted (GOTO 0, NC START).

RESET

An EMERGENCY STOP is triggered at the machine.

Axes and spindles decelerate at the current limit; the machine must be brought to a standstill

as quickly as possible.

The contour of the workpiece is not taken into account and may be damaged.

The error message cannot be acknowledged. The control must be shut down and restarted.

Now, the PLC program can be restarted (GOTO 0, NC START).

As of NC software version 340 49x-04:

In the event of serious NC software errors or PLC error messages especially defined for this

purpose service files are generated automatically.

See “Creating and Downloading of Service Files” on page 7 – 77.

4 – 24 HEIDENHAIN Service Manual iTNC 530

Page 25

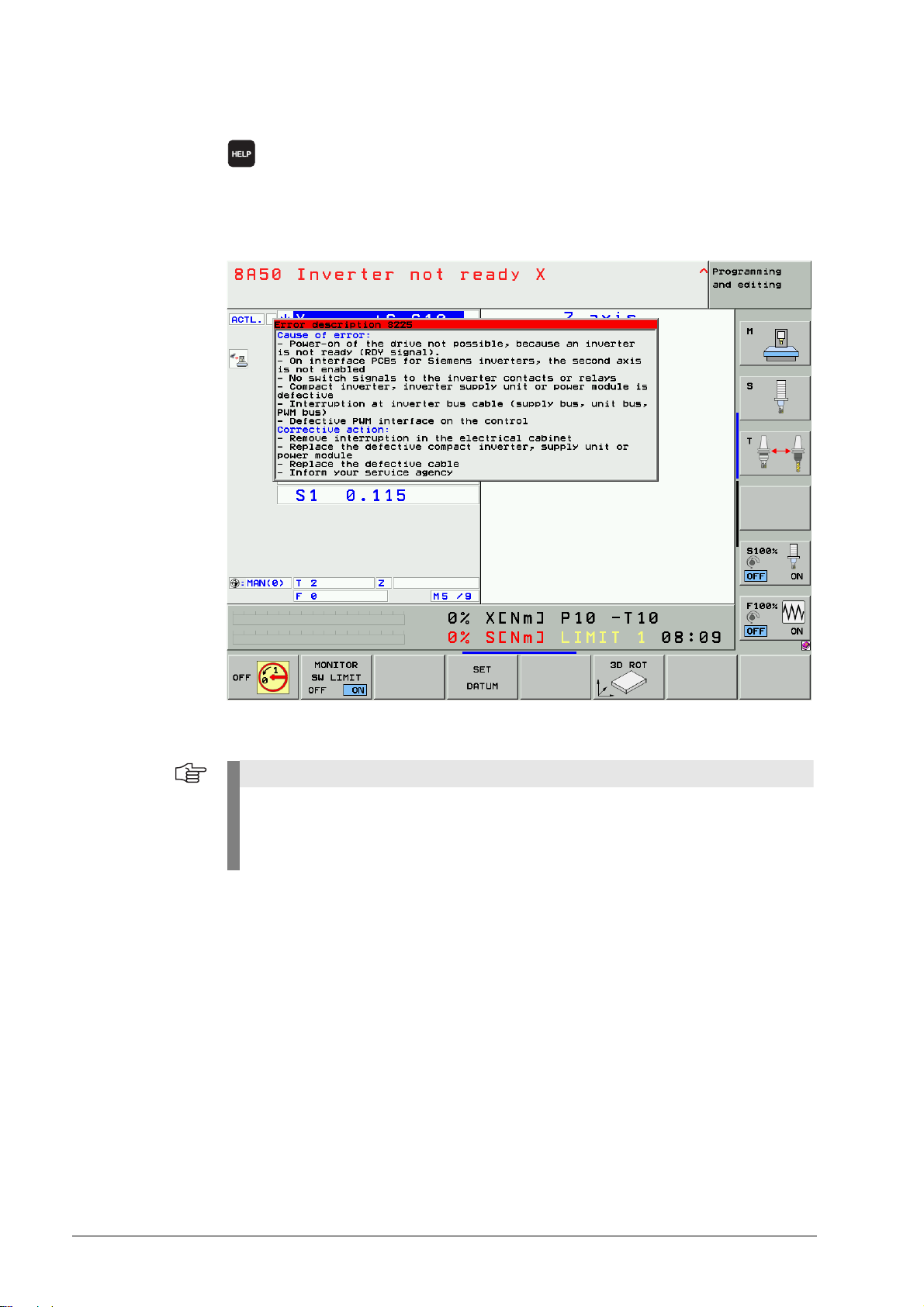

4.2 HELP Key

Note

8 Display help texts for error messages

(If you press this key again, the window will close.)

If the service technician presses the HELP key a window is shown that describes the cause

of error and possibilities of corrective action in addition to the displayed error message.

This support can also be realized for PLC error messages by the machine manufacturer!

Figure: HELP window

HELP texts cannot be displayed for error messages in red or gray windows. The control

must be rebooted.

Information on these errors can be found in the list of NC error messages, See “List of NC

Error Messages” on page 4 – 29.

July 2010 4 – 25

Page 26

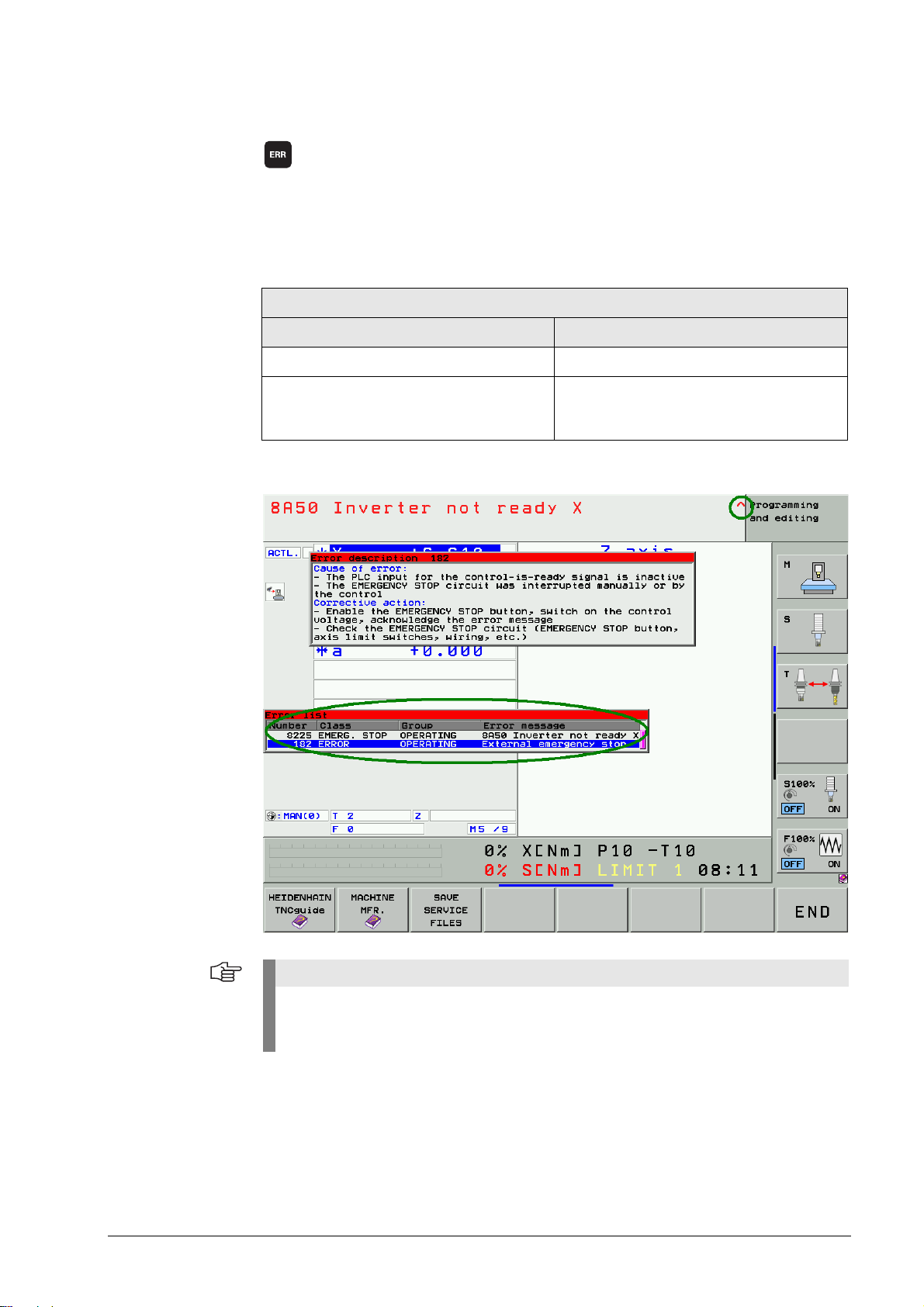

4.3 ERR Key

Note

8 Display all pending error messages in a list

(If you press this key again, the window will close.)

If there is an AND symbol (little red roof) in the header in addition to the error message, there is

more than one pending error message.

The ERR key (ERROR) is located directly over the HELP key. When this key is pressed all

pending NC and PLC error messages of the control are displayed in an own window.

List of error messages

In the ERR window In the log

In order of priority In chronological order

Errors with a higher priority are at the top of

the list.

The log is written from top to bottom, i.e.,

older errors are at the top, younger errors at

the bottom.

In addition, the help window can be called with the HELP key.

If your machine still features an old keyboard without an ERR key over the HELP key, press

the respective "space key" over the HELP key. --> If the NC software of the iTNC 530

supports the function of the ERR key, it can also be used to call the ERR list!

4 – 26 HEIDENHAIN Service Manual iTNC 530

Page 27

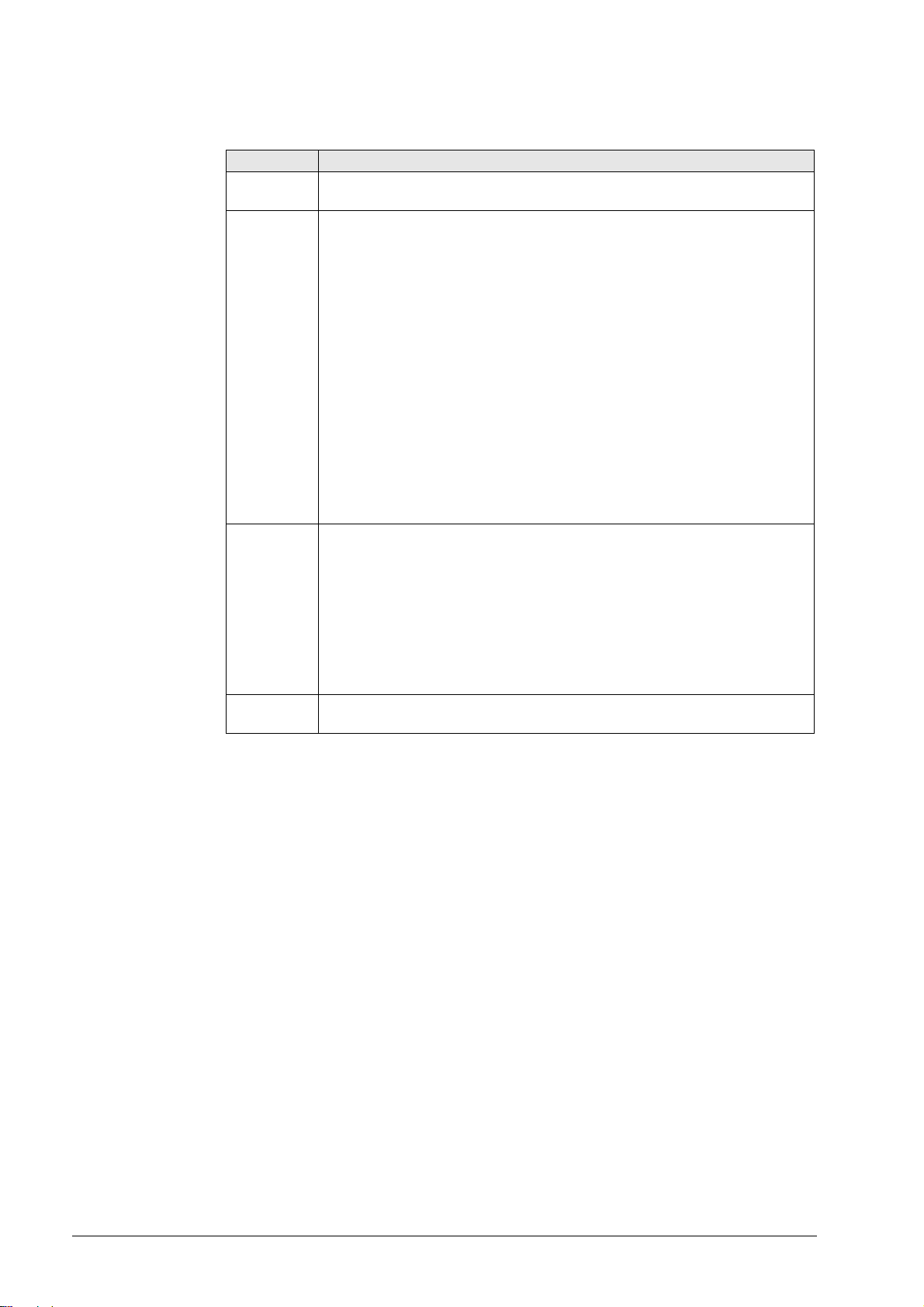

The columns in the ERR window have the following meanings:

Column Description

Number Error number (–1: no error number defined), issued by HEIDENHAIN or your

machine tool builder

Class Error class. Defines the reaction of the control:

ERROR

Program run is interrupted by the iTNC

FEED HOLD

The feed-rate release is canceled

PGM HOLD

The program run is interrupted (the control-in-operation symbol blinks)

PGM ABORT

The program run is interrupted (INTERNAL STOP)

EMERG. STOP

EMERGENCY STOP is set off

RESET

iTNC executes a system restart

WARNING

Warning message, program run resumes

INFO

Info message, program run resumes

Group Error source.

GENERAL

General error

OPERATING

Error during machining and machine traverse

PROGRAMMING

Error during programming

PLC

PLC error message of the machine manufacturer

Error

message

Displayed error text

The individual error messages can be selected with the cursor; the open help window shows

the appertaining text.

July 2010 4 – 27

Page 28

4.4 CE Key

Note

8 Clear error message (Clear Error)

Acknowledge error messages displayed by pressing the CE key.

If the error cause is still existing, the corresponding error message is displayed again. -->

Eliminate the error!

Messages regarding very fatal errors, cannot be confirmed with the CE key.

The control must be rebooted.--> Press the END key.

If this does not work --> Switch the power switch of the machine off and wait for several

seconds before you switch it on again.

4 – 28 HEIDENHAIN Service Manual iTNC 530

Page 29

4.5 List of NC Error Messages

Complete list You can find the complete list of all NC error messages (including operator errors) on the

TNCguide DVD in several languages and sorted by error numbers.

This TNCguide information is also available on our website --> www.heidenhain.de/...

This is the official list of NC error messages which contains all possible errors of HEIDENHAIN

controls that operate with the HeROS operating system.

It consists primarily of error messages related to operation and handling as well as technical error

messages.

Filtered list The list below contains the most important error messages that indicate a technical defect

in numerical and subsequently in alphabetical order.

A reference is made, if there are additional descriptions in this Service Manual.

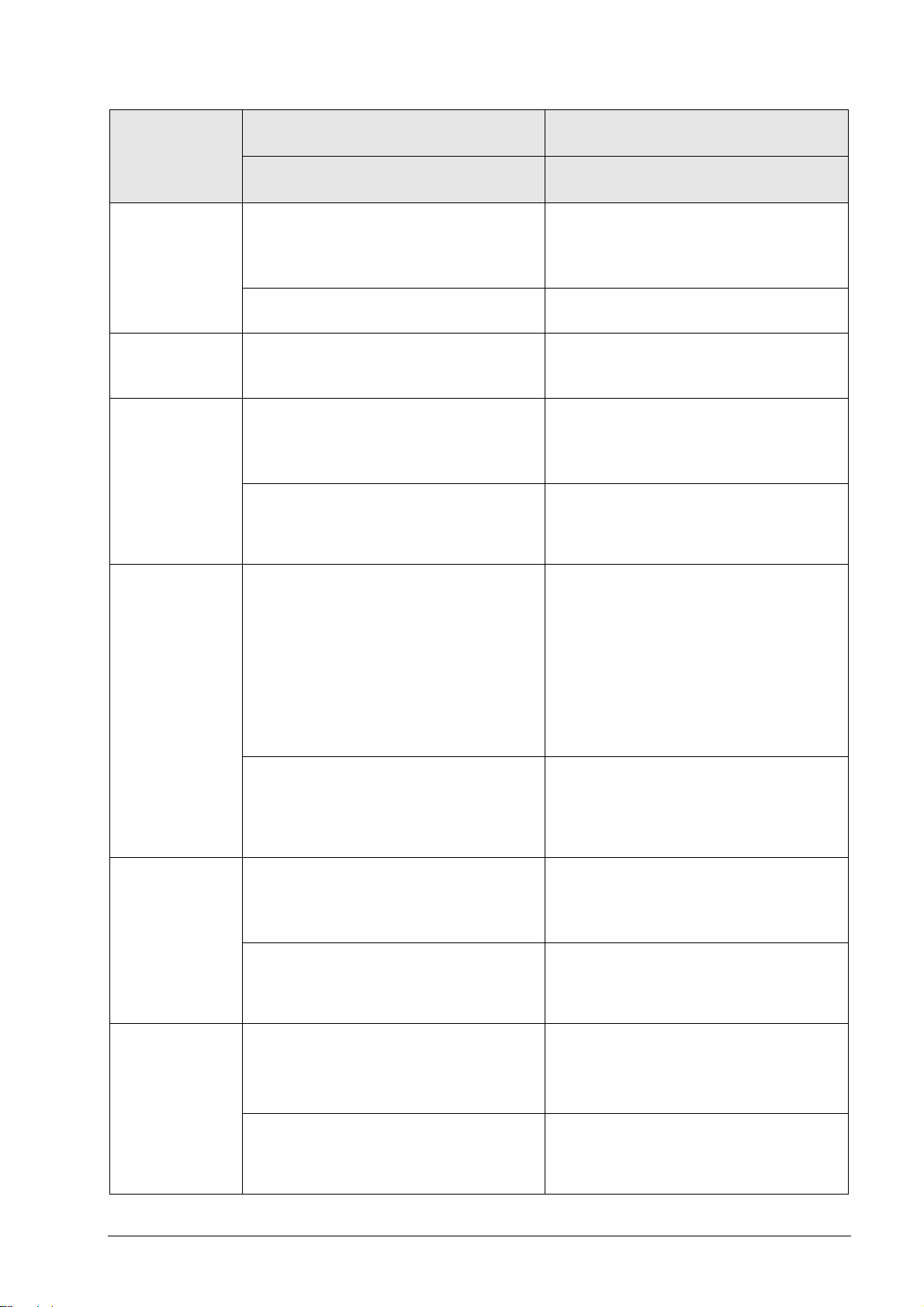

Error message Possible cause of error Measures for error diagnosis and/or

corrective action

8040 Heat-sink

temp. UV 1xx

8041 Excessive Iz

in UV 1xx

8043 No inverterready signal

8060 Leakage

current in UV 1xx

Additional information and descriptions in

the manual

Heat-sink temperature of UV 1xx power

supply unit is too high.

If the heat-sink temperature continues to

increase, the unit will be switched off.

See “Status of HEIDENHAIN inverters” on

page 3 – 682.

DC-link current of UV 1xx power supply unit

too high

See “Status of HEIDENHAIN inverters” on

page 3 – 682.

Readiness signal of the inverter (supply unit)

is inactive after the feedback control starts.

Master contactor has opened.

Error in PLC program

Inverter defective

See “Status of HEIDENHAIN inverters” on

page 3 – 682.

Insulation problem (e.g. defective motor). Check the motor.

Additional information and descriptions in

the manual

Stop the machine and let it cool down.

Continue working with lower power (reduce

the feed rate).

See Service Manual Inverter Systems and

Motors

Continue working with lower power (reduce

the feed rate).

See Service Manual Inverter Systems and

Motors

Try to restart.

Check the wiring (master contactor).

Check the PLC program.

Exchange the inverter (supply unit).

See “Checking the readiness of the inverter

system” on page 16 – 243.

See Service Manual Inverter Systems and

Motors.

Check the wiring.

See “Status of HEIDENHAIN inverters” on

page 3 – 682.

8061 No inverterready signal

July 2010 4 – 29

Readiness signal of the inverter (supply unit)

is inactive after the feedback control starts.

Master contactor has opened.

Error in PLC program

Inverter defective

See “Status of HEIDENHAIN inverters” on

page 3 – 682.

See Service Manual Inverter Systems and

Motors.

Try to restart.

Check the wiring (master contactor).

Check the PLC program.

Exchange the inverter (supply unit).

See “Checking the readiness of the inverter

system”

See Service Manual Invert

Motors.

on page 16 – 243.

er Systems and

Page 30

Error message Possible cause of error Measures for error diagnosis and/or

corrective action

8080 Uz UV 1xx

too high

8092 Pos. contr.

cyc. time error

8130 Motor brake

defective <axis>

8140 Error <axis>

field orientation

Additional information and descriptions in

the manual

DC-link voltage of the power supply unit too

high.

See “Status of HEIDENHAIN inverters” on

page 3 – 682.

MC is outputting erroneous cycle time for

CC position controller.

Hardware error

Motor brake defective. Traverse the axis to a safe position before

Field orientation impossible for mechanical

reasons.

Incorrect relation between electrical field

and mechanical motor motion.

Incorrect motor encoder signal.

Incorrect motor connection.

Mechanical brakes not released.

Additional information and descriptions in

the manual

Check the configuration datum (braking of

the spindle).

Check the braking resistor.

Replace the power supply unit.

See Service Manual Inverter Systems and

Motors.

Check machine parameter 7600.x.

Exchange the drive control board.

power-off.

Check controls for motor brakes.

Exchange the motor.

See “Controlling the motor brakes” on page

3 – 684.

See Service Manual Inverter Systems and

Motors.

Check the machine parameters for number

of signal periods and distance for the

number of signal periods.

Check the machine parameter for the linear

distance of one motor revolution.

For linear motors: Check STR column of the

motor table.

Check the speed encoder connection.

Check the motor connection.

Release brakes during orientation.

8300 Motor brake

defective <axis>

831

0 No current in

brake test <axis>

See “Speed Encoders” on page 18 – 293. See “Sequence for Finding Errors in the

Control Loop” on page 6 – 62.

See “Speed Encoders” on page 18 – 293.

See Service Manual Inverter Systems and

Motors.

Motor brake defective. Traverse the axis to a safe position before

power-off.

Check controls for motor brakes.

Exchange the motor.

See “Controlling the motor brakes” on page

3 – 684.

Manual Inverter Systems and

Motor connected incorrectly

Inverter connected incorrectly

Inverter defective

Motor defective

See Service

Motors.

Check the wiring of motor and inverter.

Check the inverter.

Check the motor.

See “Controlling the motor brakes” on page

3 – 684.

See Service Manual Inverter Systems and

Motors.

4 – 30 HEIDENHAIN Service Manual iTNC 530

Page 31

Error message Possible cause of error Measures for error diagnosis and/or

corrective action

8610 I2T value is

too high <axis>

8620 Load is too

high <axis>

8640 I2T value of

motor is too high

<axis>

Additional information and descriptions in

the manual

Excessive load over the time of the drive. Reduce the load or the duration.

See “I2t monitoring” on page 3 – 676. See Service Manual Inverter Systems and

Drive has maximum current and cannot

accelerate.

Excessive load (torque, power) on the drive.

The load of the motor is too high over the

duration.

Additional information and descriptions in

the manual

Check the motor table, power stage table

and configuration data.

Check whether the motor and power

module are designed for the load.

Motors.

Reduce the load on the drive.

Check the motor table, power stage table

and machine parameters.

Check whether the motor and power

module are designed for the load.

See “Sequence for Finding Errors in the

Control Loop” on page 6 – 62.

See Service Manual Inverter Systems and

Motors.

Reduce the load or the duration.

Check the motor table and machine

parameters.

Check whether the motor is designed for

the load.

8650 I2T value of

motor is too high

<axis>

8800 Signal LTRDY inactive

<axis>

8810 Signal LTRDY inactive

<axis>

8820 Field angle

unknown <axis>

See “I2t monitoring” on page 3 – 676. See Service Manual Inverter Systems and

Motors.

The load of the power module is too high

over the duration.

See “I2t monitoring” on page 3 – 676. See Service Manual Inverter Systems and

Inverter switch-off during closed-loop

control of a vertical axis (cause = vertical

axis).

See “Status of HEIDENHAIN inverters” on

page 3 – 682.

Inverter switch-off during closed-loop

control of a vertical axis (cause = vertical

axis).

See “Status of HEIDENHAIN inverters” on

page 3 – 682.

Field angle of the motor on the reference

point of the speed encoder has not yet been

ascertained.

Reduce the load or the duration.

Check the motor table and machine

parameters.

Check whether the power module is

designed for the load.

Motors.

Check the PLC program.

Check the wiring of the inverter.

See Service Manual Inverter Systems and

Motors.

Ch

eck the PLC program.

Check the wiring of the inverter.

See Service Manual Inverter Systems and

Motors.

Run a field orientation.

Check the motor table (column SYS).

See “Speed Encoders” on page 18 – 293.

July 2010 4 – 31

Page 32

Error message Possible cause of error Measures for error diagnosis and/or

corrective action

8830 EnDat: No

field angle <axis>

8860 Input

frequency from

speed encoder

<axis>

8870 Input

frequency from

position encoder

<axis>

8A00 No inverter

enabling %.2s

Additional information and descriptions in

the manual

Field angle of the motor with unaligned

speed encoder with EnDat interface has not

been ascertained.

The transferred EnDat serial number does

not match the stored EnDat serial number.

Connected EnDat encoder or encoder cable

is defective.

Noise on speed encoder signals Check the encoder signals.

Noise on position encoder signals Check the encoder signals.

Power-on of the drive not possible due to

missing enabling of the inverter via –SH1.

Additional information and descriptions in

the manual

Run a field orientation.

Check the motor table (column SYS).

See “Speed Encoders” on page 18 – 293.

Check the shielding.

See “Further Examination of Position and

Speed Encoders” on page 18 – 308.

Check the shielding.

See “Further Examination of Position and

Speed Encoders” on page 18 – 308.

Check the wiring.

8A10 AC fail %.2s Power-on of the drive not possible, because

an AC-fail signal (power supply) is active.

8A20 Powerfail

%.2s

8A30 Drive

enabling (I32)

%.2s

Power-on of the drive not possible, because

a powerfail signal (power supply) is active.

Power-on of the drive not possible due to

missing drive enabling via I32.

See “Checking the readiness of the inverter

system” on page 16 – 243.

See Service Manual Inverter Systems and

Motors

Test the power supply.

Check the wiring of the power supply.

See Service Manual Inverter Systems and

Motors

Test the power supply.

Check the wiring of the power supply.

See Service Manual Inverter Systems and

Motors

Check the wiring of the emergency-stop

loop.

See “Checking the global drive enable I32,

connector X42 / pin 33” on page 16 – 239.

4 – 32 HEIDENHAIN Service Manual iTNC 530

Page 33

Error message Possible cause of error Measures for error diagnosis and/or

corrective action

8A40 Enabling of

axis group %.2s

8A50 Inverter not

ready %.2s

8AF0 Encoder

<axis> defective

Additional information and descriptions in

the manual

Because of missing drive enabling for axis

groups (X150/X151), the drive cannot be

switched on.

Power-on of the drive not possible, because

an inverter is not ready (RDY signal).

Contamination of the position encoder

Encoder cable defective

Motor control board defective

See “Position Encoders” on page 18 – 277. See “Position Encoders” on page 18 – 277.

Additional information and descriptions in

the manual

Check the connector on X150/X151 for

correct fit.

Check the wiring of X150/X151.

Check MP2040.x.

See “Checking the drive enabling for the

axis groups via connector X150 and X151 (if

wired)” on page 16 – 242.

Check the Ready LED of the inverter.

Check the wiring of the inverter.

On interface PCBs for Siemens inverters,

the second axis is not enabled.

See “Checking the readiness of the inverter

system” on page 16 – 243.

See Service Manual Inverter Systems and

Motors.

Exchange position encoder.

Check encoder cable.

Exchange the motor drive control board.

8B00 <Achse>

motor encoder

defective

8B00 Zn track

%.2s error

8B10 Wrong

traverse direction

<axis>

No encoder signal available.

Interruption in motor encoder cable.

Signal amplitude of motor encoder is

missing or too small.

See “Speed Encoders” on page 18 – 293. See “Speed Encoders” on page 18 – 293.

Contamination of the motor encoder

(Zn track)

Motor encoder cable is defective.

Motor control board is defective.

See “Speed Encoders” on page 18 – 293. See “Speed Encoders” on page 18 – 293.

DIR entry in motor table is incorrect.

Incorrect motor power connection.

Check connection of motor encoder.

Check the motor encoder.

Check the amplitude of the encoder signal.

Exchange the motor.

Check the motor encoder cable.

Exchange the motor drive control board.

Check the DIR entry in the motor table.

eck the motor power connection.

Ch

See Service Manual Inverter Syst

Motors.

ems and

July 2010 4 – 33

Page 34

Error message Possible cause of error Measures for error diagnosis and/or

corrective action

8B20 Error <axis>

field orientation

8B30 Motor

temperature

%.2s too high

Additional information and descriptions in

the manual

Field orientation impossible for mechanical

reasons.

Incorrect relation between electrical field

and mechanical motor motion.

Incorrect motor encoder signal.

Incorrect motor connection.

Mechanical brakes not released.

See “Speed Encoders” on page 18 – 293. See “Sequence for Finding Errors in the

Measured motor temperature is too high.

No temperature sensor

Motor encoder cable is defective (wire

broken).

Entry in motor table is incorrect.

Incorrect or defective temperature sensor

was installed.

Additional information and descriptions in

the manual

Check the machine parameters for number

of signal periods and distance for the

number of signal periods.

Check the machine parameter for the linear

distance of one motor revolution.

For linear motors: check column STR of the

motor table.

Check the speed encoder connection.

Check the motor connection.

Release brakes during orientation.

Control Loop” on page 6 – 62.

See “Speed Encoders” on page 18 – 293.

See Service Manual Inverter Systems and

Motors.

Let the motor cool down.

Check the motor encoder cable.

Check the entry in the motor table.

Measure the temperature sensor (576

[Ohm] at 20 [°C]).

See “Speed Encoders” on page 18 – 293.

See Service Manual Inverter Systems and

Motors.

See “Speed Encoders” on page 18 – 293.

See Service Manual Inverter Systems and

Motors.

4 – 34 HEIDENHAIN Service Manual iTNC 530

Page 35

Error message Possible cause of error Measures for error diagnosis and/or

corrective action

8B40 No drive

enabling %.2s