Danfoss CCMT 2, CCMT 8, CCMT 16, CCMT 42 Data sheet

Data Sheet

Electric regulating valve

Type CCMT 2, 8, 16 and 42

One valve, 4 applications: HPV, GBV, EV and EPR

The CCMT is an electrically operated valve designed speci€cally for operation in CO2

systems.

The CCMT valve concept is designed to ful€l global refrigeration requirements.

The valve is capable of functioning either as an expansion valve, as a pressure regulator for the gascooler or as a gas bypass valve with backpressure regulation in transcritical or subcritical applications.

Features:

• Designed for CO2 systems with maximum

working pressure of 140 bar / 2030 psig.

• Applicable to R744 (CO2) and other common

refrigerants. The CCMT is compatible with the oil types PAG, POE and PVE.

• Regulating cone ensures optimum regulating accuracy, particularly at part load.

• Patented cone and balance design.

• The PEEK seat provides excellent valve tightness and robustness.

• Combined butt weld and solder connections.

• Top part with built-in strainer / €lter.

• MOPD up to 90 bar / 1305 psi

• CCMT 16 – CCMT 42 is available with or without integrated pressure transmitter.

• Standard M12 connector for simple and ƒexible connection to the motor driver.

• Low weight and compact design.

• Easy to service. Insert easily taken out by removing top part.

• For manual operation and service of the CCMT an AST-g service driver is available.

AI230186439989en-000901

Electric regulating valve, type CCMT 2, 8, 16 and 42

Portfolio overview

Related products

Table 1: Related products

Type |

Description |

Single pack |

Code no. |

|

AK-XM 208C |

Stepper output module |

1 |

080Z0023 |

|

|

|

|

080G5300 |

|

|

|

|

||

EKE 1 Series |

Superheat controller / driver |

1 |

080G5350 |

|

|

|

|

080G5400 |

|

AST-G |

Manual service driver |

1 |

034G0013 |

|

|

|

|

|

Table 2: Portfolio overview

Superheat controller / driver, type |

Electronic controller type EKC 326 |

Electronic driver type AK-XM 208C |

Temperature sensors type AKS and |

|

EKE 1 series |

and EKC 313 |

pressure transmitters type MBS |

||

|

||||

|

|

|

|

© Danfoss | Climate Solutions | 2021.03 |

AI230186439989en-000901 | 2 |

Electric regulating valve, type CCMT 2, 8, 16 and 42

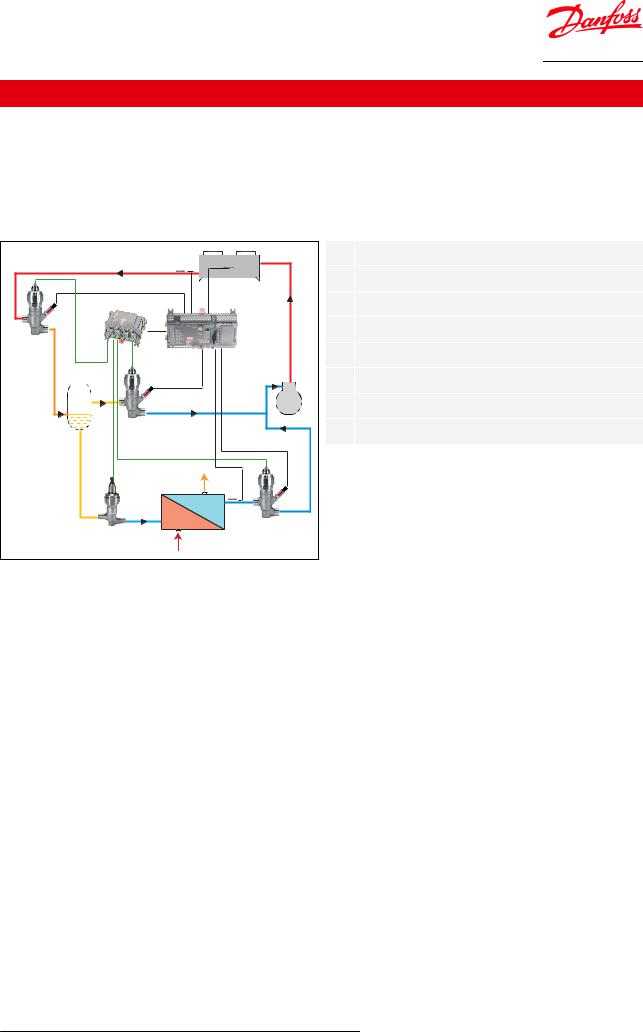

Applications

The CCMT valve is developed for transcritical CO2 applications. The CCMT valve can be used in systems with ƒash gas bypass, parallel compression as well as in stand-alone applications.

The CCMT valve can be used in transcritical and subcritical conditions.

CCMT valves are typically used as ƒash gas bypass and high pressure regulation.

Figure 1: Application

|

1 |

3 |

4 |

2 |

<![if ! IE]> <![endif]>Danfoss R64-3020.11 |

|

|

|

5 |

6 |

8 |

7 |

1Gas cooler

2High pressure valve

3Stepper motor driver

4Master controller

5Gas by-pass valve

6Electric expansion valve

7Evaporator

8Electric pressure regulator

Application 1 - High Pressure Valve (HPV)

The function of the high pressure valve is to control the high pressure in the system according to the reference from the controller. The reference can be set to obtain the optimum COP, optimum capacity or any other factors. Pressure optimization is performed by the CCMT valve, which is installed at the outlet of the gas cooler (see the €gure above) and a matching Danfoss controller. This design provides the possibility to optimize gas cooler pressure in all situations and intermediate receiver pressure independently. Please refer to the www.danfoss.com/CO2 for more information on CO2 systems.

Application 2 - Gas bypass Valve (GBV)

A gas bypass valve is typically used to regulate the intermediate pressure in a transcritical CO2 refrigeration system, in order to keep the intermediate pressure low. By venting ƒash gas generated through a gas bypass valve to the suction side of the compressor after the transcritcal expansion, the pressure can be kept at a safe level for all components situated in the liquid lines of a transcritical CO2 system . The two phase mixture from the CCMT valve has to be separated before gas enters the gas bypass. For use in the gas bypass applicaton the EKC 326A controller is recommended for CCMT 2 to CCMT 8

Application 3- Expansion Valve (EV)

A liquid expansion valve is typically used for injection in plate heat exchangers of CO2/CO2 cascades, or as an expansion valve for CO2 evaporators. For the liquid injection applications CCMT 2 to CCMT 8 is used with EKC 313 controller.

Application 4 – Electric pressure regulator (EPR)

With CCMT valves, it is possible to obtain an accurate temperature or pressure control by modulating the pressure in the evaporator.

© Danfoss | Climate Solutions | 2021.03 |

AI230186439989en-000901 | 3 |

Electric regulating valve, type CCMT 2, 8, 16 and 42

Product speci€cation

Technical data

Table 3: Technical data

Features |

Description |

|

|

Parameter |

CCMT 2 – CCMT 8 |

CCMT 16 - CCMT 42 |

|

Compatibility refrigerants |

R744 and other refrigerants. Not applicable for ƒam- |

R744 and other refrigerants. Not applicable for ƒam- |

|

mable refrigerants and Ammonia. |

mable refrigerants and Ammonia. |

||

|

|||

Refrigerant oils |

PAG, POE and PVE |

PAG, POE and PVE |

|

MOPD |

90 bar / 1305 psi |

90 bar / 1305 psi |

|

Max. working pressure (PS/MWP) |

140 bar / 2030 psig |

140 bar / 2030 psig |

|

Refrigerant temperature range (1) |

–40 – 60 °C / -40 – 140 °F |

–40 – 60 °C / -40 – 140 °F |

|

Ambient temperature |

–40 – 60 °C / -40 – 140 °F |

–40 – 60 °C / -40 – 140 °F |

|

Material speci€cation |

Stainless steel |

Stainless steel |

|

Expected lifetime |

Min. 15 years |

Min. 10 years |

|

Build in strainer / €lter |

Yes, 6 slots, 1.1 mm height x 10 mm wide |

Yes, 250 micron |

|

Comply with P.E.D. |

Fluid group I / Article 3, paragraph 3 |

Fluid group I / Article 3, paragraph 3 |

|

Approval |

CE and UL approved |

CE, UL, EAC, cUL, CRN |

|

(1) Measured at inlet of the valve |

|

|

Electrical data

Table 4: Electrical data

Features |

Description |

|

|

Parameter |

CCMT 2 – CCMT 8 |

CCMT 16 - CCMT 42 |

|

Stepper motor type |

Bi-polar - permanent magnet |

Bi-polar - permanent magnet |

|

Motor enclosure |

IP 67 |

IP 67 |

|

Step mode |

2 phase full step, microstepping (recomended) |

2 phase full step, microstepping (recomended) |

|

Phase resistance |

52 Ω ±10% |

29 Ω ±10% |

|

Phase inductance |

85 mH |

36.7 mH |

|

Phase current |

Using chopper drive: 100 mA RMS -4 % +15 % |

Using chopper drive: 300 mA RMS -4 % +15 % |

|

Holding current |

Voltage driver: Depends on application. Current con- |

Not needed. |

|

troller: Full current allowed |

|||

|

|

||

Duty cycle |

100% duty cycle is allowed / 20% recommended |

100% duty cycle is allowed / 20% recommended |

|

Max. total power |

Voltage drive: 5.5 W Current drive: 1.3 W (UL: NEC |

Voltage drive: 10W Current drive: 2.8 W |

|

class 2) |

|||

|

|

||

|

Chopper current drive: Max. 300 steps/sec. |

Chopper current drive: Max. 300 steps/sec. |

|

Step rate |

(Recomended step rate: 200 steps/ sec.) Constant volt- |

(Recomended step rate: 200 steps/ sec.) Constant volt- |

|

|

age drive: Max. 150 steps/sec. |

age drive: Max. 150 steps/sec. |

|

Total full steps |

CCMT 2 , 4 and 8: 1100 steps |

CCMT 16 : 800, CCMT 24 : 1400, CCMT 30 : 2300 and |

|

CCMT 42 : 2200 |

|||

|

|

||

Full travel time |

CCMT 2, 4 and 8: 5 sec. ( at 220 steps/sec.) |

CCMT 16 : 4 sec., CCMT 24 : 7 sec. CCMT 30 : 11.5 sec. |

|

and CCMT 42 : 11 sec.( at 200 steps/sec.) |

|||

|

|

||

Reference position |

Overdriving against full close position |

Overdriving against full close position |

|

Overdrive in close position |

Max. 10% of total full steps |

Max. 10% of total full steps and maximum one over- |

|

drive performed per hour. |

|||

|

|

||

Overdrive in open position |

Not Allowed |

Not Allowed |

|

Electrical connection |

M12 male connector with 0.3 m / 1 ft long cable (4 |

Integrated M12 male connector |

|

wire: 0.5 mm2 / 20 AWG) |

|||

|

|

||

Compatible controllers |

EKE 1A, EKE 1B, EKE 1C, EKC 313, EKC 326A , AK-XM |

EKE 1A, EKE 1B, EKE 1C, AK-XM 208C |

|

208C |

|||

|

|

||

|

|

|

Table 5: Pressure transmitter MBS 8250 (CCMT 16 - CCMT 42 with integrated pressure transmitter)

Pressure range |

- 1 to 159 bar / 14.5 – 2306 psi sealed gauge |

Electrical connection |

Round Packard Metripack |

Output signal |

10 - 90 % of V supply |

Supply voltage |

5V DC ± 0.5V |

Process connection |

7/16-20 UNF-2A ISO 11926-2; Viton o-ring |

|

|

© Danfoss | Climate Solutions | 2021.03 |

AI230186439989en-000901 | 4 |

Loading...

Loading...