Danfoss APM 0.8, APM 1.0, APM 1.2, APM 1.8, APM 2.0 Data sheet

...

Data sheet

APM motor

APM 0.8 / APM 1.0 / APM 1.2 /

APM 1.8 / APM 2.0 / APM 2.5 / APM 2.9 for energy recovery

hpp.danfoss.com.

Data sheet | APM 0.8 – 2.9 motors

Table of Contents |

1. |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 |

|||

|

2. |

Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 |

|||

|

3. |

Technical data . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . |

. |

. 4 |

|

3.1 |

APM 0.8 – 1.2 . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . .4 |

||

|

3.2 |

APM 1.8 – 2.9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 |

|||

|

4. |

Direction of rotation . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . .6 |

||

|

5. |

Shaft load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 |

|||

|

6. |

Temperature and corrosion . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . |

. |

.7 |

|

7. |

Noise level . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . .7 |

||

|

8. |

Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 |

|||

|

9. |

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 |

|||

|

10. |

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 |

|||

|

11. |

Preferred system design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 |

|||

|

11.1 |

Membrane system with energy recovery . . . . . . . |

. . . . . . . . . . . . . . . |

. |

.10 |

|

11.2 |

Membrane system with energy recovery and VFD . . |

. . . . . . . . . . . . . . . . |

. |

11 |

12.Combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

12.1Examples of motor / pump combinations . . . . . . . . . . . . . . . . . . . . . . . 12

12.2 |

Flow . . . . . . |

. . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 |

|||||

12.3 |

Energy consumption vs. pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 |

|||||||

12.4 |

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 |

|||||||

13. |

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 |

|||||||

13.1 |

APM 0.8 – 1.2 . . |

. . . . . . |

. . . . . . |

. . |

. . . . . . |

. . . . . . |

. . . |

. . . . . . 14 |

13.2 |

APM 1.8 – 2.9 . . |

. . . . . . |

. . . . . . |

. . |

. . . . . . |

. . . . . . |

. . . |

. . . . . . 15 |

14. |

Service . . . . . |

. . . . . . |

. . . . . . |

. . |

. . . . . . |

. . . . . . |

. . . |

. . . . . . 16 |

2 | Danfoss | DCS im) |2020.09 |

AI354846545311en-000101 |

Data sheet | APM 0.8 – 2.9 motors

1. Introduction |

APM motors are designed for energy recovery |

The APM motor is not self-starting but needs a |

|

systems together with an APP hydraulic pump |

rotational force to start turning. |

|

and a double shaft motor. APM motors convert |

|

|

hydraulic energy (pressure, flow) to mechanical |

|

|

energy (torque, speed). |

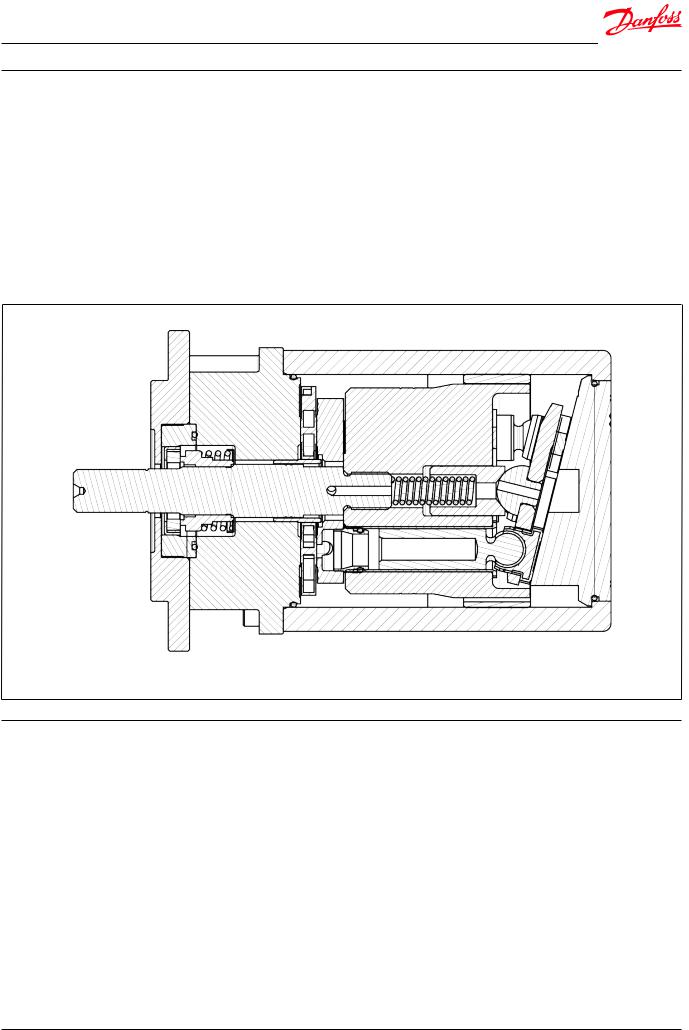

Below a sectional drawing as an example of an |

|

|

APM motor |

|

This data sheet is valid for APM hydraulic motors. |

|

|

APM hydraulic motors are build to operate on |

|

|

salt water and are based on the axial piston |

|

|

principle with fixed displacement, enabling a |

|

|

very light and compact design. Lubrication of the |

|

|

moving parts is provided by the salt water itself. |

|

|

Shaft speed is proportional to the input flow. |

|

2. Benefits |

• |

Constant torque over a wide speed range |

|

• |

Compact design |

|

• |

Easy to install |

|

• |

Long life under severe operating conditions |

|

• |

Few wear parts and low maintenance costs |

|

• |

No oil lubrication |

|

• |

Non-corroding materials |

|

• |

Made for RO applications |

Danfoss | DCS (im | 2020.09 |

AI354846545311en-000101 | 3 |

Data sheet | APM 0.8 – 2.9 motors

3. |

Technical data |

3.1 APM 0.8 – 1.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor size |

|

APM 0.8 |

APM 1.0 |

APM 1.2 |

|

|

|

|

|

|

|

|

|

|

|

Code number APM CCW |

|

180F1000 |

180F1001 |

180F1002 |

|

|

|

|

|

|

|

|

|

|

|

Geometric displace- |

|

cm³/rev. |

4.07 |

5.08 |

6.30 |

|

|

ment |

|

in³/rev. |

0.25 |

0.31 |

0.38 |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Pressure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max. inlet |

|

barg |

80 |

80 |

80 |

|

|

pressure |

|

|

|

|

|

|

|

|

psig |

1160 |

1160 |

1160 |

|

|

|

continuous |

|

||||

|

|

|

|

|

|

|

|

|

|

Min. inlet pressure |

|

barg |

10 |

10 |

10 |

|

|

continuous |

|

psig |

145 |

145 |

145 |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Outlet |

|

barg |

0.5 – 5 |

0.5 – 5 |

0.5 – 5 |

|

|

pressure |

|

psig |

7.3 – 72.5 |

7.3 – 72.5 |

7.3 – 72.5 |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Min. speed |

|

rpm |

700 |

700 |

700 |

|

|

|

|

|

|

|

|

|

|

Max. speed |

|

rpm |

3450 |

3450 |

3450 |

|

|

continuous |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Typical performance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m³/h |

0.92 |

1.12 |

1.37 |

|

|

|

|

|

|

|

|

|

|

Max. waterflow |

|

l/min |

15.3 |

18.6 |

22.9 |

|

|

|

|

|

|

|

|

|

|

|

gpm |

4.0 |

4.9 |

6.1 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Max. power at |

|

kW |

1.7 |

2.1 |

2.6 |

|

|

max. speed cont. and |

|

|

|

|

|

|

|

max. pressure |

|

HP |

2.3 |

2.8 |

3.5 |

|

|

|

|

|

|

|

|

|

|

Max. torque at max. |

|

Nm |

4.7 |

5.8 |

7.2 |

|

|

pressure |

|

lbf-ft |

3.4 |

4.3 |

5.3 |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Technical specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sound pressurre level |

|

dB(A) |

74 |

74 |

74 |

|

|

|

|

|

|

|

|

|

|

Media temperature |

|

°C |

2 – 50 |

2 – 50 |

2 – 50 |

|

|

|

|

|

|

|

|

|

|

|

°F |

35.6 – 122 |

35.6 – 122 |

35.6 – 122 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Ambient temperature |

|

°C |

0 – 50 |

0– 50 |

0 – 50 |

|

|

|

|

|

|

|

|

|

|

|

°F |

32 – 122 |

32 – 122 |

32 – 122 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Weight (dry) |

|

kg |

5.2 |

5.2 |

5.2 |

|

|

|

|

|

|

|

|

|

|

|

lb |

11.5 |

11.5 |

11.5 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

4 | Danfoss | DCS im) |2020.09 |

AI354846545311en-000101 |

Data sheet | APM 0.8 – 2.9 motors

3.2 APM 1.8 – 2.9

Motor size |

|

APM 1.8 |

APM 2.0 |

APM 2.5 |

AMP 2.9 |

|

|

|

|

|

|

|

|

Code number APM CCW |

180F1100 |

180F1101 |

180F1102 |

180F1103 |

||

|

|

|

|

|

|

|

Geometric displace- |

cm³/rev. |

9.31 |

10.0 |

12.5 |

15.3 |

|

ment |

in³/rev. |

0.57 |

0.61 |

0.76 |

0.93 |

|

|

||||||

|

|

|

|

|

|

|

Pressure |

|

|

|

|

|

|

|

|

|

|

|

|

|

Max. inlet |

barg |

80 |

80 |

80 |

80 |

|

pressure |

|

|

|

|

|

|

psig |

1160 |

1160 |

1160 |

1160 |

||

continuous |

||||||

|

|

|

|

|

|

|

Min. inlet pressure |

barg |

10 |

10 |

10 |

10 |

|

continuous |

psig |

145 |

145 |

145 |

145 |

|

|

||||||

|

|

|

|

|

|

|

Outlet pressure |

barg |

0.5 – 5 |

0.5 – 5 |

0.5 – 5 |

0.5 – 5 |

|

|

|

|

|

|

||

psig |

7.3 – 72.5 |

7.3 – 72.5 |

7.3 – 72.5 |

7.3 – 72.5 |

||

|

||||||

|

|

|

|

|

|

|

Speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

Min. speed |

rpm |

700 |

700 |

700 |

700 |

|

|

|

|

|

|

|

|

Max. speed |

rpm |

3450 |

3450 |

3450 |

3000 |

|

continuous |

||||||

|

|

|

|

|

||

Typical performance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m³/h |

2.03 |

2.18 |

2.69 |

2.83 |

|

|

|

|

|

|

|

|

Max. waterflow |

l/min |

33.9 |

36.4 |

44.8 |

47.2 |

|

|

|

|

|

|

|

|

|

gpm |

9.0 |

9.6 |

11.8 |

12.5 |

|

|

|

|

|

|

|

|

Max. power at |

kW |

3.9 |

4.2 |

5.3 |

5.6 |

|

max. speed cont. and |

|

|

|

|

|

|

|

|

|

|

|

||

max. pressure |

HP |

5.2 |

5.7 |

7.1 |

7.6 |

|

|

|

|

|

|

|

|

Max. torque at max. |

Nm |

10.8 |

11.7 |

14.7 |

18.0 |

|

pressure |

lbf-ft |

8.0 |

8.6 |

10.8 |

13.2 |

|

|

||||||

|

|

|

|

|

|

|

Technical specifications |

|

|

|

|

||

|

|

|

|

|

|

|

Sound pressure level |

dB(A) |

77 |

77 |

77 |

81 |

|

|

|

|

|

|

|

|

Media temperature |

°C |

2 – 50 |

2 – 50 |

2 – 50 |

2 – 50 |

|

|

|

|

|

|

||

°F |

35.6 – 122 |

35.6 – 122 |

35.6 – 122 |

35.6– 122 |

||

|

||||||

|

|

|

|

|

|

|

Ambient temperature |

°C |

0 – 50 |

0 – 50 |

0 – 50 |

0– 50 |

|

|

|

|

|

|

||

°F |

32 – 122 |

32 – 122 |

32 – 122 |

32 – 122 |

||

|

||||||

|

|

|

|

|

|

|

Weight (dry) |

kg |

8.6 |

8.6 |

8.6 |

8.6 |

|

|

|

|

|

|

||

lb |

19 |

19 |

19 |

19 |

||

|

||||||

|

|

|

|

|

|

|

Danfoss | DCS (im | 2020.09 |

AI354846545311en-000101 | 5 |

Loading...

Loading...