AMD Advanced Micro Devices AM29F400BT-90SIB, AM29F400BT-90SI, AM29F400BT-90SEB, AM29F400BT-90SCB, AM29F400BT-90SC Datasheet

...

PRELIMINARY

Am29F400B

4 Megabit (512 K x 8-Bit/256 K x 16-Bit)

CMOS 5.0 Volt-only Boot Sector Flash Memory

DISTINCTIVE CHARACTERISTICS

■Single power supply operation

—5.0 volt-only operation for read, erase, and program operations

—Minimizes system level requirements

■Manufactured on 0.35 µm process technology

—Compatible with 0.5 µm Am29F400 device

■High performance

—Access times as fast as 55 ns

■Low power consumption (typical values at 5 MHz)

—1 µA standby mode current

—20 mA read current (byte mode)

—28 mA read current (word mode)

—30 mA program/erase current

■Flexible sector architecture

—One 16 Kbyte, two 8 Kbyte, one 32 Kbyte, and seven 64 Kbyte sectors (byte mode)

—One 8 Kword, two 4 Kword, one 16 Kword, and seven 32 Kword sectors (word mode)

—Supports full chip erase

—Sector Protection features:

A hardware method of locking a sector to prevent any program or erase operations within that sector

Sectors can be locked via programming equipment

Temporary Sector Unprotect feature allows code changes in previously locked sectors

■Top or bottom boot block configurations available

■Embedded Algorithms

—Embedded Erase algorithm automatically preprograms and erases the entire chip or any combination of designated sectors

—Embedded Program algorithm automatically writes and verifies data at specified addresses

■Minimum 1,000,000 program/erase cycles per sector guaranteed

■Package option

—48-pin TSOP

—44-pin SO

■Compatibility with JEDEC standards

—Pinout and software compatible with single- power-supply Flash

—Superior inadvertent write protection

■Data# Polling and toggle bits

—Provides a software method of detecting program or erase operation completion

■Ready/Busy# pin (RY/BY#)

—Provides a hardware method of detecting program or erase cycle completion

■Erase Suspend/Erase Resume

—Suspends an erase operation to read data from, or program data to, a sector that is not being erased, then resumes the erase operation

■Hardware reset pin (RESET#)

—Hardware method to reset the device to reading array data

Publication# 21505 Rev: C Amendment/+2

Issue Date: April 1998

P R E L I M I N A R Y

GENERAL DESCRIPTION

The Am29F400B is a 4 Mbit, 5.0 volt-only Flash memory organized as 524,288 bytes or 262,144 words. The device is offered in 44-pin SO and 48-pin TSOP packages. The word-wide data (x16) appears on DQ15–DQ0; the byte-wide (x8) data appears on DQ7– DQ0. This device is designed to be programmed insystem with the standard system 5.0 volt VCC supply. A 12.0 V VPP is not required for write or erase operations. The device can also be programmed in standard EPROM programmers.

This device is manufactured using AMD’s 0.35 µm process technology, and offers all the features and benefits of the Am29F400, which was manufactured using 0.5 µm process technology.

The standard device offers access times of 55, 60, 70, 90, 120, and 150 ns, allowing high speed microprocessors to operate without wait states. To eliminate bus contention the device has separate chip enable (CE#), write enable (WE#) and output enable (OE#) controls.

The device requires only a single 5.0 volt power supply for both read and write functions. Internally generated and regulated voltages are provided for the program and erase operations.

The device is entirely command set compatible with the

JEDEC single-power-supply Flash standard. Commands are written to the command register using standard microprocessor write timings. Register contents serve as input to an internal state-machine that controls the erase and programming circuitry. Write cycles also internally latch addresses and data needed for the programming and erase operations. Reading data out of the device is similar to reading from other Flash or EPROM devices.

Device programming occurs by executing the program command sequence. This initiates the Embedded Program algorithm—an internal algorithm that automatically times the program pulse widths and verifies proper cell margin.

Device erasure occurs by executing the erase command sequence. This initiates the Embedded Erase

algorithm—an internal algorithm that automatically preprograms the array (if it is not already programmed) before executing the erase operation. During erase, the device automatically times the erase pulse widths and verifies proper cell margin.

The host system can detect whether a program or erase operation is complete by observing the RY/BY# pin, or by reading the DQ7 (Data# Polling) and DQ6/DQ2 (toggle) status bits. After a program or erase cycle has been completed, the device is ready to read array data or accept another command.

The sector erase architecture allows memory sectors to be erased and reprogrammed without affecting the data contents of other sectors. The device is fully erased when shipped from the factory.

Hardware data protection measures include a low VCC detector that automatically inhibits write operations during power transitions. The hardware sector protection feature disables both program and erase operations in any combination of the sectors of memory. This can be achieved via programming equipment.

The Erase Suspend feature enables the user to put erase on hold for any period of time to read data from, or program data to, any sector that is not selected for erasure. True background erase can thus be achieved.

The hardware RESET# pin terminates any operation in progress and resets the internal state machine to reading array data. The RESET# pin may be tied to the system reset circuitry. A system reset would thus also reset the device, enabling the system microprocessor to read the boot-up firmware from the Flash memory.

The system can place the device into the standby mode. Power consumption is greatly reduced in this mode.

AMD’s Flash technology combines years of Flash memory manufacturing experience to produce the highest levels of quality, reliability and cost effectiveness. The device electrically erases all bits within a sector simultaneously via Fowler-Nordheim tunneling. The data is programmed using hot electron injection.

2 |

Am29F400B |

P R E L I M I N A R Y

PRODUCT SELECTOR GUIDE

Family Part Number |

|

|

Am29F400B |

|

|

||

|

|

|

|

|

|

|

|

Speed Option |

VCC = 5.0 V ± 5% |

-55 |

|

|

|

|

|

|

|

|

|

|

|

|

|

VCC = 5.0 V ± 10% |

|

-60 |

-70 |

-90 |

-120 |

-150 |

|

|

|

||||||

|

|

|

|

|

|

|

|

Max access time, ns (tACC) |

55 |

60 |

70 |

90 |

120 |

150 |

|

|

|

|

|

|

|

|

|

Max CE# access time, ns (tCE) |

55 |

60 |

70 |

90 |

120 |

150 |

|

|

|

|

|

|

|

|

|

Max OE# access time, ns (tOE) |

30 |

30 |

30 |

35 |

50 |

55 |

|

Note: See “AC Characteristics” for full specifications.

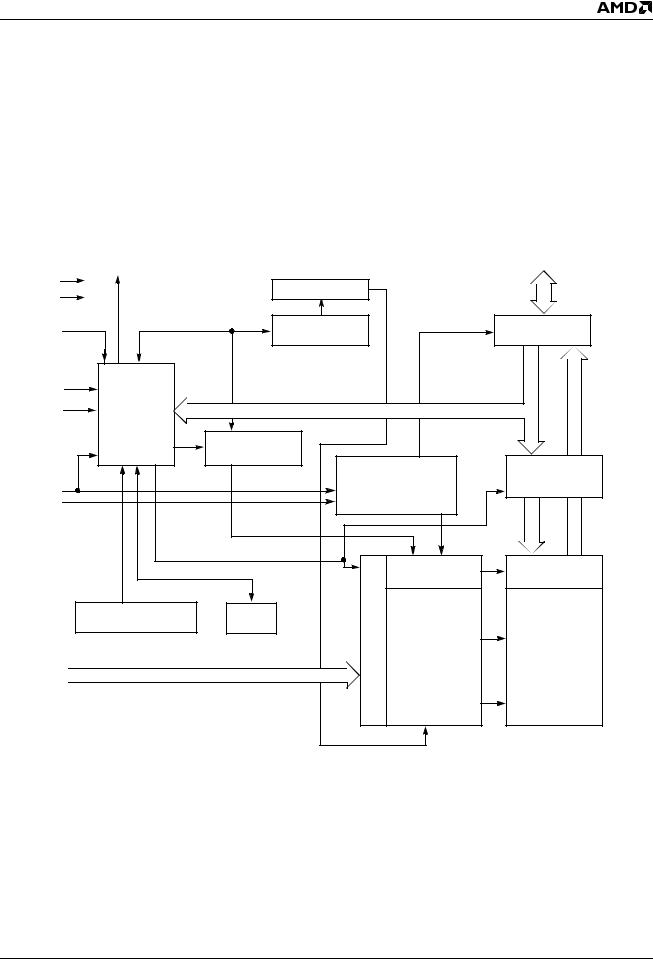

BLOCK DIAGRAM

|

RY/BY# |

|

|

|

|

DQ0–DQ15 (A-1) |

VCC |

|

|

Sector Switches |

|

|

|

VSS |

|

|

|

|

|

|

|

|

|

|

|

|

|

RESET# |

|

|

Erase Voltage |

|

|

Input/Output |

|

|

Generator |

|

|

Buffers |

|

|

|

|

|

|

||

WE# |

State |

|

|

|

|

|

BYTE# |

Control |

|

|

|

|

|

|

|

|

|

|

|

|

|

Command |

|

|

|

|

|

|

Register |

PGM Voltage |

|

|

|

|

|

|

Generator |

|

|

|

|

|

|

|

Chip Enable |

STB |

Data |

|

|

|

|

Latch |

|||

CE# |

|

|

Output Enable |

|||

|

|

|

|

|||

OE# |

|

|

|

Logic |

|

|

|

|

|

|

|

|

|

|

|

|

STB |

Y-Decoder |

|

Y-Gating |

|

|

|

|

|

|

|

|

VCC Detector |

Timer |

Latch |

|

|

|

|

|

|

|

|

|

|

|

|

|

Address |

X-Decoder |

|

Cell Matrix |

A0–A17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21505C-1 |

Am29F400B |

3 |

P R E L I M I N A R Y

CONNECTION DIAGRAMS

A15 |

|

|

1 |

48 |

|

|

|

A16 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A14 |

|

|

2 |

47 |

|

|

|

BYTE# |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A13 |

|

|

3 |

46 |

|

|

|

VSS |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A12 |

|

|

4 |

45 |

|

|

|

DQ15/A-1 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A11 |

|

|

5 |

44 |

|

|

|

DQ7 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A10 |

|

|

6 |

43 |

|

|

|

DQ14 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A9 |

|

|

7 |

42 |

|

|

|

DQ6 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A8 |

|

|

8 |

41 |

|

|

|

DQ13 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

NC |

|

|

9 |

40 |

|

|

|

DQ5 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

NC |

|

|

10 |

39 |

|

|

|

DQ12 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

WE# |

|

|

11 |

38 |

|

|

|

DQ4 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

RESET# |

|

|

12 |

37 |

|

|

|

VCC |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

NC |

|

|

13 |

36 |

|

|

|

DQ11 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

NC |

|

|

14 |

35 |

|

|

|

DQ3 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

RY/BY# |

|

|

15 |

34 |

|

|

|

DQ10 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

NC |

|

|

16 |

33 |

|

|

|

DQ2 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A17 |

|

|

17 |

32 |

|

|

|

DQ9 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A7 |

|

|

18 |

31 |

|

|

|

DQ1 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A6 |

|

|

19 |

30 |

|

|

|

DQ8 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A5 |

|

|

20 |

29 |

|

|

|

DQ0 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A4 |

|

|

21 |

28 |

|

|

|

OE# |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A3 |

|

|

22 |

27 |

|

|

|

VSS |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A2 |

|

|

23 |

26 |

|

|

|

CE# |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

A1 |

|

|

24 |

25 |

|

|

|

A0 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

48-Pin TSOP—Standard Pinout |

|

|

|

|

A16 |

|

|

1 |

48 |

|

|

|

A15 |

|

|

|

|

|

||||||

|

|

|

|

||||||

BYTE# |

|

|

2 |

47 |

|

|

|

A14 |

|

|

|

|

|

||||||

|

|

|

|

||||||

VSS |

|

|

3 |

46 |

|

|

|

A13 |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ15/A-1 |

|

|

4 |

45 |

|

|

|

A12 |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ7 |

|

|

5 |

44 |

|

|

|

A11 |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ14 |

|

|

6 |

43 |

|

|

|

A10 |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ6 |

|

|

7 |

42 |

|

|

|

A9 |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ13 |

|

|

8 |

41 |

|

|

|

A8 |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ5 |

|

|

9 |

40 |

|

|

|

NC |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ12 |

|

|

10 |

39 |

|

|

|

NC |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ4 |

|

|

11 |

38 |

|

|

|

WE# |

|

|

|

|

|

||||||

|

|

|

|

||||||

VCC |

|

|

12 |

37 |

|

|

|

RESET# |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ11 |

|

|

13 |

36 |

|

|

|

NC |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ3 |

|

|

14 |

35 |

|

|

|

NC |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ10 |

|

|

15 |

34 |

|

|

|

RY/BY# |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ2 |

|

|

16 |

33 |

|

|

|

NC |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ9 |

|

|

17 |

32 |

|

|

|

A17 |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ1 |

|

|

18 |

31 |

|

|

|

A7 |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ8 |

|

|

19 |

30 |

|

|

|

A6 |

|

|

|

|

|

||||||

|

|

|

|

||||||

DQ0 |

|

|

20 |

29 |

|

|

|

A5 |

|

|

|

|

|

||||||

|

|

|

|

||||||

OE# |

|

|

21 |

28 |

|

|

|

A4 |

|

|

|

|

|

||||||

|

|

|

|

||||||

VSS |

|

|

22 |

27 |

|

|

|

A3 |

|

|

|

|

|

||||||

|

|

|

|

||||||

CE# |

|

|

23 |

26 |

|

|

|

A2 |

|

|

|

|

|

||||||

|

|

|

|

||||||

A0 |

|

|

24 |

25 |

|

|

|

A1 |

|

|

|

|

|

||||||

|

|

|

|

||||||

48-Pin TSOP—Reverse Pinout

21505C-2

4 |

Am29F400B |

|

|

|

P R E L I M I N A R Y |

|

||

CONNECTION DIAGRAMS |

|

|

|

|

|

|

|

|

|

SO |

|

||

NC |

1 |

|

|

|

44 |

RESET# |

|

|

|||||

RY/BY# |

2 |

|

|

|

43 |

WE# |

|

|

|||||

A17 |

3 |

|

|

|

42 |

A8 |

|

|

|||||

A7 |

4 |

|

|

|

41 |

A9 |

|

|

|||||

A6 |

5 |

|

|

|

40 |

A10 |

|

|

|||||

A5 |

6 |

|

|

|

39 |

A11 |

|

|

|||||

A4 |

7 |

|

|

|

38 |

A12 |

|

|

|||||

A3 |

8 |

|

|

|

37 |

A13 |

|

|

|||||

A2 |

9 |

|

|

|

36 |

A14 |

|

|

|||||

A1 |

10 |

|

|

|

35 |

A15 |

|

|

|||||

A0 |

11 |

|

|

|

34 |

A16 |

|

|

|||||

CE# 12 |

|

|

|

33 |

BYTE# |

|

|

|

|||||

VSS 13 |

|

|

|

32 |

VSS |

|

|

|

|||||

|

|

|||||

OE# 14 |

|

|

|

31 |

DQ15/A-1 |

|

DQ0 15 |

|

|

|

30 |

DQ7 |

|

|

|

|||||

DQ8 16 |

|

|

|

29 |

DQ14 |

|

|

|

|||||

DQ1 17 |

|

|

|

28 |

DQ6 |

|

|

|

|||||

DQ9 18 |

|

|

|

27 |

DQ13 |

|

|

|

|||||

DQ2 19 |

|

|

|

26 |

DQ5 |

|

|

|

|||||

DQ10 20 |

|

|

|

25 |

DQ12 |

|

|

|

|||||

DQ3 21 |

|

|

|

24 |

DQ4 |

|

|

|

|||||

DQ11 22 |

|

|

|

23 |

VCC |

|

|

|

|||||

|

|

|||||

21505C-3

PIN CONFIGURATION

A0–A17 = 18 addresses

DQ0–DQ14 = 15 data inputs/outputs

DQ15/A-1 |

= DQ15 (data input/output, word mode), |

|

|

|

A-1 (LSB address input, byte mode) |

BYTE# |

= Selects 8-bit or 16-bit mode |

|

CE# |

= |

Chip enable |

OE# |

= |

Output enable |

WE# |

= |

Write enable |

RESET# |

= Hardware reset pin, active low |

|

RY/BY# |

= |

Ready/Busy# output |

VCC |

= +5.0 V single power supply |

|

|

|

(see Product Selector Guide for |

|

|

device speed ratings and voltage |

|

|

supply tolerances) |

VSS |

= |

Device ground |

NC |

= Pin not connected internally |

|

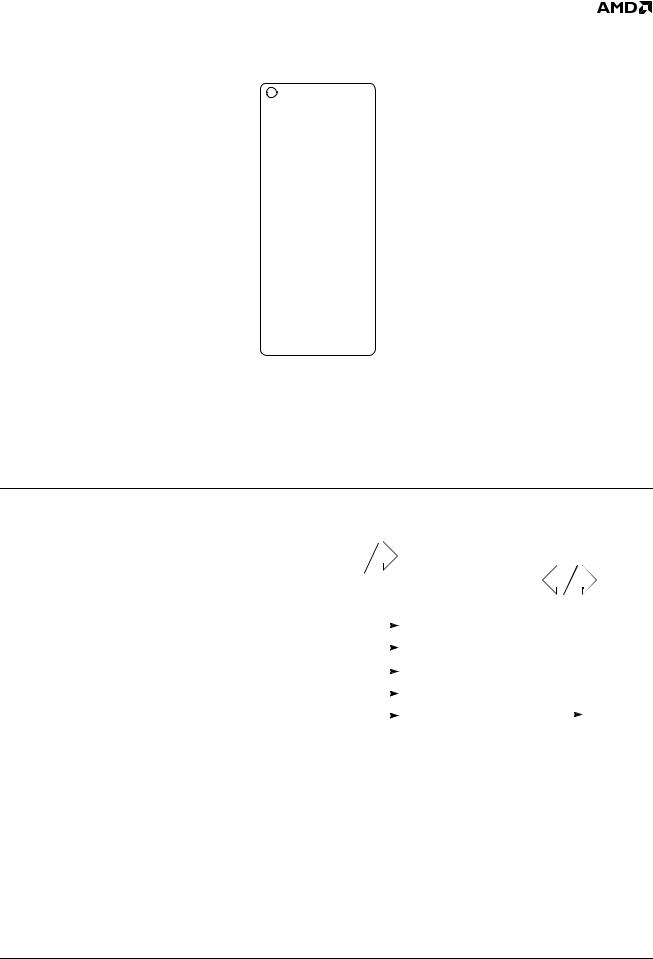

LOGIC SYMBOL

|

18 |

|

|

A0–A17 |

|

16 or 8 |

|||

|

|

|

|

||||||

|

|

|

|

|

|||||

|

|

|

|

|

DQ0–DQ15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CE# |

(A-1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OE# |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WE# |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RESET# |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BYTE# |

RY/BY# |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

21505C-4

Am29F400B |

5 |

P R E L I M I N A R Y

ORDERING INFORMATION

Standard Products

AMD standard products are available in several packages and operating ranges. The order number (Valid Combination) is formed by a combination of the elements below.

Am29F400B |

T |

-55 |

E |

C |

OPTIONAL PROCESSING

Blank = Standard Processing

B = Burn-in

(Contact an AMD representative for more information)

TEMPERATURE RANGE

C = Commercial (0°C to +70°C)

I = Industrial (–40°C to +85°C)

E = Extended (–55°C to +125°C)

PACKAGE TYPE

E= 48-Pin Thin Small Outline Package (TSOP) Standard Pinout (TS 048)

F= 48-Pin Thin Small Outline Package (TSOP) Reverse Pinout (TSR048)

S = 44-Pin Small Outline Package (SO 044)

SPEED OPTION

See Product Selector Guide and Valid Combinations

BOOT CODE SECTOR ARCHITECTURE

T = Top Sector

B = Bottom Sector

DEVICE NUMBER/DESCRIPTION

Am29F400B

4 Megabit (512 K x 8-Bit/256 K x 16-Bit) CMOS Flash Memory

5.0 Volt-only Read, Program, and Erase

Valid Combinations

Am29F400BT-55,

EC, EI, FC, FI, SC, SI

Am29F400BB-55

Am29F400BT-60,

Am29F400BB-60

Am29F400BT-70,

Am29F400BB-70

Am29F400BT-90,

EC, EI, EE,

Am29F400BB-90

FC, FI, FE,

SC, SI, SE

Am29F400BT-120,

Am29F400BB-120

Am29F400BT-150,

Am29F400BB-150

Valid Combinations

Valid Combinations list configurations planned to be supported in volume for this device. Consult the local AMD sales office to confirm availability of specific valid combinations and to check on newly released combinations.

6 |

Am29F400B |

P R E L I M I N A R Y

DEVICE BUS OPERATIONS

This section describes the requirements and use of the device bus operations, which are initiated through the internal command register. The command register itself does not occupy any addressable memory location. The register is composed of latches that store the commands, along with the address and data information needed to execute the command. The contents of

the register serve as inputs to the internal state machine. The state machine outputs dictate the function of the device. Table 1 lists the device bus operations, the inputs and control levels they require, and the resulting output. The following subsections describe each of these operations in further detail.

Table 1. Am29F400B Device Bus Operations

|

|

|

|

|

|

|

DQ8–DQ15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BYTE# |

BYTE# |

Operation |

CE# |

OE# |

WE# |

RESET# |

A0–A17 |

DQ0–DQ7 |

= VIH |

= VIL |

Read |

L |

L |

H |

H |

AIN |

DOUT |

DOUT |

High-Z |

Write |

L |

H |

L |

H |

AIN |

DIN |

DIN |

High-Z |

CMOS Standby |

VCC ± |

X |

X |

VCC ± |

X |

High-Z |

High-Z |

High-Z |

|

0.5 V |

|

|

0.5 V |

|

|

|

|

TTL Standby |

H |

X |

X |

H |

X |

High-Z |

High-Z |

High-Z |

|

|

|

|

|

|

|

|

|

Output Disable |

L |

H |

H |

H |

X |

High-Z |

High-Z |

High-Z |

|

|

|

|

|

|

|

|

|

Hardware Reset |

X |

X |

X |

L |

X |

High-Z |

High-Z |

High-Z |

|

|

|

|

|

|

|

|

|

Temporary Sector Unprotect |

X |

X |

X |

VID |

AIN |

DIN |

DIN |

High-Z |

(See Note) |

||||||||

Legend:

L = Logic Low = VIL, H = Logic High = VIH, VID = 12.0 ± 0.5 V, X = Don’t Care, DIN = Data In, DOUT = Data Out, AIN = Address In

Note: See the sections on Sector Protection and Temporary Sector Unprotect for more information.

Word/Byte Configuration

The BYTE# pin controls whether the device data I/O pins DQ15–DQ0 operate in the byte or word configuration. If the BYTE# pin is set at logic ‘1’, the device is in word configuration, DQ15–DQ0 are active and controlled by CE# and OE#.

If the BYTE# pin is set at logic ‘0’, the device is in byte configuration, and only data I/O pins DQ0–DQ7 are active and controlled by CE# and OE#. The data I/O pins DQ8–DQ14 are tri-stated, and the DQ15 pin is used as an input for the LSB (A-1) address function.

Requirements for Reading Array Data

To read array data from the outputs, the system must drive the CE# and OE# pins to VIL. CE# is the power control and selects the device. OE# is the output control and gates array data to the output pins. WE# should remain at VIH. The BYTE# pin determines whether the device outputs array data in words or bytes.

The internal state machine is set for reading array data upon device power-up, or after a hardware reset. This ensures that no spurious alteration of the memory content occurs during the power transition. No command is necessary in this mode to obtain array data. Standard microprocessor read cycles that assert valid addresses on the device address inputs produce valid data on the

device data outputs. The device remains enabled for read access until the command register contents are altered.

See “Reading Array Data” for more information. Refer to the AC Read Operations table for timing specifications and to Figure 9 for the timing diagram. ICC1 in the DC Characteristics table represents the active current specification for reading array data.

Writing Commands/Command Sequences

To write a command or command sequence (which includes programming data to the device and erasing sectors of memory), the system must drive WE# and CE# to VIL, and OE# to VIH.

For program operations, the BYTE# pin determines whether the device accepts program data in bytes or words. Refer to “Word/Byte Configuration” for more information.

An erase operation can erase one sector, multiple sectors, or the entire device. Tables 2 and 3 indicate the address space that each sector occupies. A “sector address” consists of the address bits required to uniquely select a sector. The “Command Definitions” section has details on erasing a sector or the entire chip, or suspending/resuming the erase operation.

Am29F400B |

7 |

P R E L I M I N A R Y

After the system writes the autoselect command sequence, the device enters the autoselect mode. The system can then read autoselect codes from the internal register (which is separate from the memory array) on DQ7–DQ0. Standard read cycle timings apply in this mode. Refer to the “Autoselect Mode” and “Autoselect Command Sequence” sections for more information.

ICC2 in the DC Characteristics table represents the active current specification for the write mode. The “AC Characteristics” section contains timing specification tables and timing diagrams for write operations.

Program and Erase Operation Status

During an erase or program operation, the system may check the status of the operation by reading the status bits on DQ7–DQ0. Standard read cycle timings and ICC read specifications apply. Refer to “Write Operation Status” for more information, and to “AC Characteristics” for timing diagrams.

In the CMOS and TTL/NMOS-compatible DC Characteristics tables, ICC3 represents the standby current specification.

RESET#: Hardware Reset Pin

The RESET# pin provides a hardware method of resetting the device to reading array data. When the RE-

SET# pin is driven low for at least a period of tRP, the device immediately terminates any operation in

progress, tristates all output pins, and ignores all read/write commands for the duration of the RESET# pulse. The device also resets the internal state machine to reading array data. The operation that was interrupted should be reinitiated once the device is ready to accept another command sequence, to ensure data integrity.

Current is reduced for the duration of the RESET# pulse. When RESET# is held at VIL, the device enters the TTL standby mode; if RESET# is held at VSS±0.5 V, the device enters the CMOS standby mode.

Standby Mode

When the system is not reading or writing to the device, it can place the device in the standby mode. In this mode, current consumption is greatly reduced, and the outputs are placed in the high impedance state, independent of the OE# input.

The device enters the CMOS standby mode when the CE# and RESET# pins are both held at VCC ± 0.5 V. (Note that this is a more restricted voltage range than VIH.) The device enters the TTL standby mode when CE# and RESET# pins are both held at VIH. The device requires standard access time (tCE) for read access when the device is in either of these standby modes, before it is ready to read data.

The device also enters the standby mode when the RESET# pin is driven low. Refer to the next section, “RESET#: Hardware Reset Pin”.

If the device is deselected during erasure or programming, the device draws active current until the operation is completed.

The RESET# pin may be tied to the system reset circuitry. A system reset would thus also reset the Flash memory, enabling the system to read the boot-up firmware from the Flash memory.

If RESET# is asserted during a program or erase operation, the RY/BY# pin remains a “0” (busy) until the internal reset operation is complete, which requires a time of tREADY (during Embedded Algorithms). The system can thus monitor RY/BY# to determine whether the reset operation is complete. If RESET# is asserted when a program or erase operation is not executing (RY/BY# pin is “1”), the reset operation is completed

within a time of tREADY (not during Embedded Algorithms). The system can read data tRH after the RE-

SET# pin returns to VIH.

Refer to the AC Characteristics tables for RESET# parameters and to Figure 10 for the timing diagram.

Output Disable Mode

When the OE# input is at VIH, output from the device is disabled. The output pins are placed in the high impedance state.

8 |

Am29F400B |

P R E L I M I N A R Y

Table 2. Am29F400BT Top Boot Block Sector Address Table

|

|

|

|

|

|

|

Sector Size |

Address Range (in hexadecimal) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Kbytes/ |

(x8) |

(x16) |

Sector |

A17 |

A16 |

A15 |

A14 |

A13 |

A12 |

Kwords) |

Address Range |

Address Range |

|

|

|

|

|

|

|

|

|

|

SA0 |

0 |

0 |

0 |

X |

X |

X |

64/32 |

00000h–0FFFFh |

00000h–07FFFh |

|

|

|

|

|

|

|

|

|

|

SA1 |

0 |

0 |

1 |

X |

X |

X |

64/32 |

10000h–1FFFFh |

08000h–0FFFFh |

|

|

|

|

|

|

|

|

|

|

SA2 |

0 |

1 |

0 |

X |

X |

X |

64/32 |

20000h–2FFFFh |

10000h–17FFFh |

|

|

|

|

|

|

|

|

|

|

SA3 |

0 |

1 |

1 |

X |

X |

X |

64/32 |

30000h–3FFFFh |

18000h–1FFFFh |

|

|

|

|

|

|

|

|

|

|

SA4 |

1 |

0 |

0 |

X |

X |

X |

64/32 |

40000h–4FFFFh |

20000h–27FFFh |

|

|

|

|

|

|

|

|

|

|

SA5 |

1 |

0 |

1 |

X |

X |

X |

64/32 |

50000h–5FFFFh |

28000h–2FFFFh |

|

|

|

|

|

|

|

|

|

|

SA6 |

1 |

1 |

0 |

X |

X |

X |

64/32 |

60000h–6FFFFh |

30000h–37FFFh |

|

|

|

|

|

|

|

|

|

|

SA7 |

1 |

1 |

1 |

0 |

X |

X |

32/16 |

70000h–77FFFh |

38000h–3BFFFh |

|

|

|

|

|

|

|

|

|

|

SA8 |

1 |

1 |

1 |

1 |

0 |

0 |

8/4 |

78000h–79FFFh |

3C000h–3CFFFh |

|

|

|

|

|

|

|

|

|

|

SA9 |

1 |

1 |

1 |

1 |

0 |

1 |

8/4 |

7A000h–7BFFFh |

3D000h–3DFFFh |

|

|

|

|

|

|

|

|

|

|

SA10 |

1 |

1 |

1 |

1 |

1 |

X |

16/8 |

7C000h–7FFFFh |

3E000h–3FFFFh |

|

|

|

|

|

|

|

|

|

|

Table 3. Am29F400BB Bottom Boot Block Sector Address Table

|

|

|

|

|

|

|

Sector Size |

Address Range (in hexadecimal) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Kbytes/ |

(x8) |

(x16) |

Sector |

A17 |

A16 |

A15 |

A14 |

A13 |

A12 |

Kwords) |

Address Range |

Address Range |

|

|

|

|

|

|

|

|

|

|

SA0 |

0 |

0 |

0 |

0 |

0 |

X |

16/8 |

00000h–03FFFh |

00000h–01FFFh |

|

|

|

|

|

|

|

|

|

|

SA1 |

0 |

0 |

0 |

0 |

1 |

0 |

8/4 |

04000h–05FFFh |

02000h–02FFFh |

|

|

|

|

|

|

|

|

|

|

SA2 |

0 |

0 |

0 |

0 |

1 |

1 |

8/4 |

06000h–07FFFh |

03000h–03FFFh |

|

|

|

|

|

|

|

|

|

|

SA3 |

0 |

0 |

0 |

1 |

X |

X |

32/16 |

08000h–0FFFFh |

04000h–07FFFh |

|

|

|

|

|

|

|

|

|

|

SA4 |

0 |

0 |

1 |

X |

X |

X |

64/32 |

10000h–1FFFFh |

08000h–0FFFFh |

|

|

|

|

|

|

|

|

|

|

SA5 |

0 |

1 |

0 |

X |

X |

X |

64/32 |

20000h–2FFFFh |

10000h–17FFFh |

|

|

|

|

|

|

|

|

|

|

SA6 |

0 |

1 |

1 |

X |

X |

X |

64/32 |

30000h–3FFFFh |

18000h–1FFFFh |

|

|

|

|

|

|

|

|

|

|

SA7 |

1 |

0 |

0 |

X |

X |

X |

64/32 |

40000h–4FFFFh |

20000h–27FFFh |

|

|

|

|

|

|

|

|

|

|

SA8 |

1 |

0 |

1 |

X |

X |

X |

64/32 |

50000h–5FFFFh |

28000h–2FFFFh |

|

|

|

|

|

|

|

|

|

|

SA9 |

1 |

1 |

0 |

X |

X |

X |

64/32 |

60000h–6FFFFh |

30000h–37FFFh |

|

|

|

|

|

|

|

|

|

|

SA10 |

1 |

1 |

1 |

X |

X |

X |

64/32 |

70000h–7FFFFh |

38000h–3FFFFh |

|

|

|

|

|

|

|

|

|

|

Note:

Address range is A17:A-1 in byte mode and A17:A0 in word mode. See “Word/Byte Configuration” section for more information.

Autoselect Mode

The autoselect mode provides manufacturer and device identification, and sector protection verification, through identifier codes output on DQ7–DQ0. This mode is primarily intended for programming equipment to automatically match a device to be programmed with its corresponding programming algorithm. However, the autoselect codes can also be accessed in-system through the command register.

When using programming equipment, the autoselect mode requires VID (11.5 V to 12.5 V) on address pin A9. Address pins A6, A1, and A0 must be as shown in Table 4. In addition, when verifying sector protection,

the sector address must appear on the appropriate highest order address bits (see Tables 2 and 3). Table 4 shows the remaining address bits that are don’t care. When all necessary bits have been set as required, the programming equipment may then read the corresponding identifier code on DQ7–DQ0.

To access the autoselect codes in-system, the host system can issue the autoselect command via the command register, as shown in Table 5. This method does not require VID. See “Command Definitions” for details on using the autoselect mode.

Am29F400B |

9 |

P R E L I M I N A R Y

Table 4. Am29F400B Autoselect Codes (High Voltage Method)

|

|

|

|

|

A17 |

A11 |

|

A8 |

|

A5 |

|

|

|

DQ8 |

DQ7 |

|

|

|

|

|

to |

to |

|

to |

|

to |

|

|

|

to |

to |

Description |

Mode |

CE# |

OE# |

WE# |

A12 |

A10 |

A9 |

A7 |

A6 |

A2 |

A1 |

A0 |

DQ15 |

DQ0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Manufacturer ID: AMD |

L |

L |

H |

X |

X |

VID |

X |

L |

X |

L |

L |

X |

01h |

||

Device ID: |

Word |

L |

L |

H |

|

|

|

|

|

|

|

|

|

22h |

23h |

Am29F400B |

|

|

|

|

X |

X |

VID |

X |

L |

X |

L |

H |

|

|

|

Byte |

L |

L |

H |

|

X |

23h |

|||||||||

(Top Boot Block) |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Device ID: |

Word |

L |

L |

H |

|

|

|

|

|

|

|

|

|

22h |

ABh |

Am29F400B |

|

|

|

|

X |

X |

VID |

X |

L |

X |

L |

H |

|

|

|

Byte |

L |

L |

H |

|

X |

ABh |

|||||||||

(Bottom Boot Block) |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

01h |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(protected) |

|

Sector Protection Verification |

L |

L |

H |

SA |

X |

VID |

X |

L |

X |

H |

L |

|

|

||

|

|

|

|||||||||||||

|

X |

00h |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(unprotected) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L = Logic Low = VIL, H = Logic High = VIH, SA = Sector Address, X = Don’t care.

Sector Protection/Unprotection

The hardware sector protection feature disables both program and erase operations in any sector. The hardware sector unprotection feature re-enables both program and erase operations in previously protected sectors.

Sector protection/unprotection must be implemented using programming equipment. The procedure requires a high voltage (VID) on address pin A9 and OE#. Details on this method are provided in a supplement, publication number 20185. Contact an AMD representative to obtain a copy of this document.

The device is shipped with all sectors unprotected. AMD offers the option of programming and protecting sectors at its factory prior to shipping the device through AMD’s ExpressFlash™ Service. Contact an AMD representative for details.

It is possible to determine whether a sector is protected or unprotected. See “Autoselect Mode” for details.

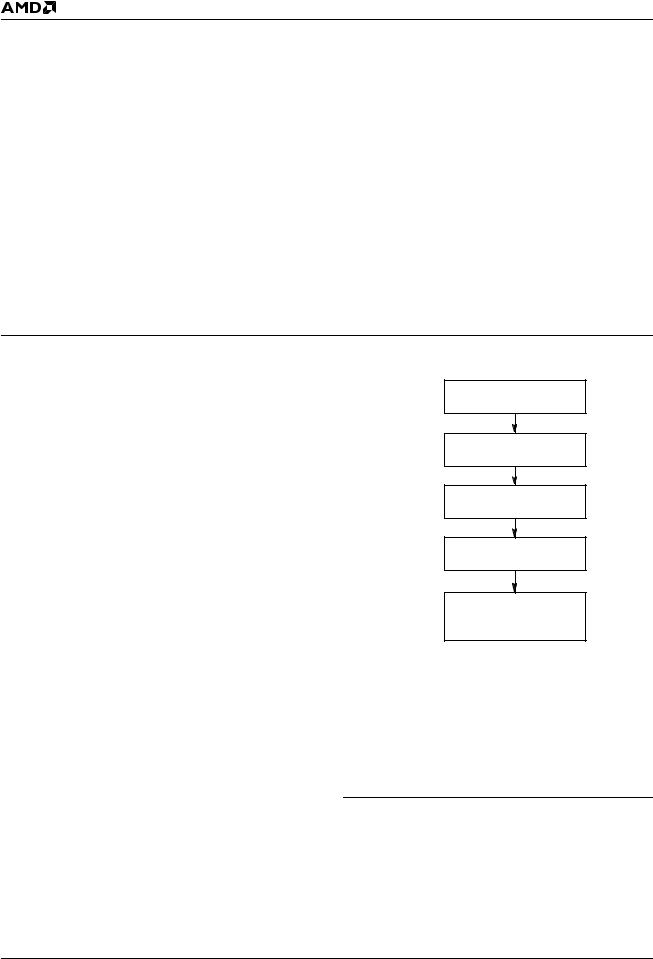

START

RESET# = VID

(Note 1)

Perform Erase or

Program Operations

RESET# = VIH

Temporary Sector

Unprotect Completed

(Note 2)

21505C-5

Temporary Sector Unprotect

This feature allows temporary unprotection of previously protected sectors to change data in-system. The Sector Unprotect mode is activated by setting the RESET# pin to VID. During this mode, formerly protected sectors can be programmed or erased by selecting the sector addresses. Once VID is removed from the RESET# pin, all the previously protected sectors are protected again. Figure 1 shows the algorithm, and Figure 18 shows the timing diagrams, for this feature.

Notes:

1.All protected sectors unprotected.

2.All previously protected sectors are protected once again.

Figure 1. Temporary Sector Unprotect Operation

Hardware Data Protection

The command sequence requirement of unlock cycles for programming or erasing provides data protection against inadvertent writes (refer to Table 5 for command definitions). In addition, the following hardware data protection measures prevent accidental erasure or programming, which might otherwise be caused by

10 |

Am29F400B |

P R E L I M I N A R Y

spurious system level signals during VCC power-up and power-down transitions, or from system noise.

Low VCC Write Inhibit

When VCC is less than VLKO, the device does not accept any write cycles. This protects data during VCC

power-up and power-down. The command register and all internal program/erase circuits are disabled, and the device resets. Subsequent writes are ignored until VCC is greater than VLKO. The system must provide the proper signals to the control pins to prevent unintentional writes when VCC is greater than VLKO.

Write Pulse “Glitch” Protection

Noise pulses of less than 5 ns (typical) on OE#, CE# or WE# do not initiate a write cycle.

Logical Inhibit

Write cycles are inhibited by holding any one of OE# = VIL, CE# = VIH or WE# = VIH. To initiate a write cycle, CE# and WE# must be a logical zero while OE# is a logical one.

Power-Up Write Inhibit

If WE# = CE# = VIL and OE# = VIH during power up, the device does not accept commands on the rising edge of WE#. The internal state machine is automatically reset to reading array data on power-up.

COMMAND DEFINITIONS

Writing specific address and data commands or sequences into the command register initiates device operations. Table 5 defines the valid register command sequences. Writing incorrect address and data values or writing them in the improper sequence resets the device to reading array data.

All addresses are latched on the falling edge of WE# or CE#, whichever happens later. All data is latched on the rising edge of WE# or CE#, whichever happens first. Refer to the appropriate timing diagrams in the “AC Characteristics” section.

Reading Array Data

The device is automatically set to reading array data after device power-up. No commands are required to retrieve data. The device is also ready to read array data after completing an Embedded Program or Embedded Erase algorithm.

After the device accepts an Erase Suspend command, the device enters the Erase Suspend mode. The system can read array data using the standard read timings, except that if it reads at an address within erasesuspended sectors, the device outputs status data. After completing a programming operation in the Erase Suspend mode, the system may once again read array data with the same exception. See “Erase Suspend/Erase Resume Commands” for more information on this mode.

The system must issue the reset command to re-ena- ble the device for reading array data if DQ5 goes high, or while in the autoselect mode. See the “Reset Command” section, next.

See also “Requirements for Reading Array Data” in the “Device Bus Operations” section for more information. The Read Operations table provides the read parameters, and Figure 9 shows the timing diagram.

Reset Command

Writing the reset command to the device resets the device to reading array data. Address bits are don’t care for this command.

The reset command may be written between the sequence cycles in an erase command sequence before erasing begins. This resets the device to reading array data. Once erasure begins, however, the device ignores reset commands until the operation is complete.

The reset command may be written between the sequence cycles in a program command sequence before programming begins. This resets the device to reading array data (also applies to programming in Erase Suspend mode). Once programming begins, however, the device ignores reset commands until the operation is complete.

The reset command may be written between the sequence cycles in an autoselect command sequence. Once in the autoselect mode, the reset command must be written to return to reading array data (also applies to autoselect during Erase Suspend).

If DQ5 goes high during a program or erase operation, writing the reset command returns the device to reading array data (also applies during Erase Suspend).

Autoselect Command Sequence

The autoselect command sequence allows the host system to access the manufacturer and devices codes, and determine whether or not a sector is protected. Table 5 shows the address and data requirements. This method is an alternative to that shown in Table 4, which is intended for PROM programmers and requires VID on address bit A9.

The autoselect command sequence is initiated by writing two unlock cycles, followed by the autoselect command. The device then enters the autoselect mode, and the system may read at any address any

Am29F400B |

11 |

P R E L I M I N A R Y

number of times, without initiating another command sequence.

A read cycle at address XX00h or retrieves the manufacturer code. A read cycle at address XX01h in word mode (or 02h in byte mode) returns the device code. A read cycle containing a sector address (SA) and the address 02h in word mode (or 04h in byte mode) returns 01h if that sector is protected, or 00h if it is unprotected. Refer to Tables 2 and 3 for valid sector addresses.

The system must write the reset command to exit the autoselect mode and return to reading array data.

Word/Byte Program Command Sequence

The system may program the device by word or byte, depending on the state of the BYTE# pin. Programming is a four-bus-cycle operation. The program command sequence is initiated by writing two unlock write cycles, followed by the program set-up command. The program address and data are written next, which in turn initiate the Embedded Program algorithm. The system is not required to provide further controls or timings. The device automatically provides internally generated program pulses and verify the programmed cell margin. Table 5 shows the address and data requirements for the byte program command sequence.

When the Embedded Program algorithm is complete, the device then returns to reading array data and addresses are no longer latched. The system can determine the status of the program operation by using DQ7, DQ6, or RY/BY#. See “Write Operation Status” for information on these status bits.

Any commands written to the device during the Embedded Program Algorithm are ignored. Note that a hardware reset immediately terminates the programming operation. The Byte Program command sequence should be reinitiated once the device has reset to reading array data, to ensure data integrity.

Programming is allowed in any sequence and across sector boundaries. A bit cannot be programmed from a “0” back to a “1”. Attempting to do so may halt the operation and set DQ5 to “1”, or cause the Data# Polling algorithm to indicate the operation was successful. However, a succeeding read will show that the data is still “0”. Only erase operations can convert a “0” to a “1”.

START

Write Program

Command Sequence

Data Poll

from System

Embedded Program algorithm in progress

Verify Data?

No

Yes

Increment Address |

No |

Last Address? |

|

|

Yes |

|

Programming |

|

Completed |

21505C-6

Note:

See Table 5 for program command sequence.

Figure 2. Program Operation

Chip Erase Command Sequence

Chip erase is a six-bus-cycle operation. The chip erase command sequence is initiated by writing two unlock cycles, followed by a set-up command. Two additional unlock write cycles are then followed by the chip erase command, which in turn invokes the Embedded Erase algorithm. The device does not require the system to preprogram prior to erase. The Embedded Erase algorithm automatically preprograms and verifies the entire memory for an all zero data pattern prior to electrical erase. The system is not required to provide any controls or timings during these operations. Table 5 shows the address and data requirements for the chip erase command sequence.

Any commands written to the chip during the Embedded Erase algorithm are ignored. Note that a hardware reset during the chip erase operation immediately terminates the operation. The Chip Erase command sequence should be reinitiated once the device has returned to reading array data, to ensure data integrity.

12 |

Am29F400B |

Loading...

Loading...