ABB Softstarters User Guide

1SFC132081M0201 EN, Rev K

Softstarters Type PSTX30...PSTX1250

Installation and commissioning manual

Original instruction

This is the Installation and commissioning manual for Softstarters Type PSTX30…PSTX1250.

Document number: 1SFC132081M0201

Revision: K

Issue date: 2017-09-07

Data can be changed without notice.

We reserve all rights to this document, even in the event that

a patent is issued and a different commercial proprietary right

is registered. Improper use, in particular reproduction and dissemination to third parties, is not permitted.

This document is written carefully. If you find an error, please

notify us as soon as possible.

The data contained in this manual is intended solely for the

product description and is not to be deemed to be a statement of guaranteed properties. In the interests of our customers, we constantly seek to ensure that our products are

developed to the latest technological

Author’s address:

ABB AB

Control Products

SE-721 61 VÄSTERÅS, Sweden

www.abb.com/lowvoltage

© Copyright 2017. All rights reserved. Data can be changed

without notice.

Read this first

Warning and safety

Thank you for selecting this ABB PSTX Softstarter.

Carefully read and make sure that you understand all

instructions before you install, connect, configure the

Softstarter.

This manual is intended for installation and advanced

usage of the PSTX Softstarter. For quick and easy

installation, see 1SFC132082M9901 - Softstarters Type

PSTX30...PSTX1250 User Manual short form. The manual

is available on: http://www.abb.com/lowvoltage

When this manual refers to http://www.abb.com/

lowvoltage: Select the link Control Products, continue

to Softstarters and type in the specified reference in the

search field.

• Only authorized and appropriately trained personnel are

permitted to install and make the electrical connection of

the Softstarter. Obey all laws and regulatons.

• Only authorized personnel are permitted to do service and

repair on the Softstarter.

• Unauthorized repair will have an effect on the warranty.

• ABB personnel must obey the instructions in ABB CISE

15.4.

• This manual is a part of the PSTX Softstarter.

Always keep this manual available when you work with

the PSTX Softstarter.

• Examine the Softstarter and the package when

you unpack your new PSTX Softstarter. If there are

damages, please speak to the transportation company

or the ABB reseller/office immediately.

Safety notes

In the manual, these symbols are used

WARNING

General warning symbol indicates the presence of

a hazard which could result in personal injury and

damage to equipment or property.

WARNING

Warning symbol indicates the presence of

hazardous voltage which could result in

personal injury.

General safety information

WARNING

Approved personnel are allowed to install and

make the electrical connection of the Softstarter

in accordance with existing laws and regulations.

WARNING

Examine the Softstarter and the package when

you unpack your new PSTX Softstarter. If there

are damages, please speak to the transportation

company or the ABB reseller/office immediately.

WARNING

Only approved personnel are allowed to do

service and repair.

Note: not approved repair can effect the warranty.

Legal Disclaimer

The PSTX Softstarter is designed to be connected to

and to communicate information and data via a network

interface. It is customers sole responsibility to provide

and continuously ensure a secure connection between

the product and your network or any other network (as

the case may be) and to establish and maintain any

appropriate measures (such as but not limited to the

installation of firewalls, application of authentication

measures, encryption of data, installation of anti-virus

programs, etc) to protect the PSTX Softstarter, the

network, its system and the interface against any kind

of security breaches, unauthorized access, interference,

intrusion, leakage and/or theft of data or information.

ABB Ltd and its affiliates are not liable for damages

and/or losses related to such security breaches, any

unauthorized access, interference, intrusion, leakage and/

or theft of data or information.

WARNING

Approved personnel are allowed to install and

make the electrical connection of the Softstarter

in accordance with existing laws and regulations.

INFORMATION

Information sign tells the reader important facts

and conditions.

Changes to data in this manual can be applied without notice.

Softstarters Type PSTX

Installation and commissioning manual

1 Introduction

2 Quick start

3 Description

4 Installation

5 Connection

6 Human machine interface (HMI)

7 Functions

8 Communication

9 Maintenance

10 Troubleshooting

11 Wiring and application diagrams

12 Third par ty licenses

13 Revision

14 Index

11

2

3

4

5

6

7

8

9

10

11

12

13

14

1 Introduction

1.1 Documentation for Softstarter PSTX30...PSTX12500

8

1.1.1 Installation and commissioning manual

1.2 Intended audience 9

1.3 Revision notes and other documents 9

1.4 Acronyms and abbreviations 9

1

1SFC132081M0201 | Installation and commissioning manual | Introduction 7

This chapter gives an introduction to the Softstarter

documentation manuals and its chapters, releases,

intended audience and it tells about concepts.

1.1.1 Installation and commissioning

manual

This manual, “Softstarters Type PSTX30...PSTX1250

Installation and commissioning manual”, contains

instructions on how to install, commission and maintain

1.1 Documentation for Softstarter

PSTX30...PSTX1250

1

For the Softstarter types PSTX30...PSTX1250, these

manuals and catalogs are available:

1SFC132081M0201

the Softstarter. It gives procedures for mechanical and

electrical installation, and installation of communication

devices. It also gives information abouts energizing,

settings and configuration.

To start quickly, see chapter 2 Quick start

or use the short form manual (1SFC132082M9901).

For chapter content,

see Table 2 Chapter contents below:

This document. Installation and commissioning manual

(English version). See chapter 1.1.1 Installation and

commissioning manual more information.

1SFC132082M9901

Installation and commissioning manual - Short form.

See chapter 1.1.2 Installation and commissioning

manual - Short form for more information.

1SFC132009C0201

Catalog Softstarters Type PSTX and PSTB.

These documents are available online in PDF format.

A printed version of the “Installation and commissioning Short form” is included with the Softstarter.

These manuals are available as online PDF-files:

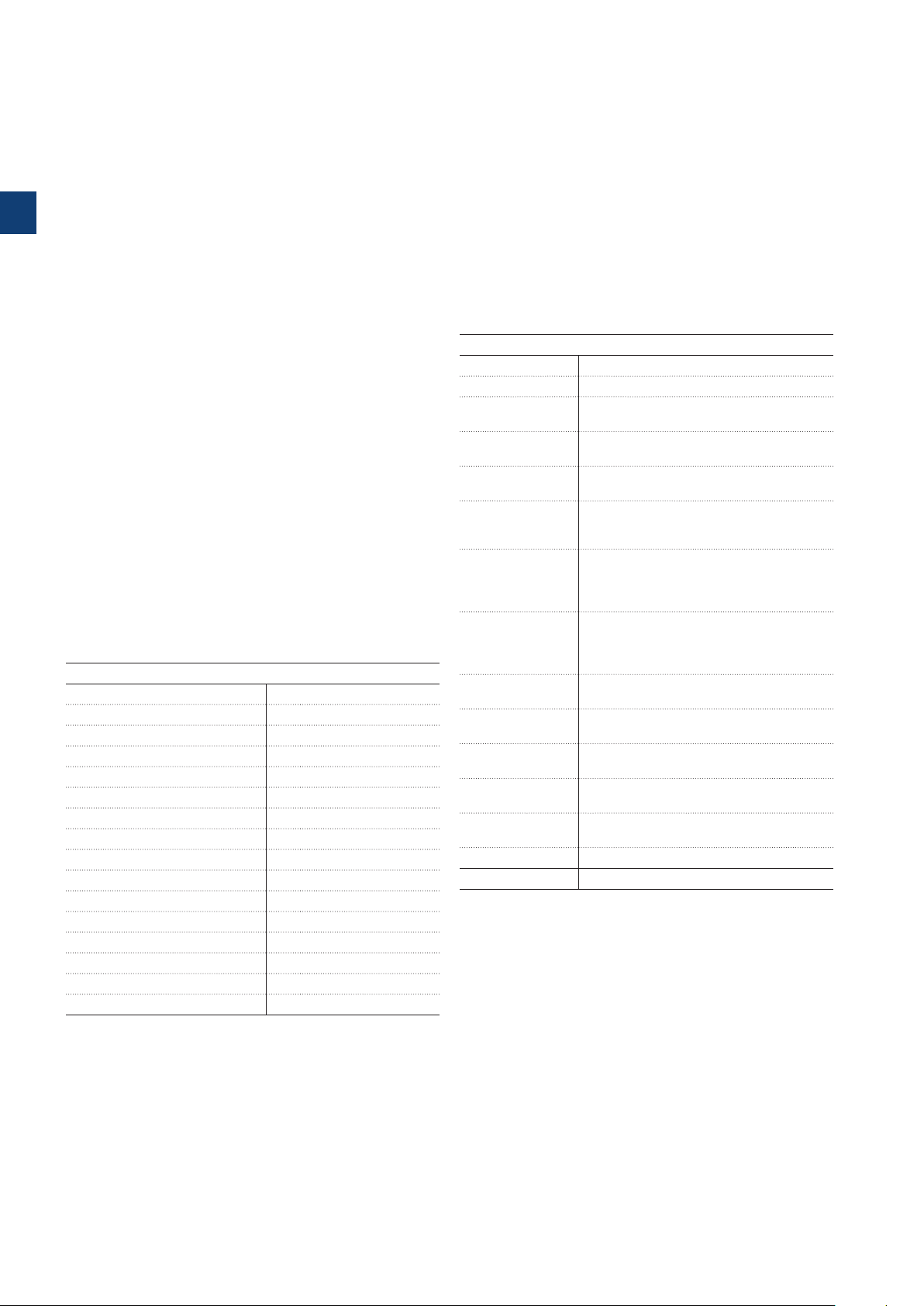

Table 1 Languages

Document ID Language

1SFC132081M1301 AR Arabic

1SFC132081M2001 ZH Chinese

1SFC132081M4601 CS Czech

1SFC132081M0101 DE German

1SFC132081M0201 EN English

1SFC132081M0701 ES Spanish

1SFC132081M1801 FI Finnish

1SFC132081M0301 FR French

1SFC132081M0901 IT Italian

1SFC132081M3101 NL Dutch

1SFC132081M4001 PL Polish

1SFC132081M1601 PT Portuguese

1SFC132081M1101 RU Russian

1SFC132081M3401 SV Swedish

1SFC132081M1901 TR Turkish

Table 2 Chapters contents

Chapters Description

1. Introduction Introduces the reader to this manual.

2. Quick start Contains information for quick installation of

3. Description Gives a description of the Softstarter with

4. Installation Contains information of the delivery, how to

5. Connection Contains instructions to make the

6. Human-Machine

Interface

7. Functions Gives a description of all functions of the

8. Communication Gives a description of the communication

9. Maintenance Gives a description of the necessary

10. Troubleshooting Contains instructions to find and correct the

11. Wiring diagrams Contains electrical and application diagrams

12. Third party

Licenses

13. Revision Shows all revisions of the manual

14. Index Index of the content of this manual

the Softstarter and get it into operation.

specifications and a list of functions.

unpack and install the Softstarter.

electrical connections, and connections for

communication devices.

Gives a description of the Human-Machine

Interface.

Gives a description of all settings and

navigation of the menu systems.

Softstarter, with their minimum, maximum

and default values. This chapter is intended

for the experienced user.

ports of the Softstarter.

maintenance and how to do it.

most common errors.

for the Softstarter.

3’rd party licenses used by Softstarter

1.1.2 Installation and commissioning

manual - Short form

The “Softstarters Type PSTX30...PSTX1250 Installation

and commissioning manual - Short form” contains brief

information about the Softstarter:

These documents can be found at:

www.abb.com/lowvoltage. Select the link Control

Products on the site, and then continue to Softstarters.

-Installation

-Electrical connections

-Basic functions

-Troubleshooting

The short form contains the languages shown in

Table 1 Languages. The short form has document ID

1SFC132082M9901.

8 Introduction | Installation and commissioning manual | 1SFC132081M0201

1.2 Intended audience

1.2.1 General

The Installation and commissioning manual is intended for

authorized installation, commissioning, and maintenance

personnel.

1.2.2 Requirements for personnel

The installation personnel must have a basic knowledge

in how to handle electrical equipment. The commissioning

and maintenance personnel must have good experience

in how to use electrical equipment. ABB personnel must

obey the instructions in ABB CISE 15.4.

1.3 Revision notes and other

documents

1

For latest information on revisions and other documents

related to the PSTX Softstarters, please see

www.abb.com/lowvoltage. Select the link Control

Products on the site, and then continue to Softstarters.

1.4 Acronyms and abbreviations

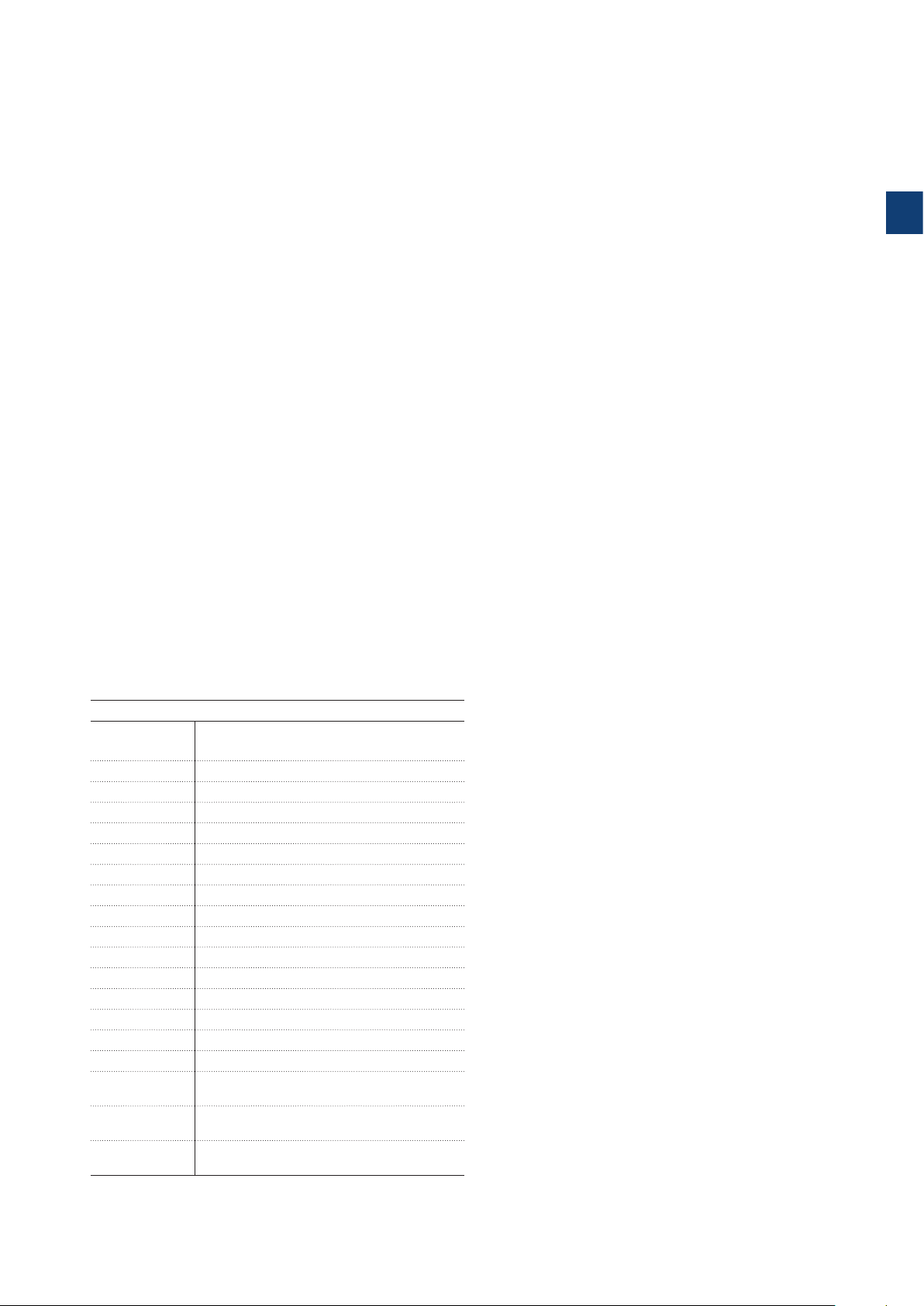

Table 3 Acronyms and abbreviations

Acronym/

Abbreviation

BP Bypass

DOL Direct-on-line

EOL Electronic overload

FB Fieldbus

FBP Fieldbus Plug

HMI Human-Machine Interface

I

e

IT Information Technology

LED Light Emitting Diode

PCBA Printed Circuit Board Assembly

PLC Programmable Logic Controller

PTC Positive Temperature Coefficient

SC Short Circuit

SCR Silicon Controlled Rectifier (thyristor)

TOR Top of Ramp (full voltage/Full-On)

U

c

U

e

U

s

*) For definition see IEC 60947-1 edition 5.0

Description

Rated operation current

Rated control circuit voltage, used for

controlling the Softstarter. *

Rated operation voltage on the motor (3 phase

main voltage feeding the motor). *

Rated control supply voltage, feeding the

electronics in the Softstarter. *

1SFC132081M0201 | Installation and commissioning manual | Introduction 9

1

10 Introduction | Installation and commissioning manual | 1SFC132081M0201

2 Quick start

2.1 Connection

12

2.2 Configuration

14

2.2.1 Basic set-up 14

2.2.2 Application set-up 14

2.3 How to start/stop the motor

15

2

1SFC132081M0201 | Installation and commissioning manual | Quick start 11

This chapter is a short guide on how to connect,

1SFC132081M0201

1SFC132081M0201

1SFC132081M0201

configure and start the Softstarter in an easy way.

This product was carefully manufactured and tested, but

damage can occur during transportation. Therefore, obey

these instructions:

WARNING

Dangerous voltage: Can cause death or serious

injury. Always set the power switch to off and lock

out all power to this device before you start to

2

work on the equipment.

1 2

WARNING!

Installation of electrical connections must be done by

authorized personnel. Obey all laws and regulations.

PSTX

PSTX

WARNING!

Before you connect the Softstarters PSTX30...

PSTX170 to the operation voltage for the first time,

apply control supply voltage to open the bypass

relays. (see 2.1 Connection). This is necessary to

avoid an accidental start of the equipment while it is

connected to operation voltage.

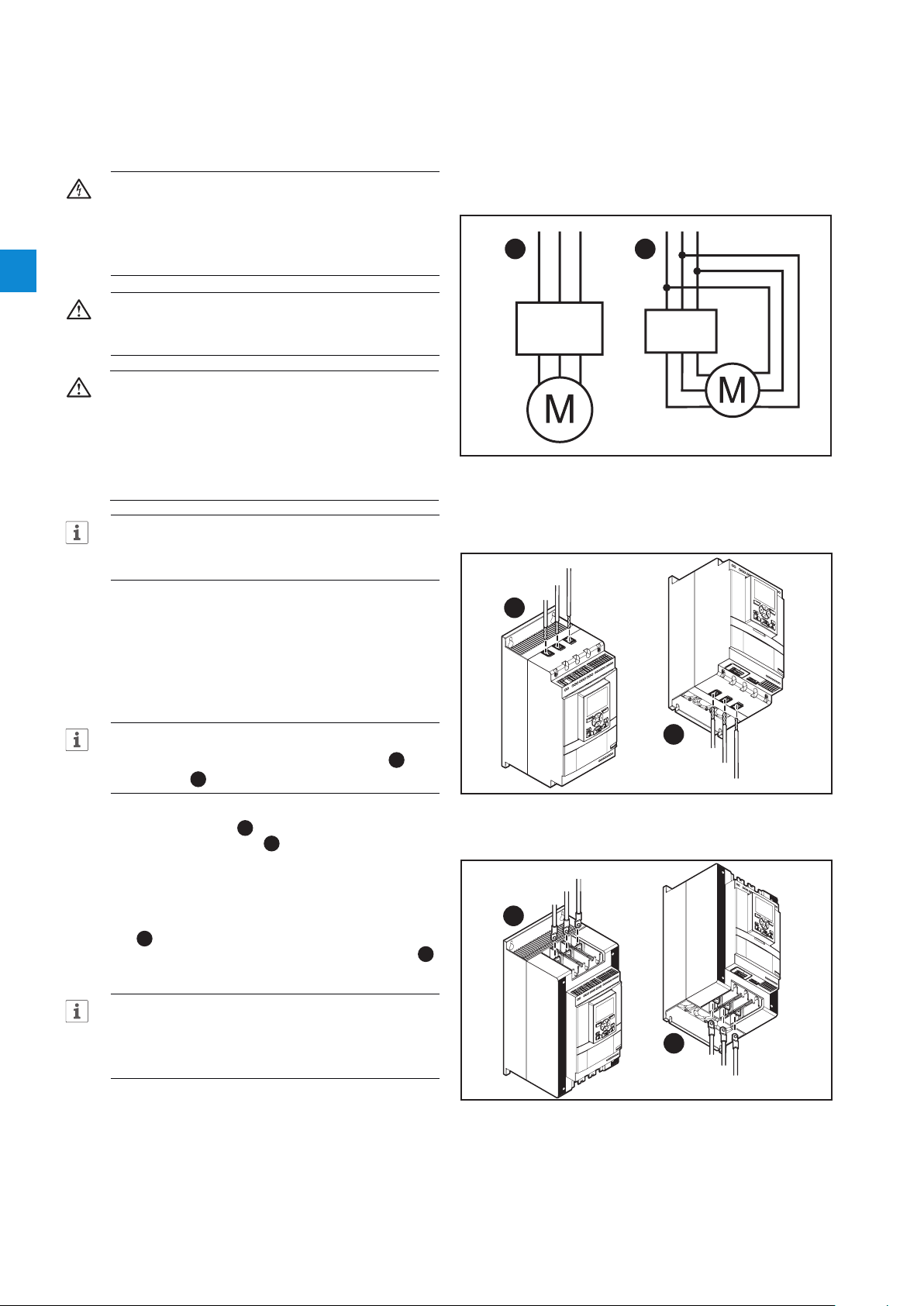

Figure 2.1

In Line (1) and Inside Delta (2) connection

INFORMATION

ABB personnel must obey the instructions in

ABB CISE 15.4.

2.1 Connection

1. To install the Softstarter

see chapter 4 Installation.

INFORMATION

You can connect PSTX Softstarters In Line 1 and

Inside Delta 2, see Figure 2.1.

2. Connect the main circuit: terminals 1L1 - 3L2 5L3 to the line side 1, and terminals 2T1 - 4T2

- 6T3 to the motor side 2, see Figure 2.2.. Use

wire connection for PSTX30...105, see Figure 2.2

and terminal connection for PSTX142...570, see

Figure 2.3.

3. Connect the line side to terminals 1L1, 3L2, 5L3.

see 1 and Figure 2.2. Connect the motor to

terminals 2T1, 4T2, 6T3 on the motor side, see 2

Figure 2.2 and Figure 2.3.

5L3

3L2

1L1

1

Figure 2.2

Terminal connection clamps

1

Line side

5L3

3L2

1L2

Line side

2

Motor side

2T1

4T2

6T3

INFORMATION

Use only wires of the same dimension when you

connect 2 wires to each terminal. (Possible for

PSTX30...105 only).

4. Connect the control supply voltage (100-250V

50/60Hz) to terminal 1 and 2.

5. Connect the functional ground (terminal 22), to a

ground point close to the Softstarter,

see Figure 2.4.

12 Quick start | Installation and commissioning manual | 1SFC132081M0201

Figure 2.3

Terminal connection bars

4T2

Motor side

6T3

2

2T1

INFORMATION

1SFC132081M0201

1SFC132081M0201

1SFC132081M0201

1SFC132081M0201

The ground is not a protective ground, it is a

functional ground. The maximum length of the

ground cable is 0.5 m. Connect the ground cable

to the installation plate were the Softstarter is

attached. The installation plate must also be

grounded.

INFORMATION

Do not use functional ground in IT-networks, commonly

found in for instance marine applications.

6. Look at the diagram, see Figure 2.7, and connect

the start/stop circuits: terminal 13, 14, 18, 19 and

20/21, with the internal 24V DC terminal. When

you use internal 24 V DC (terminals 20 or 21), the

terminals 18 and 19 must be connected to each

other. For external control circuit voltage,

see chapter 5.1.2.3 Start and Stop - terminals

13, 14, 18, 19, 20, 21.

WARNING

Use 24V DC only when you connect terminal 13, 14,

15, 16 and 17. Other voltages can cause damage

to the Softstarter and the warranty will no longer be

valid. For more information about terminal 15, 16 and

17, see chapter 5.1.2.4 Programmable inputs -

terminals 15, 16 and 17.

7. Connect terminals 4, 5, 6, 7, 8, 9, 10, 11 and

12 to use the signal output relays. These are

potential-free contacts for maximum 250 V AC, 1.5

A AC-15 and 30 V DC, 5 A DC-12.

See Figure 2.5.

8. Make sure that the operation voltage and control

supply voltage agree with the Softstarter ratings.

9. Set the control supply voltage switch to ON.

10. The green Ready LED is constant lit if the following

conditions are fulfilled:

- Control supply voltage is detected

- Mains three phase voltage is detected

- Mains frequency is within range (40-72Hz)

- Motor connection is detected

- Phase sequence is detected

- No events are active

- Enable signal is active

- If the max nbr of starts per hour function is

enabled and set to stop manual or stop automatic,

the remaining time to start counter (which can be

shown in the HMI homeview) has to be zero

Otherwise the ready LED is flashing, see Figure

2.6.

11. The language settings appear on the screen.

Select your language and push the selection soft

key “OK”. The HMI now downloads the language

data from the Softstarter. This can take some

minutes. When this is done the HMI shows the

Home view.

Figure 2.4

Functional ground, terminal 22

L1

L2

L3

N

KM1

1L13L2 5L3

2T14T2 6T3

UVW

M

3

LN

StartStop

Star 24 V DCt

Stop

Figure 2.7

Circuit diagram (Fuse and contactor version)

L1

L2

L3

N

1L13L2 5L3

2T14T2 6T3

UVW

M

3

LN

StartStop

Star 24 V DCt

Stop

Figure 2.5

Circuit diagram ( MCCB version)

L

N

100-250V

50/60 Hz K4 K4 K4

StartStopResetIn1In2 DGND DND +24V GND

PSTX

22

2014 18 1913

19 201815 16 17141321 21

22

2014 18 1913

19 201815 16 17141321 21 22

2

22

121110987654

22

121110987654

12. Configure applicable parameters as given in

chapter 7 Functions or use the assistants as

given in chapter 2.2 Configuration.

1SFC132081M0201 | Installation and commissioning manual | Quick start 13

Figure 2.6

Flashing “Ready” LED

2.2 Configuration

For a quick configuration of the Softstarter, use the

Assistants menu.

The Assistants menus are divided into:

• Basic set-up

- The Basic set-up menu is divided into 4 steps:

1. Language

2. Date and time

3. Motor data

4. System configuration

2

• Application set-up

- The Application set-up is divided into 3 steps:

1. Application set-up

2. Keep/Change values

3. Tune settings

2.2.1 Basic set-up

You see this set-up when you start the Softstarter. To

disable this set-up, see step 6 below.

1. Find the Assistants menu by pushing “Menu”.

Scroll to Assistants with the Navigation keys. Push

“Select” to enter the Assistants menu.

2. Scroll to the Basic set-up menu with the

Navigation keys. Push “Select” to enter the

menu.

3. The Basic set-up starts with step 1 of 5,

Language. Push “Edit” to change language.

Use the Navigation keys to select language and

then push “Save”.

4. Push to enter step 2(5), Date and time. Push

“Edit” and use the Navigation keys to edit date

and time, then push “Save”.

5. Push to enter step 3(5), Motor data.

Push “Edit” to change the Motor rated current

Ie. Use the Navigation keys to change the value

and then push “Save”.

2.2.2 Application set-up

1. Find the Assistants menu from the Home view by

pushing “Menu”. Scroll to Assistants with the

Navigation keys. Push “Select” to enter the

Assistants menu.

2. Scroll to the Application set-up menu with the

Navigation keys and then enter the menu by

pushing “Select”.

3. The Application set-up will start with step 1,

Application type. Scroll to the appropriate

application type and then push “Select”. For

a full Application list, see chapter 7.25 Complete

parameter list.

4. Push to enter step 2, Values. You can select

“Keep actual values” or “Change to recommended

values”. Scroll to the selection of your choice and

Push “Select” to apply.

WARNING!

Note that your saved parameter values are lost if you

select “Change to recommended values”.

5. Push to enter step 3, Tune settings. In most

cases the recommended values are sufficient, but

sometimes fine tuning is necessary. For fine tuning,

push “Edit” and then use the navigation keys

to set:

-Start ramp time: 1 - 120s

-Stop ramp time: 1 - 120s

-Start ramp initial level: 10 - 99%

-Stop ramp end level: 10 - 99%

-Current limit level: 1.5 - 7.5 x Ie

-Start mode: Voltage ramp, Torque ramp or Full

voltage start

-Stop mode: No ramp, Voltage ramp, Torque ramp,

Dynamic brake

6. Push and then push “Done” to finish the

Application set-up. If necessary, fine tuning can

also be done in the Parameters menu.

6. Push to enter step 4(5), System configuration.

Here you can set if the Softstarter enters the Basic

set-up at power on or not. Use the Navigation keys

to select Yes or No and then push “Save”.

7. Push to enter step 5(5) and then Push

“Done” to finish the Basic setup. For more

settings, enter Application set-up.

14 Quick start | Installation and commissioning manual | 1SFC132081M0201

2.3 How to start/stop the motor

WARNING

Dangerous voltage: Can cause death or serious

injury. Always set the power switch to off and lock

out all power to this device before you start to

work on the equipment.

WARNING

Approved personnel are allowed to install and

make the electrical connection of the Softstarter

in accordance with existing laws and regulations.

WARNING!

Before you connect the Softstarters PSTX30...

PSTX170 to the operation voltage for the first time,

apply control supply voltage to open the bypass

relays. (see 2.1 Connection). This is necessary to

avoid an accidental start of the equipment while it is

connected to operation voltage.

INFORMATION

ABB personnel must obey the instructions in

ABBCISE15.4.

2

1. Set the operation voltage switch to ON.

2. To start the Softstarter from the keypad, push

the R/L-key to select local control, then push the

Start key on the keypad. Push Stop to stop the

Softstarter

3. To start from hard wire control, push the R/L-key

to select hard wire control, then push the remote

Start key. Push Stop to stop the Softstarter.

1SFC132081M0201 | Installation and commissioning manual | Quick start 15

2

16 Quick start | Installation and commissioning manual | 1SFC132081M0201

3 Description

3.1 Overview

18

3.1.1 Operation functions 18

3.1.2 Protection functions 18

3.1.2.1 User defined protection 19

3.1.3 Warning functions 19

3.1.4 Fault detection functions 19

3.1.5 Softstarter overview 20

3.1.6 Type designation 21

3.1.7 Environmental influence 21

3.1.8 Specifications 21

3.2 Technical data

22

3.2.1 General 22

3.2.2 Technical data for external keypad 22

3.2.3 Semi-conductor fuses 22

3.2.4 Weights 22

3.2.5 Softstarter ratings 23

3.2.6 Dimensions 25

3

1SFC132081M0201 | Installation and commissioning manual | Description 17

This chapter gives a description of the Softstarter in

general, specifications and available components and

spare parts.

3.1 Overview

3.1.1 Operation functions

Available functions are listed below:

• Voltage start ramp

• Voltage stop ramp

• Torque start ramp

The PSTX Softstarter has the latest technology for

soft start and soft stop of squirrel cage motors. The

Softstarter has multiple advanced motor protection

features as standard.

3

WARNING

If using the Rated Operational Voltage U

/N) as source for Control Supply Voltage Us make

sure to not exceed Us 250V AC,50/60Hz.

Bypass

Softstarter range PSTX30...1250 have integrated bypass

components.

User interface

The keypad on the front has Navigation keys, Selection

soft keys, Start and Stop keys, Local or Remote key,

Information key and a clear information screen. You can

select 15 user languages.

You can control the Softstarter in 3 different ways:

• Hardwire inputs control

• Keypad control (either attached to the Softstarter front

or detached and connected with the cable included)

• Fieldbus communication interface (by built in Modbus,

Anybus module or the FieldBus Plug with adapter)

You can use only one type of control at the same time.

Default selection is hardwire inputs control.

(Phase

e

• Torque stop ramp

• Full voltage start

• No ramp

• Stand-still brake

• Current limit

• Kick start

• Slow speed

• Motor heating

• Sequence start

• Automatic restart

3.1.2 Protection functions

The PSTX Softstarter has protection functions to

protect the Softstarter, motor and other equipment. All

protections can have automatic reset or manual reset.

You can enable or disable the protection.

Available protections are listed below:

• EOL protection

• Locked rotor protection

• Phase reversal protection

INFORMATION

Keypad control has the highest priority and

overrides all other control methods.

Fans

The integrated fans for cooling work during ramping

(start/stop) and when the heatsink temperature is too

high. A thermistor monitors the temperature.

• Current imbalance protection

• Overvoltage protection

• Under voltage protection

• Ground fault protection

• Voltage imbalance protection

• Voltage outputs protection

• External thermal sensor - PT100 protection

• External thermal sensor - PTC protection

• Power factor underload protection

• Current underload protection

• User defined protection

• Too long current limit protection

• Bypass open protection

• Fieldbus failure protection

• Extension IO failure protection

• HMI failure protection

• Max number of starts

18 Description | Installation and commissioning manual | 1SFC132081M0201

• Frequency range protection

• Phase reversal protection

• Too long start time protection

• Auto restart protection

3.1.2.1 User defined protection

3.1.4 Fault detection functions

The Softstarter has a number of fault detection functions

to signal malfunction at Softstarter, motor or power

network level. The Softstarter identifies external and

internal faults. The user cannot disable fault detection

functions except for Emergency mode, chapter 7.20.1.

You can use your own specified protection, with the

programmable digital input and an external device/sensor.

The protection operates when the input signal comes at

high level (fieldbus or physical I/O).

3.1.3 Warning functions

The Softstarter has warning functions for potential risks,

that operate before a protection function operates.

A warning cannot stop the Softstarter. A reset of a

warning is not necessary.

You can change the warning level and other parameters

for the warning functions. Warnings are stored in the

event list.

Available warnings are listed below:

• Current imbalance warning

• Overvoltage warning

Available faults are listed below:

• Phase loss fault

• High current fault

• Low supply voltage fault

• Bad network fault

• Thyristor overload fault

• Short circuit fault

• Shunt fault

• Unspecified fault

• Heatsink overtemperarure fault

• Open circuit thyristor fault

• Faulty usage

• Connection fault

3

• Under voltage warning

• EOL time-to-trip warning

• EOL warning

• Total Harmonic Distortion (THD) warning

• Voltage imbalance warning

• Power factor underload warning

• Current underload warning

• Fans fault warning

• Locked rotor warning

• Thyristor overload warning

• Short circuit warning

• Number of starts warning

• Modbus configuration warning

• Phase loss warning

• Motor runtime warning

1SFC132081M0201 | Installation and commissioning manual | Description 19

3.1.5 Softstarter overview

1SFC132081M0201

Change the settings through Keypad and Fieldbus

communication.

Use the keypad to change settings for each parameter

alone or as a selection of default parameters for different

applications.

Most parameters have one possible setting, but some

parameters have extra settings for sequence start. The

default parameter settings are stored in the unit for a

reset to default.

When the fieldbus communication is selected, most

parameters can also be changed from this interface.

3

Overview, See Figure 3.1.

Terminal marking of

control circuits

Supply voltage Us

L

N

100-250V

50/60 Hz K4 K5 K6

Order code

Ready (Green)

Run (Green)

Ready

Run Fault

Technical data

according to

IEC 60 947-4-2

Technical data

according to UL 508

Com1 Com2

Anybus

connection

(Com1)

Fieldbus plug adapter

connection (Com2)

Motor side connection

Figure 3.1

Softstarter overview

3L21L1 5L3

Start StopIn1 In2DGND+24VGND

4T22T1 6T3

In0

PSTX

Protection

Symbol for

Torque control

Screen

Protection (Yellow)

Fault (Red)

Keypad

Mini USB

Country of origin

Utilization code

Approvals

Terminal marking of

control circuits

Line side connection

20 Description | Installation and commissioning manual | 1SFC132081M0201

3.1.6 Type designation

1SFC132081M0201

3.1.8 Specifications

Table 1 Type designation

Designation

(i.e. PSTX370-600-70)

PSTX Softstarter type

370 Current rating

600 Main voltage

70 Supply Voltage

Description

370 = 370A

600 = 208 - 600V 50/60 Hz

690 = 400 - 690V 50/60 Hz

70 = 100 - 250V 50/60 Hz

Type designation, see Figure 3.2.

PSTX-370-600-70

Supply Voltage

70 = 100 - 250V 50/60 Hz

Main voltage

600 = 208 - 600V 50/60 Hz

690 = 400 - 690V 50/60 Hz

Current rating

370 = 370A

Softstarter range

Figure 3.2

Type designation

Table 2 Specifications

General data Description

Degree of protection:

Main circuit

Degree of protection:

Supply and control

circuit

Operating position Vertical at ± 30°

Ambient temperature Storage: -40 °C to +70 °C

Altitude 1000 m (3281 ft.) above sea level without

Pollution degree 3

Relative humidity 5 - 95% (non condensing)

Standards IEC 60529

Standards UL UL508

PTC input IEC 60947-8 Mark A detectors

EMC

Marine approvals Speak to your ABB sales office

PSTX30...105:

IP10

PSTX30...105:

IP20

(-104 °F to 140 °F)

Operation: -25 °C to +60 °C

(-77°F to 104 °F)

De-rating: Above 40 °C (104 F) up to max.

60 °C (140 F) reduce the rated current with

0,8% per °C (0,44% per F).

derating. 1000 - 4000 m (3281 - 13123 ft.)

with derating 0,7%/100 m (0,22%/100ft)

IEC 60947-1

IEC60947-4-2

DIN 44081 and DIN 44082

IEC 60947-4-2 Class A

PSTX142...1250:

IP00

PSTX142...1250:

IP20

1

3

3.1.7 Environmental influence

The product is designed to reduce the effects on the

environment during manufacturing and use of the

product.

Most of the materials used are recyclable. Obey local

laws when you handle and recycle the materials.

You can find further information about used material and

recycling of the product at:

www.abb.com/lowvoltage

The Softstarter is designed for class A equipment.

1

Use of the product in domestic environments can cause

radio interference. If so, it can be necessary to use more

mitigation procedures.

1SFC132081M0201 | Installation and commissioning manual | Description 21

3.2 Technical data

3.2.1 General

Table 3 General

General data Description

24 V output 24 V ± 5% Max 250 mA

Rated insulation voltage, Ui600 V / 690 V

3.2.3 Semi-conductor fuses

WARNING!

Semiconductor fuses must be used to keep the

warranty on the thyristors.

INFORMATION

To achieve a type 2 coordination, semiconductor

fuses must be used.

Rated operation voltage, Ue208-600 / 690 V, 50 / 60 Hz

Rated supply voltage,Us 100-250 V, 50 / 60 Hz

3

Voltage tolerance +10% to -15%

Rated frequency 50 / 60 Hz

Frequency tolerances ± 10%

Rated impulse withstand

voltage

6 kV Operation circuit

4 kV Control and supply circuit

Relay outputs 3 programmable

Number of controlled

3

phases

Inputs Start, stop, 3 programmable inputs

(Digital I/O: In0, In1, In2), temperature

sensor input.

Outputs Relay outputs: K4 K5 K6.

Output relay

250 V AC, Ith = 5A, Ie = 1.5A (AC-15)

performance

Analog output 4-20 mA, 0-20 mA, 0-10 V, 0-10 mA

PTC input 2825 ohm ± 20% switch off resistance

1200 ohm ± 20% switch on resistance

Cooling system Fan

Recommended fuse

Control supply circuit

6 A Delayed

MCB use C characteristics

Communication 3 Fieldbus ports, Extension I/O

Communication

protocols

DeviceNet / Profibus DP / Modbus /

EtherNET/IP / Modbus TCP/ Profinet

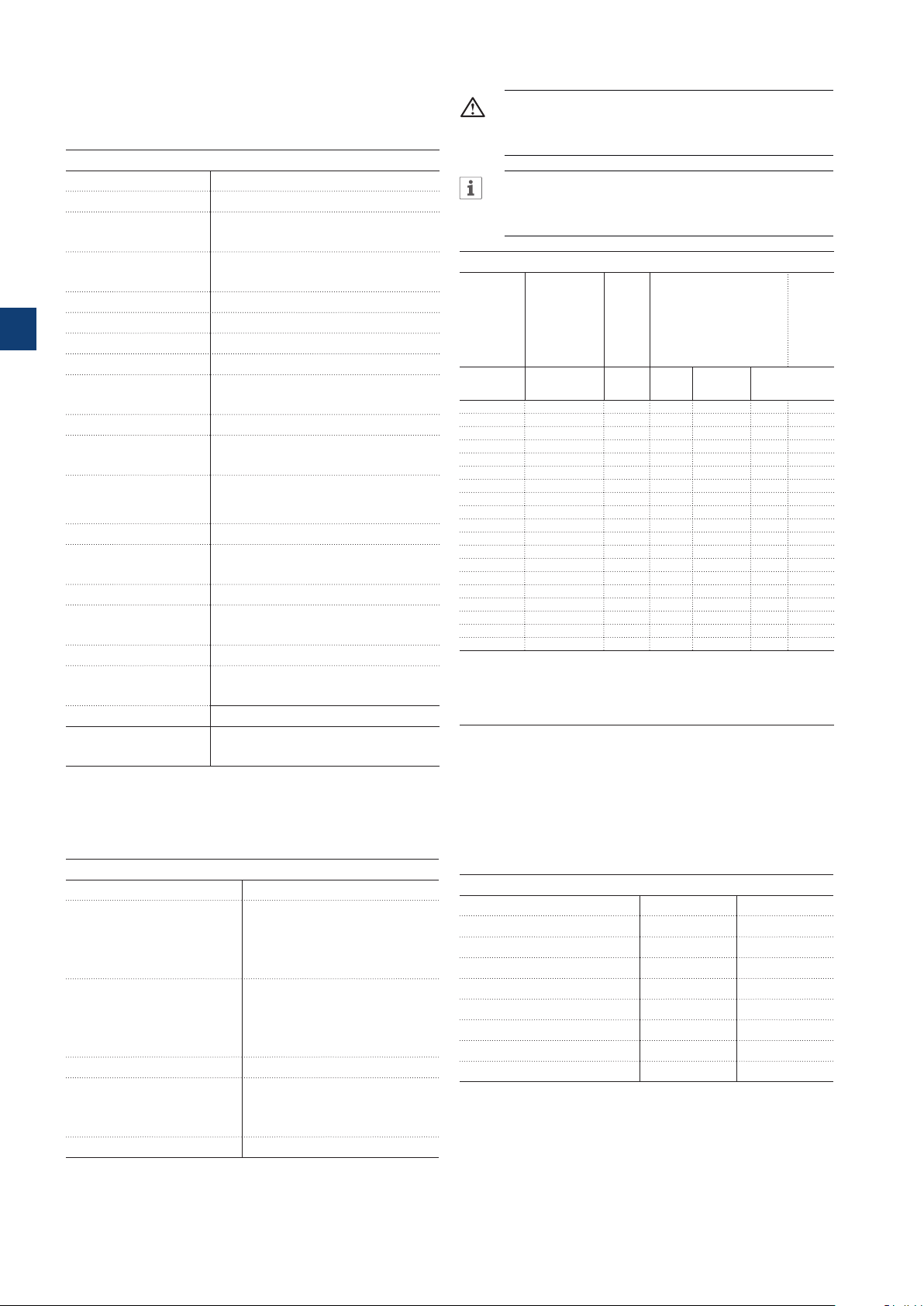

Table 5 Fuses ratings and power losses

Current

range

Max

Max fuse raiting - main

1) 2)

circuit

power

Bussmann fuses, DIN43 620

loss at

(Knife)

rated I

e

Power

require-

ments

supply

circuit

Holding

(VA) /

Type A W A Type Size

Pull-in

(VA)

PSTX30 9.0...30.0 0.8 100 170M1567 000 49/51

PSTX37 11.1...37.0 1.2 125 170M1568 000 49/51

PSTX45 13.5...45.0 1.8 160 170M1569 000 49/51

PSTX60 18.0...60.0 3.2 160 170M1569 000 49/51

PSTX72 21.6...72.0 4.7 250 170M1571 000 49/51

PSTX85 22.5...85.0 6.5 315 170M1572 000 49/51

PSTX105 31.8...106.0 10 400 170M3819 1* 49/51

PSTX142 42.9...143.0 18 500 170M5810 2 49/53

PSTX170 51.3...171.0 26 630 170M5812 2 49/53

PSTX210 63.0...210.0 48 630 170M5812 2 56/276

PSTX250 75.0...250.0 68 700 170M5813 2 56/276

PSTX300 90.0...300.0 97 800 170M6812 3 56/276

PSTX370 111.0...370.0 148 900 170M6813 3 56/276

PSTX470 141.0...470.0 99 900 170M6813 3 67/434

PSTX570 171.0...570.0 146 1000 170M6814 3 67/434

PSTX720 216.0...720.0 78 1250 170M8554 3 61/929

PSTX840 252.0...840.0 106 1500 170M6018 3 61/929

PSTX1050 3)315.0...1050.0 165 1800 170M6020 3 68/929

PSTX1250

3) 4)

1)

For the supply circuit 6 A delayed, for MCB use C characteristics.

2)

For inside delta connection the fuses shall be placed inside the delta. Contact ABB for

more information.

3)

170M6019 with fuse rating 1600 A should be used for 690 V version.

4)

For 690 V version, Bussmann fuses are only available for motors with rated current up

to 1150 A.

375.0...1250.0 234 2000 170M6021 3 68/929

You can find more detailed information at:

http://applications.it.abb.com/SOC/

3.2.2 Technical data for external keypad

3.2.4 Weights

Table 4 Technical data for external keypad

Display Display type

Status indicating LEDs Ready: Green

Run: Green

Protection: Yellow

Fault: Red

Ambient temperature Storage: -25 °C to +70 °C (-13 °F

to 158 °F)

Operation: -25 °C to +60 °C

(-13 °F to 140 °F)

Degree of protection IP66

Table 6 Weights

Type Weight in kg Weight in lbs

PSTX30...105 6,1 13,5

PSTX142...170 9,6 21,2

PSTX210...370 12,7 27,9

PSTX470 25.5 55.1

PSTX570 27.5 59.5

PSTX720 ...840 46.2 101.4

PSTX1050 64.5 141.1

PSTX1250 65 143.3

UL approval Type 1

Type 4X

Type 12

Marine approvals Speak to your ABB sales office

22 Description | Installation and commissioning manual | 1SFC132081M0201

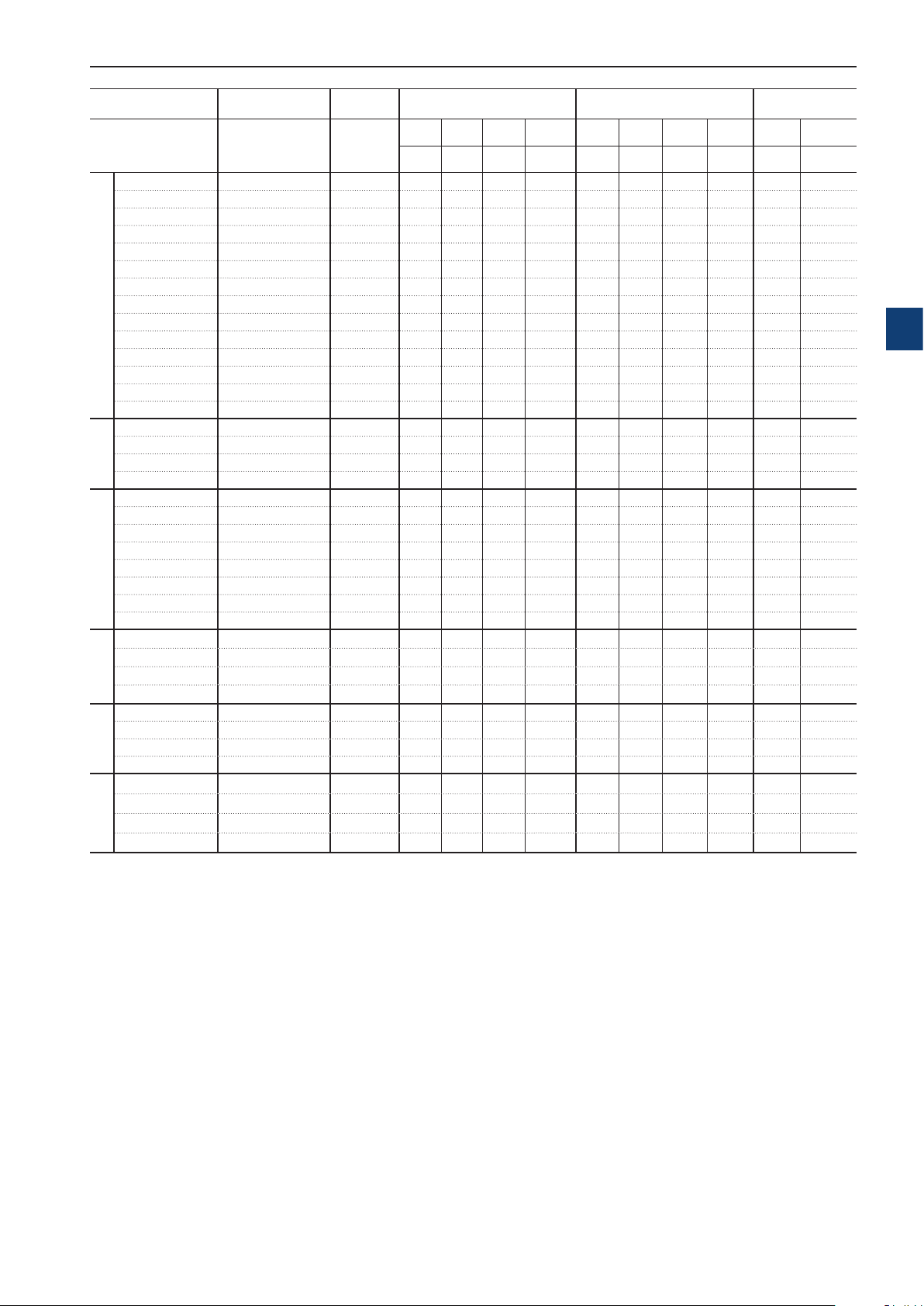

3.2.5 Softstarter ratings

PSTX30…1250 Temp ≤ + 40

IEC

Softstarter type Order number Ie range

PSTX30-600-70 1SFA898103R7000 9-30A 7,5 15 18,5 12,5 25 30 30 52

PSTX30-690-70 1SFA898203R7000 9-30A 15 18,5 25 25 30 45 30 52

PSTX37-600-70 1SFA898104R7000 11,1-37A 9 18,5 22 15 30 37 37 64

PSTX37-690-70 1SFA898204R7000 11,1-37A 18,5 22 30 30 37 55 37 64

PSTX45-600-70 1SFA898105R7000 13,5-45A 12,5 22 25 25 37 45 45 76

PSTX45-690-70 1SFA898205R7000 13,5-45A 22 25 37 37 45 59 45 76

PSTX60-600-70 1SFA898106R7000 18-60A 15 30 37 30 55 75 60 105

PSTX60-690-70 1SFA898206R7000 18-60A 30 37 55 55 75 90 60 105

PSTX30...105

PSTX72-600-70 1SFA898107R7000 21,6-72A 18,5 37 45 37 59 80 72 124

PSTX72-690-70 1SFA898207R7000 21,6-72A 37 45 59 59 80 110 72 124

PSTX85-600-70 1SFA898108R7000 25,5-85A 22 45 55 40 75 90 85 147

PSTX85-690-70 1SFA898208R7000 25,5-85A 45 55 75 75 90 132 85 147

PSTX105-600-70 1SFA898109R7000 31,8-106A 30 55 75 55 90 110 106 181

PSTX105-690-70 1SFA898209R7000 31,8-106A 55 75 90 90 110 160 106 181

PSTX142-600-70 1SFA898110R7000 42,9-143A 37 75 90 75 132 160 143 245

PSTX142-690-70 1SFA898210R7000 42,9-143A 75 90 132 132 160 220 143 245

PSTX170-600-70 1SFA898111R7000 51,3-171A 45 90 110 90 160 200 171 300

PSTX170-690-70 1SFA898211R7000 51,3-171A 90 110 160 160 200 257 171 300

PSTX142-170

PSTX210-600-70 1SFA898112R7000 63-210A 59 110 132 102 184 250 210 360

PSTX210-690-70 1SFA898212R7000 63-210A 110 132 184 184 250 315 210 360

PSTX250-600-70 1SFA898113R7000 75-250A 75 132 160 132 220 295 250 430

PSTX250-690-70 1SFA898213R7000 75-250A 132 160 220 220 295 400 250 430

PSTX300-600-70 1SFA898114R7000 90-300A 90 160 200 160 257 355 300 515

PSTX300-690-70 1SFA898214R7000 90-300A 160 200 257 257 355 500 300 515

PSTX210...370

PSTX370-600-70 1SFA898115R7000 111-370A 110 200 257 200 355 450 370 640

PSTX370-690-70 1SFA898215R7000 111-370A 200 257 355 355 450 600 370 640

PSTX470-600-70 1SFA898116R7000 141-470A 132 250 315 250 450 600 470 814

PSTX470-690-70 1SFA898216R7000 141-470A 250 315 450 450 600 800 470 814

PSTX570-600-70 1SFA898117R7000 171-570A 160 315 400 295 540 700 570 987

PSTX470...570

PSTX570-690-70 1SFA898217R7000 171-570A 315 400 560 540 700 960 570 987

PSTX720-600-70 1SFA898118R7000 216-720A 200 400 500 355 710 880 720 1247

PSTX720-690-70 1SFA898218R7000 216-720A 400 500 710 710 880 1200 720 1247

PSTX840-600-70 1SFA898119R7000 252-840A 250 450 600 450 800 1000 840 1455

PSTX720...840

PSTX840-690-70 1SFA898219R7000 252-840A 450 600 800 800 1000 1400 840 1455

PSTX1050-600-70 1SFA898120R7000 315-1050A 315 560 730 500 1000 1250 1050 1810

PSTX1050-690-70 1SFA898220R7000 315-1050A 560 730 1000 1000 1250 1700 1050 1810

PSTX1250-600-70 1SFA898121R7000 375-1250A 400 710 880 670 1200 1500 1250 2160

PSTX1050...1250

PSTX1250-690-70 1SFA898221R7000 375-1250A 710 880 1200 1200 1500 2000 1250 2160

when connected In Line

220-

380-

230V

400V 500V 690V

kW kW kW kW kW kW kW kW A A

°

Motor power

C (104 °F), 4 * Ie in 10 sec.

when connected Inside Delta

220230V

Motor power

380-

400V 500V 690V In Line

Rated current

Ie

Inside

Delta

3

1) All data for 40°C ambient. Above 40°C (104 F) up to max.

40°C (140 F) reduce the rated current with 0,8% per 40°C

(0,44% per F).

1SFC132081M0201 | Installation and commissioning manual | Description 23

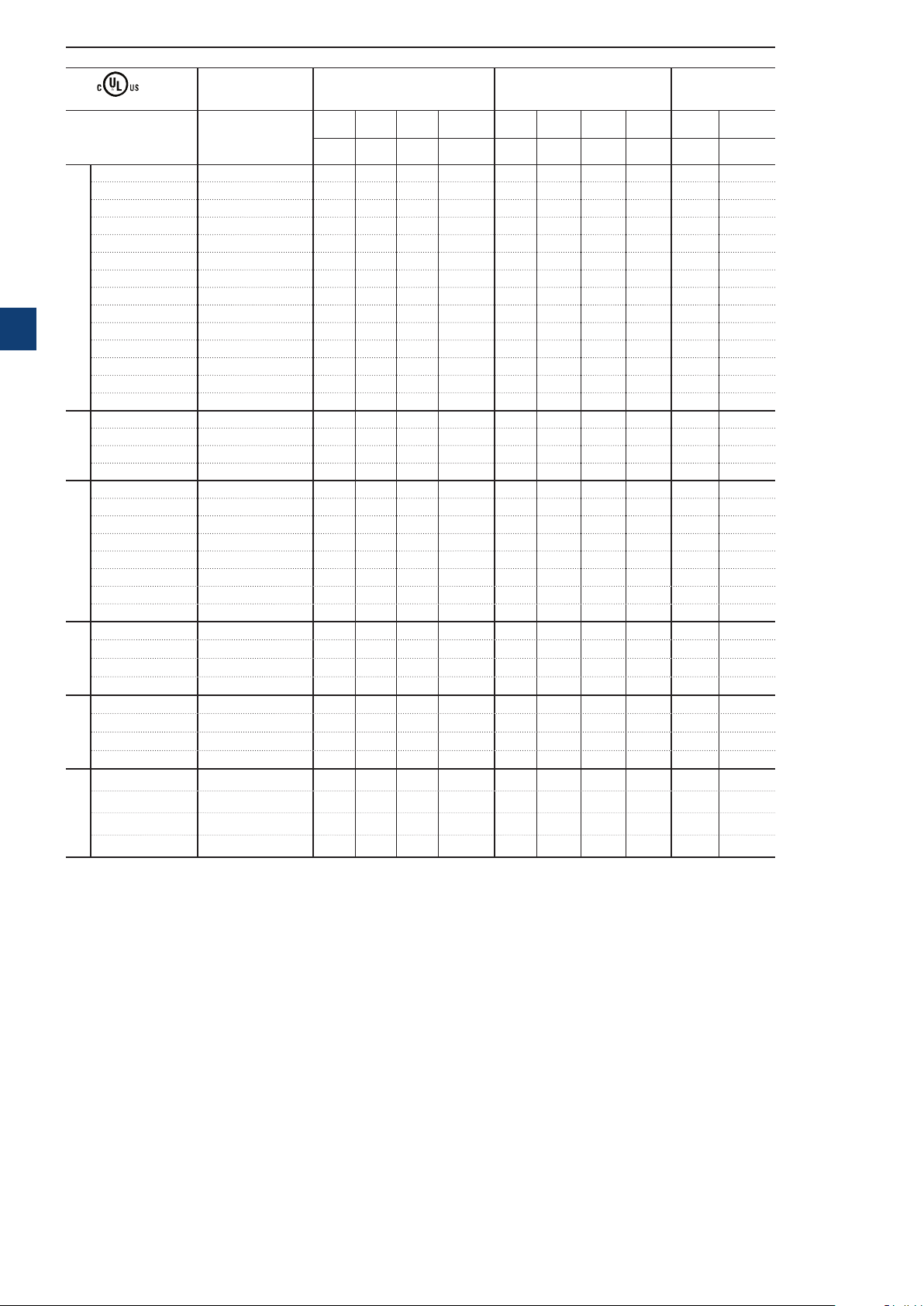

PSTX30…1250 Temp ≤ + 40

°

C (104 °F), 4 * Ie in 10 sec.

Softstarter type Order number

Motor power

when connected In Line

220240V

440480V

208V

hp hp hp hp hp hp hp hp A A

550600V 208V

Motor power

when connected Inside Delta

220-

440-

240V

480V

Rated current

550-

600V In Line

Ie

Inside

Delta

PSTX30-600-70 1SFA898103R7000 7,5 10 20 25 10 15 30 40 28 48

PSTX30-690-70 1SFA898203R7000 20 25 30 40 28 48

PSTX37-600-70 1SFA898104R7000 10 10 25 30 15 20 40 50 34 58

PSTX37-690-70 1SFA898204R7000 25 30 40 50 34 58

PSTX45-600-70 1SFA898105R7000 10 15 30 40 20 25 50 60 42 72

PSTX45-690-70 1SFA898205R7000 30 40 50 60 42 72

PSTX60-600-70 1SFA898106R7000 20 20 40 50 30 40 75 100 60 103

PSTX60-690-70 1SFA898206R7000 40 50 75 100 60 103

PSTX30...105

PSTX72-600-70 1SFA898107R7000 20 25 50 60 30 40 75 100 68 117

3

PSTX72-690-70 1SFA898207R7000 50 60 75 100 68 117

PSTX85-600-70 1SFA898108R7000 25 30 60 75 40 50 100 125 80 138

PSTX85-690-70 1SFA898208R7000 60 75 100 125 80 138

PSTX105-600-70 1SFA898109R7000 30 40 75 100 60 60 150 150 104 180

PSTX105-690-70 1SFA898209R7000 75 100 150 150 104 180

PSTX142-600-70 1SFA898110R7000 40 50 100 125 75 75 150 200 130 225

PSTX142-690-70 1SFA898210R7000 100 125 150 200 130 225

PSTX170-600-70 1SFA898111R7000 50 60 125 150 75 100 200 250 169 292

PSTX170-690-70 1SFA898211R7000 125 150 200 250 169 292

PSTX142-170

PSTX210-600-70 1SFA898112R7000 60 75 150 200 100 125 250 300 192 332

PSTX210-690-70 1SFA898212R7000 150 200 250 300 192 332

PSTX250-600-70 1SFA898113R7000 75 100 200 250 150 150 350 450 248 429

PSTX250-690-70 1SFA898213R7000 200 250 350 450 248 429

PSTX300-600-70 1SFA898114R7000 100 100 250 300 150 200 450 500 302 523

PSTX300-690-70 1SFA898214R7000 250 300 450 500 302 523

PSTX210...370

PSTX370-600-70 1SFA898115R7000 125 150 300 350 200 250 500 600 361 625

PSTX370-690-70 1SFA898215R7000 300 350 500 600 361 625

PSTX470-600-70 1SFA898116R7000 150 200 400 500 250 300 600 700 480 830

PSTX470-690-70 1SFA898216R7000 400 500 600 700 480 830

PSTX570-600-70 1SFA898117R7000 200 200 500 600 300 350 700 800 590 1020

PSTX570-690-70 1SFA898217R7000 500 600 700 800 590 1020

PSTX470...570

PSTX720-600-70 1SFA898118R7000 250 300 600 700 400 500 1000 1200 720 1240

PSTX720-690-70 1SFA898218R7000 600 700 1000 1200 720 1240

PSTX840-600-70 1SFA898119R7000 300 350 700 800 500 600 1200 1500 840 1450

PSTX840-690-70 1SFA898219R7000 700 800 1200 1500 840 1450

PSTX720...840

PSTX1050-600-70 1SFA898120R7000 400 450 900 1000 600 700 1500 1900 1062 1830

PSTX1050-690-70 1SFA898220R7000 900 1000 1500 1900 1062 1830

PSTX1250-600-70 1SFA898121R7000 400 500 1000 1200 800 900 1800 2000 1250 2160

PSTX1250-690-70 1SFA898221R7000 1000 1200 1800 2000 1250 2160

PSTX1050...1250

4 * Ie in 10 sec

Ordering data according to UL (40°C ambient)

24 Description | Installation and commissioning manual | 1SFC132081M0201

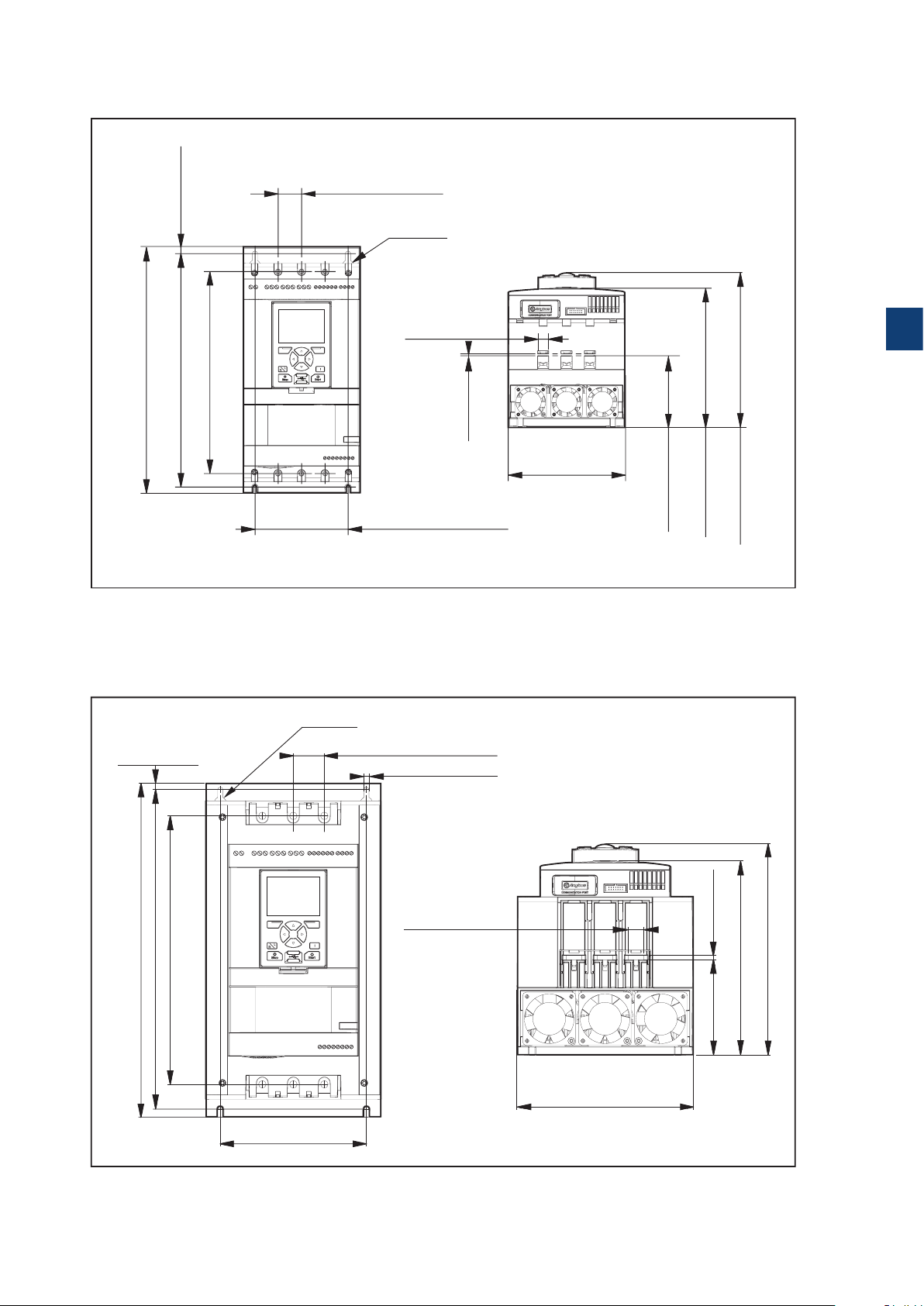

3.2.6 Dimensions

197.5 mm (7,7 in)

90,5 mm (3,6 in

178.8 mm (7 in)

1SFC132081M0201

1SFC132081M0201

PSTX30...105

30 mm (1,2 in) 4x

Ø14 (2x)

314 mm (12,4 in)

298,5 mm (11,7 in) 7,5 mm (0,3 in)

258 mm (10,2 in)

Figure 3.3

Dimensions PSTX30...105

PSTX142...170

7,5 mm (0,3 in)

Ø18 (2x)

13 mm (0,5 in) 6x

119 mm (4,7 in)

35 mm (1,3 in) 4x

6.6 mm (0,2 in) 4x

3

3 mm (0,1 in)

)

150 mm (5,9 in)

377 mm (14,8 in)

303 mm (11,9 in)

360,5 mm (14,1 in)

Figure 3.4

Dimensions PSTX142...170

165 mm (6,5 in)

17,5 mm (0,7 in) 6x

199 mm (7,8 in)

1SFC132081M0201 | Installation and commissioning manual | Description 25

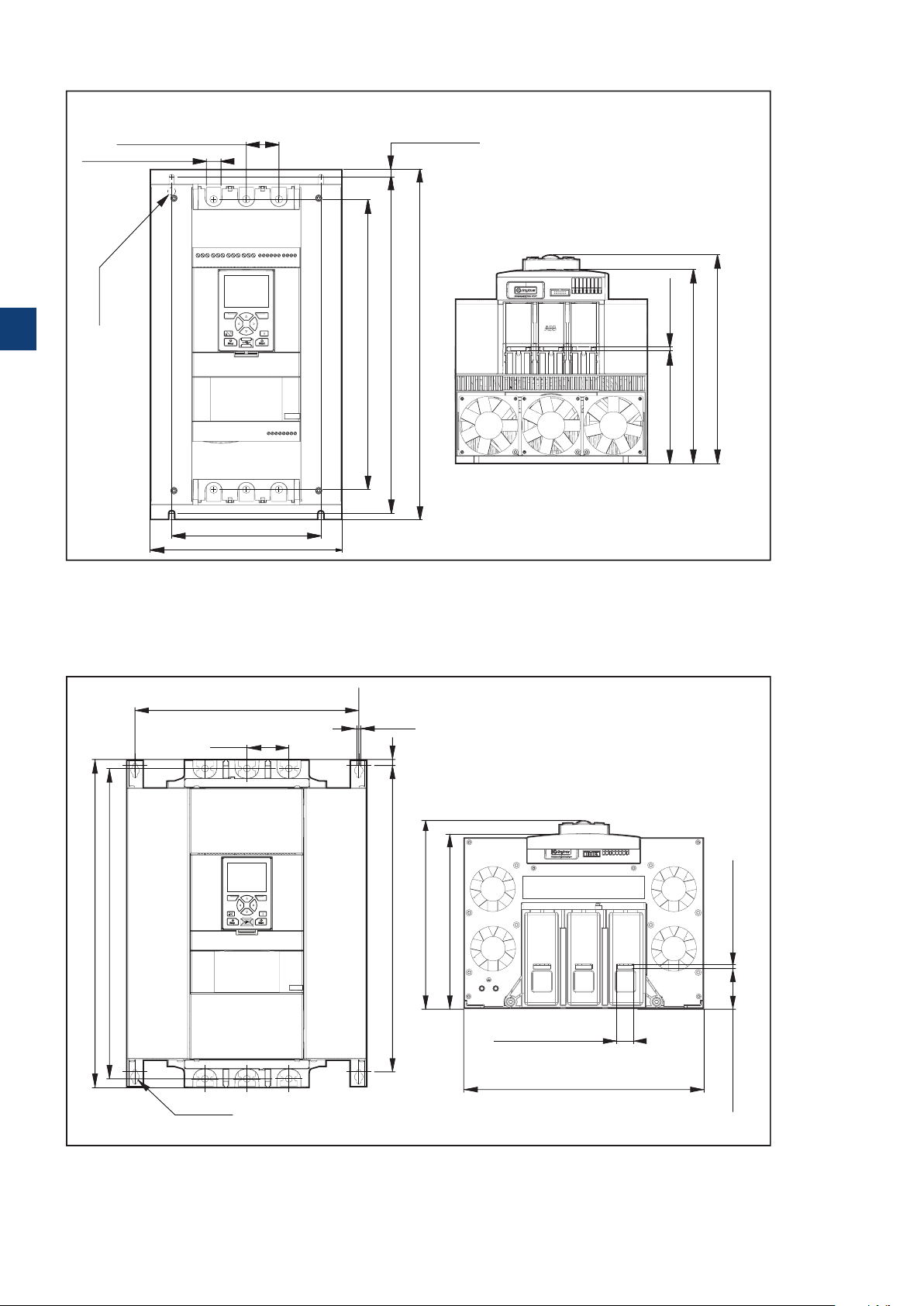

5 mm (0,2 in)

219,6 mm (8,6 in)

107,6 mm (4,2 in)

238,3 mm (9,3 in)

1SFC132081M0201

1SFC132081M0201

58.2 mm (2.3 in) 6x

PSTX210...370

43,7 mm (1,7 in) 4x

19,6 mm (0,8 in) 6x

10,5 mm (0,4 in)

Ø18 (2x)

3

389 mm (15,3 in)

470 mm (18,5 in)

451.2 mm (17,7 in)

5 mm (0,2 in)151 mm (5,9 in)

Figure 3.5

Dimensions PSTX210..370

PSTX470...570

336 mm (13.2 in) 2x

63 mm (2.5 in) 4x

493 mm (19.4 in)

466 mm (18.3 in)

Ø13 (4x)

Figure 3.6

Dimensions PSTX470..570

200 mm (7,9 in)

258 mm (10,2 in)

7 mm (0.2 in) 4x

9 mm (0.3 in)

460 mm (18.1 in)

262.82 mm (10.3 in)

282.15 mm (11.1 in)

260 mm (10,2 in)

279.1 mm (10,9 in)

6 mm (0.2 in) 6x

25 mm (0.9 in) 6x

361 mm (14.2 in)

26 Description | Installation and commissioning manual | 1SFC132081M0201

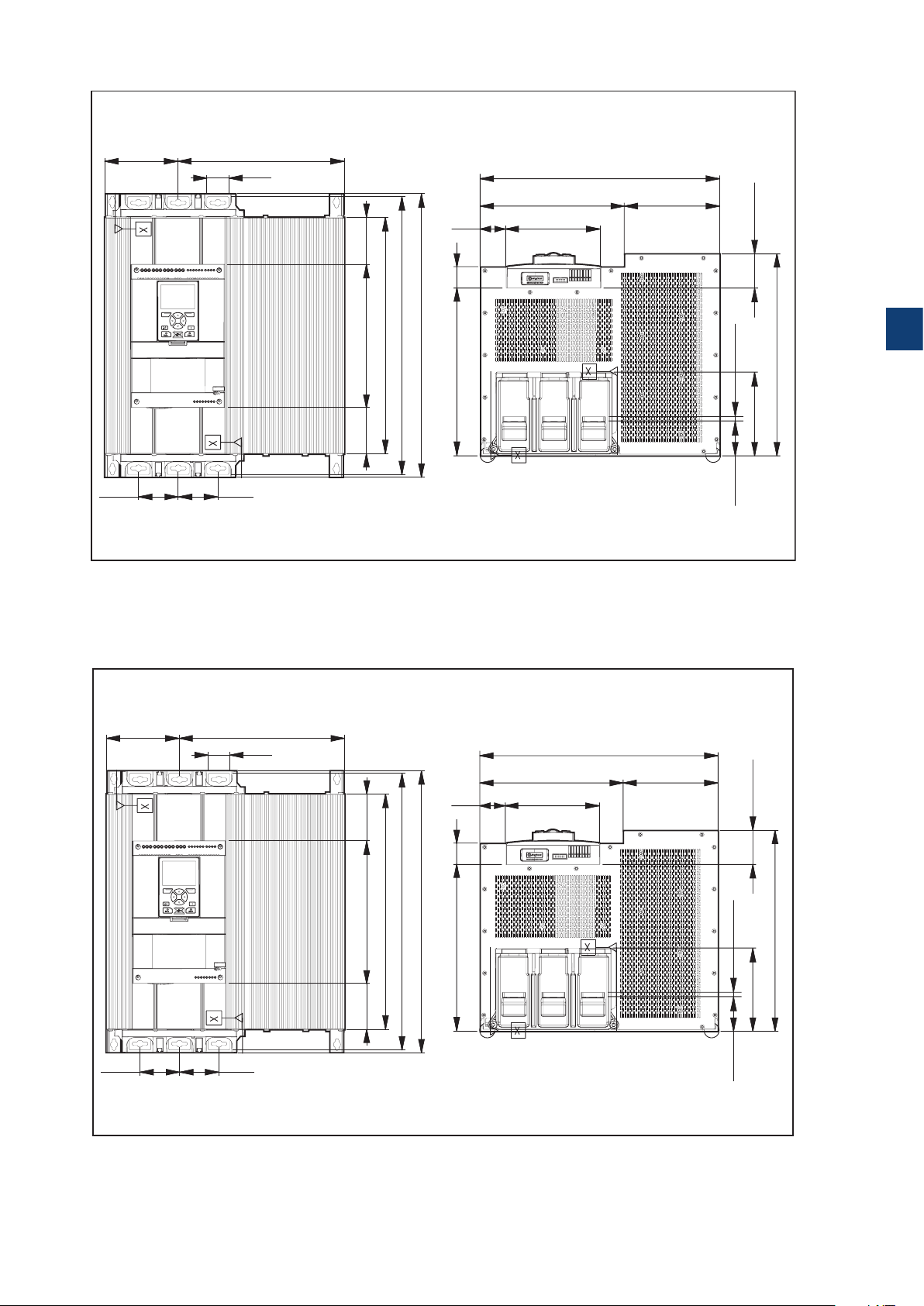

62.6 (6x) mm (in)

62.6 (6x) mm (in)

PSTX720...PSTX840

133.5(2x) mm

(5.2 in)

72(2x) mm

(2.8 in)

72(2x) mm

(2.8 in)

Figure 3.7

Dimensions PSTX720..840

PSTX1050

301.5 mm (11.8 in)

40 (6x) mm

(1.5 in)

(3.37 in)

505 mm (19.8 in)

430 mm (16.9 in)

260 mm (10.2 in) 85.6 mm

(3.3 in)

84.4 mm

46.5 mm

(1.8 in)

39 mm

(1.5 in)

515 mm (20.2 in)

304.5 mm (11.9 in)

435 mm (17.1 in)

172 mm (6.7 in)

173.4 mm (6.8 in)261.6 mm (10.2 in)

62 mm (2.4 in)

3

(0.3 in)

8 (6x) mm

366.5 mm (14.4 in)

152 (2x) mm (5.9 in)

133.5(2x) mm

(5.2 in)

72(2x) mm

(2.8 in)

Figure 3.8

Dimensions PSTX1050

72(2x) mm

(2.8 in)

301.5 mm (11.8 in)

40 (6x) mm

(1.5 in)

(3.37 in)

505 mm (19.8 in)

430 mm (16.9 in)

260 mm (10.2 in) 85.6 mm

(3.3 in)

84.4 mm

46.5 mm

(1.8 in)

39 mm

(1.5 in)

515 mm (20.2 in)

304.5 mm (11.9 in)

435 mm (17.1 in)

172 mm (6.7 in)

173.4 mm (6.8 in)261.6 mm (10.2 in)

62 mm (2.4 in)

(0.3 in)

8 (6x) mm

366.5 mm (14.4 in)

152 (2x) mm (5.9 in)

1SFC132081M0201 | Installation and commissioning manual | Description 27

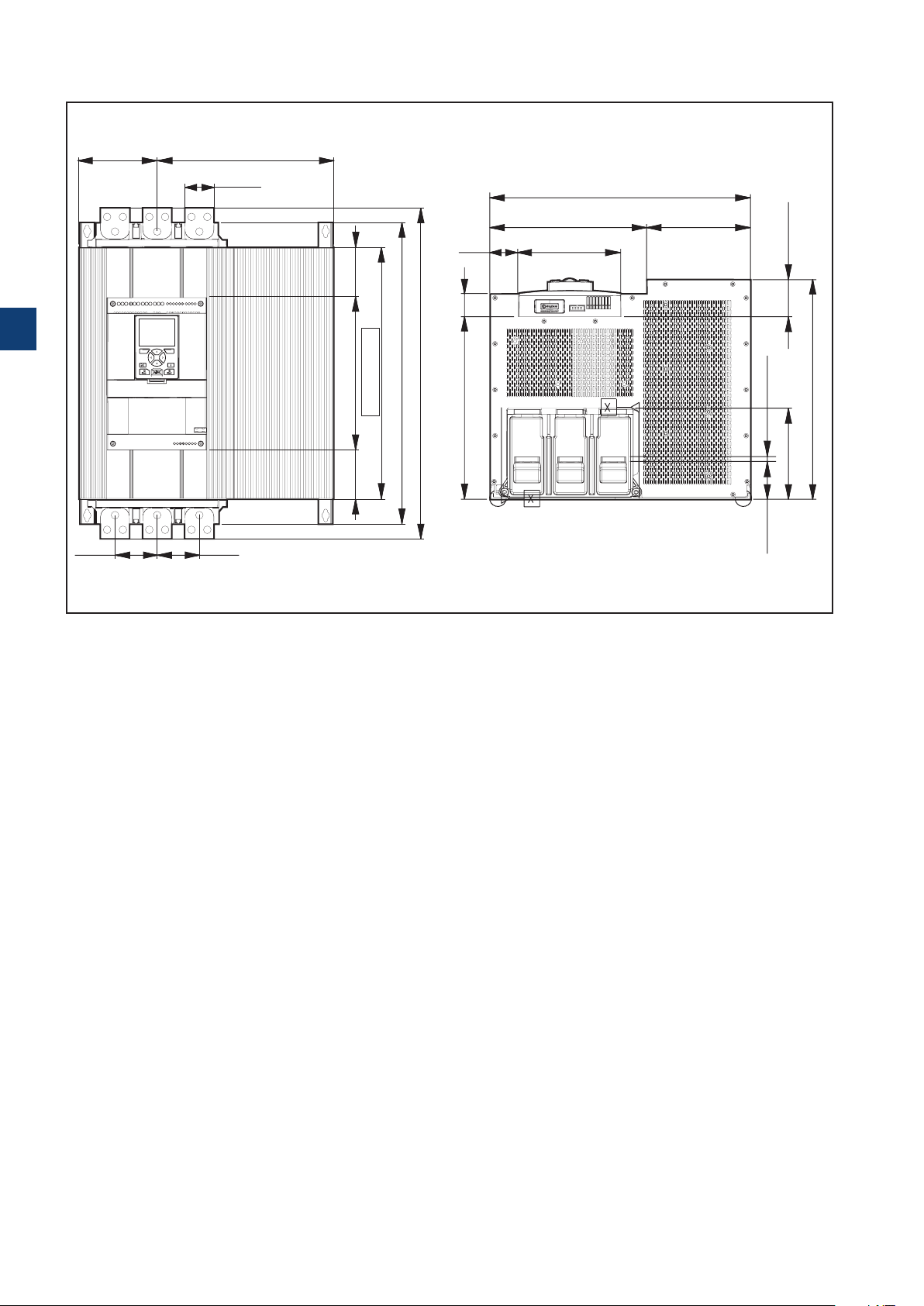

62.6 (6x) mm (in)

PSTX1250

133.5(2x) mm

(5.2 in)

3

301.5 mm (11.8 in)

50 (6x) mm

(1.9 in)

(3.32 in)

84.35 mm

46.5 mm

(1.8 in)

39 mm

(1.5 in)

435 mm (17.1 in)

173.4 mm (6.8 in)261.6 mm (10.2 in)

172 mm (6.7 in)

62 mm (2.4 in)

515 mm (20.2 in)

565 mm (22.2 in)

430 mm (16.9 in)

261.3 mm (10.2 in)

304.5 mm (11.9 in)

(3.32 in)

84.35 mm

(0.3 in)

8 (6x) mm

152 (2x) mm (5.9 in)

366.5 mm (14.4 in)

72(2x) mm

(2.8 in)

72(2x) mm

(2.8 in)

Figure 3.9

Dimensions PSTX1250

28 Description | Installation and commissioning manual | 1SFC132081M0201

3

1SFC132081M0201 | Installation and commissioning manual | Description 29

3

30 Description | Installation and commissioning manual | 1SFC132081M0201

Loading...

Loading...