ABB TRIO-20.0-TL-OUTD-S-US-480-A, TRIO-20.0-TL-OUTD-S1-US-480, TRIO-20.0-TL-OUTD-S-US-480, TRIO-20.0-TL-OUTD-S1A-US-480, TRIO-20.0-TL-OUTD-S1-US-480-A Product Manual

...

ABB Inverter

TRIO-20.0/27.6-TL-US

EEP125 R-1 Waterworks Division 40

Lancaster, CA 93535

ABB solar inverters

Product manual

TRIO-20.0/27.6-TL-US

(20.0 to 27.6 kW)

- 2 -

T001CV

List of related manuals

TRIO manuals and guides Code (English)

TRIO-20.0_27.6-TL-OUTD-US (-A) BCM.00202.1

Quick Installation Guide

- 3 -

T001CV

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important safety instructions that must be followed during installation and

maintenance of the rapid shutdown system.

SAVE THESE INSTRUCTIONS!

Keep this document in a safe place near the inverter for easy access during installation and

maintenance.

THE INSTALLER MUST READ THIS DOCUMENT IN ITS ENTIRETY BEFORE INSTALLING

THIS EQUIPMENT.

The purpose of this document is to support the qualied technician, who has received training and/

or has demonstrated skills and knowledge in construction, to install and maintain this inverter. This

manual covers only the details concerning the rapid shutdown components and how it is installed in

the allowable ABB string inverters. Information concerning the equipment connected to this product is

available from the respective manufacturers.

Warranty conditions can be found on the Rapid Shutdown product page of the website. NOTE:

Any changes or modications not approved by the manufacturer could void the warranty of this

product.

.

FCC REMARKS

The equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

- 4 -

T001CV

Product Manual

TRIO-20.0/27.6 string inverters

1 - Introduction and safety

2 - Installation location

3 - Mounting and wiring

4 - Operations

5 - Troubleshooting

6 - Maintenance

7 - Appendix

TRIO-20.0-276-TL-OUTD-US(-A) Product manual

BCG.00627.2_AB NA

© Copyright 2015 ABB. All Rights Reserved.

- 5 -

T002TC

Table of Contents

Warnings in this document ...................................................................................................................9

Equipment safety warnings ................................................................................................. 9

Introduction and safety ............................................................................................................................9

General installation warnings............................................................................................10

Assembly warnings ............................................................................................................10

Electrical connection warnings .........................................................................................10

Safety instructions ...............................................................................................................................11

General information ............................................................................................................ 11

Thermal and voltage hazard .............................................................................................. 11

Clothing and protective devices .......................................................................................12

Location of safety notices and labels ...............................................................................12

Appropriate usage ................................................................................................................................12

Conditions of Use ...............................................................................................................12

Environmental Conditions .................................................................................................13

Improper or Prohibited Use ...............................................................................................13

Arc fault detection (AFD) .....................................................................................................................13

Available versions ................................................................................................................................14

Regulatory label ..................................................................................................................15

Transportation and handling ...............................................................................................................17

Lifting ...................................................................................................................................17

Incoming inspection ...........................................................................................................17

Installation location ................................................................................................................................17

Handling the TRIO ...............................................................................................................19

Select the installation location ............................................................................................................20

Environmental check ..........................................................................................................20

Installation position ............................................................................................................21

Mounting and wiring .............................................................................................................................23

Labeled illustration of TRIO ................................................................................................................23

Wall mounting .......................................................................................................................................25

Installation method with flexible conduit .........................................................................26

Installation method with rigid conduit ..............................................................................29

Wiring details ........................................................................................................................................30

AC overcurrent protection .................................................................................................30

Wiring box components .....................................................................................................31

TRIO-XX.X-TL-OUTD-S-US-480 ..........................................................................................32

TRIO-XX.X-TL-OUTD-S-US-480-A ......................................................................................32

TRIO-XX.X-TL-OUTD-S1-US-480........................................................................................33

TRIO-XX.X-TL-OUTD-S1-US-480-A ....................................................................................33

TRIO-XX.X-TL-OUTD-S1A-US-480 .....................................................................................34

TRIO-XX.X-TL-OUTD-S1A-US-480-A .................................................................................34

TRIO-XX.X-TL-OUTD-S1B-US-480 .....................................................................................35

TRIO-XX.X-TL-OUTD-S1B-US-480-A .................................................................................35

- 6 -

T002TC

Independent or parallel configuration of inputs ...............................................................................36

Dual MPPT configuration – independent mode ..............................................................36

Single MPPT configuration – parallel mode (non-AFD models) ....................................37

Setting the input mode switch a01 ...................................................................................37

Connection to the PV field (DC side) ..................................................................................................40

Connection of DC inputs -S model ...................................................................................40

Connection of DC inputs -S1, –S1A, and -S1B models .................................................41

String protection -S1, -S1A, and –S1B models ..............................................................41

Grid output connection (AC side) .......................................................................................................42

Characteristics and sizing of the AC output conductors ...............................................42

Wire installation ..................................................................................................................42

Connection to the AC terminal block ...............................................................................43

Auxiliary grounding electrode conductor (GEC) ............................................................44

Labeled illustration of communication card 09 ................................................................................45

Connections to the communication card .........................................................................46

Serial communication a07 (RS-485)..................................................................................46

Daisy Chain units for connection to a monitoring system ............................................47

Remote on/off a07 ...............................................................................................................48

Auxiliary +5 V output a07 ...................................................................................................49

Configurable relay a05 .......................................................................................................49

Environmental sensors a06 ...............................................................................................50

Auxiliary +24 V service output a06 ...................................................................................51

Setting the country standard and language ......................................................................................51

Saving the country standard and language ....................................................................52

Operations .............................................................................................................................................. 53

Monitoring and data transmission .....................................................................................................53

Types of data available ...................................................................................................... 53

User interface ........................................................................................................................................53

Display and keypad ............................................................................................................54

LED indicators .....................................................................................................................55

Descriptions of symbols and display fields ....................................................................56

Cyclical display of general information............................................................................56

Statistics menu ...................................................................................................................57

Settings menu .....................................................................................................................58

Information menu ................................................................................................................66

Commissioning .....................................................................................................................................67

Configure inverter settings ................................................................................................67

Power ON the inverter ........................................................................................................67

Dynamic behavior of the display during operation ........................................................69

Troubleshooting ..................................................................................................................................... 71

Arc fault detection self-test errors ......................................................................................................71

Obtaining the service level password ................................................................................................72

Resetting the inverter/switchbox association ...................................................................................72

Display messages and error codes ...................................................................................................73

Making a service call ............................................................................................................................86

- 7 -

T002TC

Maintenance ........................................................................................................................................... 87

Routine maintenance ...........................................................................................................................87

Recommended system maintenance .................................................................................................88

Preventative maintenance ...................................................................................................................88

Storage and dismantling .....................................................................................................................89

Appendix .................................................................................................................................................91

System description .............................................................................................................................91

Protective devices within the inverter ................................................................................................92

Ground fault detection and interruption scheme ............................................................................93

Topographic diagram of the equipment ............................................................................................94

Efficiency curves ..................................................................................................................................96

Voltage and temperature derating due to altitude ............................................................................97

Automatic power reduction .................................................................................................................98

MPPT configuration examples ..........................................................................................................102

Environmental sensors ......................................................................................................................103

Connection diagrams for environmental sensors ........................................................104

Technical data and types ...................................................................................................................105

Technical data and types (continued) ..............................................................................................106

- 8 -

T002TC

This page is intentionally blank.

- 9 -

T003CH1

Warnings in this document

This is a list of special safety symbols used in this manual that highlight potential safety risks and/or useful

information. The symbol usage is described below:

CAUTION

The reader should stop, use caution and fully understand the operations

explained before proceeding.

DANGEROUS VOLTAGE

The product works with high voltages. All work on the TRIO must follow

the described documentation and must comply with all prevailing codes and

regulations associated with high voltages.

HOT TEMPERATURE

Some surfaces may become hot; wear appropriate personal protective

equipment (PPE) when working with this product.

UL1741 Standard for Safety for Inverters, Converters, Controllers and

Interconnection System Equipment for use with Distributed Energy

Resources. CSA-C22.2 No. 107.1-01 - General Use Power Supplies.

Equipment safety warnings

In addition to the safety and hazard symbols, the following symbols are also used in this

installation guide

Equipment Ground, protective earth

Alternating current (AC)

ø

Phase

Direct current (DC) Grounding (earth)

1

Introduction and safety

T004CC1

- 10 -

1- Introduction and safety

General installation warnings

The TRIO transformerless inverter is designed and tested according to international safety

requirements (UL1741/IEEE1547); however, certain safety precautions must be observed when

installing and operating this inverter. Read and follow all instructions, cautions and warnings in

this installation manual.

All operations regarding transport, installation start-up, and maintenance must be carried out by

qualied, trained personnel and in compliance with all prevailing local codes and regulations.

Assembly warnings

Prior to installation, inspect the unit to ensure absence of any transport or handling damage,

which could affect insulation integrity or safety clearances. The failure to do so could result in

safety hazards.

Assemble the inverter per the instructions in this manual. Use care when choosing the installation

location and adhere to specied cooling requirements.

Unauthorized removal of necessary protection features, improper use, incorrect installation or

operation may lead to serious safety and shock hazards and/or equipment damage.

Electrical connection warnings

This grid-tied inverter system operates only when properly connected to the AC utility grid. Before

connecting the TRIO grid-tied inverter to the AC utility grid, contact the local power distribution

company to receive the appropriate approvals. The inverter-to-AC utility grid connection must be

made only by qualied technical personnel.

Wiring methods used should be in accordance with the National Electric Code,

ANSI/NFPA 70 and/or any prevailing local codes and regulations.

Output circuits must be isolated from the enclosure. System grounding, required

by Sections 690.41 - 690.43 of the National Electric Code, ANSI/NFPA 70, is the

responsibility of the installer.

The inverter should be connected only to a dedicated branch circuit. Models

that include AC output overcurrent protection (-S1B) are intended for equipment

disconnection and protection, not system disconnection. It is the responsibility of

the end user to provide PV system disconnection and protection for the AC output

circuit.

Connect only to a circuit provided with the maximum branch OCPD in accordance

with the CSA document available at www.abb.com/solarinverters and listed in the

technical data sheet of the appendix, section 7.

- 11 -

T004CC1

1- Introduction and safety

Safety instructions

These servicing instructions are for use by qualied personnel only. To reduce the risk of electric shock, do not

perform any servicing other than that specied in the operating instructions. Be sure all ammable materials

including construction items are away from the unit. Do not install the inverter in or near potentially explosive areas.

The TRIO is not provided with an isolation transformer and is intended to be installed per NFPA 70, 690.35 with an

ungrounded PV array. These models have no grounded input conductors. Install the TRIO inverter in accordance

with the electrical standards prescribed by the applicable National Electric Code (NEC), and/or by other local codes

and regulations.

General information

The equipment has been manufactured in accordance with the strictest accident-prevention

regulations and supplied with safety devices suitable for the protection of components and

operators. Inform ABB about non-standard installation conditions.

It is essential to provide operators with correct information. They must read and comply with the

technical information given in the manual and any other attached documentation. The instructions

given in the manual do not replace the information and warnings on the safety labels mounted

on the product. They do not replace the safety regulations enforced in the country of installation.

Maintenance operations must be carried out according to the maintenance section 6 of this

manual. Do not use the equipment if any operating anomalies are found. Liabilities arising from

commercial components are delegated to their respective manufacturers.

Thermal and voltage hazard

Depending upon ambient temperatures during operation and immediately following

shutdown, surface temperatures on the cooling ns (heat sink) and some areas of

the chassis may be extremely hot to the touch.

Prior to touching any part of the inverter, use care to ensure surfaces and equipment are at touchsafe temperatures and voltages before proceeding.

The customer and/or installer must appropriately instruct all personnel who may come near

the equipment, and highlight, if necessary with notices or other means, the hazardous areas or

operations (magnetic elds, hazardous voltages, high temperatures, possibility of discharges,

generic hazard, etc.).

T004CC1

- 12 -

1- Introduction and safety

Anytime the inverter has been disconnected from the AC utility grid, use extreme caution, as

some components can retain charge sufcient to create a shock hazard and may need time to

dissipate the charge. To minimize occurrence of such conditions, comply with all corresponding

safety symbols and markings present on the unit and in this manual.

Clothing and protective devices

Appropriate Personal Protective Equipment (PPE) must be worn at all times when servicing

this equipment under any conditions which may subject personnel to hazardous voltages or

temperatures that are not touch-safe.

All operations on the equipment should be performed with properly electrically-insulated

instruments.

Location of safety notices and labels

Note the location of safety notices on the inverter for notication and protection. Labels must

not be hidden with external objects or parts such as rags, boxes, or other such equipment. They

should be cleaned periodically and always maintained in view.

Appropriate usage

The TRIO inverter is a photovoltaic inverter that converts direct current of a connected PV array into alternating

current and feeds that power into the AC utility grid. This inverter is designed for outdoor use, but can be used

indoors if installed to specied environmental and mounting parameters stated in this manual, and adherence to

codes enforced by the jurisdiction, such as the National Electric Code. (See environmental conditions below and

environmental checks in Installation location, section 2.)

If installed indoors, the inverter must be inaccessible to unqualied persons.

Conditions of Use

WARNING!

This inverter utilizes a transformerless design and requires connected

array(s) to be oating with respect to ground; it can be used only with photovoltaic

modules that do not require one of the terminals to be grounded.

• The DC and AC operating currents MUST NOT exceed the limits documented in the technical

specications in the Appendix, section 7.

• The inverter is certied for use only with photovoltaic arrays connected to its input channel(s).

Do not connect batteries or other types of power sources.

• The inverter can only be used if all the technical requirements in this manual are observed

and applied.

- 13 -

T004CC1

1- Introduction and safety

Environmental Conditions

Adverse environmental conditions can lead to a reduction in performance. The equipment should

be installed outdoors, but only in environmental conditions indicated in this manual. Care must

be taken to provide adequate ventilation if installed indoors.

Improper or Prohibited Use

The following actions are dangerous and not consistent with acceptable practice under the terms

of the warranty:

• Installing the equipment in environments with ammable conditions.

• Using the equipment with safety devices not working or disabled.

• Using the equipment or parts of the equipment by connecting it to other machines or

equipment, unless otherwise expressed.

• Modifying areas that are operator-restricted and/or altering parts of the equipment in order to

vary the performance or change its protection.

• Cleaning with corrosive products that may corrode parts of the equipment or with products

that might generate electrostatic charges.

• Using or installing the equipment or parts of it without having read and correctly interpreted

the contents of this manual.

• Blocking airow to the cooling ns (e.g., warming or drying rags) on the unit or accessory

parts is dangerous and could compromise the inverter operation.

Arc fault detection (AFD)

The 2011 National Electric Code (NEC) and 2013 Canadian Electric Code (CEC) includes the requirement that a

photovoltaic system with a DC voltage greater than 80V, and which is on a building or whose DC conductors enter

a building, be equipped with a listed device which can detect a series DC arc fault and interrupt the circuit. This

functionality is commonly referred to as a DC Arc Fault Circuit Interruption. The 2014 NEC Arc Fault requirements

are not limited to systems on or in buildings and apply to all PV systems with a DC voltage greater than 80V. See

690.11 of the National Electric Code for more information.

The DC arc fault detection (AFD) solution is based on Digital Signal Processor (DSP) technology. The AFD module

has two independent channels, designed to accommodate the two independent MPPT channels associated with

all ABB string inverters, and has two current sensors and associated circuitry to identify the presence of a series

DC arc fault at the input of either inverter MPPT channel.

The DC AFD module performs a self-test every time the system is started and the inverter display shows the result,

which can only be pass or fail. If the inverter fails, an error code will be displayed and the inverter will not connect

to the grid. If it passes, the inverter connects and works normally.

If a DC arc fault is detected during normal operations, the inverter disconnects from the AC grid. The DC arc

fault error is indicated on the inverter display screen, and lock out of inverter operation is initiated until the fault is

manually reset.

T004CC1

- 14 -

1- Introduction and safety

NOTE: Refer to Arc Fault Detection Self-Test Errors (-A Models Only) in the Troubleshooting,

section 5, for display error messages and instructions to reset fault conditions or manually

start the self-test procedure.

Available versions

The inverters can be divided into two groups according to their rated output power of 20.0 kW or 27.6 kW. For

inverters of equal output power, the differences between models are the congurations of the wiring box. A

description of the wiring box congurations available can be found below.

20.0 kW MODELS

TRIO-20.0-TL-OUTD-S-US-480

TRIO-20.0-TL-OUTD-S-US-480-A

TRIO-20.0-TL-OUTD-S1-US-480

TRIO-20.0-TL-OUTD-S1-US-480-A

TRIO-20.0-TL-OUTD-S1A-US-480

TRIO-20.0-TL-OUTD-S1A-US-480-A

TRIO-20.0-TL-OUTD-S1B-US-480

TRIO-20.0-TL-OUTD-S1B-US-480-A

Dimensions (HxWxD):

41.7 x 27.6 x 11.5 in

1061 x 702 x 292 mm

Weight:

157 lbs./71kg

27.6 kW MODELS

TRIO-27.6-TL-OUTD-S-US-480

TRIO-27.6-TL-OUTD-S-US-480-A

TRIO-27.6-TL-OUTD-S1-US-480

TRIO-27.6-TL-OUTD-S1-US-480-A

TRIO-27.6-TL-OUTD-S1A-US-480

TRIO-27.6-TL-OUTD-S1A-US-480-A

TRIO-27.6-TL-OUTD-S1B-US-480

TRIO-27.6-TL-OUTD-S1B-US-480-A

Dimensions (HxWxD):

41.7 x 27.6 x 11.5 in

1061 x 702 x 292 mm

Weight:

168 lbs/76kg

Wiring box congurations available

TRIO-20/27.6-TL-OUTD-S-US-480 DC Disconnect Switch

TRIO-20/27.6-TL-OUTD-S-US-480-A

DC Disconnect Switch

Integrated PV AFCI Type 1 device for arc fault detection (AFD)

TRIO-20/27.6-TL-OUTD-S1-US-480

DC Disconnect Switch

8 string DC Input Fuses

Class II DC Surge Protection

TRIO-20/27.6-TL-OUTD-S1-US-480-A

DC Disconnect Switch

8 string DC Input Fuses

Class II DC Surge Protection

Integrated PV AFCI Type 1 device for arc fault detection (AFD)

- 15 -

T004CC1

1- Introduction and safety

POWER ALARM GFI ESC UP DOWN ENTER

TRIO

Wiring box congurations available

TRIO-20/27.6-TL-OUTD-S1A-US-480

DC Disconnect Switch

8 string DC Input Fuses

Class II DC Surge Protection

Class II AC Surge Protection

TRIO-20/27.6-TL-OUTD-S1A-US-480-A

DC Disconnect Switch

8 string DC Input Fuses

Class II DC Surge Protection

Class II AC Surge Protection

Integrated PV AFCI Type 1 device for arc fault detection (AFD)

TRIO-20/27.6-TL-OUTD-S1B-US-480

DC Disconnect Switch

8 string DC Input Fuses

Class II DC Surge Protection

AC Fused Disconnect Switch

TRIO-20/27.6-TL-OUTD-S1B-US-480-A

DC Disconnect Switch

8 string DC Input Fuses

Class II DC Surge Protection

AC Fused Disconnect Switch

Integrated PV AFCI Type 1 device for arc fault detection (AFD)

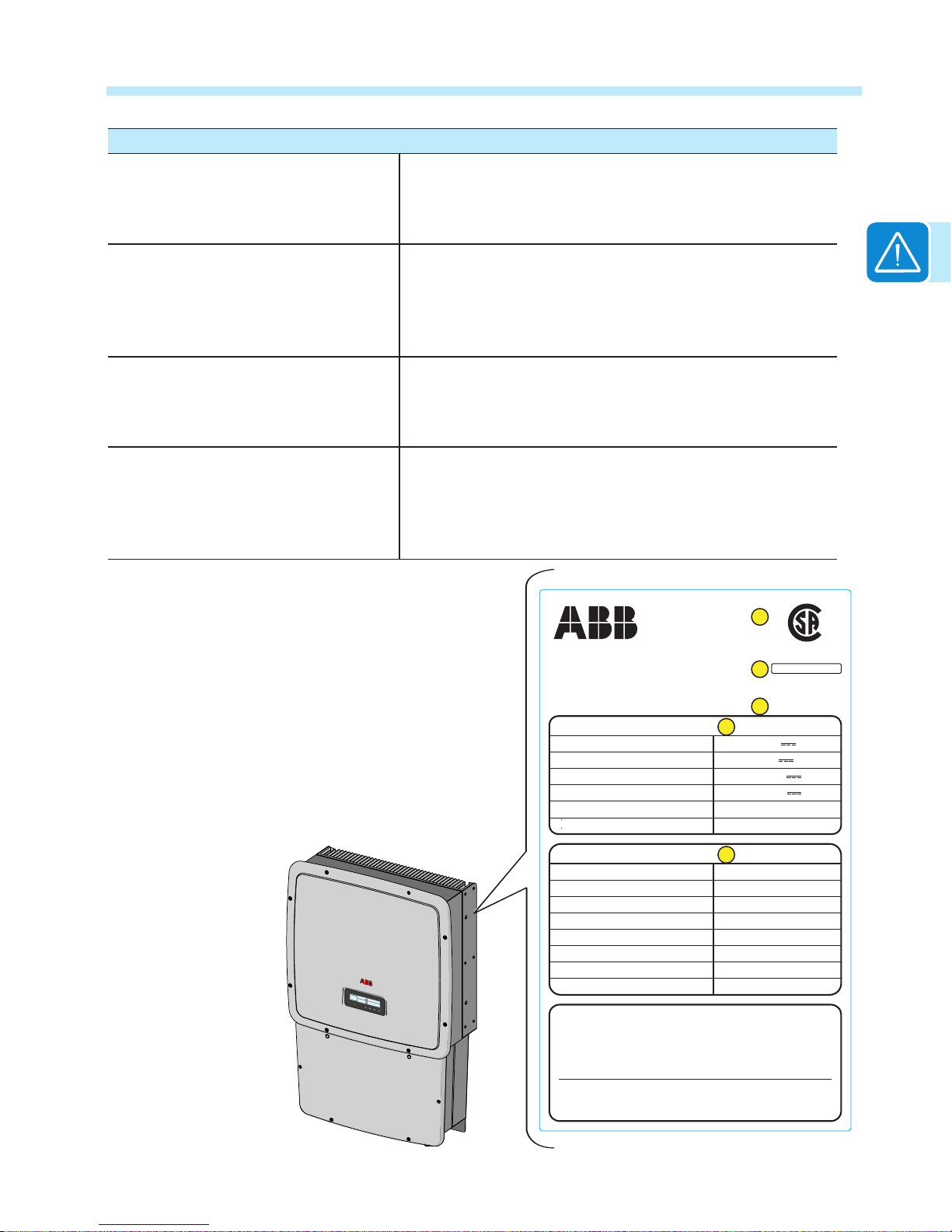

Regulatory label

Technical data in this manual does not

supersede the data on the labels afxed

to the equipment. The nameplate

shown is afxed to the inverter and

provides the following information:

1. Certication

2. Product origin

3. Model name

4. DC input data

5. AC output data

UL 1741

CSA-C22.2 No. 107.1-01

C US

®

Made in Italy

www.abb.com/solar

SOLAR GRID TIED INVERTER

UTILITY INTERACTIVE - TRANSFORMERLESS INVERTER

MODEL: TRIO-20.0-TL-OUTD-S-US-480-A

OperatingAmbient Temperature:-25 to +60°C (-13 to +140 °F),with OutputPower Derating

Type of Enclosure:NEMA 4X

Photovoltaic Arc-Fault Circuit Protection - Type 1

( ):

1

For More Details Refer to the Instructions Manual

( ):

2

For each of the two input channels

( ):

3

Adjustable from 57.0 Hz to 59.8 Hz

( ):

4

Adjustable from 60.2 Hz to 63.0 Hz

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesidered operation.

Nominal Input Operating Voltage

Max. Input Voltage

Range of Input Operating Voltage

Range of Input Voltage @Full Power

Max. Input Current

Max. Input Short Circuit Current (P.V. Panels

DC RATING

Nominal Output Voltage

Operating Voltage Range

Nominal Output Frequency

Operating Frequency Range

Output Power Factor

Max. Output Current

AC RATING

Max. Continuous Output Power

Max. Output Overcurrent Protection

25 A ( )( )

1 2

30 A ( )( )

1 2

700 V

1000 V ( )

1

200 - 950 V ( )

1

450 - 800 V ( )

1

60 Hz (factory preset)

59.3 ( ) - 60.5 Hz ( )

3 4

>0.995

27 A (rms)

480 V~ 3Ø

40 A (rms)

20000 W @ 45°C amb.

422-528 V~

1

2

3

4

5

T004CC1

- 16 -

1- Introduction and safety

This page is intentionally blank.

- 17 -

T005CH2

Transportation and handling

Transportation of the equipment, especially by road, must be carried out by suitable ways and means for protecting

the components (in particular, the electronic components) from violent shocks, humidity, vibration, etc. During

handling, do not make any sudden or fast movements that can create dangerous swinging.

NOTE: During transportation the crated TRIO inverters should only be stacked three high.

For storage purposes, units in their original unopened packaging can be stacked ve high on a at

dry surface capable of withstanding the weight.

DO NOT stack with equipment or products other than those indicated or store in damaging, corrosive

environments.

Lifting

ABB packages and protects individual components using suitable means to make their transport

and subsequent handling easier. Due to the weight and complexity of this equipment, ABB

recommends the process of loading and unloading of this equipment be done by an experienced

or specialized staff knowledgeable in material handling.

Where indicated or where there is a provision, eyebolts or handles can be inserted and used as

lifting points. Do not lift several units or parts of the equipment at the same time, unless otherwise

indicated.

Incoming inspection

It is the customer’s responsibility to examine the condition of the unit. Upon receipt of the inverter,

please check the following:

• Inspect the shipping container for any external damage.

• Inventory the contents against the table below and verify receipt of all items.

• Use care not to discard any equipment, parts, or manuals.

• Call the delivering carrier if damage or shortage is detected.

2

Installation location

T006CC2

- 18 -

2 - Installation

If inspection reveals damage to the inverter, contact the supplier or authorized distributor for a

repair/return determination and instructions regarding the process.

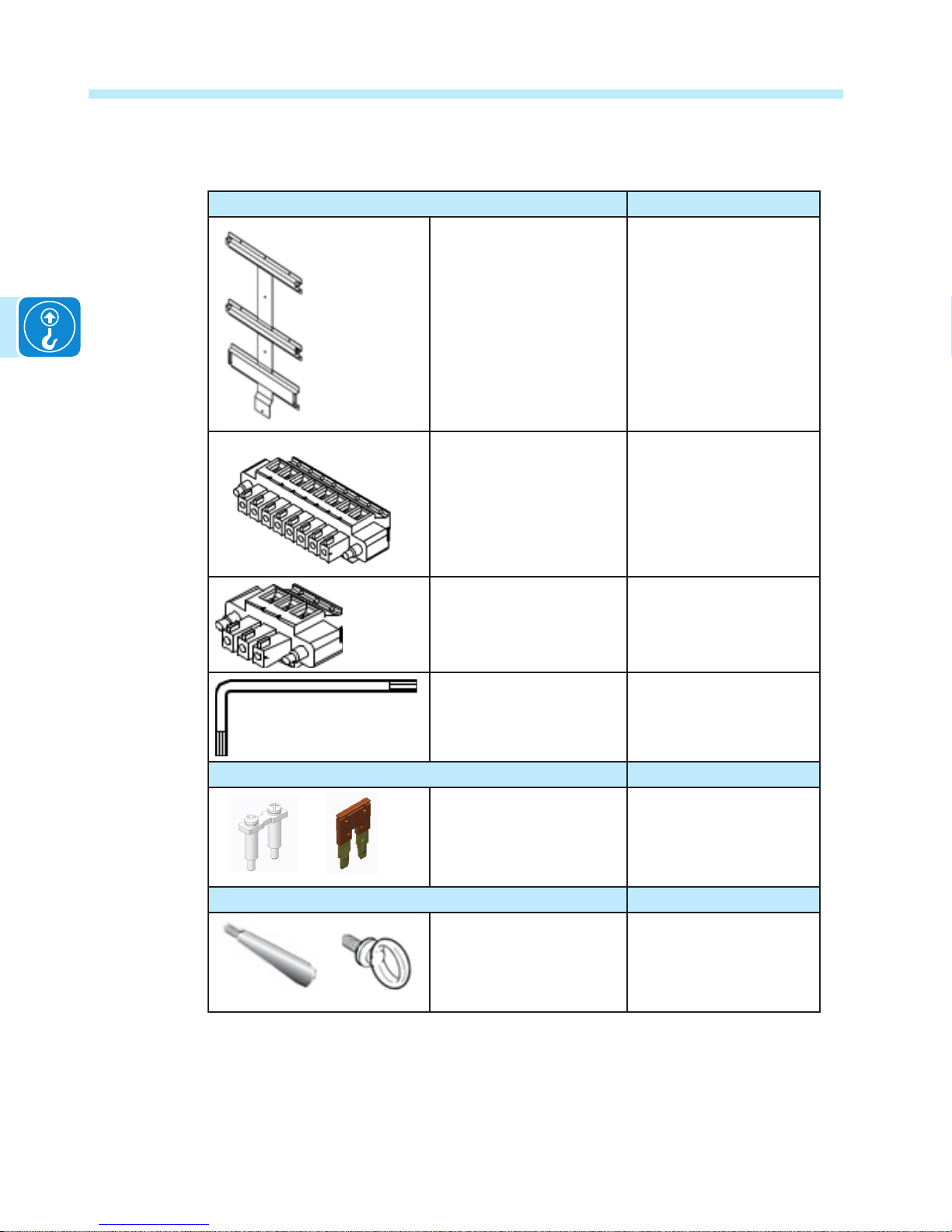

COMPONENTS FOR ALL MODELS QTY/PART NO.

(1) Mounting bracket,

(10 each) wall anchor,

screw, washer,

(1) locking screw for securing wiring box to mounting

bracket

Bracket

XAK.V0L03.0

OR

Mounting kit

XAK.V0L01.0

8 pin connector 4

82000005908-G

3 pin connector 2

82000005907-G

Torx wrench;

90°; T20; 64x23mm,

1

81510000077

COMPONENTS FOR NON-AFD MODELS ONLY QTY/PART NO

Jumpers for conguration

of parallel input channels

2 each

Reliance RAQ2-16,

ABB JB12-2

OPTIONAL COMPONENT QTY/PART NO

Optional lifting kit includes

handles and eyebolts for

lifting the inverter

1 kit M12

3M2200HNDK0

- 19 -

T006CC2

2 - Installation

Handling the TRIO

The TRIO inverter and wiring box are shipped as separate components within a common

container. They are designed to be installed individually allowing an easier installation process.

The inverter unit weighs 143 pounds or less, depending on the version, and should always be

lifted by two persons.

An optional lifting kit, with handles and eyebolts for lifting the inverter, is available and can be

used to assist in hanging the inverter on the mounting bracket.

T006CC2

- 20 -

2 - Installation

Select the installation location

WARNING!

The TRIO inverter must be installed by qualied installers and/or licensed electricians

according to the applicable local code regulations (NEC, CEC, and other).

Once physically mounted, the wiring must be carried out with the equipment disconnected from the

grid (power disconnect switch open) and the photovoltaic modules shaded or isolated.

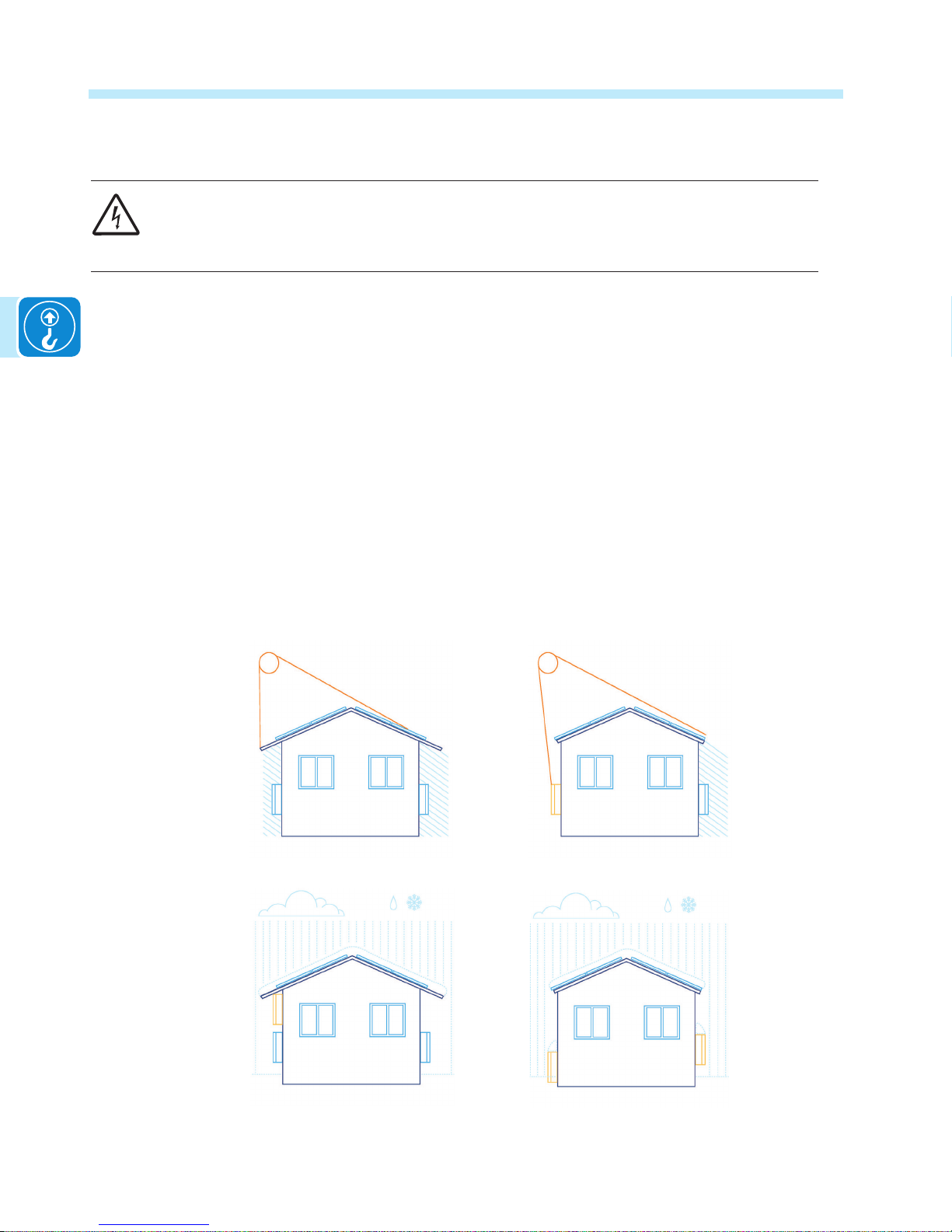

Environmental check

• See technical data in the Appendix, section 7, to check the environmental parameters to be

observed (degree of protection, temperature, humidity, altitude, etc.).

• The maximum operational ambient air temperature MUST be considered when choosing the

inverter installation location.

• Installing the inverter where operating temperatures exceed the specications will result in

power derating. It is recommended the inverter be installed within the specied temperature

range.

• Do not install in direct sunlight. If the preferred mounting location is in direct sunlight, install

the ABB Sun Shield on the inverter in order to provide the necessary shade.

• Do not install in small closed spaces where air cannot circulate freely.

• Due to acoustical noise (about 50dBA at 1 m) from the inverter, do not install in rooms where

people live or where the prolonged presence of people or animals is expected.

• To avoid overheating, always make sure the ow of air around the inverter is not blocked.

• Do not install in places where gases or ammable substances may be present.

Properly installed

Direct sun on left inverteruse ABB Sun Shade

Air restricted for top left

inverter - not properly installed

Air restricted by snow for both

inverters - not properly installed

- 21 -

T006CC2

2 - Installation

Installation position

When choosing the installation location and position, comply with the following conditions:

• Install on a wall or strong structure capable of bearing the weight.

• Install vertically with a maximum incline of +/- 5°. If the mounted inverter is tilted to an angle

greater than the maximum noted, heat dissipation can be inhibited, and may result in less

than expected output power.

• Install in a safe place where all switch handles and controls remain easy to reach and meet

height requirements of the applicable electrical code. Install at eye level so the display and

status LEDs can be easily seen.

• Ensure sufcient working area in front of the inverter to allow easy access and compliance

with the minimum clearance requirements of NEC 110.34(A).

• When planning the installation, maintain clearance distances shown to allow normal control

functions and easy maintenance operations.

32

in

20

in

6 in

6 in

UNO

T006CC2

- 22 -

2 - Installation

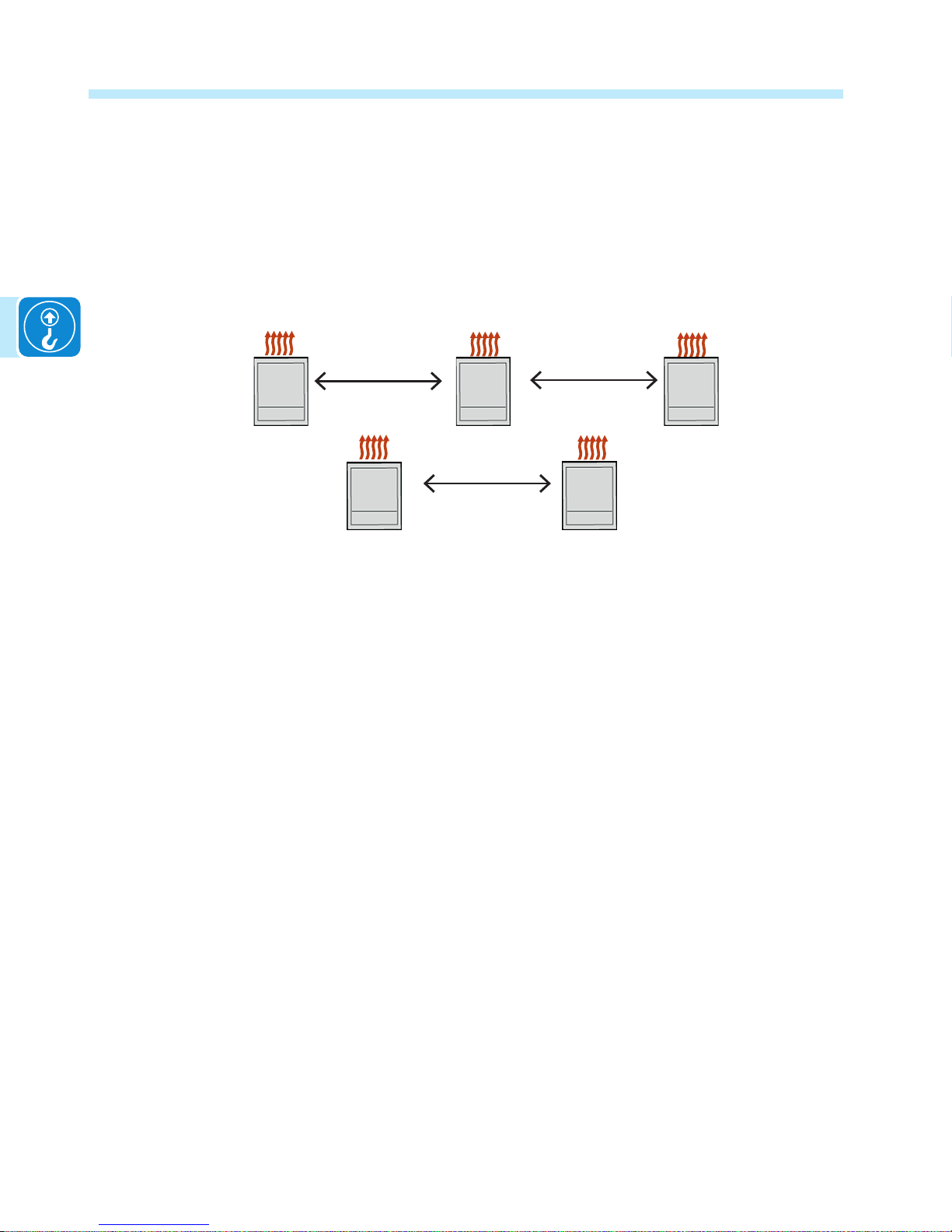

For multiple-inverter installations, position the inverters side-by-side, maintaining minimum

clearances. If the space available does not allow the side-by-side arrangement, multiple inverters

can be placed in the staggered arrangement shown; this minimizes heat dissipation from lower

inverters affecting operation of other inverters.

Minimum clearances illustrated include width of inverter plus additional allowances for inverters

arranged above or below.

Side-by-side arrangement

6”

6”

38”

38”

38”

- 23 -

T007CH3

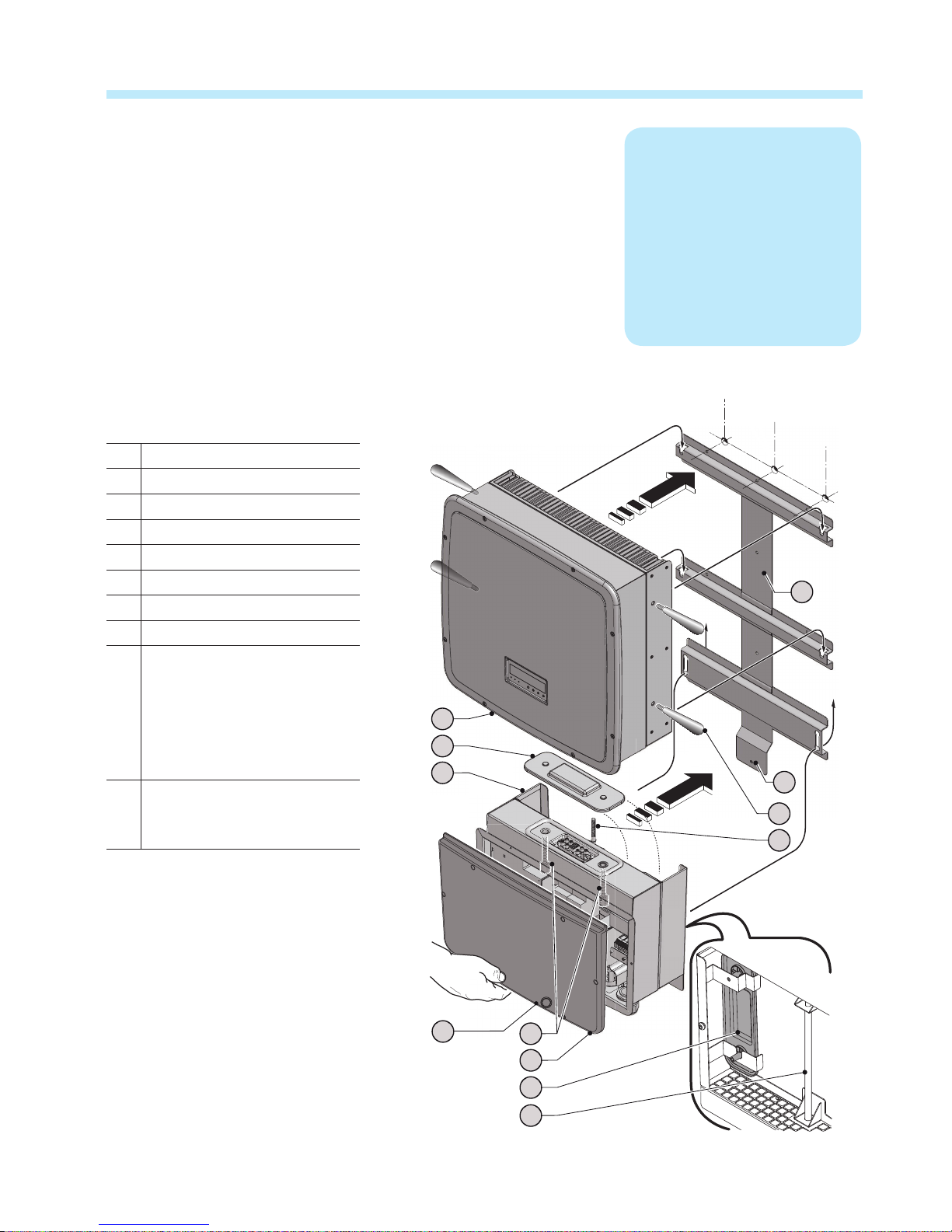

Labeled illustration of TRIO

01 mounting bracket

02 wiring box

03 inverter

04 coupling connector cover

05 clamp screw

06 optional handles

07 connector screws

08 wiring box cover

31 bottom locking tab for

securing mounting bracket

to wiring box and inverter,

can also be used as exterior

grounding electrode, if

required

32 hole on wiring box cover and

wiring box chassis used to

insert a padlock, if required

3

Mounting and wiring

31

06

05

03

04

08

04

05

02

07

01

32

T008CC3

- 24 -

3 - Mounting and wiring

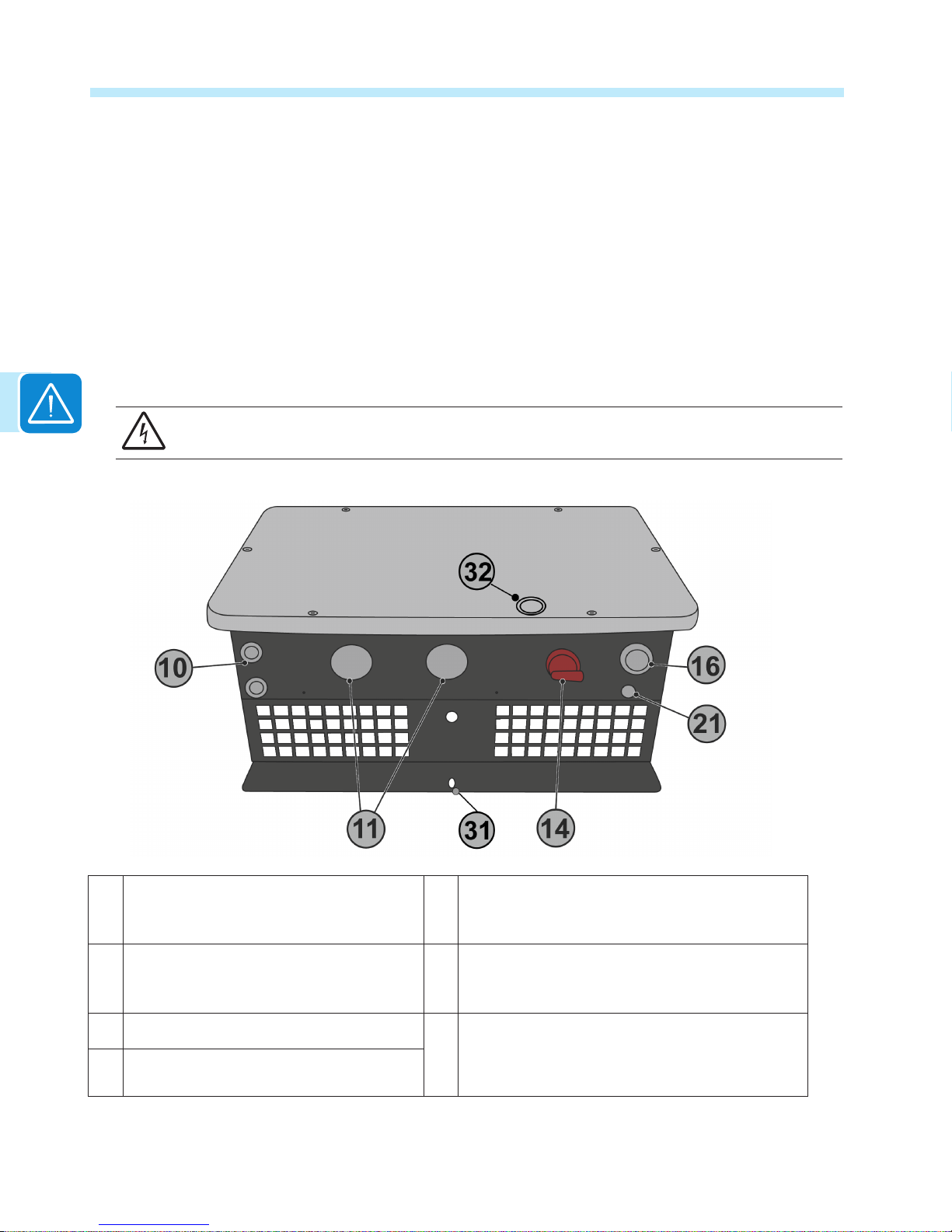

Conduit entries for all versions are located on the bottom of the wiring box along with the DC disconnect switch

handle 14. Conduit entries are illustrated below. The appropriate conduit connector must be used in order to

maintain required spacing between wiring groups and preserve the integrity of the NEMA 4X environmental rating.

• A silkscreen printed label on the wiring box front cover 08 illustrates the ON/OFF positioning of the disconnect

switch handle.

• In the OFF position (open and locked), the DC disconnect switch handle will be turned counter-clockwise in a

position parallel to the inverter mounting surface as illustrated below.

• In the ON position, the DC disconnect switch handle must be pushed in and turned clockwise to a position

perpendicular to the inverter mounting surface.

• The cover is only removable with the DC disconnect switch handle set to the OFF position.

• A padlock can be inserted in the slot on the switch handle when in the OFF position to prevent the disconnect

from being turned to the ON position.

WARNING! The DC switch (14) disconnects the photovoltaic array current from the inverter when

the switch is in OFF position. It DOES NOT disconnect the AC from the grid.

10 Service and communications cable open-

ing with plastic threaded plug, Trade size

1/2“

21 Anti-condensation valve (eliminates

condensation buildup) DO NOT REMOVE!

11 DC cable openings with plastic threaded

plug, Trade size 1”, 1 ½”

31 Bottom locking tab for securing mounting bracket

to inverter and wiring box, can also be used as

exterior grounding electrode terminal if required.

14 DC disconnect switch handle.

32 Hole on wiring box cover and wiring box chassis

used to insert a padlock,if required.

16 AC cable opening with plastic threaded

plug, Trade size 1”

T008CC3

- 25 -

3 - Mounting and wiring

Wall mounting

When mounting the TRIO, rst secure the mounting bracket to the desired location and then install

the wiring box followed by the inverter unit.

Included in the shipping package is a mounting kit with stainless steel screws and wall anchors for mounting the

powder coated, stainless steel bracket to a wall or structure The overall dimensions of the mounting bracket are

expressed in millimeters and inches.

991.91mm

39.05’’

0

18mm

0.7’’

164.36mm

6.47’’

382.63mm

15.06’’

554.9mm

21.84’’

730.41mm

28.75’’

978.9mm

38.54’’

0

101mm

3.97’’

301mm

11.85’’

0

21mm

0.82’’

501mm

19.72’’

581mm

22.87’’

25mm

0.98’’

T008CC3

- 26 -

3 - Mounting and wiring

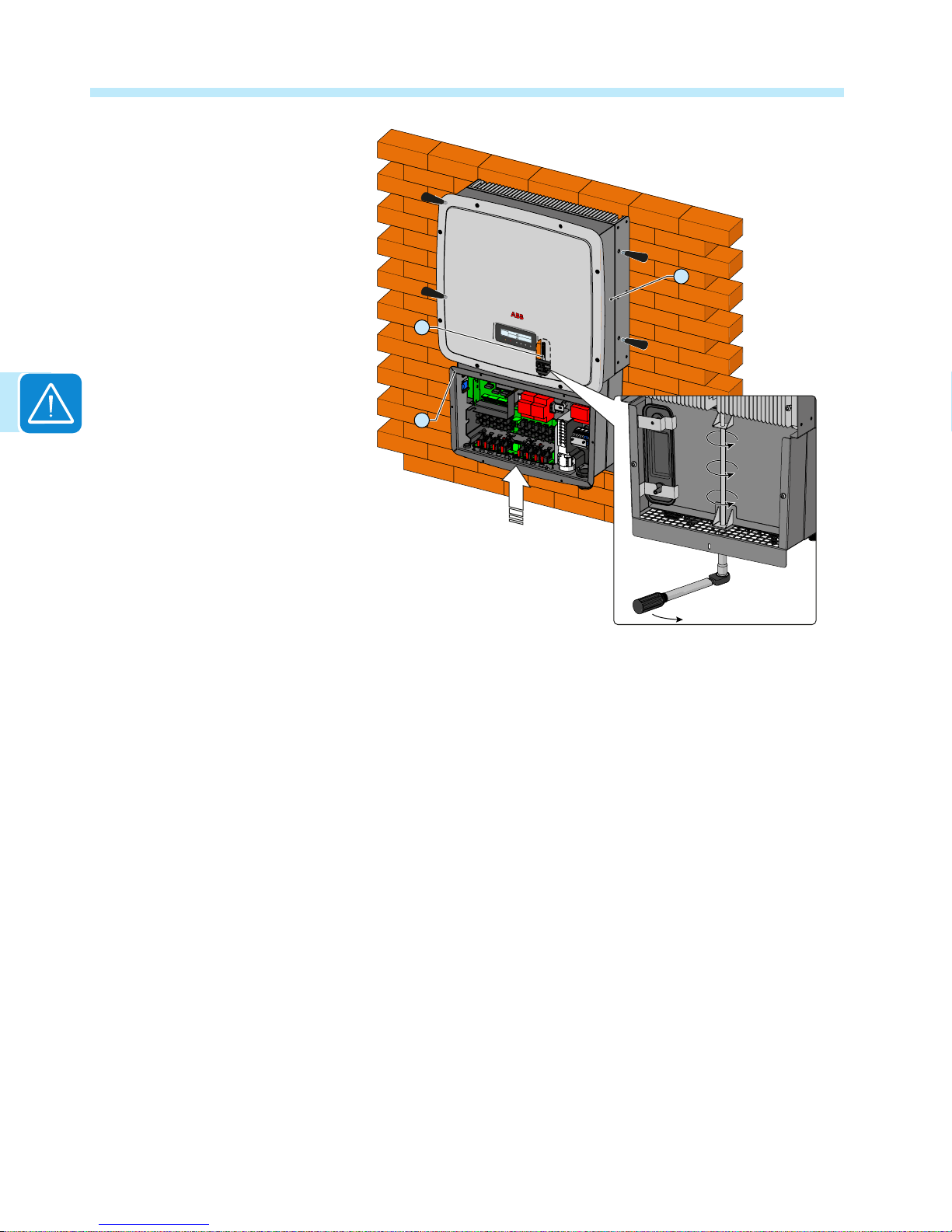

The process of joining the inverter and wiring box together should be completed before the

conduit is secured. When completely tightened the wiring box will move up to meet the inverter.

It is recommended to employ exible conduit methods to allow for easy removal of the inverter, if

ever required.

Installation method with flexible conduit

When installing exible conduit with the TRIO, provide enough conduit to allow for approximately

1-1½” of vertical movement between the inverter and wiring box. Prior to making the conductor

connections in the wiring box, provide enough conductor to allow for the movement of the wiring

box in the nal stages.

01

A

A

A

A

A

A

A

A

A

A

10 x Ø 10 mm

• Using a level, position the bracket

01 level on the wall, using it as a

drilling template.

• Using a 10mm drill bit, drill the

required 10 holes A 70mm deep.

• Using the 10 (ten) 10mm diameter

wall anchors, screw the bracket to

the wall.

• When installing in seismic Zone

3 or higher, the ve center wall

anchors must be xed into a

wood/steel wall stud or concrete/

masonry wall.

T008CC3

- 27 -

3 - Mounting and wiring

01

04

04

05

09

02

08

07

• Remove the front cover 08 from

the wiring box.

• Install the wiring box 02 onto the

bracket by inserting the heads of

the rear screws into the slots in

the bracket.

Note: it is not necessary to

install the inverter 03 at this

time.

• Unscrew the connector screws

07 and remove the wiring boxto-inverter cover 04 so that

the connector can be reached

between the wiring box and the

inverter.

• Put the wiring box-to-inverter

cover in the special pocket

provided at the back of the wiring

box.

• Locate the four bolts protruding

from the rear of the inverter

chassis; these are used as

mounting studs and are inserted

into the four associated slots on

the mounting bracket.

• Lift the inverter using two people

and orient it to the bracket so the

four studs are just above their

associated slots.

• Once aligned, lower the inverter

unit into position, ensuring all

four studs are seated in their

respective bracket slots.

• For ease of lifting, the optional

lifting kit is recommended (part #

3M2200HNDK0). The kit includes

both handles and eye bolts which

screw into the inverter heatsink.

POWER ALARM GFI ESC UP DOWN ENTER

TRIO

01

09

02

07

03

T008CC3

- 28 -

3 - Mounting and wiring

POWER ALARM GFI ESC UP DOWN ENTER

TRIO

05

02

03

• Join together the wiring box and

inverter by tightening the coupling

screw 05, working from the

underside of the wiring box.

• Using a 20mm socket, tighten the

clamp screw 05 to lift the inverter

wiring box toward the inverter until

mating connectors of the wiring

box and inverter chassis seat fully.

Do not completely tighten at

this time.

T008CC3

- 29 -

3 - Mounting and wiring

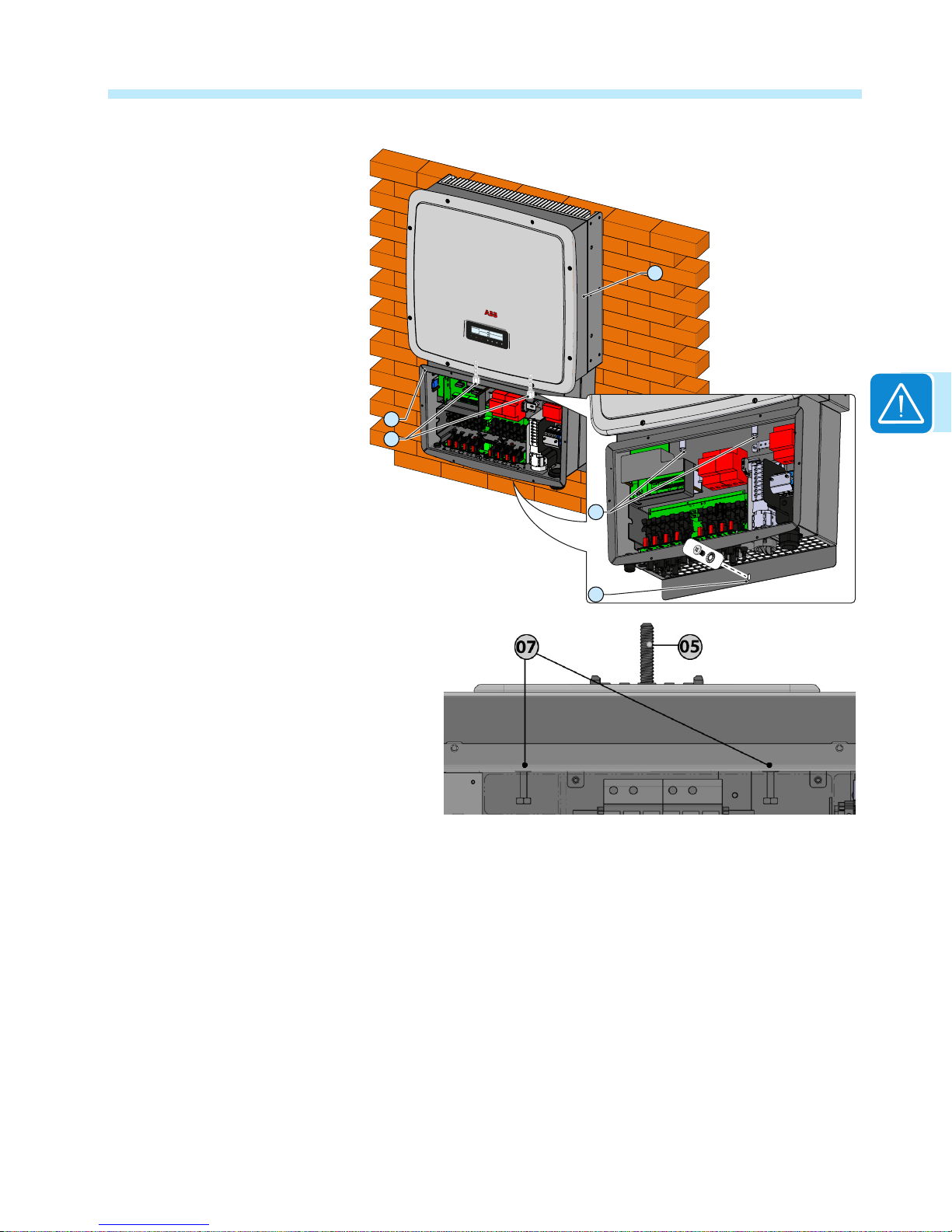

Installation method with rigid conduit

If installing rigid conduit with the TRIO, mount the inverter as instructed above before making the

rigid conduit connections. The inverter wiring box moves up in the installation procedure and the

connection of rigid conduit would prevent this necessary movement if installed prior to mounting

the inverter.

• Once the wiring box and inverter

are connected, screw in the two

connector screws 07 located

inside the wiring box to fully lock

and seal the connection.

• Using a 13mm socket wrench,

nish tightening each of the two

connector screws 07 to at least

13.3-14.75 ft-lbs (18-20Nm)

torque.

• After tightening the connector

screws 07, nish tightening the

clamp screw 05 at the bottom

of the wiring box to 13.3 ft-lbs

(18Nm) of torque.

• Anchor the connected wiring

box and inverter to the lower

end of the bracket by tightening

the locking screw 27 located

underneath the wiring box.

• Upon completion, replace the

front cover of the wiring box 08

and torque screws to at least 21

in-lbs (2Nm) to ensure proper

waterproof sealing.

POWER ALARM GFI ESC UP DOWN ENTER

TRIO

02

03

07

07

27

Loading...

Loading...