YOKOGAWA DY015, DY025, DY040, DY050, DY080 User's Manual

...

User’s |

Model DY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Manual |

Vortex Flowmeter |

|||||||||||

|

(Integral Type, Remote Type) |

|||||||||||

|

Model DYA |

|||||||||||

|

Vortex Flow Converter |

|||||||||||

|

(Remote Type) |

|||||||||||

|

|

|

|

|

|

|

|

|

|

IM 1F6A0-01E |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IM 1F6A0-01E

8th Edition

Yokogawa Electric Corporation

|

|

|

|

CONTENTS |

|

|

|

CONTENTS |

|

INTRODUCTION .............................................................................................................................................. |

|

iv |

||

1. |

HANDLING PRECAUTIONS ................................................................................................................ |

1-1 |

||

|

1.1 |

Model and Specifications ........................................................................................................................... |

1-1 |

|

|

1.2 |

Precautions Regarding Transportation and Storage Location ............................................................... |

1-1 |

|

|

1.3 |

Precautions Regarding Installation Locations ........................................................................................ |

1-1 |

|

2. |

INSTALLATION .................................................................................................................................... |

2-1 |

||

|

2.1 |

Precautions Regarding Installation Locations ........................................................................................ |

2-1 |

|

|

2.2 |

Piping |

........................................................................................................................................................... |

2-1 |

|

2.3 |

Precautions Regarding Installation .......................................................................................................... |

2-4 |

|

|

2.4 |

Piping to Improve Durability ...................................................................................................................... |

2-5 |

|

|

2.5 |

Cryogenic and High process Temperature Version Insulation ............................................................... |

2-5 |

|

|

2.6 |

Installing the Vortex Flow-meter ................................................................................................................ |

2-6 |

|

3. |

WIRING ................................................................................................................................................. |

|

3-1 |

|

|

3.1 |

Wiring Precautions ..................................................................................................................................... |

3-1 |

|

|

3.2 |

Wiring for Output Condition ...................................................................................................................... |

3-1 |

|

|

3.3 |

Connection .................................................................................................................................................. |

3-2 |

|

|

3.4 |

Wiring Cables and Wires ............................................................................................................................ |

3-4 |

|

|

3.5 |

Connection of the Remote Type Signal Cable .......................................................................................... |

3-4 |

|

|

3.6 |

Method of Finishing the Signal Cable End(DYC) ..................................................................................... |

3-5 |

|

|

|

3.6.1 |

For Vortex Flowmeter (DY-N) ........................................................................................................................... |

3-5 |

|

|

3.6.2 |

For Vortex Flow Converter (DYA) .................................................................................................................... |

3-6 |

|

3.7 |

Wiring Cautions .......................................................................................................................................... |

3-7 |

|

|

3.8 |

Grounding ................................................................................................................................................... |

3-7 |

|

4. |

BASIC OPERATING PROCEDURES .................................................................................................. |

4-1 |

||

|

4.1 |

Construction of the Display ....................................................................................................................... |

4-1 |

|

|

4.2 |

Display Contents in Display Section ........................................................................................................ |

4-2 |

|

|

4.3 |

Display Contents in Display Section ........................................................................................................ |

4-3 |

|

|

|

4.3.1 |

Change the Display Mode from % Display to Engineering Unit ....................................................................... |

4-4 |

|

|

4.3.2 |

Indicate the Total Rate in the Lower Display ..................................................................................................... |

4-5 |

|

4.4 |

Setting Mode ............................................................................................................................................... |

4-6 |

|

|

|

4.4.1 |

Structure of Setting Mode Display ..................................................................................................................... |

4-6 |

|

|

4.4.2 |

Method of Parameter Setting .............................................................................................................................. |

4-7 |

|

4.5 |

Operation for the BT200 ............................................................................................................................. |

4-9 |

|

|

|

4.5.1 |

Connection Method for the BT200 .................................................................................................................... |

4-9 |

|

|

4.5.2 |

Displaying Flow Rate Data .............................................................................................................................. |

4-10 |

|

|

4.5.3 |

Setting Parameters ............................................................................................................................................ |

4-11 |

|

4.6 |

Operation for HART Communicator ........................................................................................................ |

4-13 |

|

|

|

4.6.1 |

Interconnection between digitalYEWFLO and HART Communicator ........................................................... |

4-13 |

|

|

4.6.2 |

Communication Line Requirements ................................................................................................................ |

4-14 |

|

|

4.6.3 |

Keys and Functions of Model 275 ................................................................................................................... |

4-15 |

|

|

4.6.4 |

Display ............................................................................................................................................................. |

4-16 |

|

|

4.6.5 |

Calling Up Menu Addresses ............................................................................................................................. |

4-17 |

|

|

4.6.6 |

Entering, Setting and Sending Data ................................................................................................................. |

4-18 |

|

|

4.6.7 |

Parameters Configuration ................................................................................................................................. |

4-18 |

|

|

4.6.8 |

Unique Functions of HART Communicator .................................................................................................... |

4-19 |

|

|

4.6.9 |

Data Renewing ................................................................................................................................................. |

4-19 |

|

|

4.6.10 |

Checking for Problems ..................................................................................................................................... |

4-19 |

|

|

4.6.11 |

Write Protect .................................................................................................................................................... |

4-20 |

IM 1F6A0-01E

8th Edition : Nov. 2005(KP)

All Rights Reserved, Copyright © 2001. Yokogawa Electric Corporation

i |

IM 1F6A0-01E |

|

|

|

|

CONTENTS |

|

|

4.6.12 |

Menu Tree ........................................................................................................................................................ |

4-21 |

5. |

PARAMETERS ..................................................................................................................................... |

5-1 |

||

|

5.1 |

Parameter Setup ......................................................................................................................................... |

5-1 |

|

|

5.2 |

Multi-Variable Type Parameter (Only for /MV) ........................................................................................... |

5-1 |

|

|

5.3 |

Parameters List ........................................................................................................................................... |

5-1 |

|

|

5.4 |

Parameter Description ............................................................................................................................... |

5-9 |

|

|

5.5 |

Error Code Lists ........................................................................................................................................ |

5-17 |

|

6. |

OPERATION ......................................................................................................................................... |

6-1 |

||

|

6.1 |

Adjustment .................................................................................................................................................. |

6-1 |

|

|

|

6.1.1 |

Zero Adjustment ................................................................................................................................................. |

6-1 |

|

|

6.1.2 |

Span Adjustment ................................................................................................................................................ |

6-1 |

|

|

6.1.3 |

Loop test ............................................................................................................................................................. |

6-1 |

|

|

6.1.4 |

Totalizer Function Start and Totalized Value Reset ............................................................................................ |

6-1 |

|

|

6.1.5 |

Unit of Pulse Output (Scaling) ........................................................................................................................... |

6-2 |

|

|

6.1.6 |

Power Failure ..................................................................................................................................................... |

6-2 |

|

6.2 |

Adjustment for Manual Mode .................................................................................................................... |

6-2 |

|

|

|

6.2.1 |

Low Cut Adjustment .......................................................................................................................................... |

6-2 |

|

|

6.2.2 |

Tuning ................................................................................................................................................................ |

6-2 |

|

6.3 |

Other Maintenance ..................................................................................................................................... |

6-3 |

|

|

|

6.3.1 |

Cleaning Precautions .......................................................................................................................................... |

6-3 |

7. |

MAINTENANCE ................................................................................................................................... |

7-1 |

||

|

7.1 |

Changing the Terminal Box Orientation ................................................................................................... |

7-2 |

|

|

7.2 |

Indicator Removal and Rotation ................................................................................................................ |

7-3 |

|

|

7.3 |

Amplifier Unit Removal .............................................................................................................................. |

7-3 |

|

|

7.4 |

Amplifier Unit Assembling ......................................................................................................................... |

7-3 |

|

|

7.5 |

Vortex Shedder Removal ............................................................................................................................ |

7-4 |

|

|

7.6 |

Setting Switches ......................................................................................................................................... |

7-6 |

|

|

|

7.6.1 |

Setting of Burnout Switch .................................................................................................................................. |

7-6 |

|

|

7.6.2 |

Setting of Write Protect Switch .......................................................................................................................... |

7-6 |

|

7.7 |

Software Configuration .............................................................................................................................. |

7-7 |

|

8. |

TROUBLESHOOTING .......................................................................................................................... |

8-1 |

||

|

8.1 |

Flow .............................................................................................................................................................. |

|

8-1 |

|

8.2 |

Flow (Only for /MV) ..................................................................................................................................... |

8-4 |

|

9. |

GENERAL DESCRIPTION ................................................................................................................... |

9-1 |

||

|

9.1 |

Outline ......................................................................................................................................................... |

9-1 |

|

|

9.2 |

Standard Specifications ............................................................................................................................. |

9-2 |

|

|

9.3 |

Model and Suffix Codes ............................................................................................................................. |

9-5 |

|

|

9.4 |

Option Specifications ................................................................................................................................. |

9-7 |

|

|

|

9.4.1 |

Option Specifications ......................................................................................................................................... |

9-7 |

|

|

9.4.2 |

Option Multi-Variable (Build in Temperature Sensor) Type (/MV)(*1) ............................................................ |

9-9 |

|

|

9.4.3 |

Option Specifications (Hazardous Area Classifications) ................................................................................. |

9-11 |

|

9.5 |

Sizing |

......................................................................................................................................................... |

9-14 |

|

9.6 |

External Dimensions ................................................................................................................................ |

9-18 |

|

10. |

EXPLOSION PROTECTED TYPE INSTRUMENT ............................................................................. |

10-1 |

||

|

10.1 |

CENELEC ATEX (KEMA) .......................................................................................................................... |

10-1 |

|

|

|

10.1.1 |

Technical Data .................................................................................................................................................. |

10-1 |

|

|

10.1.2 |

Installation ........................................................................................................................................................ |

10-2 |

|

|

10.1.3 |

Operation .......................................................................................................................................................... |

10-2 |

|

|

10.1.4 |

Maintenance and Repair ................................................................................................................................... |

10-2 |

|

|

10.1.5 |

Installation Diagram of Intrinsically safe (and Note) ...................................................................................... |

10-3 |

|

|

10.1.6 |

Installation Diagram of Type of Protection “n” ............................................................................................... |

10-3 |

ii |

IM 1F6A0-01E |

|

|

|

CONTENTS |

|

10.1.7 |

Data Plate ......................................................................................................................................................... |

10-4 |

|

10.1.8 |

Screw Marking ................................................................................................................................................. |

10-4 |

10.2 |

FM ............................................................................................................................................................... |

|

10-5 |

|

10.2.1 |

Technical Data .................................................................................................................................................. |

10-5 |

|

10.2.2 |

Wiring ............................................................................................................................................................... |

10-5 |

|

10.2.3 |

Operation .......................................................................................................................................................... |

10-5 |

|

10.2.4 |

Maintenance and Repair ................................................................................................................................... |

10-5 |

|

10.2.5 |

Installation Diagram ......................................................................................................................................... |

10-6 |

|

10.2.6 |

Data Plate ......................................................................................................................................................... |

10-7 |

10.3 |

SAA ............................................................................................................................................................ |

|

10-7 |

|

10.3.1 |

Technical Data .................................................................................................................................................. |

10-7 |

|

10.3.2 |

Installation ........................................................................................................................................................ |

10-8 |

|

10.3.3 |

Operation .......................................................................................................................................................... |

10-8 |

|

10.3.4 |

Maintenance and Repair ................................................................................................................................... |

10-8 |

|

10.3.5 |

Installation Diagram ......................................................................................................................................... |

10-8 |

|

10.3.6 |

Data Plate ......................................................................................................................................................... |

10-9 |

10.4 |

CSA .......................................................................................................................................................... |

|

10-10 |

|

10.4.1 |

Technical Data ................................................................................................................................................ |

10-10 |

|

10.4.2 |

Wiring ............................................................................................................................................................. |

10-11 |

|

10.4.3 |

Operation ........................................................................................................................................................ |

10-11 |

|

10.4.4 |

Maintenance and Repair ................................................................................................................................. |

10-11 |

|

10.4.5 Installation Diagram Intrinsically Safe (and Note) ........................................................................................ |

10-11 |

|

|

10.4.6 |

Data Plate ....................................................................................................................................................... |

10-12 |

10.5 |

TIIS ........................................................................................................................................................... |

|

10-13 |

11. PRESSURE EQUIPMENT DIRECTIVE .............................................................................................. |

11-1 |

||

INSTALLATION AND OPERATING PRECAUTIONS FOR JIS FLAMEPROOF EQUIPMENT ................. |

EX-1 |

||

REVISION RECORD

iii |

IM 1F6A0-01E |

INTRODUCTION

INTRODUCTION

The DY series of vortex flowmeters have been fine-tuned to your order specifications prior to shipment. Before use, read this manual thoroughly and familiarize yourself fully with the features, operations and handling of digitalYEWFLO to have the instrument deliver its full capabilities and to ensure its efficient and correct use.

■Notices Regarding This Manual

•This manual should be passed to the end user.

•The contents of this manual are subject to change without prior notice.

•All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means without the written permission of Yokogawa Electric Corporation (hereinafter simply referred to as Yokogawa).

•This manual neither does warrant the marketability of this instrument nor it does warrant that the instrument will suit a particular purpose of the user.

•Every effort has been made to ensure accuracy in the contents of this manual. However, should any questions arise or errors come to your attention, please contact your nearest Yokogawa sales office that appears on the back of this manual or the sales representative from which you purchased the product.

•This manual is not intended for models with custom specifications.

•Revisions may not always be made in this manual in conjunction with changes in specifications, constructions and/or components if such changes are not deemed to interfere with the instrument’s functionality or performance.

■Notices Regarding Safety and Modification

•For the protection and safety of personnel, the instrument and the system comprising the instrument, be sure to follow the instructions on safety described in this manual when handling the product. If you handle the instrument in a manner contrary to these instructions, Yokogawa does not guarantee safety.

•If this instrument is used in a manner not specified in this manual, the protection provided by this instrument may be impaired.

•As for explosionproof model, if you yourself repair or modify the instrument and then fail to return it to its original form, the explosion-protected construction of the instrument will be impaired, creating a hazardous condition. Be sure to consult Yokogawa for repairs and modifications.

Safety and Modification Precautions

•The following general safety precautions must be observed during all phases of operation, service, and repair of this instrument. Failure to comply with these precautions or with specific WARNINGS given elsewhere in this manual violates safety standards of design, manufacture, and intended use of the instrument. Yokogawa assumes no liability for the customer's failure to comply with these requirements. If this instrument is used in a manner not specified in this manual, the protection provided by this instrument may be impaired.

•The following safety symbol marks are used in this user's manual and instrument.

WARNING

A WARNING sign denotes a hazard. It calls attention to procedure, practice, condition or the like, which, if not correctly performed or adhered to, could result in injury or death of personnel.

CAUTION

A CAUTION sign denotes a hazard. It calls attention to procedure, practice, condition or the like, which, if not correctly performed or adhered to, could result in damage to or destruction of part or all of the product.

IMPORTANT

An IMPORTANT sign denotes that attention is required to avoid damage to the instrument or system failure.

NOTE

A NOTE sign denotes information necessary for essential understanding of operation and features.

Functional grounding terminal

Direct current

iv |

IM 1F6A0-01E |

INTRODUCTION

Warranty

•The warranty of this instrument shall cover the period noted on the quotation presented to the Purchaser at the time of purchase. The Seller shall repair the instrument free of charge when the failure occurred during the warranty period.

•All inquiries on instrument failure should be directed to the Seller’s sales representative from whom you purchased the instrument or your nearest sales office of the Seller.

•Should the instrument fail, contact the Seller specifying the model and instrument number of the product in question. Be specific in describing details on the failure and the process in which the failure occurred. It will be helpful if schematic diagrams and/or records of data are attached to the failed instrument.

•Whether or not the failed instrument should be repaired free of charge shall be left solely to the discretion of the Seller as a result of an inspection by the Seller.

■The Purchaser shall not be entitled to receive repair services from the Seller free of charge, even during the warranty period, if the malfunction or damage is due to:

•improper and/or inadequate maintenance of the instrument in question by the Purchaser.

•handling, use or storage of the instrument in question beyond the design and/or specifications requirements.

•use of the instrument in question in a location not conforming to the conditions specified in the Seller's General Specification or Instruction Manual.

•retrofitting and/or repair by an other party than the Seller or a party to whom the Seller has entrusted repair services.

•improper relocation of the instrument in question after delivery.

•reason of force measure such as fires, earthquakes, storms/ floods, thunder/lightning, or other reasons not attributable to the instrument in question.

v |

IM 1F6A0-01E |

■ Using the Vortex Flowmeter Safely

WARNING

(1) Installation

•Installation of the vortex flowmeter must be performed by expert engineer or skilled personnel. No operator shall be permitted to perform procedures relating to installation.

•The vortex flowmeter is a heavy instrument. Be careful that no damage is caused to personnel through accidentally dropping it, or by exerting excessive force on the vortex flowme-

ter. When moving the vortex flowmeter, always use a trolley and have at least two people carry it.

•When the vortex flowmeter is processing hot fluids, the instrument itself may become extremely hot. Take sufficient care not to get burnt.

•Where the fluid being processed is a toxic substance, avoid contact with the fluid and avoid inhaling any residual gas, even after the instrument has been taken off the line for maintenance and so forth.

•All procedures relating to installation must comply with the electrical code of the country where it is used.

(2) Wiring

•The wiring of the vortex flowmeter must be performed by expert engineer or skilled personnel. No operator shall be permitted to perform procedures relating to wiring.

•When connecting the wiring, check that the supply voltage is within the range of the voltage specified for this instrument before connecting the power cable. In addition, check that no voltage is applied to the power cable before connecting the wiring.

•The functional grounding must be connected

securely at the terminal with the  mark to avoid danger to personnel.

mark to avoid danger to personnel.

(3) Operation

•Only expert engineer or skilled personnel are permitted to open the cover.

(4) Maintenance

•Maintenance on the vortex flowmeter should be performed by expert engineer or skilled personnel. No operator shall be permitted to perform any operations relating to maintenance.

•Always conform to maintenance procedures outlined in this manual. If necessary, contact Yokogawa.

INTRODUCTION

•Care should be taken to prevent the build up of dirt, dust or other substances on the display panel glass or data plate. If these surfaces do get dirty, wipe them clean with a soft dry cloth.

(5) Explosion Protected Type Instrument

•For explosion proof type instrument, the description in Chapter 10 “EXPLOSION PROTECTED TYPE INSTRUMENT” is prior to the other description in this user's manual.

•Only trained persons use this instrument in the industrial location.

•The functional grounding  must be connected to a suitable IS grounding system.

must be connected to a suitable IS grounding system.

•Take care not to generate mechanical spark when access to the instrument and peripheral devices in hazardous locations.

(6)European Pressure Equipment Directive (PED)

•When using the instrument as a PED-compliant product, be sure to read Chapter 11 before use.

vi |

IM 1F6A0-01E |

1. HANDLING PRECAUTIONS

1. HANDLING PRECAUTIONS

The Model DY Vortex Flowmeter and Model DYA Vortex Flow Converter are thoroughly tested at the factory before shipment. When these instruments are delivered, perform a visual check to ascertain that no damage occurred during shipment.

This section describes important cautions in handling these instruments. Read carefully before using them.

If you have any problems or questions, contact your nearest YOKOGAWA service center or sales representative.

1.1 Model and Specifications

The model and important specifications are indicated on the data plate attached to the case. Verify that they are the same as those specified in the original order, referring to paragraph 9.2 to 9.5. In any correspondence, always give model (MODEL), serial number (NO) and calibrated range (RANGE) from the data plate.

4 ~ 20mA DC / PULSE |

TAG NO. |

MPa at 38°C |

|

*1) |

|

10.5 ~ 42V DC |

3UA |

*2) |

|

*1): |

K factor at 15°C |

|

*2): |

The product - producing country. |

F010101.EPS |

Figure 1.1(a) Example of Data Plate for Integral Type

MPa at 38°C |

TAG NO. |

|

|

|

3WA |

4 ~ 20mA DC / PULSE |

TAG NO. |

10.5 ~ 42V DC |

3YA |

1.2Precautions Regarding Transportation and Storage Location

To protect against accidental damage to digitalYEWFLO while transporting it to a new location, pack it in the original

packing as when shipped from the Yokogawa factory.

WARNING

The Vortex Flowmeter is a heavy instrument. Please be careful to prevent persons from injuring when it is handled.

Deterioration in insulation or corrosion can occur for unexpected reasons if digitalYEWFLO is left uninstalled for a prolonged period after delivery. If digitalYEWFLO is likely to be stored over a prolonged period, observe the following precautions.

■Store the vortex flowmeter with forwarded statement.

■Choose a storage location that satisfies the following requirements:

•Not exposed to rain or splashwater.

•Less susceptible to mechanical vibration or shock.

•Kept within the temperature and humidity ranges shown

in the following table, preferably at normal temperature and humidity (approximately 25°C, 65%)

Temperature |

–40°C to +80°C |

|

|

Humidity |

5 to 100% (no condensation) |

|

|

T010201.EPS

1.3Precautions Regarding Installation Locations

(1) Ambient Temperature

Avoid an area which has wide temperature variations. When the installation area is subjected to heat radiation from process plant, ensure adequate heat prevention or ventilation.

(2) Atmospheric Conditions

Avoid installing the vortex flowmeter in a corrosive atmosphere. When the vortex flowmeter must be installed in a corrosive atmosphere, adequate ventilation must be provided.

F010102.EPS

Figure 1.1(b) Example of Data Plate for Remote Type

1-1 |

IM 1F6A0-01E |

1. HANDLING PRECAUTIONS

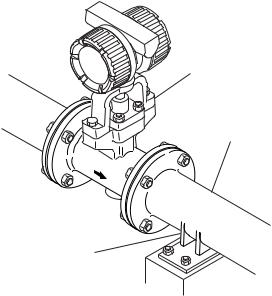

(3) Mechanical Shock or Vibration

The vortex flowmeter is of sturdy construction, but select an area subject to minimize mechanical vibrations or impact shock. If the flowmeter is subject to vibrations, it is recommended that pipeline supports to be provided as shown in Figure 1.2.

(4) Other Considerations

•Choose a location where is sufficient clearance around digitalYEWFLO exist to allow such work as routine inspections.

•Choose a location that ensures easy wiring and piping.

digitalYEWFLO Vortex Flowmeter

Pipeline

Pipeline Support

F010301.EPS

Figure 1.2

1-2 |

IM 1F6A0-01E |

2. INSTALLATION

2. INSTALLATION

WARNING

This instrument must be installed by expert engineer or skilled personnel. The procedures described in this chapter are not permitted for operators.

2.1Precautions Regarding Installation Locations

(1) Ambient Temperature

Avoid an area which has wide temperature variations. When the installation area is subjected to heat radiation from process plant, ensure adequate heat prevention or ventilation.

(2) Atmospheric Conditions

(4) Precautions Regarding Piping

(a)Ensure that the process connector bolts are tightened firmly.

(b)Ensure that no leak exists in the process connection pipeline.

(c)Do not apply a pressure higher than the specified maximum working pressure.

(d)Do not loosen or tighten the flange mounting bolts when the assembly is pressurized.

(e)Handle the vortex flowmeter carefully when measuring dangerous liquids, so that the liquids do not splash into eyes or on face. When using dangerous gases, be careful not to inhale them.

2.2 Piping

See Table 2.1 about Valve Position and Straight Pipe Length and so on.

Avoid installing the vortex flowmeter in a corrosive atmosphere. When the vortex flowmeter must be installed in a corrosive atmosphere, adequate ventilation must be provided

(3) Mechanical Shock or Vibration

The vortex flowmeter is of sturdy construction, but select an area subject to minimize mechanical vibration or impact shock. If the flowmeter is subject to vibrations, it is recommended that pipeline supports to be provided as shown in Figure 2.1.

digitalYEWFLO Vortex Flowmeter

Pipeline

Pipeline Support

F020101.EPS

Figure 2.1

2-1 |

IM 1F6A0-01E |

2. INSTALLATION

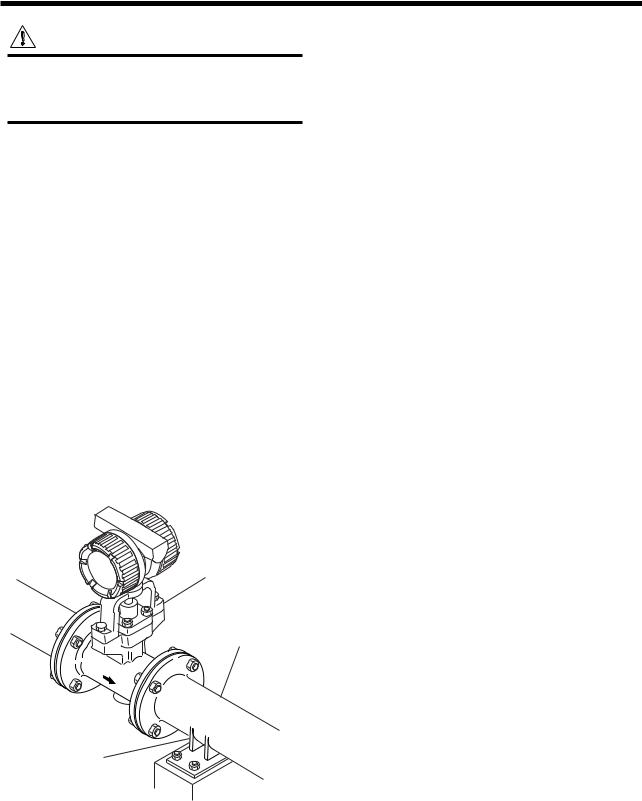

Table 2.1 Installation

Description |

Figure |

Piping support:

Typical vibration immunity level is 1G for normal piping condition.

Piping support shoud be fixed in case of over 1G vibration level.

Installation direction:

If a pipe is always filled with liquids, the pipe can be installed vertically or at inclined angle.

Adjacent pipes:

The process pipline inner diameter should be larger than the digitalYEWFLO inner diameter.

Use the following adjacent pipe.

Norminal size 15mm up to 50mm : Sch 40 or less. Norminal size 80mm up to 300mm : Sch 80 or less.

Reducer pipe: |

|

|

|

|

|

|

|

|

digitalYEWFLO |

|

|

||||||||

|

|

|

|

|

|

|

Flow |

|

|

||||||||||

Ensure the upstream straight pipe length to be 5D or more, and the |

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

downstream straight pipe length to be 5D or more for per reducer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

pipe. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(D: digitalYEWFLO nominal diameter) |

Reducer |

|

|

|

|

|

|

5D or more |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5D or more |

|

|

|||||

Expander pipe: |

|

|

|

|

|

|

|

|

digitalYEWFLO |

|

|

||||||||

Ensure the upstream straight pipe length to be 10D or more, and |

|

|

|

|

|

|

|

Flow |

|

|

|||||||||

the downstream straight pipe length to be 5D or more for per |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

expander pipe. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Expander |

|

|

|

|

|

|

10D or more |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5D or more |

|

|

|||||

Bent pipe and straight pipe length: |

|

|

|

|

|

digitalYEWFLO |

|||||||||||

Ensure the upstream straight pipe length to be 10D or more, and |

|

|

|

|

|

|

|

|

Flow |

|

|

|

|

|

|||

the downstream straight pipe length to be 5D or more for per bent |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

pipe. |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

10DxN or more |

|

|

|

5D or more |

||||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N: Number of bent pipe |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Valve position and straight pipe length: |

|

|

|

|

digitalYEWFLO |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

■Install the valve on the downstream side of the flowmeter. The upstream straight pipe length dependent on the element

Refer to each element above for

located on the upstream such as reducer/expander, bent and straight pipe run. etc., refer to description as above. Keep 5D or more for

downstream straight pipe length.

Flow |

Valve |

digitalYEWFLO |

|

■ In case the valve has to be installed on the upstream of the |

|

|

|

flowmeter, ensure the upstream straight pipe length to be 20D |

|

|

|

or more, and the downstream straight pipe length be 5D or more. |

|

|

|

|

|

|

|

|

|

20D or more |

5D or more |

|

|

|

|

|

|

|

digitalYEWFLO |

Fluid vibration:

For a gas line which uses a position-type or roots-type blower compressor or a high-pressure liquid line (about 1MPa or more) which uses piston-type or plunger-type pump, fluid vibrations may be produced.

In this case, install valve on the upstream side of digitalYEWFLO.

For inevitable fluid vibration, put a vibration damping device such as

throttling plate or expansion section in the upstream side of digitalYEWFLO digitalYEWFLO.

Piston-type or plunger pump: |

|

Install the accumulator on the upstream side of digitalYEWFLO to |

digitalYEWFLO |

reduce fluid vibrations. |

|

F020102-1.EPS

2-2 |

IM 1F6A0-01E |

2. INSTALLATION

Description |

|

|

|

|

|

|

|

Figure |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

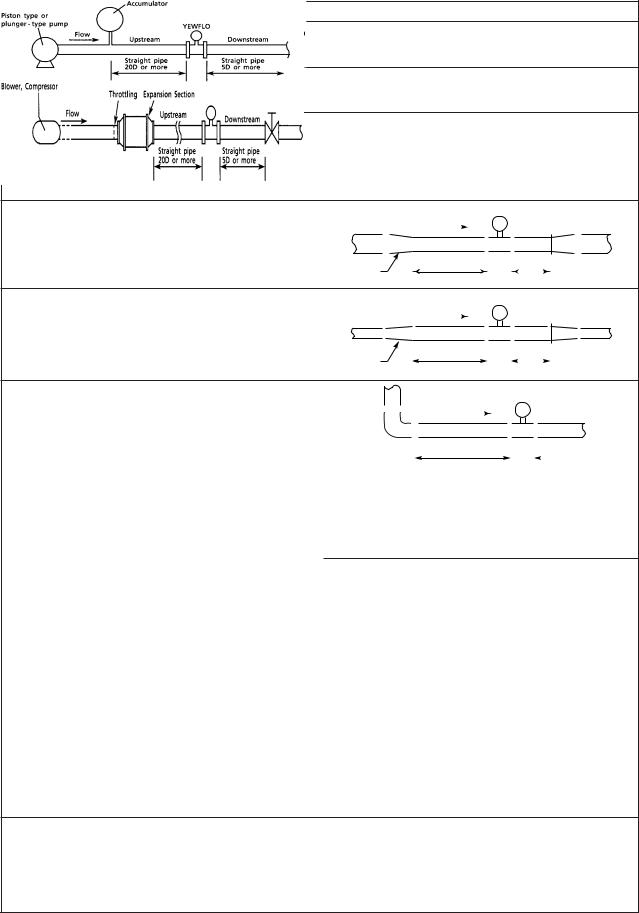

Valve positon (T-type piping exist): |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When pulsation causes by a T-type piping exist, install the valve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

on the upstream of the flowmeter. |

|

|

|

|

|

Relocating |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

Example:As shown in the figure, when the valve V1 is turned |

|

|

|

|

|

|

|

digitalYEWFLO |

|

|

Valve (Off) |

|||||||||||||||||||

Flow |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

off, the fluid flow throught B as to meter A the flow is zero. But |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

due to the pulsating pressure is detected, the meter is zero |

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

point become fluctuating. To avoid this, change the valve V1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

location to V1'. |

|

|

|

|

|

V1’ |

|

|

|

|

|

|

|

|

|

|

V1 |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressure and Temperature Taps: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressure tap |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

Pressure tap outlet: install this tap between 2D and 7D on the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

digitalYEWFLO |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

Temperature tap |

|

|

||||||||||||||||||||||

downstream side of a flowmeter. |

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Temperature tap outlet: install this on the downstream side 1D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Upstream |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

to 2D away from a pressure tap. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Flow |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

downstream |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

2 to 7D |

|

1 to 2D |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mounting Gasket: |

|

|

|

|

|

|

|

digitalYEWFLO |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

Avoid mounting gaskets which protrude into the pipe line. This |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

may cause inaccurate readings. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Use the gaskets with bolt holes, even if digitalYEWFLO is the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

wafer type. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When using a spiral gasket(without bolt holes), confirm the size |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

with the gasket -manufacturer, as standard items may not be |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pipeline Flange |

|

||||||||||||||

used for certain flange ratings. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pipeline |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

No good |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heat-Insulation: |

|

|

|

|

|

|

|

digitalYEWFLO |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bracket |

|

|

|

|

|

|

|

|

|

|

|||||

When an integral-type flowmeter or a remote type detector is |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

installed and the pipe carrying higt-temperature fluids is |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heat-Insulator |

||||||||

heat-insulated, do not wrap adiabatic materials around the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

installation bracket of the converter. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flushing of the pipe line: |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Flush and clean scale, incrustation and sludge on the inside of |

digitalYEWFLO |

||||||

pipe for newly installed pipe line and repaired pipe line before |

|||||||

|

|

|

|

|

|

||

the operation. For flushing, the flow should flow through |

|

|

|

|

|

|

|

bypass-piping to avoid damaging the flowmeter. If there is no |

|

|

|

|

|

|

|

bypass-piping, install short pipe instead of the flowmeter. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Short pipe |

||

|

|

|

|

|

|

|

|

F020102-2.EPS

2-3 |

IM 1F6A0-01E |

2.3Precautions Regarding Installation

WARNING

In case of high process temperature, care should be taken not to burn yourself because the surface of body and case reach a high temperature.

(1)Gas or Steam Measuring Precautions

•Piping to Prevent Standing Liquid

Mount digitalYEWFLO in a vertical pipeline to avoid liquid traps. When digitalYEWFLO is installed horizontally, raise that part of the pipeline in which the digitalYEWFLO is installed.

(Good)

(Good) |

|

|

|

|

|

|

|

|

Flow |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Flow

(No Good)

Flow

F020301.EPS

Figure 2.2

(2) Liquid Measurement Precautions

To insure accurate measurement, the digitalYEWFLO

must always have a full pipe.

•Piping Requirements for Proper Operation

Allow the flow to flow against gravity. When the flow is moving with gravity, lift the down-stream pipe length above the digitalYEWFLO installation level to maintain full pipeline.

Flow

|

|

|

|

|

(No Good) |

|

|

(No Good) |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Flow |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Good) |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

h h>0 |

|||||||||||

|

|

|

|

|

|

|

|

|

(Good) |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

h |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Flow |

|

|

|

|

Flow |

|

|

|

|

h>0 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

F020302.EPS |

|||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Figure 2.3

2. INSTALLATION

•Piping for Avoiding Bubbles

Flows containing both gas and liquid cause problems. Avoid gas bubbles in a liquid flow. Piping should be carried out to avoid bubble generation.

Install the valve on the downstream side of the flowmeter because pressure drop across the control valve may cause gas to come out of the solution.

|

|

|

|

|

(Good) |

|

|

|

(No Good) |

|

Control |

|

||

|

|

|

|

|

|

|

Value |

|

|

Flow

(Good)

Flow

Flow

F020303.EPS

Figure 2.4

(3) Multi-Phase Flow

digitalYEWFLO can measure gas, liquid and steam when there is no change in state. However, accurate measurement of mixed flows (e.g. gas and liquid) is not possible.

(No Good)

Mist flow (No Good)

Liquid

Flow

Stratified flow (No Good)

Gas Flow

Bubble flow

F020304.EPS

Figure 2.5

2-4 |

IM 1F6A0-01E |

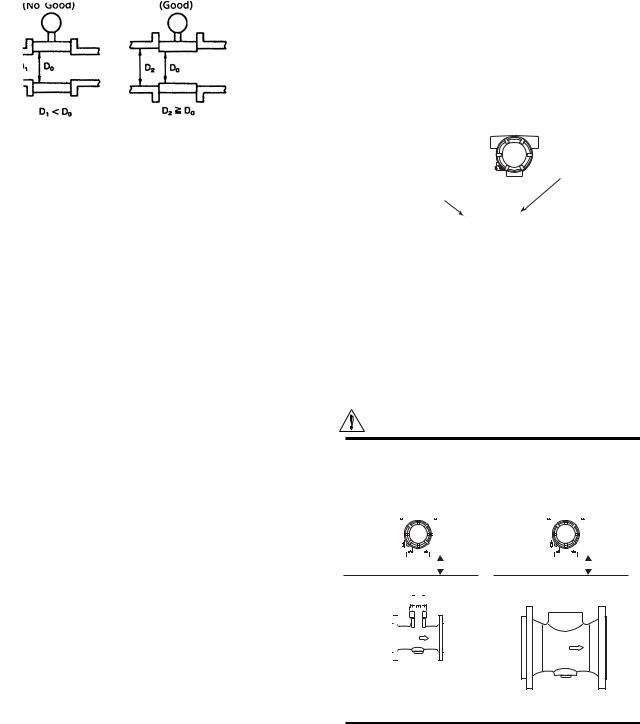

(4) Pipeline Diameter and digitalYEWFLO

The process pipeline inner diameter should be slightly larger than the vortex flowmeter inner diameter, schedule 40 or lower pipe should be used for 1/2 to 2 inch flowmeters and schedule 80 or lower pipes for 3 to 8 inch flowmeters.

(No Good) |

|

(Good) |

D1 |

|

D2 |

|

|

D1 |

|

D2 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

D1 < D2 |

|

|

|

|

||||

|

|

|

|

|

D1 D2 |

|||||

F020305.EPS

Figure 2.6

(5) Waterproof Construction

The vortex flowmeter is of IP67, NEMA4X

tightprotection. However, it cannot be used under water.

2.4 Piping to Improve Durability

(1) Pipe cleaning

•Flushing of pipe line (Cleaning)

Flush and clean scale, incrustation and sludge on the inside of pipe wall for newly installed pipe line and repaired pipe line before the operation.

•Fluid Carrying Solids

Do not measure fluids that carry solids (e.g. sand and pebbles). Make sure users periodically remove solids adhering to the vortex shedder.

•Obstruction of flow fluids may cause to make a chemical reaction and the fluid will be crystallized and hardened, and be deposited on the pipe wall and shedder bar.

In those cases, clean shedder bar.

(2) Bypass piping

Installing a bypass, as illustrated in the figure below, permits the digitalYEWFLO to be checked or cleaned conveniently (vortex shedder, etc.).

Bypass shut-off valve

digitalYEWFLO

Flow

Upstream shut-off valve |

|

Downstream shut-off valve |

F020401.EPS

Figure 2.7

2.5Cryogenic and High process Temperature Version Insulation

When you are using cryogenic type and high process temperature version of digitalYEWFLO Vortex Flowmeter (Option code/HT /LT), refer to illustrated insulation method as shown in Figure 2.8

2. INSTALLATION

(1) Installing Cryogenic Vortex Flowmeter

For cryogenic applications, use stainless steel mounting bolts and nuts to install the flowmeter. These can be ordered separately from YOKOGAWA. Cover the flowmeter body with heat insulating material so that the flowmeter can be maintained at ultra-low temperatures (refer to the Figure 2.8).

(2) Maintenance for Cryogenic Applications

DY/LT uses special materials that produce vortex flowmeter for cryogenic applications. When you are replacing a shedder bar, specify cryogenic type shedder bar. To avoid condensing in the terminal box, ensure that the wire connecting port is well sealed.

Bracket

Cold insulating material

F020501.EPS

Figure 2.8

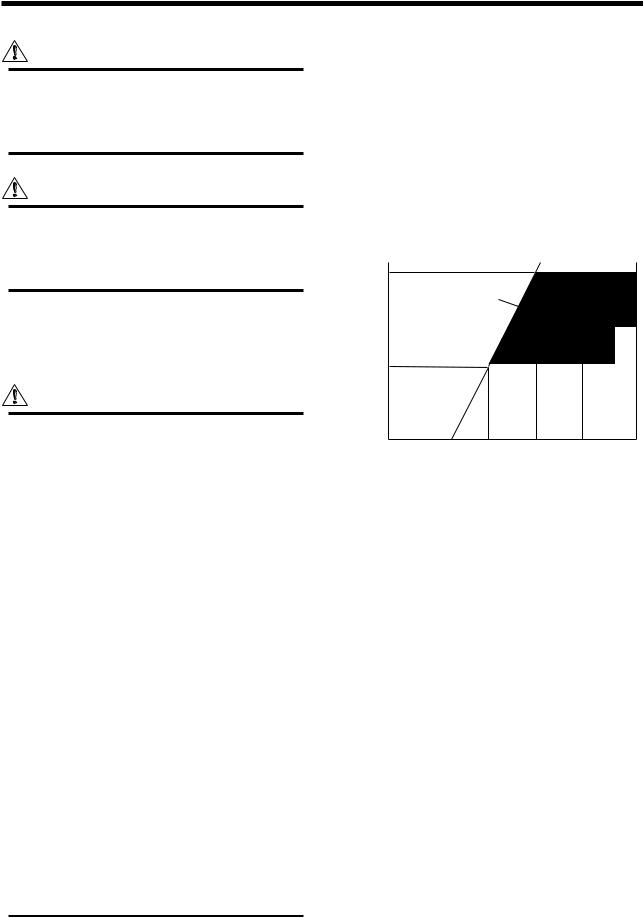

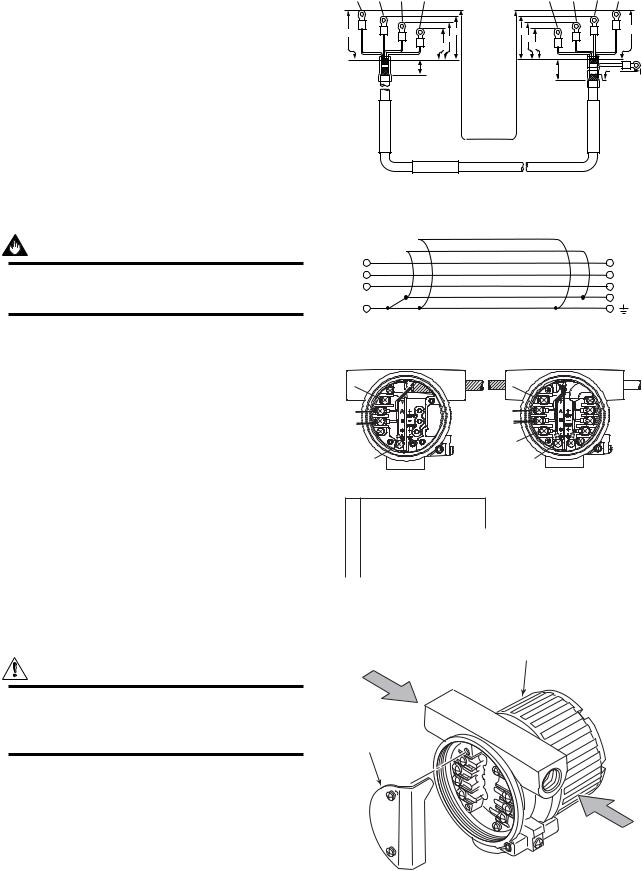

(3)Installing High Process Temperature Vortex Flowmeter

Installation of the flowmeter is the same as the standard type. Cover the flowmeter body with heat insulating material following instruction of “CAUTION”.

CAUTION

Keep the upper limit of heat insulating material to prevent overheating of the terminal box.

Seal the heat insulating material to avoid hot-air leakage.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50mm min. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50mm min. |

||

UPPER LIMIT OF |

|

|

|

|

|

|

|

|

|

|

|

|

UPPER LIMIT OF |

|

|

|

|

|

|

|

|

|

|

|||||||||||

HEAT INSULATING |

|

|

|

|

|

|

|

|

|

|

|

|

HEAT INSULATING |

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

MATERIAL |

|

|

|

|

|

|

|

|

|

|

|

|

MATERIAL |

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nominal Size: 100mm or under

Nominal Size: 150mm or over

F020501a.EPS

(4)Maintenance for High Process Temperature Applications

DY/HT uses special materials that produce vortex flowmeter for High Process Temperature applications When you are replacing a shedder bar or a gasket, specify High Process Temperature type.

2-5 |

IM 1F6A0-01E |

2.6Installing the Vortex Flowmeter

WARNING

The Vortex Flowmeter is a heavy instrument. Please be careful to prevent persons from injuring whin it is handled.

Before installing the instrument verify the following. The direction of flow should match to the arrow mark on the instrument body. When changing the orientation of the terminal box, refer to "7.1."

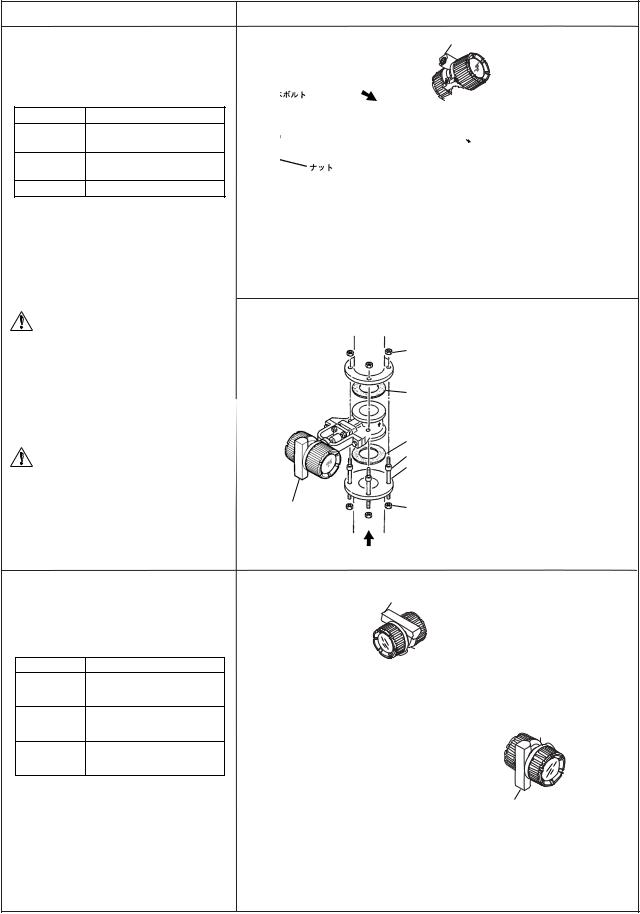

Installation of Vortex flowmeter of the wafer and flange type is shown in Table 2.3.

When installing the wafer type vortex flowmeter, it is important to align the instrument bore with the inner diameter of the adjacent piping.

To establish alignment, use the four collars supplied with the instrument.

1.Four collars are supplied for 1/2 inch (15mm) to 1- 1/ 2inch (40mm), 2 inch of JIS 10K or ANSI class 150 or JPI class 150, and 3 inch of ANSI class 150 or JPI class 150. Install the instrument as illustrated in Table 2.2.

2.If the adjacent flanges have eight bolt holes, insert the stud bolts in the holes on the instrument shoulder. Refer to Figure 2.9.

Stainless steel stud bolts and nuts are available on order. When they are to be supplied by the user, refer to Table 2.2 for stud bolt length. Gaskets must be supplied by the user.

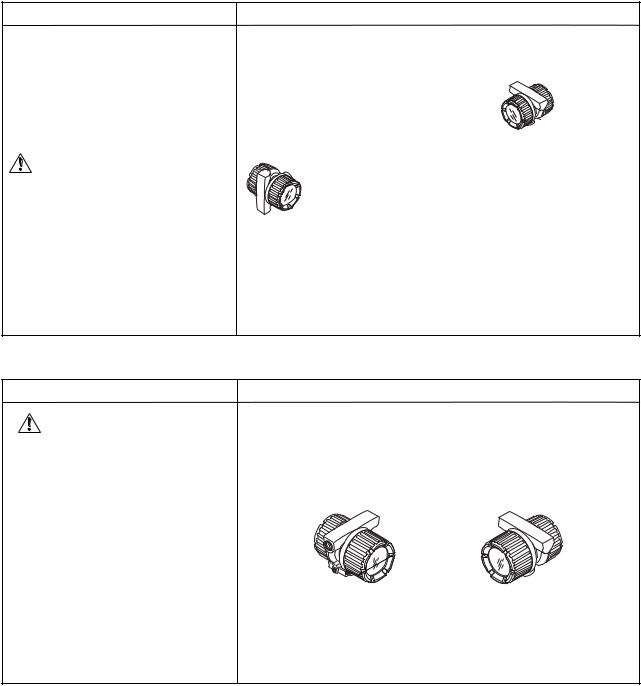

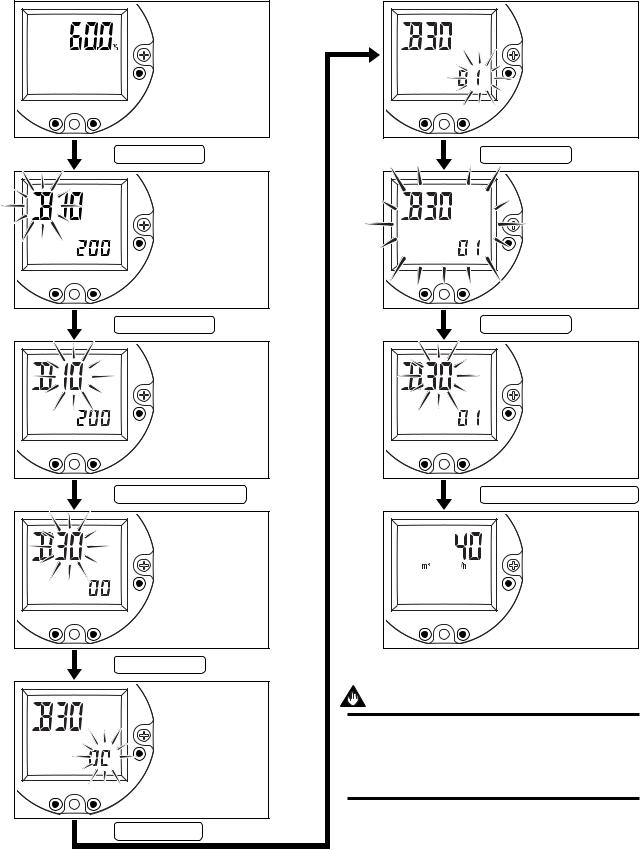

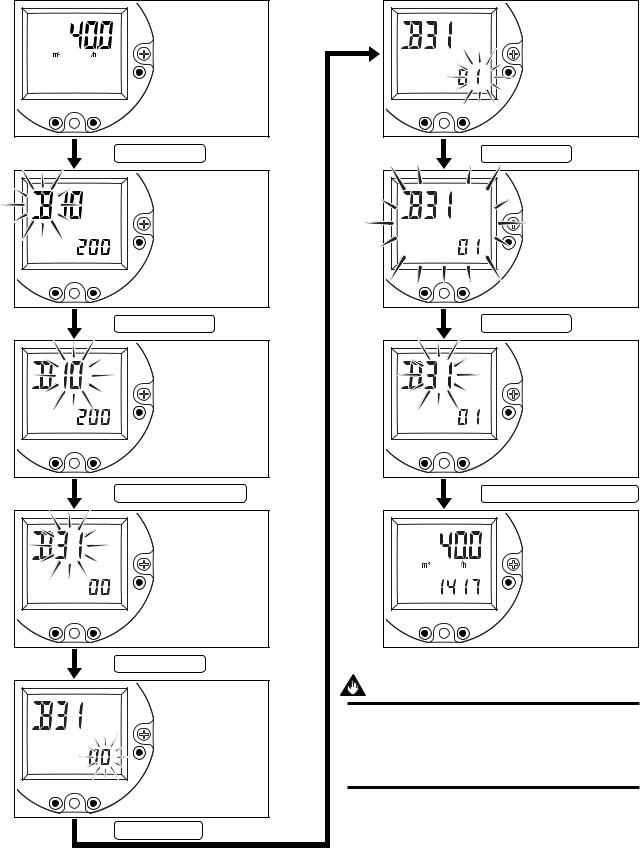

3.Gasket: