Yokogawa ISC202 User Manual

User’s

Manual

Model ISC202G [Style: S2], ISC202S [Style: S3]

2-wire Inductive Conductivity

Transmitter

IM 12D06A03-01E

7th Edition

IM 12D06A03-01E

IM 12D06A03-01E

IM 12D06A03-01E

7th Edition: Oct. 2009(YK)

All Rights Reserved, Copyright © 2001, Yokogawa Electric Corporation

TABLE OF CONTENTS

PREFACE

1. Introduction And General Description ............................................................. 1-1

1-1. Instrument check ............................................................................................ 1-1

1-2. Application ...................................................................................................... 1-3

2. GENERAL SPECIFICATIONS ............................................................................. 2-1

2-1. Specifications .................................................................................................. 2-1

2-2. Model and suffix codes ................................................................................... 2-6

2-3. Control Drawing ISC202S mA HART

®

Specification (IECEx). ....................... 2-7

2-4. Control Drawing ISC202S mA HART

®

Specification (ATEX) ......................... 2-8

2-5. Control Drawing ISC202S mA HART

®

Specification

(FM Intrinsically safe design) ........................................................................... 2-9

2-6. Control Drawing ISC202S mA HART

®

Specification

(FM Non-incendive design) ............................................................................ 2-10

2-7. Control Drawing of ISC202S mA HART

®

Specification (CSA) ......................2-11

2-8. Control Drawing of ISC202S FF/PB Specification (IECEx) .......................... 2-12

2-9. Control Drawing of ISC202S FF/PB Specification (ATEX) ........................... 2-13

2-10. Control Drawing of ISC202S FF/PB Specification

(FM Intrinsically safe Entity) ........................................................................... 2-14

2-11. Control Drawing of ISC202S FF/PB Specification

(FM Intrinsically safe FISCO) ......................................................................... 2-16

2-12. Control Drawing of ISC202S FF/PB Specification

(FM Non-incendive Entity) ............................................................................. 2-18

2-13. Control Drawing of ISC202S FF/PB Specification

(FM Non-incendive FNICO) ........................................................................... 2-19

2-14. Control Drawing of ISC202S FF/PB Specification (CSA) ........................... 2-20

3. Installation And Wiring....................................................................................... 3-1

3-1. Installation and dimensions ............................................................................ 3-1

3-1-1. Installation site .................................................................................................................3-1

3-1-2. Mounting methods ...........................................................................................................3-1

3-2. Preparation ..................................................................................................... 3-2

3-2-1. Cables, terminals and glands ..........................................................................................3-2

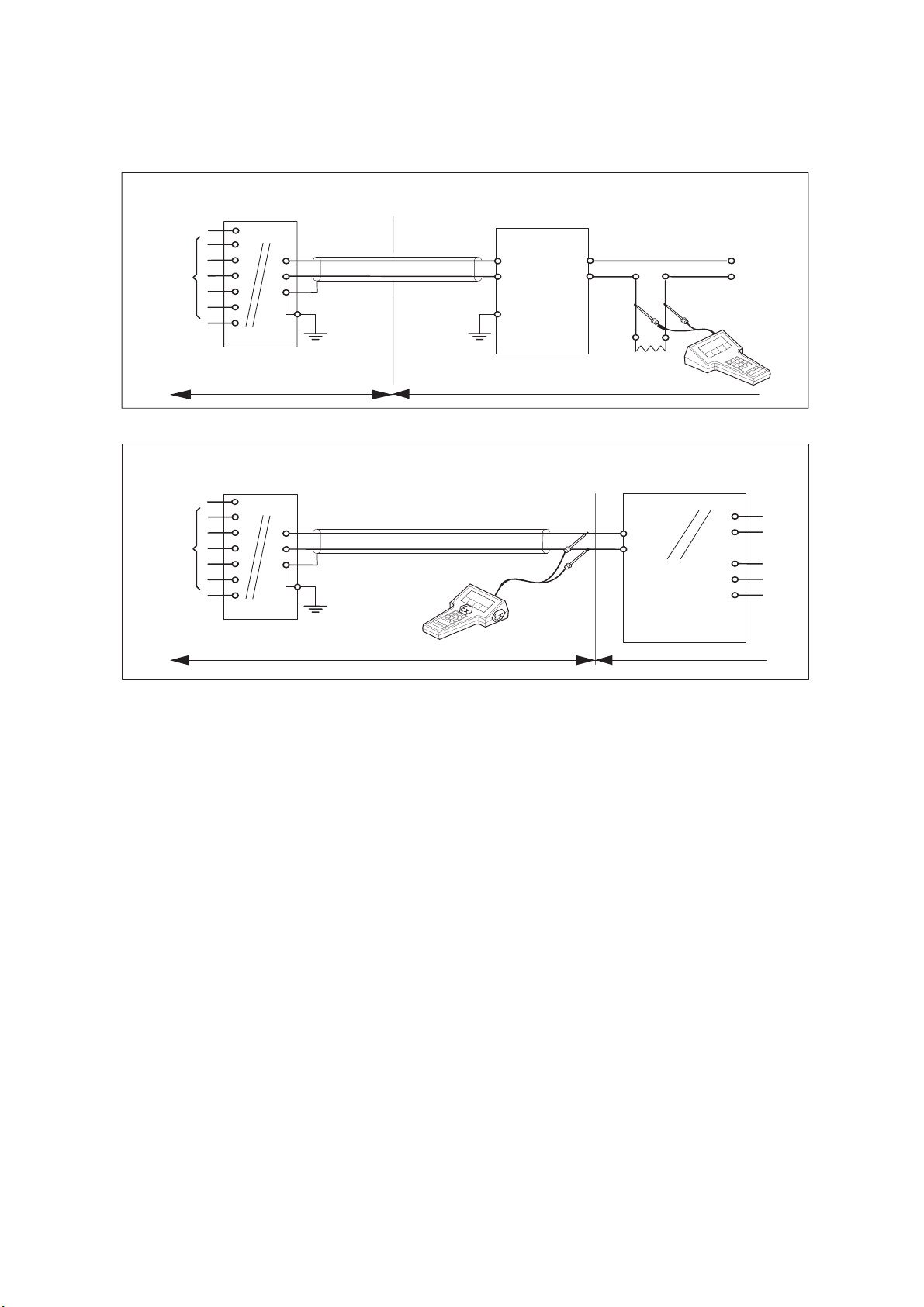

3-3. Wiring of sensors ............................................................................................ 3-3

3-3-1. General precautions ........................................................................................................3-3

3-3-2. Additional precautions for installations in hazardous areas ...........................................3-3

3-3-3. Installation in: Hazardous Area-Non-Incendive ..............................................................3-3

3-4 Wiring of the power supply .............................................................................. 3-4

3-4-1 General precautions .........................................................................................................3-4

3-4-2. Connection of the power supply ......................................................................................3-4

3-4-3. Switching the instrument on ............................................................................................3-4

3-5. Sensor wiring .................................................................................................. 3-4

3-6. Other sensor systems ..................................................................................... 3-5

3-6-1. Sensor cable connections using junction box (BA10) and extension cable (WF10) .......3-5

4. Operation; Display Functions And Setting ...................................................... 4-1

4-1. Operator interface ........................................................................................... 4-1

4-2. Explanation of operating keys ......................................................................... 4-2

4-3. Setting passcodes .......................................................................................... 4-3

4-3-1. Passcode protection ........................................................................................................4-3

4-4. Display examples ............................................................................................ 4-3

4-5. Display functions ............................................................................................. 4-4

IM 12D06A03-01E

5. Parameter setting ............................................................................................... 5-1

5-1. Maintenance mode ......................................................................................... 5-1

5-1-1. Introduction ......................................................................................................................5-1

5-1-2. Manual calibration to determine the cell constant (C.C.) ................................................5-2

5-1-3. Second Line display. Referring to the first compensated conductivity. ...........................5-3

5-1-4. Second Line display. Referring to the second compensated conductivity. .....................5-4

5-1-5. Manual activation of HOLD ............................................................................................5-5

5-2. Commissioning mode ..................................................................................... 5-6

5-2-1. Linear output (Range) ......................................................................................................5-7

5-2-2. HOLD ..............................................................................................................................5-8

5-2-3. Temperature compensation .............................................................................................5-9

5-2-4. Temperature compensation for first conductivity value .................................................5-11

5-2-5. Temperature Compensation for second conductivity value ..........................................5-12

5-3.Service Codes ............................................................................................... 5-13

5-3-1. Parameter specific functions .........................................................................................5-13

5-3-2. Temperature measuring functions .................................................................................5-13

5-3-3. Temperature compensation functions ...........................................................................5-14

5-3-4. mA output functions .......................................................................................................5-16

5-3-5. User interface ................................................................................................................5-18

5-3-6. Communication setup ....................................................................................................5-19

5-3-7. General .........................................................................................................................5-19

6. Calibration ....................................................................................................... 6-1

6-1 When is calibration necessary? ....................................................................... 6-1

6-2. Calibration procedure ..................................................................................... 6-2

7. Maintenance ....................................................................................................... 7-1

7-1. Periodic maintenance for the EXA 202 transmitter ......................................... 7-1

7-2. Periodic maintenance of the sensor ............................................................... 7-1

8. Troubleshooting ................................................................................................. 8-1

8-1. Introduction ..................................................................................................... 8-1

8-2. Self diagnostics of the conductivity sensor ..................................................... 8-1

8-3. Self diagnostics of the temperature sensor .................................................... 8-1

8-4. Self diagnostics of the electronics .................................................................. 8-1

8-5. Checking during operation .............................................................................. 8-1

9. Error messages and explanation ...................................................................... 9-1

10. Spare Parts ..................................................................................................... 10-1

11. Appendix 1 ....................................................................................................... 1-1

11-1. User setting for non-linear output table (code 31, 35) ................................... 1-1

11-2. User entered matrix data (code 23 to 28) ..................................................... 1-1

11-3. Matrix data table (user selectable in code 22) .............................................. 1-2

11-4. Configuration Checklist For ISC202 ............................................................. 1-3

11-5. Coded service settings (default) ................................................................... 1-3

11-6. Device Description (DD) menu structure ...................................................... 1-4

IM 12D06A03-01E

In this manual a

mA

sign appears if it concerns the ISC202G-A and ISC202S-A, -N, -K.

12. APPENDIX 2 ...................................................................................................... 2-1

12-1. Preface ....................................................................................................... 2-1

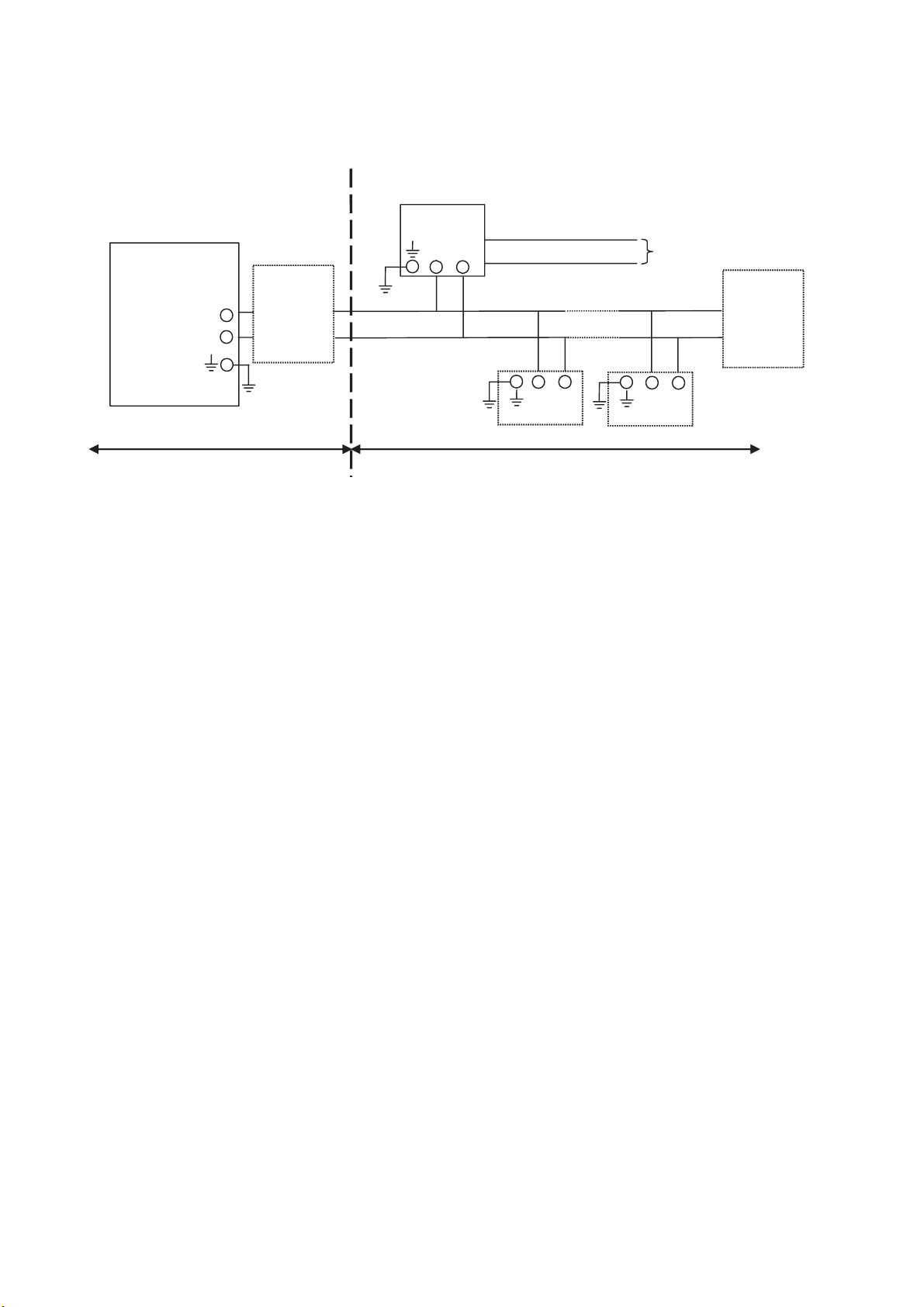

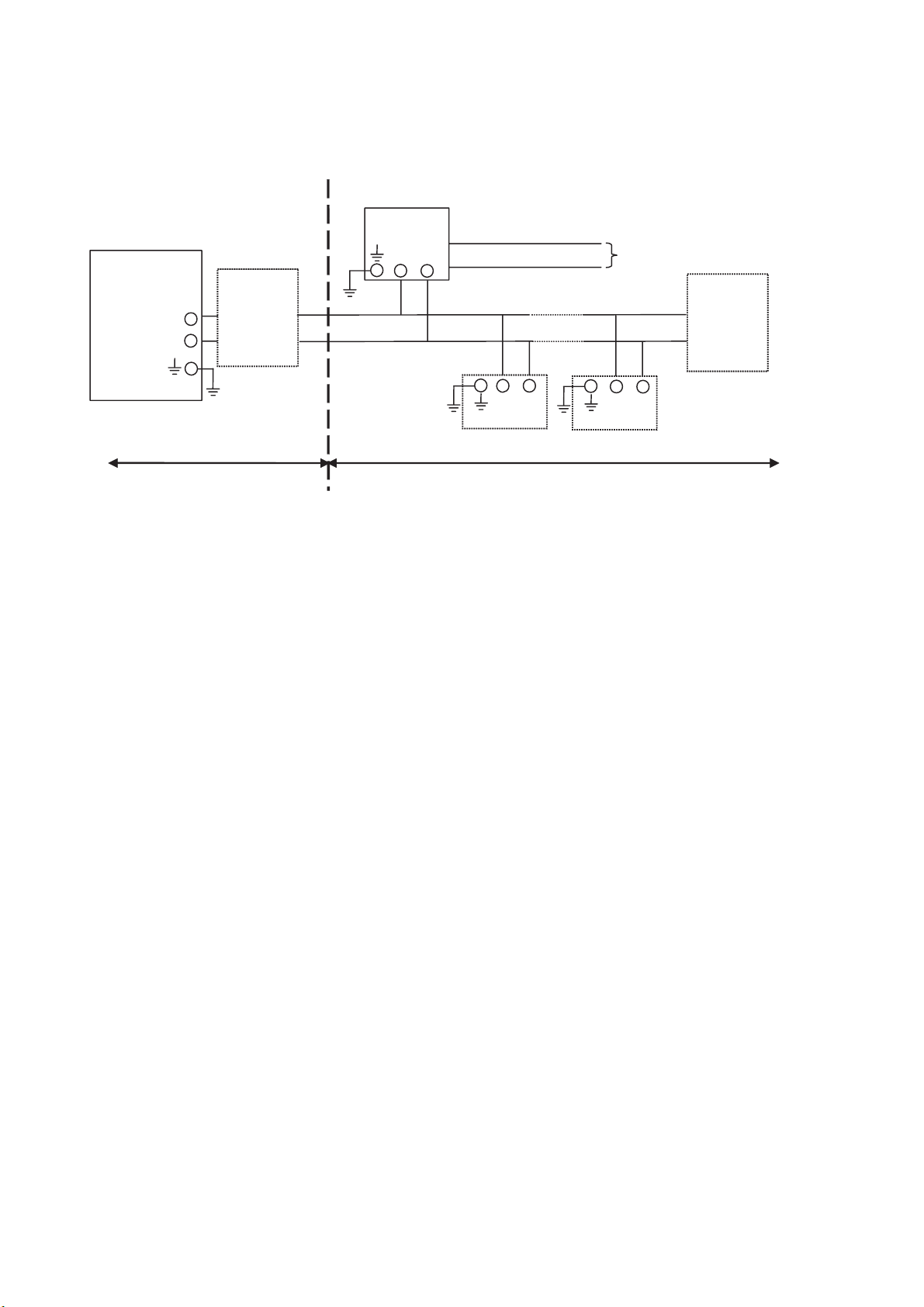

12-2. Wiring diagrams ............................................................................................ 2-1

12-3. Peripheral products ....................................................................................... 2-2

12-3-1. PH201G*B Dedicated Distributor .................................................................................2-2

12-3-2. BA20 Junction Terminal Box ........................................................................................2-3

12-3-3. WF10J Extension Cable ...............................................................................................2-4

12-4. Quick reference for parameter setting ......................................................... 2-5

12-4-1. Settings Performed in Maintenance Mode ................................................ 2-6

12-4-1-1 Calibration with solution of known conductivity ..................................... 2-6

12-4-1-2 Selecting Items for Display ......................................................................................2-6

12-4-2. Commissioning Mode Settings ............................................................... 2-7

12-4-2-1 Output Range Setting ...............................................................................................2-7

12-4-2-2 Setting Hold Functions ..............................................................................................2-7

12-4-2-3 Temperature Compensation ....................................................................................2-8

12-4-2-4 Correcting Zero Offset Error by Calibration in Air (Air Set) .......................................2-8

12-4-3. Actual Setting Examples ........................................................................ 2-9

12-4-3-1 Setting Output in terms of Concentration ..............................................................2-10

12-4-3-2 Key Operation Procedure Examples ......................................................................2-15

12-5. Installation factor adjustment ..................................................................... 2-19

13. Appendix 3 QUALITY INSPECTION ................................................................. 3-1

13-1. ISC202G 2-Wire Inductive Conductivity Transmitter .................................... 3-1

13-2. ISC202S 2-Wire Inductive Conductivity Transmitter ..................................... 3-6

13-3. ISC202G, ISC202S 2-Wire Inductive Conductivity Transmitter

(Fieldbus Communication) ..............................................................................3-11

13-4. ISC202G, ISC202S 2-Wire Inductive Conductivity Transmitter

(Profibus Communication) ............................................................................. 3-15

Customer Maintenance Parts List for ISC202G (Style : S2)

.......CMPL12D06A03-02E

Customer Maintenance Parts List for ISC202S (Style : S3) ...CMPL12D06A03-23E

Revision Record ..........................................................................................................i

IM 12D06A03-01E

PREFACE

Electric discharge

The EXA analyzer contains devices that can be

damaged by electrostatic discharge. When servicing

this equipment, please observe proper procedures

to prevent such damage. Replacement components

should be shipped in conductive packaging. Repair

work should be done at grounded workstations using

grounded soldering irons and wrist straps to avoid

electrostatic discharge.

Installation and wiring

The EXA analyzer should only be used with equip-

ment that meets the relevant international and

regional standards. Yokogawa accepts no responsi-

bility for the misuse of this unit.

The instrument is packed carefully with shock

absorbing materials, nevertheless, the instrument

may be damaged or broken if subjected to strong

shock, such as if the instrument is dropped. Handle

with care.

Although the instrument has a weatherproof

construction, the transmitter can be harmed if it

becomes submerged in water or becomes exces-

sively wet.

Do not use an abrasive material or solvent when

cleaning the instrument.

Do not modify the ISC202 transmitter.

Electrostatic charge may cause an explosion hazard.

Avoid any actions that cause the generation of elec-

trostatic charge, e.g., rubbing with a dry cloth.

Warning label

Because the enclosure of the Dissolved Oxygen

transmitter Type ISC202S-A, -P, -F are made of alu-

minium, if it is mounted in an area where the use of

category 1 G Zone 0 apparatus is required, it must

be installed such, that, even in the event of rare

incidents, ignition sources due to impact and friction

sparks are excluded.

DANGERDANGER

CAUTIONCAUTION

WARNING

WARNING

Notice

• This manual should be passed on to the end

user.

• The contents of this manual are subject to

change without prior notice.

• The contents of this manual shall not be

reproduced or copied, in part or in whole,

without permission.

• This manual explains the functions contained in

this product, but does not warrant that they are

suitable the particular purpose of the user.

• Every effort has been made to ensure accuracy

in the preparation of this manual.

However, when you realize mistaken

expressions or omissions, please contact the

nearest Yokogawa Electric representative or

sales office.

• This manual does not cover the special

specifications. This manual may be left

unchanged on any change of specification,

construction or parts when the change does

not affect the functions or performance of the

product.

• If the product is not used in a manner specified

in this manual, the safety of this product may be

impaired.

Yokogawa is not responsible for damage to the

instrument, poor performance of the instrument

or losses resulting from such, if the problems are

caused by:

• Improper operation by the user.

• Use of the instrument in improper applications

• Use of the instrument in an improper

environment or improper utility program

• Repair or modification of the related instrument

by an engineer not authorized by Yokogawa.

Safety and Modification Precautions

• Follow the safety precautions in this manual

when using the product to ensure protection and

safety of the human body, the product and the

system containing the product.

IM 12D06A03-01E

The following safety symbols are used on the

product as well as in this manual.

DANGER

This symbol indicates that an operator must

follow the instructions laid out in this manual in

order to avoid the risks, for the human body, of

injury, electric shock, or fatalities. The manual

describes what special care the operator must

take to avoid such risks.

This symbol indicates that the operator must

refer to the instructions in this manual in

order to prevent the instrument (hardware) or

software from being damaged, or a system

failure from occurring.

This symbol gives information essential for

understanding the operations and functions.

This symbol indicates Protective Ground

Terminal

This symbol indicates Function Ground

Terminal (Do not use this terminal as the

protective ground terminal.)

This symbol indicates Alternating current.

This symbol indicates Direct current.

DANGERDANGER

WARNINGWARNING

CAUTIONCAUTION

Warranty and service

Yokogawa products and parts are guaranteed

free from defects in workmanship and material

under normal use and service for a period of

(typically) 12 months from the date of shipment

from the manufacturer. Individual sales organi-

zations can deviate from the typical warranty

period, and the conditions of sale relating to the

original purchase order should be consulted.

Damage caused by wear and tear, inadequate

maintenance, corrosion, or by the effects of

chemical processes are excluded from this war-

ranty coverage.

In the event of warranty claim, the defective

goods should be sent (freight paid) to the service

department of the relevant sales organization for

repair or replacement (at Yokogawa discretion).

The following information must be included in the

letter accompanying the returned goods:

• Part number, model code and serial number

• Original purchase order and date

• Length of time in service and a description of

the process

• Description of the fault, and the circumstances

of failure

• Process/environmental conditions that may be

related to the installation failure of the device

• A statement whether warranty or non-warranty

service is requested

• Complete shipping and billing instructions for

return of material, plus the name and phone

number of a contact person who can be

reached for further information.

Returned goods that have been in contact with

process fluids must be decontaminated/disin-

fected before shipment. Goods should carry a

certificate to this effect, for the health and safety

of our employees. Material safety data sheets

should also be included for all components of

the processes to which the equipment has been

exposed.

IM 12D06A03-01E

ATEX Documentation

This procedure is only applicable to the countries

in European Union.

GB

All instruction manuals for ATEX Ex related prod-

ucts are available in English, German and French.

Should you require Ex related instructions in your

local language, you are to contact your nearest

Yokogawa office or representative.

DK

Alle brugervejledninger for produkter relateret

til ATEX Ex er tilgængelige på engelsk, tysk og

fransk. Skulle De ønske yderligere oplysninger

om håndtering af Ex produkter på eget sprog, kan

De rette henvendelse herom til den nærmeste

Yokogawa afdeling eller forhandler.

I

Tutti i manuali operativi di prodotti ATEX con-

trassegnati con Ex sono disponibili in inglese,

tedesco e francese. Se si desidera ricevere i man-

uali operativi di prodotti Ex in lingua locale, met-

tersi in contatto con l’ufficio Yokogawa più vicino o

con un rappresentante.

E

Todos los manuales de instrucciones para los pro-

ductos antiexplosivos de ATEX están disponibles

en inglés, alemán y francés. Si desea solicitar las

instrucciones de estos artículos antiexplosivos en

su idioma local, deberá ponerse en contacto con

la oficina o el representante de Yokogawa más

cercano.

NL

Alle handleidingen voor producten die te maken

hebben met ATEX explosiebeveiliging (Ex)

zijn verkrijgbaar in het Engels, Duits en Frans.

Neem, indien u aanwijzingen op het gebied van

explosiebeveiliging nodig hebt in uw eigen taal,

contact op met de dichtstbijzijnde vestiging van

Yokogawa of met een vertegenwoordiger.

SF

Kaikkien ATEX Ex -tyyppisten tuotteiden käyt-

töhjeet ovat saatavilla englannin-, saksan- ja

ranskankielisinä. Mikäli tarvitsette Ex -tyyppisten

tuotteiden ohjeita omalla paikallisella kielellännne,

ottakaa yhteyttä lähimpään Yokogawa-toimistoon

tai -edustajaan.

P

Todos os manuais de instruções referentes aos

produtos Ex da ATEX estão disponíveis em Inglês,

Alemão e Francês. Se necessitar de instruções na

sua língua relacionadas com produtos Ex, deverá

entrar em contacto com a delegação mais próxima

ou com um representante da Yokogawa.

F

Tous les manuels d’instruction des produits

ATEX Ex sont disponibles en langue anglaise,

allemande et française. Si vous nécessitez des

instructions relatives aux produits Ex dans votre

langue, veuillez bien contacter votre représentant

Yokogawa le plus proche.

D

Alle Betriebsanleitungen für ATEX Ex bezogene

Produkte stehen in den Sprachen Englisch,

Deutsch und Französisch zur Verfügung. Sollten

Sie die Betriebsanleitungen für Ex-Produkte in

Ihrer Landessprache benötigen, setzen Sie sich

bitte mit Ihrem örtlichen Yokogawa-Vertreter in

Verbindung.

S

Alla instruktionsböcker för ATEX Ex (explosions-

säkra) produkter är tillgängliga på engelska, tyska

och franska. Om Ni behöver instruktioner för

dessa explosionssäkra produkter på annat språk,

skall Ni kontakta närmaste Yokogawakontor eller

representant.

GR

IM 12D06A03-01E

LT

LV

PL

EST

SLO

H

BG

RO

M

CZ

SK

IM 12D06A03-01E

Introduction 1-1

1. INTRODUCTION AND GENERAL DESCRIPTION

The Yokogawa EXA 202 is a 2-wire transmitter designed for industrial process monitoring, measurement

and control applications. This user’s manual contains the information needed to install, set up, operate

and maintain the unit correctly. This manual also includes a basic troubleshooting guide to answer typi-

cal user questions.

Yokogawa can not be responsible for the performance of the EXA transmitter if these instructions are not

followed.

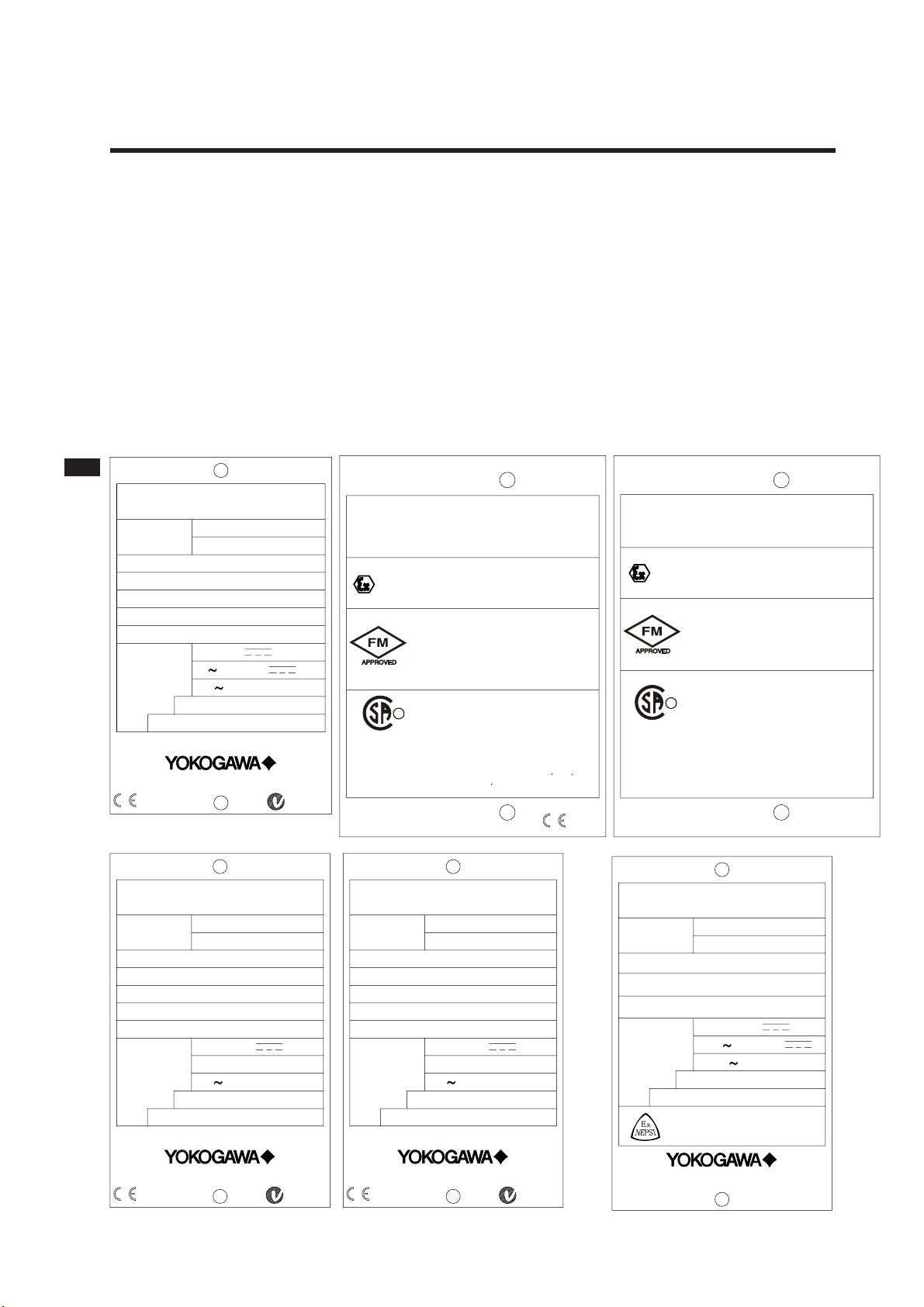

1-1. Instrument check

Upon delivery, unpack the instrument carefully and inspect it to ensure that it was not damaged during

shipment. If damage is found, retain the original packing materials (including the outer box) and then

immediately notify the carrier and the relevant Yokogawa sales office.

Make sure the model number on the textplate affixed to the side of the instrument agrees with your

order. Examples of nameplates are shown below.

No. IECEx KEM 06.0054X

ISC202S-N

II 3 G

Ex nA[nL] IIC T4

Ex nA[nL] IIC T6 for Ta:40

°C

IP65

SEE CONTROL DRAWING

No. KEMA 06ATEX0223

EEx nA[nL] IIC T4

EEx nA[nL] IIC T6 for Ta:40

°C

IP65

SEE CONTROL DRAWING

NI CL I, DIV 2, GP ABCD AND

CL I, ZN 2, GP IIC

T4

WARNING

Substitution of

components may

impair suitability

for class I, Division 2.

AVERTISSEMENT

La substitution de composants

peut rendre ce materiel

inacceptable pour les

emplacements de

Classe I, Division 2.

Ex nA[nL] IIC

NI CL I, DIV 2, GP ABCD

T4

T6 for Ta:40

°C

SEE CONTROL DRAWING

LR81741 C

R

Type 4X

Install per CONTROL DRAWING

IKE028-A10 P.7 to P.8

IP65 Type 3S

N200

MODEL

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

STYLE

ISC202

-10 55°C

4 20mA DC

Made in Japan Tokyo 180-8750 JAPAN

No.

24V DC

ISC TRANSMITTER

No. IECEx KEM 06.0054X

ISC202S-A

No. KEMA 06ATEX0222 X

Ex ia IIC T4

Ex ia IIC T6 for Ta:40

°C

SEE CONTROL DRAWING

IS CL I, DIV 1, GP ABCD

AND AEx ia IIC

T4

Zone 0 Ex ia IIC T4

Zone 0 Ex ia IIC T6 for Ta:40

°C

IP65

SEE CONTROL DRAWING

II 1G

LR81741 C

CL I, DIV 1, GP ABCD

Ex ia IIC T4

Ex ia IIC T6 for Ta:40

°C

SEE CONTROL DRAWING

WARNING

Substitution of

components may impair

intrinsic safety

AVERTISSEMENT

intrinseque.

peut compromeltre la securite

La substitution de composants

R

IP65

Type 4X

Install per CONTROL DRAWING

IKE028-A10 P.5 to P.6

IP65 Type 3S

0344

Figure 1-1. Nameplate

mA

N200

MODEL

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

STYLE

ISC202G-F

-10 55°C

FF-TYPE113

Made in Japan Tokyo 180-8750 JAPAN

No.

9 TO 32VDC

DISSOLVED OXYGEN TRANSMITTER

N200

MODEL

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

STYLE

ISC202G-P

-10 55°C

PROFIBUS-PA

Made in Japan Tokyo 180-8750 JAPAN

No.

9 TO 32VDC

DISSOLVED OXYGEN TRANSMITTER

MODEL

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

STYLE

Made in Japan Tokyo 180-8750 JAPAN

No.

24V DC

-10 55°C

4 20mA DC

ISC202S-K

SEE USER’S MANUAL BEFORE USE

Ex ia IIC T6 for Ta:40

˚C

Ex ia IIC T4

Cert No. GYJ081158X

ISC TRANSMITTER

IM 12D06A03-01E

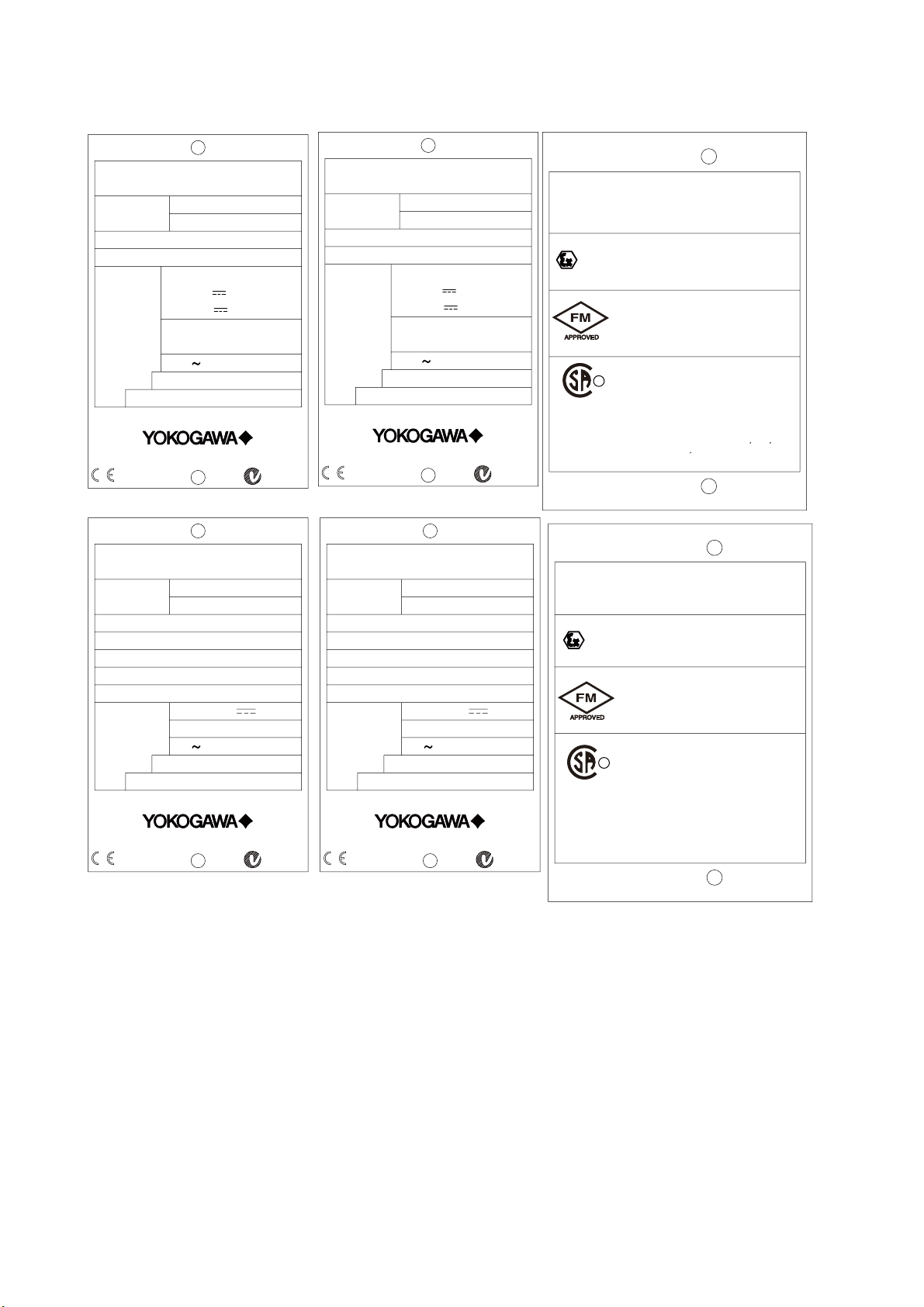

1-2 Introduction

NOTE:

Check that all the parts are present, including mounting hardware, as specified in the option codes

at the end of the model number. For a description of the model codes, refer to Section 2 of this

manual under General Specifications.

Basic Parts List: Transmitter ISC202

User’s Manual English

Optional mounting hardware when specified (See model code)

Figure 1-2. Nameplate

N200

MODEL

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

STYLE

ISC202S-B

-10 55°C

FF-TYPE 113

Made in Japan Tokyo 180-8750 JAPAN

No.

9 TO 32VDC

ISC TRANSMITTER

N200

MODEL

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

STYLE

ISC202S-D

-10 55°C

PROFIBUS-PA

Made in Japan Tokyo 180-8750 JAPAN

No.

9 TO 32VDC

ISC TRANSMITTER

No.

ISC202S-B/-D

II 3 G

Ex nA[nL] IIC T4

Ex nA[nL] IIC T6 for Ta:40

°C

IP65

SEE CONTROL DRAWING

No.

EEx nA[nL] IIC T4

EEx nA[nL] IIC T6 for Ta:40

°C

IP65

SEE CONTROL DRAWING

NI CL I, DIV 2, GP ABCD AND

CL I, ZN 2, GP IIC

T4

WARNING

Substitution of

components may

impair suitability

for class I, Division 2.

AVERTISSEMENT

La substitution de composants

peut rendre ce materiel

inacceptable pour les

emplacements de

Classe I, Division 2.

Ex nA[nL] IIC

NI CL I, DIV 2, GP ABCD

T4

T6 for Ta:40

°C

SEE CONTROL DRAWING

LR81741 C

R

Type 4X

Install per CONTROL DRAWING

IKE029-A10 P.9 to P.10

IP65 Type 3S

KEMA 07ATEX0053

IECEx KEM 07.0028X

FNICO field device

N200

MODEL

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

STYLE

ISC202S-F

-10 55°C

Made in Japan Tokyo 180-8750 JAPAN

No.

FISCO

17.5VDC

or 24VDC

/380mA/5.32W

/250mA/1.2W

FF-TYPE111 or 511

Li=0 μH, Ci=220pF

0344

ISC TRANSMITTER

N200

MODEL

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

STYLE

ISC202S-P

-10 55°C

Made in Japan Tokyo 180-8750 JAPAN

No.

FISCO

17.5VDC

or 24VDC

/380mA/5.32W

/250mA/1.2W

PROFIBUS-PA

Li=0 μH, Ci=220pF

0344

ISC TRANSMITTER

No.

ISC202S-F/-P

No.

Ex ia IIC T4

SEE CONTROL DRAWING

IS CL I, DIV 1, GP ABCD

AND AEx ia IIC

T4

Zone 0 Ex ia IIC T4

IP65

SEE CONTROL DRAWING

FISCO field device

II 1G

LR81741 C

CL I, DIV 1, GP ABCD

Ex ia IIC T4

SEE CONTROL DRAWING

WARNING

Substitution of

components may impair

intrinsic safety

AVERTISSEMENT

intrinseque.

peut compromeltre la securite

La substitution de composants

R

Type 4X

Install per CONTROL DRAWING

IKE029-A10 P.5 to P.8

IP65 Type 3S

KEMA 07ATEX0052 X

IECEx KEM 07.0028X

IP65

IM 12D06A03-01E

Introduction 1-3

1-2. Application

The EXA transmitter is intended to be used for continuous on-line measurement in industrial installa-

tions. The unit combines simple operation and microprocessor-based performance with advanced self-

diagnostics and enhanced communications capability to meet the most advanced requirements. The

measurement can be used as part of an automated process control system. It can also be used to indi-

cate dangerous limits of a process, to monitor product quality, or to function as a simple controller for a

dosing/neutralization system.

Yokogawa designed the EXA transmitter to withstand harsh environments. The transmitter may be

installed

either indoors or outside because the IP65 and NEMA 4X housing and cabling glands ensure the unit is

adequately protected. The flexible polycarbonate window on the front door of the EXA allows pushbutton

access to the keypad, thus preserving the water and dust protection of the unit even during routine main-

tenance operations.

A variety of EXA hardware is optionally available to allow wall, pipe, or panel mounting. Selecting a prop-

er installation site will permit ease of operation. Sensors should normally be mounted close to the trans-

mitter in order to ensure easy calibration and peak performance. If the unit must be mounted remotely

from the sensors, WF10 extension cable can be used up to a maximum of 50 mtr (150 feet) with a BA10

junction box.

The EXA is delivered with a general purpose default setting for programmable items. (Default settings

are listed in Section 5 and again in Chapter 11). While this initial configuration allows easy start-up, the

configuration should be adjusted to suit each particular application. An example of an adjustable item is

the type of temperature sensor used. The EXA can be adjusted for two different types of temperature

sensors.

To record such configuration adjustments, write changes in the space provided in Chapter 11 of this

manual. Because the EXA is suitable for use as a monitor, a controller or an alarm instrument, program

configuration possibilities are numerous.

Details provided in this user’s manual are sufficient to operate the EXA with all Yokogawa sensor

systems and a wide range of third-party commercially available probes. For best results, read this manu-

al in conjunction with the corresponding sensor user’s manual.

Yokogawa designed and built the EXA to meet the CE regulatory standards. To assure the user of

continued accurate performance in even the most demanding industrial installations.

IM 12D06A03-01E

1-4 Introduction

IM 12D06A03-01E

Specifications 2-1

2-1. Specifications

A) Input specifications

: One inductive conductivity sensor and one

temperature sensor. Compatible with the

ISC40 series with integrated temperature sen-

sor. ISC202S: use with ISC40S

B) Input range

- Conductivity:

0 to 1999 mS/cm at 25 °C (77˚F)

reference temperature.

- Temperature:

-20 to 140 °C (4 to 284˚F)

- Cable length: max. 60 mtr (200 feet)

10 mtr (35 feet) fixed sensor

cable + 50 mtr (165 feet)

WF10 extension cable.

Influence of cable can be

adjusted by doing an

AIR CAL with the cable

connected to a dry cell.

C) Functional specifications

Accuracy (under reference conditions):

(Output span is 0 – 100 S/cm or more)

- Conductivity :

Linearity : ± (0.4 %FS + 0.3 S/cm)

Repeatability : ± (0.4 %FS + 0.3 S/cm)

- Temperature : ± 0.3ºC (0.6ºF)

Note: The following tolerance is added to the

above performance.

mA output tolerance: ±0.02 mA of

“4-20 mA”

- Step response 8 seconds for 90% (2

decade step).

E) Indicating range:

- Main display 0 to 1999 mS/cm (1

st

compensation)

- Message display 0 to 1999 mS/cm (2

nd

compensation),

Temperature -20 to 140 ºC

(0 to 280 ºF)

Concentration 0 to 100.0%

Temperature

compensation methods

NaCl, T.C., Matrix

mA- Output

Cell constant [cm

-1

]

Reference Temperature (ºC/ºF)

Software Release.

F) Transmission signal:

- General Isolated output of 4-20 mA

DC.Burn up (21 mA) or Burn

down (3.6 mA when HART

®

or distributor comm. is non-

used, 3.9 mA when HART®

or distributor comm. is used)

or pulse of 21 mA to signal

failure.

- Hold Outputs may be set to hold

the last or a fixed value during

maintenance.

G) Transmission range:

- Conductivity Minimum span: 100 S/cm

Maximum span: 1999 mS/cm

Setting value at 4 mA output:

90 % of setting value at 20

mA output

H) Serial Communication:

Bi-directional HART® digital communication

superimposed on the 4-20 mA signal.

I) DD specification

The ISC202G(S) Device Description (DD)

is available enabling communications with

the hand held communicator and compatible

devices. For more information contact your

local Yokogawa sales offices.

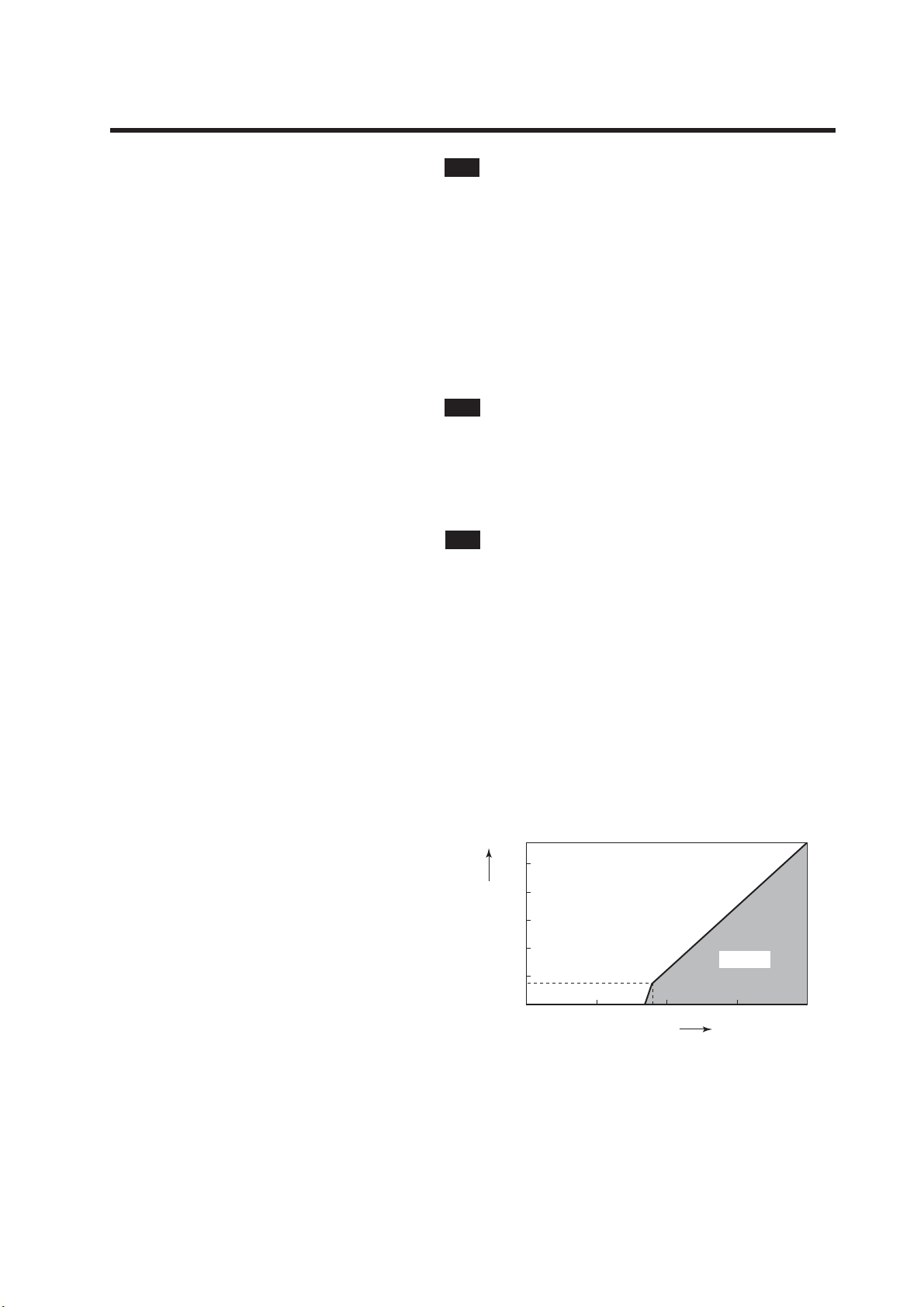

Maximum load resistance :

For the ISC202G, see figure 2-1.

200 or less with the PH201G

50 or less with the SDBT

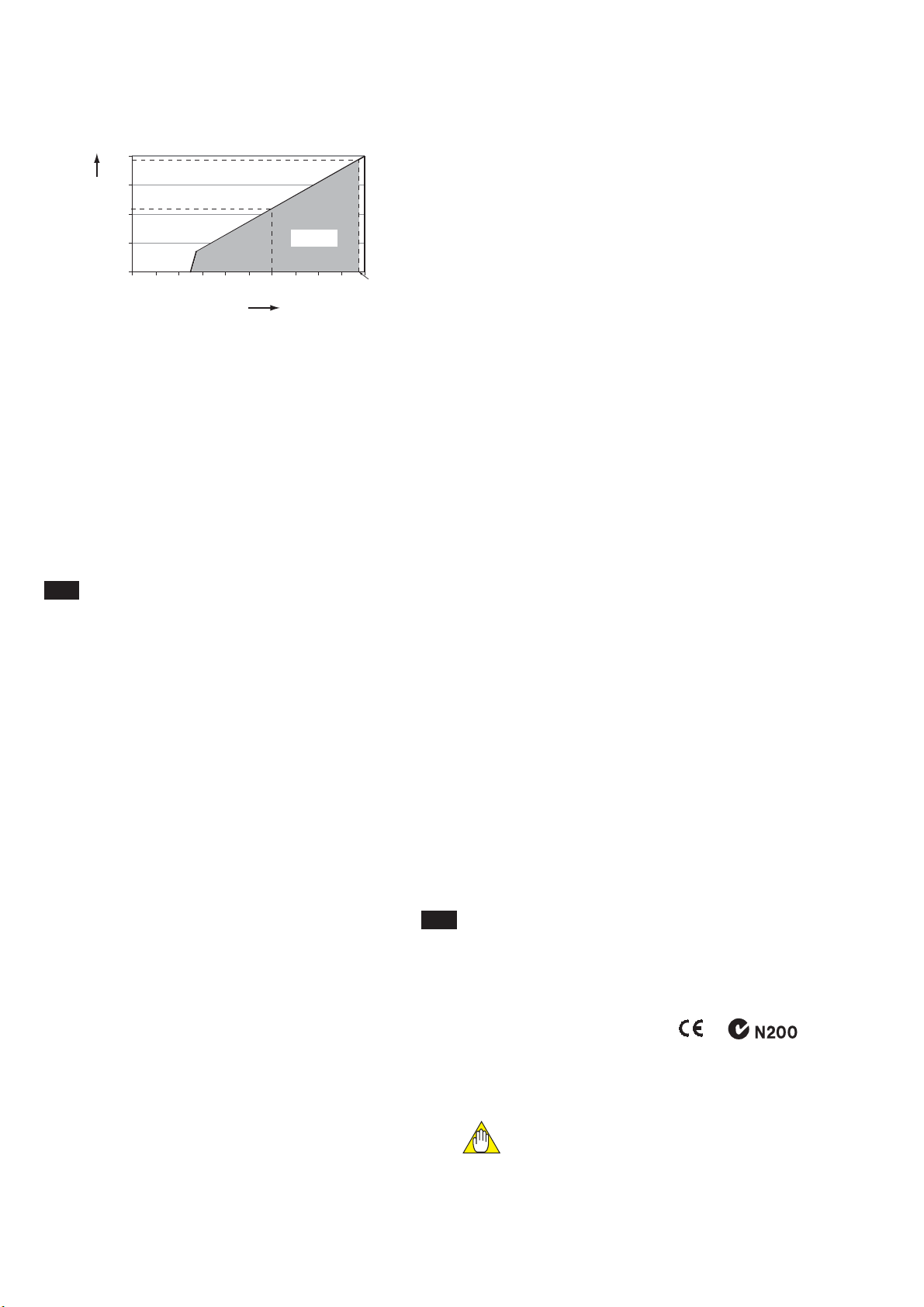

For the ISC202S, see figure 2-2.

1000

1150

800

600

400

200

150

0

10 201817 30 400

Voltage (V)

Load Resistance ()

Possible

F05.EPS

Fig.2-1 Supply voltage/ load diagram for the ISC202G

mAmA

mAmA

mAmA

2. GENERAL SPECIFICATIONS

IM 12D06A03-01E

2-2 Specifications

0

200

400

600

800

12 16

17

20 24 28 32

425

775

Voltage (V)

Load Resistance ()

31.5 V

Possible

Fig.2-2 Supply voltage/ load diagram for the ISC202S

J) Temperature compensation:

- Sensor types: Pt1000 or 30k NTC

- Automatic:

-20 to 140 ºC (0 to 280 ºF)

- Algorithm:

selectable as mentioned below

NaCl according to IEC 60746-3

tables.

Two T.C. setting possible between

0.00 to 3.50 %/°C

Matrix: user selectable/

configurable. 8 selectable for

concentrated solutions, 1 free

programmable.

K) Sensor diagnostics:

Abnormal temperature (open, short), abnormal

conductivity values (E5/E6 free programmable),

e.g. dry cell, wiring problems.

L) Calibration:

Manual, calibration Input pre-measureds data

(cell constant).

M) Logbook:

Software record of important events and diag-

nostic data.

N) Display:

Custom liquid crystal display.

- Main display: 3½ digits, 12.5 mm high, zero

change included.

- Message display: 6 alphanumeric

characters, 7 mm high.

- Special fields: Flags for status indication :

FAIL and HOLD.

- Measuring units: S/cm or mS/cm

- Key prompts:

YES, NO, >, ^, ENT, Menu pointer

- Keys: 6 keys operated through

flexible window with tactile

feedback. One hidden key

behind the front cover.

O) Power supply:

Power supply : Normal 24 V DC loop powered

system, see Figure 2-1, 2-2.

ISC202G: 17 - 40 V DC

ISC202S: 17 - 31.5 V DC

- Input Isolation: Maximum 1000 VDC

mAmA

P) Housing:

- Material : Cast aluminium case with

chemically resistant coat-

ing, cover with flexible

polycarbonate window.

- Color : Case : Off-white (Equivalent to

Munsell 2.5Y8.4/1.2)

Cover : Deepsea Moss

green(Equivalent to Mun-

sell 0.6GY3.1/ 2.0)

- Cable gland : 2-Pg13.5

Q) Mounting:

Pipe, Wall or Panel.

R) Shipping details:

Package size : W x H x D, 290 x 300 x 290 mm

(11.5 x 11.8 x 11.5 inch).

S) Environment and operational conditions:

- Ambient temp.:

-10 to 55 ºC (+10 to +130 ºF)

LCD operational

temperature is specified

-

10 to 70 ºC (14 to 160 ºF)

Excursions to -30 to +70 ºC

will not damage the instrument.

- Storage temp.:

-30 to +70 ºC (-20 to +160 ºF).

- Relative humidity: 10 to 90% RH at 40 ºC

ambient temperature, non

condensing

- Data protection: EEPROM for configuration

and logbook. Battery

supported clock.

- Watchdog timer : Checks microprocessor.

- Automatic safeguard: Return to measurement

after 10 minutes when

no keystroke.

Operation protection: 3 digital pass codes (pro-

grammable).

Power down: No effect, reset to meas-

urement.

T) HART

®

specifications:

Minimum cable diameter: 0.51 mm, 24 AWG.

Maximum cable length: 1500 m

Refer to standard HART® specifications for more

details.

See www.hartcomm.org

U) EMC Conformity standard ,

EN 61326-1 Class A, Table 2

(For use in industrial locations)

EN 61326-2-3

EN 61326-2-5 (pending)

CAUTION

This instrument is a Class A product, and it is

designed for use in the industrial environment.

Please use this instrument in the industrial

environment only.

mAmA

IM 12D06A03-01E

Specifications 2-3

V) Explosionproof type

Refer to Control Drawings.

Item

Description

Code

Factory

Mutual (FM)

-N

-A

-N

-A

CENELEC

ATE X

2.EPS

FM Non-incendive safe Approval

Applicable standard: FM3600, FM3611, FM3810

Non-incendive Safe for Class I, Division 2,

Groups ABCD, Zone 2

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Non-incendive Safe Apparatus Parameters

Vmax=31.5 V, Ci=22 nF, Li=35 H

FM Intrinsically safe Approval

Applicable standard: FM3600, FM3610, FM3810

Intrinsically Safe for Class I, Division 1, Groups ABCD

Class I, Zone 0, AEx ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Intrinsically Safe Apparatus Parameters

Vmax=31.5 V, Imax=100 mA,

Pmax=1.2 W, Ci=22 nF, Li=35 H

CENELEC ATEX (KEMA) Type of protection "n"

Applicable standard: EN60079-0:2006,

EN60079-15:2003

Certificate: KEMA 06ATEX0223

EEx nA [nL] IIC, Group: II, Category: 3G

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui=31.5 V, Ci=22 nF, Li=35 H

CENELEC ATEX (KEMA) Intrinsically safe Approval

Applicable standard: EN60079-0, EN50020

EN60079-26

Certificate: KEMA 06ATEX0222 X

Ex ia IIC, Group: II, Category: 1G

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui=31.5 V, Ii=100 mA, Pi=1.2 W, Ci=22 nF, Li=35 H

IECEx Type of protection "n"

Applicable standard: IEC 60079-15:2001,

IEC 60079-0:2004

Certificate: IECEx KEM 06.0054X

Ex nA [nL] IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui=31.5 V, Ci=22 nF, Li=35 H

IECEx Intrinsically safe

Applicable standard: IEC 60079-0, IEC60079-11,

IEC60079-26

Certificate: IECEx KEM 06.0054X

Zone 0 Ex ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui=31.5 V, Ii=100 mA, Pi=1.2 W, Ci=22 nF, Li=35 H

-N

-A

T12E.EPS

IECEx

Scheme

Item

Description

Code

CSA Non-incendive safe Approval or

type of protection "n"

Applicable standard: C22.2, No.0-M1991,

C22.2, No.04-M2004, C22.2, No.157-M1992,

C22.2, No.213-M1987, C22.2, No.61010-1

Class I, Division 2, Groups ABCD

Ex nA [nL] IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui(Vmax)=31.5 V, Ci=22 nF, Li=35 H

-N

CSA Intrinsically safe Approval

Applicable standard: C22.2, No. 0-M1991,

C22.2, No. 04-M2004, C22.2, No. 157-M1992,

C22.2, No. 61010-1

Ex ia Class I, Division 1, Groups ABCD

Ex ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui(Vmax)=31.5 V, Ii(Imax)=100 mA,

Pi(Pmax)=1.2 W, Ci=22 nF, Li=35 H

-A

Canadian

Standards

Association

(CSA)

mA

Item

Description

Code

Factory

Mutual (FM)

FM Non-incendive safe Approval

Applicable standard: FM3600, FM3611, FM3810

Non-incendive Safe for Class I, Division 2,

Groups ABCD, Zone 2

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Non-incendive Safe Apparatus Parameters

FM Intrinsically safe Approval

Applicable standard: FM3600, FM3610, FM3810

Intrinsically Safe for Class I, Division 1, Groups ABCD

Class I, Zone 0, AEx ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Intrinsically Safe Apparatus Parameters

FM.EPS

Vmax=32 V, Pmax=1.2 W,

Ci=220 pF, Li=0 H

Vmax=32 V, Pmax=5.32 W,

Ci=220 pF, Li=0 H

Entity

FNICO

-F

-P

or

-D

-B

or

Vmax=24 V, Imax=250 mA,

Pmax=1.2 W, Ci=220 pF, Li=0 H

Vmax=17.5 V, Imax=380 mA,

Pmax=5.32 W, Ci=220pF, Li=0 H

Entity

FISCO

Item

Description

Code

CENELEC ATEX (KEMA) Type of protection "n"

Applicable standard: EN60079-0:2006,

EN60079-15:2003

Certificate: KEMA 07ATEX0053

EEx nA [nL] IIC, Group: II, Category: 3G

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui=32 V, Ci=220 pF, Li=0 H

CENELEC ATEX (KEMA) Intrinsically safe Approval

Applicable standard: EN60079-0, EN50020

EN60079-26

Certificate: KEMA 07ATEX0052 X

Ex ia IIC, Group: II, Category: 1G

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Ui=24 V, Ii=250 mA, Pi=1.2 W, Ci=220 pF, Li=0 H

CENELEC

ATE X

ATEX.EPS

Entity

CENELEC

ATE X

CENELEC

ATE X

FISCO

-F

-P

or

-D

-B

or

CENELEC ATEX (KEMA) Intrinsically safe Approval

Applicable standard: EN60079-0, EN50020

EN60079-26, EN60079-27

Certificate: KEMA 07ATEX0052 X

Ex ia IIC, Group: II, Category: 1G

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Ui=17.5 V, Ii=380 mA, Pi=5.32 W, Ci=220 pF, Li=0 H

Item

Description

Code

IEC.EPS

Entity

FISCO

-F

-P

or

-D

-B

or

IECEx Type of protection "n"

Applicable standard: IEC 60079-15:2001,

IEC 60079-0:2004

Certificate: IECEx KEM 07.0028X

Ex nA [nL] IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui=32 V, Ci=220 pF, Li=0 H

IECEx Intrinsically safe

Applicable standard: IEC 60079-0, IEC60079-11,

IEC60079-26

Certificate: IECEx KEM 07.0028X

Zone 0 Ex ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Ui=24 V, Ii=250 mA, Pi=1.2 W, Ci=220 pF, Li=0 H

IECEx Intrinsically safe

Applicable standard: IEC 60079-0, IEC60079-11,

IEC60079-26, IEC60079-27

Certificate: IECEx KEM 07.0028X

Zone 0 Ex ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Ui=17.5 V, Ii=380 mA, Pi=5.32 W, Ci=220 pF, Li=0 H

IECEx

Scheme

IECEx

Scheme

IECEx

Scheme

mA

Item

Description

Code

CSA Non-incendive safe Approval or

type of protection "n"

Applicable standard: C22.2, No.0-M1991,

C22.2, No.04-M2004, C22.2, No.157-M1992,

C22.2, No.213-M1987, C22.2, No. 61010-1

Class I, Division 2, Groups ABCD

Ex nA [nL] IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

CSA Intrinsically safe Approval

Applicable standard: C22.2, No. 0-M1991,

C22.2, No. 04-M2004, C22.2, No. 157-M1992,

C22.2, No. 61010-1

Ex ia Class I, Division 1, Groups ABCD

Ex ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

CSA.EPS

Canadian

Standards

Association

(CSA)

Ui(Vmax)=24 V, Ii(Imax)=250 mA,

Pi(Pmax)=1.2 W, Ci=220 pF, Li=0 H

Ui(Vmax)=17.5 V, Ii(Imax)=380 mA,

Pi(Pmax)=5.32 W, Ci=220 pF, Li=0 H

Entity

FISCO

Ui(Vmax)=32 V, Ci=220 pF, Li=0 H

Ui(Vmax)=32 V, Ci=220 pF, Li=0 H

Entity:

FNICO:

-F

-P

or

-D

-B

or

IM 12D06A03-01E

2-4 Specifications

NEPSI Certification (ISC202S-K)

NEPSI Intrinsically Safe Type

Cert No. GYJ081158X

• Applicable Standard:

GB3836.1-2000, GB3836.4-2000

• Type of Protection and Marking Code:

Ex ia IIC T4/T6

• Ambient Temperature :

T6; –10 to 40°C, T4; –10 to 55°C

Note 1 Entity Parameters

• Intrinsically safe input parameters

(terminal + and -):

Maximum Input Voltage (Ui) = 31.5 V

Maximum Input Current (Ii) = 100 mA

Maximum Input Power (Pi) = 1.2 W

Maximum Internal Capacitance (Ci) = 22 nF

Maximum Internal Inductance (Li) = 35 H

• Intrinsically safe output parameters and maximum

external parameters

(terminal 11 and 17):

Uo=14.4 V, Io=20 mA, Po=190 mW, Co=600

nF, Lo=88 mH

Note 2 Installation

• Electrostatic charges on the display window shall

be avoided.

• The external earth connection facility shall be

connected reliably.

• The instrument modification or parts replacement

by other than authorized representative of

Yokogawa Electric Corporation and will void

NEPSI Intrinsically safe certification.

• The user shall not change the configuration in

order to maintain/ensure the explosion protection

performance of the equipment. Any change may

impair safety.

• For installation, use and maintenance of

the product, the end user shall observe the

instruction manual and the following standards:

GB50257-1996 "Code for construction and

acceptance of electric device for explosion

atmospheres and fire hazard electrical

equipment installation engineering''.

GB3836.13-1997 "Electrical apparatus for

explosive gas atmospheres Part 13: Repair and

overhaul for apparatus used in explosive gas

atmospheres".

GB3836.15-2000 "Electrical apparatus for

explosive gas atmospheres- Part 15: Electrical

installations in hazardous area (other than

mines)" .

GB3836.16-2006 "Electrical apparatus for

explosive gas atmospheres- Part 16: lnspection

and maintenance of electrical installation (other

than mines)".

mA-HART

®

communication

A. Input : Two wire system 4-20 mA

B. Power supply :

ISC202G : up to 40 volts

ISC202S : up to 31.5 volts

Note: The transmitter contains a switched

power supply, drawing its energy

from the 0-4 mA section of the

signal. Consequently the 17 volt

limit is applied at 4 mA. The

characteristic of the unit is such that

above about 7 mA on the output, the

terminal voltage can drop to 14.5

volts without problem.

C. Transmission: Isolated output of 4 to 20 mA DC.

D. Signal : Maximum load 425 at 24 VDC.

(see fi gure 2-1)

Burn to signal failure acc.

NAMUR Recommendation NE43

(18.01.1994)

E. Operating range : 3.9 to 21 mA

F. Communication

: HART

®

, 1200 Baud, FSK

modulated on 4 to 20 mA signal

G. Configuration : Local with 6 keys

H. Software : Firmware based on Yokogawa stack.

I. Hardware :

Yokogawa HART® Modem F9197UB

J. Other Control systems

: Yokogawa PRM, Rosemount

AMS, Siemens PDM

K. Hand Terminal : Rosemount HHT 275/375

L. Other control systems: Yokogawa PRM, Rose-

mount AMS, Siemens PDM\

M. Output span :

- Conductivity : min 0.01S/cm, max. 1999 mS/

cm.

(max 90% zero suppression)

- Resistivity : min 0.001k

·cm, max.

999 M·cm.

(max 90% zero

suppression) The instrument

is user programmable for

linear or non-linear conductivity

ranges.

N. Cable specification

: 0.5 mm diameter or 24 AWG

over maximum length of 1500 m

O. DD specification

: The ISC202 Device Description

is available enabling

communications with the

Handheld Communicator and

compatible devices.

mA

mA

IM 12D06A03-01E

Specifications 2-5

PROFIBUS-PA communications

A. Input signal: Digital

B. Supply voltage: 9 to 32 V DC

C. Operating current: 26.0 mA

D. Operating values: According to IEC 1158-2

E. Bus connection

: Fieldbus interface base on

IEC1158-2 according to FISCO-

Model

F. Power supply: Power supply is achieved depend-

ant on the application by means of

segment coupler

G. Data transfer: According to PROFIBUS- PA pro-

file class B based on EN 50170

and DIN 19245 part 4

H. GSD file: The actual file can be down-

loaded from www.profibus.com

Configuration: Local with 6 keys

I. Software: Firmware based on Siemens

DPC31 stack.

J. Hardware:

PC- or PCMCIA-interfaces from

Siemens

K. Other control: Siemens PDM systems

L Electrical connection:

Terminals acc. to IEC 1158-2

M. Fieldbus-cable-types:

Twisted and shielded two

wire cable according to

recommendation based on IEC

1158-2 Cable diameter: 6 to 12

mm (0.24 to 0.47 inch)

FOUNDATION FIELDBUS H1 communications

A. Input signal: Digital

B. Supply voltage: 9 to 32 V DC

C. Operating current: 26.0 mA (base current)

D. Operating values: According to IEC 1158-2

E. Bus connection

: Fieldbus interface based on IEC

1158-2 according to FISCO-Model

F. Power supply:

Power supply is achieved

dependant on application by

means of segment coupler

G. Data transfer:

FF specification Rev. 1.4 Basic

device

H. Function blocks:

3 x AI, Transducer, Resource

I. Files: Actual file can be downloaded from

our homepage

J. Configuration: locally with 6 keys

K. Software:

National Instruments:

NI-FBUS configurator

L. Hardware: F-BUS interfaces from National

Instruments (AT-FBUS, PCMIA-

FBUS)

M. Other control systems:

YOKOGAWA PRM, DTM

IM 12D06A03-01E

2-6 Specifications

2. 2-wire Inductive conductivity transmitter (Explosionproof type)

Model Suffix Code Option Code Description

2-wire inductive conductivity transmitter

Intrinsic mA with HART (ATEX, CSA, FM)

Intrinsic mA with HART (NEPSI)

Intrinsic safe Profibus (ATEX, CSA, FM)

Intrinsic safe FF (ATEX, CSA, FM)

Non incendive FF (ATEX, CSA, FM) (*2)

Non incendive mA with HART (ATEX, CSA, FM) (*2)

Non incendive Profibus (ATEX, CSA, FM) (*2)

Japanese

English

Pipe, wall mounting bracket (Stainless steel)

Panel Mounting bracket(Stainless steel)

Hood for sun protection (Carbon steel)

Hood for sun protection (Stainless steel)

Stainless steel tag plate

G1/2

1/2NPT

Epoxy baked finish (*1)

/U

/PM

/H

/H2

/SCT

/AFTG

/ANSI

/X1

-A

-K

-P

-F

-B

-N

-D

-J

-E

ISC202S

Type

Language

Option Mounting Hardware

Hood

Tag Plate

Conduit Adapter

(*1) The housing is coated with epoxy resin.

(*2) When the instrument with Suffix Code "-B, -N, -D" is used, take measures so that the display window is not exposed

to direct sunlight.

[Style: S3]

2-2. Model and suffix codes

1. 2-wire Inductive conductivity transmitter (General purpose)

Model Suffix Code Option Code Description

2-wire Inductive conductivity transmitter

mA with HART

Profibus

FF

Japanese

English

Pipe, wall mounting bracket (Stainless steel)

Panel Mounting bracket(Stainless steel)

Hood for sun protection (Carbon steel)

Hood for sun protection (Stainless steel)

Stainless steel tag plate

G1/2

1/2NPT

Screw terminal (*1)

Epoxy baked finish (*2)

/U

/PM

/H

/H2

/SCT

/AFTG

/ANSI

/TB

/X1

-A

-P

-F

-J

-E

ISC202G

Type

Language

Option Mounting Hardware

Hood

Tag Plate

Conduit Adapter

(*1) It can be specified when the suffix code -A is selected.

(*2) The housing is coated with epoxy resin.

[Style: S2]

IM 12D06A03-01E

Specifications 2-7

2-3. Control Drawing ISC202S mA HART

®

Specification (IECEx).

・ Electrical data of the ISC202S.

- Supply and output circuit (terminals + and -):

Maximum input voltage U

i

= 31.5 V. Maximum input current I

i

= 100 mA.

Maximum input power P

i

= 1.2 W.

Effective internal capacitance C

i

= 22 nF.

Effective internal inductance L

i

= 35 PH.

- Sensor input circuit (terminals 11 through 17):

Maximum output voltage U

o

= 14.4 V. Maximum output current I

o

= 20 mA.

Maximum allowed external capacitance C

o

= 600 nF (for ISC202S-A),

C

o

= 3.5 PF (for ISC202S-N)

Maximum allowed external inductance L

o

= 88 mH (for ISC202S-A),

L

o

= 200mH (for ISC202S-N)

・ Barriers and power supply specification must not exceed the maximum values as

shown in the diagram above. These safety descriptions cover most of the commonly

used industry standard barriers, isolators and power supplies.

・ The Hand Held Communicator must be of a IECEx certified intrinsically safe type in

case it is used on the intrinsically safe circuit in the hazardous area or of a IECEx

certified non-incendive type in case it is used in the non-incendive circuit in the

hazardous area.

ISC202S

((Inductive Conductivity-transmitter)

Safe area

Uo = 31 .5 V o lt DC

Io = 100 mA

Po = 1.2 Watt

Ex ia or ib C er tifi e d R e p e a t e r

Power Supply

(HAR T Co mpa t ib le )

Output

Supply

ISC40S Sensor

terminals 11-17

+

_

G

ISC40S Sensor

terminals 11-17

Zone 0 or 1

Hazardous area Safe area

+

_

G

Functional

earth

Fanctional

earth

Intrins ic a lly s a fe d e s ig n

IECE x sta nd ard Ex ia IIC : T4 for a mb ient tem p . < 55 °C

T6 for ambient temp. < 40°C

ISC202S

+

_

Load

Resistance

Ex ia or ib

Certified safety b arrier or p o w e r

with Rint=300

:

Io = 100 mA

Uo = 31.5 Volt DC

Zone 0 or 1

Hazardous area

Fanctional

earth

+

_

24 volts DC Nominal

Sup p ly V olta g e .

Intrins ic a lly s a fe d e s ign

IECE x sta nd ard E x ia IIC : T 4 fo r am bie nt tem p. < 55 °C

T6 for a mb ient te m p. < 40 °C

(HAR T c omp atible)

(Induc tive C ond uc tivity-tra n sm itte r)

Certificate nr. IECEx KEM 06.0054X

Certificate nr. IECEx KEM 06.0054X

IM 12D06A03-01E

2-8 Specifications

2-4. Control Drawing ISC202S mA HART

®

Specification (ATEX)

ISC2 0 2 S

(Inductive Conduc tivity transmitter)

Safe area

Uo = 31 .5 V o lt DC

Io = 100 mA

Po = 1.2 Watt

EEx ia o r ib C e r tifie d Rep e a te r

Power Supply

(HA R T Com p a t ib le )

Output

Supply

ISC40S Sensor

terminals 11-17

(KEMA 00ATEX1067 X)

+

_

G

ISC40S Sensor

terminals 11-17

(KEMA 00ATEX1067 X)

Hazardous area Safe area

+

_

G

Functional

earth

Functional

earth

Intr insica lly s afe d esig n

CEN E LE C s tand ard E Ex ia IIC: T4 for amb ient temp . < 5 5° C

T6 for ambient temp. < 40°C

Certificate nr. KEM A 06ATEX 0222 X

ISC20 2S

+

_

Load

Resistance

EEx ia or ib

Certified safety barrier or power

with Rint=300

:

Io = 100 mA

Uo = 31.5 Volt DC

Hazardous area

Functional

earth

+

_

24 volts DC Nominal

Supply Voltage.

Intrinsically safe design

CENELE C s tan da rd EE x ia IIC : T 4 fo r am bie nt te mp . < 5 5° C

T6 for ambient temp.< 40°C

Certificate nr. KEM A 06ATEX 0222 X

(HART compatible)

(Indutive Condu c tivity tra ns m itter)

Zone 0 or 1

Zone 0 or 1

・ Electrical data of the ISC202S.

- Supply and output circuit (terminals + and -):

Maximum input voltage U

i

= 31.5 V. Maximum input current I

i

= 100 mA.

Maximum input power P

i

= 1.2 W.

Effective internal capacitance C

i

= 22 nF.

Effective internal inductance L

i

= 35 PH.

- Sensor input circuit (terminals 11 through 17):

Maximum output voltage U

o

= 14.4 V. Maximum output current I

o

= 20 mA.

Maximum allowed external capacitance C

o

= 600 nF (for ISC202S-A),

C

o

= 3.5 PF (for ISC202S-N)

Maximum allowed external inductance L

o

= 88 mH (for ISC202S-A),

L

o

= 200mH (for ISC202S-N)

・ Barriers and power supply specification must not exceed the maximum values as

shown in the diagram above. These safety descriptions cover most of the commonly

used industry standard barriers, isolators and power supplies.

・ The Hand Held Communicator must be of a ATEX certified intrinsically safe type in

case it is used on the intrinsically safe circuit in the hazardous area or of a ATEX

certified non-incendive type in case it is used in the non-incendive circuit in the

hazardous area.

IM 12D06A03-01E

Specifications 2-9

・ Electrical data of the ISC202S.

- Supply circuit (terminals + and -):

Maximum input voltage V

max

= 31.5 V. Maximum input current I

max

= 100 mA.

Maximum input power P

max

= 1.2 W.

Effective internal capacitance C

i

= 22 nF. Effective internal inductance L

i

= 35 PH.

- Sensor input circuit (terminals 11 through 17):

Maximum output voltage V

t

= 14.4 V. Maximum output current I

t

= 20 mA.

Maximum allowed external capacitance C

a

= 600 nF

Maximum allowed external inductance L

a

= 88 mH.

・If Hand Held Terminal (HHT) is not connected to the power supply lines of the ISC202S (see figure 1):

Any FM Approved barrier or power supply may be used that meets the following requirements.

V

oc

or V

t

d 31.5 V; I

sc

or I

t

d 100 mA; C

a

t 22nF + C

cable

; L

a

t 35PH + L

cable

If HHT is connected to the power supply lines of the ISC202S (see figure 2):

The Hand Held Terminal must be FM Approved. Refer to the manufacturers control drawing of the

HHT and the barrier/power supply to determine the cable parameters.

(V

oc

or V

t

) + V

HHT

d 31.5 V; (I

sc

or I

t

) + I

HHT

d 100 mA;

C

a

t 22nF + C

cable

+ C

HHT

; L

a

t 35P H + L

cable

+ L

HHT

When installing this equipment, follow the manufacturer’s installation drawing.

Installation should be in accordance with ANSI/ISA RP 12.06.01 “Installation of Intrinsically Safe

Systems for Hazardous (Classified) Locations” and the National Electrical Code (ANSI/NFPA 70).

Control equipment connected to the barrier/power supply must not use or generate more than 250

Vrms or Vdc.

・ Resistance between Intrinsically Safe Ground and earth ground must be less than 1.0 Ohm.

・ In case of using cable glands in Outdoor location, they shall be UV rated or made of metal.

WARNING

- Substitution of components may impair Intrinsic Safety

- To prevent ignition of flammable or combustible atmospheres, disconnect power before servicing or

read, understand and adhere to the manufacturer’s’live maintenance procedures.

ISC40S Sens o r

terminals 11-17

Max. cab lele ngth: 60 mtr.

Cable dia. : 3…12 mm.

ISC40S Sensor

terminals 11-17

Max. cablelength: 60 mtr.

Cable dia.: 3…12 mm.

Ùnclassified Location

FM Approved

Power Supply

(HART compatible)

Output

Supply

+

_

G

Classified Location

Unclassified Location

+

_

G

Functional

earth

Fanctional

earth

Intrinsically safe design

FM Class I, Div.1, Group ABCD, T4 for ambient temp. < 55°C

T6 for ambient temp. < 40°C

ISC202S transmitter

+

-

Load

Resistance

Classified Location

Fanctional

earth

+

_

24 volts DC N ominal

Supply Voltage.

FM Approved safety barrier or

power supply

with Rint = 300 :

(HART compatible)

For electrical data:

see text below.

For electrical data:

see text below.

Intrinsically safe design

FM Class I, Div.1, Group ABCD, T4 for ambient temp. < 55°C

T6 for ambient temp. < 40°C

ISC202S transmitter

Figure 1

Figure 2

2-5. Control Drawing ISC202S mA HART

®

Specification (FM Intrinsically safe design)

Application Doc. No.: IKE028-A10 P.5 to P.6

IM 12D06A03-01E

2-10 Specifications

・ Electrical data of the ISC202S.

- Supply circuit (terminals + and -):

Maximum input voltage V

max

= 31.5 V. Maximum input power P

max

= 1.2 W

Effective internal capacitance Ci = 22 nF Effective internal inductance Li = 35 H

- Sensor input circuit (terminals 11 through 17):

Maximum output voltage V

t

= 14.4 V. Maximum output current I

t

= 20 mA.

Maximum allowed external capacitance C

a

= 2.25 F.

Maximum allowed external inductance L

a

= 160 mH.

・ The Hand Held Terminal must be FM Approved in case it is used in the classified location.

When installing this equipment, follow the manufacturers installation drawing.

Installation shall be in accordance with Article 501.4(B) of the National Electrical Code

(ANSI/NFPA 79).

Non-incendive field wiring may be installed in accordance with Article 501 of the National

Electrical Code.

・ Grounding shall be in accordance with Article 250 of the National Electrical code

・ In case of using cable glands in Outdoor location, they shall be UV rated or made of metal.

WARNING

- Substitution of components may impair suitability for Division 2

- Do not remove or replace while circuit is live unless area is know to be non-hazardous

- Explosion Hazard – Do not disconnect equipment unless area is know to be non-hazardous

- Do not reset circuit breaker unless power has been removed from the equipment or the area is

know to be non-hazardous

ISC40S Sensor

terminals 11

-17

Max. cablelength: 60 mtr.

Cable dia. : 3…12 mm.

ISC40S Sensor

terminals 11

-17

Max. cablelength: 60 mtr.

Cable dia.: 3…12 mm

Ùnclassified Location

+

_

G

Classified Location Unclassified Location

+

_

G

Functional

earth

N

onincendive design

FM Class I, Div.2, Group ABCD, T4 for ambient temp. < 55°C

T6 for ambient temp. < 40°C

ISC202S transmitter

+

-

Load

Resistance

Classified Location

Functional

earth

FM Approved

p

ower supply

Voc

≤

31.5 V DC

For electrical data:

see text below.

For electrical data:

see text below.

N

onincendive design

FM Class I, Div.2, Group ABCD, T4 for ambient temp. < 55°C

T6 for ambient temp. < 40°C

ISC202S tramsmitter

+

-

FM Approved

p

ower supply

Voc

≤

31.5 VDC

2-6. Control Drawing ISC202S mA HART

®

Specification (FM Non-incendive design)

Application Doc. No.: IKE028-A10 P.7 to P.8

IM 12D06A03-01E

Specifications 2-11

2-7. Control Drawing of ISC202S mA HART

®

Specification (CSA)

Electrical data of the ISC202S.

- Supply and output circuit (terminals + and -)

Maximum input voltage V

max

= 31.5 V. Maximum input current I

max

= 100 mA.

Maximum input power P

max

= 1.2 W.

Effective internal capacitance C

i

= 22 nF. Effective internal inductance L

i

= 35 PH.

- Sensor input circuit (terminals 11 through 17):

Maximum output voltage V

oc

= 14.4 V. Maximum output current I

sc

= 20 mA.

Maximum allowed external capacitance C

a

= 600 nF.

Maximum allowed external inductance L

a

= 88 mH.

・ Barriers and power supply should be CSA certified. The specifications must not exceed

the maximum values as shown in the diagram above. Installation should be in

accordance with Canadian Electrical Code, Part I.

Maximum safe area voltage should not exceed 250 V

RMS

.

For Class I, Div. 2, Group ABCD the CSA certified barrier is not required, and the Sensor

input circuit (terminals 11 through 17) is non-incendive having the parameters:

Maximum output voltage V

oc

= 14.4 V.

Maximum output current I

sc

= 20 mA.

Maximum allowed external capacitance C

a

= 3.5μF.

Maximum allowed external inductance L

a

= 200 mH.

・The Hand Held Communicator must be of a CSA certified intrinsically safe type in case it

is used on the intrinsically safe circuit in the hazardous area, or of a CSA certified

non-incendive type in case it is used on the non-incendive circuit in the hazardous area.

Safe area

Vmax = 31.5 VoltDC

Imax = 100 mA

Pmax = 1.2 Watt

CSA certified

Power Supply

(HAR T com pa tible) )

Output

Supply

ISC40S Sensor

terminals 11-17

+

_

G

ISC40S Sensor

terminals 11-17

Hazardous area Safe area

+

_

G

Functional

earth

Functional

earth

Intrinsically safe design

CSA Ex ia Class I, Div.1, Group ABCD, T4 for ambient temp. < 55°C

T6 for ambient tem p. < 4 0° C

ISC202S transmitter

+

-

Load

Resistance

Imax = 100 mA

Vmax = 31.5 VoltDC

Hazardous area

Functional

earth

+

_

24 volts DC N o minal

Supply Voltage.

CSA c ertified sa fety b arrier o r

power supply with Rint=300 :

(HAR T c om p a tible)

Su it ab le v a lue s a r e:

For electrical data:

see text below.

For electrical data:

see text below.

Suitable v a lu es a re:

Intrinsically safe design

CSA E x ia C las s I, D iv.1 , G ro up A B C D , T4 for amb ient tem p. < 5 5 °C

T6 for ambient tem p . < 4 0 °C

ISC202S transmitter

IM 12D06A03-01E

2-12 Specifications

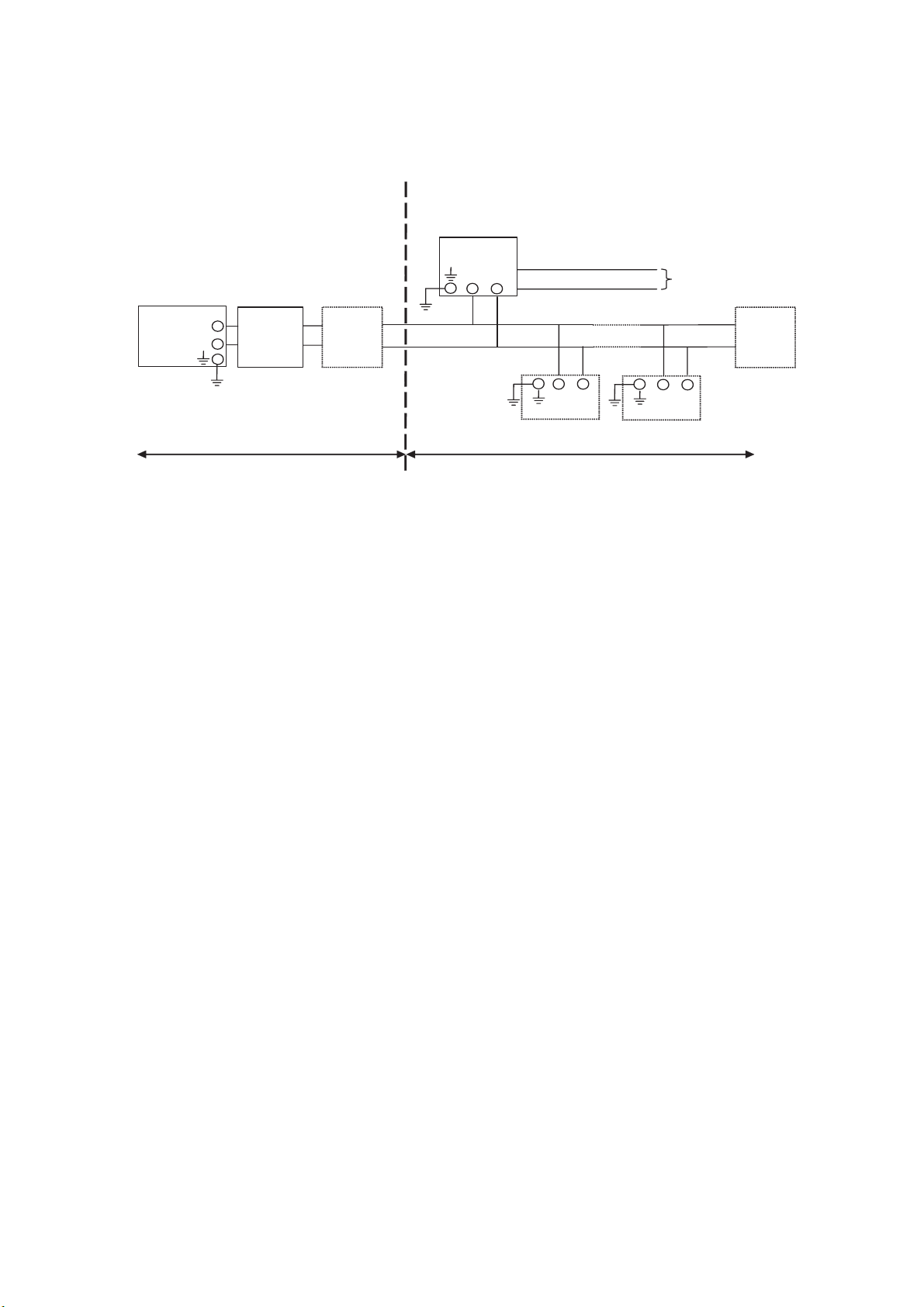

2-8. Control Drawing of ISC202S FF/PB Specification (IECEx)

Safe area

Hazardous area

Zone 0 or 1

Safe area

Apparatus

I.S.

interface

I.S.

certified

Terminator

Ui = 24 V or Ui = 17,5 V

Ii = 250 mA Ii= 380 mA

Pi = 1,2 W Pi = 5,32 W

Ex ia IIC

T4 for ambient te mp. d 55 q C

ISC202S-F

or ISC202S-P

I.S.

certified

Terminator

-

+

-

+

Transm itter

Transm itter

Sensor

Connections

-

+

-

+

x Sensor(s) are of a passive type to be regarded as 'simple apparatus'.

x Electrical data of the ISC202S-F & ISC202S-P:

- Supply and output circuit:

Maximum input voltage Ui = 24 V

Maximum input current Ii = 250 mA

Maximum input power Pi = 1.2 W

Effective internal capacitance Ci = 220 pF;

Effective internal inductance Li = 0 H.

or

FISCO field device

Maximum input voltage Ui =17.5 V

Maximum input current Ii =380 mA

Maximum input power Pi =5.32 W

Effective internal capacitance Ci = 220 pF;

Effective internal inductance Li = 0 H.

- Sensor input circuit:

Maximum output voltage Uo = 14.4 V; Maximum output current Io = 20 mA

Maximum allowed external capacitance Co = 600 nF

Maximum allowed external inductance Lo = 88 mH

x Any I.S. interface may be used that meets the following requirements:

Uo d 24 V

Io d 250 mA

Po d 1.2 W

Co t 220 pF + Ccable; Lo t 0 H + Lcable

or

FISCO power supply

Uo d 17.5 V

Io d 380mA

Po d 5.32 W

Co t 220 pF + Ccable; Lo t 0 H + Lcable

x Electrical data of the ISC202S-B & ISC202S-D (Type of protection “n”)

- Supply and output circuit:

Maximum input voltage Ui = 32 V

Effective internal capacitance Ci = 220 pF; Effective internal inductance Li = 0 H.

- Sensor input circuit:

Maximum output voltage Uo = 14.4 V; Maximum output current Io = 20 mA

Maximum allowed external capacitance Co = 3.5 F

Maximum allowed external inductance Lo = 200 mH

IM 12D06A03-01E

Specifications 2-13

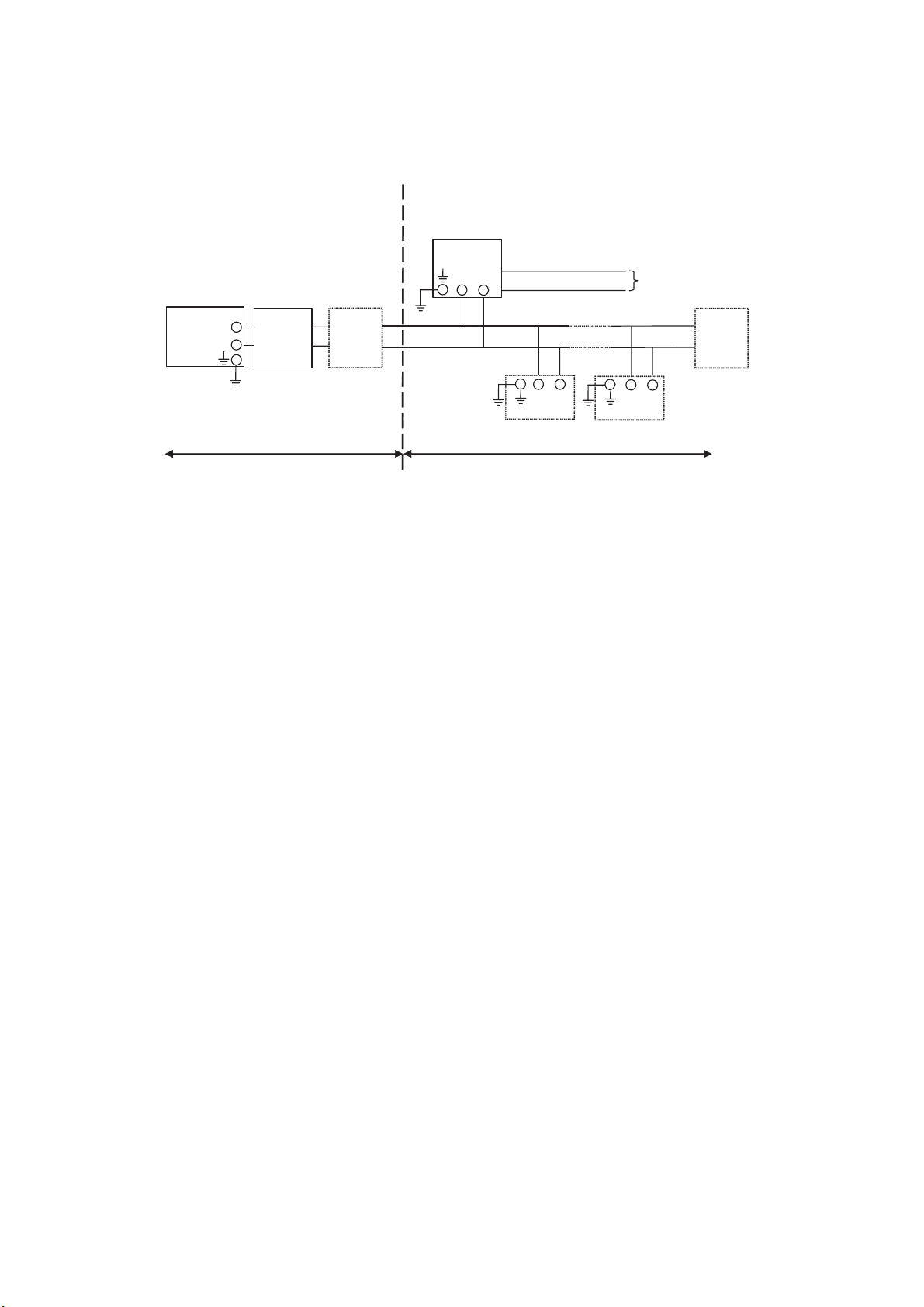

2-9. Control Drawing of ISC202S FF/PB Specification (ATEX)

Safe area

Hazardous area

Zone 0 or 1

Safe area

Apparatus

I.S.

interface

I.S.

certified

Terminator

Ui = 24 V or Ui = 17,5 V

Ii = 250 mA Ii= 380 mA

Pi = 1,2 W Pi = 5,32 W

Ex ia IIC

T4 for ambient temp. d 55 qC

ISC202S-F

o

r

ISC202S-P

I.S.

certified

Terminator

-

+

-

+

Transmitter

Transmitter

Sensor

Connections

-

+

-

+

x Sensor(s) are of a passive type to be regarded as 'simple apparatus'.

x Electrical data of the ISC202S-F & ISC202S-P:

- Supply and output circuit:

Maximum input voltage Ui =24 V

Maximum input current Ii =250 mA

Maximum input power Pi =1.2 W

Effective internal capacitance Ci = 220 pF;

Effective internal inductance Li = 0 H.

or

FISCO field device

Maximum input voltage Ui = 17.5 V

Maximum input current Ii = 380 mA

Maximum input power Pi = 5.32 W

Effective internal capacitance Ci = 220 pF;

Effective internal inductance Li = 0 H.

- Sensor input circuit:

Maximum output voltage Uo = 14.4V; Maximum output current Io = 20 mA

Maximum allowed external capacitance Co = 600 nF

Maximum allowed external inductance Lo = 88 mH

x Any I.S. interface may be used that meets the following requirements:

Uo d 24 V

Io d 250 mA

Po d 1.2 W

Co t 220 pF + Ccable; Lo t 0 H + Lcable

or

FISCO power supply

Uo d 17.5 V

Io d 380 mA

Po d 5.32 W

Co t 220 pF + Ccable; Lo t 0 H + Lcable

x Electrical data of the ISC202S-B & ISC202S-D (Type of protection “n”)

- Supply and output circuit:

Maximum input voltage Ui = 32 V

Effective internal capacitance Ci = 220 pF; Effective internal inductance Li = 0 H.

- Sensor input circuit:

Maximum output voltage Uo= 14.4 V; Maximum output current Io = 20 mA

Maximum allowed external capacitance Co = 3.5 F

Maximum allowed external inductance Lo = 200 mH

IM 12D06A03-01E

2-14 Specifications

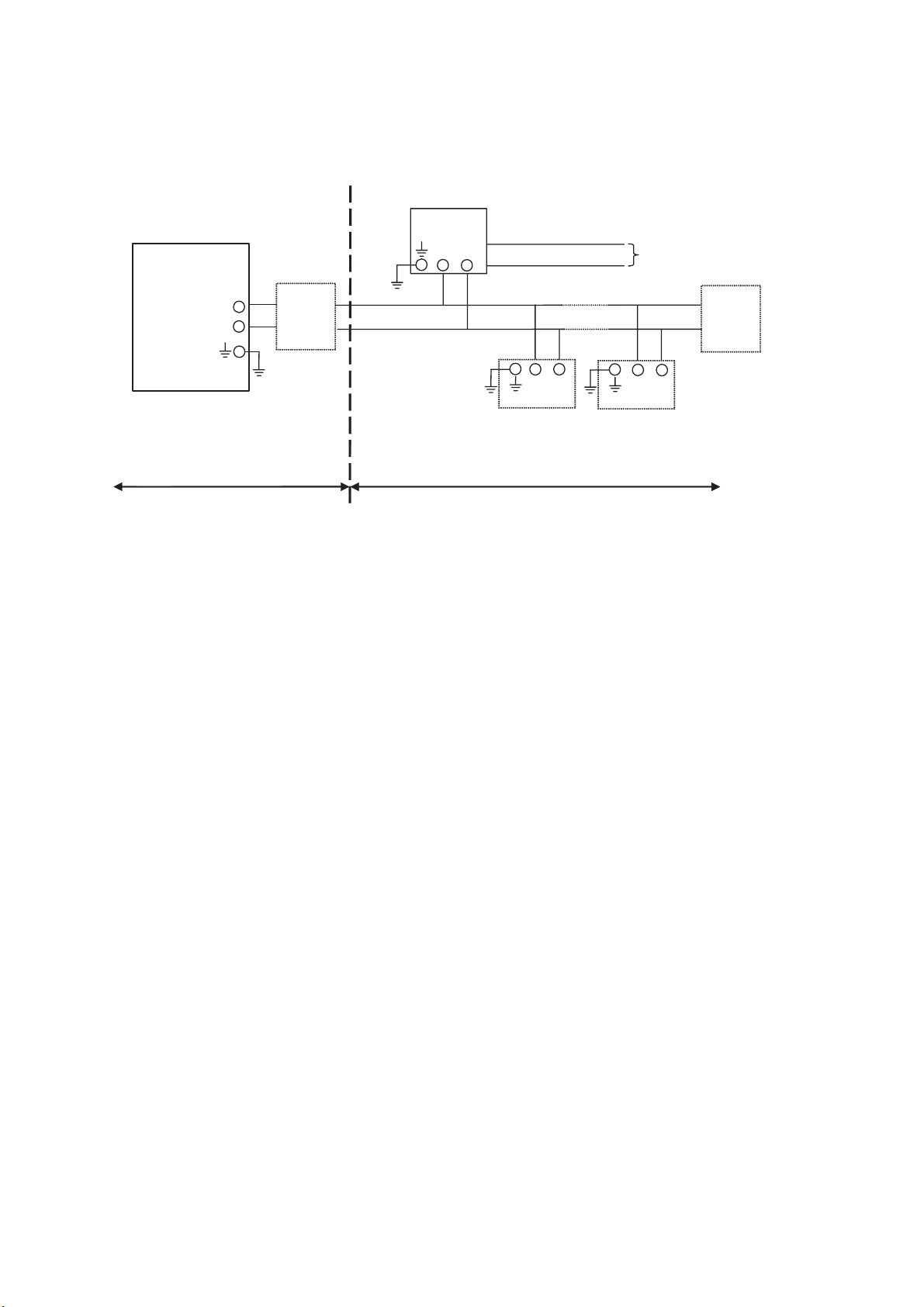

2-10. Control Drawing of ISC202S FF/PB Specification (FM Intrinsically safe Entity)

Unclassified Location

Classified Location

Division 1

FM Approved

barrier

Voc (Vt) d 24 V

Ioc (It) d 250 mA

Poc (Pt) d 1.2 W

Ca t 220pF+ Ccable

La t 0 H + Lcable

Sensor

Connections

Max. cablelength: 60 mtr.

Cable dia. : 3…12 mm.

FM Class I, DIV. 1, Group ABCD

T4 for ambient temp. d 55 qC

-

+

I.S.

certified

Terminator

I.S.

certified

Terminator

ISC202S-F

or ISC202S-P

Transmitter

Transmitter

-

+

Sensor

Connections

-

+

-

+

x Sensor(s) are of a passive type to be regarded as 'simple apparatus', devices which

neither store nor generate voltages over 1.5 V, currents over 0.1 A, power over 25 mW or

energy over 20 PJ, or are FM Approvals entity approved and meet connection

requirements.

x Electrical data of the ISC202S-F & ISC202S-P:

- Supply circuit:

Maximum input voltage Vmax = 24 V

Maximum input current Imax = 250 mA

Maximum input power Pi = 1.2 W

Effective internal capacitance Ci = 220 pF; Effective internal inductance Li = 0 PH.

- Sensor input circuit:

Maximum output voltage Vt = 14.4 V; Maximum output current It = 20 mA

Maximum allowed external capacitance Ca = 600 nF

Maximum allowed external inductance La = 88 mH

x Any FM Approved barrier may be used that meets the following requirements:

Voc or Vt d 24 V

Ioc or It d 250 mA

Poc or Pt d 1.2 W

Ca t 220 pF + Ccable; La t 0 H + Lcable

When installing this equipment, follow the manufacturer’s installation drawing.

Installation should be in accordance with ANSI/ISA RP 12.06.01 “Installation of