Yokogawa OX400 User Manual

User’s

Manual Model OX400

Low Concentration Zirconia

Oxygen Analyzer

[Style: S2]

IM 11M10B01-01E

R

IM 11M10B01-01E

3rd Edition

<INTRODUCTION>

INTRODUCTION

nSafety, Protection, and Modification of the Product

•In order to protect the system controlled by the product and the product itself and ensure safe operation, observe the safety precautions described in this user’s manual. We assume no liability for safety if users fail to observe these instructions when operating the product.

•If this instrument is used in a manner not specified in this user’s manual, the protection provided by this instrument may be impaired.

•If any protection or safety circuit is required for the system controlled by the product or for the product itself, prepare it separately.

•Be sure to use the spare parts approved by Yokogawa Electric Corporation (hereafter simply referred to as YOKOGAWA) when replacing parts or consumables.

•Modification of the product is strictly prohibited.

•The following symbols are used in the product and user’s manual to indicate that there are precautions for safety:

nNotes on Handling User’s Manuals

•Please hand over the user’s manuals to your end users so that they can keep the user’s manuals on hand for convenient reference.

•Please read the information thoroughly before using the product.

•The purpose of these user’s manuals is not to warrant that the product is well suited to any particular purpose but rather to describe the functional details of the product.

•No part of the user’s manuals may be transferred or reproduced without prior written consent from YOKOGAWA.

•YOKOGAWA reserves the right to make improvements in the user’s manuals and product at any time, without notice or obligation.

•If you have any questions, or you find mistakes or omissions in the user’s manuals, please contact our sales representative or your local distributor.

nWarning and Disclaimer

The product is provided on an “as is” basis. YOKOGAWA shall have neither liability nor responsibility to any person or entity with respect to any direct or indirect loss or damage arising from using the product or any defect of the product that YOKOGAWA can not predict in advance.

Media No. IM 11M10B01-01E |

3rd Edition : May. 2011 (YK) |

IM 11M10B01-01E |

All Rights Reserved Copyright © 2009, Yokogawa Electric Corporation |

|

|

ii |

<INTRODUCTION> |

|

|

n Notes on Hardware

• Appearance and Accessories

Check the following when you receive the product:

•Appearance

•Standard accessories

Contact our sales representative or your local distributor if the product’s coating has come off, it has been damaged, or there is shortage of required accessories.

• Model and Suffix Codes

The name plate on the product contains the model and suffix codes. Compare them with those in the general specification to make sure the product is the correct one. If you have any questions, contact

our sales representative or your local distributor.

n Symbol Marks

Throughout this user’s manual, you will find several different types of symbols are used to identify different sections of text.This section describes these icons.

WARNING

WARNING

Identifies instructions that must be observed in order to avoid physical injury and electric shock or death of the operator.

CAUTION

CAUTION

Identifies instructions that must be observed in order to prevent the software or hardware from being damaged or the system from becoming faulty.

NOTE

NOTE

Identifies important information required to understand operations or functions.

n About Unique Representations Used in this Operation Manual

When operation keys, contents displayed on the display, and lamp displays are specifically described in the text or anywhere else in this operation manual, in principle, they are represented in the following ways.

• Operation key |

|

Represented by [ ]. |

Example: [ENT] key |

IM 11M10B01-01E

<INTRODUCTION> |

iii |

|

|

•Display contents on the display

Represented by “ ”. Example: Main display --> “HEAt”

Example: Sub-display --> “CAL”

Example: Data display --> “10.00” (in the ON state)

Example LED lamp -->  PPM (in the ON state),

PPM (in the ON state),  PPM (in the OFF state)

PPM (in the OFF state)

•Graphical representation of the flashing state

Represented by italic characters or the

mark.

mark.

Flashing state |

1.000 |

Flashing state of decimal point |

1.000 |

|

|

|

|

•Representation of digital characters

The OX400 employs a 7-segment alphanumeric digital display. For the correspondence between the display characters on the display and alphanumeric characters for explanation, see Figure

5.2.

n Operation Parameters

The OX400 is shipped with default parameters as shown in Table 8.1. Change them according to the purpose of use. For how to change parameters, see Chapter 6, “Operation and Parameters.” It is

recommended to write down the changed operation parameters as user set values as shown in Table 8.1.

n Notes on Use

The OX400 is a product that conforms to the general safety requirements of the IEC standard. Be sure to observe the following precautions when you operate it.

Handling Precautions

Handling Precautions

•Installation location

The OX400 is structurally non-explosion proof so you cannot use it in an explosive atmosphere.

Also, see 3.1, “Installation Location.”

•Power supply

Be sure to check that the power supply voltage specification of the OX400 matches the voltage of the power supply before turning on the power.

•Protective ground

Be sure to connect the power plug of the OX400 to the 3P socket with a protective ground pin in order to prevent electric shock.

•Fuse

Be sure to use a designated fuse in order to prevent a fire. Be sure to turn off the power before replacing the fuse. Never use a fuse holder other than a designated one.

•Removing cover

There is a heated area inside the OX400, and touching it directly may cause a burn injury. Never remove the cover except to replace the sensor.

IM 11M10B01-01E

iv

<INTRODUCTION>

•When opening the cover to replace the sensor, turn off the power switch, remove the power plug from the socket, and wait for 1.5 hours or more before opening the cover.

•Before connecting wires to the terminal block on the rear panel of the OX400, remove the power plug from the socket in order to prevent electric shock.After finishing the wiring, secure the removed special terminal cover with screws.

•The OX400 is a measuring instrument intended to be installed indoors, so do not install it in a location that is exposed to direct sunlight, rain, and wind.

•Do not use the OX400 in a location that may be subject to vibrations and impact. Doing so may cause destruction and damage to the internal sensor.

•Do not apply a pressure of 30 kPaG or more to the gas inlet. Doing so may cause destruction of the suction pump and damage to the sensor. Be sure to reduce the sample gas pressure to the atmospheric pressure level before introducing the gas.

•Be sure to use metal piping for the gas piping; particularly when handling oxygen concentration in 1 vol % or less. Use of piping materials such as polyethylene, vinyl, rubber, and plastic may cause significant errors in measurements because of their large oxygen transmission and absorption rates.

•The presence of corrosive gas components (H2S, SOx, HCl, NH3, HF, and the like) or potentially toxic elements (Si, Sn, Cd,Te,As, P, and the like) in the sample gas may cause deterioration of the sensor. Be sure to remove them with an activated carbon filter or the like in the previous step of the OX400 before introducing the gas.

•The presence of combustible gas in the sample gas may cause errors in measurements because oxygen in the sample gas will be consumed by combustion. Be sure to remove it with a filter or the like in the step before introducing the sample gas into the OX400.

•Make sure the temperature of the sample gas is 50°C or less.

•Be careful because the presence of water droplets in the sample gas may cause damage to the sensor.

•Keep the supply gas flow rate and pressure as constant as possible while introducing the gas.

•Keep the sample gas outlet open to the atmosphere during operation. If a gas line must be used to discharge gas, use a gas line with a connector that has the largest possible diameter in order to prevent back pressure.

•Do not use the supplied power cord with another device.

•Power cable suffix codes of “-D” can be used in Japan, because another cable doesn’t conform to PSE marking.

IM 11M10B01-01E

<INTRODUCTION>

uAfter-sales Warranty

nDo not modify the product.

nDuring the warranty period, for repair under warranty carry or send the product to the local sales representative or service office.Yokogawa will replace or repair any damaged parts and return the product to you. Before returning a product for repair under warranty, provide us with the model name and serial number and a description of the problem.Any diagrams or data explaining the problem would also be appreciated.

•If we replace the product with a new one, we won’t provide you with a repair report.

•Yokogawa warrants the product for the period stated in the pre-purchase quotation Yokogawa shall conduct defined warranty service based on its standard. When the customer site is located outside of the service area, a fee for dispatching the maintenance engineer will be charged to the customer.

n In the following cases, customer will be charged repair fee regardless of warranty period.

•Failure of components which are out of scope of warranty stated in instruction manual.

•Failure caused by usage of software, hardware or auxiliary equipment, whichYokogawa Electric did not supply.

•Failure due to improper or insufficient maintenance by user.

•Failure due to modification, misuse or outside-of-specifications operation whichYokogawa does not authorize.

•Failure due to power supply (voltage, frequency) being outside specifications or abnormal.

•Failure caused by any usage out of scope of recommended usage.

•Any damage from fire, earthquake, storms and floods, lightning, disturbances, riots, warfare, radiation and other natural changes.

n Yokogawa does not warrant conformance with the specific application at the user site.Yokogawa will not bear direct/indirect responsibility for damage due to a specific application.

n Yokogawa Electric will not bear responsibility when the user configures the product into systems or resells the product.

n Maintenance service and supplying repair parts will be covered for five years after the production ends. For repair for this product, please contact the nearest sales office described in this instruction manual.

IM 11M10B01-01E

vi |

<INTRODUCTION> |

|

|

IM 11M10B01-01E

<CONTENTS>

Model OX400

Low Concentration Zirconia Oxygen Analyzer

[Style: S2]

|

|

|

IM 11M10B01-01E 3rd Edition |

|

CONTENTS |

|

|

||

INTRODUCTION........................................................................................................ |

|

i |

||

uAfter-sales Warranty........................................................................................... |

v |

|||

1. |

Outline........................................................................................................ |

|

|

1-1 |

2. |

Specifications............................................................................................ |

|

2-1 |

|

|

2.1 |

Standard Specifications................................................................................... |

2-1 |

|

|

2.2 |

Characteristics................................................................................................... |

2-3 |

|

|

2.3 |

Model and Suffix Codes.................................................................................... |

2-4 |

|

|

2.4 |

StandardAccessories....................................................................................... |

2-4 |

|

|

2.5 |

External Dimensions......................................................................................... |

2-5 |

|

|

2.6 |

Piping Diagram................................................................................................ |

2-10 |

|

|

2.7 |

Wiring Diagram................................................................................................ |

2-11 |

|

3. |

Installation................................................................................................. |

|

3-1 |

|

|

3.1 |

Installation Location.......................................................................................... |

3-1 |

|

|

3.2 |

How to Install...................................................................................................... |

3-2 |

|

|

|

3.2.1 |

Installing Desktop Type...................................................................... |

3-2 |

|

|

3.2.2 |

Installing Panel Mount Type............................................................... |

3-3 |

|

|

3.2.3 |

Mounting Activated Carbon Filter....................................................... |

3-4 |

4. |

Piping and Wiring...................................................................................... |

4-1 |

||

|

4.1 |

Piping.................................................................................................................. |

|

4-1 |

|

4.2 |

Wirings................................................................................................................ |

|

4-2 |

|

|

4.2.1 |

Power Supply Wiring.......................................................................... |

4-2 |

|

|

4.2.2 |

Signal Wiring....................................................................................... |

4-3 |

|

|

4.2.3 |

Communication.................................................................................. |

4-5 |

5. |

Names and Functions............................................................................... |

5-1 |

||

|

5.1 |

Front Panel......................................................................................................... |

5-1 |

|

|

5.2 |

Rear Panel.......................................................................................................... |

5-3 |

|

6. |

Operation and Parameters....................................................................... |

6-1 |

||

|

6.1 |

Startup and Settings......................................................................................... |

6-2 |

|

|

|

6.1.1 |

Setting Output Range “rnG”............................................................... |

6-2 |

|

|

6.1.2 |

Setting Secondary Output “oUt2”....................................................... |

6-4 |

|

|

6.1.3 |

Setting HOLD Function “HoLd”.......................................................... |

6-4 |

|

|

6.1.4 |

Setting Burnout Function “nAMU”...................................................... |

6-5 |

|

|

6.1.5 |

SettingAlarms (Oxygen Concentration High/LowAlarms) “ALM”..... |

6-6 |

IM 11M10B01-01E

ii |

<CONTENTS> |

|

|

|

|

6.1.6 |

Setting Calibration Gas Concentration “SEt.C”.................................. |

6-7 |

|

|

|

6.1.7 |

Setting Sensor Constant “SEnS”........................................................ |

|

6-7 |

|

|

6.1.8 |

Setting Output Smoothing “SMoo”..................................................... |

|

6-8 |

|

|

6.1.9 |

Setting Multi-Selector “MLS”.............................................................. |

|

6-8 |

|

|

6.1.10 |

Checking Calibration Coefficient “CoEF”........................................... |

|

6-8 |

|

|

6.1.11 |

Displaying Cell Resistance Value “CEL.r”.......................................... |

|

6-9 |

|

|

6.1.12 |

Displaying Software Revision “rEV”................................................... |

|

6-9 |

|

6.2 |

Calibration “CAL”............................................................................................ |

|

6-10 |

|

|

6.3 |

Communication............................................................................................... |

|

6-12 |

|

|

6.4 |

Measurement Gas Sampling Using Aspirator.............................................. |

|

6-14 |

|

|

6.5 |

Switching Measurement Flow Path Using Multi-Selector........................... |

6-15 |

||

|

6.6 |

Numerical Value, Decimal Point, and Unit Input Operation........................ |

6-16 |

||

7. |

Inspection and Maintenance.................................................................... |

|

7-1 |

||

|

7.1 |

Routine Inspection and Maintenance............................................................. |

|

7-1 |

|

|

7.2 |

Inspection in the Event of an Error.................................................................. |

|

7-1 |

|

|

|

7.2.1 |

Inspection in the Event of an Alarm (ALM)......................................... |

|

7-2 |

|

|

7.2.2 |

Inspection in the Event of an Error (ERR).......................................... |

|

7-2 |

|

7.3 |

How to Replace Sensor..................................................................................... |

|

7-3 |

|

|

|

7.3.1 |

Removing Sensor............................................................................... |

|

7-3 |

|

|

7.3.2 |

Installing Sensor................................................................................. |

|

7-5 |

|

7.4 |

How to Replace Activated Carbon Filter......................................................... |

|

7-6 |

|

|

7.5 |

How to Replace the Line Filter......................................................................... |

|

7-8 |

|

8. |

Appendix.................................................................................................... |

|

|

8-1 |

|

|

8.1 |

Parameter Settings............................................................................................ |

|

8-1 |

|

Customer Maintenance Parts List (Style: S2).................... |

CMPL 11M10B01-02E |

||||

Revision Information................................................................................................ |

|

|

i |

||

IM 11M10B01-01E

<1. Outline> |

1-1 |

1.Outline

The OX400 is a highly accurate and reliable low concentration zirconia oxygen analyzer that is capable of measuring a wide range of concentrations, from 0-10 ppm up to 0-100 vol% O2. This is the latest oxygen analyzer fromYokogawa, and its development was based on the company’s long experience and strong track record with this technology.

Aproprietary new thin-film deposition technology was used in the zirconia sensor that creates a molecular bond between the zirconia element and the platinum layer. This prevents separation, enables a reduction in sensor size and ensures a high-speed response and long life.

The OX400 can be used to control and monitor various semiconductor applications, and to control environment, air leakage into inert gas, and other processes.

Features

Long life and high-speed response

•Thanks to the use ofYokogawa’s proprietary new thin-film deposition technology, the sensor has three times the lifespan of those used in our earlier products.

•A cylindrical sensor design facilitates the replacement of measurement gases, thereby helping to assure a high-speed response.

High performance and high reliability

•Superior repeatability and linearity even at low oxygen concentrations

•Either pump or aspirator sampling can be selected, depending on the application.

Built-in functions and a variety of self-diagnosis functions

•Comes with multi selector, auto range, partial range, and pump on/off functions

•A variety of self-diagnosis functions are provided that detect malfunctions such as heater temperature error, temperature sensor burnout, and sensor resistance value error.

Superior maintainability

•The sensor can be replaced on-site.

•Compact and lightweight for easy installation.

Applications

•Oxygen concentration control in semiconductor-related diffusion and drying furnaces and in LCD manufacturing processes

•Oxygen concentration control in solder pot flow and re-flow ovens, and glove boxes used in electronics manufacturing, and in gas production processes

•Oxygen concentration measurements to prevent dust explosions during powder transfer

IM 11M10B01-01E

1-2 |

<1. Outline> |

|

|

IM 11M10B01-01E

<2. Specifications> |

2-1 |

2.Specifications

2.1Standard Specifications

Measurement object

: Oxygen concentrations in inert gases containing no flammable gas, silica, corrosive gas, or liquid

(including water vapor).

Measurement system: Zirconia system

Sampling method: Pump, aspirator, or no suction device.

Pump and aspirator suction flow rate

:Approx. 1.0 l/min.

Aspirator suction conditions

:Air or N2, supply pressure 65 to 100 kPaG, total discharge flow 10 l/min max. (when gas inlet and outlet are at ambient atmospheric pressure).

Sample gas conditions

Flow rate |

: 200 ± 25 ml/min (only applies to sensor). |

Temperature |

: 0-50°C (non-condensing). |

Humidity |

: Non-condensing. |

Pressure |

: 0-300 PaG |

Measurement range: 0-10 ppm O2 to 0-100 vol% O2

Resolution: 0.01 ppm O2.

Display : 4 digit LED.

Main display: O2 concentration (auto switching).

Sub display: Parameter or alarm/error number

Unit |

: %, ppm. |

|

Output range |

|

|

|

Auto |

: 0-10 ppm, 0-100 ppm, 0-1000 ppm, 0-1%, 0-10%, 0-100% (default) |

|

|

Other : 0-0 ppm, 0-00 ppm, 0-000 ppm, 0-%, 0-0% can be set, |

|

|

is an integer from 2 to 9. |

|

Fixed |

: Set to 0-10 ppm, 0-100 ppm, 0-1000 ppm, 0-1%, 0-10%, or 0-100%. |

|

Partial |

: Lower value or upper value of range can be set. |

Note : Span (upper value-lower value) is 20% FS or more of above fixed range.

Example: 200-400 ppm when fixed range is 0-1000 ppm, 20-40 ppm when fixed range is 0-

100 ppm.

Analog output: 2 outputs

Primary |

: 4 to 20 mADC (maximum load resistance: 550Ω ) |

Secondary |

: Select from 0-1, 0-5, 0-10 V DC ( load resistance: 10 kΩ or greater) |

IM 11M10B01-01E

2-2 |

<2. Specifications> |

|

|

Contact output: 3 outputs

Error contact, O2 concentration high/low alarm contact, range marker output

Multi selector (optional)

: Contact output for switching sample gas flow, measument flow information contact output. Note : For details , see external dimensions.

Contact output specifications

General : Relay Nominal contact capacity:

2 A 30V DC, 2 A 240 V AC (120 V AC for 100 V power supply) for resistive load

Maximum power: 60 W, 480 VA

Maximum voltage: 30 V DC, 264 VAC (132 VAC for 100 V power supply) Maximum current: 2ADC/AC

Contact input: Voltage-free contact, 1 point

: Remote switching for sample gas suction pump ON/OFF

Self-diagnostics

Error (failure) : Sensor unit error, heater temperature error, temperature sensor disconnection, device temperature error, CPU error, fan stop.

Alarm (warning) : Heater unstable, sensor defect, electromotive force abnormal, asymmetry voltage error, calibration error, sensor resistance error, O2 concentration upper/lower, over range.

Serial communication

Comm. signal |

: RS-232 , one way |

Baud rate |

: 38,400 bps |

Data (ASCII) |

: O2 concentration, unit, alarm/error |

Calibration methods: |

|

(1) 3 point: |

10 ppm, 1000 ppm, Air |

(2) 2 point: |

zero and span calibration may be set freely |

(3)1 point:

(4)Air calibration

Warm-up time : Within 20 min

Power supply:

Power supply : 100 - 120 VAC/200 - 240 VAC, 50/60 Hz

Acceptable range: 100 to 120 V AC ±10%, 50/60 Hz 200 to 240 VAC ±10%, 50/60 Hz

Power consumption

:100 to 120 VAC, 200 VAmax.

200 to 240 VAC, 400 VAmax.

Dimensions : 213 (W) x 132 (H) x approx. 375 (D) mm

Weight :Approx. 5 kg

Finish : Polyester coating

IM 11M10B01-01E

<2. Specifications> |

2-3 |

|

|

Line connection

Gas inlet : Rc1/4 or 1/4NPTfemale

Gas outlet : Rc1/4 or 1/4NPTfemale

Electrical connection

External output terminals: M3 screw

Contact input/output terminals: M3 screw

Serial communication: D-sub 9 pin connector

Ground: within power cord connector

Environment and operational conditions

Installation conditions: Indoors, panel or wall mounting, non explosion area

Ambient temperature: 0 to 40°C, non-condensing Ambient humidity: 5 to 85% RH

Storage temperature: -5 to 50°C

Conformance to Safety and EMC standards |

R |

C US |

Safety : EN 61010-1

CAN/CSA-C22.2 No. 61010-1-04, ULStd. No. 61010-1

EMC: EN 61326-1 Class A, Table 2 (for use in industrial locations) EN 61326-2-3, EN 61000-3-2, EN 61000-3-3

(Note1) This instrument is a Class A product, and it is designed for use in the industrial environment. Please use this instrument in the industrial environment only.

(Note1) The current or voltage signal output cable length and contact input cable length must be no longer than 30 m for CE marking. RS232 connection cable length must be no longer than 3 m.

Installation altitude: |

2000 m or less |

Category based on IEC 61010: |

II (Note) |

Pollution degree based on IEC 61010: |

2 (Note) |

Note: Installation category, called over-voltage category, specifies impulse withstand voltage.

Category II is for electrical equipment.

Pollution degree indicates the degree of existence of solid, liquid, gas or other inclusions which may reduce dielectric strength. Pollution degree 2 is the normal indoor environment.

2.2Characteristics

Repeatability

: ±1% FS (Hereafter, either 10, 100, 1000 ppm, 1%, 10%, or 100% O2 is FS)

Linearity

:±2% FS

±3% FS (0-100 ppm or less)

IM 11M10B01-01E

2-4 |

<2. Specifications> |

|

|

Response time : 90% response

:Within 10 sec (0-1% or more)

:Within 30 sec (less than 0-1%)

Drift

:±2% FS / week

2.3Model and Suffix Codes

|

|

|

|

|

[Style: S2] |

Model |

|

Suffix Code |

Option |

Description |

|

|

Code |

||||

OX400 |

|

|

|

|

Low Concentration Zirconia Oxygen Analyzer |

Power supply |

-5 |

|

|

100-120 V AC |

|

(Note 1) |

-3 |

|

|

200-240 V AC |

|

|

|

|

|

||

Sampling method |

-P |

|

Built-in pump |

||

|

|

|

-A |

|

With aspirator |

|

|

|

-N |

|

No suction device |

Line connection |

|

R |

|

Rc 1/4 |

|

|

|

|

T |

|

1/4 NPT |

User’s manual |

|

-J |

|

Japanese |

|

|

|

|

-E |

|

English |

|

|

|

|

||

Power cable (Note 1) |

-D |

|

UL/CSA cable (2 m) |

||

|

|

|

-F |

|

VDE cable (2.5 m) |

|

|

|

-H |

|

GB cable (2.5 m) |

|

|

|

-Q |

|

BS cable (2 m) |

|

|

|

-R |

|

SAA cable (2.5 m) |

|

|

|

|

||

Option |

Mounting hardware |

/P |

Panel mount |

||

|

|

Multi selector function |

/MS |

Multi selector function |

|

|

|

|

Filter |

/A |

Activated carbon filter (Note 2) |

|

|

|

|

|

|

(Note 1) Power cable of two-pole with earthing plug is attached.

Suffix code “-D” of power cable can not be specified when “-3” of power supply is specified.

Power cable of “-D” can be used in Japan, because another cable doesn’t conform to PSE marking. (Note 2) When “R” of line connection is specified, K9643KH filter (Rc1/4) is attached,

when “T” of line connection is specified, K9643KJ filter (1/4NPT) is attached.

2.4StandardAccessories

Check the standard and optional accessories when you receive the product.

Accessories

Item |

Part no. and rating |

Qt’y |

Fuse |

A1113EF: |

1 |

|

Time-lag T3.15 conformed to IEC60127 |

|

|

|

|

User’s manual |

IM 11M10B01-01E (English), -01 (Japanese) |

1 |

Aspirator kit |

K9643KA(Rc1/4), K9643KB (1/4NPT) |

Optional |

Panel mount kit |

K9643KC |

Optional |

Activated carbon filter |

K9643KH (Rc1/4), K9643KJ (1/4NPT) |

Optional |

IM 11M10B01-01E

|

|

<2. Specifications> |

2-5 |

|

|

|

|

|

|

Consumables |

|

|

|

|

|

|

|

|

|

|

Item |

Part no. and rating |

Qt’y |

|

|

|

|

|

|

|

Activated filter element kit (15 times replacement) |

K9643KK |

1 |

|

|

|

|

|

|

|

Filter kit (5 times replacement) |

K9643KL |

1 |

|

|

|

|

|

|

|

Sensor assembly (including O-ring) |

K9643KG |

1 |

|

|

|

|

|

|

|

Snap ring (retainer) |

Y9011EV |

1 (*) |

|

|

|

|

|

|

|

Plate |

K9213FB |

1 (*) |

|

|

|

|

|

|

|

Filter |

K9643FB |

1 (*) |

|

|

|

|

|

|

|

Snap ring plier |

K9643ZE |

1 |

|

|

|

|

|

|

(*) Qt’y of 10 pieces or more can be purchased.

2.5 External Dimensions |

|

|

Unit: mm |

Panel mount type with built-in pump or no suction device (OX400----/P) |

|

||

260 |

|

Mount |

|

238 |

10 to 20 20 |

330 |

19.3 |

6 |

|

|

|

101.6 |

132 |

|

|

6 |

|

|

|

Note: Pump ON/OFF switch; when no suction device [-N] is specified for the sampling method, this switch is not installed.

Frame |

Frame |

240 ±1

225 ±1

Ventilation |

Screw |

|

|

holes |

|

4xM5 screw

4xM5 screw

Panel Cutout

Seal

|

|

|

|

|

|

|

|

|

|

|

|

|

|

±0.3 |

+2 0 |

|

||||

101.6 |

135 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes on mounting

1.Make sure the bottom supports do not block the ventilation outlet on the bottom panel of the measuring instrument.

2.Maintain at least 100 mm of free space around the measuring instrument in order to ensure adequate ventilation.

3.Make sure the panel is at least 2 mm thick.

IM 11M10B01-01E

2-6 |

<2. Specifications> |

|

|

|

Panel mount type with aspirator (OX400--A--/P) |

|

Unit: mm |

||

|

260 |

|

Mount |

|

|

|

|

||

|

238 |

10 to 20 20 |

330 |

19.3 |

|

6 |

|

|

|

|

101.6 |

132 |

|

|

|

6 |

|

|

|

|

Frame |

Frame |

|

40 to 50 |

|

|

|

(Line connection : in case of Rc1/4) |

|

Ventilation |

Screw |

|

|

|

|

|

|

holes |

|

60 to 70 |

|

|

|

||

|

|

(Line connection : in case of 1/4NPT) |

|

|

|

240 ±1 |

|

Bushing |

|

225 ±1 |

|

Aspirator |

Seal |

|

|

|

|

|

|

|

(Line connection : in case of Rc1/4) |

±0.3 |

|

|

|

+2 0 |

|

Connector |

|

101.6 |

135 |

|

|

|

|

Bushing |

|

4xM5 screw |

|

|

(Line connection : in case of 1/4NPT) |

|

|

Aspirator |

|

Panel Cutout |

|

|

|

|

|

Notes on mounting

1.Make sure the bottom supports do not block the ventilation outlet on the bottom panel of the measuring instrument.

2.Maintain at least 100 mm of free space around the measuring instrument in order to ensure adequate ventilation.

3.Make sure the panel is at least 2 mm thick.

IM 11M10B01-01E

<2. Specifications> |

2-7 |

|

|

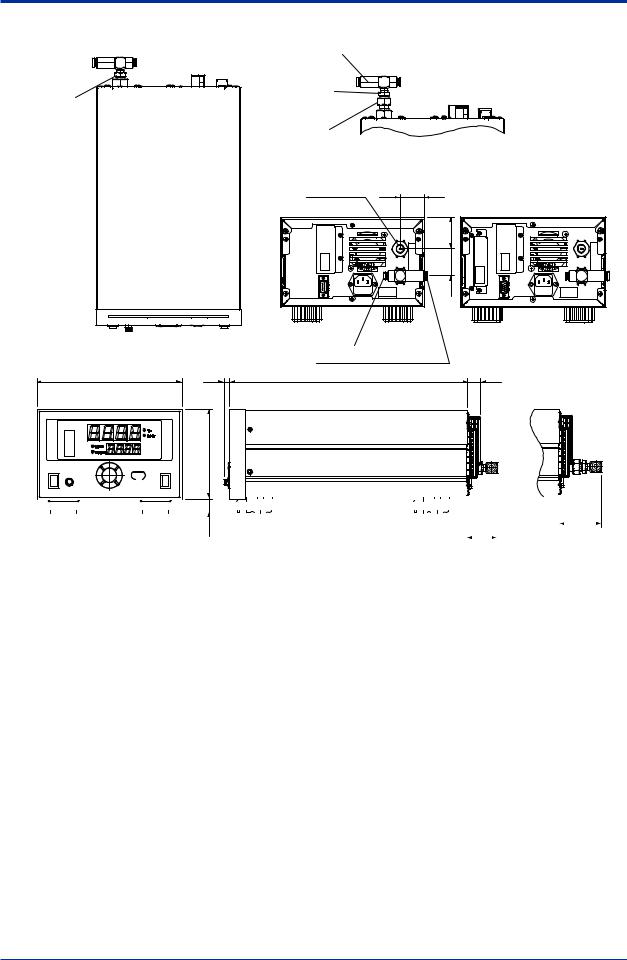

Desktop type with built-in pump or no suction device (OX400----)

Unit: mm

Rear

Sample gas inlet |

35.3 |

With multi selector function

46 |

40 |

Sample gas outlet

213 |

|

10 to 20 |

350 |

19.3 |

|

|

|

|

|

132 |

20

Note: Pump ON/OFF switch; when no suction device [-N] is specified for the sampling method, this switch is not installed.

Notes on installation

Hot air is discharged from the air outlet on the rear panel of the OX400. Maintain at least 100 mm of free space around the OX400 to ensure adequate ventilation.

IM 11M10B01-01E

2-8 |

|

<2. Specifications> |

|

|

|

Desktop type with aspirator (OX400--A--) |

|

Unit: mm |

|||

|

|

(Line connection : |

|

|

|

|

|

Aspirator |

|

|

|

|

|

in case of Rc1/4) |

|

|

|

|

Aspirator |

|

(Line connection : |

||

|

|

|

|||

|

Bushing |

|

Bushing |

in case of 1/4NPT) |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Connector |

|

|

|

|

|

Sample gas inlet |

35.3 |

Rear |

|

|

|

|

||

|

|

|

With multi selector function |

|

|

46 |

|

|

|

40 |

|

|

Aspirator gas inlet (Φ6) |

|

|

|

10 to 20 |

Aspirator and sample gas outlet (Φ8) |

|

213 |

350 |

19.3 |

|

|

132 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60 to 70 |

|

||

20 |

|

|

|

|

|

|

|

|

|

|

|

|

40 to 50 |

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Line connection : |

||||||||||||||||||||||||||||||

Notes on installation |

|

|

|

|||||||||||||||||||||||||||||||||||||||||

|

|

(Line connection : |

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

Hot air is discharged from the air outlet on the rear panel of the OX400. |

|

|

in case of 1/4NPT) |

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

Maintain at least 100 mm of free space around the OX400 to ensure |

|

|

|

in case of Rc1/4) |

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

adequate ventilation. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

IM 11M10B01-01E

|

|

|

|

|

|

<2. Specifications> |

2-9 |

Activated carbon filter |

|

|

|

|

|

|

|

Activated carbon filter of |

Maintenance space |

Unit: mm |

|||||

option code “/A” |

|

The filter holder including |

more than 200 |

|

|||

|

K9643KH: Rc1/4 |

|

piping connection can be |

|

|||

|

|

moved upward to replace |

|

|

|||

|

K9643KJ: 1/4NPT |

|

29.5 |

|

|||

|

|

a filter element. |

|

|

|||

2-M5 screws |

|

|

|

|

Sample gas inlet |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

(Rc1/4 or 1/4NPT) |

|

110 ± 0.5 |

Mark “A” |

110 |

± 0.5 |

150 (157) 130 |

|

||

In case of |

K9643KJ |

|

|||||

|

|

|

|

|

|

||

|

|

|

|

|

|

Sample gas outlet |

|

|

|

|

|

|

|

(Rc1/4 or 1/4NPT) |

|

Fixing holes |

2-Ф6.5 holes |

15 |

|

10 |

|

||

|

|

|

|

|

47 |

|

|

|

|

|

|

25 |

|

Maintenance space |

more than |

|

|

|

|

|

|

||

|

|

|

|

|

|

The filter holder including |

200 |

|

|

|

|

|

35 |

piping connection can be |

|

|

|

|

|

47 |

moved downward to |

|

|

|

|

|

|

|

replace a filter element. |

|

|

|

|

|

|

35 |

|

|

|

|

|

|

|

60 |

|

|

|

IM 11M10B01-01E

2-10 |

<2. Specifications> |

2.6Piping Diagram

Built-in pump (Sampling method [-P])

Filter2 |

Suction pump |

|

|

IN |

|

|

|

Sample gas |

P |

|

Oxygen |

|

|

Restriction |

|

Pipe connection Filter1 |

|

sensor |

|

Throttle |

|

||

Rc1/4 or |

Heater |

|

|

valve |

|

||

1/4NPT |

(Operable from |

|

|

the front panel) |

|

|

|

OUT |

|

Flow meter |

|

|

|

|

With aspirator (Sampling method [-A])

|

IN |

Filter2 |

|

Sample gas |

|

|

|

|

|

Oxygen |

|

|

|

|

|

|

|

Filter1 |

sensor |

Air or N2 |

supply gas |

Throttle |

Heater |

inlet Φ6 connector |

valve |

||

(Operable from |

|

||

|

|

|

|

|

|

the front panel) |

Restriction |

|

|

|

|

Aspirator |

|

|

|

|

|

|

Flow meter |

OUT Φ8 connector

Note: If no suction device [-N] is specified, the aspirator is removed from this diagram.

IM 11M10B01-01E

Loading...

Loading...