VEGA FLEX81 User Manual

Operating Instructions

TDR sensor for continuous level and interface measurement of liquids

VEGAFLEX 81

4 … 20 mA/HART two-wire Coax probe

Document ID: 42279

Quick start

|

Quick start |

|

|

The quick start procedure enables a quick setup with many applica- |

|

|

tions.You can find further information in the respective chapters of the |

|

|

operating instructions manual. |

|

Mounting |

Distance from the metallic vessel wall > 300 mm.Distance from |

|

|

→ non-metallic vessel wall > 500 mm.The probe must not touch any |

|

|

installations or the vessel wall. |

|

|

For further information see chapter "Mounting". |

|

Electrical connection |

1. Make sure that the power supply corresponds to the specifica- |

|

|

tions on the type label. |

|

|

2. Connect the instrument according to the following illustration |

|

|

|

2 |

|

4...20mA |

3 |

|

|

|

(+)1 |

2(-) |

5 6 7 8 |

4 |

1

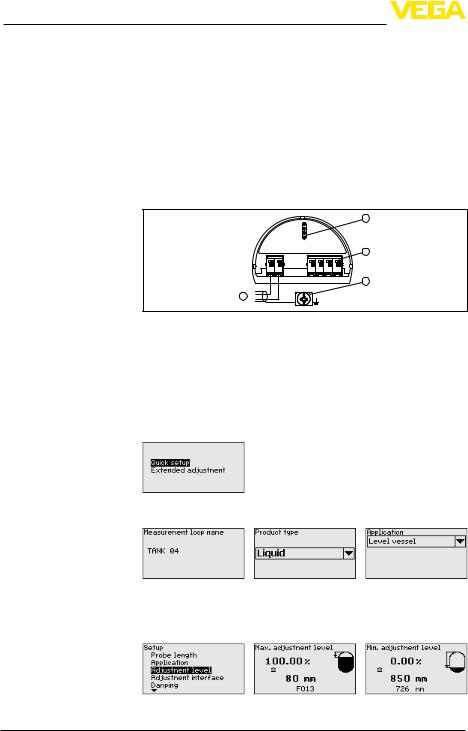

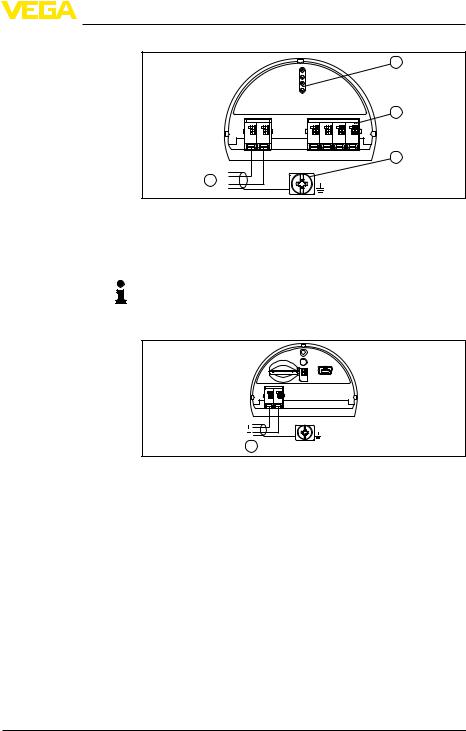

Fig. 1: Electronics and connection compartment, single chamber housing

1Voltage supply, signal output

2For display and adjustment module or interface adapter

3For external display and adjustment unit

4Ground terminal for connection of the cable screen

See also chapter "Connecting to power supply"

Set parameters |

For standard applications we recommend selecting the "Quick setup" |

|

in the display and adjustment module. |

1.In this menu item you can select the application.You can choose between level and interface measurement.

2.In the menu item "Medium - Dielectric constant" you can define the medium type (medium).

3.Carry out the adjustment in the menu items "Min. adjustment" and "Max. adjustment".

130612-EN-42279

2 |

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

Quick start

4.A "Linearization" is recommended for all vessels in which the vessel volume does not increase linearly with the level - e.g.in a horizontal cylindrical or spherical tank.Activate the appropriate curve.

5.A "False signal suppression" detects, marks and saves the false signals so that they are no longer taken into account for level measurement.We generally recommend a false signal suppression.

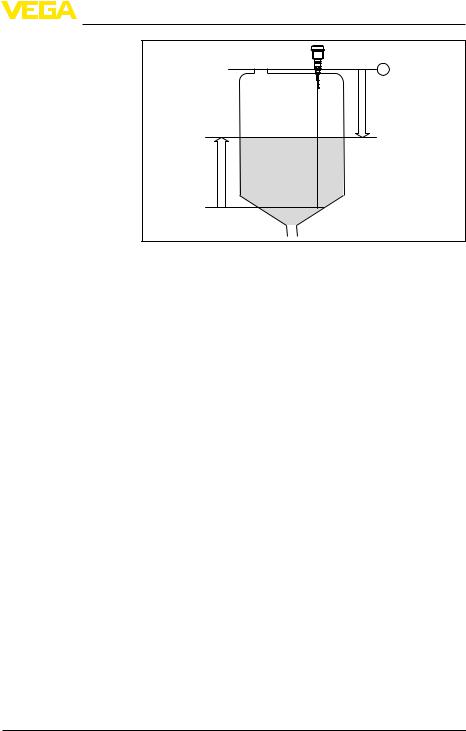

Parameterization example The sensor measures the distance from the sensor (reference plane) to the product surface.

|

|

|

1 |

|

1 |

|

|

|

4 |

|

4 |

|

|

2 |

3 |

2 |

3 |

|

|

|

|

||

|

|

|

5 |

|

5 |

|

Fig. 2: Measuring ranges - VEGAFLEX 81 |

|

|

||

|

1 |

Reference plane |

|

|

|

|

2 |

Probe length L |

|

|

|

|

3 |

Measuring range (default setting refers to the measuring range in water) |

|||

|

4 |

Upper dead band (in this area no measurement is possible) |

|||

|

5 |

Lower dead band (in this area no measurement is possible) |

|||

|

For this adjustment, the distance is entered when the vessel is full |

||||

|

and nearly empty.If these values are not known, an adjustment with |

||||

|

other distances, for example, 10 % and 90 % is also possible.Starting |

||||

|

point for these distance specifications is always the seal surface of |

||||

|

the thread or flange. |

|

|

|

|

Further steps |

1. |

In the menu "Additional settings", menu item "Damping" you can |

|||

|

|

adjust the requested damping of the output signal. |

|||

2. Select the parameter of the current output and the output characteristics in the menu item "Current output".

42279-EN-130612

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

3 |

Contents

Contents

1 About this document |

6 |

|

1.1 |

Function............................................................................................................................ |

|

1.2 |

Target group...................................................................................................................... |

6 |

1.3 |

Symbolism used............................................................................................................... |

6 |

2 For your safety |

7 |

|

2.1 |

Authorised personnel........................................................................................................ |

|

2.2 |

Appropriate use................................................................................................................ |

7 |

2.3 |

Warning about incorrect use............................................................................................. |

7 |

2.4 |

General safety instructions................................................................................................ |

7 |

2.5 |

CE conformity................................................................................................................... |

7 |

2.6 |

NAMUR recommendations............................................................................................... |

8 |

2.7 |

Environmental instructions................................................................................................ |

8 |

3 Product description |

9 |

|

3.1 |

Configuration.................................................................................................................... |

|

3.2 |

Principle of operation...................................................................................................... |

10 |

3.3 |

Packaging, transport and storage................................................................................... |

13 |

3.4 |

Accessories and replacement parts................................................................................ |

13 |

4 |

Mounting |

15 |

||

|

4.1 |

General instructions........................................................................................................ |

||

|

4.2 |

Mounting instructions...................................................................................................... |

15 |

|

5 |

Connecting to power supply |

19 |

||

|

5.1 |

Preparing the connection................................................................................................ |

||

|

5.2 |

Connecting..................................................................................................................... |

20 |

|

|

5.3 |

Wiring plan, single chamber housing.............................................................................. |

22 |

|

|

5.4 |

Wiring plan, double chamber housing............................................................................. |

22 |

|

|

5.5 |

Wiring plan, Ex-d-ia double chamber housing................................................................ |

24 |

|

|

5.6 |

Wiring plan - version IP 66/IP 68, 1 bar........................................................................... |

25 |

|

|

5.7 |

Supplementary electronics............................................................................................. |

26 |

|

|

5.8 |

Switch-on phase............................................................................................................. |

26 |

|

6 |

Set up with the display and adjustment module |

28 |

||

|

6.1 |

Insert display and adjustment module............................................................................. |

||

|

6.2 |

Adjustment system.......................................................................................................... |

29 |

|

|

6.3 |

Parameter adjustment - Quick setup............................................................................... |

30 |

|

|

6.4 |

Parameter adjustment - Extended adjustment................................................................ |

33 |

|

|

6.5 |

Saving the parameter adjustment data........................................................................... |

52 |

|

7 |

Setup with PACTware |

53 |

||

|

7.1 |

Connect the PC............................................................................................................... |

||

|

7.2 |

Parameter adjustment with PACTware............................................................................ |

54 |

|

|

7.3 |

Set up with the quick setup............................................................................................. |

55 |

|

|

7.4 |

Saving the parameter adjustment data........................................................................... |

59 |

|

8 |

Set up with other systems |

60 |

||

|

8.1 |

DD adjustment programs................................................................................................ |

||

|

8.2 |

Field Communicator 375, 475......................................................................................... |

60 |

|

9 |

Diagnostics and service |

61 |

||

|

9.1 |

Maintenance................................................................................................................... |

||

|

|

|

|

|

4 |

|

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

||

130612-EN-42279

42279-EN-130612

|

|

Contents |

9.2 |

Diagnosis memory.......................................................................................................... |

61 |

9.3 |

Status messages............................................................................................................ |

62 |

9.4 |

Rectify faults................................................................................................................... |

66 |

9.5 |

Exchanging the electronics module................................................................................ |

69 |

9.6 |

Software update.............................................................................................................. |

70 |

9.7 |

How to proceed in case of repair..................................................................................... |

70 |

10 Dismounting |

|

|

10.1 |

Dismounting steps.......................................................................................................... |

71 |

10.2 |

Disposal.......................................................................................................................... |

71 |

11 Supplement |

|

|

11.1 |

Technical data................................................................................................................. |

72 |

11.2 |

Dimensions..................................................................................................................... |

82 |

Safety instructions for Ex areas

Please note the Ex-specific safety information for installation and operation in Ex areas.These safety instructions are part of the operating instructions manual and come with the Ex-approved instruments.

Editing status: 2013-06-11

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

5 |

1 About this document

1 About this document

1.1Function

This operating instructions manual provides all the information you need for mounting, connection and setup as well as important instructions for maintenance and fault rectification.Please read this information before putting the instrument into operation and keep this manual accessible in the immediate vicinity of the device.

1.2Target group

This operating instructions manual is directed to trained specialist personnel.The contents of this manual should be made available to these personnel and put into practice by them.

1.3Symbolism used

•

→

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or malfunctions can result.

Warning: If this warning is ignored, injury to persons and/or serious damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

List

The dot set in front indicates a list with no implied sequence.

Action

This arrow indicates a single action.

1Sequence of actions

Numbers set in front indicate successive steps in a procedure.

Battery disposal

This symbol indicates special information about the disposal of batteries and accumulators.

130612-EN-42279

6 |

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

42279-EN-130612

2 For your safety

2 For your safety

2.1Authorised personnel

All operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator.

During work on and with the device the required personal protective equipment must always be worn.

2.2Appropriate use

VEGAFLEX 81 is a sensor for continuous level measurement.

You can find detailed information on the application range in chapter "Product description".

Operational reliability is ensured only if the instrument is properly used according to the specifications in the operating instructions manual as well as possible supplementary instructions.

2.3Warning about incorrect use

Inappropriate or incorrect use of the instrument can give rise to application-specific hazards, e.g.vessel overfill or damage to system components through incorrect mounting or adjustment.

2.4General safety instructions

This is a state-of-the-art instrument complying with all prevailing regulations and guidelines. The instrument must only be operated in a technically flawless and reliable condition.The operator is responsible for the trouble-free operation of the instrument.

During the entire duration of use, the user is obliged to determine the compliance of the necessary occupational safety measures with the current valid rules and regulations and also take note of new regulations.

The safety instructions in this operating instructions manual, the national installation standards as well as the valid safety regulations and accident prevention rules must be observed by the user.

For safety and warranty reasons, any invasive work on the device beyond that described in the operating instructions manual may be carried out only by personnel authorised by the manufacturer.Arbitrary conversions or modifications are explicitly forbidden.

The safety approval markings and safety tips on the device must also be observed.

2.5CE conformity

The device fulfills the legal requirements of the applicable EC guidelines.By affixing the CE marking, we confirm successful testing of the product.

You can find the CE Certificate of Conformity in the download section of our homepage.

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

7 |

2 For your safety

Electromagnetic compatibility

Instruments with plastic housing as well as in four-wire or Ex-d-ia version are designed for use in an industrial environment.Nevertheless, electromagnetic interference from electrical conductors and radiated emissions must be taken into account, as is usual with a class A instrument according to EN 61326-1.If the instrument is used in a different environment, the electromagnetic compatibility to other instruments must be ensured by suitable measures.

2.6NAMUR recommendations

NAMUR is the automation technology user association in the process industry in Germany. The published NAMUR recommendations are accepted as the standard in field instrumentation.

The device fulfills the requirements of the following NAMUR recommendations:

•

•

•

•

NE 21 – Electromagnetic compatibility of equipment

NE 43 – Signal level for malfunction information from measuring transducers

NE 53 – Compatibility of field devices and display/adjustment components

NE 107 – Self-monitoring and diagnosis of field devices

For further information see www.namur.de.

2.7Environmental instructions

Protection of the environment is one of our most important duties. That is why we have introduced an environment management system with the goal of continuously improving company environmental protection.The environment management system is certified according to DIN EN ISO 14001.

Please help us fulfill this obligation by observing the environmental instructions in this manual:

•Chapter "Packaging, transport and storage"

•Chapter "Disposal"

130612-EN-42279

8 |

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

42279-EN-130612

3 Product description

3 Product description

3.1Configuration

Type plate |

The nameplate contains the most important data for identification and |

|

use of the instrument: |

1 |

16 |

2 |

15 |

|

3 |

14 |

4 |

5 |

13 |

6 |

|

7 |

12 |

|

8 |

||

|

||

9 |

11 |

|

10 |

||

|

Fig. 3: Layout of the type label (example)

1Instrument type

2Product code

3Approvals

4Power supply and signal output, electronics

5Protection rating

6Probe length

7Process and ambient temperature, process pressure

8Material, wetted parts

9Hardware and software version

10Order number

11Serial number of the instrument

12Symbol of the device protection class

13ID numbers, instrument documentation

14Reminder to observe the instrument documentation

15Notified authority for CE marking

16Approval directives

Serial number |

With the serial number of the instrument on the type label you can find |

|

the following data on our homepage: |

•Article number of the instrument (HTML)

•Delivery date (HTML)

•Order-specific instrument features (HTML)

•Operating instructions at the time of shipment (PDF)

•Order-specific sensor data for an electronics exchange (XML)

•Test certificate pressure transmitters (PDF)

Go to www.vega.com, "VEGA Tools" and "Serial number search".

As an alternative, you can find the data via your Smartphone:

•Download the Smartphone-App "VEGA Tools" from the "Apple App Store " or the "Google Play Store"

•Scan the Data-Matrix-Code on the type label of the instrument or

•Enter the serial number manually into the App

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

9 |

3 Product description

Scope of this operating |

This operating instructions manual applies to the following instrument |

||

instructions manual |

versions: |

||

|

• |

Hardware from 1.0.0 |

|

|

• |

Software from 1.0.0 |

|

|

• |

Only for instrument versions without SIL qualification |

|

Versions |

The instrument and the electronics version can be determined via the |

||

|

product code on the type label as well as on the electronics. |

||

|

• |

Standard electronics: Type FX80H.- |

|

Scope of delivery |

The scope of delivery encompasses: |

||

|

• |

Sensor |

|

|

• |

Documentation |

|

|

–– |

this operating instructions manual |

|

|

|

–– |

Test certificate measuring accuracy (optional) |

|

|

–– |

Operating instructions manual "Display and adjustment mod- |

|

|

–– |

ule" (optional) |

|

|

Supplementary instructions "GSM/GPRS radio module" |

|

|

|

–– |

(optional) |

|

|

Supplementary instructions manual "Heating for display and |

|

|

|

–– |

adjustment module" (optional) |

|

|

Supplementary instructions manual "Plug connector for con- |

|

|

|

–– |

tinuously measuring sensors" (optional) |

|

|

Ex-specific "Safety instructions" (with Ex versions) |

|

|

|

–– |

if necessary, further certificates |

|

3.2 |

Principle of operation |

|

Application area |

TheVEGAFLEX 81 is a level sensor with coax probe for continuous |

||

|

level or interface measurement, suitable for applications in liquids. |

||

Functional principle - |

High frequency microwave pulses are guided along a steel cable or |

||

level measurement |

a rod.Upon reaching the product surface, the microwave pulses are |

||

reflected.The running time is evaluated by the instrument and outputted as level.

130612-EN-42279

10 |

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

3 Product description

1

d

h

Fig. 4: Level measurement

1 Sensor reference plane (seal surface of the process fitting) d Distance to the interface (HART value 1)

h Height - Level

Probe end tracking

To increase sensitivity, the probe is equipped with probe end tracking. In products with a low dielectric constant, this function is very helpful. This is the case, for example, in plastic granules, packing chips or in vessels with fluidized products.

Between a dielectric constant of 1.5 and 3, the function switches on, if required.As soon as the level echo can no longer be detected, probe end tracking is automatically activated.The measurement is continued with the last calculated dielectric constant.

The accuracy thus depends on the stability of the dielectric constant.

If you measure a medium with a dielectric constant below 1.5, probe end tracking is always active.In this case, you have to enter the dielectric constant of the medium.A stable dielectric constant is very important here.

Functional principle - in- High frequency microwave impulses are guided along a steel cable or terface measurement rod.Upon reaching the product surface, a part of the microwave impulses is reflected.The other part passes through the upper product and is reflected by the interface.The running times to the two product

layers are processed by the instrument.

42279-EN-130612

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

11 |

3 Product description

1

L3 |

d2 |

|

d1 |

||

|

L2 TS

h2 |

L1 |

|

h1 |

Prerequisites for interface measurement

Fig. 5: Interface measurement

1 Sensor reference plane (seal surface of the process fitting) d1 Distance to the interface (HART value 1)

d2 Distance to the level (HART value 3)

TS Thickness of the upper medium (d1 - d2) h1 Height - Interface

h2 Height - Level

L1 Lower medium

L2 Upper medium

L3 Gas phase

Upper medium (L2)

•The upper medium must not be conductive

•The dielectric constant of the upper medium or the actual distance to the interface must be known (input required).Min.dielectric constant:1.6.You can find a list of dielectric constants on our home page: www.vega.com.

•The composition of the upper medium must be stable, no varying products or mixtures

•The upper medium must be homogeneous, no stratifications within the medium

•Min.thickness of the upper medium 50 mm (1.97 in)

•Clear separation from the lower medium, emulsion phase or detritus layer max.50 mm (1.97 in)

•If possible, no foam on the surface

Lower medium (L1)

•The dielectric constant must be 10 higher than the dielectric constant of the upper medium, preferably electrically conductive. Example:upper medium dielectric constant 2, lower medium at least dielectric constant 12.

Gas phase (L3)

•Air or gas mixture

•Gas phase - dependent on the application, gas pahse does not always exist (d2 = 0)

12 |

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

130612-EN-42279

42279-EN-130612

|

|

|

3 Product description |

|

|

Output signal |

The instrument is always preset to the application "Level measure- |

|

|

||

|

|

ment". |

|

|

|

|

|

For the interface measurement, you can select the requested output |

|||

|

|

signal with the setup. |

|

|

|

|

|

3.3 Packaging, transport and storage |

|

|

|

Packaging |

Your instrument was protected by packaging during transport. Its |

|

|

||

|

|

capacity to handle normal loads during transport is assured by a test |

|||

|

|

based on ISO 4180. |

|

|

|

|

|

The packaging of standard instruments consists of environment- |

|

|

|

|

|

friendly, recyclable cardboard.For special versions, PE foam or PE |

|

|

|

|

|

foil is also used.Dispose of the packaging material via specialised |

|

|

|

|

|

recycling companies. |

|

|

|

Transport |

Transport must be carried out under consideration of the notes on the |

||||

|

|

transport packaging.Nonobservance of these instructions can cause |

|||

|

|

damage to the device. |

|

|

|

Transport inspection |

The delivery must be checked for completeness and possible transit |

||||

|

|

damage immediately at receipt. Ascertained transit damage or con- |

|||

|

|

cealed defects must be appropriately dealt with. |

|

|

|

Storage |

Up to the time of installation, the packages must be left closed and |

|

|

||

|

|

stored according to the orientation and storage markings on the |

|

|

|

|

|

outside. |

|

|

|

|

|

Unless otherwise indicated, the packages must be stored only under |

|||

|

|

the following conditions: |

|

|

|

|

|

• |

Not in the open |

|

|

|

|

• |

Dry and dust free |

|

|

|

|

• |

Not exposed to corrosive media |

|

|

|

|

• |

Protected against solar radiation |

|

|

|

|

• |

Avoiding mechanical shock and vibration |

|

|

Storage and transport |

• |

Storage and transport temperature see chapter "Supplement - |

|

|

|

temperature |

Technical data - Ambient conditions" |

|

|

||

|

|

• |

Relative humidity 20 … 85 % |

|

|

|

|

3.4 Accessories and replacement parts |

|

|

|

PLICSCOM |

The display and adjustment module PLICSCOM is used for measured |

||||

|

|

value indication, adjustment and diagnosis.It can be inserted into the |

|||

|

|

sensor or the external display and adjustment unit and removed at |

|

|

|

|

|

any time. |

|

|

|

|

|

You can find further information in the operating instructions "Display |

|||

|

|

and adjustment module PLICSCOM" (Document-ID 27835). |

|

|

|

VEGACONNECT |

The interface adapterVEGACONNECT enables the connection of |

|

|

||

|

|

communication-capable instruments to the USB interface of a PC.For |

|||

|

|

parameter adjustment of these instruments, the adjustment software |

|||

|

|

PACTware with VEGA-DTM is required. |

|

|

|

|

|

||||

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

13 |

||||

3 Product description

|

You can find further information in the operating instructions "Interface |

|

adapter VEGACONNECT" (Document-ID 32628). |

VEGADIS 81 |

TheVEGADIS 81 is an external display and adjustment unit forVEGA |

|

plics® sensors. |

|

For sensors with double chamber housing the interface adapter |

|

"DISADAPT" is also required forVEGADIS 81. |

|

You can find further information in the operating instructions "VE- |

|

GADIS 81" (Document-ID 43814). |

VEGADIS 62 |

VEGADIS 62 is suitable for measured value indication and adjustment |

|

of sensors with HART protocol.It is looped into the 4 … 20 mA/HART |

|

signal cable. |

|

You can find further information in the operating instructions "VE- |

|

GADIS 62" (Document-ID 36469). |

PLICSMOBILE T61 |

The PLICSMOBILET61 is an external GSM/GPRS radio unit for |

|

transmission of measured values and for remote parameter adjust- |

|

ment of plics® sensors.The adjustment is carried out via PACTware/ |

|

DTM by using the integrated USB connection. |

|

You can find further information in the supplementary instructions |

|

"PLICSMOBILE T61" (Document-ID 36849). |

Protective cap |

The protective cover protects the sensor housing against soiling and |

|

intense heat from solar radiation. |

|

You will find additional information in the supplementary instructions |

|

manual "Protective cover" (Document-ID 34296). |

Flanges |

Screwed flanges are available in different versions according to the |

|

following standards:DIN 2501, EN 1092-1, ANSI B 16.5, JIS B 2210- |

|

1984, GOST 12821-80. |

|

You can find additional information in the supplementary instructions |

|

manual "Flanges according to DIN-EN-ASME-JIS" (Document-ID |

|

31088). |

Electronics module |

The electronics module VEGAFLEX series 80 is a replacement part |

|

forTDR sensors ofVEGAFLEX series 80.There is a different version |

|

available for each type of signal output. |

|

You can find further information in the operating instructions manual |

|

"Electronics module VEGAFLEX series 80". |

Display and adjustment |

The display and adjustment module can be optionally replaced by a |

module with heating |

display and adjustment module with heating function. |

|

You can use this display and adjustment module in an ambient tem- |

|

perature range of -40 … +70 °C. |

|

You can find further information in the operating instructions "Display |

|

and adjustment module with heating" (Document-ID 31708). |

14 |

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

130612-EN-42279

42279-EN-130612

|

|

|

4 Mounting |

|

|

|

4 |

Mounting |

|

|

|

4.1 General instructions |

||

Screwing in |

On instruments with process fitting thread, the hexagon must be tight- |

|||

|

|

ened with a suitable screwdriver.Wrench size see chapter "Dimen- |

||

|

|

sions". |

||

|

|

Warning: |

||

|

|

The housing must not be used to screw the instrument in! Applying |

||

|

|

tightening force can damage internal parts of the housing. |

||

Protection against mois- |

Protect your instrument further through the following measures |

|||

ture |

against moisture penetration: |

|||

|

|

• |

Use the recommended cable (see chapter "Connecting to power |

|

|

|

supply") |

||

|

|

• |

Tighten the cable gland |

|

|

|

• |

Loop the connection cable downward in front of the cable gland |

|

|

|

This applies particularly to: |

||

|

|

• |

Outdoor mounting |

|

|

|

• |

Installations in areas where high humidity is expected (e.g.through |

|

|

|

cleaning processes) |

||

|

|

• |

Installations on cooled or heated vessels |

|

Protective caps |

In the case of instrument housings with self-sealing NPT threads, it is |

|||

|

|

not possible to have the cable entries screwed in at the factory.The |

||

|

|

openings for the cable glands are therefore covered with red protec- |

||

|

|

tive caps as transport protection. |

||

|

|

Prior to setup you have to replace these protective caps with ap- |

||

|

|

proved cable glands or close the openings with suitable blind plugs. |

||

|

|

The suitable cable glands and blind plugs come with the instrument. |

||

Suitability for the process |

Make sure that all parts of the instrument exposed to the process are |

|||

conditions |

suitable for the existing process conditions. |

|||

|

|

These are mainly: |

||

|

|

• |

Active measuring component |

|

|

|

• |

Process fitting |

|

|

|

• |

Process seal |

|

Process conditions are particularly:

•Process pressure

•Process temperature

•Chemical properties of the medium

•Abrasion and mechanical influences

You can find the specifications of the process conditions in chapter "Technical data" as well as on the nameplate.

4.2 Mounting instructions

Installation position |

MountVEGAFLEX 81 in such a way that the distance to vessel instal- |

|

|

lations or to the vessel wall is at least 300 mm (12 in).In non-metallic |

|

|

|

|

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

15 |

|

4 Mounting

vessels, the distance to the vessel wall should be at least 500 mm

(19.7 in).

During operation, the probe must not touch any installations or the vessel wall.If necessary, fasten the probe end.

In vessels with conical bottom it can be advantageous to mount the sensor in the center of the vessel, as measurement is then possible nearly down to the lowest point of the bottom.Keep in mind that measurement all the way down to the tip of the probe may not be possible.The exact value of the min.distance (lower dead band) is stated in chapter "Technical data".

|

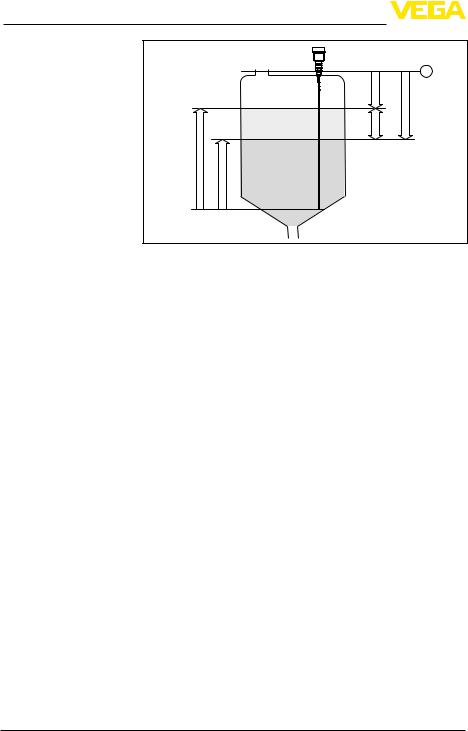

Fig. 6: Vessel with conical bottom |

Welding work |

Before beginning the welding work, remove the electronics module |

|

from the sensor.By doing this, you avoid damage to the electronics |

|

through inductive coupling. |

Inflowing medium |

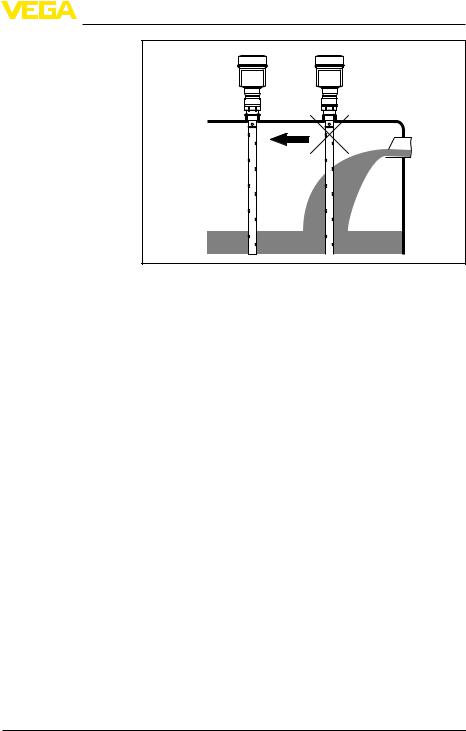

Do not mount the instruments in or above the filling stream.Make sure |

|

that you detect the product surface, not the inflowing product. |

130612-EN-42279

16 |

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

4 Mounting

42279-EN-130612

|

Fig.7:Mounting of the sensor with inflowing medium |

Measuring range |

The reference plane for the measuring range of the sensors is the |

|

sealing surface of the thread or flange. |

|

Keep in mind that a min.distance must be maintained below the refer- |

|

ence plane and possibly also at the end of the probe - measurement |

|

in these areas is not possible (dead band). These dead bands are |

|

listed in chapter "Technical data".Keep in mind for the adjustment that |

|

the default setting for the measuring range refers to water. |

Pressure |

The process fitting must be sealed if there is gauge or low pressure in |

|

the vessel.Before use, check if the seal material is resistant against |

|

the measured product and the process temperature. |

|

The max.permissible pressure is specified in chapter "Technical |

|

data" or on the type label of the sensor. |

Steam boiler applications Vapours, superimposed gases, high pressures and temperature differences can change the spreading speed of radar impulses.

There are two possibilities to correct these deviations.

Corrective value in the process control system

In the technical data under "Influence of superimposed gas and pressure on accuracy" you can find a table with deviation values in some typical gases or in steam.

In the control system (DCS) you can correct the measurement results of theVEGAFLEX 81 with these values.

The prerequisite is constant temperature and pressure in the vessel.

Automatic correction via the reference distance

The VEGAFLEX 81 can be equipped optionally with a running time correction via reference distance.The probe can carry out an automatic running time correction with it.

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

17 |

4 Mounting

The reference point must hence not be overfilled.The upper dead band is hence 450 mm (17.7 in).

1

1

7 |

6 |

|

2

4

3

5

Fig. 8: Measuring ranges - VEGAFLEX 81 with steam compensation

1Reference plane

2Probe length L

3Measuring range

4Upper dead band

5Lower dead band

6Additional upper dead band by steam compensation

7Reference measurement distance to steam compensation

130612-EN-42279

18 |

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

42279-EN-130612

|

|

|

5 Connecting to power supply |

|

|

5 |

Connecting to power supply |

|

|

5.1 Preparing the connection |

|

Safety instructions |

Always keep in mind the following safety instructions: |

||

|

|

• |

Connect only in the complete absence of line voltage |

|

|

• |

If overvoltage surges are expected, overvoltage arresters should |

|

|

|

be installed |

Voltage supply |

Power supply and current signal are carried on the same two-wire |

||

|

|

cable.The operating voltage can differ depending on the instrument |

|

|

|

version. |

|

|

|

The data for power supply are specified in chapter "Technical data". |

|

|

|

Provide a reliable separation between the supply circuit and the |

|

|

|

mains circuits according to DIN EN 61140 VDE 0140-1. |

|

|

|

Keep in mind the following additional factors that influence the operat- |

|

|

|

ing voltage: |

|

|

|

• |

Lower output voltage of the power supply unit under nominal load |

|

|

(e.g.with a sensor current of 20.5 mA or 22 mA in case of fault |

|

|

|

• |

message) |

|

|

Influence of additional instruments in the circuit (see load values in |

|

|

|

|

chapter "Technical data") |

Connection to signal con- The signal conditioning instruments VEGAMET and VEGASCAN ditioning instruments have digital sensor recognition.When connectingVEGAFLEX 81, an

up-to-date version of the signal conditioning instrument software is required.For a software update go to "www.vega.com/downloads" and "Software".

Connection cable |

The instrument is connected with standard two-wire cable without |

|

screen.If electromagnetic interference is expected which is above the |

|

test values of EN 61326-1 for industrial areas, screened cable should |

|

be used. |

Use cable with round cross section for instruments with housing and cable gland.To ensure the seal effect of the cable gland (IP protection rating), find out which cable outer diameter the cable gland is suitable for.

•5 … 9 mm (0.20 … 0.35 in)

•6 … 12 mm (0.24 … 0.47 in)

•10 … 14 mm (0.40 … 0.55 in)

Use a cable gland fitting the cable diameter.

We generally recommend the use of screened cable for HART multidrop mode.

Cable gland ½ NPT |

With plastic housing, the NPT cable gland or the Conduit steel tube |

|

|

must be screwed without grease into the threaded insert. |

|

|

Max.torque for all housings see chapter "Technical data". |

|

|

|

|

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

19 |

|

5 Connecting to power supply

Cable screening and |

|

|

If screened cable is necessary, connect the cable screen on both |

|

grounding |

|

|

ends to ground potential.In the sensor, the screen must be connected |

|

|

|

|

|

directly to the internal ground terminal. The ground terminal on the |

|

|

|

|

outside of the housing must be connected to the potential equalisa- |

|

|

|

|

tion (low impedance). |

|

|

|

|

If potential equalisation currents are expected, the connection on the |

|

|

|

|

processing side must be made via a ceramic capacitor (e.g.1 nF, |

|

|

|

|

1500V).The low-frequency potential equalisation currents are thus |

|

|

|

|

suppressed, but the protective effect against high frequency interfer- |

|

|

|

|

ence signals remains. |

|

|

|

|

Warning: |

|

|

|

|

Significant potential differences exist inside galvanization plants as |

|

|

|

|

well as on vessels with cathodic corrosion protection.Considerable |

|

|

|

|

equalisation currents can flow over the cable screen if the screen is |

|

|

|

|

grounded on both ends. |

|

|

|

|

To avoid this in such applications, the cable screen must be connect- |

|

|

|

|

ed to ground potential only at one end (in the switching cabinet). The |

|

|

|

|

cable screen must not be connected to the internal ground terminal in |

|

|

|

|

the sensor and the outer ground terminal on the housing must not be |

|

|

|

|

connected to the potential equalisation! |

|

|

|

|

Information: |

|

|

|

|

The metallic parts of the instrument (process fitting, transmitter, con- |

|

|

|

|

centric tube, etc.) are conductively connected with the inner and outer |

|

|

|

|

ground terminal on the housing.This connection exists either directly |

|

|

|

|

via connecting metallic parts or, in case of instruments with external |

|

|

|

|

electronics, via the screen of the special connection cable. |

|

|

|

|

You can find specifications on the potential connections inside the |

|

|

|

|

instrument in chapter "Technical data". |

|

|

|

|

5.2 Connecting |

||

Connection technology |

|

The voltage supply and signal output are connected via the spring- |

||||

|

|

|

|

loaded terminals in the housing. |

||

|

|

|

|

The connection to the display and adjustment module or to the inter- |

||

|

|

|

|

face adapter is carried out via contact pins in the housing. |

||

|

|

|

|

Information: |

||

|

|

|

|

The terminal block is pluggable and can be removed from the |

||

|

|

|

|

electronics.To do this, lift the terminal block with a small screwdriver |

||

|

|

|

|

|||

|

|

|

|

and pull it out.When reinserting the terminal block, you should hear it |

||

|

|

|

|

snap in. |

||

Connection procedure |

|

Proceed as follows: |

||||

|

|

|

1. |

Unscrew the housing cover |

||

|

|

|

2. |

If a display and adjustment module is installed, remove it by turn- |

||

|

|

|

|

|

ing it slightly to the left. |

|

|

|

|

3. |

Loosen compression nut of the cable entry |

||

|

|

|

4. |

Remove approx.10 cm (4 in) of the cable mantle, strip approx. |

||

|

|

|

|

|

1 cm (0.4 in) of insulation from the ends of the individual wires |

|

|

|

|

5. |

Insert the cable into the sensor through the cable entry |

||

|

|

|

|

|

|

|

20 |

|

|

|

|

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

|

130612-EN-42279

5 Connecting to power supply

Fig. 9: Connection steps 5 and 6 - Single chamber housing

42279-EN-130612

Fig. 10: Connection steps 5 and 6 - Double chamber housing

6. Insert the wire ends into the terminals according to the wiring plan

Information:

Solid cores as well as flexible cores with wire end sleeves are inserted directly into the terminal openings.In case of flexible cores without end sleeves, press the terminal from above with a small screwdriver; the terminal opening is freed.When the screwdriver is released, the terminal closes again.

You can find further information on the max.wire cross-section under "Technical data/Electromechanical data"

7.Check the hold of the wires in the terminals by lightly pulling on them

8.Connect the screen to the internal ground terminal, connect the outer ground terminal to potential equalisation

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

21 |

5 Connecting to power supply

9.Tighten the compression nut of the cable entry.The seal ring must completely encircle the cable

10.Reinsert the display and adjustment module, if one was installed

11.Screw the housing cover back on

The electrical connection is hence finished.

5.3Wiring plan, single chamber housing

The following illustration applies to the non-Ex, Ex-ia and Ex-d version.

Electronics and connection compartment

2

4...20mA |

3 |

|

1 |

2 |

(-) |

5 |

6 |

7 |

8 |

4 |

(+) |

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

Fig. 11: Electronics and connection compartment, single chamber housing

1Voltage supply, signal output

2For display and adjustment module or interface adapter

3For external display and adjustment unit

4Ground terminal for connection of the cable screen

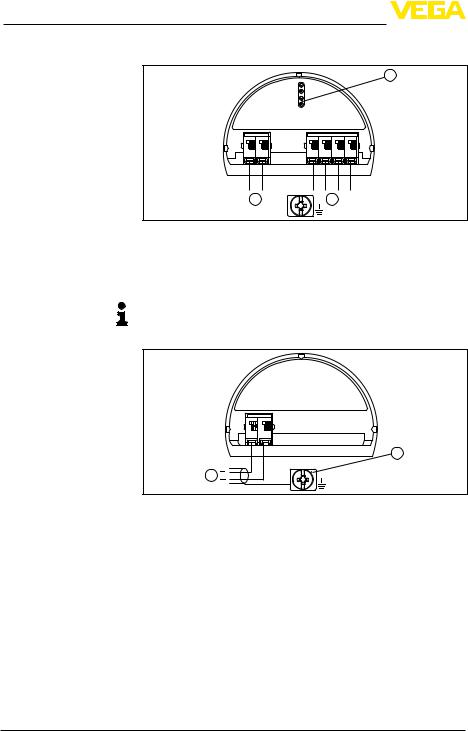

5.4Wiring plan, double chamber housing

The following illustrations apply to the non-Ex as well as to the Ex-ia version.

Electronics compartment |

2 |

4...20mA

(+) |

2 |

(-) |

5 |

6 |

7 |

8 |

1 |

|

1 1

Fig. 12: Electronics compartment, double chamber housing

1Internal connection to the connection compartment

2For display and adjustment module or interface adapter

22 |

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

130612-EN-42279

5 Connecting to power supply

Connection compartment

2

4...20mA |

3 |

|

Connection compartment - Radio module PLICSMOBILE

(+) |

2 |

(-) |

5 |

6 |

7 |

8 |

4 |

1 |

|

1

Fig. 13: Connection compartment, double chamber housing

1Voltage supply, signal output

2For display and adjustment module or interface adapter

3For external display and adjustment unit

4Ground terminal for connection of the cable screen

Information:

The use of an external display and adjustment unit and a display and adjustment module in parallel in the connection compartment is not supported.

Status

SIM-Card

Test

USB

Bus

(+)1 |

2(-) |

1

Fig. 14: Connection compartment radio module PLICSMOBILE 1 Voltage supply

You can find detailed information on connection in the supplementary instructions "PLICSMOBILE GSM/GPRS radio module".

42279-EN-130612

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

23 |

5 Connecting to power supply

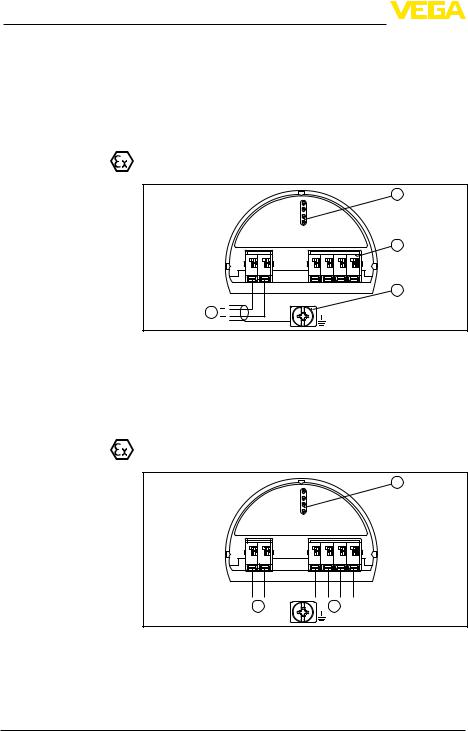

5.5Wiring plan, Ex-d-ia double chamber housing

Electronics compartment |

2 |

4...20mA

(+) |

2 |

(-) |

5 |

6 |

7 |

8 |

1 |

|

1 3

Fig. 15: Electronics compartment, double chamber housing

1Internal connection to the connection compartment

2For display and adjustment module or interface adapter

3Internal connection to the plug connector for external display and adjustment unit (optional)

Note:

If an instrument with Ex-d-ia approval is used, HART multidrop op-

eration is not possible.

Connection compartment

4...20mA |

|

|

(+)1 |

2(-) |

2 |

1 |

|

|

Fig. 16: Connection compartment, Ex-d double chamber housing

1Voltage supply, signal output

2Ground terminal for connection of the cable screen

130612-EN-42279

24 |

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

5 Connecting to power supply

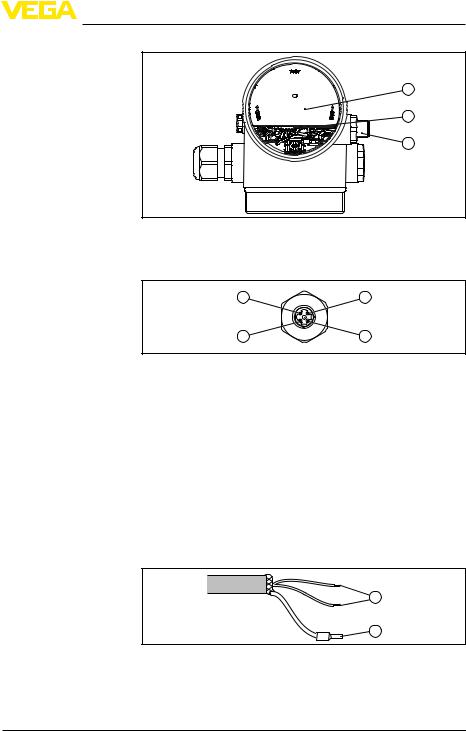

DIS-ADAPT with plug |

|

connector M12 x 1 for |

|

external display and |

|

adjustment unit |

1 |

|

2

3

Fig. 17: View to the electronics compartment

1DIS-ADAPT

2Internal plug connection

3Plug connector M12 x 1

42279-EN-130612

Wire assignment, connection cable

4 |

3 |

1 |

2 |

Fig. 18: Top view of the plug connector

1Pin 1

2Pin 2

3Pin 3

4Pin 4

Contact pin |

Colour connection ca- |

Terminal, electronics |

|

ble in the sensor |

module |

Pin 1 |

Brown |

5 |

Pin 2 |

White |

6 |

Pin 3 |

Blue |

7 |

Pin 4 |

Black |

8 |

5.6Wiring plan - version IP 66/IP 68, 1 bar

1

2

Fig.19:Wire assignment fix-connected connection cable

1brown (+) and blue (-) to power supply or to the processing system

2Shielding

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

25 |

5 Connecting to power supply

Supplementary electronics - Second current output

5.7Supplementary electronics

You can use the supplementary electronics - second current output to provided a second measured value.

Both current outputs are passive and need a power supply.

Supplementary electronics - Radio module PLICSMOBILE

26

4 |

I |

4 |

I I |

20mA |

20mA |

|

(+)1 2(-) |

(+)7 |

8(-) |

1 |

3 |

|

2 |

|

|

Fig. 20: Connection compartment double chamber housing, supplementary electronics - second current output

1First current output (I) - Voltage supply and signal output (HART)

2Second current output (II) - Voltage supply and signal output (without HART)

3Ground terminal for connection of the cable screen

The radio module PLICSMOBILE is an external GSM/GPRS radio unit for transmission of measured values and for remote parameter adjustment.

Status

SIM-Card

Test

USB

Bus

(+)1 |

2(-) |

1

Fig. 21: Radio module PLICSMOBILE integrated in the connection compartment

1 Voltage supply

You can find detailed information on connection in the supplementary instructions "PLICSMOBILE GSM/GPRS radio module".

5.8Switch-on phase

After connecting the instrument to power supply or after a voltage recurrence, the instrument carries out a self-check for approx.30 s:

• |

Internal check of the electronics |

42279 |

• |

Indication of the instrument type, hardware and software version, |

|

measurement loop name on the display or PC |

||

• |

Indication of the status message "F 105 Determine measured |

- |

value" on the display or PC |

-EN |

|

• |

The output signal jumps to the set error current |

130612 |

|

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

|

|

|

5 Connecting to power supply

As soon as a plausible measured value is found, the corresponding current is outputted to the signal cable.The value corresponds to the actual level as well as the settings already carried out, e.g.factory setting.

42279-EN-130612

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

27 |

6 Set up with the display and adjustment module

6Set up with the display and adjustment module

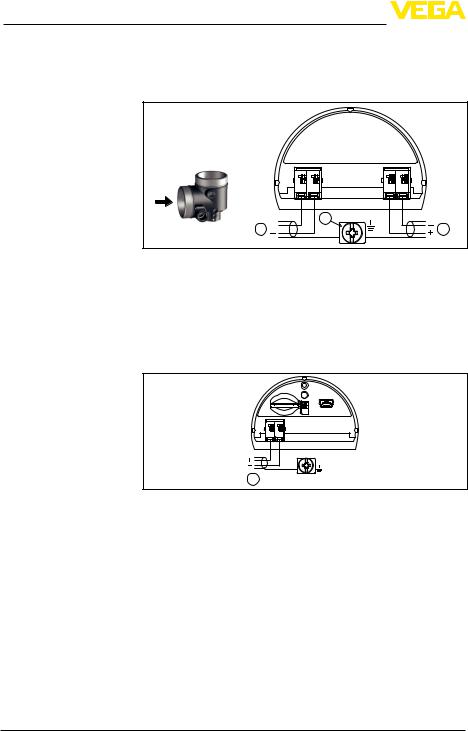

6.1Insert display and adjustment module

The display and adjustment module can be inserted into the sensor and removed any time.Four positions displaced by 90° can be selected. It is not necessary to interrupt the power supply.

Proceed as follows:

1.Unscrew the housing cover

2.Place the display and adjustment module in the requested position onto the electronics and turn to the right until it snaps in

3.Screw housing cover with inspection window tightly back on Removal is carried out in reverse order.

The display and adjustment module is powered by the sensor, an additional connection is not necessary.

Fig. 22: Insertion of the display and adjustment module with single chamber housing into the electronics compartment

130612-EN-42279

28 |

VEGAFLEX 81 • 4 … 20 mA/HART two-wire |

Loading...

Loading...