Siemens Cgiiv, Cghs, Cgiihs, Cggv, Cgghs User Manual

...

Induction Motors/

Generators

Installation

Operation

Maintenance

Large Frame Vertical

680, 800, 1120 Frames

Types CGV, CGHS, CGIIV, CGIIHS, CGGV, CGGHS, CAZV, CAZHS, CAZBV, CAZBHS

ANIM-03535-0814

(Supercedes all previous issues of ANIM-03535) ©2014 Siemens Industry, Inc. All rights reserved.

Table of Contents

TABLE OF CONTENTS |

Page |

OPERATION |

Page |

1 |

11 |

||

SAFETY PROCEDURES |

2 |

Initial Start |

11 |

INTRODUCTION |

3 |

Out of Service/Storage |

11 |

Warranty |

3 |

Normal Operation |

12 |

Receiving |

3 |

Trouble Shooting |

13 |

Handling |

4 |

MAINTENANCE |

15 |

Temporary Storage |

4 |

Preventive Maintenance |

15 |

Description |

4 |

Inspection |

15 |

Type Designations |

4 |

Corrective Maintenance |

16 |

INSTALLATION |

5 |

Rotor Cleaning |

17 |

Location |

5 |

Stator Cleaning |

17 |

Foundation |

5 |

Insulation Resistance |

17 |

Mounting |

5 |

Drying Insulation |

17 |

External Wiring |

6 |

Bearings |

18 |

Changing Direction of Rotation |

7 |

Bearing Replacement |

20 |

Vibration |

7 |

Kingsbury-type Bearings |

22 |

System Frequency (Resonance) |

7 |

Shaft or Flange Face Runout |

27 |

Alignment |

7 |

SPARE PARTS |

28 |

Shimming Technique |

8 |

Identification |

28 |

Tests Before Operation |

9 |

Vertical Solid & Hollow Shaft Nomenclature |

34 |

Typical Motor Control Settings |

10 |

MOTOR SERVICE RECORD |

35 |

Note - These instructions do not purport to cover all details or variations in equipment, nor to provide for every possible contingency to be met in connection with installation, operation or maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the user’s purposes, the matter should be referred to;

1. Your local Siemens Sales Office. --Or--

2. Siemens Technical Support Communication Center: Inside the U.S.: 1-800-333-7421

Outside the U.S.: +1 423-262-5710

Online: www.industry.usa.siemens.com/industry and click on Industry Services

The contents of this instruction manual shall not become part of or modify any prior or existing agreement, commitment or relationship. The sales contract contains the entire obligation of Siemens. The warranty contained in the contract between the parties is the sole warranty of Siemens. Any statements contained herein do not create new warranties or modify the existing warranty.

Siemens machines are built in accordance with the latest applicable revision of the National Electric Code, Underwriters Laboratories Standards and Procedures, and NEMA (National Electrical Manufacturers Association) Standards. These publications and this instruction manual should be thoroughly read and understood prior to beginning any work on this equipment.

The information contained within is intended to assist operating personnel by providing information on the general characteristics of the purchased equipment. It does not relieve the user of the responsibility of using accepted engineering practices in the installation, operation and maintenance of this equipment.

Should a conflict arise between the general information in this manual and the contents of the drawings and supplementary material, the latter shall take precedence.

The illustrations in this book show typical machines. Special features deviate from those pictured.

- 1 -

Safety Procedures

This equipment contains hazardous voltages. Death, serious personal injury or property damage can result if safety instructions are not followed.

The successful and safe operation of motors and generators is dependent upon proper handling, installation, operation and maintenance, as well as upon proper design and manufacture. Failure to follow certain fundamental installation and maintenance requirements may lead to personal injury and the failure and loss of the motor as well as damage to other property.

Only qualified personnel should work on or around this equipment after becoming thoroughly familiar with all warnings, safety notices and maintenance procedures contained herein. Only qualified personnel should be involved in the inspection, maintenance and repair procedure and all plant safety procedures must be observed.

Qualified Person: For the purpose of this manual and product labels, a Qualified person is one who is familiar with the installation, construction and operation of the equipment, and the hazards involved. In addition, he or she has the following qualifications:

a.Is trained and authorized to energize, de-energize, clear, ground and tag circuits and equipment in accordance with established safety practices.

b.Is trained in the proper care and use of protective equipment, such as rubber gloves, hard hat, safety glasses, face shields, flash clothing, etc., in accordance with established safety practices.

c.Is trained in rendering first aid.

Danger: For the purpose of this manual and product labels, Danger indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Warning: For the purpose of this manual and product labels, Warning indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Caution: For the purpose of this manual and product labels, Caution indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It is also used to alert against unsafe practices.

Motors should be installed and grounded per local and national codes.

Do not operate this equipment in excess of the values given on nameplate or contrary to the instructions contained in this manual. The equipment (or a prototype) has been factory tested and found satisfactory for the condition for which it was sold. Operating in excess of these conditions can cause stresses and strains beyond design limitations. Failure to heed this warning may result in equipment damage and possible personal injury.

DANGER

DANGER

Hazardous voltage.

Will cause death, serious injury, electrocution or property damage.

Disconnect all power before working on this equipment.

NOTE

Squirrel cage induction machines can be driven by various types of prime movers. These will act as induction generators. This instruction manual applies to both motors and induction generators. However, for clarity reasons, the machine will be referred to as a “motor”.

- 2 -

Introduction

DANGER

DANGER

Hazardous voltage.

Will cause death, serious injury, electrocution or property damage.

Disconnect all power before working on this equipment.

These instructions present general recommendations for installation, operation and maintenance of induction motors built at the Norwood plant. If additional information is required, contact Siemens Energy & Automation.

Warranty

See your sales contract for warranty coverage. Documentation of storage maintenance, alignment and regreasing may be required for certain warranty considerations.

Receiving

Motors are shipped in first class condition. They have been inspected and are skidded to prevent damage from ordinary handling during shipment.

Inspect new motors for shipping invoice. Make the examination before removing from cars or trucks. If damage or indication of rough handling is evident, file a claim with the carrier at once, and notify your Siemens sales representative.

Remove only the shipping invoice. Do not remove tags pertaining to lubrication, operation and storage instructions. Read and follow all instructions to insure that no damage to motor bearings, (due to condensation) and motor windings occurs during storage.

Use care in handling. Dropping the motor or otherwise imposing shock loads can cause unseen and undetected damage to bearings. This damage such as false brinelling of the races of anti-friction bearings can result in early bearing failure.

If supplied, energize space heaters to help prevent condensation within the motor enclosure.

Motors having oil lubricated bearings are shipped WITHOUT OIL in the bearing reservoir. These bearings and journal surfaces are protected during shipment by a TEMPORARY film of rust inhibiting oil.

Immediately upon receiving a unit with oil lubricated bearings:

1.Check for moisture accumulation. Remove any traces of oxidation before putting the motor in service.

2.Fill bearing reservoirs to normal level with a nonfoaming, non-detergent turbine oil (See Maintenance Section).

3.Rotate the shaft several turns, by hand, to distribute the oil over bearing parts.

- 3 -

Introduction

WARNING

Heavy equipment.

Improper handling may cause death, serious injury or property damage.

Check lifting devices before lifting. Use proper slings, chains and spreaders.

Note any warning plates on motor and follow instructions on each plate.

Handling

Lifting devices are provided for handling only. An experienced rigger should be used to install motors.

To avoid damage, the use of spreader bars is recommended on other than single point lifts. Lifting devices are provided to facilitate handling with shackles and cables. Avoid pounding or bumping shaft, coupling or bearing parts, as shocks may damage bearings.

NOTE WEIGHT BEFORE LIFTING. The weight is indicated on the outline drawing. Apply tension gradually to cables. Do not jerk or attempt to move the unit suddenly.

Temporary Storage

If the equipment is not to be installed and operated soon after arrival, store it in a clean, dry, well- ventilated place, free from vibration and rapid or wide variations in temperature. Rotate the shaft a minimum of 10 complete turns by hand each month to coat the bearings with lubricant which will retard oxidation or corrosion, and prevent possible false brinelling. If drain plugs are provided in enclosed motors, they must be removed periodically to drain any water accumulation from the motor. Consider a unit in storage when:

1.It has been delivered to the job site and is awaiting installation.

2.It has been installed but operation is delayed over 30 days pending completion of plant construction.

3.There are long (30 day) periods between operating cycles.

4.The plant (or department) is shut down for 30 days.

5.Energize space heaters, if supplied.

NOTE

Storage requirements vary, depending on the length of storage and the climate. For storage periods of thirty (30) days or longer or climate variations, consult Siemens Storage Recommendations ANIM-03114. Storage maintenance is to be documented for warranty information.

Description

"P" flanged, vertical type units above NEMA frames 680/800/1120 are the subjects of this manual. The instructions include high thrust, oil lubricated spherical roller or Kingsbury-type bearings.

Check rating plate for your particular type construction.

Type Designations

The motor type designation consists of a basic letter or letters indicating the motor enclosure type to which other letters may be added denoting modifications.

Motor Type |

Motor Enclosure |

|

|

|

|

CGV, CGHS |

Open Drip Proof or Weather |

|

Protected Type I |

||

|

||

|

|

|

CGIIV, CGIIHS |

Weather Protected Type II |

|

|

|

|

CGGV, CGGHS |

Totally-Enclosed Water-to-Air |

|

Cooled |

||

|

||

CAZV, CAZHS |

Totally-Enclosed Air-to-Air |

|

Cooled with shaft-mounted fan |

||

|

||

CAZBV, CAZBHS |

Totally-Enclosed Air-to-Air |

|

Cooled using auxiliary blower |

||

|

- 4 -

Installation

NOTE

The information contained in this book is intended to assist operating personnel by providing information on the general characteristics of the purchased equipment.

IT DOES NOT relieve the user of the responsibility of using accepted engineering practices in the installation, operation and maintenance of this equipment, and complying with Federal, State and local rules and regulations, including OSHA.

Location

Select a location for the motor and driven unit that will:

1.Be clean, dry, well ventilated, properly drained, and provide accessibility for inspection, lubrication and maintenance. Outdoor installations may require protection from the elements.

2.Provide adequate space for motor removal without shifting the driven unit.

3.Permit the motor to safely deliver adequate power. Temperature rise of a standard motor is based on operation at an altitude not higher than 3,300 feet above sea level.

4.Avoid condensation of moisture in bearings and on windings. Motors should not be stored or operated in areas subject to rapid temperature changes unless motors are energized or protected with space heaters.

Foundation

Concrete (reinforced as required) makes the best foundation, particularly for large motors and driven units. In sufficient mass it provides rigid support that minimizes deflection and vibration. It may be located on soil, structural steel, or building floors provided the total weight (motor, driven unit, foundation) does not exceed the allowable bearing load of the support.

Allowable bearing loads of structural steel and floors can be obtained from engineering handbooks. Building codes of local communities give the recommended allowable bearing loads for different types of soil. For rough calculation the foundation should be approximately 2-1/2 times total unit weight.

NOTE

If normal vibration or noise will be objectionable (as in office buildings), it may be advisable to use vibration dampeners between the machine or driven/drive unit, and the foundation.

Mounting

Mount the machine securely and align accurately with the driven equipment.

1.Direct mounted to driven/drive equipment: the two units must be firmly secured and the driven equipment placed on an adequate foundation.

2.Floor plate mounted equipment must be very rigid and free from vibration.

Any excessive vibration of either method will cause loss of alignment, premature bearing wear and eventual breakdown.

NOTE

If motor is driving a pump and the back pressure is maintained after shut-down, protect the motor with quickacting check values or non-reverse mechanism within the motor.

Flange Mounting

Solid Shaft Motors

To mount round frame motor to driven unit proceed as follows:

NOTE

Round frame motors can be rotated within flange mounting bolt spacing to gain a satisfactory position for grease fittings and conduit attachments, and to mate run-out differences to avoid shimming flange fits. Terminal boxes without accessory devices can be turned to four equally spaced positions for access to conduit system; arrange the system so that water will not accumulate and drain into motor connection box.

1.Use a hoist; rig a sling around the lifting lugs.

2.Position motor (per note above) and move toward driven unit - engaging cleaned flanged surfaces.

3.Insert flange mounting bolts and tighten to snug tight.

4.Secure attachments between motor and shaft and load. (i.e. set screws tightened against shaft key.)

5.Turn shaft by hand; check for free rotation; binding; scraping; sticking.

6.Tighten all flange bolts. (Avoid warping or springing the flange.)

7.Turn shaft again to check for free rotation.

- 5 -

Installation

Hollow Shaft Motors

The motor should be set on its base first, and the driven shaft inserted through the hollow shaft. There are times, however, when these motors are lifted and lowered over the driven shaft. In either case, do not cause damage to the shaft by bending or scraping the threads.

Proceed as follows:

1.Remove coupling cover and raise motor with sling and hoist.

2. Slowly lower motor; carefully engage stud ( if used) and rabbet. (Position motor to allow access for power connection and lubrication.) Install flange nuts (bolts, if used) and snug.

3.Insert pump drive shaft into hollow shaft; arrange coupling and driven shaft in line with Gib Key Slot.

4.Insert Gib Key, connect driven shaft to coupling and adjust pump nut for proper impeller clearance. (Remove Locking Bar if provided.)

5.Turn shaft by hand to check for free rotation and shaft alignment. There must be no binding, scraping, or sticking.

6.If used, check the operation of the non-reverse device: also check action of self-release coupling, if that type of coupling is used (see Figure 12).

NOTE

A self-release coupling is shipped with three bolts holding it in place. These bolts must be removed to allow coupling to operate.

7.After alignment, uniformly and securely tighten all flange nuts (bolts).

8.Turn shaft by hand again; check for free rotation.

9.Replace coupling cover.

CAUTION

Continuous upthrust may damage motors.

Eliminate upthrust before operating.

CAUTION

Improper lubrication can cause damage to bearings.

Check oil reservoir for proper oil grade and level before stating or storing motor.

External Wiring

DANGER

DANGER

Hazardous voltage.

Will cause death, serious injury, electrocution or property damage.

Disconnect all power before working on this equipment.

NOTE

Before running motor, see Initial Start in Operation Section.

CAUTION

FOR MOTORS EQUIPPED WITH BACKSTOP OR NON-REVERSE DEVICE

Attempting to rotate motor with non-reverse device in wrong direction may result in severe damage to the motor.

Connect power supply phases to motor terminals exactly as indicated on motor nameplate to insure proper direction of rotation. Any other connection will result in wrong direction of rotation.

Starting and overload control devices must be matched to motor rating. For safety or convenience they may need to be installed some distance from the motor. Follow the control manufacturer’s instructions to make proper installations and connections. Observe the following:

1.Connect electrical power supply to conform to National Electric Code and any local regulations. Line voltage and wire capacity must match motor rating stamped on the nameplate.

2.With the driven equipment disconnected, momentarily energize the motor to check rotation.

3.If motor is three-phase type, reverse rotation (if required) by interchanging any two of the three power leads.

- 6 -

Installation

Changing Direction of Rotation

Look for rotation plates usually mounted on opposite drive end of the motor.

CAUTION

Excessive heat.

Motor may overheat if motor cooling fans run in the wrong direction. Run motor in direction shown on motor or change fans.

NOTE

If open or enclosed units have non-reverse ratchets and rotation is changed, the ratchets must be changed.

The internal rotor fan direction must be considered if changing direction of rotation.

To reverse rotation – consult factory.

Vibration

After flange mounting bolts have been tightened, check end play. Run the unit at a minimum load and check vibration.

The standard unfiltered vibration limits per NEMA MG1 for a resiliently mounted motor are:

Speed, |

Rotational |

Velocity,in/s Peak |

RPM |

Frequency/Hz |

(mm/s) |

3600 |

60 |

0.15 (3.8) |

1800 |

30 |

0.15 (3.8) |

1200 |

20 |

0.15 (3.8) |

900 |

15 |

0.12 (3.0) |

720 |

12 |

0.12 (3.0) |

600 |

10 |

0.12 (3.0) |

If vibration is excessive, loosen flange mounting bolts and shift within mounting flange clearance. If this shifting does not reduce vibration to acceptable limit, and unit is coupled to load, check shaft alignment and system reed frequency.

System Frequency (Resonance)

To achieve reasonable vibration levels when a motor, pump, and support are operating together, the responsibility is with the system designer.

If the probable vibration characteristics of a system are calculated before construction begins proper design can often reduce trouble before it becomes a costly reality. The effect of most pump heads because of the access openings for coupling, bearing, and pump adjustments, will lower the system reed frequency.

Generally, the reed frequency of the unit alone mounted on an infinite mass is at least 15% above or below the unit operating speed. If the system reed frequency is at or near operating speed, a decision must be made to raise or lower the system reed frequency by altering the rigidity of the motor-support structure.

Alignment

Accurate shaft alignment between motor and driven equipment is essential. Improper alignment may result in vibration, bearing overloads and excessive shaft stresses. Flexible couplings will not compensate for excessive misalignment.

Alignment Procedure (Solid Shaft)

The following checking procedure applies to a unit consisting of motor/generator, coupling, and a driven/drive component. Although applicable to most types of couplings, it is primarily intended for the rabbet-fit type. For other types, where the procedures differ, refer to the coupling manufacturer's Installation and Maintenance Instructions.

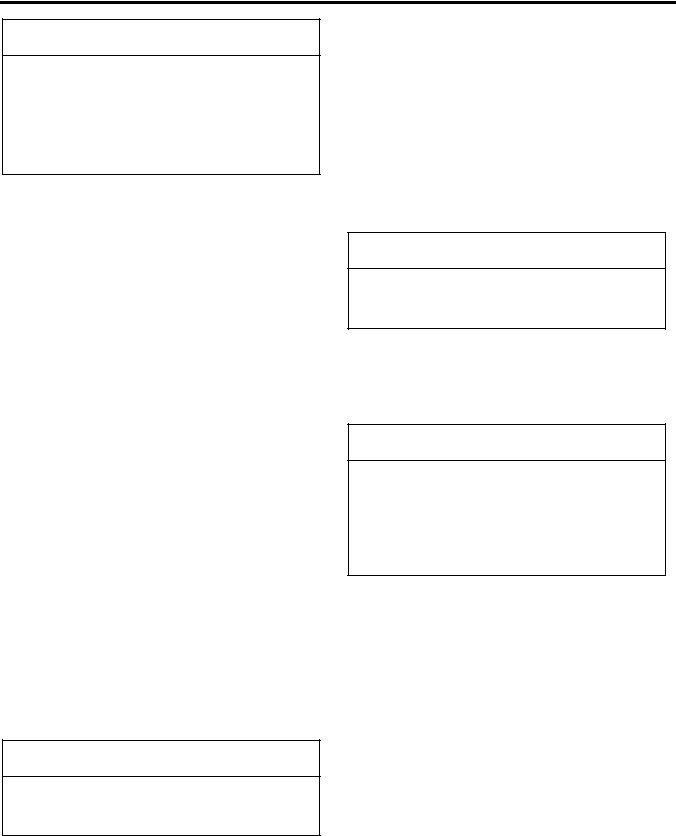

Work in one plane at a time and test for parallel or angular alignment with a dial indicator mounted as shown in Figure 1. Proceed as follows:

1.Set indicator dial to zero, at starting point.

2.Slowly turn both coupling halves a complete turn.

3.Observe dial reading at 90 degree increments from starting point.

4.Acceptable parallel alignment occurs when the total indicator readings do not exceed 0.002 inches.

5.Acceptable angular alignment occurs when the total indicator readings do not exceed 0.002 in./ft. radius to dial indicator.

Figure 1

- 7 -

Installation

Alignment Procedure (Hollow Shaft)

Hollow shaft units require accurate alignment with respect to the unit shaft and the driven/drive equipment shaft. The pump shaft acts as a pendulum supported by the top coupling and unit bearing.

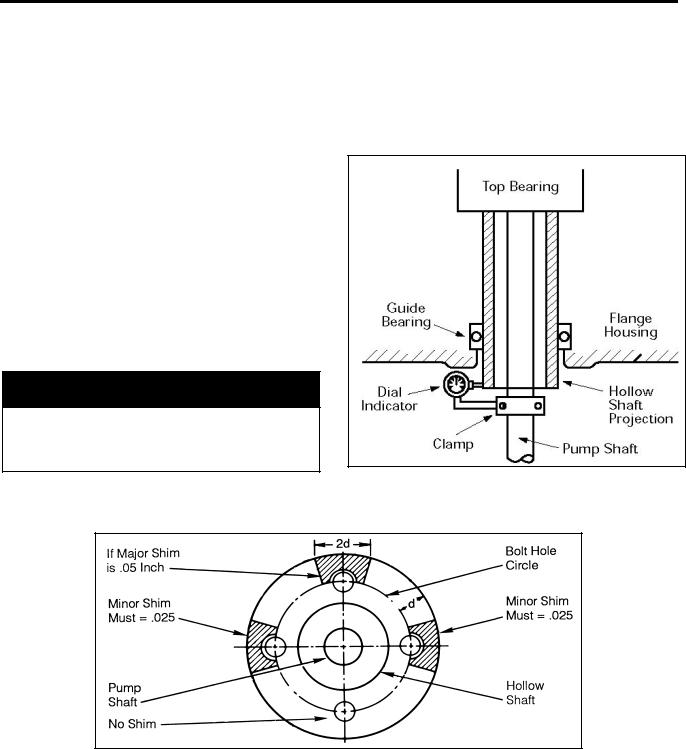

Align the unit as follows:

1.Clamp dial indicator to pump shaft, align with basebolt plane and set dial indicator to zero (Figure 2).

2.Remove top cover and rotate both unit and pump shafts.

3.Read dial indicator at 90 degree increments from starting point.

4.Acceptable alignment occurs when indicator readings do not exceed 0.0005 inches.

5.Shim flange faces if necessary (Figure 3).

When alignment and vibration of unit are within limits, engage drive. Run unit at minimum load and check for vibration - continue to increase load and checking vibration until full load is obtained.

CAUTION

Excessive vibration may cause damage to bearings or other motor components.

Determine and correct cause(s) of vibration before operating.

Shimming Technique

To avoid the possibility of twisting the flange when shimming between the flanges, minor shims should be one-half the thickness of the major shim. Shims should not penetrate deeper than the bolt hole circle and not be wider than twice the penetration distance (Figure 3).

Figure 2

Figure 3

- 8 -

Installation

Tests Before Operation

Insulation Resistance

Check insulation resistance prior to connecting motor to power supply. A hand cranked or solid state electronic insulation resistance tester, at least 500 volts d.c., but not over rated voltage, is usually used (see Maintenance).

See IEEE Recommended Practice for Testing Insulation Resistance Rotating Machinery IEEE Std 43.

Dielectric (Hi-Pot) Tests

All motors receive a factory dielectric test in accordance with ANSI and IEEE Standards.

DANGER

DANGER

Dielectric testing may result in personal injury or death.

Operate dielectric test equipment only with qualified personnel, in accordance with manufacturer’s instructions.

If a dielectric test is made on an old or repaired winding, to evaluate service reliability, the test voltage applied may vary from the rated terminal voltage to some higher value. The factory should be consulted when establishing the test voltage and procedure for testing old or repaired equipment.

NOTE

If normal vibration or noise will be objectionable (as in Instruments that operate on the principle of the Kelvin Bridge are preferred. (See "Temperature Measuring Devices" - IEEE Publication No. 119.)

The cold resistance, or the resistance at normal room temperature, must be measured after the machine has been idle for some time, usually before starting, or cold resistance value may be obtained from the factory.

The cold temperature of the coils should be measured because coil temperature may not be the same as the surrounding air.

The average temperature of the winding is obtained by taking resistance measurements, at the motor load terminals and using the following equation:

T = Rr (234.5 +t) −234.5

Where T = hot temperature in degrees C R = hot resistance

r = cold resistance at temperature t

t = cold temperature of winding in deg C (amb)

As an example, assume the cold resistance of 0.50 ohms at 25°C, and the hot resistance (taken immediately after motor is de-energized, and has stopped rotating) is 0.61 ohms, then:

CAUTION

Excessive dielectric testing may cause damage to insulation.

Test only in accordance with IEEE Std. 43.

Winding Resistance (Temperature)

The change in resistance of a winding provides an accurate measure of the average temperature of a winding, and is generally used to determine the temperature of the stator windings. The measurements must be made carefully with instruments known to be accurate, and preferably with the same instruments for both hot and cold measurements.

T = 00..5061 (234.5 +25) −234.5

T =82

The temperature measured by imbedded detectors or by the change in resistance is generally higher than thermometer measurements and is closer to the true hottest spot temperature in the machine. For this reason, the Standards permit higher observable temperatures when measurements are taken in this manner.

- 9 -

Installation

Typical Motor Control Settings

|

|

|

Alarm |

|

|

Trip |

Timer Trip |

||

|

|

|

|

|

(Shutdown) |

Setting (1) |

|||

Winding Temperature |

130°C |

|

|

155°C |

|

||||

• |

Class B Insulation |

|

|

|

|||||

• |

Class F Insulation |

155°C |

|

|

170°C |

|

|||

Motor Bearing Temperature |

|

|

|

|

|

|

|

||

(Thermocouple or RTD’s) |

90°C |

|

|

95°C |

|

||||

• |

Sleeve Bearing |

|

|

|

|||||

• |

Antifriction Bearing |

100°C |

|

|

105°C |

|

|||

Ground Fault |

4 Amps (2) |

|

|

8 Amps (2) |

0.2 sec. (2) |

||||

Primary |

|

|

Primary |

|

|||||

|

|

|

Circuit |

|

|

Circuit |

|

||

Instantaneous Overcurrent |

|

|

|

|

|

|

|

||

• With ½ Cycle Delay |

1.8 times Locked Rotor Amps (2) |

|

|||||||

• |

Without Time Delay |

2.4 times Locked Rotor Amps (2) |

|

||||||

Maximum Voltage |

110 % of Rated Voltage |

10 sec. |

|||||||

Minimum Voltage (the minimum voltage |

90 % of Rated Voltage |

10 sec. |

|||||||

also applies to starting unless otherwise |

|||||||||

specified) |

|

|

|

|

|

|

|

||

Maximum Frequency Deviation |

|

|

|

|

±5% |

10 sec. |

|||

Maximum of Voltage Plus Frequency Deviation |

|

|

±10% |

10 sec. |

|||||

Maximum Voltage Unbalance (3) |

|

|

|

|

1% |

15 sec. |

|||

Maximum Current Unbalance (3) |

|

|

|

|

8% |

15 sec. |

|||

|

|

|

|

|

|

|

|||

|

Suggested Vibration Limits |

|

|

|

|||||

|

RPM |

|

3600 |

|

1800 |

|

1200 |

900 and |

|

|

|

|

|

|

|

|

|

|

Slower |

Shaft (mils, pk-to-pk) – Alarm (4) |

|

2.8 |

|

3.2 |

|

3.8 |

4.5 |

||

Shaft (mils, pk-to-pk) – Trip (4) |

|

3.3 |

|

3.7 |

|

4.3 |

5.0 |

||

Housing (in./sec.) - Trip |

|

0.25 |

|

0.25 |

|

0.25 |

0.25 |

||

(1)Maximum time at maximum condition before control device is to operate.

(2)Increase as necessary to avoid nuisance trips.

(3)This is the maximum deviation from the average of the three phases.

(4)Applies only when vibration probes are supplied.

-10 -

Operation

Initial Start

WARNING

Improper operation may cause personal injury or damage to equipment.

Operate within nameplate ratings and in accordance with instructions in this manual.

CAUTION

Do not exceed number of Siemens specified hot and cold starts per hour.

Will cause overheating.

Allow time between starts to permit stator windings and rotor cage to cool.

NOTE

If motor has been out of service or in storage for more than 30 days, consult Siemens Storage Recommendations ANIM-03114, Preparation for

Service

CAUTION

FOR MOTORS EQUIPPED WITH BACKSTOP OR NONREVERSE DEVICE

Attempting to rotate motor with non-reverse device in wrong direction may result in severe damage to the motor.

Connect power supply phases to motor terminals exactly as indicated on motor nameplate to insure proper direction of rotation. Any other connection will result in wrong direction of rotation.

After installation is completed, but before motor is put in regular service, make an initial start as follows:

1.Check that motor, starting, and control device connections agree with wiring diagrams.

2.Check that voltage, phase, and frequency of line circuit (power supply) agree with motor nameplate.

3.If motor has been out of service or in storage (installed or uninstalled) se Out of Service/Storage Section before proceeding.

4.Check motor service record and tags accompanying motor. Be certain bearings have been properly lubricated and oil wells are filled. See motor outline drawing to determine proper oil level.

5.If possible, remove external load (disconnect drive) and turn shaft by hand to assure free rotation. This may have been done during installation procedure; if so, and conditions have not changed, this check may not be necessary.

6.If drive is disconnected, run motor at no load long enough to be certain that no unusual condition exists. Listen and monitor for excessive noise, vibration, clicking or pounding and that oil rings are turning if so equipped. If present, stop motor immediately. Investigate the cause and correct before putting motor in service.

7.If drive cannot be disconnected, interrupt the starting cycle after motor has accelerated to low speed. Carefully observe for unusual conditions as motor coasts to a stop. Repeat several times if necessary. Refer to motor’s Starting Duty nameplate (if so equipped) or Motor Data Sheet for recommended number of starts and cooling period between starts.

8.If both bearings are insulated, make sure ground strap or brush is connected so rotor is grounded. Disconnect ground strap, if used, only when unit is not operating to check bearing insulation integrity.

9.When checks are satisfactory, operate at lowest load possible and look for any unusual condition. Increase load slowly to maximum, checking unit for satisfactory operation.

Out of Service/Storage (over 30 Days)

Cleaning

Both the interior and exterior of the motor should be free of spilled oil, water, dust and dirt. The exterior should be wiped and the interior blown out with compressed air at reduced pressure or with a small hand bellows.

WARNING

WARNING

Flying dirt, dust or other particles.

May cause eye injury.

Wear safety glasses and dust mask when using compressed air.

Make sure that the bearings and lubricant cavities are free of dust and dirt, and that oil plugs are tight. Scratches, bruises, or rust on the shaft journal must be carefully removed.

- 11 -

Loading...

Loading...