siemens CYCLE 95 User Manual

SCHOOL CENTRE ŠKOFJA LOKA

CNC LESSON - CYCLE 95 – Stock removal cycle

Up to this lesson students already become familiar with the basics of program function, as well as the lathe settings for making basic models / shapes:

-basics and coordinate system

-reference points and machine settings

-tool data and tool measuring

-structure of program sentence and program itself

-zero offset

-defining the way of programming and the way of presenting parameters

-M – commands: M0, M1, M2, …..M30

-G – codes: G0, G1, G2, G3 and chamfer CHF and radius RND

-cutter radius compensation G40, G41, G42

-work with subprograms

If it is necessary to subtract more material we would have to write a lot of program sentences with basic program functions. The feeder SINUMERIK 810D/840D makes it possible to work on the product to the final shape without intermediate points, which are calculated by the computer itself, however we define only the final shape. The working can be rough or only fine or both – complete machining. We can turn longitudinally or transversally, as well as outside and inside.

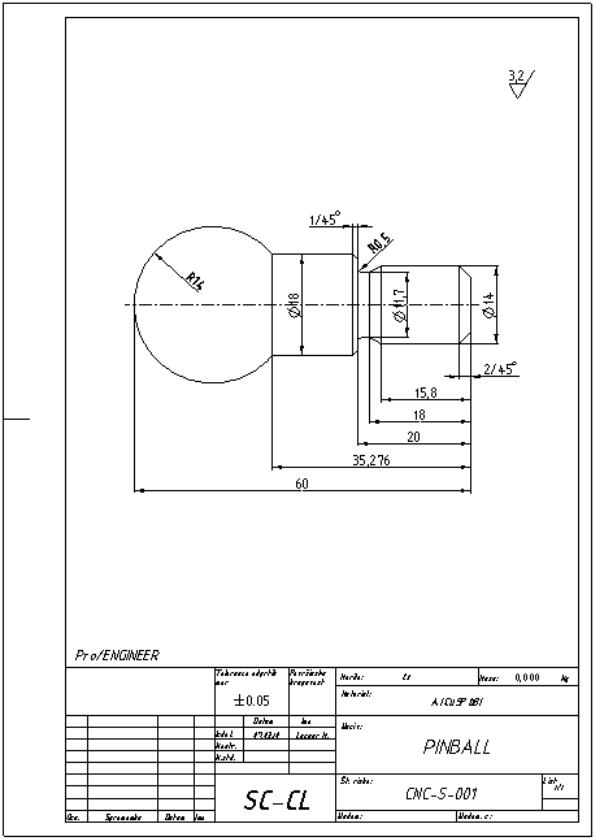

With the use of Cycle 95 we will make a pinball according to the drawing, first from one side and then from the other one. The product to be functional still needs a thread and that will be another lesson next time.

Picture 1: Model of the product

Picture 2: Drawing of the product

Work procedure:

1.We start the program WinNC and select the feeder Sinumerik 840D Turn

2.We create a new workpiece directory with the name CaRPs and inside the directory a new main program with the name PINBALL, which will get the ending MPF.

3.We write down the main program with the use of Cycle 95.

Picture 3: Cycle 95

Loading...

Loading...