Raymarine SMARTPILOT Manual

SmartPilot

Series

Commissioning

Guide

Document reference: 81273-1

Date: Date: December 2005

Autohelm, HSB (High Speed Bus), SailPilot, SeaTalk and SportPilot are registered trademarks of Raymarine Ltd. Raymarine, SmartPilot, AST (Advanced Steering Technology), AutoAdapt, AutoLearn, AutoRelease, AutoSeastate, AutoTack, AutoTrim, FastTrim, GyroPlus, RayGyro, RayPilot and WindTrim are trademarks of Raymarine Ltd

© Handbook contents copyright Raymarine plc

i

Important Information

About the documentation provided

Welcome to Raymarine SmartPilot. The autopilot system that will steer your boat to a heading automatically, accurately, reliably and comfortably.

SmartPilot documentation is arranged so that you can install, commission and quickly use your SmartPilot, keeping to hand only the information necessary.

•Installation Sheets - One per element of the system, these easy to understand sheets guide you through the installation process. These can be discarded once the installation is complete.

•SmartPilot Commissioning Guide - This book. Describes how to connect, commission and configure the system.

•Quick Start Guide - Once commissioned, use your Smart Pilot right away with this handy guide to the main operations.

•SmartPilot Operating Guide - Detailed operating information about your SmartPilot.

Note: This handbook contains important information about the installation and commissioning of your new Raymarine product. At the back there is an index and glossary of terms. To get the best from the product please read this handbook thoroughly.

SmartPilot Controller Compatibility

This handbook allows you to commission your SmartPilot with any of the available SmartPilot controllers. The control method for each controller is detailed below.

|

ST6001 & ST6002 |

|

ST7001 & ST7002 |

|

ST8001 & ST8002 |

|

Controller |

|

Controller |

|

Controller |

|

|

|

|

|

|

• |

standby & auto |

• |

standby & auto |

• |

standby & auto |

|

function keys |

|

function keys |

|

function keys |

• |

+1, -1, +10 & -10 course |

• +1, -1, +10 & -10 course |

• |

Rotary course change |

|

|

change keys |

|

change keys |

|

control |

• disp & track extended |

• |

resp, track, mode, |

• |

resp, track, mode, |

|

|

function keys |

|

res’m, disp, up & |

|

res’m, disp, up & |

|

|

|

down extended function |

|

down extended function |

|

|

|

keys |

|

keys |

|

|

|

|

|

|

ii |

SmartPilot Series Commissioning Guide |

Safety notices

WARNING: Product installation

This equipment must be installed and operated in accordance with the instructions contained in this handbook. Failure to do so could result in poor product performance, personal injury and/or damage to your boat.

CAUTION:

Before installing the SmartPilot computer and drive unit, check that they are the correct voltage for your boat’s supply.

As correct performance of the boat’s steering is critical for safety, we STRONGLY RECOMMEND that an Authorized Raymarine Service Representative fits this product. You will only receive full warranty benefits if you can show that an Authorized Raymarine Service Representative has installed or commissioned this product.

WARNING: Electrical safety

Make sure the power supply is switched off before you make any electrical connections.

WARNING: Calibration requirement

We supply this product calibrated to default settings that should provide initial stable performance for most boats. To ensure optimum performance on your boat, you must complete

Chapter 2: .

WARNING: Navigation aid

Although we have designed this product to be accurate and reliable, many factors can affect its performance. As a result, it should only be used as an aid to navigation and should never replace common sense and navigational judgement. Always maintain a permanent watch so you can respond to situations as they develop.

Your SmartPilot will add a new dimension to your boating enjoyment. However, it is the skipper’s responsibility to ensure the safety of the boat at all times by following these basic rules:

•Ensure that someone is present at the helm AT ALL TIMES, to take manual control in an emergency.

•Make sure that all members of crew know how to disengage the autopilot.

•Regularly check for other boats and any obstacles to navigation – no matter how clear the sea may appear, a dangerous situation can develop rapidly.

Important Information |

iii |

•Maintain an accurate record of the boat’s position by using either a navigation aid or visual bearings.

•Maintain a continuous plot of your boat’s position on a current chart. Ensure that the locked autopilot heading will steer the boat clear of all obstacles. Make proper allowance for tidal set – the autopilot cannot.

•Even when your autopilot is locked onto the desired track using a navigation aid, always maintain a log and make regular positional plots. Navigation signals can produce significant errors under some circumstances and the autopilot will not be able to detect these errors.

EMC Guidelines

All Raymarine equipment and accessories are designed to the best industry standards for use in the recreational marine environment. Their design and manufacture conforms to the appropriate Electromagnetic Compatibility (EMC) standards, but correct installation is required to ensure that performance is not compromised.

Although every effort has been taken to ensure that they will perform under all conditions, it is important to understand what factors could affect the operation of the product.

The guidelines given here describe the conditions for optimum EMC performance, but it is recognized that it may not be possible to meet all of these conditions in all situations. To ensure the best possible conditions for EMC performance within the constraints imposed by any location, always ensure the maximum separation possible between different items of electrical equipment.

For optimum EMC performance, it is recommended that wherever possible:

•Raymarine equipment and cables connected to it are:

•At least 3 ft (1 m) from any equipment transmitting or cables carrying radio signals e.g. VHF radios, cables and antennas. In the case of SSB radios, the distance should be increased to 7 ft (2 m).

•More than 7 ft (2 m) from the path of a radar beam. A radar beam can normally be assumed to spread 20 degrees above and below the radiating element.

•The equipment is supplied from a separate battery from that used for engine start. Voltage drops below 10 V, and starter motor transients, can cause the equipment to reset. This will not damage the equipment, but may cause the loss of some information and may change the operating mode.

iv |

SmartPilot Series Commissioning Guide |

•Raymarine specified cables are used. Cutting and rejoining these cables can compromise EMC performance and must be avoided unless doing so is detailed in the installation manual.

•If a suppression ferrite is attached to a cable, this ferrite should not be removed. If the ferrite needs to be removed during installation it must be reassembled in the same position.

EMC suppression ferrites

The following illustration shows typical cable suppression ferrites used with Raymarine equipment. Always use the ferrites supplied by Raymarine.

D3548-6

Connections to other equipment

If your Raymarine equipment is to be connected to other equipment using a cable not supplied by Raymarine, a suppression ferrite MUST always be attached to the cable near to the Raymarine unit.

Handbook information

To the best of our knowledge, the information in this handbook was correct when it went to press. However, Raymarine cannot accept liability for any inaccuracies or omissions it may contain. In addition, our policy of continuous product improvement may change specifications without notice. As a result, Raymarine cannot accept liability for any differences between the product and the handbook.

|

|

v |

Contents |

|

|

Important Information ................................................................................................. |

i |

|

About the documentation provided ........................................................................ |

i |

|

WARNING: |

Product installation.............................................................. |

ii |

WARNING: |

Electrical safety ..................................................................... |

ii |

WARNING: |

Calibration requirement..................................................... |

ii |

WARNING: |

Navigation aid ........................................................................ |

ii |

EMC Guidelines |

..................................................................................................... |

iii |

EMC suppression ferrites ......................................................................... |

iv |

|

Connections to other equipment.............................................................. |

iv |

|

Handbook information .......................................................................................... |

iv |

|

Contents ............................................................................................................................ |

|

v |

Chapter 1: System Connections ................................................................................. |

1 |

|

1.1 Before you start ................................................................................................ |

1 |

|

1.2 The SmartPilot computer .................................................................................. |

2 |

|

SmartPilot types................................................................................................ |

2 |

|

1.3 Removing and replacing the connector cover .................................................. |

3 |

|

WARNING: |

Electrical safety ..................................................................... |

3 |

Computer inputs, outputs and fuses ........................................................ |

4 |

|

1.4 Connecting the Power and the Drive unit ......................................................... |

5 |

|

Grounding the SmartPilot ........................................................................ |

7 |

|

1.5 Fuse Protection ................................................................................................ |

8 |

|

1.6 How to connect SmartPilot system elements ................................................... |

8 |

|

Securing the Cables.................................................................................. |

9 |

|

1.7 How to connect SeaTalk equipment ................................................................. |

9 |

|

Single control unit, single power supply .................................................. |

9 |

|

Isolated control unit, single power supply (S2 and S3 computers only) . 10 |

||

Separate SmartPilot computer and instrument power ........................... |

10 |

|

WARNING: |

Use correct fuse ................................................................... |

10 |

Connecting SeaTalk or NMEA compasses .............................................. |

11 |

|

1.8 How to connect NMEA equipment ................................................................. |

12 |

|

WARNING: |

Connections to other equipment .................................. |

12 |

SmartPilot computer NMEA inputs/outputs.................................................... |

13 |

|

NMEA connectivity overview ................................................................. |

13 |

|

1.9 How to connect optional components ........................................................... |

14 |

|

GyroPlus yaw sensor....................................................................................... |

14 |

|

Handheld remotes .......................................................................................... |

14 |

|

External alarm ................................................................................................ |

15 |

|

Wind vane (sail boats) .................................................................................... |

15 |

|

vi |

SmartPilot Series Commissioning Guide |

Off switch (S2 and S3 only).............................................................................. |

15 |

Connecting spool valves (S2 and S3 only) .............................................. |

15 |

Selecting clutch voltage (S3 & S3G only)................................................ |

16 |

1.10Secure the cables ........................................................................................... |

17 |

S1 systems |

17 |

S2 and S3 systems........................................................................................... |

17 |

Chapter 2: SmartPilot ...................................................................Commissioning |

19 |

WARNING: ................................................... |

19 |

SmartPilot ................................................................Controller Compatibility |

19 |

2.1 Dockside Checks ............................................................................................ |

19 |

WARNING: ............................................................. |

19 |

Step 1 - Switch ............................................................................................on |

20 |

Troubleshooting ..................................................................................... |

20 |

Step 2 - Check .........................................the SeaTalk and NMEA connections |

20 |

SeaTalk ...............................................................................connections |

20 |

NMEA navigator .................................................................connections |

21 |

Wind instrument .................................................................connections |

21 |

Step 3 - Check ..................................................the autopilot operating sense |

21 |

Check the ...........................................................rudder position sensor |

21 |

Check the ........................................................autopilot steering sense |

22 |

Step 4 - Adjust ............................................................key SmartPilot settings |

22 |

Enter Dealer ...............................................................Calibration mode |

23 |

Set the vessel .................................................................................type |

23 |

Set the drive ...................................................................................type |

25 |

Align the ............................................................rudder position sensor |

26 |

Set the rudder ...............................................................................limits |

26 |

Save the ............................................................................new settings |

26 |

2.2 Seatrial Calibration ......................................................................................... |

27 |

Seatrial safety ................................................................................................. |

27 |

Calibrating ..................................................................................the compass |

28 |

Initial procedure ..................................................................................... |

28 |

Adjusting ...........................................................the heading alignment |

31 |

Adjusting SmartPilot ............................................................steering settings |

31 |

AutoLearn .............................................................................................. |

31 |

WARNING: ................................................................. |

31 |

Manual set .......................................................................-up: Non-G Systems |

34 |

Checking ...............................................................SmartPilot operation |

34 |

Response .......................................................................................level |

34 |

Adjusting ......................................................................the rudder gain |

35 |

Adjusting .................................................................the counter rudder |

36 |

Further adjustments .................................................................(Non-G) |

37 |

Contents |

vii |

Chapter 3: Adjusting SmartPilot Settings ............................................................. |

39 |

3.1 Calibration basics ........................................................................................... |

39 |

Calibration groups.......................................................................................... |

39 |

Accessing the Calibration modes.................................................................... |

40 |

3.2 Display Calibration ......................................................................................... |

41 |

Display Calibration screens............................................................................. |

42 |

Display bar selection .............................................................................. |

42 |

Heading selection................................................................................... |

42 |

Pop-up pilot time-out (ST7001, ST7002, ST8001 & ST8002 only) .......... |

42 |

Data pages ............................................................................................ |

43 |

3.3 User Calibration ............................................................................................. |

44 |

3.4 Seatrial Calibration ........................................................................................ |

45 |

3.5 Dealer Calibration .......................................................................................... |

45 |

Accessing Dealer Calibration .......................................................................... |

45 |

Dealer Calibration screens and settings.......................................................... |

47 |

SeaTrial Calibration lock ....................................................................... |

47 |

Vessel type ............................................................................................ |

47 |

Drive type .............................................................................................. |

48 |

Align rudder ........................................................................................... |

48 |

Rudder limit .......................................................................................... |

49 |

Rudder gain .......................................................................................... |

49 |

Counter rudder....................................................................................... |

49 |

Rudder damping .................................................................................... |

50 |

AutoTrim ............................................................................................... |

50 |

Response level ...................................................................................... |

51 |

Turn rate limit ........................................................................................ |

51 |

Off course warning angle....................................................................... |

52 |

Joystick mode (PWR STEER) ................................................................... |

52 |

AutoRelease (I/O drives only) ................................................................. |

53 |

AutoTack angle ...................................................................................... |

53 |

Gybe inhibit ........................................................................................... |

53 |

Wind selection ....................................................................................... |

54 |

WindTrim (wind response) ..................................................................... |

54 |

Cruise speed........................................................................................... |

54 |

AutoAdapt ............................................................................................. |

55 |

Latitude.................................................................................................. |

55 |

System reset ................................................................................................... |

56 |

WARNING: Losing settings at system reset ..................................... |

56 |

Dealer Calibration defaults ............................................................................. |

57 |

Dealer Calibration options.............................................................................. |

58 |

viii |

SmartPilot Series Commissioning Guide |

|

Chapter 4: Fault Finding & Maintenance ............................................................... |

59 |

|

4.1 Fault finding |

................................................................................................... |

59 |

SmartPilot alarm messages............................................................................. |

60 |

|

4.2 Maintenance .................................................................................................. |

62 |

|

EMC, servicing and safety guidelines .............................................................. |

62 |

|

Product support .............................................................................................. |

63 |

|

World wide web..................................................................................... |

63 |

|

Telephone help line................................................................................ |

63 |

|

Help us to help you ................................................................................ |

63 |

|

SmartPilot Specifications.......................................................................................... |

65 |

|

WARNING: |

Potential ignition source .................................................. |

66 |

Glossary ........................................................................................................................... |

|

67 |

Index.................................................................................................................................. |

|

69 |

1

Chapter 1: System Connections

This chapter describes how to connect the elements of the SmartPilot system together and integrate connections from other equipment on your boat.

1.1 Before you start

Ensure the following core elements of the system have been fitted in accordance with the supplied installation guides:

•Compass

•Rudder Reference

•SmartPilot Computer (S1, S1G, S2, S2G, S3, S3G)

•SmartPilot Controller (ST6001, ST6002, ST7001, ST7002, ST8001 or ST8002)

•Drive Unit

Note: For Volvo Penta IPS autopilot systems the rudder reference and drive units are not required. For more information, please refer to the Connections guide supplied with the DPU.

The remainder of this chapter covers the connection of these units. When complete, the core system will be connected like this:

The SmartPilot system

Key components |

SmartPilot |

Controller |

Fluxgate |

compass |

SmartPilot |

computer |

Rudder |

position sensor |

Drive |

unit |

D6403-1 |

2 |

SmartPilot Series Commissioning Guide |

1.2 The SmartPilot computer

The SmartPilot computer lies at the heart of the autopilot system. It processes information from the sensors in the system so it can steer the boat using the drive unit:

•it contains a microprocessor and electronic circuitry to control the drive unit and the drive motor.

•it is the central distribution point for the autopilot system, with terminals to take power from the boat’s distribution panel and inputs/outputs for all other autopilot components

•it has inputs/outputs for SeaTalk and NMEA so you can connect it to Raymarine and other manufacturer’s equipment.

SmartPilot types

S1G, S2G and S3G Smartpilots have a built-in yaw sensor (Gyro) which measures the boat’s rate of turn. This information is used to enhance course keeping in adverse weather and sailing conditions.

Non-G systems do not contain a built-in Gyro. These can be upgraded with a dealer-fitted internal Gyro or connecting an external Gyro unit.

SmartPilot |

Supply |

Drive unit compatibility |

Built-in |

Version |

voltage |

|

Gyro? |

|

|

|

|

S1G |

12 V |

All Raymarine Type 1 12 V drives and pumps |

Yes |

|

|

(excluding 12 V Constant Running pump). |

|

|

|

|

|

S1 |

12 V |

All Raymarine Type 1 12 V drives and pumps |

No |

|

|

(excluding 12 V Constant Running pump). |

|

|

|

|

|

S2G |

12 V |

All Raymarine Type 1 12 V drives and pumps |

Yes |

|

|

(including 12 V Constant Running pump). |

|

|

|

|

|

S2 |

12 V |

All Raymarine Type 1 12 V drives and pumps |

No |

|

|

(including 12 V Constant Running pump). |

|

|

|

|

|

S3G |

12 V or 24 V |

All Raymarine 12 V and 24 V Type 1, Type 2 and |

Yes |

|

|

Type 3 drives and pumps. Drive voltage must be |

|

|

|

matched to boat’s supply voltage. |

|

|

|

|

|

S3 |

12 V or 24 V |

All Raymarine 12 V and 24 V Type 1, Type 2 and |

No |

|

|

Type 3 drives and pumps. Drive voltage must be |

|

|

|

matched to boat’s supply voltage. |

|

|

|

|

|

Volvo |

12 V or 24 V |

Only to be used with Volvo Penta IPS Drive sys- |

Yes |

Penta IPS |

|

tems. |

|

(S3G) |

|

|

|

|

|

|

|

Chapter 1: System Connections |

3 |

1.3 Removing and replacing the connector cover

WARNING: Electrical safety

Before you make any electrical connections, ensure the power supply is switched off and you have read the EMC installation guidelines (see page iii.)

S1 Systems |

S2 and S3 Systems |

•hold the bottom of the connector cover

•gently lift the connector cover away from the base and the lid will come free

•use a flat-bladed screwdriver or small coin to rotate the catch 1/4 turn (90°) in either direction – until you hear a click and the slot is horizontal

•lift off the cover

To open

PULL

-1 D6385

•replace the cover

•gently press the sides of the cover until you hear it click

To close

2

1

To open

-1 D6387

•replace the cover

•turn the catch so the slot is vertical

•push in the catch until you hear it click

To close

2

1 - D6388

-1 D6386

4 |

SmartPilot Series Commissioning Guide |

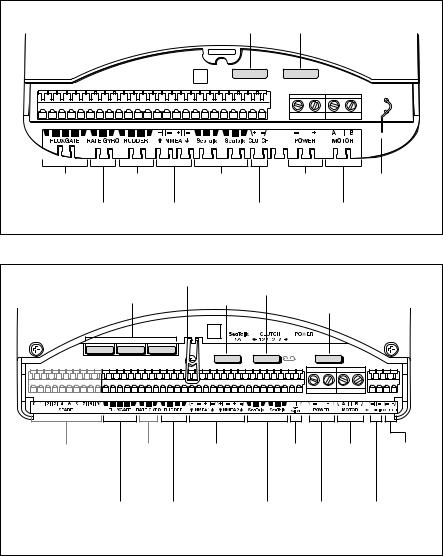

Computer inputs, outputs and fuses

S1 Systems

|

|

|

|

SeaTalk fuse |

Power fuse |

Note: Spare fuses located |

|

|

|

|

(2 A) |

(15 A) |

in the connector cover |

|

|

|

|

SEATALK |

POWER IN |

RF GND |

|

|

|

|

|

||

Fluxgate |

Rudder position |

|

SeaTalk |

Power |

RF ground |

|

compass inputs |

sensor inputs |

inputs/outputs |

inputs |

connection |

||

External GyroPlus |

NMEA 0183 |

|

(12 V) |

Drive motor |

||

Drive clutch |

||||||

yaw sensor inputs |

input/ouput |

|

ouputs |

|

outputs |

|

|

|

|

|

|

|

D6389-1 |

S2 and S3 Systems

|

|

Fuse puller |

Clutch fuse |

|

|

|

|||

|

|

|

SeaTalk fuse |

(4 A) |

Power fuse |

|

|

||

Spare fuses |

|

S2: 30 A |

|

|

|||||

(5 A) |

|

|

|

|

|

||||

|

|

|

|

|

|

S3: 40 A |

|

|

|

|

|

|

|

|

|

|

|

|

|

Spare connectors |

External |

NMEA 0183 |

|

Off switch |

Drive |

Drive clutch |

|||

(S3 only) |

GyroPlus |

inputs/outputs |

|

|

inputs |

motor |

outputs |

||

yaw sensor |

|

|

|

|

outputs |

S3: |

|||

|

|

inputs |

|

|

|

|

|

|

selectable for |

|

|

|

|

|

|

|

|

|

12 V or 24 V |

Fluxgate |

Rudder |

|

|

SeaTalk |

Power inputs |

Drive solenoid |

|||

compass |

position |

|

|

inputs/ |

S2: 12 V |

|

return inputs |

||

inputs |

|

sensor inputs |

|

outputs |

S3: 12 V or 24 V |

(for drives/pumps |

|||

|

|

|

|

|

|

|

|

with solenoids) |

|

|

|

|

|

|

|

|

|

|

D5193-2 |

Chapter 1: System Connections |

5 |

1.4 Connecting the Power and the Drive unit

CAUTION:

Use of incorrect power cable size could cause your SmartPilot to malfunction and will reduce the power supplied to the drive unit. Ensure the correct size is used and if in doubt, use a heavier gauge cable.

Note: For Volvo Penta IPS autopilot systems a motor connection is not required. For more information, please refer to the Connections guide supplied with the DPU.

To connect the power and motor connections, follow the steps below:

1.Measure the total length of cable run from the boat’s distribution panel to the SmartPilot computer.

2.Select the appropriate size cable (distribution panel to SmartPilot computer):

Cable length |

S1 |

S2 & |

Cable |

Copper |

|

|

S3 |

gauge |

area |

Type 1 drive 12/24 V; I/O drive;

Volvo Penta IPS system (S3G); CR pump solenoids*

up to 3m (10ft) up to 5m (16ft) up to 7m (23ft) up to 10m (32ft)

¸¸

¸ |

¸ |

14 AWG |

2.5 mm2 |

¸ |

¸ |

12 AWG |

2 |

|

¸ |

10 AWG |

4 mm |

|

6 mm2 |

||

|

|

8 AWG |

10 mm2 |

|

|

|

Type 2 drive 12 V |

¸ |

|

|

up to 5m (16ft) |

¸ |

10 AWG |

6 mm2 |

up to 7m (23ft) |

|

8 AWG |

2 |

|

|

|

10 mm |

Type 2 drive 24 V |

¸ |

|

|

up to 3m (10ft) |

¸ |

12 AWG |

4 mm2 |

up to 5m (16ft) |

¸ |

10 AWG |

2 |

up to 10m (32ft) |

|

8 AWG |

6 mm |

|

10 mm2 |

||

|

|

|

|

Type 3 drive 12 V |

¸ |

|

|

up to 5m (16ft) |

|

8 AWG |

10 mm2 |

|

|

|

|

Type 3 drive 24 V |

¸ |

|

|

up to 5m (16ft) |

¸ |

10 AWG |

6 mm2 |

up to 7m (23ft) |

|

8 AWG |

2 |

|

|

|

10 mm |

Note: * These specifications apply to the cabling for CR |

solenoids. Power the CR pump |

||

motor separately, as specified in the CR pump installation guide. |

|

||

6 |

SmartPilot Series Commissioning Guide |

3. Select the appropriate circuit breaker or fuse:

Drive unit |

S1 |

S2 & |

Fuse |

Thermal over-current |

|

|

S3 |

|

circuit breaker |

|

|

|

|

|

Rotary, linear, hydraulic pump, |

¸ |

¸ |

25 A |

20 A |

hydraulic linear |

|

¸ |

25 A |

20 A |

Type 1: 12 V |

|

¸ |

40 A |

30 A |

Type 1: 24 V |

|

¸ |

30 A |

30 A |

Type 2: 12 V |

|

¸ |

40 A |

30 A |

Type 2: 24 V |

|

|

|

|

Type 3: 12 V and 24 V |

|

|

|

|

|

|

|

|

|

I/O drive |

¸ |

¸ |

15 A |

10 A |

|

|

|

|

|

CR pump solenoids |

|

¸ |

10 A |

10 A |

Volvo Penta IPS system (S3G) |

|

|

|

|

4.Route the cables back to the SmartPilot computer.

5.Connect the cables to the POWER inputs.

S1 Systems |

S2 & S3 Systems |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

• Strip 8–10 mm (½ in) of insulation from |

• Strip 8–10 mm (½ in) of insulation from |

|||||||||

the end of each cable. |

the end of each cable. |

|||||||||

• Use a small screwdriver to loosen the |

• For the POWER connection: |

|||||||||

screw on the terminal block. |

Attach the suppression ferrite (supplied) |

|||||||||

• Insert the stripped cable into the terminal |

around both the positive and negative |

|||||||||

and tighten the screw. |

power cables, between the cable clamp |

|||||||||

|

|

|

|

|

|

and SmartPilot computer. |

||||

|

|

|

|

|

|

When you attach the ferrite, you must |

||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

loop both power cables so that the ferrite |

||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

encloses two passes of each cable. |

||||

|

|

|

|

|

|

Secure the ferrite with the small tie-wrap. |

||||

|

|

|

|

|

|

• Use a small screwdriver to loosen the |

||||

|

|

|

|

|

|

screw on the terminal block. |

||||

|

|

|

|

|

|

• Insert the stripped cable into the terminal |

||||

|

|

|

|

|

|

and tighten the screw. |

||||

D6390-2 |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

Ferrite

D6391-2

Chapter 1: System Connections |

7 |

6.Connect the drive cables to the MOTOR inputs. These cables can be connected any way round as their orientation is verified later in the process.

A |

B |

MOTOR |

|

|

D6392-1 |

Grounding the SmartPilot

S1 Systems |

S2 & S3 Systems |

|

|

CAUTION: |

CAUTION: |

S1 systems MUST be connected to |

S2 & S3 systems MUST NOT be |

ships ground. |

connected to ships ground. |

Failure to connect the SmartPilot to ships |

If the installed location has a metallic sur- |

ground may cause it, or other on-board |

face, you must insulate the base of the |

electronics to function incorrectly. |

computer so it is not earthed. |

•Use flat tinned copper braid, 30 A rating (¼ in) or greater. Equivalent stranded wire diameter 4mm or greater.

•Using the supplied yellow (¼ in) female spade connector, connect the braid to

RF GND on the SmartPilot computer.

•The other end of the earth strap should be connected to metal in contact with the water. If this is not possible, it can be connected to the negative pole of the battery (ideally at the battery itself).

•Keep the length of the earth strap as short as possible

S1 systems only |

|

|

RF GND |

|

|

|

|

|

|

A |

B |

OR |

POWER |

MOTOR |

|

|

|

|

D6378-1 |

8 |

SmartPilot Series Commissioning Guide |

1.5 Fuse Protection

The POWER and SeaTalk terminals are fuse protected against short-circuits and misconnections.

Your SmartPilot computer is supplied with spare fuses. The fuses used in the computer are standard automotive blade fuses, so replacements are easily available. Your Raymarine dealer can also provide a replacement fuse pack.

1.6 How to connect SmartPilot system elements

All SmartPilot computer terminals will accept stranded cable up to 2.5 mm2 (14 AWG).

Connect the following elements as shown in the diagram:

1.Compass

2.Rudder Sensor

3.SmartPilot Controller via SeaTalk

Note: For Volvo Penta IPS autopilot systems a rudder sensor is not required. For more information, please refer to the Connections guide supplied with the DPU.

|

|

|

|

|

|

SmartPilot computer terminals |

|

|

|

||||

Red |

Yellow |

|

Red |

Yellow |

Red |

Blue |

|

Red |

Screen |

Yellow |

|||

Screen |

Green |

Blue |

Screen |

Screen |

Green |

|

Screen Yellow |

Red |

|||||

FLUXGATE |

|

RATE GYRO |

RUDDER |

NMEA |

SeaTalk |

|

SeaTalk CLUTCH |

||||||

|

|

|

|

External |

|

|

|

NMEA |

|

|

|

Clutch |

|

|

|

|

|

Rate Gyro |

|

|

|

Input and |

|

|

|

(Linear, Rotary |

|

|

|

|

|

(Optional) |

|

|

Output (Optional) |

|

|

& I/O drives only) |

|||

Compass |

|

|

|

|

Rudder sensor |

|

Controller |

|

|

|

|||

|

1 |

|

|

|

|

|

2 |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D6307-1 |

Chapter 1: System Connections |

9 |

Securing the Cables

1.Strip at least 5 mm (¼ in) of insulation from the end of each cable

2.Use a small screwdriver to push the small plastic lever on top of the terminal and release the cable clamp

3.Insert the stripped cable and release the lever to grip the cable

1.7How to connect SeaTalk equipment

Note: For Volvo Penta IPS autopilot systems, please refer to the Connections guide supplied with the DPU.

You can use SeaTalk to connect your SmartPilot to:

•additional SeaTalk controllers: you can use any controller to operate the SmartPilot and view autopilot information

•SeaTalk equipment (such as instruments, chartplotters, radar and GPS):

•the SmartPilot can use information from this equipment to enhance course keeping and provide additional features.

•you can also display information from the SeaTalk equipment on the SmartPilot controller.

The following illustrations show some typical ways to connect simple SeaTalk systems.

Single control unit, single power supply

The simplest type of system has the SmartPilot computer providing power to a single SeaTalk bus that includes a single controller and several instruments.

Single control unit, single power supply

SeaTalk

SmartPilot |

Course computer |

power supply |

|

computer |

(via breaker/fuse) |

|

SeaTalk bus |

SmartPilot |

SeaTalk instruments |

controller |

|

D6300-1

10 |

SmartPilot Series Commissioning Guide |

Isolated control unit, single power supply (S2 and S3 computers only)

If you have two control units, we recommend that you connect one to each SeaTalk terminal. In the following illustration:

•the SmartPilot computer provides power to the SeaTalk system

•one control unit is connected on its own to SeaTalk A so it is isolated against any possible failure of SeaTalk B

If the SeaTalk B line fails, the isolated control unit will switch to Standby mode as a safety measure. By pressing auto on the isolated control unit you can regain full autopilot control.

Isolated control unit, single power supply

|

|

Course computer |

|

|

power supply |

|

SmartPilot |

(via breaker/fuse) |

|

|

|

ASeaTalk |

computer |

|

BSeaTalk |

SeaTalk bus |

|

|

|

|

Isolated |

Second |

ST60 instruments |

control unit |

control unit |

|

Extra connection on larger SeaTalk systems

D6383-1

Note: Depending on the number of SeaTalk units and the total length of SeaTalk cabling, you may need to provide12 V power supply to each end of the SeaTalk bus (‘ring-main’ style). Refer to the instrument handbook for more information.

Separate SmartPilot computer and instrument power

Another option is to provide separate power supplies to the SmartPilot computer and SeaTalk system so you can have independent, switched instrument and pilot systems.

Note: DO NOT connect the SeaTalk RED wire at the SmartPilot terminal

WARNING: Use correct fuse

The fuse supplying the instrument system MUST be rated at 5A or less.

The behavior of the computer and the instruments now depend on where power is applied to the system.

Chapter 1: System Connections |

11 |

•Computer AND instrument power supplies ON:

The system will function normally.

•Only computer power supply ON:

The controller and instruments do not power up.

•Only instrument power supply ON:

The controller shows a PILOT OFF or NO LINK message.

Separate SmartPilot computer and instrument power supplies

SmartPilot computer

SeaTalk

SmartPilot

controller

Screen Yellow

Do not connect Red wire

Do not connect Red wire

(Cut back and insulate)

Computer power supply

(via breaker/fuse)

SeaTalk bus

SeaTalk

SeaTalk instruments

Instrument SeaTalk

bus 12 V power supply

(via breaker/fuse rated at 5 A or less)

D6302-2

Connecting SeaTalk or NMEA compasses

You can connect SeaTalk or NMEA compasses to the SmartPilot computer, either to replace the fluxgate compass or provide supplementary compass signals.

When you connect more than one compass to the autopilot system, the computer processes their signals in this order of priority:

1.Fluxgate compass

2.NMEA compass

3.SeaTalk compass

This means that if you want to use a NMEA compass as the primary compass, you need to disconnect the fluxgate compass.

To connect a SeaTalk or NMEA compass to the autopilot system:

•NMEA compass: connect it to a NMEA input on the computer

•SeaTalk compass: connect it to the SeaTalk bus or the SeaTalk terminals

12 |

SmartPilot Series Commissioning Guide |

1.8 How to connect NMEA equipment

If you have equipment on your boat that transmits or receives NMEA 0183 data (e.g. GPS), you can connect this equipment to the SmartPilot. NMEA equipment can be connected in any combination of these ways:

•using the SmartPilot computer NMEA input/output

•using the NMEA input on the back of the SmartPilot controller. (Refer to the Controller handbook for NMEA data details)

•using the SeaTalk/NMEA interface (part number: E85001) to convert the NMEA data to SeaTalk data

WARNING: Connections to other equipment

If you are connecting Raymarine equipment to other equipment using a non-Raymarine cable, you MUST attach an appropriate suppression ferrite to the cable near to the Raymarine unit.

SmartPilot computer terminals |

|

|||

|

|

|

Controller (rear) |

|

|

|

|

SeaTalk |

|

|

Red |

|

||

|

Screen |

Yellow |

|

|

|

|

SeaTalk |

|

|

NMEA |

|

NMEA |

NMEA |

|

|

|

|||

GPS |

NMEA |

NMEA |

||

Other |

||||

radar |

instrument |

|||

Instrument |

||||

|

|

|

||

|

|

|

D6303-1 |

|

Chapter 1: System Connections |

13 |

SmartPilot computer NMEA inputs/outputs

Note: Do NOT connect more than one piece of equipment to each SmartPilot computer NMEA input.

NMEA connectivity overview

S1 Systems |

S2 & S3 Systems |

The S1 has a single NMEA input/output to receive and transmit information from NMEA equipment.

S2 and S3 systems have two sets of NMEA inputs/outputs to receive and transmit information from NMEA equipment.

SmartPilot computer NMEA inputs

NMEA 0183 |

S1 |

S2 & |

Information extracted |

received |

|

S3 |

|

|

|

|

|

APB |

¸ |

¸ |

cross track error, bearing to waypoint, waypoint |

|

|

|

number |

|

|

|

|

BWC |

¸ |

¸ |

bearing to waypoint, distance to waypoint, way- |

BWR |

¸ |

¸ |

point number, time |

|

|

|

|

GGA |

¸ |

¸ |

latitude/longitude, time |

GLL |

¸ |

¸ |

|

|

|

|

|

HDG |

¸ |

¸ |

heading |

HDM |

¸ |

¸ |

|

HDT |

¸ |

¸ |

|

|

|

|

|

MWV |

¸ |

¸ |

apparent wind angle, apparent wind speed |

|

|

|

|

RMA |

¸ |

¸ |

course over ground (COG), speed over ground |

|

|

|

(SOG), latitude/longitude, variation |

|

|

|

|

RMB |

¸ |

¸ |

cross track error, bearing to waypoint, distance to |

|

|

|

waypoint, waypoint number |

|

|

|

|

RMC |

¸ |

¸ |

course over ground (COG), speed over ground |

|

|

|

(SOG), latitude/longitude, time, variation |

|

|

|

|

VHW |

¸ |

¸ |

speed through water, heading |

|

|

|

|

VTG |

¸ |

¸ |

course over ground (COG), speed over ground |

|

|

|

(SOG) |

|

|

|

|

VWR |

¸ |

¸ |

relative apparent wind angle, relative apparent |

|

|

|

wind speed |

|

|

|

|

XTE |

¸ |

¸ |

cross track error |

|

|

|

|

ZDA |

¸ |

¸ |

time, date |

Note: When connected to a NMEA navigator, S2 & S3 systems look at NMEA 1 first. If NMEA 1 has no data, it then looks at NMEA 2. If both channels have the same type of navigation data, NMEA 1 is used.

14 |

|

|

|

SmartPilot Series Commissioning Guide |

|

|

|||

|

SmartPilot computer NMEA outputs* |

|||

|

|

|

|

|

|

NMEA 0183 |

S1 |

S2 & S3 |

Information sent |

|

sent |

|

(NMEA port) |

|

|

|

|

|

|

|

BWC |

¸ |

2 |

bearing to waypoint*, distance to waypoint*, |

|

|

|

|

waypoint number*, time* |

|

|

|

|

|

|

GLL |

¸ |

2 |

latitude/longitude*, time* |

|

|

|

|

|

|

HDG |

¸ |

2 |

|

|

HDM |

¸ |

1 & 2 |

heading |

|

HDT |

¸ |

2 |

|

|

|

|

|

|

|

VTG |

¸ |

2 |

course over ground* (COG), |

|

|

|

|

speed over ground* (SOG) |

* Note: The computer will only transmit these items if it has received the appropriate data.

Notes: (1) S1G systems provide fast heading (HDM) output at 5 Hz 0.1º resolution

(2)S2G & S3G computers provide fast heading (HDM) output at 10 Hz 0.1º resolution.

This fast heading data is suitable for use with the MARPA function on radar equipment.

(3)In Volvo Penta IPS systems, NMEA port 1 is reserved for connection to the DPU, NMEA port 2 remains available for general purpose NMEA connections. For more information, please refer to the Connections guide supplied with the DPU.

1.9How to connect optional components

Note: For installation, refer to the guide supplied with the component.

GyroPlus yaw sensor

Non-G SmartPilots do not contain a built-in Gyro, but you have the option of adding:

•an external GyroPlus (part number: E12101)

•or a dealer-fitted internal GyroPlus (part number: A18069)

Handheld remotes

Two wireless Raymarine handheld remote control systems are available:

•the Smart Controller system can act as the sole pilot controller in your system or as a full-function remote for systems with other fixed pilot controllers.

•the compact S100 Controller system gives you full course control away from the main steering position

Chapter 1: System Connections |

15 |

External alarm

The SmartPilot sounds all critical alarms from all controllers. On large or noisy boats you can fit a Raymarine external alarm (part number: Z035, connected through E85001 interface box) as a high volume audible repeater.

Wind vane (sail boats)

The SmartPilot computer can use wind angle information from a wind vane or instrument to maintain a course relative to the wind. You can provide wind angle information to the autopilot system by connecting it to a suitable SeaTalk or NMEA instrument (providing wind angle and speed information)

Off switch (S2 and S3 only)

The SmartPilot computer has inputs so you can fit an off switch if required. By closing a circuit, this switch will turn off the computer power supply.

Connect a suitable off switch to the OFF SWITCH inputs on the computer.

Connecting an Off switch

SmartPilot computer terminals

Off switch (closes circuit to turn off course computer power)

D5396-2

Other manufacturers’ drive units (S2 and S3 only)

If you are connecting another manufacturer’s drive unit, refer to the specifications (see page 65) for information on the SmartPilot computer’s drive motor, drive clutch and drive solenoid terminals. Connect the drive unit to these terminals as necessary. For more information, contact the drive unit manufacturer.

Connecting spool valves (S2 and S3 only)

If the drive has spool valves, connect them to the motor and solenoid terminals on the computer as shown below. The computer provides a negative ground for the spool valves even when it is switched off.

16 |

SmartPilot Series Commissioning Guide |

CAUTION:

Do NOT connect the solenoid return cables to boat’s negative ground, as this will bypass the current protection devices inside the SmartPilot computer.

SmartPilot S2 & S3 connections

If electronic steering or jog lever is used on the same solenoids, fit diodes (suggested type: 1N4004) as indicated to prevent backfeeding the course computer.

Return cables |

Diodes |

Electronic steering or jog lever

12 V |

Spool valves |

|

(diodes across |

||

24 V |

||

spool valves) |

||

|

D5397-3

Selecting clutch voltage (S3 & S3G only)

You can use the S3 and S3G SmartPilot computers with other manufacturers’ drives that have either 12 V or 24 V clutches. If you do this, you may have to reposition the clutch fuse.

Important: All Raymarine 12 V and 24 V drive units with a clutch have a 12 V clutch, so you do NOT need to re-position the clutch fuse.

If you are using another manufacturer’s drive, ascertain the operating voltage of the CLUTCH. Ensure the clutch fuse is set to the correct voltage, i.e. to the left for a 12 V clutch, or right for a 24 V clutch. If necessary, select the appropriate clutch voltage by re-positioning the clutch fuse.

It is important to appreciate that the fuse position does NOT depend on the voltage used on your boat, but on the operating voltage of the CLUTCH.

Fuse position: 12 V CLUTCH |

Fuse position: 24 V CLUTCH |

4 |

4 |

D5398-3

Loading...

Loading...