HP ProLiant DL360 User Manual

HP ProLiant DL360 G6 Server

User Guide

Abstract

This document describes installation, administration, and troubleshooting for this server. This document is for the person who installs, administers, and troubleshoots servers and storage systems. HP assumes you are qualified in the servicing of computer equipment and trained in recognizing hazards in products with hazardous energy levels.

Part Number: 517689-004

August 2011

Edition: 4

© Copyright 2009, 2011 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Microsoft®, Windows®, Windows NT® , and Windows Server® are U.S. registered trademarks of Microsoft Corporation.

Contents |

|

Component identification............................................................................................................... |

7 |

Front panel components................................................................................................................................ |

7 |

Front panel LEDs and buttons......................................................................................................................... |

8 |

Rear panel components ................................................................................................................................ |

9 |

Rear panel LEDs and buttons ....................................................................................................................... |

10 |

System board components .......................................................................................................................... |

11 |

DIMM slots ...................................................................................................................................... |

12 |

System maintenance switch ............................................................................................................... |

12 |

NMI jumper..................................................................................................................................... |

13 |

HP Systems Insight Display LEDs .................................................................................................................. |

13 |

Systems Insight Display LED combinations..................................................................................................... |

14 |

SAS and SATA device numbers ................................................................................................................... |

15 |

SAS and SATA hard drive LEDs ................................................................................................................... |

16 |

SAS and SATA hard drive LED combinations ................................................................................................ |

16 |

Fan modules .............................................................................................................................................. |

17 |

T-10/T-15 Torx screwdriver ......................................................................................................................... |

18 |

Operations................................................................................................................................. |

19 |

Power up the server.................................................................................................................................... |

19 |

Power down the server ............................................................................................................................... |

19 |

Extend the server from the rack.................................................................................................................... |

19 |

Access the HP Systems Insight Display .......................................................................................................... |

20 |

Remove the access panel ............................................................................................................................ |

21 |

Install the access panel ............................................................................................................................... |

21 |

Remove the BBWC battery pack .................................................................................................................. |

21 |

Remove the air baffle.................................................................................................................................. |

22 |

Install the air baffle..................................................................................................................................... |

22 |

Remove the PCI riser board assembly........................................................................................................... |

23 |

Install the PCI riser board assembly .............................................................................................................. |

24 |

Setup......................................................................................................................................... |

26 |

Optional installation services....................................................................................................................... |

26 |

Rack planning resources ............................................................................................................................. |

26 |

Optimum environment................................................................................................................................. |

26 |

Space and airflow requirements ........................................................................................................ |

27 |

Temperature requirements ................................................................................................................. |

27 |

Power requirements .......................................................................................................................... |

28 |

Electrical grounding requirements ...................................................................................................... |

28 |

Rack warnings ........................................................................................................................................... |

28 |

Contents of the server shipping carton .......................................................................................................... |

29 |

Installing hardware options ......................................................................................................................... |

29 |

Installing the server into the rack .................................................................................................................. |

29 |

Powering up and configuring the server........................................................................................................ |

31 |

Installing the operating system ..................................................................................................................... |

31 |

Registering the server.................................................................................................................................. |

32 |

Hardware options installation....................................................................................................... |

33 |

Contents |

3 |

Introduction ............................................................................................................................................... |

33 |

Processor and fan module option................................................................................................................. |

33 |

Memory options......................................................................................................................................... |

38 |

Memory subsystem architecture ......................................................................................................... |

39 |

Single-, dual-, and quad-rank DIMMs ................................................................................................. |

39 |

DIMM identification.......................................................................................................................... |

40 |

Memory configurations ..................................................................................................................... |

40 |

General DIMM slot population guidelines ........................................................................................... |

42 |

Installing a DIMM............................................................................................................................. |

44 |

Hot-plug SAS and SATA hard drive options .................................................................................................. |

45 |

Removing hard drive blanks .............................................................................................................. |

46 |

Removing hard drive bezel blanks ..................................................................................................... |

46 |

Removing the dual hard drive bezel blank .......................................................................................... |

46 |

Removing a hot-plug SAS hard drive .................................................................................................. |

47 |

Installing a SAS hard drive................................................................................................................ |

47 |

DVD-ROM and DVD-RW drive option........................................................................................................... |

48 |

Hard drive blackplane option...................................................................................................................... |

51 |

Controller options....................................................................................................................................... |

55 |

Installing the cache module ............................................................................................................... |

56 |

Installing the BBWC battery pack....................................................................................................... |

57 |

Expansion board options ............................................................................................................................ |

58 |

Installing an expansion board ........................................................................................................... |

58 |

Installing a PCI-X riser board ............................................................................................................. |

59 |

HP ProLiant DL360 G6 PCI thermal - power option ........................................................................................ |

60 |

HP NC522SFP Dual Port 10GbE Server Adapter option................................................................................. |

63 |

Redundant hot-plug power supply option ...................................................................................................... |

63 |

HP Trusted Platform Module option .............................................................................................................. |

65 |

Installing the Trusted Platform Module board ....................................................................................... |

66 |

Retaining the recovery key/password................................................................................................. |

67 |

Enabling the Trusted Platform Module................................................................................................. |

68 |

Cabling ..................................................................................................................................... |

69 |

Cabling overview....................................................................................................................................... |

69 |

Hard drive backplane cabling ..................................................................................................................... |

69 |

BBWC battery pack cabling........................................................................................................................ |

70 |

DVD-ROM and DVD-RW drive cabling ......................................................................................................... |

71 |

Power button and Systems Insight Display cabling ......................................................................................... |

71 |

PCI power cabling ..................................................................................................................................... |

72 |

Software and configuration utilities ............................................................................................... |

73 |

Configuration tools..................................................................................................................................... |

73 |

SmartStart software .......................................................................................................................... |

73 |

HP ROM-Based Setup Utility .............................................................................................................. |

73 |

Array Configuration Utility ................................................................................................................ |

76 |

Option ROM Configuration for Arrays................................................................................................ |

77 |

Re-entering the server serial number and product ID............................................................................. |

77 |

Management tools...................................................................................................................................... |

78 |

Automatic Server Recovery................................................................................................................ |

78 |

ROMPaq utility................................................................................................................................. |

78 |

Integrated Lights-Out 2 technology ..................................................................................................... |

78 |

Erase Utility ..................................................................................................................................... |

79 |

Redundant ROM support................................................................................................................... |

79 |

USB support .................................................................................................................................... |

79 |

Internal SD support........................................................................................................................... |

80 |

Contents |

4 |

Diagnostic tools ......................................................................................................................................... |

80 |

HP Insight Diagnostics ...................................................................................................................... |

80 |

HP Insight Diagnostics survey functionality .......................................................................................... |

80 |

Integrated Management Log.............................................................................................................. |

81 |

Remote support and analysis tools ............................................................................................................... |

81 |

HP Insight Remote Support software ................................................................................................... |

81 |

Keeping the system current.......................................................................................................................... |

82 |

Drivers ............................................................................................................................................ |

82 |

ProLiant Support Packs...................................................................................................................... |

82 |

Operating System Version Support..................................................................................................... |

82 |

HP Smart Update Manager ............................................................................................................... |

82 |

Change control and proactive notification .......................................................................................... |

83 |

Care Pack ....................................................................................................................................... |

83 |

Troubleshooting .......................................................................................................................... |

84 |

Troubleshooting resources ........................................................................................................................... |

84 |

Pre-diagnostic steps .................................................................................................................................... |

84 |

Important safety information .............................................................................................................. |

84 |

Symptom information........................................................................................................................ |

86 |

Prepare the server for diagnosis......................................................................................................... |

86 |

Loose connections ...................................................................................................................................... |

88 |

Service notifications.................................................................................................................................... |

89 |

Server health LEDs...................................................................................................................................... |

89 |

Troubleshooting flowcharts .......................................................................................................................... |

89 |

Start diagnosis flowchart................................................................................................................... |

89 |

General diagnosis flowchart.............................................................................................................. |

90 |

Server power-on problems flowchart .................................................................................................. |

92 |

POST problems flowchart.................................................................................................................. |

95 |

OS boot problems flowchart.............................................................................................................. |

97 |

Server fault indications flowchart ....................................................................................................... |

98 |

POST error messages and beep codes ....................................................................................................... |

100 |

System battery.......................................................................................................................... |

102 |

Regulatory compliance notices ................................................................................................... |

103 |

Regulatory compliance identification numbers ............................................................................................. |

103 |

Federal Communications Commission notice............................................................................................... |

103 |

FCC rating label ............................................................................................................................ |

103 |

Class A equipment ......................................................................................................................... |

103 |

Class B equipment.......................................................................................................................... |

103 |

Declaration of conformity for products marked with the FCC logo, United States only...................................... |

104 |

Modifications........................................................................................................................................... |

104 |

Cables .................................................................................................................................................... |

104 |

Canadian notice (Avis Canadien) .............................................................................................................. |

104 |

European Union regulatory notice.............................................................................................................. |

105 |

Disposal of waste equipment by users in private households in the European Union ........................................ |

105 |

Japanese notice ....................................................................................................................................... |

106 |

BSMI notice ............................................................................................................................................. |

106 |

Korean notice .......................................................................................................................................... |

106 |

Chinese notice ......................................................................................................................................... |

107 |

Laser compliance ..................................................................................................................................... |

107 |

Battery replacement notice ........................................................................................................................ |

107 |

Taiwan battery recycling notice ................................................................................................................. |

108 |

Power cord statement for Japan ................................................................................................................. |

108 |

|

Contents 5 |

Acoustics statement for Germany (Geräuschemission) |

..................................................................................108 |

Electrostatic discharge............................................................................................................... |

109 |

Preventing electrostatic discharge .............................................................................................................. |

109 |

Grounding methods to prevent electrostatic discharge.................................................................................. |

109 |

Specifications........................................................................................................................... |

110 |

Environmental specifications...................................................................................................................... |

110 |

Server specifications................................................................................................................................. |

110 |

Power supply specifications....................................................................................................................... |

110 |

Hot-plug power supply calculations ............................................................................................................ |

112 |

Technical support...................................................................................................................... |

113 |

Before you contact HP .............................................................................................................................. |

113 |

HP contact information.............................................................................................................................. |

113 |

Customer Self Repair ................................................................................................................................ |

113 |

Acronyms and abbreviations...................................................................................................... |

121 |

Index....................................................................................................................................... |

124 |

Contents 6

Component identification

Front panel components

Item |

Description |

|

|

1 |

Hard drive bay 5 (optional)* |

2 |

Hard drive bay 6 (optional)* |

3 |

DVD tray/hard drive bays 7 and 8 (optional)* |

4 |

HP Systems Insight Display ("Access the HP Systems Insight |

|

Display" on page 20) |

5 |

Front USB connector |

6 |

Video connector |

7 |

Hard drive bay 4 |

8 |

Hard drive bay 3 |

9 |

Hard drive bay 2 |

10 |

Hard drive bay 1 |

*An optional hard drive backplane is required when the server is configured with eight hard drives.

Component identification 7

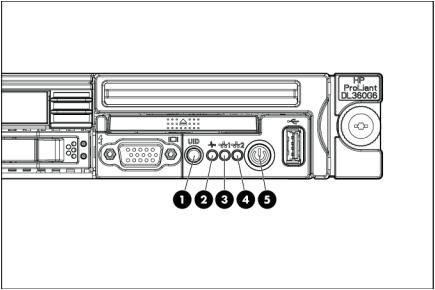

Front panel LEDs and buttons

Item |

Description |

Status |

|

|

|

1 |

UID LED/button |

Blue = Identification is activated. |

|

|

Flashing blue = System is being managed remotely. |

|

|

Off = Identification is deactivated. |

|

|

|

2 |

Health LED |

Green = System health is normal. |

|

|

Amber = System health is degraded. To identify the component in a |

|

|

degraded state, see "HP Systems Insight Display and LEDs ("HP |

|

|

Systems Insight Display LEDs" on page 13)". |

|

|

Red = System health is critical. To identify the component in a critical |

|

|

state, see "HP Systems Insight Display and LEDs ("HP Systems Insight |

|

|

Display LEDs" on page 13)". |

|

|

Off = System health is normal (when in standby mode). |

|

|

|

3 |

NIC 1 link/activity LED |

Green = Network link exists. |

|

|

Flashing green = Network link and activity exist. |

|

|

Off = No link to network exists. |

|

|

If power is off, the front panel LED is not active. For status, view the |

|

|

RJ-45 connector LEDs. |

|

|

|

4 |

NIC 2 link/activity LED |

Green = Network link exists. |

|

|

Flashing green = Network link and activity exist. |

|

|

Off = No link to network exists. |

|

|

If power is off, the front panel LED is not active. For status, view the |

|

|

RJ-45 connector LEDs. |

|

|

|

5 |

Power On/Standby button |

Green = System is on. |

|

and system power LED |

Amber = System is in standby, but power is still applied. |

|

|

Off = Power cord is not attached, power supply failure has occurred, |

|

|

no power supplies are installed, facility power is not available, or the |

|

|

power button cable is disconnected. |

|

|

|

Component identification 8

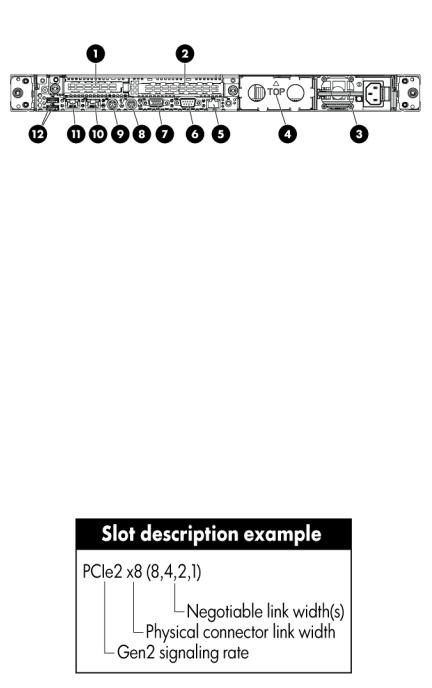

Rear panel components

Item |

Description |

|

|

1 |

Slot 1 PCIe2 x8 (8, 4, 2, 1) |

2 |

Slot 2 PCIe2 x16 (16, 8, 4, 2, 1), 75W +EXT 75W* |

3 |

Power supply bay 1 (populated) |

4 |

Power supply bay 2 |

5 |

iLO 2/NIC connector |

6 |

Serial connector |

7 |

Video connector |

8 |

Mouse connector |

9 |

Keyboard connector |

10 |

NIC 2 connector |

11 |

NIC 1 connector |

12 |

USB connectors (2) |

*This expansion slot provides 75 W of power to an adapter, with an additional 75 W of power supplied by external power.

Component identification 9

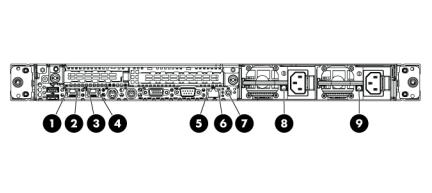

Rear panel LEDs and buttons

Item |

Description |

Status |

|

|

|

|

|

1 |

10/100/1000 |

Green = Link exists. |

|

|

NIC 1 link LED |

Off = No link exists. |

|

2 |

10/100/1000 |

Green = Activity exists. |

|

|

NIC 1 activity LED |

Flashing green = Activity exists. |

|

|

|

Off = No activity exists. |

|

|

|

|

|

3 |

10/100/1000 |

Green = Link exists. |

|

|

NIC 2 link LED |

Off = No link exists. |

|

|

|

|

|

4 |

10/100/1000 |

Green = Activity exists. |

|

|

NIC 2 activity LED |

Flashing green = Activity exists. |

|

|

|

Off = No activity exists. |

|

|

|

|

|

5 |

iLO 2 NIC activity |

Green = Activity exists. |

|

|

LED |

Flashing green = Activity exists. |

|

|

|

Off = No activity exists. |

|

|

|

|

|

6 |

iLO 2 NIC link LED |

Green = Link exists. |

|

|

|

Off = No link exists. |

|

7 |

UID button/LED |

Blue = Identification is activated. |

|

|

|

Flashing blue = System is being managed |

|

|

|

remotely. |

|

|

|

Off = Identification is deactivated. |

|

|

|

|

|

8 |

Power supply 2 LED |

Green = Normal |

|

|

|

Off = One or more of the following conditions |

|

|

|

exists: |

|

|

|

• |

AC power unavailable |

|

|

• |

Power supply failed |

|

|

• Power supply in standby mode |

|

|

|

• Power supply exceeded current limit |

|

|

|

|

|

9 |

Power supply 1 LED |

Green = Normal |

|

|

|

Off = One or more of the following conditions |

|

|

|

exists: |

|

|

|

• |

AC power unavailable |

|

|

• |

Power supply failed |

|

|

• Power supply in standby mode |

|

|

|

• Power supply exceeded current limit |

|

|

|

|

|

Component identification 10

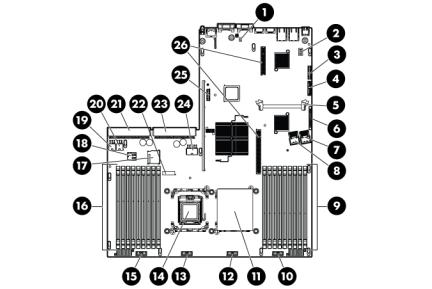

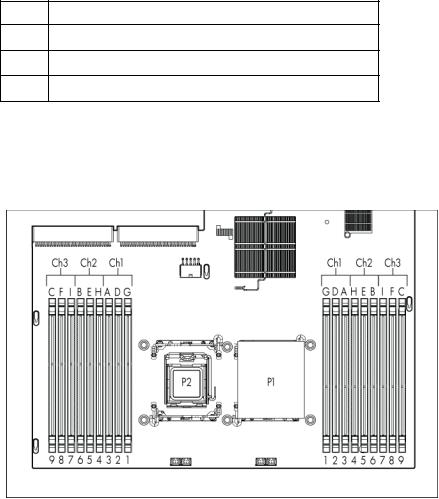

System board components

Item |

Description |

|

|

1 |

NMI jumper |

2 |

System maintenance switch |

3 |

10Gb sideband connector (MII) |

4 |

SATA DVD-ROM drive connector |

5 |

SAS cache module connector |

6 |

Power button connector |

7 |

Hard drive data connector 1 (drives 1-4) |

8 |

Hard drive data connector 2 (drives 5-8) |

9 |

Processor 1 DIMM slots (9) |

10 |

Fan module 4 connector |

11 |

Processor socket 1 (populated) |

12 |

Fan module 3 connector |

13 |

Fan module 2 connector |

14 |

Processor socket 2 |

15 |

Fan module 1 connector |

|

|

16 |

Processor 2 DIMM slots (9) |

|

|

17 |

SD card slot |

|

|

18 |

Internal USB connector |

|

|

19 |

Hard drive power connector 1 |

|

|

20 |

Hard drive power connector 2 |

|

|

21 |

Power supply connector 1 |

|

|

22 |

System battery |

|

|

23 |

Power supply connector 2 |

|

|

Component identification 11

Item Description

24PCI power connector

25TPM connector

26PCIe riser board connectors (2)

DIMM slots

DIMM slots are numbered sequentially (1 through 9) for each processor. The supported AMP modes use the letter assignments for population guidelines.

System maintenance switch

Position |

Default |

Function |

|

|

|

S1 |

Off |

Off = iLO 2 security is enabled. |

|

|

On = iLO 2 security is disabled. |

S2 |

Off |

Off = System configuration can be |

|

|

changed. |

|

|

On = System configuration is locked. |

|

|

|

S3 |

Off |

Reserved |

S4 |

Off |

Reserved |

S5 |

Off |

Off = Power-on password is enabled. |

|

|

On = Power-on password is disabled. |

S6 |

Off |

Off = No function |

|

|

On = Clear NVRAM |

|

|

|

S7 |

— |

Reserved |

S8 |

— |

Reserved |

S9 |

— |

Reserved |

S10 |

— |

Reserved |

Component identification 12

When the system maintenance switch position 6 is set to the On position, the system is prepared to erase all system configuration settings from both CMOS and NVRAM.

CAUTION: Clearing CMOS and/or NVRAM deletes configuration information. Be sure to properly configure the server or data loss could occur.

NMI jumper

The NMI jumper allows administrators to perform a memory dump before performing a hard reset. Crash dump analysis is an essential part of eliminating reliability problems, such as hangs or crashes in OSs, device drivers, and applications. Many crashes can freeze a system, requiring you to do a hard reset. Resetting the system erases any information that would support root cause analysis.

Systems running Microsoft® Windows® experience a blue-screen trap when the OS crashes. When this happens, Microsoft® recommends that system administrators perform an NMI event by temporarily shorting the NMI header with a jumper. The NMI event enables a hung system to become responsive again.

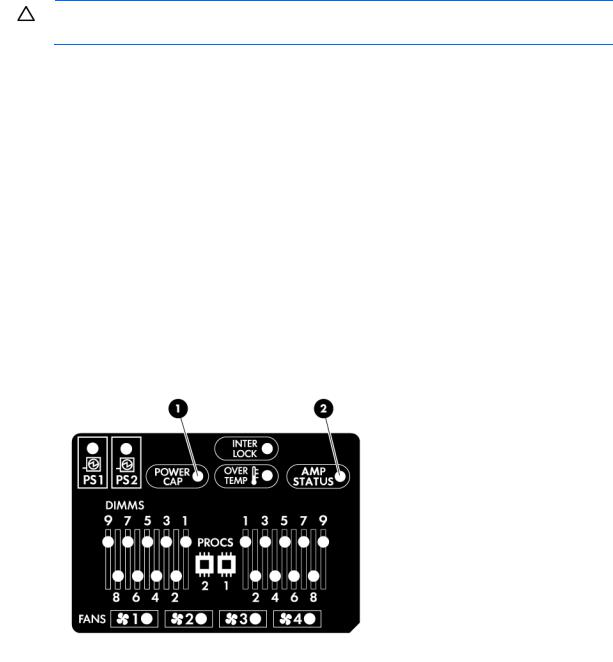

HP Systems Insight Display LEDs

The HP Systems Insight Display LEDs represent the system board layout. The display provides status for all internal LEDs and enables diagnosis with the access panel installed.

To view the LEDs, access the HP Systems Insight Display (on page 20).

Item |

Description |

Status |

|

|

|

1 |

Power cap LED |

To determine Power cap status, see |

|

|

"Systems Insight Display LED |

|

|

combinations (on page 14)." |

|

|

|

2 |

AMP status |

Green = AMP mode enabled |

|

|

Amber = Failover |

|

|

Flashing amber = Invalid configuration |

|

|

Off = AMP mode disabled |

|

|

|

Component identification 13

Item |

Description |

Status |

|

|

|

|

All other LEDs |

Amber = Failure |

|

|

Off = Normal |

|

|

For possible failure causes, see "Systems |

|

|

Insight Display LED combinations (on |

|

|

page 14)." |

|

|

|

Systems Insight Display LED combinations

When the health LED on the front panel illuminates either amber or red, the server is experiencing a health event. Combinations of illuminated Systems Insight Display LEDs, the system power LED, and the health LED indicate system status.

Systems Insight Display |

Health LED |

System power |

Status |

|

LED and color |

|

LED |

|

|

|

|

|

|

|

Processor (amber) |

Red |

Amber |

One or more of the following conditions may |

|

|

|

|

exist: |

|

|

|

|

• Processor in socket X has failed. |

|

|

|

|

• Processor X is not installed in the socket. |

|

|

|

|

• Processor X is unsupported. |

|

|

|

|

• ROM detects a failed processor during |

|

|

|

|

|

POST |

|

|

|

|

|

Processor (amber) |

Amber |

Green |

Processor in socket X is in a pre-failure |

|

|

|

|

condition. |

|

DIMM (amber) |

Red |

Green |

One or more DIMMs have failed. |

|

DIMM (amber) |

Amber |

Green |

DIMM in slot X is in a pre-failure condition. |

|

Overtemperature (amber) |

Amber |

Green |

The Health Driver has detected a cautionary |

|

|

|

|

temperature level. |

|

Overtemperature (amber) |

Red |

Amber |

The server has detected a hardware critical |

|

|

|

|

temperature level. |

|

Riser interlock (amber) |

Red |

Green |

The PCI riser board assembly is not seated |

|

|

|

|

properly. |

|

Fan (amber) |

Amber |

Green |

One fan has failed or has been removed. |

|

Fan (amber) |

Red |

Green |

Two or more fans have failed or been |

|

|

|

|

removed. |

|

Power supply (amber) |

Red |

Amber |

• Only one power supply is installed and |

|

|

|

|

|

that power supply is in standby. |

|

|

|

• |

Power supply fault |

|

|

|

• |

System board fault |

|

|

|

|

|

Power supply (amber) |

Amber |

Green |

• Redundant power supply is installed and |

|

|

|

|

|

only one power supply is functional. |

|

|

|

• AC power cord is not plugged into |

|

|

|

|

|

redundant power supply. |

|

|

|

• Redundant power supply fault |

|

|

|

|

• Power supply mismatch at POST or |

|

|

|

|

|

power supply mismatch through hot-plug |

|

|

|

|

addition. |

|

|

|

|

|

Power cap (off) |

— |

Amber |

Standby |

|

Power cap (green) |

— |

Flashing green |

Waiting for power |

|

Component identification 14

Systems Insight Display |

Health LED |

System power |

Status |

LED and color |

|

LED |

|

|

|

|

|

Power cap (flashing |

— |

Amber |

Power cap has been exceeded. |

amber) |

|

|

|

Power cap (green) |

— |

Green |

Power is available. |

IMPORTANT: If more than one DIMM slot LED is illuminated, further troubleshooting is required. Test each bank of DIMMs by removing all other DIMMs. Isolate the failed DIMM by replacing each DIMM in a bank with a known working DIMM.

SAS and SATA device numbers

•Four hard drive configuration

•Eight hard drive configuration

Component identification 15

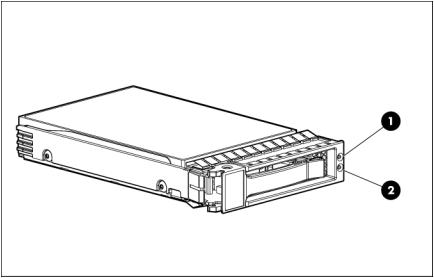

SAS and SATA hard drive LEDs

Item |

Description |

|

|

1 |

Fault/UID LED (amber/blue) |

2 |

Online LED (green) |

SAS and SATA hard drive LED combinations

Online/activity |

Fault/UID LED |

Interpretation |

LED (green) |

(amber/blue) |

|

|

|

|

On, off, or flashing |

Alternating amber |

The drive has failed, or a predictive failure alert has been received |

|

and blue |

for this drive; it also has been selected by a management |

|

|

application. |

|

|

|

On, off, or flashing |

Steadily blue |

The drive is operating normally, and it has been selected by a |

|

|

management application. |

On |

Amber, flashing |

A predictive failure alert has been received for this drive. |

|

regularly (1 Hz) |

Replace the drive as soon as possible. |

On |

Off |

The drive is online, but it is not active currently. |

Flashing regularly |

Amber, flashing |

Do not remove the drive. Removing a drive may terminate the |

(1 Hz) |

regularly (1 Hz) |

current operation and cause data loss. |

|

|

The drive is part of an array that is undergoing capacity expansion |

|

|

or stripe migration, but a predictive failure alert has been received |

|

|

for this drive. To minimize the risk of data loss, do not replace the |

|

|

drive until the expansion or migration is complete. |

|

|

|

Flashing regularly |

Off |

Do not remove the drive. Removing a drive may terminate the |

(1 Hz) |

|

current operation and cause data loss. |

|

|

The drive is rebuilding, erasing, or it is part of an array that is |

|

|

undergoing capacity expansion or stripe migration. |

|

|

|

Flashing irregularly |

Amber, flashing |

The drive is active, but a predictive failure alert has been received |

|

regularly (1 Hz) |

for this drive. Replace the drive as soon as possible. |

Flashing irregularly |

Off |

The drive is active, and it is operating normally. |

Component identification 16

Online/activity |

Fault/UID LED |

Interpretation |

LED (green) |

(amber/blue) |

|

|

|

|

Off |

Steadily amber |

A critical fault condition has been identified for this drive, and the |

|

|

controller has placed it offline. Replace the drive as soon as |

|

|

possible. |

|

|

|

Off |

Amber, flashing |

A predictive failure alert has been received for this drive. Replace |

|

regularly (1 Hz) |

the drive as soon as possible. |

Off |

Off |

The drive is offline, a spare, or not configured as part of an array. |

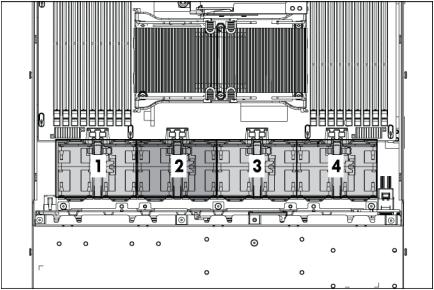

Fan modules

Install fan 2 only when processor 2 is installed. When only one processor is installed, always install the fan blank.

Item |

Description |

|

|

1 |

Fan module 1 |

2 |

Fan module 2 |

3 |

Fan module 3 |

4 |

Fan module 4 |

Component identification 17

T-10/T-15 Torx screwdriver

The server includes a T-10/T-15 Torx screwdriver that ships on the air baffle. Use the screwdriver to loosen screws or thumbscrews, as needed, during procedures.

Component identification 18

Operations

Power up the server

To power up the server, press the Power On/Standby button.

Power down the server

WARNING: To reduce the risk of personal injury, electric shock, or damage to the equipment, remove the power cord to remove power from the server. The front panel Power On/Standby button does not completely shut off system power. Portions of the power supply and some internal circuitry remain active until AC power is removed.

IMPORTANT: If installing a hot-plug device, it is not necessary to power down the server.

1.Back up the server data.

2.Shut down the operating system as directed by the operating system documentation.

3.If the server is installed in a rack, press the UID LED button on the front panel. Blue LEDs illuminate on the front and rear panels of the server.

4.Press the Power On/Standby button to place the server in standby mode. When the server activates standby power mode, the system power LED changes to amber.

5.If the server is installed in a rack, locate the server by identifying the illuminated rear UID LED button.

6.Disconnect the power cords.

The system is now without power.

Extend the server from the rack

NOTE: If the optional cable management arm option is installed, you can extend the server without powering down the server or disconnecting peripheral cables and power cords. These steps are only necessary with the standard cable management solution.

1.Power down the server (on page 19).

2.Disconnect all peripheral cables and power cords.

3.Loosen the front panel thumbscrews.

4.Extend the server on the rack rails until the server rail-release latches engage.

WARNING: To reduce the risk of personal injury or equipment damage, be sure that the rack is adequately stabilized before extending a component from the rack.

WARNING: To reduce the risk of personal injury, be careful when pressing the server rail-release latches and sliding the server into the rack. The sliding rails could pinch your fingers.

Operations 19

5.After performing the installation or maintenance procedure, slide the server into the rack:

a.Slide the server fully into the rack.

b.Secure the server by tightening the thumbscrews.

6.Connect the peripheral cables and power cords.

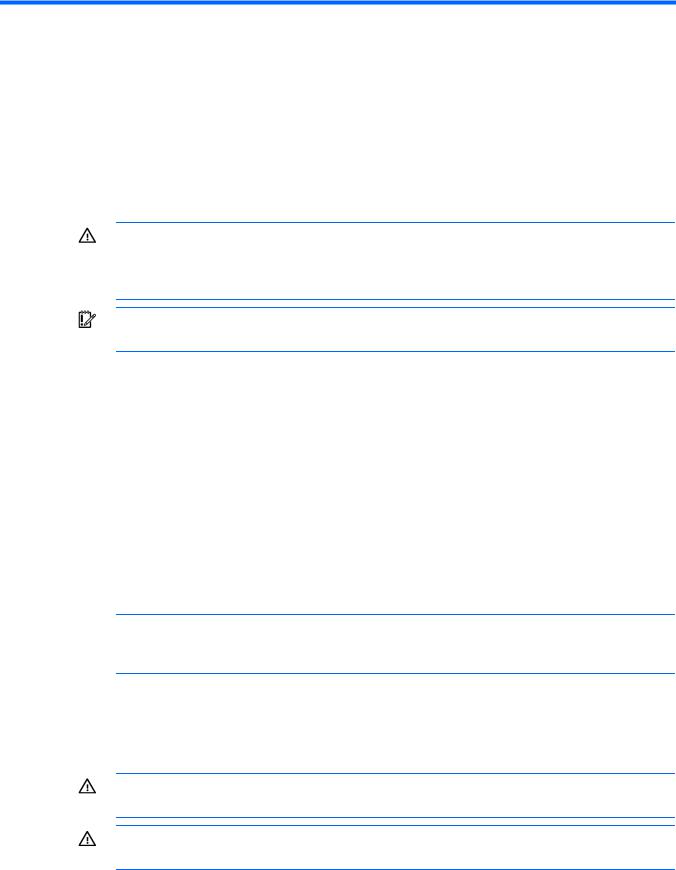

Access the HP Systems Insight Display

To eject the HP Systems Insight Display:

1.Press and release the display.

2.Extend the display from the chassis.

The display can be rotated up to 90 degrees.

Operations 20

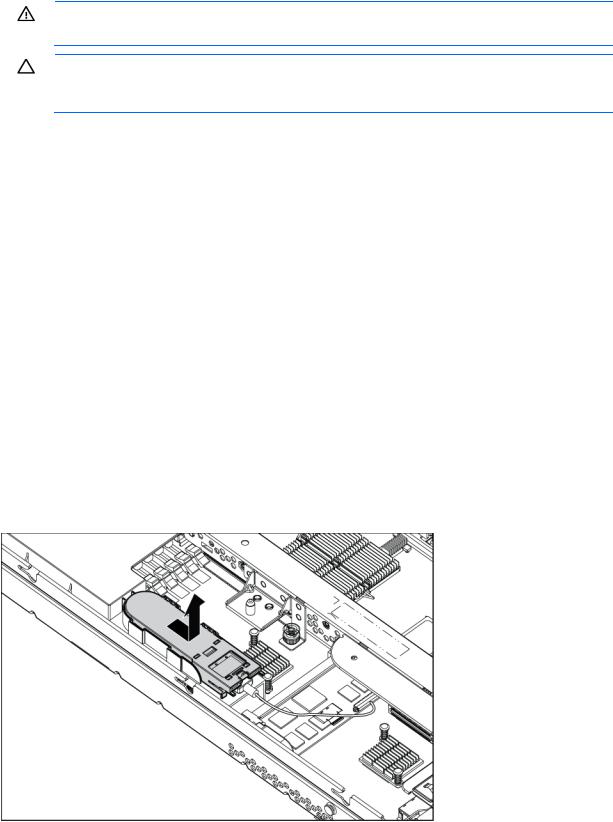

Remove the access panel

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the internal system components to cool before touching them.

CAUTION: Do not operate the server for long periods with the access panel open or removed. Operating the server in this manner results in improper airflow and improper cooling that can lead to thermal damage.

To remove the component:

1.Power down the server (on page 19).

2.Extend the server from the rack (on page 19).

3.Open the locking latch, slide the access panel to the rear of the chassis, and remove the access panel. If the locking latch is locked use a T-15 Torx screwdriver to unlock the latch.

Install the access panel

1.Place the access panel on top of the server with the hood latch open. Allow the panel to extend past the rear of the server approximately 1.25 cm (0.5 in).

2.Push down on the hood latch. The access panel slides to a closed position.

3.Use the T-15 Torx screwdriver provided with the server to tighten the security screw on the hood latch.

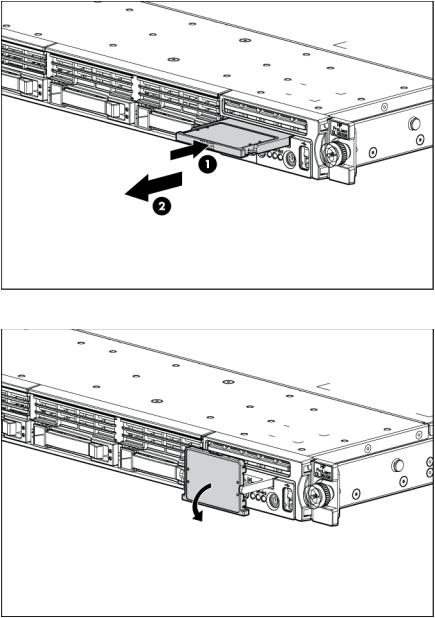

Remove the BBWC battery pack

1.Power down the server (on page 19).

2.Extend the server from the rack (on page 19).

3.Remove the access panel (on page 21).

4.Remove the BBWC battery pack.

Operations 21

Remove the air baffle

1.Power down the server (on page 19).

2.Extend the server from the rack (on page 19).

3.Remove the access panel (on page 21).

4.Remove the BBWC battery pack, if installed ("Remove the BBWC battery pack" on page 21).

5.Remove the air baffle.

Install the air baffle

CAUTION: For proper cooling do not operate the server without the access panel, baffles, expansion slot covers, or blanks installed. If the server supports hot-plug components, minimize the amount of time the access panel is open.

Operations 22

1.Install the air baffle.

2.Install the BBWC battery pack, if removed ("Installing the BBWC battery pack" on page 57).

3.Install the access panel (on page 21).

4.Slide the server into the rack.

5.Power up the server (on page 19).

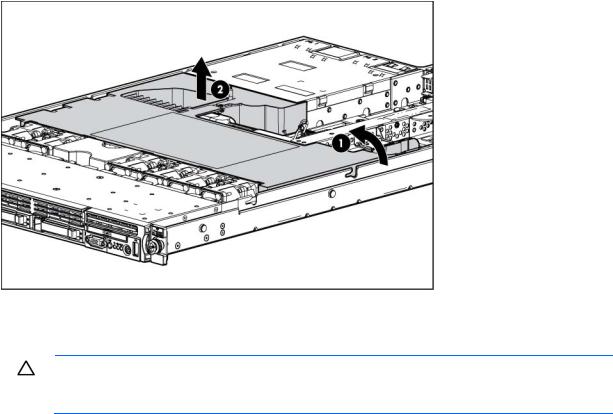

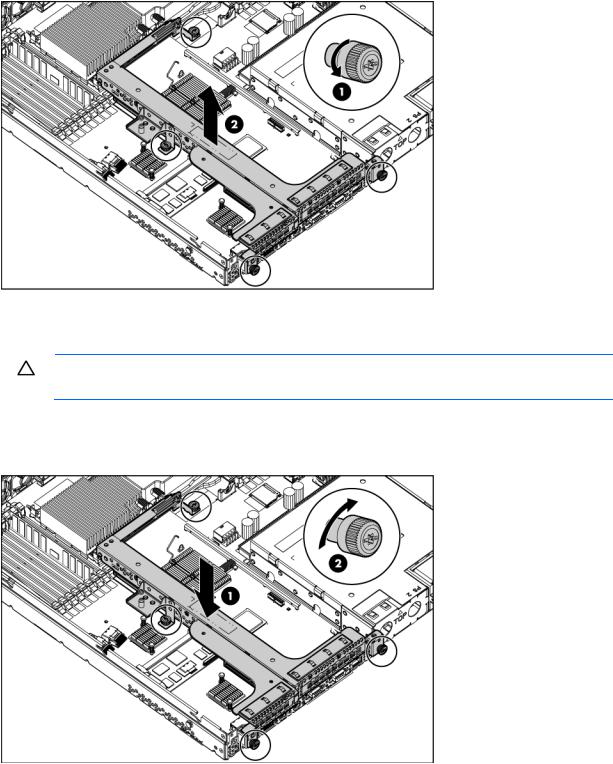

Remove the PCI riser board assembly

CAUTION: To prevent damage to the server or expansion boards, power down the server and remove all AC power cords before removing or installing the PCI riser board assembly.

1.Power down the server (on page 19).

2.Extend the server from the rack (on page 19).

3.Remove the access panel (on page 21).

4.Remove the BBWC battery pack, if installed ("Remove the BBWC battery pack" on page 21).

5.Remove the air baffle (on page 22).

6.Remove the PCI riser board assembly:

a.Disconnect external cables connected to any existing expansion boards.

b.Loosen the four PCI riser board assembly thumbscrews.

Operations 23

c. Lift the assembly to unseat the PCI riser boards, and then remove the assembly.

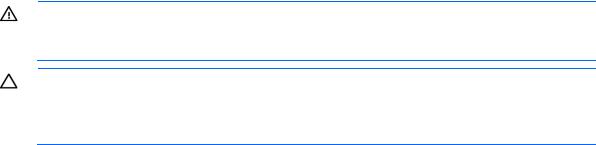

Install the PCI riser board assembly

CAUTION: To prevent damage to the server or expansion boards, power down the server and remove all AC power cords before removing or installing the PCI riser board assembly.

1.Align the PCI riser boards with the corresponding connectors on the system board, and then install the assembly.

2.Tighten the four PCI riser board assembly thumbscrews.

3.Install the air baffle (on page 22).

4.Install the BBWC battery pack, if removed ("Installing the BBWC battery pack" on page 57).

5.Install the access panel (on page 21).

6.Slide the server into the rack.

Operations 24

7.Power up the server (on page 19).

Operations 25

Setup

Optional installation services

Delivered by experienced, certified engineers, HP Care Pack services help you keep your servers up and running with support packages tailored specifically for HP ProLiant systems. HP Care Packs let you integrate both hardware and software support into a single package. A number of service level options are available to meet your needs.

HP Care Pack Services offer upgraded service levels to expand your standard product warranty with easy-to-buy, easy-to-use support packages that help you make the most of your server investments. Some of the Care Pack services are:

•Hardware support

o 6-Hour Call-to-Repair

o 4-Hour 24x7 Same Day

o 4-Hour Same Business Day

•Software support

o Microsoft®

o Linux

oHP ProLiant Essentials (HP SIM and RDP)

oVMWare

•Integrated hardware and software support

oCritical Service

o Proactive 24

o Support Plus

o Support Plus 24

•Startup and implementation services for both hardware and software

For more information on HP Care Pack Services, see the HP website (http://www.hp.com/services/carepack).

Rack planning resources

The rack resource kit ships with all HP branded or Compaq branded 9000, 10000, and H9 series racks. For more information on the content of each resource, see the rack resource kit documentation.

Optimum environment

When installing the server in a rack, select a location that meets the environmental standards described in this section.

Setup 26

Space and airflow requirements

To allow for servicing and adequate airflow, observe the following space and airflow requirements when deciding where to install a rack:

•Leave a minimum clearance of 63.5 cm (25 in) in front of the rack.

•Leave a minimum clearance of 76.2 cm (30 in) behind the rack.

•Leave a minimum clearance of 121.9 cm (48 in) from the back of the rack to the back of another rack or row of racks.

HP servers draw in cool air through the front door and expel warm air through the rear door. Therefore, the front and rear rack doors must be adequately ventilated to allow ambient room air to enter the cabinet, and the rear door must be adequately ventilated to allow the warm air to escape from the cabinet.

CAUTION: To prevent improper cooling and damage to the equipment, do not block the ventilation openings.

When vertical space in the rack is not filled by a server or rack component, the gaps between the components cause changes in airflow through the rack and across the servers. Cover all gaps with blanking panels to maintain proper airflow.

CAUTION: Always use blanking panels to fill empty vertical spaces in the rack. This arrangement ensures proper airflow. Using a rack without blanking panels results in improper cooling that can lead to thermal damage.

The 9000 and 10000 Series Racks provide proper server cooling from flow-through perforations in the front and rear doors that provide 64 percent open area for ventilation.

CAUTION: When using a Compaq branded 7000 Series rack, you must install the high airflow rack door insert [P/N 327281-B21 (42U) or P/N 157847-B21 (22U)] to provide proper front-to-back airflow and cooling.

CAUTION: If a third-party rack is used, observe the following additional requirements to ensure adequate airflow and to prevent damage to the equipment:

•Front and rear doors—If the 42U rack includes closing front and rear doors, you must allow 5,350 sq cm (830 sq in) of holes evenly distributed from top to bottom to permit adequate airflow (equivalent to the required 64 percent open area for ventilation).

•Side—The clearance between the installed rack component and the side panels of the rack must be a minimum of 7 cm (2.75 in).

Temperature requirements

To ensure continued safe and reliable equipment operation, install or position the system in a well-ventilated, climate-controlled environment.

The maximum recommended ambient operating temperature (TMRA) for most server products is 35°C (95°F). The temperature in the room where the rack is located must not exceed 35°C (95°F).

CAUTION: To reduce the risk of damage to the equipment when installing third-party options:

•Do not permit optional equipment to impede airflow around the server or to increase the internal rack temperature beyond the maximum allowable limits.

•Do not exceed the manufacturer’s TMRA.

Setup 27

Power requirements

Installation of this equipment must comply with local and regional electrical regulations governing the installation of information technology equipment by licensed electricians. This equipment is designed to operate in installations covered by NFPA 70, 1999 Edition (National Electric Code) and NFPA-75, 1992 (code for Protection of Electronic Computer/Data Processing Equipment). For electrical power ratings on options, refer to the product rating label or the user documentation supplied with that option.

WARNING: To reduce the risk of personal injury, fire, or damage to the equipment, do not overload the AC supply branch circuit that provides power to the rack. Consult the electrical authority having jurisdiction over wiring and installation requirements of your facility.

CAUTION: Protect the server from power fluctuations and temporary interruptions with a regulating uninterruptible power supply (UPS). This device protects the hardware from damage caused by power surges and voltage spikes and keeps the system in operation during a power failure.

When installing more than one server, you may need to use additional power distribution devices to safely provide power to all devices. Observe the following guidelines:

•Balance the server power load between available AC supply branch circuits.

•Do not allow the overall system AC current load to exceed 80 percent of the branch circuit AC current rating.

•Do not use common power outlet strips for this equipment.

•Provide a separate electrical circuit for the server.

For more information on the hot-plug power supply and calculators to determine server power consumption in various system configurations, refer to the HP Enterprise Configurator website (http://h30099.www3.hp.com/configurator/).

Electrical grounding requirements

The server must be grounded properly for proper operation and safety. In the United States, you must install the equipment in accordance with NFPA 70, 1999 Edition (National Electric Code), Article 250, as well as any local and regional building codes. In Canada, you must install the equipment in accordance with Canadian Standards Association, CSA C22.1, Canadian Electrical Code. In all other countries, you must install the equipment in accordance with any regional or national electrical wiring codes, such as the International Electrotechnical Commission (IEC) Code 364, parts 1 through 7. Furthermore, you must be sure that all power distribution devices used in the installation, such as branch wiring and receptacles, are listed or certified grounding-type devices.

Because of the high ground-leakage currents associated with multiple servers connected to the same power source, HP recommends the use of a PDU that is either permanently wired to the building’s branch circuit or includes a nondetachable cord that is wired to an industrial-style plug. NEMA locking-style plugs or those complying with IEC 60309 are considered suitable for this purpose. Using common power outlet strips for the server is not recommended.

Rack warnings

Setup 28

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

•The leveling jacks are extended to the floor.

•The full weight of the rack rests on the leveling jacks.

•The stabilizing feet are attached to the rack if it is a single-rack installation.

•The racks are coupled together in multiple-rack installations.

•Only one component is extended at a time. A rack may become unstable if more than one component is extended for any reason.

WARNING: To reduce the risk of personal injury or equipment damage when unloading a rack:

•At least two people are needed to safely unload the rack from the pallet. An empty 42U rack can weigh as much as 115 kg (253 lb), can stand more than 2.1 m (7 ft) tall, and may become unstable when being moved on its casters.

•Never stand in front of the rack when it is rolling down the ramp from the pallet. Always handle the rack from both sides.

Contents of the server shipping carton

Unpack the server shipping carton and locate the materials and documentation necessary for installing the server. All the rack mounting hardware necessary for installing the server into the rack is included with the rack or the server.

The contents of the server shipping carton include:

•Server

•Power cord

•Printed setup documentation, Documentation CD, and software products

•Rack mounting hardware kit and documentation

In addition to these supplied items, you may need:

•T-10/T-15 Torx screwdriver (on page 18)

•Hardware options

•Operating system or application software

Installing hardware options

Install any hardware options before initializing the server. For options installation information, refer to the option documentation. For server-specific information, refer to "Hardware options installation (on page 33)."

Installing the server into the rack

To install the server into a rack with square, round, or threaded holes, refer to the instructions that ship with the rack hardware kit.

If you are installing the server into a telco rack, order the appropriate option kit at the RackSolutions.com website (http://www.racksolutions.com/hp). Follow the server-specific instructions on the website to install the rack brackets.

Use the following information when connecting peripheral cables and power cords to the server.

Setup 29

WARNING: This server is very heavy. To reduce the risk of personal injury or damage to the equipment:

•Observe local occupational health and safety requirements and guidelines for manual material handling.

•Get help to lift and stabilize the product during installation or removal, especially when the product is not fastened to the rails. When the server weighs more than 22.5 kg (50 lb), at least two people must lift the server into the rack together. A third person may be required to help align the server if the server is installed higher than chest level.

•Use caution when installing the server in or removing the server from the rack; it is unstable when not fastened to the rails.

CAUTION: Always plan the rack installation so that the heaviest item is on the bottom of the rack. Install the heaviest item first, and continue to populate the rack from the bottom to the top.

1.Install the server and cable management arm into the rack. See the installation instructions that ship with the HP 1U Quick Deploy Rail System.

2.Connect the peripheral devices to the server.

Item |

Description |

|

|

1 |

Slot 1 PCIe2 x8 (8, 4, 2, 1) |

2 |

Slot 2 PCIe2 x16 (16, 8, 4, 2, 1), 75W +EXT 75W* |

3 |

Power supply bay 1 (populated) |

4 |

Power supply bay 2 |

5 |

iLO 2/NIC connector |

6 |

Serial connector |

7 |

Video connector |

8 |

Mouse connector |

9 |

Keyboard connector |

10 |

NIC 2 connector |

11 |

NIC 1 connector |

12 |

USB connectors (2) |

*This expansion slot provides 75 W of power to an adapter, with an additional 75 W of power supplied by external power.

3.Connect the power cord to the server.

Setup 30

Loading...

Loading...