Graco Inc Hydra-Clean 247552, Hydra-Clean 247549, Hydra-Clean 247553, Hydra-Clean 258665, Hydra-Clean 258664 User Manual

...

Instructions - Parts

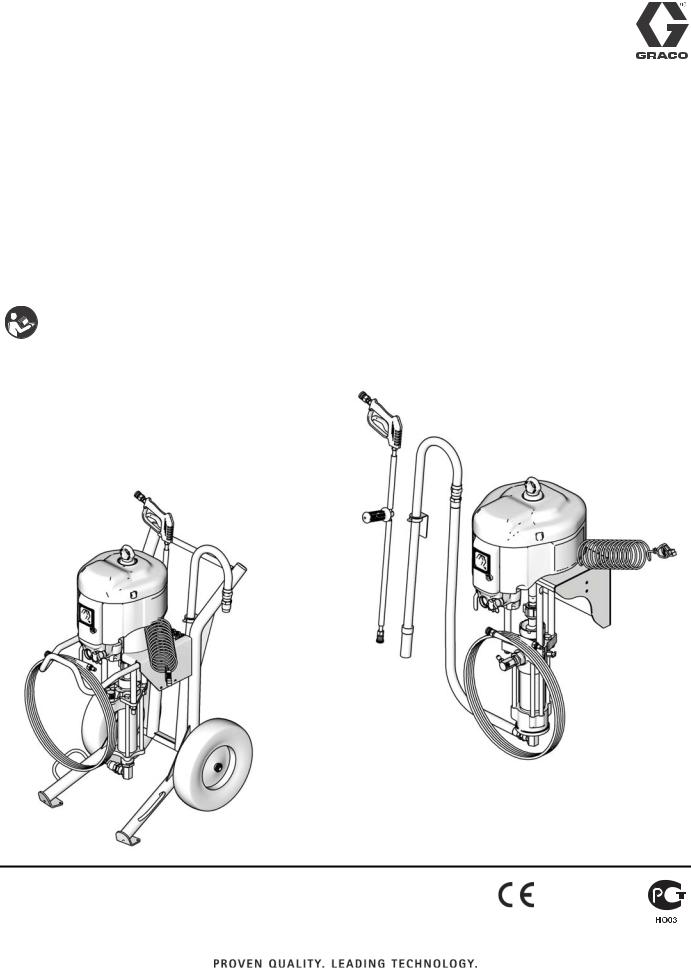

Hydra-Clean Packages |

ENG |

® |

312585E |

Package solutions for pressure washing applications. For use only with water and cleaning solutions.

Important Safety Instructions

Read all warnings and instructions in this manual and in your respective pump manual. Save these instructions.

See page 3 for model information, including maximum working pressure.

Wall Mount Packages

Cart Mount Packages

TI11273A

TI11267A

II 2 G

II 2 G

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Wall Mount Packages . . . . . . . . . . . . . . . . . . . . . 6

Flush Before Using Equipment . . . . . . . . . . . . . . 6

Integrated Air Control Module . . . . . . . . . . . . . . . 6

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 9

Cleaning Solutions . . . . . . . . . . . . . . . . . . . . . . . 9

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Starting the Pump . . . . . . . . . . . . . . . . . . . . . . . 10

Adjusting the Pump . . . . . . . . . . . . . . . . . . . . . . 10

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Disconnect the Displacement Pump . . . . . . . . . 13

Reconnect the Displacement Pump . . . . . . . . . 13

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

247549 Cart Mount Package . . . . . . . . . . . . . . |

14 |

247550 Wall Mount Package . . . . . . . . . . . . . . |

15 |

247551, 247553, and 258664 |

|

Cart Mount Packages . . . . . . . . . . . . . . . . . |

16 |

247552, 247554, and 258665 |

|

Wall Mount Packages . . . . . . . . . . . . . . . . . |

17 |

Parts Listings . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

Wall Mounting Bracket Diagram . . . . . . . . . . . . . . |

20 |

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

Pump Performance Charts . . . . . . . . . . . . . . . . . . |

22 |

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . |

24 |

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

2 |

312585E |

Models

Check your package’s identification plate (ID) for the 6-digit part number of your package. To order replacement parts, see Parts starting on page 14.

All packages include integrated air controls, hose

and gun, and ground wire.

and gun, and ground wire.

Models

ID

ID

TI11530A

|

|

|

|

|

Maximum Air |

|

|

|

Includes: |

|

|

Maximum Working |

|

Input |

|

|

Displacement |

|

|

||

|

|

|

|

|

|

|||||

|

|

Pressure |

|

Pressure |

|

|

Pump Size |

|

|

|

Part No. |

|

psi (MPa, bar) |

|

psi (MPa, bar) |

|

Ratio |

(cc per cycle) |

Portable Cart |

Wall Mount |

|

|

|

|

|

|

|

|

|

|

|

|

247549 |

1250 (8.6, |

86.2) |

|

100 (0.7, 7.0) |

|

12:1 |

550 cc |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

247550 |

1250 (8.6, |

86.2) |

|

100 (0.7, 7.0) |

|

12:1 |

550 cc |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

247551 |

2275 (15.7, |

156.9) |

|

100 (0.7, 7.0) |

|

23:1 |

580 cc |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

247552 |

2275 (15.7, |

156.9) |

|

100 (0.7, 7.0) |

|

23:1 |

580 cc |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

247553 |

3065 (21.1, |

211.3) |

|

100 (0.7, 7.0) |

|

30:1 |

430 cc |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

247554 |

3065 (21.1, |

211.3) |

|

100 (0.7, 7.0) |

|

30:1 |

430 cc |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

258664 |

4000 (31.0, |

310.3) |

|

100 (0.7, 7.0) |

|

45:1 |

290 cc |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

258665 |

4000 (31.0, |

310.3) |

|

100 (0.7, 7.0) |

|

45:1 |

290 cc |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Related Manuals |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|||

Manual |

|

|

Description |

|

|

|

|

|||

|

|

|

|

|

|

|

||||

312745 |

|

247599 Displacement Pump |

|

|

|

|

||||

|

|

|

|

|

|

|

||||

311825 |

|

Dura-Flo Displacement Pump; 1800 and |

|

|

|

|

||||

|

|

2400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

311827 |

|

Dura-Flo Displacement Pump; 600, 750, |

|

|

|

|

||||

|

|

900, and 1200 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

311238 |

|

NXT Air Motor |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||

311239 |

|

NXT Integrated Air Control Module |

|

|

|

|

||||

|

|

|

|

|

|

|

||||

308511 |

|

Hydra-Clean Spray Gun |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

312585E |

3 |

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable.

WARNING

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

•Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are present.

•Ground all equipment in the work area. See Grounding instructions.

•Use only grounded hoses.

•Hold gun firmly to side of grounded pail when triggering into pail.

•If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until you identify and correct the problem.

•Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

•Do not operate the unit when fatigued or under the influence of drugs or alcohol.

•Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

•Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material, request MSDS forms from distributor or retailer.

•Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

•Do not alter or modify equipment.

•Use equipment only for its intended purpose. Call your distributor for information.

•Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

•Do not kink or over bend hoses or use hoses to pull equipment.

•Keep children and animals away from work area.

•Comply with all applicable safety regulations.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

•Do not put your hand over the spray tip.

•Do not stop or deflect leaks with your hand, body, glove, or rag.

•Do not spray without tip guard and trigger guard installed.

•Engage trigger lock when not spraying.

•Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning, checking, or servicing equipment.

4 |

312585E |

Warnings

WARNING

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

•Keep clear of moving parts.

•Do not operate equipment with protective guards or covers removed.

•Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

•Read MSDS’s to know the specific hazards of the fluids you are using.

•Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

•Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic fumes, burns, and hearing loss. This equipment includes but is not limited to:

•Protective eyewear

•Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

•Hearing protection

312585E |

5 |

Installation

Installation

The Graco warranty will not apply if cleaning solutions other than those recommended by Graco are used in these units. Only use solutions that are not harmful to the wetted parts. See the Technical Data in the displacement pump manuals 311825, 311827, and 312745.

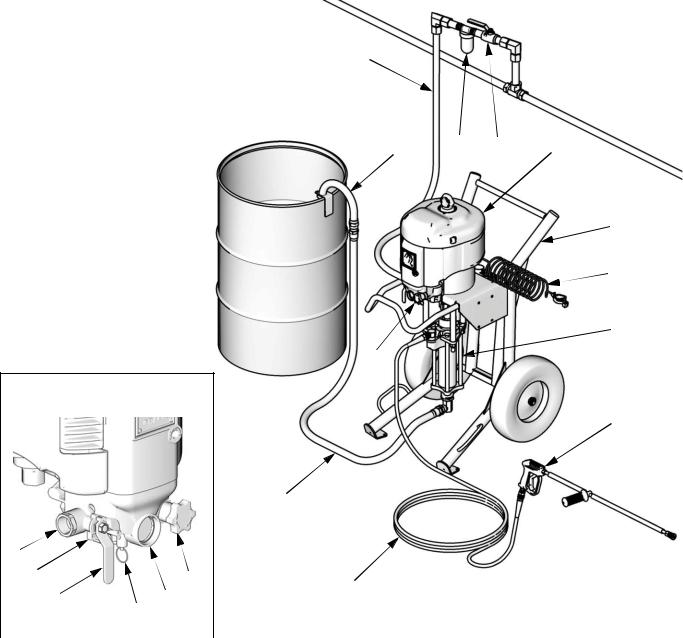

See FIG. 1. Connect the suction hose (P) between the pump fluid inlet and the suction tube (R), using thread sealant on the male threads. Screw on the suction tube strainer. Place the suction tube in the supply drum, and adjust it so it is 1 in. (25 mm) off the bottom of the drum. Tighten the thumbscrew of the pipe hanger onto the drum.

Connect the spray hose (S) to the pump outlet manifold. For two gun spraying, remove the plug in the manifold and connect another spray hose. Connect the spray gun

(T) to the hose (S). Use thread sealant on the male threads.

Flush Before Using Equipment

The equipment was tested with lightweight oil, which is left in the fluid passages to protect parts. To avoid contaminating your fluid with oil, flush the equipment with a compatible solvent before using the equipment. See your respective pump manual. See Related Manuals on page 3.

Integrated Air Control Module

See FIG. 1. The integrated air control module (C) is included with all packages. It includes the following (see 311239 for detailed information):

•Bleed-type master air valve (D): required in your system to relieve air trapped between it and the air motor when the valve is closed.

Wall Mount Packages

1.Ensure the wall is strong enough to support the weight of the pump assembly and accessories, fluid, hoses, and stress caused during pump operation.

2.Ensure that the mounting location has sufficient clearance for easy operator access.

3.Position the wall bracket at a convenient height, ensuring that there is sufficient clearance for the fluid suction line and for servicing the displacement pump.

4.Drill four 7/16 in. (11 mm) holes using the bracket as a template. Use any of the three mounting hole groupings in the bracket. See Wall Mounting Bracket Diagram, page 20.

5.Bolt the bracket securely to the wall using bolts and washers designed to hold in the wall’s construction.

6.Attach the pump assembly to the mounting bracket.

7.Connect air and fluid hoses.

Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury from splashing or moving parts.

•Pump air regulator (E): adjusts air pressure to the motor and fluid outlet pressure of pump. View the gauge (F) to read air pressure.

•Safety relief valve (G): automatically opens to relieve air pressure, to prevent pump overpressurization.

•Air filter (H): removes harmful contaminants from entering the air control module and air motor.

6 |

312585E |

Installation

K

R M L B

N

N

U

U

A

A

C

Detail of Integrated Air

Control Module (C)

T

|

|

|

|

P |

|

|

|

J |

|

|

|

|

|

|

|

H |

E |

S |

TI11380A |

|

|

|

D |

||||

|

|

F |

|

|

||

|

|

|

G |

|

|

|

|

|

|

TI8322C |

|

|

|

|

|

|

|

|||

FIG. 1: Typical Installation (Cart Mount Package Shown) |

|

|||||

|

|

|

|

|

|

|

A |

Displacement Pump |

|

|

N |

Portable Cart |

|

B |

Air Motor |

|

|

P |

Fluid Suction Hose |

|

C |

Integrated Air Control Module (includes items D-H) |

R |

Fluid Suction Tube and Strainer |

|||

D |

Bleed-type Master Air Valve (required) |

S |

Fluid Spray Hose |

|||

E |

Pump Air Regulator |

|

|

T |

Spray Gun and Wand |

|

F |

Air Pressure Gauge |

|

|

U |

Ground Wire (required) |

|

GSafety Relief Valve

HAir Filter (hidden)

JAir Inlet

KAir Supply Line

LAir Line Shutoff Valve

MAir Line Filter

312585E |

7 |

Installation

Grounding

Air and fluid hoses: use only electrically conductive hoses.

Although water generally provides a natural electrical ground, the following equipment must be grounded if the cleaning chemicals are volatile.

The equipment must be grounded. Grounding reduces the risk of static and electric shock by providing an escape wire for the electrical current due to static build up or in the event of a short circuit.

When cleaning in enclosed areas, such as storage tanks, locate the pump and air compressor outside the area and well away from it. Provide adequate ventilation. If the area you are cleaning has stored flammable materials. take appropriate precautions to avoid static sparking. Consult your local codes.

Pump: use supplied ground wire and clamp. See FIG. 2. Use the ground screw (GS) and lockwasher (LW) to attach the ground wire (U) at the rear of the air motor. Tighten the screw securely. Connect the other end of the ground wire to a true earth ground.

Air compressor: follow manufacturer’s recommendations.

Spray gun / Dispense valve: ground through connection to a properly grounded fluid hose and pump.

Fluid supply container: follow local code.

Object being sprayed: follow local code.

Solvent pails used when flushing: follow local code. Use only conductive metal pails, placed on a grounded surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts grounding continuity.

To maintain grounding continuity when flushing or relieving pressure: hold metal part of the spray gun/dispense valve firmly to the side of a grounded metal pail, then trigger the gun/valve.

GS, LW

U |

TI8250A |

FIG. 2. Ground Wire

8 |

312585E |

Loading...

Loading...