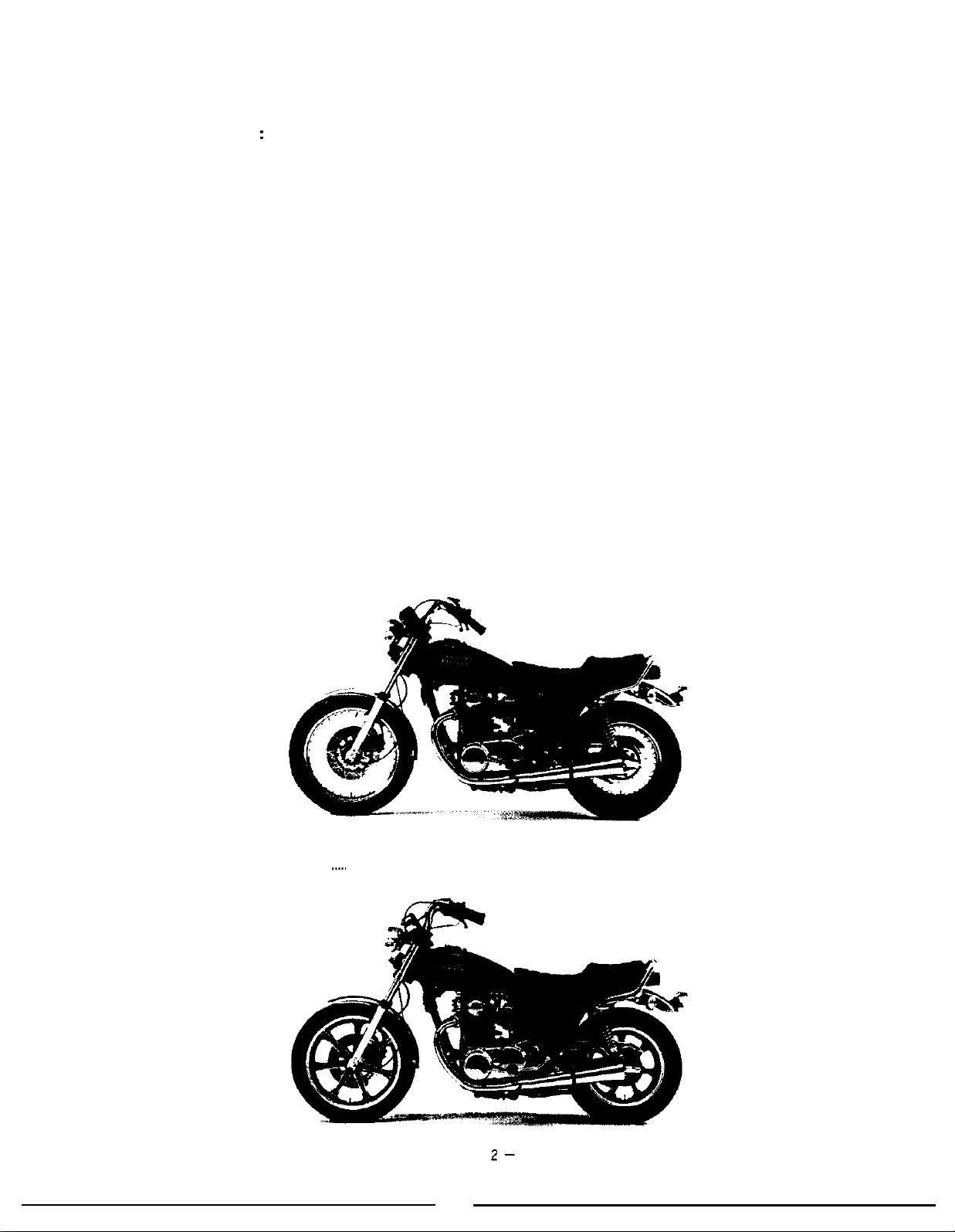

Yamaha XS650H 1978, XS650H 1979, XS650G 1978, XS650G 1979, XS650SH 1978 Supplementary Service Manual

...

INDEX

This manual has been combined with previous

service manuals to provide complete service

information for: XS650H/SH.

Please read and give special consideration to

the “NOTICE” on the preceding page for your

safety.

XS650H/SH

XS650

MODELS 1978-80

SUPPLEMENT

FOREWORD

This Supplementary Service Manual has been prepared to introduce new

service and new data for the XS650H/XS650SH. For complete information

on service procedure, it is necessary to use this Supplementary Service

Manual together with following manuals:

’

XS650E Service Manual (LIT-11616-00-76)

!’XS650SE Supplementary Service Manual (LIT-11616-01-08)

XS650SF/2F Supplementary Service Manual (LIT-11616-01-65)

XS650G/SG

NOTE:

This Supplementary Service Manual contains information regarding periodic

maintenance to the emission control system for the

Please read this material carefully.

Supplementary Service Manual (LIT-1 1616-01-75)

SERVICE DEPT.

INTERNATIONAL DIVISION

YAMAHA MOTOR CO., LTD.

XS650H/XS650SH.

NOTICE

This manual was written by the Yamaha Motor Company primarily for use

by Yamaha dealers and their qualified mechanics.

an entire mechanic’s education into one manual, so it is assumed that

persons using this book to perform maintenance and repairs on Yamaha

motorcycles have a basic understanding of the mechanical concepts and

procedures inherent to motorcycle repair technology. Without such know-

ledge, attempted repairs or service to this model may render it unfit for use

and/or unsafe.

It is not possible to put

I

1

This model has been designed and manufactured to perform within certain

specifications in regard to performance and emissions. Proper service with

the correct tools is necessary to ensure that the motorcycle will operate as

designed.

that you contact a Yamaha dealer before continuing. Before attempting any

service, check with your Yamaha dealer for any service information changes

that apply to this model: This policy is intended to provide the customer

with the most satisfaction from his motorcycle and to conform with federal

environmental quality objectives.

Yamaha Motor Company, Ltd. is continually striving to further improve all

models manufactured by Yamaha. Modifications and significant changes in

specifications or procedures will be forwarded to all Authorized Yamaha

dealers and will, where applicable, appear in future editions of this manual.

If there is any question about a service procedure it is imperative

I -

Particularly important information is distinguished in this manual by the

following notations:

NOTE

:

A NOTE provides key information to make procedures easier

or clearer.

CAUTION: A CAUTION indicates special procedure that must be fol-

lowed to avoid damage to the motorcycle.

WARNING:

A WARNING indicates special procedures that must be followed to avoid injury to a motorcycle operator or person

inspecting or repairing the motorcycle.

Starting Serial Number

XS650HH

XS650SHH

. . . . . . . . . . . . .

. . . . . . . .

4N9-000101

..__.

4M4-000101

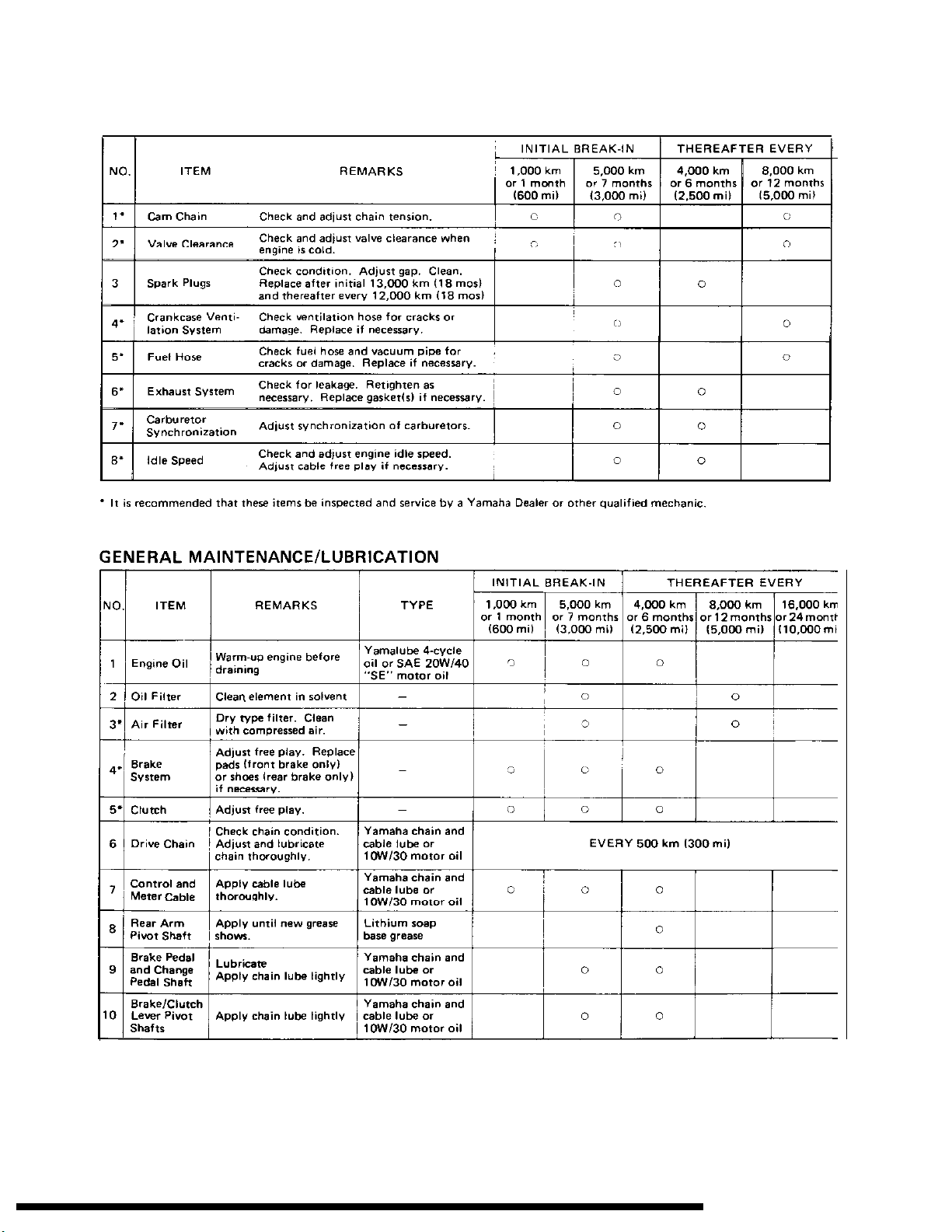

MAINTENANCE AND LUBRICATION CHART

PERIODIC MAINTENANCE EMISSION CONTROL SYSTEM

-3

t

c

c

*ENGINE

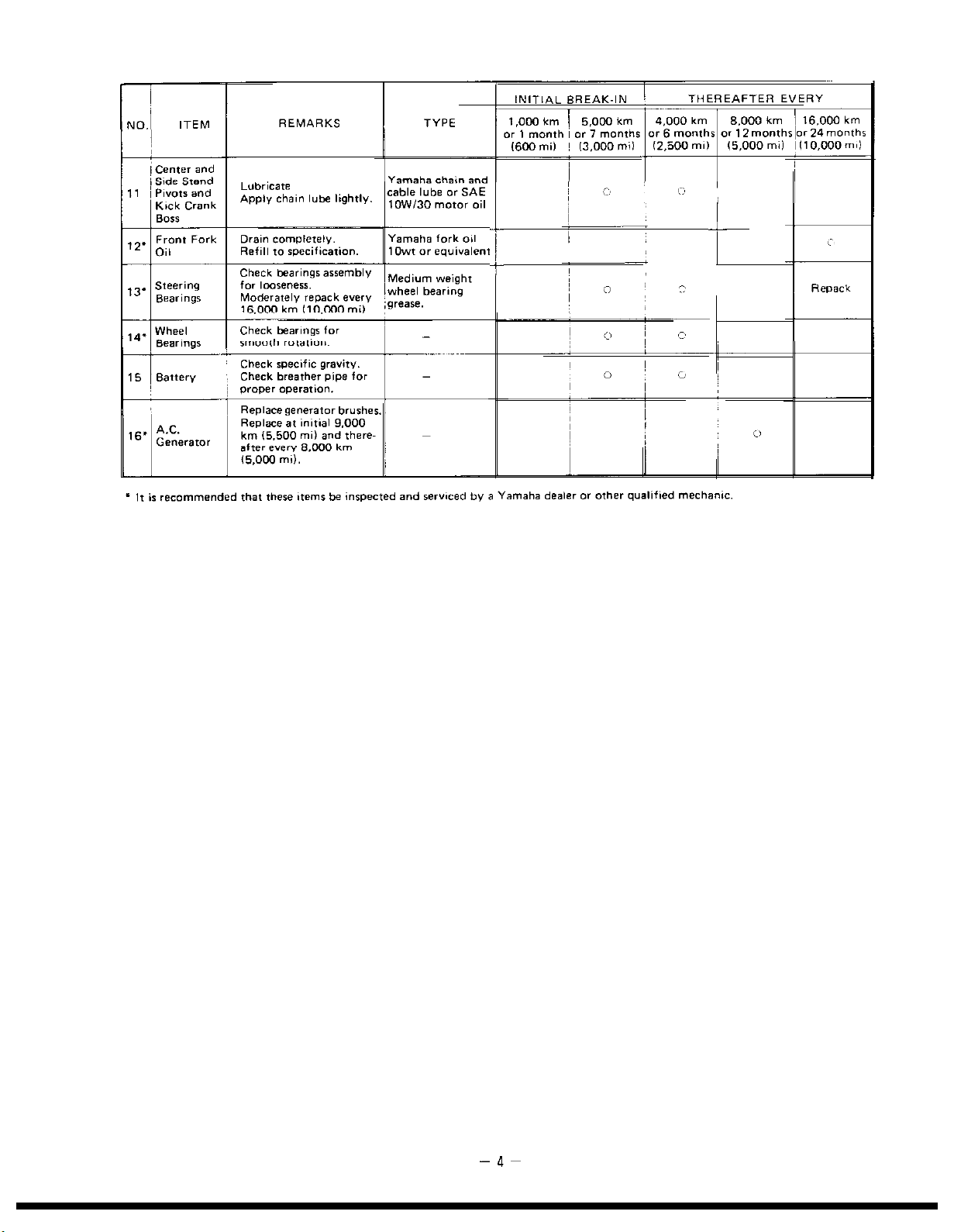

A. IGNITION TIMING

The ignition system is modified for easier

maintenance. Thus, the following “ignition

timing check” should be changed,

Ignition timing check

1. Ignition timing is checked with a timing

light by observing the position of the

rotor pointer and the marks stamped on

the timing plate.

The timing plate is marked as follows.

“ll”

Firing range for No. 1

(L.H.)

B. PICK-UP COIL ASSEMBLY

The method of mounting the pick-up coil

assembly is changed for easier service work.

Thus, the followings “Pick-up coil assembly

removal” and “Pick-up coil assembly reinstallation” should be changed.

Pick-up coil assembly removal

Remove the pick-up coil securing screws and

remove the pick-up coil

assembly.

“T” Top Dead Center for No.

fL.H.1

cylinder

2. Connect the timing light to the left

cylinder spark plug lead wire.

3. Start the engine and keep the engine

speed as specified. Use a tachometer to

check the engine speed.

Specified engine speed:

1,200 r/min

_

L

4.

The rotor pointer should be within

the limits of

”

fl

”

on the timing plate.

If it exceeds the limits or does not

steady, check the timing plate for tightness and/or ignition system for damage.

NOTE:

Ignition timing is not adjustable.

1,

Pick-up coil assembly reinstallation

Install the pick-up coil assembly on to the

stator

assembly.

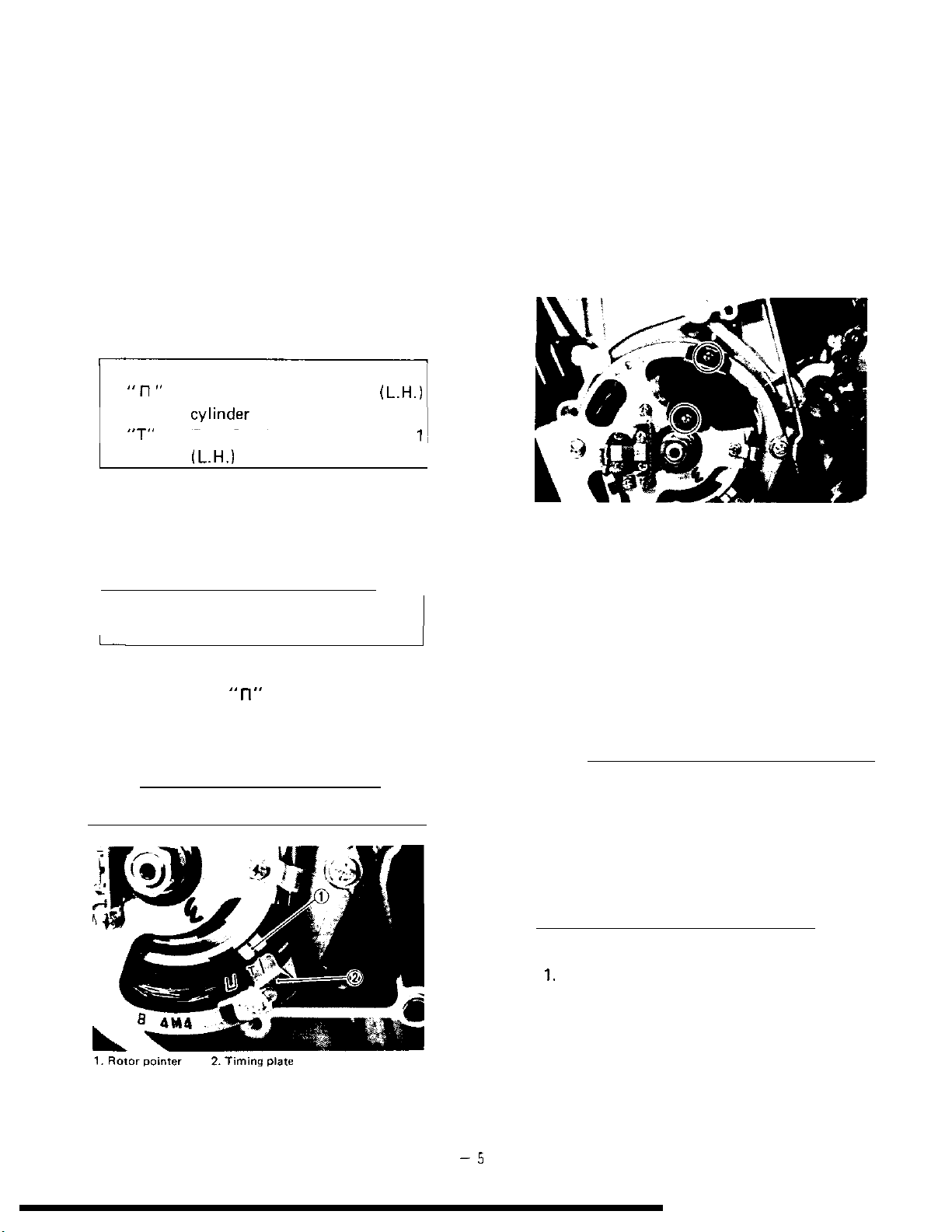

C. FUEL LEVEL

The carburetor is furnished with a drain screw

to provide easy access to service work. Thus,

the following

“Fuel level measurement”

should be added.

Fuel level measurement

NOTE:

Before checking the fuel level, note the following:

1.

Place the motorcycle on a level surface.

2. Adjust the motorcycle position by placing a suitable stand or a garage jack

under the engine so that the carburetor

is positioned vertically.

1.

Connect the level gauge (special tool) or

a vinyl pipe of 6 mm (0.24 in) in inside

diameter to the float bowl nozzle left or

right side carburetor.

2.

Set the gauge as shown and loosen the

drain screw.

-5

3. Start the engine and stop it after a few

minutes of run. This procedure is

sary

to obtain the correct fuel level.

neces-

Fuel level:

1 f 1 mm

from the carburetor mixing chamber

body edge.

(0.04?

0.04 in) above

YL___-A

NOTE:

Make sure the fuel petcock is “ON” or “RES”

oosition.

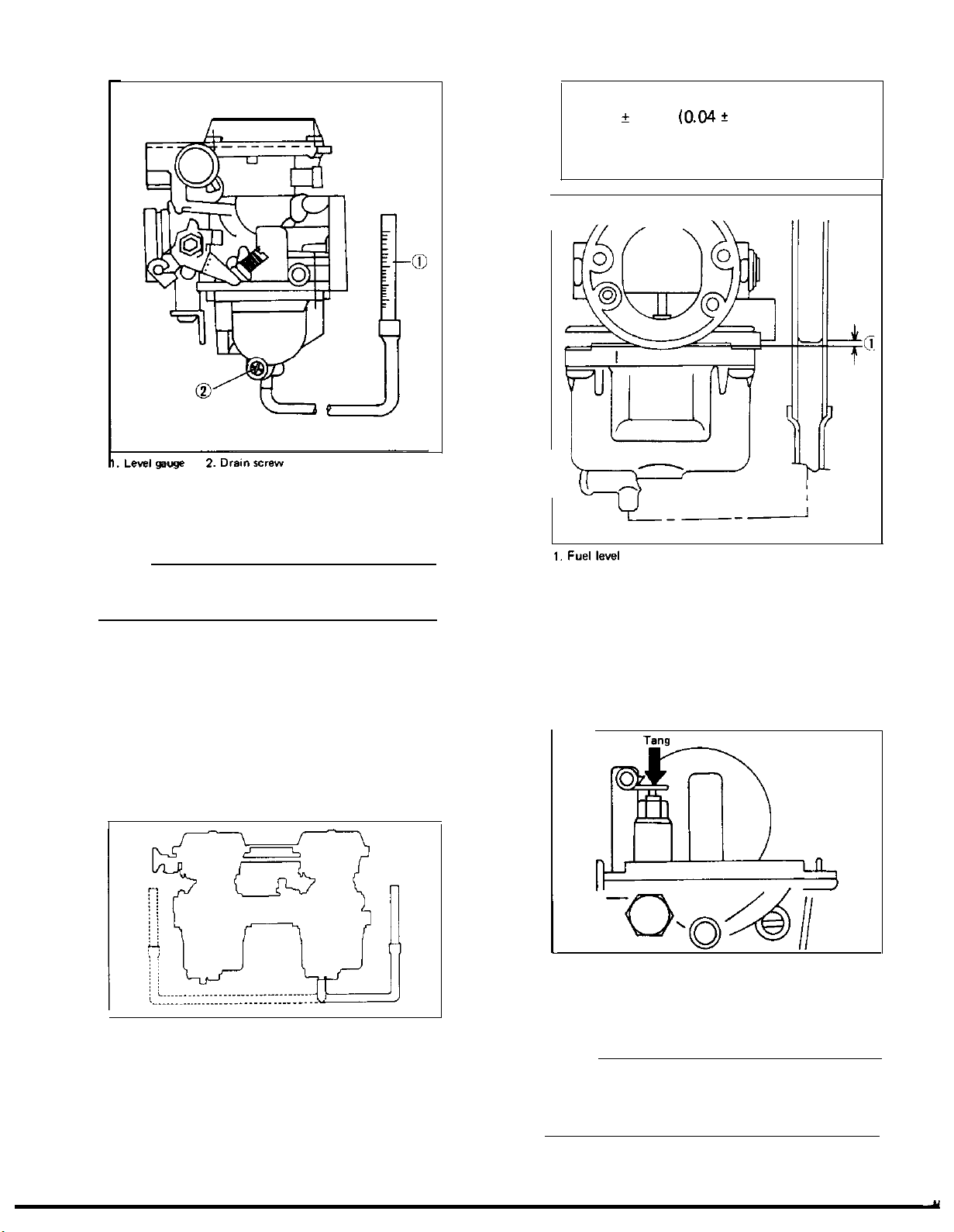

Note the fuel level and bring the gauge

4.

to the other end of the carburetor line

and repeat step 3 above. Note the fuel

level again and compare it with the

previous gauge reading. They should be

equal. If not, place a suitable size of

wooden piece or the. alike under the

center stand and adjust.

5. Check the fuel level one by one. The

level should be in the specified range.

6. If the fuel level is incorrect, remove the

carburetor assembly from the motorcycle and check the fuel

float assembly(s) for damage.

7. If no damage is found, correct the fuel

level by slightly bending the float arm

tang. Recheck the fuel level.

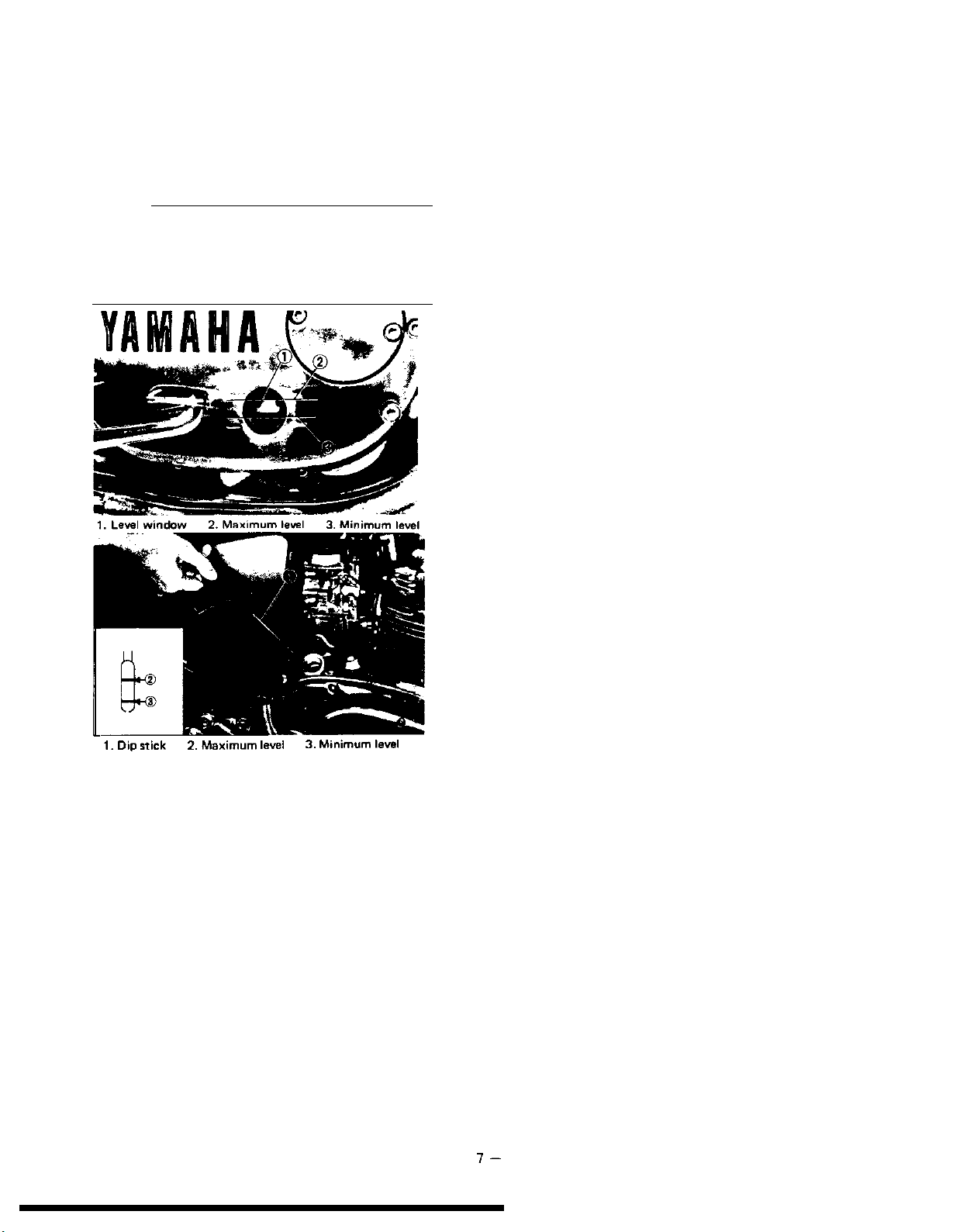

D. ENGINE OIL LEVEL MEASUREMENT

1.

Place the motorcycle on the center stand.

Warm up the engine for several minutes.

NOTE:

Be sure the motorcycle is positioned straight

up when checking the oil level; a slight tilt

toward the side can produce false readings.

valve(s)

and

-6-

Y

2

With the engine stopped, check the oil

level through the level window located at

the lower part of the right side crankcase

cover, or screw the dip stick completely

out and then the stick in the hole.

NOTE:

Wait a few minutes until the oil level settles

before checking. When checking engine oil

level with the dip stick, let the unscrewed dip

stick rest on the case threads.

1.

Dip stick

2.

Maximum

level

Minimum

level

3.

3. The oil level should be between maximum and minimum levels. If the level

is lower, add sufficient oil to raise it to

the proper level.

l-

Loading...

Loading...