Schneider Electric Altivar212 User Manual

www.schneider-electric.com

Altivar 212

Variable speed drives for asynchronous motors

LONWORKS

®

communication manual

VW3 A21 212

01/2011

S1A53848

2 S1A53848 01/2011

The information provided in this documentation contains general descriptions and/or technical characteristics

of the performance of the products contained herein. This documentation is not intended as a substitute for

and is not to be used for determining suitability or reliability of these products for specific user applications. It

is the duty of any such user or integrator to perform the appropriate and complete risk analysis, evaluation and

testing of the products with respect to the relevant specific application or use thereof. Neither Schneider

Electric nor any of its affiliates or subsidiaries shall be responsible or liable for misuse of the information

contained herein. If you have any suggestions for improvements or amendments or have found errors in this

publication, please notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical, including

photocopying, without express written permission of Schneider Electric.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must be

followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2011 Schneider Electric. All rights reserved.

S1A53848 01/2011 3

Table of Contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 2 Hardware setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Receipt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Opening the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the LonWorks communication card in ATV212 . . . . . . . . . . . . . . . . . . . . . . . 15

Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Use of open Style Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Description of terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3 Connecting to the bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cable routing practices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connecting the LonWorks connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Communication parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Configuration of the control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configuring the behaviour on configuration interruption. . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 5 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Communication detected fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

List of type supported by ATV212 Service LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 6 Functional profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Objects supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

LonMark Node Object profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

LonMark Variable Speed Motor Drive profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 7 Network variables and configuration properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

List of network variables and configuration properties . . . . . . . . . . . . . . . . . . . . . . . . . 42

Commands and setpoints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Status and output velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Monitoring of digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Monitoring of analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Control of digital outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Emergency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Parameter access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Network management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table of Contents

Table of Contents

4 S1A53848 01/2011

S1A53848 01/2011 5

§

Safety Information

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before trying

to install, operate, or maintain it. The following special messages may appear throughout this documentation

or on the equipment to warn of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

PLEASE NOTE

The word “drive” as used in this manual refers to the controller portion of the adjustable speed drive as defined

by NEC.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel. No

responsibility is assumed by Schneider Electric for any consequences arising out of the use of this material.

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard

exists, which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all

safety message that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death or serious

injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, can result in death, serious

injury or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can result in injury or equipment

damage.

CAUTION

CAUTION, used without the safety alert symbol, indicates a potentially hazardous situation which, if not

avoided, can result in equipment damage.

6 S1A53848 01/2011

About the Book

About the Book

At a Glance

Document Scope

The purpose of this document is to:

• install the card in the drive,

• show you how to configure the Altivar 212 to use LONWORKS

®

for monitoring and control.

NOTE: Read and understand this document and all related documents (see below) before installing,

operating, or maintaining your ATV212.

Validity Note

This documentation is valid for the Altivar 212 L

ONWORKS fieldbus.

Related Documents

You can download the latest versions of these technical publications and other technical information on

www.schneider-electric.com.

Product Related Information

Title of Documentation Reference Number

ATV212 Quick Start S1A53825

ATV212 Installation manual S1A53832

ATV212 Programming manual S1A53838

ATV212 Modbus manual S1A53844

ATV212 Metasys N2 manual S1A53846

ATV212 Apogée FLN P1 manual S1A53847

ATV212 BACnet manual S1A53845

ATV212 other option manuals: see www.schneider-electric.com

DANGER

UNINTENDED EQUIPMENT OPERATION

• Read and understand this manual before installing or operating the Altivar 212 drive.

• Any changes made to the parameter settings must be performed by qualified personnel.

Failure to follow these instructions will result in death or serious injury.

About the Book

S1A53848 01/2011 7

(1) For additional information, refer to NEMA ICS 1.1 (latest edition), “Safety Guidelines for the Application, Installation, and

Maintenance of Solid State Control” and to NEMA ICS 7.1 (latest edition), “Safety Standards for Construction and Guide

for Selection, Installation and Operation of Adjustable-Speed Drive Systems.”

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Read and understand this manual before installing or operating the drive. Installation, adjustment, repair,

and maintenance must be performed by qualified personnel.

• The user is responsible for compliance with all international and national electrical code requirements with

respect to grounding of all equipment.

• Many parts of this drive, including the printed circuit boards, operate at the line voltage. DO NOT TOUCH.

Use only electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with voltage present.

• DO NOT short across terminals PA/+ and PC/– or across the DC bus capacitors.

• Before servicing the drive:

- Disconnect all power, including external control power that may be present.

- Place a “DO NOT TURN ON” label on all power disconnects.

- Lock all power disconnects in the open position.

- WAIT 15 MINUTES to allow the DC bus capacitors to discharge.

- Measure the voltage of the DC bus between the PA/+ and PC/– terminals to ensure that the voltage is

less than 42 Vdc.

- If the DC bus capacitors do not discharge completely, contact your local Schneider Electric

representative. Do not repair or operate the drive

• Install and close all covers before applying power or starting and stopping the drive.

Failure to follow these instructions will result in death or serious injury.

WARNING

DAMAGE DRIVE EQUIPMENT

Do not operate or install any drive or drive accessory that appears damaged.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

LOSS OF CONTROL

• The designer of any control scheme must consider the potential failure modes of control paths and, for

certain critical control functions, provide a means to achieve a safe state during and after a path failure.

Examples of critical control functions are emergency stop and overtravel stop.

• Separate or redundant control paths must be provided for critical control functions.

• System control paths may include communication links. Consideration must be given to the implications

of unanticipated transmission delays or failures of the link (1).

Failure to follow these instructions can result in death, serious injury, or equipment damage.

About the Book

8 S1A53848 01/2011

S1A53848 01/2011 9

Introduction

1

Introduction

Thank you for purchasing the LONWORKS

®

option card (VW3 A21 212) for Altivar 212 drive.

By installing this card into the Altivar 212, data communication can be made with a host computer or other

device via LONWORKS

®

network.

The communication card has an open-style 3-pin connector for connection to the network. It supports free

topology (TP/FT-10) at 78 kbit/s.

Data exchanges give access to all Altivar 212 functions:

• Control (start, stop, reset, setpoint),

• Monitoring (status, current, voltage, thermal state...),

• Diagnostics (alarms).

The L

ONWORKS resource files (.XIF...) that provide the network configuration tools (LonMaker

®

...) with device

information are available on www.schneider-electric.com.

LONWORKS

®

, LONMARK

®

, LonMaker

®

, Neuron are trademarks of Echelon Corporation registered in the United

States and other countries.

LONMARK

®

and LONMARK

®

Logo are managed, granted, and used by LONMARK

®

International under a license

granted by Echelon Corporation.

Introduction

10 S1A53848 01/2011

S1A53848 01/2011 11

Hardware setup

2

Hardware setup

What's in this Chapter?

This chapter contains the following topics:

Topic Page

Receipt 12

Opening the drive 13

Hardware description 16

Use of open Style Connector 16

Description of terminals 17

Hardware setup

12 S1A53848 01/2011

Receipt

•

Check that the card reference printed on the label is the same as that on the delivery note corresponding

to the purchase order.

• Remove the option card from its packaging and check that it has not been damaged in transit.

• The LONWORKS card is shipped together with the following accessories. On opening the packing case,

check to see if the following accessories are contained or not.

- 1 cabling label,

- 3 neuron ID labels (barcode EAN128),

- 1 screw.

Hardware setup

S1A53848 01/2011 13

Opening the drive

1 Any procedure in this section must be performed when product is powered off.

2 Open the ATV212 front cover.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Read and understand the instructions in "About the book" chapter, before performing the procedure in this

section.

Failure to follow these instructions will result in death or serious injury.

ATV212H products up to 22 kW .

Turn the screw on the

front panel 90°

counter-clockwise to

align the dot on the

screw with the unlock

position.

To avoid damaging

the screw, do not

apply excessive force

or turn the screw more

than 90°.

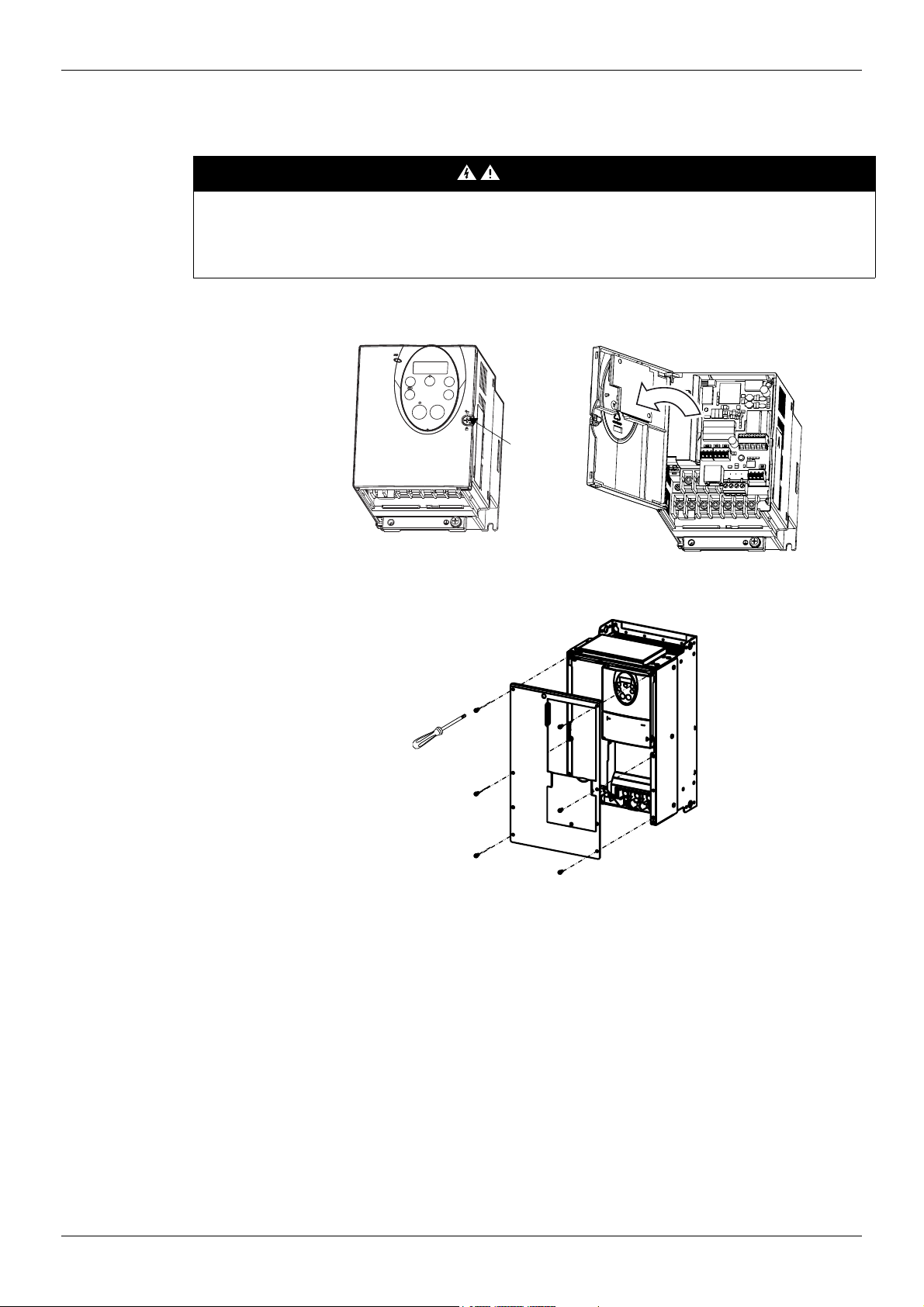

ATV212H products from 22 kW

Remove the screws.

Lift off the cover.

Pull the front panel toward you

and swing it open to the left

Screw

Hardware setup

14 S1A53848 01/2011

ATV212W up to 7.5 kW ATV212W above 7.5 kW

Hardware setup

S1A53848 01/2011 15

Installing the LONWORKS communication card in ATV212

Note: To install or remove the terminal board, make it slide in or out in parallel with board.

DANGER

UNINTENDED EQUIPMENT OPERATION

z Do not plug or unplug the terminal board while drive is powered.

z Check the tightening of the mounting screw after any manipulation on the terminal board.

Failure to follow these instructions will result in death or serious injury.

1 Open the ATV212 front cover,

remove the terminal board

mounting screw and take off the

ATV212 standard terminal board.

See paragraph How to open the

front cover, page 13

. Be careful

not to lose the terminal board

mounting screw when removed

since it may be used again. On

drives from 0.75 to 2.2 kW the

board features a plastic tag to

hold the mounting screw in place.

2 Make the power and control

wiring connections before

installing communication card.

3 Install the L

ONWORKS

communication card. Fit the

board mounting screw (M3

tapping type) and tighten to 0.7 to

0.8 Nm

4 Stick the cabling label for

communication card on the

standard cabling label stuck on

front cover (internal side)

ATV212. And stick the

communication card nameplate

close to the standard nameplate.

Be careful not to cover slits on

the ATV212 enclosure.

B

A

GND

SCR

PLC

VIA

U

VIB

U

I

PT

C

SW1

00

Sin

k

PL

C

S

ou

r

c

e

SW1

02

I

U

SW101

T

e

r

m

SW1

03

PLC

VIA U

VIB U

I

P

T

C

SW100

Sink

P

LC

S

ou

r

ce

SW102

I

U

SW101

T

e

r

m

SW103

P24M

NETASHLD NETB

G/E

ON ORKS

R

L

W

S1A58023

VIB

Sink

PTC

Source

SW100 SW200

VW3A21212

SERVICE LED

SERVICE SW

Hardware setup

16 S1A53848 01/2011

Hardware description

Use of open Style Connector

General

Use the open style connector to connect the drive to L

ONWORKS fieldbus. Connection details are given in the

"Connecting to the bus" section page 19

.

CC

G/E FLA

RJ45

FLB

FLC

FR

RES

NETA

NETB

SHLD

VIB PP

P24M

LONWORKS OpenStyle connector

Selector switch SW100

- VIB function

(VIB/PTC)

- Logic for F, R, RES terminal

(SINK/SOURCE)

RJ45 port

Service LED

Terminal board

mounting screw

hole (M3 screw)

Connector to drive

VIB

SINK

PTC

SOURCE

SW200 (1)

Commissioning button

(1) The SW200 switch enables to send the network address to the master.

DANGER

UNINTENDED EQUIPMENT OPERATION

• Modify only the setting of the switches when the product is switched off.

• Do not change the setting of the SW100 unless your system is wired for SINK logic.

Failure to follow these instructions will result in death or serious injury.

CAUTION

RISK OF BODY INJURY

Use a screwdriver to change the position of the switches.

Failure to follow these instructions can result in injury or equipment damage.

Hardware setup

S1A53848 01/2011 17

Description of terminals

(1) Voltage conversion

(2) PTC (Positive Temperature Coefficient): Resettable thermal fuse resistor for over current protection.

Terminal

symbol

Function Electrical specifications Internal circuits

CC Control circuit equipotential terminal -

-

VIB

Multifunction programmable analog

input. It has speed setpoint function in

the default setting (0 to 50 Hz

frequency with 0 to 10 Vdc input). In

addition, this terminal can be used as

PTC (2) input by setting switch SW100

and the parameters [Mot PTC

selection] F645 and [PTC resistor

value] F646.

Voltage: 10 Vdc

Internal impedance: 30 kΩ

PP

Voltage supply for reference

potentiometer.

Voltage: 10 Vdc

Max current: 10 mA

Protected against short

circuits.

F

Multifunctional programmable logic

input.

It has forward rotation function in

default setting.

ON: forward rotation drive

OFF: slowdown and stop

No voltage contact input

24 Vdc

5 mA or less.

SINK/SOURCE can be

selected with SW100.

R

Multifunctional programmable logic

input. It has Preset speed 1 in default

setting.

RES

Multifunctional programmable logic

input. It has Fault Reset in default

setting

P24M 24 VDC power supply output

24 Vdc

50 mA

NETA

L

ONWORKS transmission data /

reception data.

No polarity.

SHLD

L

ONWORKS communication shield

terminal.

This terminal is not connected

to any other circuit of the card.

Ground this terminal in a

location separated from the

ground of power line.

NETB

L

ONWORKS transmission data /

reception data.

No polarity.

G/E Grounding terminal

Please connect to network

ground.

FLA

FLB

FLC

Multifunctional programmable relay

contact outputs. Default setting is set to

detect the activation of the drive

protection function.

Contact across FLA-FLC is closed and

FLB-FLC is open during normal

operation.

30 Vdc, 0.5 A

250 Vac, 1 A

(cos

ϕ = 1)

250 Vac, 0.5A

(cos

ϕ = 0.4)

PP

+24V

(1)

F, R, RES

SINK

SOURCE

(2)

Spark

gap

Hardware setup

18 S1A53848 01/2011

S1A53848 01/2011 19

Connecting to the bus

3

Connecting to the bus

What's in this Chapter?

This chapter contains the following topics:

Topic Page

Topology 20

Cable routing practices 21

Card connector pinout 22

Connecting the L

ONWORKS connector 22

Connecting to the bus

20 S1A53848 01/2011

Topology

The LONWORKS card supports free topology (TP/FT-10) wiring and operates as well with bus, loop or star

topologies:

Free topology system

Free topology has many advantages:

1. The installer is free to select the method of wiring that best suits the installation, reducing the need for

advanced planning and allowing last minute changes at the installation site.

2. If installers have been trained to use one style of wiring for all installations, free topology technology can be

introduced without requiring retraining.

3. Retrofit installations with existing wiring plants can be accommodated with minimal, if any rewiring.

Typical wiring topologies

Star topology

Doubly terminated bus topology

Termination

Termination

Termination

Termination

Loop topology

Termination

Mixed topology

Loading...

Loading...