Schneider Electric ALTIVAR 58 TRX User Manual

Catalog

03

ALTIVAR® 58 TRX

AC DRIVES

File 8806 / 8839 / 8998

CONTENTS

Description Page

Drives Product Support and Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

®

58 TRX AC Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Altivar

Class 8839 58M Enclosed AC Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Class 8839 Econoflex™ AC Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Class 8998 Motor Control Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

DRIVES PRODUCT SUPPORT AND CONTACTS

Drives Product Support Group Customer Information Center

The Product Support Group is available 24

hours a day, 365 days a y ear . W e will w ork with

you ov er the telephone to d iagnose applicatio n

or product problems and to advise the correct

course of action.

Telephone: 919-266-8600

Fax: 919-217-6508

E-mail: drivepsg@SquareD.com

Field Services Customer Literature Center

Square D Field Services is committed to

providing quality on-site service. No matter

how routine or complex the task, we have the

engineering and technic al e xpertise to pro vide

service for any manufacturer’s equipment.

Our coordination center will respond to your

requests 24 hours a day, seven days a week.

Simply call our toll-free number to arrange onsite service.

Serving all Square D authorized distributors

and customers in the U.S., Monday through

Friday, 8:00 a.m. to 8:00 p.m. EST.

Telephone: 888-SquareD (1-888-778-2733)

To obtain hard copy support literature for your

product or application needs, contact the

Square D Customer Literature Center.

Telephone: 800-392-8781

Fax: 800-824-7151

Telephone: 800-634-2003

T raining Square D Website

Square D offers a variety of instructor-led and

self-paced skill enhancing an d product trainin g

programs for our employees, distributors,

customers, and suppliers. For more

informat ion, call the Square D Or ganization al

Development Department.

Visit the vi rtual work zone at the Square D

website to quic kly find and downloa d technica l

literature and mark eting collateral. The web site

offers a variety of solutions for your drive

applications. It includes software tools, new

product information, and product selection

information.

Telephone: 847-397-2600

Web Address: http://www.SquareD.com

Conditions of Sale Square D/Schneider Electric Sales Offices

Refer to the Digest. Visit www.SquareD.com for the location of the

sales office nearest you.

2

© 2000–2003 Schneider Electric All Rights Reserved

09/2003

Altivar 58 TRX AC Drives

09/2003

ATV58 TRX Fam10827Retouced. ti f

Altivar

®

58 TRX AC Drives

Contents

DESCRIPTION PAGE

PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

USER INTERFACE OPTIONS AND ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ATV58 TRX TYPE H DRIVE CONTROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ATV58 TRX TYPE E DRIVE CONTROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ATV58 TRX TYPE F DRIVE CONTROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ATV58 TRX TYPE N DRIVE CONTROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ATV58 TYPE FVC DRIVE CONTROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TERMINAL LOCATIONS FOR ATV58 TRX TYPE H AND TYPE FVC DRIVES . . . . . . . . . . . . 18

DESCRIPTION OF POWER TERMINALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

CONDUIT CONNECTIONS FOR TYPE E AND TYPE F DRIVE CONTROLLERS . . . . . . . . . . 20

DESCRIPTION OF CONTROL TERMINALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DESCRIPTION OF ATV58 TYPE FVC CONTROL TERMINALS . . . . . . . . . . . . . . . . . . . . . . . 22

KEYPAD DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

POWERSUITE OPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

MAGELIS TERMINAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SUMMARY OF USER INTERFACE OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

I/O EXTENSION CARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

COMMUNICATION OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

VENTILATION KITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

CONDUIT ENTRY KITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

DYNAMIC BRAKING RESISTOR KITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

ELECTROMAGNETIC COMPATIBILITY (EMC) KITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

RFI FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

LINE REACTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

MOTOR PROTECTING OUTPUT FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

MACRO-CONFIGURATION PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DRIVE CONTROLLER IDENTIFICATION SCREEN: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DISPLAY PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

ADJUSTMENT PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

DRIVE AND MOTOR CONFIGURATION PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

DRIVE CONTROL PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

CONFIGURABLE I/O FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

FUNCTION COMPATIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

ASSIGNMENT OF LOGIC INPUTS (LIx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

ASSIGNMENT OF ANALOG INPUTS (AIx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

ASSIGNMENT OF ANALOG INPUTS (AIx) WITH ANALOG I/O EXTENSION CARD . . . . . . . 60

ASSIGNMENT OF LOGIC OUTPUTS (R2 OR LOx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

ASSIGNMENT OF ANALOG OUTPUTS (AOx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

FAULT MANAGEMENT PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

ADDITIONAL FUNCTIONALITY PROVIDED IN THE ATV58 TYPE FVC DRIVE . . . . . . . . . . . 68

ATV58 TYPE FVC ADJUSTMENT PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

ATV58 TYPE FVC ANALOG INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

ATV58 TYPE FVC ANALOG OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

ATV58 TYPE FVC LOGIC OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

PARAMETER SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

MENU OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

COMMUNICATION PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

POWER SECTION CONSTRUCTION INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

PERFORMANCE INFORMATION (CONSTANT TORQUE RATED PRODUCTS) . . . . . . . . . . 95

SPEED REGULATION (CONSTANT TORQUE RATED PRODUCTS) . . . . . . . . . . . . . . . . . . . 97

INSTALLATION RECOMMENDATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

WIRING RECOMMENDATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

ATV58 TRX TYPE H SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

ATV58 TRX TYPE FVC SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

WEIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

SUGGESTED SPECIFICATIONS FOR ATV58 TRX TYPE H CONTROLLERS . . . . . . . . . . . 137

© 2000–2003 Schneider Electric All Rights Reserved

3

Altivar

®

58 TRX AC Drives

Product Overview

ATV58 TRX Type H Product Famil y

PRODUCT OVERVIEW

Altivar® 58 (ATV58) TRX AC driv e control lers off er superior p erformance in a

compact package. A TV58 TRX d rive contr ollers are d esign ed for modularity,

allowing you to customize the product to your exact needs. A variety of

multilingual operator interface options, I/O extension cards, communication

ATV58 TRX Fam10827R etouced.tif

cards, and hardware options are available.

ATV58 TRX drive controllers incorporate sensorless flux vector control for

three-phase asynchronous squirrel cage AC motors. They are available in

the follow ing confi gur ations:

•Type H

•Type FVC

•Type E

•Type F

•Type N

The ATV58 TRX Type H drive controller can be used in variable torque or

ATV58Family.tif

constant torque appl ications . Ea ch ATV58 TRX drive controlle r inco rporates

random switching frequency modulation to reduce motor noise. For variable

torque applications, the ATV58 TRX Type H controller includes features for

additional energy savings and quiet motor operation. For constant torque

applications, the ATV58 TRX Type H drive co ntrolle r f eature s a 1:100 sp eed

range with excellent torque performance through the entire range.

ATV58 Type FVC Product Family

ATV58 TRX Type E and Type F Product

Family

The ATV58 Type FVC drive controller offers the highest level of AC drive

performance. It is for use in constant torque applications requiring a 1:1000

speed range and torque at ze ro sp eed, or where respons e time to a change

in load is critical t o the application.

The Type H and Type FVC drive controlle rs ca n be m ounted in an encl osure

integrating othe r equipment, or wa ll-mounted using the o ptional conduit en try

kits.

TypeEF_Family.tif

The Type E, Type F, and Type N configurations offer a packaged product

ready to mount in a variety of environments.

• The ATV58 TRX Type E drive controller is Type 1 rated and has an

integrated output contactor.

• The ATV58 TRX Type F drive controller is Type 12 rated and contains

integrated line fuses.

• The ATV58 TRX Type N drive controller is Type 4/4X rated.

Each ATV58 TRX drive controller has an integrated RS-485 port. This port

has a variety of uses to fit your application requirements, including:

®

• Use as a multidrop Modbus

TypeN_Family.tif

• Connection for a keypad

port

• Connection for Magelis® termi n als

• Connection of PC or Pocket PC commissioning software

ATV58 TRX Type N Product Famil y

4

© 2000–2003 Schneider Electric All Rights Reserved

09/2003

keypad photo.tif

Keypad Display (Left) and

Remote Mounting Kit (Right)

Altivar

®

58 TRX AC Drives

User Interface Options and Accessories

USER INTERFACE OPTIONS AND ACCESSORIES

Keypad Display

The operator keypad display can be mounted directly to the drive or

connected via a remote mountin g kit. It can be us ed to ope rate the drive, or

to display, configure, and adjust parameters. It can also be used to upload

and download configu rations.

OpInterfaceNew.tif

PowerSuite™ Software

®

PC Conn Kit.tif

This Windows

configure, and adjust parameters as well as upload and download

configurations . It can also be used to operate the driv e and vie w fau lt history .

The software may be used in a stand-alone mode to create or modify a

configuration and transfer it to an ATV58 TRX drive controller.

-based PC and Pocket PC software can be used to display,

PowerSuite Software

I/O Option Boards

IO_cards.tif

I/O Option Bo ards

A variety of optio n boards are a vailab le to e xpand th e I/O to match the n eeds

of the installation. The option boards mount internally without requiring

additional panel space.

Communication Option Boards

ComCards.tif

Individual communication cards are available to integrate the ATV58 TRX

drive controll er into many indus trial a nd building autom ati on co mmunication

protocols. Th ese all ow the user to control, a djust , and obt ain the status of an

ATV58 TRX drive controller. The communication card mounts internally

without requiring additional space.

Communication Option Boar ds

09/2003

© 2000–2003 Schneider Electric All Rights Reserved

5

Altivar

®

58 TRX AC Drives

User Interface Options and Accessories

VentKits.tif

Ventilation Kits

CondEntKits.tif

Ventilation Kits

Ventilation fan kits are available for packaging the drive in a smaller

enclosure. The ve ntilation f an is p ow ered inte rnally and mo unts on top o f the

ATV58 TRX drive controller without requiring additional panel space.

Conduit Entrance Kits

Conduit entrance kits are available for wall-mount applications. The kits

attach to the bottom of the ATV58 TRX drive controller a nd are pro vide d with

multiple conduit knockouts.

Conduit Entrance Kits

Dynamic Braking Resistor Kits

Dynamic Braking Resistor Kits

Dynamic braking resistors packaged in Type 1 enclosures are available for

applications requiring fast cycle times. These kits mount separately.

DynBrake.tif

6

© 2000–2003 Schneider Electric All Rights Reserved

09/2003

ATV58 TRX Type H Product Family

The ATV58 TRX series of adjustable

frequency AC drive controllers is a

Transparent Ready

TM

product line

providing extended functionality and an

extended hor sep o wer range for the ATV58

AC drive family. The ATV58 TRX series

includes an analog output, expanded

firmware capabilities, and a horsepower

range up to 500 hp. As a Transparent

Ready product equipped with an Ethernet

communication card, the ATV58 TRX

product line can be configured, controlled,

monitored, and diagnosed o ver an Ethernet

network with a standar d Web browser. No

special software or drivers are needed.

Altivar

®

58 TRX AC Drives

Type H Drive Controllers

ATV58 TRX TYPE H DRIVE CONTROLLERS

Features

The ATV58 TRX Type H drives are used for controlling three-phase

asynchronous motors ranging from:

• 1 to 350 hp CT (1 to 500 hp VT), 400/460 Vac, three-phase input

ATV58 TRX Fam10827Retouced.tif

• 0.5 to 7.5 hp CT (0.5 to 30 hp VT), 208/230 Vac, single-phase input

• 2 to 40 hp CT (2 to 50 hp VT), 208/230 Vac, three-phase input

The ATV58 TRX Type H drive controller uses the latest in AC drive

technology. Power modules are used on the entire product family. The

modules contain insulated gate bipolar transistors (IGBTs) to produce a

pulse width modulated (PWM) output waveform to the motor. The power

modules minimize part count and improve reliability.

The T y pe H drive controllers integrate third-ge neration senso rless flux vector

control for three-phase asynchronous squirrel cage AC motors. This allows

the drive cont roller to deliv er needed tor que with ex cellent dynamic response

over a wide speed range.

ATV58 TRX Type H drive controllers are capable of:

• Producing transient torque of 200% (±10%) of nominal motor torque for

2 seconds

• Producing transient torque of 170% (±10%) of nominal motor torque for

60 seconds

• Producing 160% of rated motor torque at 0.6 Hz with encoder feedback,

or at 1 Hz without tachometer or encoder feedback (open loop)

• Regulating rated motor speed within 1% without tachometer or encoder

feedbac k, or with in ±0.02 % with an enco der f eed bac k ci rcuit (op tion ca rd)

Each Type H drive controller has a selectable switching frequency that can

be adjusted to ma tch th e appli catio n requi rement s. The s wi tch ing fre quenc y

can be programmed to fold back in the event of excessive heat. The drive

controller reverts back to the programmed choi ce upon reac hing the normal

thermal state.

09/2003

In addition, each 1 5 hp (CT) to 5 0 hp (VT) 208/2 30 V ac Type H controller and

each 25 hp (CT) to 100 hp (VT) 400/460 V ac Ty pe H contro ller includ es a line

reactor integrated into the heatsink plenum. The line reactor improves

reliability and reduces input currents to the drive controller.

Most A TV58 TRX drive controllers are avai lable with an in tegrated EMC fil ter.

This filter reduc es conduct ed and rad iated em issions, and comp lies with IEC

product standards IEC 61800-3 and EN 61800-3 for drive controllers.

Compliance with these standards meets the requirements of the European

directive on EMC .

Configuration tools, operator interfaces, I/O extension options, and

communication options are shared throughout the product range.

© 2000–2003 Schneider Electric All Rights Reserved

7

Altivar

®

58 TRX AC Drives

Type H Drive Controllers

Ratings

ATV58 TRX Type H drive controllers may be rated for constant torque (CT), variable torque (VT), and

variable torque low noise (VTLN) applications .

• CT applications usually require 100% of motor-rated torque through the entire speed range, high

transient torque capability, and speed regulation.

• VT applications , such as c entrifugal f ans an d centrifugal pu mps, do not require high tr ansient to rque

capability. Thi s typically al lows a d rive to be r ated f or additional h orsepow er and additio nal current as

compared to the constant torque rating.

• VTLN applications, such as centrifugal fans and centrifugal pumps, do not require high transient

torque capability. However , this r ating use s a higher s witch ing frequen cy f or quieter mo tor oper ation.

As a result, the drive ma y be rated at th e same horsepow er and current as the cons tant torque rating ,

particularly at large horsepower sizes.

The 125–500 hp driv e controll ers are listed in this cat alog with r atings typi cally use d for VT application s.

With proper selection, this range of controllers can also be used in CT applications, such as

compressors, conveyors, and extruders, where high performance is not required at low speeds. The

125–500 hp product ratings in this catalog are for applications that require 100% rated torque down to

6 Hz. If the application req uires more than 1 10% trans ient torque for on e minute , selec t the approp riate

horsepower product. For assistance with selecting the proper AC drive controller for constant torque

applications, co nsu lt your local Square D drives special is t.

Application information is also available in product data bulletin SC100, Adjustable Frequency

Controllers Application Guide, available at www.SquareD.com, or the NEMA Standards Publication:

Application Guide For AC Adjustable Speed Drive Systems.

▼ Refer to page 127 for a

complete list of catalog

numbers. An “X” in the

catalog number indicates that

the product does not hav e an

internal EMC filter. If an

internal EMC filter is required,

delete the “X” from the

catalog number.

■ When these drive controllers

are used with a single-phase

input, a line reactor (3%

minimum) must be used.

▼ Refer to page 127 for a

complete list of catalog

numbers. An “X” in the

catalog number indicates that

the product does not hav e an

internal EMC filter. If an

internal EMC filter is required,

delete the “X” from the

catalog number.

■ When these drive controllers

are used with a single-phase

input, a line reactor (3%

minimum) must be used.

Ratings for ATV58 TRX Type H Constant Torque; 208/230 Vac, Single-Phase Input with 3-Phase Output;

Switching Frequency at 4 kHz

Frame Size

1 ATV58HU09M2ZU 0.37 0.5 2.3 3.1 42

1 ATV58HU18M2ZU 0.75 1 4.1 5.6 64

2 ATV58HU29M2ZU 1.5 2 7.8 10.6 107

2 ATV58HU41M2ZU 2.2 3 11 15.0 156

3 ATV58HU72M2ZU

4 ATV58HU90M2ZU

4 ATV58HD12M2ZU

Ratings for ATV58 TRX Type H Variable Torque, Low Noise; 208/230 Vac, Single-Phase Input with 3-Phase Output;

Switching Frequency: ATV58HU09M2–D12M2 at 8 kHz; ATV58HD16M2–D46M2 at 4 KHz

Frame Size

1 ATV58HU09M2ZU 0.37 0.5 2.5 2.8 42

1 ATV58HU18M2ZU 0.75 1 4.8 5.3 64

2 ATV58HU29M2ZU 1.5 2 7.8 8.6 107

2 ATV58HU41M2ZU 2.2 3 11 12.1 156

3 ATV58HU72M2ZU

4 ATV58HU90M2ZU

4 ATV58HD12M2ZU

6 ATV58HD16M2XZU

6 ATV58HD23M2XZU

7 ATV58HD28M2XZU

7 ATV58HD33M2XZU

7 ATV58HD46M2XZU

Drive Controller

Catalog Number

Drive Controller

Catalog Number

Motor Po wer

208/230 Vac

▼

kW HP A A W

■

■

■

3 4 13.7 18.6 160

4 5 18.2 24.8 176

5.5 7.5 24.2 32.9 204

Motor Power

208/230 Vac

▼

kWHPAAW

■

■

■

3 4 14.3 15.7 160

4 5 17.5 19.3 176

5.5 7.5 25.3 27.8 204

■

7.5 10 30.8 33.9 323

■

11 15 46.2 50.8 550

■

15 20 60 66.0 745

■

18.5 25 75 82.5 895

■

22 30 88 96.8 900

Rated

Output Current

Rated

Output Current

Transient

Output Current

Transient

Output Current

Total Dissipated

Power at Rated Load

Total Dissipated

Power at Rated Load

8

© 2000–2003 Schneider Electric All Rights Reserved

09/2003

Altivar

Type H Drive Controllers

Ratings for ATV58 TRX Type H Constant Torque

208/230 Vac, 3-Phase Input with 3-Phase Output

Switching Frequency: ATV58HU29M2–D23M2 at 4 kHz, ATV58HD28M2–D46M2 at 2 kHz

®

58 TRX AC Drives

▼ Refer to page 127 for a

complete list of catalog

numbers. An “X” in the

catalog number indicates that

the product does not hav e an

internal EMC filter. If an

internal EMC filter is required,

delete the “X” from the

catalog number.

▼ Refer to page 127 for a

complete list of catalog

numbers. An “X” in the

catalog number indicates that

the product does not hav e an

internal EMC filter. If an

internal EMC filter is required,

delete the “X” from the

catalog number.

Frame Size

2 ATV58HU29M2ZU 1.5 2 7.8 10.6 107

2 ATV58HU41M2ZU 2.2 3 11 15 160

3 ATV58HU54M2ZU 3 4 13.7 18.6 190

3 ATV58HU72M2ZU 4 5 18.2 24.8 240

4 ATV58HU90M2ZU 5.5 7.5 24.2 32.9 255

4 ATV58HD12M2ZU 7.5 10 31 42.2 350

6 ATV58HD16M2XZU 11 15 47 63.9 745

6 ATV58HD23M2XZU 15 20 60 81.6 895

7 ATV58HD28M2XZU 18.5 25 75 102 900

7 ATV58HD33M2XZU 22 30 88 119.7 1030

7 ATV58HD46M2XZU 30 40 116 157.8 1315

Ratings for ATV58 TRX Type H Variable Torque

208/230 Vac, 3-Phase Input with 3-Phase Output

Drive Controller

Catalog Number

Motor Power

208/230 V

▼

kW HP A A W

Rated

Output Current

Transient

Output Current

Total Dissipated

Power at Rated Load

Switching Frequency: ATV58HU29M2–D23M2 at 4 kHz, ATV58HD28M2–D46M2 at 2 kHz

Frame Size

2 ATV58HU29M2ZU 1.5 2 7.5 8.3 107

2 ATV58HU41M2ZU 2.2 3 10.6 11.7 158

3 ATV58HU54M2ZU 3 4 14.3 15.7 190

3 ATV58HU72M2ZU 4 5 16.7 18.4 198

4 ATV58HU90M2ZU 5.5 7.5 24.2 26.6 235

4 ATV58HD12M2ZU 7.5 10 30.8 33.9 323

6 ATV58HD16M2XZU 11 15 46.2 50.1 550

6 ATV58HD16M2XZU 15 20 60 66 745

6 ATV58HD23M2XZU 18.5 25 75 82.5 895

7 ATV58HD28M2XZU 22 30 88 96.8 900

7 ATV58HD33M2XZU 30 40 116 127.6 1030

7 ATV58HD46M2XZU 37 50 143 157.3 1315

Drive Controller

Catalog Number

Motor Power

208/230 Vac

▼

kW HP A A W

Rated

Output Current

Transient

Output Current

Total Dissipated

Power at Rated Load

▼ Refer to page 127 for a

complete list of catalog

numbers. An “X” in the

catalog number indicates that

the product does not hav e an

internal EMC filter. If an

internal EMC filter is required,

delete the “X” from the

catalog number.

09/2003

Ratings for ATV58 TRX Type H Variable Torque, Low Noise

208/230 Vac, 3-Phase Input with 3-Phase Output

Switching Frequency: ATV58HU29M2–D23M2 at 8 kHz, ATV58HD28M2–D46M2 at 4 kHz

Frame Size

2 ATV58HU29M2ZU 1.5 2 7.5 8.3 107

2 ATV58HU41M2ZU 2.2 3 10.6 11.7 158

3 ATV58HU54M2ZU 3 4 14.3 15.7 190

3 ATV58HU72M2ZU 4 5 16.7 18.4 198

4 ATV58HU90M2ZU 5.5 7.5 24.2 26.6 235

4 ATV58HD12M2ZU 7.5 10 30.8 33.9 323

6 ATV58HD16M2XZU 11 15 46.2 50.1 745

6 ATV58HD23M2XZU 15 20 60 66 890

7 ATV58HD28M2XZU 18.5 25 75 82.5 980

7 ATV58HD33M2XZU 22 30 88 96.8 975

7 ATV58HD46M2XZU 30 40 116 127.6 1215

Drive Controller

Catalog Number

Motor Power

208/230 V

▼

kW HP A A W

Rated Output

Current

Transient

Output Current

Total Dissipated

Power at Rated Load

© 2000–2003 Schneider Electric All Rights Reserved

9

Altivar

®

58 TRX AC Drives

Type H Drive Controllers

Ratings for ATV58 TRX Type H Constant Torque

400 /460 Vac, 3-Phase Input with 3-Phase Output

Switching Frequency: ATV58HU18N4–D46N4 at 4 kHz, ATV58HD54N4–D79N4 at 2 kHz

▼ Refer to page 127 for a

complete list of catalog

numbers. An “X” in the

catalog number indicates that

the product does not hav e an

internal EMC filter. If an

internal EMC filter is required,

delete the “X” from the

catalog number.

▼ Refer to page 127 for a

complete list of catalog

numbers. An “X” in the

catalog number indicates that

the product does not hav e an

internal EMC filter. If an

internal EMC filter is required,

delete the “X” from the

catalog number.

Frame Size

2 ATV58HU18N4ZU 0.75 1 2.3 3.1 57

2 ATV58HU29N4ZU 1.5 2 4.1 5.6 97

2 ATV58HU41N4ZU 2.2 3 5.8 7.9 120

3 ATV58HU54N4XZU 3 4 7.8 10.6 170

3 ATV58HU72N4XZU 4 5 10.5 14.3 210

3 ATV58HU90N4XZU 5.5 7.5 13 17.7 295

4 ATV58HD12N4XZU 7.5 10 17.6 23.9 360

4 ATV58HD16N4XZU 11 15 24.2 32.9 480

5 ATV58HD23N4XZU 15 20 33 44.9 590

6 ATV58HD28N4XZU 18.5 25 40.7 55.4 421

6 ATV58HD33N4XZU 22 30 48.4 65.8 491

6 ATV58HD46N4XZU 30 40 66 89.8 625

7 ATV58HD54N4XZU 37 50 79.2 107.7 677

7 ATV58HD64N4XZU 45 60 93.5 127.2 837

7 ATV58HD79N4XZU 55 75 115.5 157.1 1090

Ratings for ATV58 TRX Type H Variable Torque, Low Noise

400/460 Vac, 3-Phase Input with 3-Phase Output

Drive Controller

Catalog Number

Motor Power

400/460 Vac

▼

kWHPAAW

Rated

Output Current

Transient

Output Current

Total Dissipated

Power at Rated Load

Switching Frequency: ATV58HU18N4–D46N4 at 8 kHz, ATV58HD54N4–D79N4 at 4 kHz

Frame Size

2 ATV58HU18N4ZU 0.75 1 2.1 2.3 57

2 ATV58HU29N4ZU 1.5 2 3.4 3.7 97

2 ATV58HU41N4ZU 2.2 3 4.8 5.3 119

3 ATV58HU54N4XZU — 5 7.6 8.4 209

3 ATV58HU72N4XZU — 7.5 11 12.1 291

3 ATV58HU90N4XZU — 10 14 15.4 352

4 ATV58HD12N4XZU — 15 21 23.1 472

4 ATV58HD16N4XZU — 20 27 29.7 584

5 ATV58HD23N4XZU — 25 34 37.4 654

6 ATV58HD28N4XZU 18.5 25 34 37.4 502

6 ATV58HD33N4XZU 22 30 40 44 584

6 ATV58HD46N4XZU 30 40 52 57.2 714

7 ATV58HD54N4XZU 37 50 65 71.5 732

7 ATV58HD64N4XZU 45 60 77 84.7 904

7 ATV58HD79N4XZU 55 75 96 105.6 1183

Drive Controller

Catalog Number

Motor Power

400/460 Vac

▼

kWHPAAW

Rated

Output Current

Transient

Output Current

Total Dissipated

Power at Rated Load

10

© 2000–2003 Schneider Electric All Rights Reserved

09/2003

Altivar

®

58 TRX AC Drives

Type H Drive Controllers

Ratings for ATV58 TRX Type H Variable Torque

400/460 Vac, 3-Phase Input with 3-Phase Output

Switching Frequency: ATV58HU18N4–D23N4 at 8 kHz, ATV58HD28N4-D46N4 at 4 kHz, ATV58HD54N4–C33N4X at 2 kHz

▼ Refer to page 127 for a

complete list of catalog

numbers. An “X” in the

catalog number indicates that

the product does not hav e an

internal EMC filter.

■ The ATV58HD28N4 is rated

for 8 kHz operation at 25 hp.

Frame Size

2 ATV58HU18N4ZU 0.75 1 2.1 2.3 57

2 ATV58HU29N4ZU 1.5 2 3.4 3.7 97

2 ATV58HU41N4ZU 2.2 3 4.8 5.3 119

3 ATV58HU54N4XZU 3 4 6.2 6.8 170

3 ATV58HU72N4XZU 4 5 7.6 8.4 209

3 ATV58HU90N4XZU 5.5 7.5 11 12.1 291

4 ATV58HD12N4XZU 7.5 10 14 15.4 352

4 ATV58HD16N4XZU 11 15 21 23.1 472

5 ATV58HD23N4XZU 15 20 27 29.7 584

6 ATV58HD28N4XZU

6 ATV58HD28N4XZU 22 30 40 44 618

6 ATV58HD33N4XZU 30 40 52 57.2 713

6 ATV58HD46N4XZU 37 50 65 71.5 770

7 ATV58HD54N4XZU 45 60 77 84.7 987

7 ATV58HD64N4XZU 55 75 96 105.6 1075

7 ATV58HD79N4XZU 75 100 124 136.4 1439

8 ATV58HC10N4XZU 90 125 156 172 2250

9 ATV58HC13N4XZU 110 150 180 198 2750

9 ATV58HC15N4XZU 132 200 240 264 3300

9 ATV58HC19N4XZU 160 250 302 332 4000

10 ATV58HC23N4XZU 200 300 361 397 5000

10 ATV58HC25N4XZU 220 350 414 455 5500

10 ATV58HC28N4XZU 250 400 477 525 6250

10 ATV58HC31N4XZU 280 450 515 567 7000

10 ATV58HC33N4XZU 315 500 590 649 7875

Drive Controller

Catalog Number

Motor Power

400/460 Vac

▼

kW HP A A W

■

18.5 25 34 37.4 474

Rated

Output Current

Transient

Output Current

Total Dissipated

Power at Rated Load

09/2003

© 2000–2003 Schneider Electric All Rights Reserved

11

Altivar

®

58 TRX AC Drives

Type E Drive Controllers

ATV58 TRX Type E Product Family

ATV58 TRX TYPE E DRIVE CONTROLLERS

The ATV58 TRX family of adjustable-frequency AC drive controllers is used

to control three-phase async hronous motors . The ATV58 TRX T ype E model

contains an ATV58 TRX T ype H driv e controller p ackaged i n a compact , T y pe

1 enclosure. It is for use in mechanic al ro om s , OEM eq uipment, and fac tory

floor applications . Th e f oll owi ng Type E drive controller mod els are a v aila b le:

ATV58NEMAb_w no back.tif

• 1 to 7½ hp (0.75 to 5.5 kW), 400/460 Vac, three-phase input

• ½ to 3 hp (0.37 to 2.2 kW), 200/240 Vac, single-phase input

• 2 to 3 hp (1.5 to 2.2 kW), 200/240 Vac, three-phase input

Each ATV58 TRX Type E drive controller contains:

• A GV2 manual motor starter, ATV58 TRX drive controller, and an output

contactor

• A three-position selector switch wired for “RUN FORWARD”

• A manual speed potentiometer mounted on the front of the enclosure

• Space for two additional 16-mm operators

• Four conduit openings that are closed with plugs

• A transparent plastic door for viewing the status LEDs and a separatelysupplied keypad

All ATV58 TRX communication and I/O options can be used in the Type E

controllers. The Type E drive controllers c an be used on constant or vari able

torque applications. The ratings are shown in the tables below.

200 Vac -10% / 240 Vac +10% at 50/60 Hz ±5%, Single-Phase Input with 3-Phase Output

Rated

Frame

Size

1 ATV58EU09M2ZU 0.37 0.5 2.3 3.1

1 ATV58EU18M2ZU 0.75 1 4.1 5.6

2 ATV58EU29M2ZU 1.5 2 7.8 10.6

3 ATV58EU41M2ZU

200 Vac -10% / 240 Vac +10% at 50/60 Hz ±5%, 3-Phase Input with 3-Phase Output

Frame

Size

2 ATV58EU29M2ZU 1.5 2 7.8 10.6

3 ATV58EU41M2ZU 2.2 3 11 15

400 Vac -10% / 460 Vac +10% at 50/60 Hz ±5%, 3-Phase Input with 3-Phase Output

Frame

Size

2 ATV58EU18N4ZU 0.75 1 2.3 3.1

2 ATV58EU29N4ZU 1.5 2 4.1 5.6

2 ATV58EU41N4ZU 2.2 3 5.8 7.9

3 ATV58EU54N4ZU 3 – 7.8 10.6

3 ATV58EU72N4ZU 4 5 10.5 14.3

3 ATV58EU90N4ZU 5.5 7.5 13 17.7

▲ For dimensions, see page 122; for wiring diagrams, see pages 109 and 110.

▼ Power indicated is for a switching frequency between 0.5 and 4 kHz, and at steady state. For switching

◆ For 60 seconds.

■ A line reactor (3% minimum) must be used with this drive controller.

Drive Controller

▲

Catalog Number

Drive Controller

▲

Catalog Number

Drive Controller

▲

Catalog Number

frequency between 8 and 16 kHz, use the next largest size drive control ler . (F or examp le, f or 2 hp, ord er driv e

controller ATV58EU41M2ZU.) If the duty cycle (t hat is, the drive controller run t i me) does not exceed 60% (36

second maximum for a 60 second cycle), this is not necessary.

Motor Power

kW HP A A

■

2.2 3 11 15

Motor Power

kW HP A A

Motor Power

kW HP A A

▼

Output Current

Rated

▼

Output Current

Rated

▼

Output Current

Transient

Output Current

Transient

Output Current

Transient

Output Current

◆

◆

◆

12

© 2000–2003 Schneider Electric All Rights Reserved

09/2003

Altivar

®

58 TRX AC Drives

Type F Drive Controllers

ATV58 TRX TYPE F DRIVE CONTROLLERS

The ATV58 TRX family of adjustable-frequency AC drive controllers is used

to control three-phase asynchronous motors. ATV58 TRX Type F models

contain an ATV58 TRX Type H drive controller packaged in a compact Type

12 enclosure. They are for use in mech anical rooms, OEM equipment, and

factory floor applications requiring a local load break switch and input line

ATV58NEMAb_w no back.tif

fusing. Th e following models are available:

• 1 to 7.5 hp (0.75 to 5.5 kW), 400/460 Vac, three-phase input

• ½ to 3 hp (0.37 to 2.2 kW), 200/240 Vac, single-phase input

• 2 to 3 hp (1.5 to 2.2 kW), 200/240 Vac, three-phase input

ATV58 TRX Type F Product Family

Each ATV58 TRX Type F drive controller contains:

• A Vario load break switch, input li ne fuses, and an ATV58 TRX drive

controller

• Start Stop push buttons

• A manual speed potentiometer mounted on the front of the enclosure

• Space for one additional 16-mm operator

• Four conduit openings that are closed with plugs

• A transparent plastic door to allow viewing of status LEDs and a

separately supplied keypad

All ATV58 TRX communications and I/O options can be used in the Type F

drive controllers. The Type F drive controllers can be used on constant or

variable torque applications. The ratings are shown in the tables below.

200 Vac -10% / 240 Vac +10% at 50/60 Hz ±5%, Single-Phase Input with 3-Phase Output

Rated

Frame

Size

1 ATV58EU09M2FZU 0.37 0.5 2.3 3.1

1 ATV58EU18M2FZU 0.75 1 4.1 5.6

2 ATV58EU29M2FZU 1.5 2 7.8 10.6

3 ATV58EU41M2FZU

200 Vac -10% / 240 Vac +10% at 50/60 Hz ±5%, 3-Phase Input with 3-Phase Output

Frame

Size

2 ATV58EU29M2FZU 1.5 2 7.8 10.6

3 ATV58EU41M2FZU 2.2 3 11 15

400 Vac -10% / 460 Vac +10% at 50/60 Hz ±5%, 3-Phase Input with 3-Phase Output

Frame

Size

2 ATV58EU18N4FZU 0.75 1 2.3 3.1

2 ATV58EU29N4FZU 1.5 2 4.1 5.6

2 ATV58EU41N4FZU 2.2 3 5.8 7.9

3 ATV58EU54N4FZU 3 – 7.8 10.6

3 ATV58EU72N4FZU 4 5 10.5 14.3

3 ATV58EU90N4FZU 5.5 7.5 13 17.7

▲ For dimensions, see page 122; for wiring diagrams, see pages 111 and 112.

▼ Power indicated is for a switching frequency between 0.5 and 4 kHz, and at steady state. For switching

◆ For 60 seconds.

■ A line reactor (3% minimum) must be used with this drive controller.

Drive Controller

▲

Catalog Number

Drive Controller

▲

Catalog Number

Drive Controller

▲

Catalog Number

frequency between 8 and 1 6 kH z, use t he n e xt l arge st size drive controller. (For example, for 2 hp, order drive

controller A TV58EU41M2F ZU.) If the duty cycle (that is , the drive co ntroller run time) does not e xceed 60% (36

second maximum for a 60 second cycle), this is not necessary.

Motor Pow er

kW HP A A

■

2.2 3 11 15

Motor Pow er

kW HP A A

Motor Pow er

kW HP A A

▼

Output Current

Rated

▼

Output Current

Rated

▼

Output Current

Transient

Output Current

Transient

Output Current

Transient

Output Current

◆

◆

◆

09/2003

© 2000–2003 Schneider Electric All Rights Reserved

13

Altivar

®

58 TRX AC Drives

Type N Drive Controllers

ATV58 TRX Type N Pr odu ct F am il y

ATV58 TRX TYPE N DRIVE CONTROLLERS

The ATV58 TRX family of adjustable-frequency AC drive controllers is used

to control three-phase asynchronous motors .The ATV58 TRX T ype N models

contain an ATV58 TRX Type H drive controller packaged in a Type 4/4x

stainless steel enc losure . The y a re for use in food and b e v er age wa sh-do w n

applications. The Type N drive controller was tested f or co rrosion resis tance

ATV58NEMA4Xb_w no back.tif

per UL-50 and exceeds this standard. The UL-50 corrosion test was

conducted using ASTM B117-1985.

The following models are available:

• 1 to 10 hp (0.75 to 7.5 kW), 400/460 Vac, 3-phase input.

• ½ to 3 hp (0.37 to 2.2 kW), 208/230 Vac, single-phase input.

• ½ to 5 hp (0.37 to 4.0 kW), 208/230 Vac, 3-phase input.

Each Type N driv e co ntroll er is furnished with f o ur cond uit open ings th at are

closed with Type 4/4x plugs. The drive is available with a keypad mounted

behind a transparen t boot to allo w view ing and oper ation of the k eyp ad while

maintaining the Type 4/4x rating. If a keypad is not required, a closing plate

can be installed to maintain the Type 4/4x rating. All ATV58 TRX

communication and I/O options can be used in the Type N controllers. The

Type N drive controllers can be used on constant or variable torque

applications. The ratings are shown in the tables below.

208 to 230 Vac, Single-Phase Input with 3-Phase Output

Rated Output

Frame

Size

1 ATV58NU09M2• 0.37 0.5 2.3 3.1

1 ATV58NU18M2• 0.75 1 4.1 5.6

2 ATV58NU29M2• 1.5 2 7.8 10.6

2ATV58NU41M2•■2.2 3 11 15

208 to 230 Vac, 3-Phase Input with 3-Phase Output

Frame

Size

2 ATV58NU29M2• 1.5 2 7.8 10.6

2ATV58NU41M2• 2.2311 15

3 ATV58NU54M2• 3 – 13.7 18.6

3 ATV58NU72M2• 4 5 18.2 24.7

400 to 460 Vac, 3-Phase Input with 3-Phase Output

Frame

Size

2 ATV58NU18N4• 0.75 1 2.3 3.1

2 ATV58NU29N4• 1.5 2 4.1 5.6

2 ATV58NU41N4• 2.2 3 5.8 7.9

3 ATV58NU54N4• 3 – 7.8 10.6

3 ATV58NU72N4• 4 5 10.5 14.3

3 ATV58NU90N4• 5.5 7.5 13 17.7

4 ATV58ND12N4• 7.5 10 17.6 24

▲ Complete the catalog number by entering K U f or ATV58 Type N drive controllers with factory-installed keypad,

❋ Power indicated is for a switching frequency between 0.5 and 4 kHz, and at steady state. For switching

◆ For 60 seconds.

■ When these drive controllers are used with a single-phase input, a line reactor (3% minimum) must be used.

Drive Controller

Catalog Number

Drive Controller

Catalog Number

Drive Controller

Catalog Number

or ZU for controllers without a fa ctory-installed keypad. F or dimensions, see page 122 ; for wiring diagram s, see

page 108.

frequency between 8 and 16 kHz, derate the drive controller by one horsepower size (for example, for ½ hp,

order drive controller ATV58NU18M2). If the duty cycle (i.e., drive controller run time) does not exceed 60%

(36 second maximum for a 60 second cycle), derating is not required for operation above 8 kHz.

Motor Power

▲

kW HP A A

Motor Power

▲

kW HP A A

Motor Power

▲

kW HP A A

❋

Current

Rated Output

❋

Current

Rated

❋

Output Current

Transient Output

◆

Current

Transient Output

◆

Current

Transient Output

◆

Current

14

© 2000–2003 Schneider Electric All Rights Reserved

09/2003

ATV58 Type FVC Product Family

The ATV58 Type FVC series of adjustable

frequency AC drive controllers is a

Transparent ReadyTM product line

providing extended functionality. The

A TV58 T ype FVC series includes an analog

output, expanded firmware capabilities,

and a horsepower range up to 75 hp. As a

Transparent Ready product equipped with

an Ethernet communication card, the

ATV58 Type FVC product line can be

configured, controlled, monitored, and

diagnosed ov er an Ethernet network with a

standard Web br owser. No sp ecial software

or drivers are needed.

Altivar

®

58 TRX AC Drives

Type FVC Drive Controllers

ATV58 TYPE FVC DRIVE CONTROLLERS

Features

The ATV58 Type FVC family of adjusta ble freque ncy A C drive con trollers are

used for controlling three-phase asynchronous motors ranging from

ATV 58F ami l y.ti f

1 to 75 hp (constant torque), 400/460 Vac, 3-phase input.

The ATV58 TRX operator interfaces, configuration tools, I/O extension

options, and communication options are shared throughout the product

range, except the general purpose option card which is not for use with the

ATV58 Type FVC controllers.

The ATV58 Type FVC driv e con troller uses the l atest in A C driv e te chnol og y.

Intelligent Power Modul es ( IPMs ) are use d on th e en tire prod uct family. The

IPMs contain insulated gate bipolar transistors (IGBTs) to produce a pulse

width modulated (PWM) output waveform to the motor. IPMs minimize part

count and improve reliability.

The ATV58 Type FVC drive controller integrates fourth-generation

sensorless flux vector control for 3-phase asynchronous squirrel cage AC

motors. This allows the drive controller to deliver needed torque with

excellent dynamic response over a wide speed range.

ATV58 Type FVC drive controllers are capable of:

• Producing transi ent torque of 2 00% (typical value ±10%) of nominal m otor

torque for 2 seconds

• Producing transi ent torque of 1 70% (typical value ±10%) of nominal m otor

torque for 60 seconds

• Producing 160% of rated motor torque at 0 Hz with encoder feedback

(closed loop) or at 0 .5 Hz w it hou t ta ch om ete r or enc od er feedback (open

loop)

• Regulating rated motor speed within 1% without tachometer or encoder

feedback or within ±0.01% with an encoder feedback circuit

09/2003

Every Type FVC drive c ontroller h as selectab le s w itching freque ncy that c an

be adjusted to match the appli cation nee ds. The swi tching freq uency can be

programmed to f ol d-bac k in the e vent of ex cess iv e h eat. Th e d rive contro ller

reverts back to the programmed choice upon reaching the normal thermal

state.

In addition, each 25 hp to 75 hp 40 0/46 0 Vac dri ve controller include s a li ne

reactor integrated into the heatsink plenum. This line reactor improves

product reliability and reduces input currents to the drive controller.

Every ATV58 Type FVC drive controller is supplied with an integrated EMC

filter. This filter reduces conducted and radiated emissions, and complies

with IEC product standards IEC 61800-3 and EN 61800-3 for drive

controllers. Compli ance wi th the se st and ards mee ts the req uirements of th e

European directive on EMC.

© 2000–2003 Schneider Electric All Rights Reserved

15

Altivar

®

58 TRX AC Drives

Type FVC Drive Controllers

Applications

The ATV58 Type FVC product is recommended in place of the ATV58 TRX Type H drive controllers in

the following applications:

• Applications that require encoder feedback and the installation of an I/O extension card or a

communication card

• Applications that require PID regulation of a process loop

• Applications requiring improved open loop torque performance at low speed

• Applications requiring high torque performance at low speed with encoder feedback

• Applications requiring holding torque at zero speed

The A TV58 Type FVC product has th e follo wing hardw are not supplied with the ATV58 TRX Type H base

product:

• Differential analog input, +/- 10 Vdc (+10 Vdc supplied from drive)

• RS422 encoder input, 5 V (max. frequency input: 200 kHz)

• Encoder power supply (5 V, 200 mA)

• A keypad is supplied with the drive controller

The A TV58 Type FVC product has the follow ing software f eatures not supplied with the A TV58 TRX Type

H base product:

• Faster motor control algorithm in open loop and closed loop

• PID regulator with trim input

• Motor pre-fluxing options; continuous or by logic input

• Ability to customize the shape of the acceleration and deceleration ramps. Selectable acceleration

and deceleration ram p inc rem ents are 0.1seconds or 0.01 seconds.

• Ability to use +/- speed trim around a speed reference input

• PI and IP mode of operation f or matching init ial response tim e vs.ability to sup press speed o versh oot

• Variable torque macro has been removed. No variable torque ratings.

The ATV58 Type FVC drive controller is rated for Constant Torque (CT) applications. Constant To rque

applications usually require motor-rated torque through the entire speed range, high transient torque

capability, and precise speed regulation.

16

© 2000–2003 Schneider Electric All Rights Reserved

09/2003

Altivar

Type FVC Drive Controllers

Ratings

Ratings for ATV58 Type FVC Constant Torque

400 /460 Vac, 3-Phase Input with 3-Phase Output

Switching Frequency: ATV58FHU18N4–D46N4 at 4 kHz, ATV58FHD54N4–D79N4 at 2 kHz

®

58 TRX AC Drives

Frame Size

2 ATV58FHU18N4KU 0.75 1 2.3 3.1 57

2 ATV58FHU29N4KU 1.5 2 4.1 5.6 97

2 ATV58FHU41N4KU 2.2 3 5.8 7.9 120

3 ATV58FHU54N4KU 3 4 7.8 10.6 170

3 ATV58FHU72N4KU 4 5 10.5 14.3 210

3 ATV58FHU90N4KU 5.5 7.5 13 17.7 295

4 ATV58FHD12N4KU 7.5 10 17.6 23.9 360

4 ATV58FHD16N4KU 11 15 24.2 32.9 480

5 ATV58FHD23N4KU 15 20 33 44.9 590

6 ATV58FHD28N4KU 18.5 25 40.7 55.4 421

6 ATV58FHD33N4KU 22 30 48.4 65.8 491

6 ATV58FHD46N4KU 30 40 66 89.8 625

7 ATV58FHD54N4KU 37 50 79.2 107.7 677

7 ATV58FHD64N4KU 45 60 93.5 127.2 837

7 ATV58FHD79N4KU 55 75 115.5 157.1 1090

Drive Controller

Catalog Number

Motor Power

400/460 Vac

kW HP A A W

Rated

Output Current

Transient

Output Current

Total Dissipated

Power at Rated Load

09/2003

© 2000–2003 Schneider Electric All Rights Reserved

17

Altivar

®

58 TRX AC Drives

Terminal Locations for Type H and Type FVC Drives

TERMINAL LOCATIONS FOR ATV58 TRX TYPE H AND TYPE FVC DRIVES

NOTE: These illustrations show

the locations of the majo r terminal

groups.

FrameSize1.eps

FrameSize23.eps

FrameSize45.eps

Control Terminals

Frame Size 1 Frame Sizes 2 and 3

Ground Terminal

Power Terminals

FrameSize6.eps

Ground Terminal

Control Terminals

Power Terminals

Control Terminals

Control Terminals

Ground Terminal

Frame Sizes 4 and 5

Power Terminals

Control Terminals

FrameSize7.eps

Frame Size 6

18

© 2000–2003 Schneider Electric All Rights Reserved

Power Terminals

Ground Terminal

Power Terminals

Ground Terminal

Frame Size 7

09/2003

Terminal Locations for Type H and Type FVC Drives

TERMINAL LOCATIONS FOR ATV58 TRX TYPE H DRIVES

Altivar

®

58 TRX AC Drives

Dwg1Conn.eps

DANGER

Control Terminals

Ground Terminals

T/L3

S/L2

R/L1

PB PA PC

P0

R/L1

S/L2

T/L3 U/T1

PA

V/T2 W/T3

Power Terminals

PA PO

Ground Terminals

Frame Size 8 Frame Size 9

PB U/T1 V/T2 W/T3

PC

Dwg2Conn.eps

Control Terminals

Power Terminals

09/2003

R/L1 S/L2 T/L3

PC

PB PO

Power Terminals

Frame Size 10

Ground Terminals

PA

PA

Dwg3Conn.eps

Control Terminals

U/T1

V/T2

W/T3

© 2000–2003 Schneider Electric All Rights Reserved

19

Altivar

®

58 TRX AC Drives

Description of Power Terminals

ATV58*U09M2 - U18M2

L1 L2 + – U V W

ATV58*U29M2 - D12M2

ATV58*U18N4 - D23N4

L1 L2 L3 PA PB U V W

ATV58*D16M2 - D46M2

ATV58*U28N4 - D79N4

L1 L2 L3 PA PB U V W

ATV58HC10N4X

L1 L2 L3

ATV58HC13N4X–C19N4X

L1

L2 L3

PA

(+)

PC

(–)

PA

+

U

–

PC

PA

(–)

(+)

VW

UV

W

PowrTermsNew.eps

DESCRIPTION OF POWER TERMINALS

As shown in the drawing to the left, the ATV58 TRX power term inal

arrangements differ from model to model. The locations of the power

terminals are shown on pages 18–19. The following tables describe the

characteristics of the power terminals and list maximum wire sizes and

tightening torques for the various ATV58 TRX models.

Function of Power Terminals

Terminal Function Found On

Ground terminal (2 provided on some mod els). All A T V58 TRX models.

L1

L2

L3 All models except U09M2• and U18M2•

+

–

PA

PB

U

V

W

K13

K14

Input power.

Connection for DB module. Models U09M2• and U18M2•.

Connection for DB resistor.

Output connections to motor. All models.

N.O. auxiliary contact on controller’s output

contactor. Maximum rating is 10 A at 600 Vac.

All models.

All models except U09M2•, U18M2•, and

C10N4–C33N4.

ATV58EU09M2ZU – U90N4FZ4.

ATV58HC23N4X–C33N4X

L2 L3

L1

PC

(–)

ATV58Exxxxxxx

1

J2B

4

J2A

L3

ATV58EU09M2ZU and ATV58EU18M2ZU

(single-phase input only)

1

J2B

*

J2A

L3

* L3 is not used

PA

PA

UV

(+)

2345678

V W K13K14 PA

U

32

1

L2 L1

2345678

V W K13K14 +

U

32

1

L2 L1

PB

W

–

ATV58 TRX Power Terminals

Power Terminal Wire Size and Torque

Type FVC, Type H, and Type N Models

U09M2, U18M2 14 (1.5) 5.0 (0.55)

U29M2, U41M2, U18N4, U29N4, U41N4 8 (6) 7.5 (0.85)

U54M2, U72M2, U54N4, U72N4, U90N4 8 (6) 7.5 (0.85)

U90M2, D12M2, D12N4, D16N4, D23N4 6 (10) 20 (2.25)

D16M2, D23M2, D28N4, D33N4, D46N4 2/0 (35) 88 (10)

D28M2, D33M2, D46M2, D54N4, D64N4, D79N4 4/0 (70) 170 (19)

C10N4X–C19N4X 500 MCM 375 (42)

C23N4X–C33N4X Supply crimp style lugs to fit selected wire size.

Maximum Wire Size

AWG (mm2)

Type E and Type F Models

All models 10 (4) 5.0 (0.55)

◆ 75 °C copper.

◆

Torque

lb-in (N•m)

CONDUIT CONNECTIONS FOR TYPE E AND TYPE F

DRIVE CONTROLLERS

The ATV58 TRX Type E and Type F drive controllers are furnished with four

conduit openings at the bottom of the device. The conduit openings are

closed with Type 1 rated plugs. The holes are intended for input and output

power wiring, control wiring, and connection to e xternal components su ch as

DB resistors or line reactors . To m aintain the enclosure rating, do not remo ve

the plugs from unused conduit holes. Conduit holes are pre-drilled for the

conduit listed in the table belo w.

Type E and Type F Models Conduit Hole Size C onduit Size Hub Catalog No.

ATV58EU09M2ZU

ATV58EU18M2ZU

All other ATV58 Type E and Type F

Drive Controllers

7/8 inch 1/2 inch 25211-16102

1 and 3/32 inch 3/4 inch 25211-24102

20

© 2000–2003 Schneider Electric All Rights Reserved

Flexible conduit must be used up to the drive controller to facilitate removal

of the terminal block cover. A minimum of 2 feet is recommended.

09/2003

R2A

R2C

AO1

COM

R1A

R1B

R1C

AI1

+10

ATV58 TRX Control Terminals

Altivar

®

58 TRX AC Drives

Description of Control Terminals

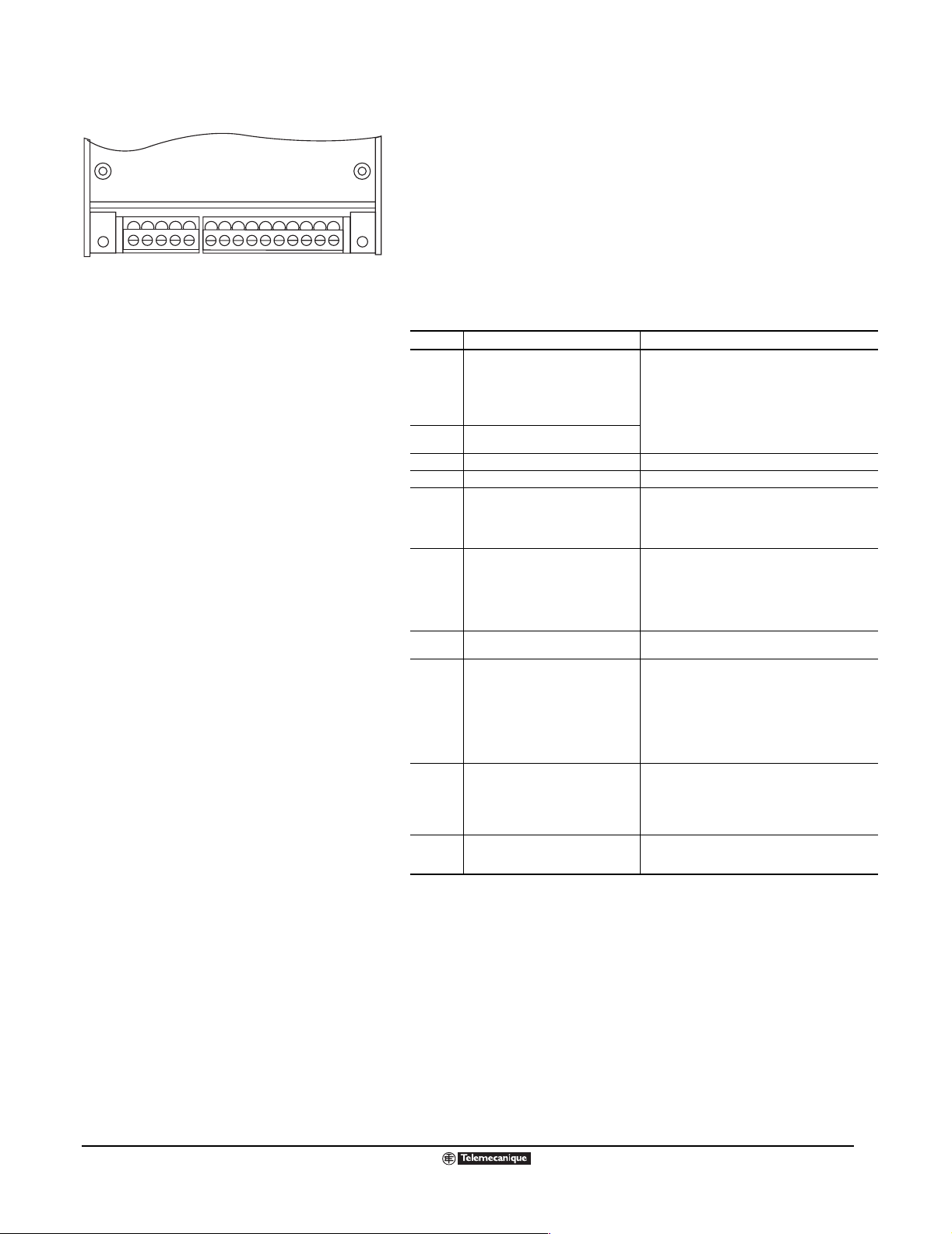

DESCRIPTION OF CONTROL TERMINALS

All ATV58 TRX Type E, Type F, Type H, and Type N models have the same

control terminals, sho wn in th e figu re to the left. The locations of the control

Terminal.eps

LI1

LI2

AI2

LI3

LI4

+24

S

termin als varies from model to model as shown on pa ges 18 and 19.

The control terminal strip contains two pu ll-apart terminal bloc ks, on e f or the

relay outpu ts a nd o ne for the low- level inputs and outp uts. The S terminal is

used for the s hield con nection. Max imum wi re size for a ll control t erminals is

14 AWG (1.5 mm

2

). Tightening torque is 3.5 lb-in (0.4 N•m). The

characteristics of the control terminals are shown in the table below.

Terminal Function Characteristics

R1A to R1C is a N.O. contact. When the

R1A

R1B

R1C

R2A

R2C

S Shield connection

COM Common for logic and analog inputs

AO1

AI1

+10

AI2

LI1

LI2

LI3

LI4

+24 Power supply for logic inputs

drive controller is powered with no fault,

the contact is closed.

R1B to R1C is a N.C. contact. When the

drive controller is powered with no fault,

the contact is open.

N.O. programmable relay R2

Analog current output

X–Y mA analog output, with X and Y

programmable from 0–20 mA.

Factory setting: 0–20 mA.

Analog input 1 (voltage)

Used for speed reference input

Supply for reference potentiometer

(1 to 10 kΩ)

Programmable analog input

Used for speed reference input or

feedback, depending on configuration.

Programmable logic inputs

Function depends on configuration.

Min.: 10 mA, 24 Vdc

Max. inductive load: 1.5 A for 250 Vac and 30 Vdc

Max. resistive load: 5 A for 250 Vac or 30 Vdc

Maximum load impedance = 500 Ω

Resolution: 0.04 mA (9 bits)

Linearity: +/- 0.1 mA

Accuracy: +/- 0.2 mA

The analog output is updated every 2 mS, maximum.

0 to 10 Vdc, Impedance = 30 kΩ

Frequency resolution analog reference:

(high speed/1024) Hz (10 bit)

Accuracy ±1%, linearity ±0.5% of the maximum output

frequency

Sampling time: 5 ms

Optically isolated

10 V ± 1%, protected against short circuits and overloads

10 mA maximum

X to Y mA, with X and Y being programmable from

0 to 20 mA (factory setting: 0 to 20 mA)

Impedance = 100 Ω

Frequency resolution analog reference:

(high speed/1024) Hz (10 bit)

Accuracy ±1%, linearity ±0.5% of the maximum output

frequency

Sampling time: 5 ms

Optically isolated

Supplied by +24 Vdc

State 0 if < 5 V, state 1 if > 11 V

Vmax = 30 V

Impedance = 3.5 kΩ

Sampling time: 5 ms

Optically isolated

+24 V protected against short circuits and overloads

Minimum 20 V, maximum 30 V

200 mA maximum

09/2003

© 2000–2003 Schneider Electric All Rights Reserved

21

Altivar

®

58 TRX AC Drives

Description of Type FVC Control Terminals

DESCRIPTION OF ATV58 TYPE FVC CONTROL TERMINALS

The A TV58 Type FVC control terminals are shown belo w . The location o f the control terminal strip varies

from model to model. See page 18.

The control terminal strip contains f our pull-apa rt terminal blocks , one for th e relay outputs and three f or

the low-level inputs and outputs. The S terminals are used to connect shield wires of multi-conductor

control cables f o r the low l ev el i nputs , outputs , and enco der . Maximum wire siz e f or all cont rol terminals

is 16 AWG (1.5 mm

terminals are shown in the table below.

2

). Tightening torque is 2.2 lb-in (0.25 N•m). The characteristics of the control

LI 1

LI 2

R1A

R1B

R1C

R2A

R2C

COM

AI 1A

AI1B

+ 10

AI 2

S S

Shielding connection screw for

analog I/O and logic inputs

A01

LI 3

LI 4

+ 24

AA-BB-5 V

0 V

Shielding connection

screw for encoder

cable

Function of Termi nals

Terminals Function Electrical Characte ri sti cs

R1A

R1B

R1C

R2A

R2C

COM Common for logic and

AI1A

AI1B

+ 10 Supply for reference

AI2 Programmable analog input • Input 0-20 MA, programmable for X-Y mA by configuring X and Y (0 to 20).

AO1 Programmable analog

LI1

LI2

LI3

LI4

+ 24 Power supply for logic inputs • Voltage + 24 V protected against short circuits and overload, minimum 18 V,

A

AB

B-

+ 5 V

0 V

R1A to R1C is a N.O.

contact. When the drive

controller is powered w ith no

fault, the contact is closed.

R1B to R1C is a N.C.

contact. When the drive

controller is powered w ith no

fault, the contact is open.

N.O. contact of R2

programmable relay

analog inputs

Differential analog input • ± 10V, impedance 40 kΩ in differential mode, 20 kΩ in common mode.

potentiometer (1 to 10 kΩ)

output

Programmable logic inputs

function depends on

configuration

Encoder inputs • For Incremental optical encoder with RS422-compatible differential outputs.

Power supply for encoder • Voltage 5 V (maximum 5.5 V) protected against short circuits and overloads.

• Minimum switching capacity: 10mA for 24 Vdc.

• Maximum switching capacity on inductive load: 1.5 A for 250 V Vac (cos ϕ 0.4) and

30 Vdc (L/R 7 ms).

• Maximum response time: 20 ms.

• Maximum permissible voltage ± 30 V.

• Resolution 11 bits + sign.

• Accuracy ± 0.5% of maximum value.

• Linearity ± 0.2% of maximum value.

• Sampling time 2 ms maximum.

• Voltage + 10 V (-0 + 10%) 10 mA maximum protected against short circuits and

overloads.

• Impedance 100 Ω.

• Maximum permissible current 50 mA.

• Resolution 0.02 mA.

• Accuracy ± 1% of maximum value.

• Linearity ± 5% of maximum value.

• Sampling time 2 ms maximum.

• Output 0-20 MA, programmable for X-Y mA by configuring X and Y (0 to 20).

• Load impedance 500 Ω maximum.

• Resolution 0.02 mA.

• Accuracy ± 1% of maximum value.

• Linearity ± 5% of maximum value.

• Sampling time 2 ms maximum.

• Impedance 3.5 kΩ.

• Power supply + 24 V (maximum 30 V).

• State 0 if < 5 V, state 1 if > 11V.

• Sampling time 2 ms maximum.

maximum 30 V.

• Maximum current 120 mA.

• Impedance 330 Ω.

• Maximum 5000 pulses/rev., minimum 100 pulses/rev.

• Maximum frequency 200 kHZ at high speed (HSP).

• Maximum current 200 mA.

arrange of terms copy.eps

22

© 2000–2003 Schneider Electric All Rights Reserved

09/2003

KeypadFront.eps

LOC PROG

ESC

Top row

Four 7-segment LCDs

16-character LCD display

(shows messages in plain

language)

Thumbscrew to secure

unit to the drive controller

ENT

RUN

STOP

RESET

FWD

REV

The Front of the Keypad Display Showing

the LCDs and Command Keys

Command keys

Altivar

®

58 TRX AC Drives

Keypad Display

KEYPAD DISPLAY

The backlit keypad display is shown to the left.

• The four 7-s egmen t LCDs display codes , par amet er v alu es , and run-tim e

data. They are readable from a distance of three feet.

• The 16-character LCD display defines in plain language the name of the

parameter being view ed, adju sted, as signed, o r configu red. Thi s line a lso

describes fault messages.

• The top row provides the following status information:

When flashing, this indicates the commanded direction of

motor rotation. When steady, it indicates the actual direction of

motor rotation.

LOC

PROG

The functions of the keys are explained below:

This indicates when the drive controller is in keypad

command mode.

This appears when the access co ntrol s witch (located on th e rear

of the unit, see the figure t o the low er left) i s in partial loc k position

or total unloc k position when “PROG ” is flashing, a parameter was

modified but not yet saved.

Press to move within menus or among the parameters, or to

adjust a displayed value up or down.

ESC

ENT

Press to return to the previous menu, or abandon an adjustment

in progress and return to the original value.

Press to select a menu, or validate and save a choice

or adjustment.

If command by the keypad is selected, the following keys are active:

FWD

REV

RUN

STOP

RESET

Press to change direction of motor rotation.

Press to start the motor.

Press to stop the motor or reset a fault. The STOP key can also

stop the drive controller in terminal block command mode.

09/2003

© 2000–2003 Schneider Electric All Rights Reserved

23

t

ps

OGUE

E

U

ON

al

p

CRO-CO

ON

SC

o

ge

ge

D

d

d

n

Altivar

®

58 TRX AC Drives

Keypad Display

KeypadRear.eps

Connector:

- for direct connection to drive controller

- for remote mounting, the keypad can be

connected using a cable provided in kit

VW3A58103

Locked Position: Display only; adjustment and

configuration parameters are not accessible

Partial Lock Position: Adjustment parameters accessible

Total Unlock Position: Adjustment and configuration

parameters accessible

The Back of the Keypad Display Showing

the Access Control Switch and Connector

Subsequen

Power-U

Power-U

DIAL

DISPLAYOF

MA

IDENTIFICATI

Initi

NFIGURATI

Power, volta

Choice

f langua

Configuration File Storage

The keypad can store four configuration files. This is useful for configuring

multiple drives and verifying configurations.

Access Control

On the back of the keypad display is a three-position, access control switch

and a connector (see th e figure to the left). Ac cess ma y also be co ntrolled b y

using an access code.

The switch setting can deter unwanted tampering with adjustment and/or

configuration pa rame ters . PR OG is d isplayed in th e uppe r right-han d corner

of the display when the switch is in partial lock position or total unlock

position.

The follo wing section des cribes the oper ations allow ed for th e various acc ess

control switch settings.

Accessing Menus

When a keypad display is the user interface, access is controlled by the

three-position switch on the back of the keypad.

• With the switch in the locked position, the user can:

— Select the dialog language

— Display the macro-configuration

— Identify the ATV58 TRX drive controlle r

— Display the state of the controller, the electrical values, and the fault

register

• With the switch in the partially locked position, the user can:

— Perform the operations possible when the switch is in locked position

— Modify settings

MenuFlow.eps

• With the switch in the total unlock position, the user can:

— Perform the oper ations po ssib le whe n the s witch i s in loc ked or partial

locked positi ons

— Change the macro-configuration

— Modify the motor power

— Modify all configuration parameters

— Enable control via the keypad display buttons

— Store, load, or protect the parameter files

When a PC is the user interface, no access restrictions exist unless an

access code is c on fig ured (in which case , the access code m u st be entered

DISPLAY MOD

MEN

E

isplaye

uring operatio

to perform any actions.)

Menu Structure

24

© 2000–2003 Schneider Electric All Rights Reserved

09/2003

POWERSUITE OPTION

Altivar

®

58 TRX AC Drives

PowerSuite™ Software Option and Magelis® Terminal

PowerSuite software is a Windows®-based program providing an intuitive, graphical user interface for

the Altivar 11, Altiv ar 28, and Alt ivar 58 TRX driv e controllers , and Altistart

®

48 softstart controllers. The

software is designed to run on:

®

• Any PC using the Microsoft

Windows 95, Windows 98, Windows NT®, or Windows XP® operating

system

PowersuiteScreen150.eps

®

Jornada® 520 or 540 series Pocket PC (PPC) using the Windows CE V3.0 operating system

•HP

®

• HP Jornada 560 series PPC or Compaq

iP A Q™ 3800 and 39 00 series PPC, usi ng the Windows CE

V3.0 2002 operating system. PowerSuite V1.5 or later is needed for iPAQ PPCs.

The PowerSuite commissioning software allows you to:

• Create, modify, and store controller configurations

• Transfer data to and from the controller

• Print a hard copy of the controller configuration for reference

In addition, for ATV28, ATV58, and ATS48 controllers:

• Operate the controller to verify proper commissioning

• Display and view run time data

• Display and view faults and fault history

When using the PC software, no access restrictions exist unless an access code has been configured.

MAGELIS TERMINAL

The Magelis terminal offers a unique solution for upgrading the user interface to one drive or multiple

drives. The Mag elis terminal can be used to conne ct up to 8 drive controllers via a Modbus RS-485

multi-drop link. The Magelis terminal can be used with ATV28 and ATV58 TRX drive controllers. The

display is 240 x 64 pixel monochrome matrix backlit display.

The Magelis terminal has a factory loaded HMI application.This is easily modified with the XBT-L1003

software package to customize and configure the display. The terminal can be used to monitor, make

adjustments to , and diagnose th e drive controller . Driv e status, opera ting parameters , and I/O status can

be viewed.

09/2003

The terminal requires a 24 Vdc power supply. A cable, (XBTZ908) is included for connection to a

TSXSCA62 tap. The ATV58 TRX drive can be connected to the tap with the RS-485 Connection Kit

(VW3A58306U) cable.

© 2000–2003 Schneider Electric All Rights Reserved

25

Altivar

®

58 TRX AC Drives

Summary of User Interface Options and I/O Extension Cards

SUMMARY OF USER INTERFACE OPTIONS

The following table lists the various user interface options and provides a catalog number for ordering.

User Interface Option Description Catalog Number

Keypad Display This plug-in terminal is inserted into a slot on the front panel of the ATV58 TRX controller. VW3A58101U

Kit for Remote Location of

Keypad Display

PowerSuite Software PowerSuite commissioning software on CD VW3A8104

PC Connection Kit

PPC Connection Kit

RS-485 Connection Kit

Magelis Terminal This option is used with RS-485 connection kit. A cable, XBT2908 is included in the kit. XBTHM017010A8

This kit may be used to locate the keypad display remotely (for example, on the door of the

enclosure). The kit includes a 3-meter (9.8 foot) cable with connectors; a translucent protective

cover for the keypad; and seals and screws for IP65 mounting on an enclosure door.

Includes the following to connect a PC to an ATV11, ATV28, ATV58, or AT S48 controller:

• 1 m cable with RJ45 connectors

• RS-232 to RS-485 adapter with RJ45 and DB9 female connectors

• RJ45 to DB9 adapter for use with an ATV58 controller

• Cable adapter for use with an ATV11 controller, VW3A11301

Includes the follo wing to co nnect a Jornada or i PAQ PPC to a n ATV11, ATV 28, ATV58, or ATS48

controller:

• 1/2 m cable with RJ45 connectors

• RS-232 to RS-485 adapter with RJ45 and DB9 female connectors

• RJ45 to DB9 adapter for use with an ATV58 controller

• Cable adapter for use with an ATV11 controller, VW3A11301

This kit allows RS-485 multidrop serial link connection to PLCs, man-machine terminals. It is

connected in place of the keypad display, and therefore prevents the use of the keypad display

at the same time that the ATV58 TRX controller is connected to PLCs . The kit includes a 3-meter

(9.8 foot) cable with one male 9-pin SUB-D connector and one male 15-pin SUB-D connector;

and a manual.

VW3A58103

VW3A8106

VW3A8111

VW3A58306U

I/O Extension Cards

I/O EXTENSION CARDS

Overview of I/O Extension Cards

The ATV58 TRX controller can be specially adapted for certain applications by installing an I/O

IO_cards.tif

extension card. One I/O extens io n ca rd ca n be m oun ted into the ATV58 TRX drive controller. Space is

already provided in the controller for the c ard; no retrofitt ing or additio nal panel spa ce is require d. Three

models are available:

• I/O Extension Card with Analog Input (VW3A58201 U).

• I/O Extension Card with Encoder Inputs (VW3A58202U).

• Pump Switching Option Card (VW3A58210U).

If these I/O extension cards do not meet your needs, Schneider Electric can design and supply

customer-specific I/O extension cards, incorporating both hardware functions (I/O) and software

functions.

A 115 Vac logic input module (VW3A58275U) is available for applications requiring 115 Vac control

circuits.

The following sections describe the I/O options in greater detail.

26

© 2000–2003 Schneider Electric All Rights Reserved

09/2003

COM

AI 3A

AI 3B

+ 10

- 10AOLI 5

LI 6

+ 24

Terminals for the I/O Extension Card

with Analog Inputs

LO

LO+

Altivar

®

58 TRX AC Drives

I/O Extension Cards

I/O Extension Card with Analog Inputs (VW3A58201U)

This model inclu des tw o 24 Vd c logic inputs , one 24 Vdc o pen collec tor logic

output, one 0 to 20 mA X-Y co nfigur ab l e analo g outp ut, and one bi polar ±1 0

V ac ana log input. The analog i npu t m ay be used for speed correction w ith a

AnalogIOTerms.eps

tachogenerator, f or f eed bac k of the PI fun ction, f o r proce ssing of PT C mo tor

protection probes, or for summing the frequency reference.

The figure to the left sho ws the location of the terminals for this I/O ca rd. The

following tables describe the terminal functions and characteristics. See

page 50 for a summary of configurable I/O functions.

Functions and Characteristics of Terminals

Terminal Function Characteristics

COM Common for analog inputs and outputs 0 V

AI3A Differential analog input

AI3B Differential analog input

+10 Supply for analog inputs + 10 V, Is = 10 mA maximum

-10 Supply for analog inputs - 10 V, Is = 10 mA maximum

AO Analog output

LI5

LI6

+24 Supply for logic inputs +24 V, Is = 200 mA maximum

LO Logic output Open collector output

LO+ Supply for logic output +24 V supply, Is = 20 mA maximum

◆ The 200 mA is the sum of the current supplied by the +24 on the control board and

the +24 on the I/O extension card.

Logic inputs

Specifications

Protected against short circuits and overloads

Available internal supplies

Logic Inputs LI

Logic Output LO

Analog Output AO

Analog Input AI

◆ The 200 mA is the sum of the current supplied by the +24 on the control board and

the +24 on the I/O extension card.

1 output +10 V ± 1%, Is = 10 mA maximum

1 output -10 V ±1%, Is = 10 mA maximum

1 output +24 V (20 V min., 30 V max.), Is = 200 mA maximum

2 reassignable logic inputs. Impedance = 3.5 kΩ. Compatible with level 1 PLCs

according to IEC 65A-68. Maximum shielded cable length: 330 ft (100 m).

Supply: +24 Vac (11 V min., 30 V max.)

State 0 if < 5 V, state 1 if > 11 V.

The logic inputs are sampled every 5 ms, maximum.

1 reassignable open collec tor logic output , compati ble wi th le vel 1 P LCs accordi ng to

IEC 65A-68.

Supply: +24 V (12 V min., 30 V max.),

maximum current = 20 mA with internal source or 200 mA with external source.

The logic output is updated every 5 ms, maximum.

1 reassignable 0 - 20 mA analog output, (x - y configurable).

Maximum load impedance = 500 Ω.

Resolution: 0.04 mA (9 bits)

Linearity: ± 0.1 mA

Accuracy: ± 0.2 mA

The analog output is updated every 5 ms, maximum.

1 reassignable 0 ± 10 V bipolar differential input.

Impedance = 30 kΩ. Adjustable gain.

Maximum allowable voltage: ± 30 V

Freq. reference resolution: 0.1 Hz for 100 Hz (0.1% of max. freq.), 10 bits plus sign.

Accuracy: ± 0.5%

Linearity: ± 0.2% of the maximum output frequency

The analog input is sampled every 5 ms, maximum.

Maximum length of shielded cable: 66 ft (20 m)

If configured for thermal sensors, use 750 Ω maximum at 20 °C (68 °F)

(three 250 Ω sensors in series).

± 10 V, impedance = 30 kΩ

0 - 20 mA, (x - y configurable)

Load impedance = 500 Ω maximum

2 logic inputs

Impedance = 3.5 kΩ

Supplied by +24 V

◆

◆

09/2003

© 2000–2003 Schneider Electric All Rights Reserved

27

Altivar

®

58 TRX AC Drives

I/O Extension Cards

COMAA –BB –AOLI 5

Terminals for the I/O Extension Card

with Encoder Inputs

LI 6

+ 24

LO

LO+

I/O Extension Card with Encoder Inputs (VW3A58202U)

This card includes two 24 Vdc logic inputs, one 24 Vdc open collector logic