Schneider Electric ACRC501, ACRC500, ACRC502 User Manual

Operation and Maintenance Manual

InRow® Chilled Water Cooling Units

InRow® RC

ACRC500, ACRC501, ACRC502

990-3237B-001

Publication Date: November 2014

Schneider Electric IT Corporation Legal Disclaimer

The information presented in this manual is not warranted by the Schneider Electric IT Corporation to be

authoritative, error free, or complete. This publication is not meant to be a substitute for a detailed operational

and site specific development plan. Therefore, Schneider Electric IT Corporation assumes no liability for

damages, violations of codes, improper installation, system failures, or any other problems that could arise

based on the use of this Publication.

The information contained in this Publication is provided as is and has been prepared solely for the purpose of

evaluating data center design and construction. This Publication has been compiled in good faith by Schneider

Electric IT Corporation. However, no representation is made or warranty given, either express or implied, as to

the completeness or accuracy of the information this Publication contains.

IN NO EVENT SHALL SCHNEIDER ELECTRIC IT CORPORATION, OR ANY PARENT, AFFILIATE OR

SUBSIDIARY COMPANY OF SCHNEIDER ELECTRIC IT CORPORATION OR THEIR RESPECTIVE

OFFICERS, DIRECTORS, OR EMPLOYEES BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL,

PUNITIVE, SPECIAL, OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR

LOSS OF BUSINESS, CONTRACT, REVENUE, DATA, INFORMATION, OR BUSINESS INTERRUPTION)

RESULTING FROM, ARISING OUT, OR IN CONNECTION WITH THE USE OF, OR INABILITY TO USE THIS

PUBLICATION OR THE CONTENT, EVEN IF SCHNEIDER ELECTRIC IT CORPORATION HAS BEEN

EXPRESSLY ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. SCHNEIDER ELECTRIC IT

CORPORATION RESERVES THE RIGHT TO MAKE CHANGES OR UPDATES WITH RESPECT TO OR IN

THE CONTENT OF THE PUBLICATION OR THE FORMAT THEREOF AT ANY TIME WITHOUT NOTICE.

Copyright, intellectual, and all other proprietary rights in the content (including but not limited to software, audio,

video, text, and photographs) rests with Schneider Electric It Corporation or its licensors. All rights in the

content not expressly granted herein are reserved. No rights of any kind are licensed or assigned or shall

otherwise pass to persons accessing this information.

This Publication shall not be for resale in whole or in part.

Table of Contents

General Information...........................................................1

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Notices During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Commissioning ..................................................................4

Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Initial inspection checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical inspection checklist . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mechanical inspection checklist . . . . . . . . . . . . . . . . . . . . . . . . 6

User interface inspection checklist . . . . . . . . . . . . . . . . . . . . . . 7

Start-up inspection checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Final inspection checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation...........................................................................8

Display Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Scrolling status screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Main menu screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Navigating the main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Navigating sub-menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Using the Path statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Password entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Start the cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Stop the cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

General Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cooling unit configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

View the state of input and output contacts . . . . . . . . . . . . . . 14

Edit the normal state of input and output contacts . . . . . . . . . 14

Cooling Group Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Configure the cooling group . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Identify the cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Configure Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

InRow RC Operation and Maintenance Manual i

Control the Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

How the Cool mode works . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

PID settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Tune the PID loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Run hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Service intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Display Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Password & timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Date & time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Adjust display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Display units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Configure the network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

View Status Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Scrolling status screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cooling unit status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cooling group status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

About the cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

View event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Clear event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Respond to Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

View active alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Clear active alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Alarm messages and suggested actions . . . . . . . . . . . . . . . . . 27

Network Management Card .............................................30

Quick Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

TCP/IP configuration methods . . . . . . . . . . . . . . . . . . . . . . . . 30

Schneider Electric Device IP Configuration Wizard . . . . . . . . 30

.ini file utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

BOOTP & DHCP configuration . . . . . . . . . . . . . . . . . . . . . . . . 32

Local access to the control console . . . . . . . . . . . . . . . . . . . . 33

Remote access to the control console . . . . . . . . . . . . . . . . . . 33

Control console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

ii

InRow RC Operation and Maintenance Manual

Access a Configured Network Management Card . . . . . . . . . . . . . . . . 35

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Web interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Telnet and SSH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Simple Network Management Protocol (SNMP) . . . . . . . . . . . 36

FTP/SCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Recover From a Lost Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Maintenance ....................................................................39

Monthly Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Quarterly Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Functional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Semi-Annual Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 41

Cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Troubleshooting...............................................................42

iiiInRow RC Operation and Maintenance Manual

General Information

Important Safety Information

Read the instructions carefully to become familiar with the equipment before trying to install, operate, service,

or maintain it. The following special messages may appear throughout this manual or on the equipment to warn

of potential hazards or to call attention to information that clarifies or simplifies a procedure.

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard

exists which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, can result in death

or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, can result in minor

or moderate injury.

NOTICE

NOTICE addresses practices not related to physical injury including certain environmental

hazards, potential damage or loss of data.

1InRow RC Operation and Maintenance Manual

Safety Notices During Operation

Read and adhere to the following important safety considerations when working with this equipment. Follow all

local and national regulations when handling refrigerants. Service to the components in the refrigeration loop

should be performed only by a certified HVAC technician.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work

practices. See NFPA 70E or CSA Z462.

• This equipment must be installed and serviced by qualified personnel only.

• Turn off all power supplying this equipment before working on or inside the equipment.

• Always use a properly rated voltage sensing device to confirm power is off.

• Replace all devices, doors, and covers before turning on power to this equipment.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD FROM MOVING PARTS

Keep hands, clothing, and jewelry away from moving parts. Check the equipment for

foreign objects before closing the doors and starting the equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD TO EQUIPMENT OR PERSONNEL

All work must be performed by Schneider Electric qualified personnel.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

HAZARD TO EQUIPMENT OR PERSONNEL

Ensure that all spare parts and tools are removed from the equipment before operating it

Failure to follow these instructions can result in injury or equipment damage.

InRow RC Operation and Maintenance Manual2

NOTICE

STATIC ELECTRICITY HAZARD

Circuit boards contained within this unit are sensitive to static electricity. Use one or more

electrostatic-discharge device while handling the boards.

Failure to follow these instructions can result in equipment damage.

3InRow RC Operation and Maintenance Manual

Commissioning

After installation, complete the following checklists to verify that all components are working properly and that

the equipment is ready to begin operation.

Checklists

Initial inspection checklist

The initial inspection ensures that the equipment has been properly installed, the location of the cooling unit has

been properly prepared and the cooling unit is free of damage.

WARNING

DAMAGE TO EQUIPMENT OR PERSONNEL

Do not run service utilities in front of the fan outlet.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

NOTE: The vapor barrier minimizes moisture infiltration. Without a vapor barrier, it will be difficult to maintain

the humidity in the room. Do not introduce unconditioned outside air into the space.

Ensure that:

The installation procedure is complete according to the requirements of this installation manual.

The walls, floor, and ceiling of the room where the cooling unit is located are sealed with a vapor barrier.

There is no evidence of damage to the cooling unit.

The clearance around the equipment is in accordance with local and national codes and regulations as well

as this installation manual.

The cooling unit is level and joined to the adjacent racks

The cooling unit is not installed at the open end of a row.

InRow RC Operation and Maintenance Manual4

Electrical inspection checklist

The electrical inspection verifies that all electrical connections are secure and correct and that the equipment is

properly grounded.

WARNING

ELECTRICAL HAZARD

• Electrical service must conform to local and national electrical codes and regulations.

• The equipment must be grounded.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Ensure that:

Incoming voltages match the phase and voltage listing on the nameplate.

Electrical wiring complies with local and national codes and regulations.

Equipment is properly grounded.

Front door is properly grounded.

Electrical connections are tight, including contactors, terminal blocks, controllers, switches, relays, auxiliary

devices, and field connections.

Circuit breakers are properly connected and securely attached to the DIN rail.

5InRow RC Operation and Maintenance Manual

Mechanical inspection checklist

The mechanical inspection verifies that all mechanical components and connections are secure.

CAUTION

PIPING INSTALLATION

Failure to properly install piping may result in improper cooling unit operation or possible

damage to the cooling unit or surrounding equipment.

Failure to follow these instructions can result in equipment damage.

Ensure that:

Condensate drain line is at least the size of the drain connection.

Mechanical connections are tight.

Fans are turning freely and the blades are not distorted or bent.

Pipe fittings are tight.

Air is bled from the water system. If air remains in the system, bleed it out now.

Supply chilled water temperature is recorded.

Chilled water flow is correct based on the performance requirements of the cooling unit.

Field-installed traps and piping are in accordance with the installation manual. Strainers are in place in the

chilled water supply loop. Proper piping practices have been followed.

Piping is adequately supported and isolated when necessary.

Field-installed service valves are open.

Water outlet temperature sensor is positioned correctly. For top-connected cooling units, the wire with only a

green wire tie is positioned in connector J23. For bottom-connected cooling units, the wire with both green

and white wire ties is positioned in connector J23.

Piping in the building and on the roof is properly insulated.

Covers and guards are in place.

InRow RC Operation and Maintenance Manual6

User interface inspection checklist

The user interface inspection verifies that the sensors and internal communication links are installed properly.

Check that the outdoor heat exchanger is connected to the cooling unit and to the other cooling units in the

room if you are using cooling group controls.

Ensure that:

An A-Link bus is connected to each cooling unit and a terminator is plugged into all unused A-Link

connectors.

The input contacts and output relays are connected correctly.

The building management system is connected correctly and a terminator is wired into the final cooling unit.

The temperature sensors located on the front of the equipment are connected correctly.

The rack temperature sensors are installed correctly.

The network port is connected correctly and an IP address has been assigned to the cooling unit.

The optional rope water detection device is installed properly.

Start-up inspection checklist

The start-up inspection ensures that the equipment is operating properly after the initial start-up. This inspection

verifies that all modes of operation are working correctly and that the cooling unit is ready for normal operation.

While the equipment is operating, ensure that:

The cooling unit is free from malfunctions, including chilled water leaks, unusual vibrations, or other

irregularities, in each mode of operation.

The current draw of fan motors and transformers for the cooling operation is within the ratings of the

respective circuit breakers.

Record the current at the main power connection of the main circuit breaker.

Record all current draws on the load side of any circuit breakers used for each device.

Compare the circuit breaker setting for each device to the actual current measured and the full load amps of

the device to verify that the current draws are acceptable.

Feed B can supply power to all functions in the equipment.

The cool cycle engages.

The correct water outlet temperature sensor is positioned in connector J23.

Air filters are clean and free of debris. Replace air filters as needed.

The clogged filter alarm is operating properly.

Cover 1/3 of the filter area to initiate the alarm.

Final inspection checklist

The final inspection verifies that the system is clean, and the start-up form has been sent to Schneider Electric.

Ensure that:

The system is clean and free from debris.

Packaging materials are disposed of properly.

The start-up form was completed and sent to Schneider Electric.

7InRow RC Operation and Maintenance Manual

Operation

Display Interface

Status

Check

Log

Warning

Critical

ESC

?

na1958a

Item Description Function

Critical Alarm LED (red) When lit, a critical alarm condition exists and requires your

immediate attention.

Warning Alarm LED (yellow) When lit, a warning alarm condition exists. Failure to correct this

condition could cause a critical alarm.

Check Log LED (yellow) When lit, at least one new event has been logged since the last time

the log was checked. Only events that pertain to the operation of the

cooling unit will activate the LED.

Status LED (green) When lit, the cooling unit is receiving electrical power. When flashing

green, the cooling unit is downloading firmware for the controller.

This takes several minutes.

Liquid Crystal Display (LCD) View alarms, status data, context-sensitive help, and modify

configurable items.

UP and DOWN arrow keys Select menu items and access information.

ESC key Return to previous screen or cancel current operation.

ENTER key Open menu items and input changes to cooling group level and

cooling unit level settings.

HELP key Display context-sensitive help. Press the HELP key for information

about each option on the screen and for instructions on performing

tasks.

InRow RC Operation and Maintenance Manual8

Using the Display

Every time you apply power to the cooling unit, the display interface initializes, causing the LEDs to cycle and

the alarm-tone to activate.

Scrolling status screens

After start-up, the interface displays the firmware revision number of the display interface. The display interface

then scrolls automatically and continuously through screens of status information. Press the up or down arrow

key to interrupt the automatic scrolling and view a specific status screen. To return to the scrolling status

screens, press ESC from one of the main menu screens.

Status Screen Name Status Information Displayed

InRow RC • On/Standby

• Unit identifier

• Cooling Unit name

• Cooling Unit location

Group • Alarms/No Alarms

• Cool Outpt (Cool Output) kW

• Cool Setpt (Cool Setpoint) °C (or °F)

• Max Rack (Maximum Rack Temperature) °C (or °F)

Unit • Alarms/No Alarms

• Cool Output kW

• Max Rack In (Maximum Rack Inlet Temperature) °C (or °F)

• Air Flow l/s (liters per second) or CFM (cubic feet per minute)

Main menu screens

On any top-level status screen, press the ENTER or ESC key to open the first

main menu screen.

NOTE: Once a period of inactivity (at the keys of the display interface)

exceeds the Password Timeout setting, the display interface returns to

the scrolling status screens.

For information on setting the time-out duration, see

“Password & timeout” on page 21.

All main menu choices are displayed on a series of six main menu screens.

Navigating the main menu

Selector arrow: Press the up or down arrow key to move the selector arrow

to a main menu option. Press the ENTER key to view the selected sub-menu

screen. In the example shown below, the selector arrow points to the Set Date

and Time setting. To select that item, press the ENTER key.

Time: 13:15:23

Date: 18-Nov-2010

Format: dd/mm/yyyy

na5271a

NOTE: If the selector arrow is on the top line of a main menu screen, press the

up arrow key to move the selector arrow to the top line of the previous screen.

On/Standby

View Alarms

Clear Alarms

View Event Log

Clear Event Log

Configure Modbus

Set Date & Time

Set Password

Set Display Units

Configure Display

Configure Network

About InRow RC

Set Identification

Service Intervals

View Run Hours

Configure Unit

Configure Group

Set Group PIDs

View Group Status

View Unit Status

Set Group Setpoints

Set Unit Threshlds

na5388a

9InRow RC Operation and Maintenance Manual

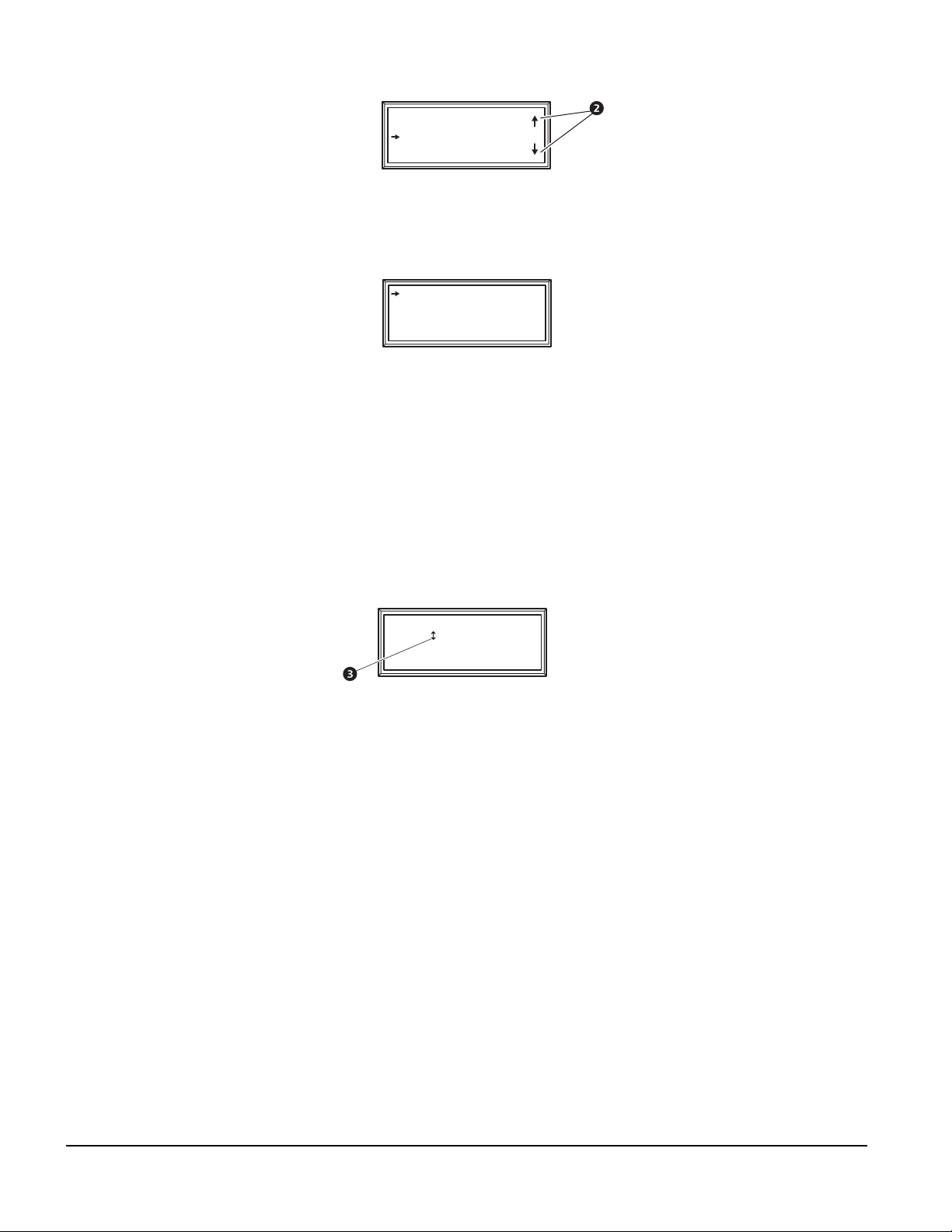

Continue arrows: Continue arrows indicate that additional options or settings are available on a menu or

status screen. Press the up or down arrow key to view the additional items.

Clear Event Log

Configure Modbus

Set Date & Time

Set Password

na1623f

Navigating sub-menus

Selecting a option displays the sub-menu screen for that option. In this example, the selector arrow is on the

top line of the Set Date and Time sub-menu screen.

Time: 13:15:23

Date: 18-Nov-2010

Format: dd/mm/yyyy

na1623g

Use the up or down arrow key to move the selector arrow to an option, and press the ENTER key.

• List of choices: If the setting is a list of choices, an input arrow displays next to the setting. Press the

up or down arrow key to select the menu option to change. Then press the ENTER key to exit the input

mode and save the setting. Press the ESC key to exit without saving.

• Numbers or text fields: If the setting is a number or text field, use the arrow keys to select the value of

the first character, and press the ENTER key to move to the next character. Press the ENTER key after

the last character is set to exit the input mode and save the setting. Press the ESC key to exit without

saving. If an invalid value is entered, the display interface beeps and restores the previous valid value to

the field.

Input arrows: Input arrows next to a selected setting indicate that the setting can be modified by pressing

the up or down arrow key. Press the ENTER key to save the change or the ESC key to cancel the change.

Time: 13:15:23

Date: 18-Nov-2010

Format: dd/mm/yyyy

na1622aa

Using the Path statement

Select the main- and sub-menu options specified in the path statement to view or configure a setting. The path

statement lists the main- and sub-menu items you select to navigate to the item to view or modify. The parts of

the path statement are defined below:

Path: Main > Set Password > Change Passwords

Main >: Your starting point is the main menu.

Set Password >: Scroll to and select this option from the main menu.

Change Passwords >: Scroll to and select this option from the sub-menu.

Subsequent options are listed and defined under the path statement.

InRow RC Operation and Maintenance Manual10

Loading...

Loading...