Schneider Electric ACRD601, ACRD602, ACRD602P, ACRD600P, ACRD601P User Manual

...

Installation Manual

InRow® Direct Expansion Air Conditioners

InRow RD DX

ACRD600, ACRD601, ACRD602,

ACRD600P, ACRD601P, ACRD602P

990-5711C-001

Publication Date: April 2017

Schneider Electric IT Corporation Legal Disclaimer

The information presented in this manual is not warranted by the Schneider Electric IT Corporation to be

authoritative, error free, or complete. This publication is not meant to be a substitute for a detailed operational

and site specific development plan. Therefore, Schneider Electric IT Corporation assumes no liability for

damages, violations of codes, improper installation, system failures, or any other problems that could arise

based on the use of this Publication.

The information contained in this Publication is provided as is and has been prepared solely for the purpose of

evaluating data center design and construction. This Publication has been compiled in good faith by Schneider

Electric IT Corporation. However, no representation is made or warranty given, either express or implied, as to

the completeness or accuracy of the information this Publication contains.

IN NO EVENT SHALL SCHNEIDER ELECTRIC IT CORPORATION, OR ANY PARENT, AFFILIATE OR

SUBSIDIARY COMPANY OF SCHNEIDER ELECTRIC IT CORPORATION OR THEIR RESPECTIVE

OFFICERS, DIRECTORS, OR EMPLOYEES BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL,

PUNITIVE, SPECIAL, OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR

LOSS OF BUSINESS, CONTRACT, REVENUE, DATA, INFORMATION, OR BUSINESS INTERRUPTION)

RESULTING FROM, ARISING OUT, OR IN CONNECTION WITH THE USE OF, OR INABILITY TO USE THIS

PUBLICATION OR THE CONTENT, EVEN IF SCHNEIDER ELECTRIC IT CORPORATION HAS BEEN

EXPRESSLY ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. SCHNEIDER ELECTRIC IT

CORPORATION RESERVES THE RIGHT TO MAKE CHANGES OR UPDATES WITH RESPECT TO OR IN

THE CONTENT OF THE PUBLICATION OR THE FORMAT THEREOF AT ANY TIME WITHOUT NOTICE.

Copyright, intellectual, and all other proprietary rights in the content (including but not limited to software, audio,

video, text, and photographs) rests with Schneider Electric IT Corporation or its licensors. All rights in the

content not expressly granted herein are reserved. No rights of any kind are licensed or assigned or shall

otherwise pass to persons accessing this information.

This Publication shall not be for resale in whole or in part.

Table of Contents

Safety.................................................................................1

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Considerations While Installing This Equipment . . . . . . . . . . . . . 2

General Information...........................................................3

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Save these instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Symbols used in this manual . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Waste Electrical and Electronic Equipment (WEEE) disposal . 3

Inspecting the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Filing a claim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Storing the Equipment Before Installation . . . . . . . . . . . . . . . . . . . . . . . 3

Moving the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Model Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Standard unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Install kit inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Exterior components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Interior components (ACRD60x) . . . . . . . . . . . . . . . . . . . . . . . . 7

Interior components (ACRD60xP) . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Refrigeration piping diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connections overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Piping connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Communication connections . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Room Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Air distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Incoming power supply requirement . . . . . . . . . . . . . . . . . . . . 16

Service access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Weights and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

InRow RD Installation Manual i

Access Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Top piping and power access locations—top view, looking down (ACRD600/P series) 19

Bottom piping and power access locations—bottom view, looking up (ACRD600/P series)

20

Equipment Guidelines......................................................21

Working Conditions and Environmental Limits . . . . . . . . . . . . . . . . . . 21

Installation........................................................................22

Removing the Doors and Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Removing the front and rear doors . . . . . . . . . . . . . . . . . . . . . 23

Removing and installing the side panel . . . . . . . . . . . . . . . . . . 24

Removing the electrical panel cover . . . . . . . . . . . . . . . . . . . . 25

Joining the Equipment to Enclosures. . . . . . . . . . . . . . . . . . . . . . . . . . 26

Joining to NetShelter™ SX enclosures . . . . . . . . . . . . . . . . . . 26

Joining to NetShelter VX and VS enclosures . . . . . . . . . . . . . 26

Leveling the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mechanical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Refrigeration piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connect refrigerant lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Flooded receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Humidifier (ACRD60xP only) . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Condensate pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Condensate overflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Leak sensor (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Adding a holding charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Adding compressor oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Customer interface connections . . . . . . . . . . . . . . . . . . . . . . . 37

Form C alarm contacts and shutdown input . . . . . . . . . . . . . . 39

Rack temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Communication connections . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Network port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Wiring configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Top routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Bottom routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Strain relief (ACRD602/602P only) . . . . . . . . . . . . . . . . . . . . . 45

Connect flooded receiver heater . . . . . . . . . . . . . . . . . . . . . . . 46

Voltage selections—ACRD60x units . . . . . . . . . . . . . . . . . . . . 46

Voltage selections – ACRD60xP units . . . . . . . . . . . . . . . . . . 47

ii

InRow RD Installation Manual

Charging with Refrigerant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Calculating R410A charge . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Charging the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Compressor Oil Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Oil charging procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Accessories .....................................................................54

Low Temperature Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Install kit inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Bulb location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Heater connection location . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

iiiInRow RD Installation Manual

Safety

Important Safety Information

Read the instructions carefully to become familiar with the equipment before trying to install, operate, service,

or maintain it. The following special messages may appear throughout this manual or on the equipment to warn

of potential hazards or to call attention to information that clarifies or simplifies a procedure.

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard

exists which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, can result in death

or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, can result in minor

or moderate injury.

NOTICE

NOTICE addresses practices not related to physical injury including certain environmental

hazards, potential damage or loss of data.

1InRow RD Installation Manual

Safety Considerations While Installing This Equipment

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work

practices. See NFPA 70E or CSA Z462.

• This equipment must be installed and serviced by qualified personnel only.

• Turn off all power supplying this equipment before working on or inside the equipment.

• Always use a properly rated voltage sensing device to confirm power is off.

• Replace all devices, doors, and covers before turning on power to this equipment.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD FROM MOVING PARTS

Keep hands, clothing, and jewelry away from moving parts. Check the equipment for

foreign objects before closing the doors and starting the equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD TO EQUIPMENT OR PERSONNEL

All work must be performed by Schneider Electric qualified personnel.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD OF EQUIPMENT FALLING OVER

• Use two or more persons at all times to move or turn this equipment.

• Always push, pull, or turn while facing the front and rear of this equipment. Never push,

pull, or turn while facing the sides of this equipment.

• Slowly move this equipment across uneven surfaces or door thresholds.

• Lower leveling feet to floor when this equipment is at rest.

• Lower leveling feet and attach joining brackets to adjacent racks when this equipment is

in final position.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

InRow RD Installation Manual2

General Information

Overview

Save these instructions

This manual contains important instructions that must be followed during the installation of this equipment.

Symbols used in this manual

Indicates that more information is available in another location.

Equipment Disposal

Waste Electrical and Electronic Equipment (WEEE) disposal

Schneider Electric products comply with international directives on the Restriction of

Hazardous Substances (RoHS) in electronic and electrical equipment and the disposal of

Waste Electrical and Electronic Equipment (WEEE). Dispose of any waste electronic or

electrical equipment with the appropriate recycling center. Contact Schneider Electric for

assistance.

Inspecting the Equipment

Your InRow air conditioner has been tested and inspected for quality assurance before shipment from

Schneider Electric. Carefully inspect both the exterior and interior of the equipment immediately upon receipt to

ensure that the equipment has not been damaged during transit.

Verify that all parts ordered were received as specified and that the equipment is the correct type, size, and

voltage.

Filing a claim

If damage is identified on receipt of the equipment, note the damage on the bill of lading and file a damage

claim with the shipping company. Contact Schneider Electric Worldwide Customer Support for information on

how to file a claim with the shipping company. The shipping claim must be filed at the receiving end of the

delivery.

NOTE: In case of shipping damage, do not operate the equipment. Keep all packaging for inspection by the

shipping company and contact Schneider Electric.

Storing the Equipment Before Installation

If the equipment will not be installed immediately, store it in a safe place, protected from the weather.

NOTICE

HAZARD TO EQUIPMENT

Leaving the equipment uncovered and exposed to possible damage from the

environment will void the factory warranty.

Failure to follow these instructions can result in equipment damage.

3InRow RD Installation Manual

Moving the Equipment

The recommended tools for moving the equipment while it is still on the pallet include the following:

Pallet Jack Forklift

NOTE: The equipment can be rolled to its final location using its casters if the floor is smooth and clean.

Model Identification

Standard unit

The model number can be found on the outside of the shipping crate and on the nameplate located inside the

equipment as shown. Use the table below to verify that the equipment is the correct size and voltage.

Model Configuration Voltage Frequency Reheat Humidifier Air Pattern

ACRD600

ACRD601

ACRD602

ACRD600P

ACRD601P

ACRD602P

Air-cooled 200-240 50-60 Hz N/A N/A Back to front

Air-cooled 460-480 60 Hz N/A N/A Back to front

Air-cooled 380-415 50-60 Hz N/A N/A Back to front

Air-cooled 200-240

Air-cooled 460-480

Air-cooled 380-415

50-60 Hz Electric

60 Hz Electric

50-60 Hz Electric

NAMEPLATE

Steam canister

(replaceable)

Steam canister

(replaceable)

Steam canister

(replaceable)

Back to front

Back to front

Back to front

na5809a

InRow RD Installation Manual4

Component Identification

Install kit inventory

na2505b

Item Description Quantity Item Description Quantity

Threaded ring seal straight fitting,

female, 1 1/4-in. to 3/4-in.* I.D.

Humidifier inlet water connection,

shutoff

• 1/4-in. NPT*** and 1/4-in. BSPT**

4

1 ea

M6 x 16-mm TORX screw with

washer

Strain relief, metal (ACRD602 and

602P only)

5

2

(ACRD600P)

• 1/4-in. NPT*** (ACRD601P)

• 1/4-in. BSPT** (ACRD602P)

Condensate drain outlet, shutoff, 3/8-in.

1

1

1

Wire clip 9

BSPT**

Condensate overflow hose adapter

2

Tie wrap, 200 mm (8 in.) 10

clamp, double snap

Threaded ring seal male straight -

2

Tie wrap, 390 mm (15.3 in.) 3

3/4-in.* I.D.

Gas shutoff valve, 3/4-in. I.D. 2

Temperature sensor 3

Rotalock gasket, 1 1/4-in. 4

Resistor, 150 Ohm 1

Cable tie 10

Condensate overflow hose

1

adapter

M5 x 10-mm TORX® screw with washer

5

Reducer, 3/8-in. to 1/2-in. BSPT** 1

(spare parts)

M6 x 12-mm TORX screw with washer

5

Reducer, 3/8-in. to 1/2-in. NPT*** 1

(spare parts)

M6 x 10-mm self-tapping TORX screw

5

Voltage jumper ****

(spare parts)

*Standard wall thickness

**British Standard Pipe Thread

***National Pipe Thread

****Quantity and wire connections vary depending

on model number. See “Voltage selections—

ACRD60x units” on page 46.

5InRow RD Installation Manual

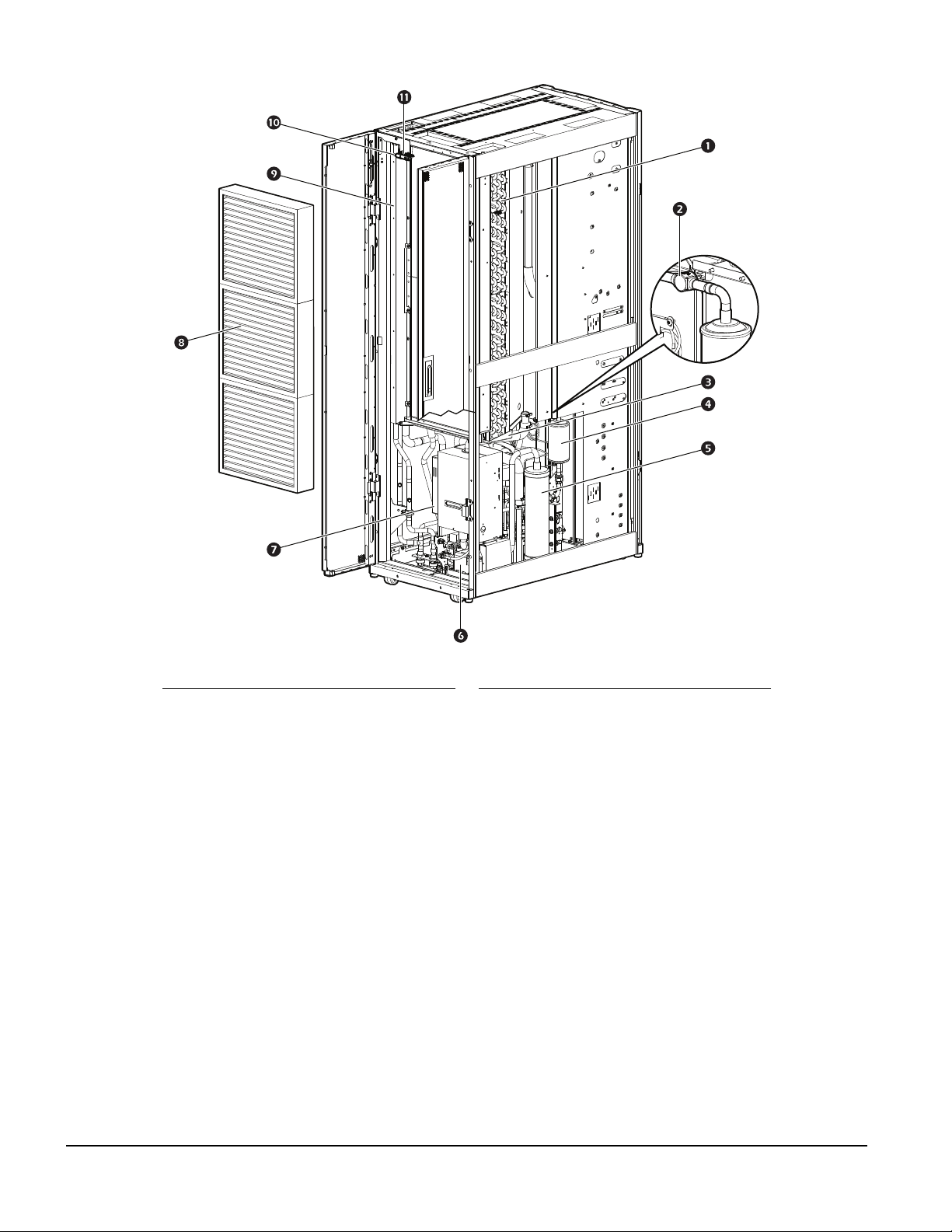

Exterior components

Item Description Item Description

Removable rear doors

Side panel lock

Removable side panel

Adjustable leveling foot

Caster

Door handle and lock

Display interface

Removable front door

na5807a

InRow RD Installation Manual6

Interior components (ACRD60x)

Front

Item Description Item Description

Condensate drain pan

Electronic expansion valve

Compressor

Variable frequency drive (for

compressor)

Supply air temperature sensor

Main circuit breaker

Fan (2)

Fan guard (2)

Electrical panel

Communication and external device

connectors

Ground lug

Humidity sensor

na5823a

7InRow RD Installation Manual

Rear

Item Description Item Description

Evaporator coil

Sight glass

Condensate drain pan

Filter drier

Oil separator

Condensate pump

Air filters

Pipe chase

Return air temperature sensor

na5824a

InRow RD Installation Manual8

Interior components (ACRD60xP)

Front

Item Description Item Description

Electric heater

Condensate drain pan

Electronic expansion valve

Humidifier

Compressor

Main circuit breaker

Fan (2)

Fan guard (2)

Electrical panel

Communication and external device

connectors

Variable frequency drive (for compressor)

Supply air temperature sensor

Ground lug

Humidity sensor

na5821a

9InRow RD Installation Manual

Rear

Item Description Item Description

Evaporator coil

Sight glass

Condensate drain pan

Filter drier

Oil separator

Condensate pump

Humidifier

Air filters

Pipe chase

Humidity sensor

Return air temperature sensor

na5822a

InRow RD Installation Manual10

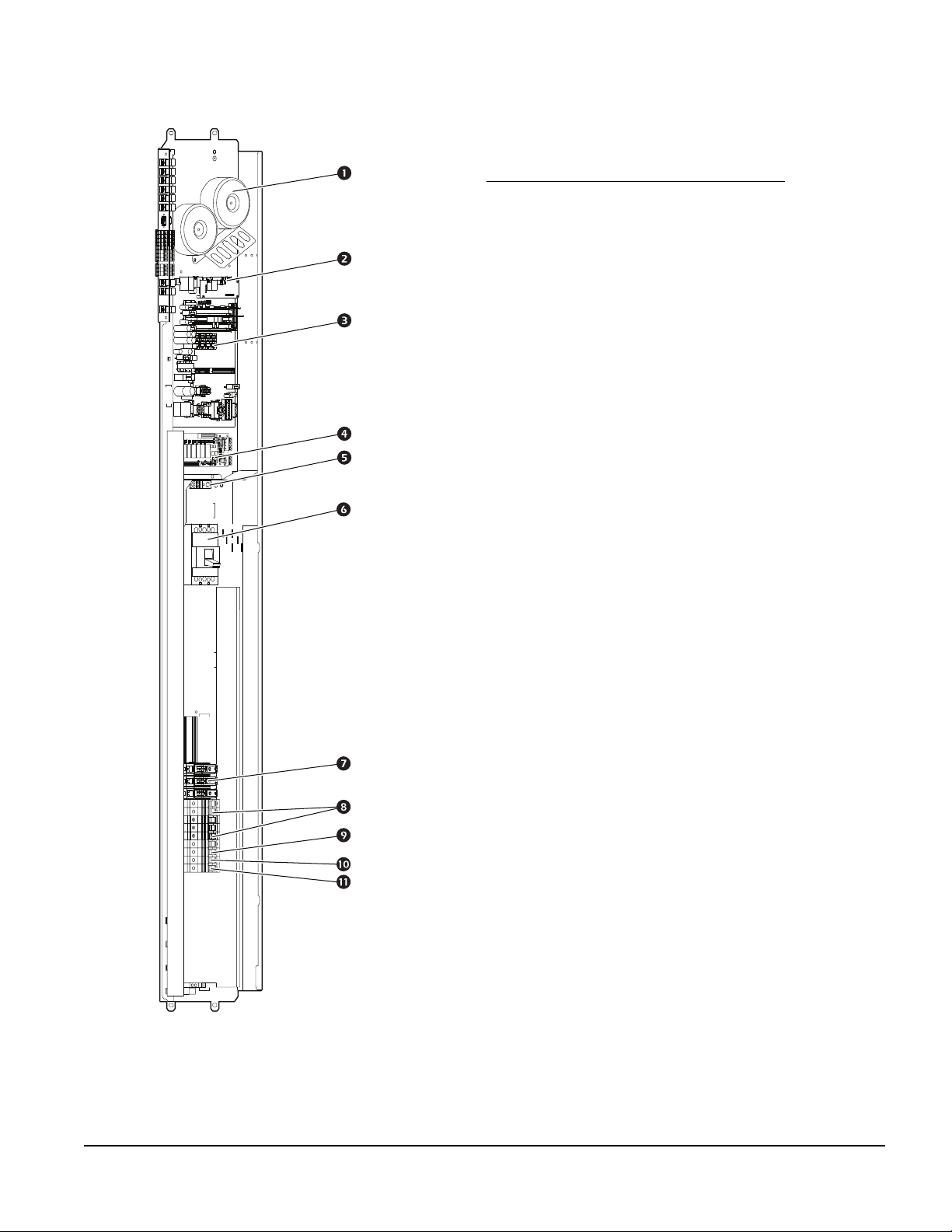

Electrical panel

ACRD600, ACRD601, ACRD602

Item Description

Transformers

Display interface connectors

Main controller board

Relay board

Ground lug

Main circuit breaker

Compressor fuse block

(ACRD600, ACRD601)

Compressor circuit breaker

(ACRD602)

Fan circuit breakers

Fuse not populated

Transformer A fuse

Transformer C/MB fuse

na2724b

11InRow RD Installation Manual

ACRD600P, ACRD601P, ACRD602P

Item Description

Transformers

Display interface connectors

Main controller board

Relay board

Ground lug

Main circuit breaker

Compressor fuse block

(ACRD600P, ACRD601P)

Compressor circuit breaker

(ACRD602P)

Fan circuit breakers

Controller fuse

Heater circuit breaker

Humidifier circuit fuse

Heater contactors

Humidifier contactor

na2032b

InRow RD Installation Manual12

Refrigeration piping diagram

BOTTOM PIPING TOP PIPING

CONDENSER

HOT GAS

HOT GAS

LIQUID

RD

RECEIVER

RD

Item Description Item Description

Pitch in direction of refrigerant flow Pressure relief valve

Reduction of piping diameter for

P-trap

vertical piping run (if necessary)

Shutoff valves S-trap

CONDENSER

LIQUID

na2543a

RECEIVER

Head pressure control valve Inverted P-trap

Check valve

NOTE: All lines are Type L ACR hard-drawn copper pipes.

NOTE: Shutoff valves shown nearest to the condenser are provided in receiver kit.

NOTE: Pitch all lines in the direction of refrigerant flow: 4 mm per m (1/2 in. per 10 ft).

NOTE: Route piping through the top or bottom of the InRow RD cooling unit.

NOTE: Trap the vertical discharge line every 6 m (20 ft) to ensure proper oil return.

NOTE: The maximum piping run is 91 m (300 ft) equivalent length. Size the piping pursuant to accepted

refrigeration practice.

NOTE: Condenser can be placed up to 4.5 m (15 ft) below the indoor cooling unit for equivalent line lengths of

8 m (25 ft) or less.

For Condensers Mounted Below the Level of the Indoor Unit

Piping Equivalent Length – m (ft)

91 (300) 76 (250) 61 (200) 46 (150) 30 (100) 15 (50) 8 (25)

Allowable Distance From Bottom

of Condenser to Bottom of

0.3 (1) 1.5 (5) 2.1 (7) 2.7 (9) 3.3 (11) 3.9 (13) 4.5 (15)

Indoor Unit* – m (ft)

*When condenser is installed below unit level, use 7/8 in. pipe for liquid line.

Note: Condenser can be placed higher than indoor cooling unit but height shall be no more than 27 m (90 ft), regardless

of piping length.

13InRow RD Installation Manual

Connections overview

All connections to and from the equipment can be made through either the top or the bottom of the equipment.

Once the corresponding connectors are sweated or soldered into place, the equipment can be disconnected

without additional soldering, welding, or gluing. See the following tables for information about the sizes and

types of connectors.

Power connections

Minimum

Circuit

Ampacity

Model Voltage

ACRD600 200-240 V,

50/60 Hz

ACRD601 460-480 V,

60 Hz

ACRD602 380-415 V,

50/60 Hz

ACRD600P 200-240 V,

50/60 Hz

ACRD601P 460-480 V,

60 Hz

ACRD602P 380-415 V,

50/60 Hz

*Consult local and national codes for wire size, conduit requirements, and overload protection.

(MCA)

51.6 80 - 29.7* 36.6 14.6

24.0 40 - 28.1* 16.6 14.6

30.7 50 25.2 28.1* 16.6 14.6

77.6 110 - 29.7* 36.6 23.5

36.5 50 - 28.1* 16.6 23.5

45.4 65 34.2 28.1* 16.6 23.5

Maximum

Overload

Protection

(MOP)

Full Load

Amperes

(FLA)

Locked Rotor

Amperes (LRA)

Piping connections

Connection Type

ACRD600

ACRD600P

ACRD601

ACRD601P

Compressor

Compressor

Rated Load

Amperes (RLA)

Power

(kW)

ACRD602

ACRD602P

Refrigerant discharge

Refrigerant liquid

Humidifier water supply

(ACRD600P, ACRD601P,

ACRD602P only)

Condensate drain Quick coupling

* Use a new Teflon gasket (supplied) to prevent leakage. Tighten Rotalock nut to 90 Nm (66 ft-lb).

1 1/4-in. Rotalock*

1 1/4-in. Rotalock*

Quick coupling 1/4-in. NPT or

3/4-in. ID 3/4-in. ID 3/4-in. ID

3/4-in. ID 3/4-in. ID 3/4-in. ID

1/4-in. NPT 1/4-in. BSPT

1/4-in. BSPT

1/2-in. female NPT or

1/2-in. female BSPT

1/2-in. female NPT or

1/2-in. female BSPT

1/2-in. female NPT or

1/2-in. female BSPT

InRow RD Installation Manual14

Communication connections

Wire Size

Torque

Connection Type

Rack temperature 1 RJ-45 - - -

Rack temperature 2 RJ-45 - - -

Rack temperature 3 RJ-45 - - -

A-Link IN RJ-45 - - -

A-Link OUT RJ-45 - - -

Network port RJ-45 - - -

Customer output, Normally Closed (NC) Screw connector AWG 24 (0.2 mm2) AWG 18

Customer output, Common (COM) Screw connector AWG 24 (0.2 mm2) AWG 18

Customer output, Normally Open (NO) Screw connector AWG 24 (0.2 mm2) AWG 18

Supply GND Screw connector AWG 24 (0.2 mm2) AWG 18

Supply 12 Vdc Screw connector AWG 24 (0.2 mm2) AWG 18

Supply 24 Vdc Screw connector AWG 24 (0.2 mm2) AWG 18

Customer input + Screw connector AWG 24 (0.2 mm2) AWG 18

Customer input – Screw connector AWG 24 (0.2 mm2) AWG 18

Modbus D1 Screw connector AWG 24 (0.2 mm2) AWG 18

Modbus D0 Screw connector AWG 24 (0.2 mm2) AWG 18

Modbus GND Screw connector AWG 24 (0.2 mm2) AWG 18

Minimum Maximum

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

15InRow RD Installation Manual

Room Preparation

During the design of the data center, consider ease of entry for the equipment, floor loading factors, and

accessibility to piping and wiring. In addition, the room temperature and humidity combination should conform

to the environmental operating envelope as defined in the following graphics.

90

80

70

60

50

40

30

20

10

0

10 15 20 25 30 35 40 45 50

RELATIVE HUMIDITY (% RH)

ACCEPTABLE

OPERATING

RANGE

AMBIENT TEMPERATURE (°C) AMBIENT TEMPERATURE (°F)

UNACCEPTABLE

OPERATING LIMITS

90

80

70

60

50

40

30

20

10

ACCEPTABLE

OPERATING

RANGE

0

60 65 70 75 80 85 90 95 100 105 110 115

UNACCEPTABLE

OPERATING LIMITS

RELATIVE HUMIDITY (% RH)

Seal the room with a vapor barrier to minimize moisture infiltration. Polyethylene film is recommended for

ceiling and wall applications. Apply rubber- or plastic-based paints to concrete walls and floors.

Insulate the room to minimize the influence of exterior heat loads. Reduce fresh air to the minimum required by

local and national codes and regulations. Fresh air imposes extreme load variation on the cooling equipment

from summer to winter and causes increased system operating costs.

Air distribution

The equipment distributes air in a back-to-front discharge pattern, removing hot air from a hot aisle and

discharging cooled air into a cold aisle.

NOTE: The equipment is designed for free air discharge or for use with the Rack Air Containment System or

EcoAisle Containment System. The equipment is not intended to be connected to a duct system.

na2544a

Incoming power supply requirement

ELECTRICAL HAZARD

• Electrical service must conform to local and national electrical codes and regulations.

• The equipment must be grounded.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

InRow RD Installation Manual16

Loading...

Loading...