Renault Dxi13 Service Manuals

Andrew Burrows Oil pump / Tightening torques 13/02/16

Oil filler pipes, tightening torques

Oil filler pipes

Plastic lock |

27±2 Nm |

Dipstick guide bolts |

20±4 Nm |

1 / 1

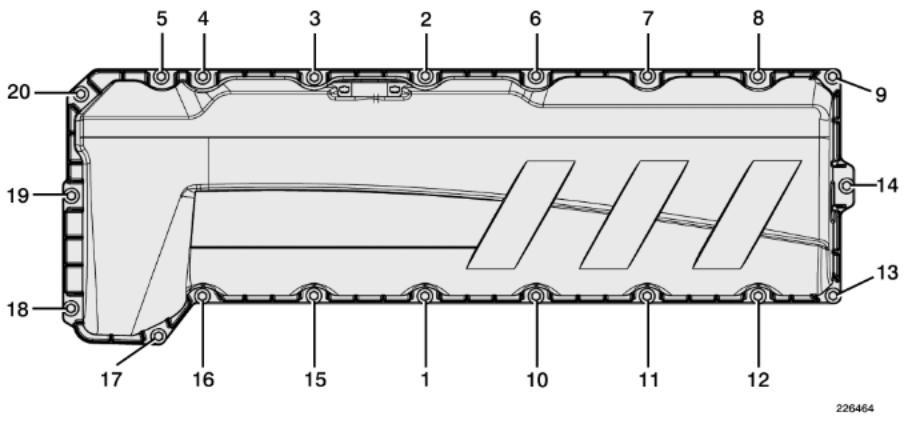

Andrew Burrows Cylinder head cover / Tightening torques 13/02/16

Cylinder head cover, tightening torques

The item numbers indicate the tightening sequence.

Cylinder head cover securing bolts |

24±4 Nm |

1 / 1

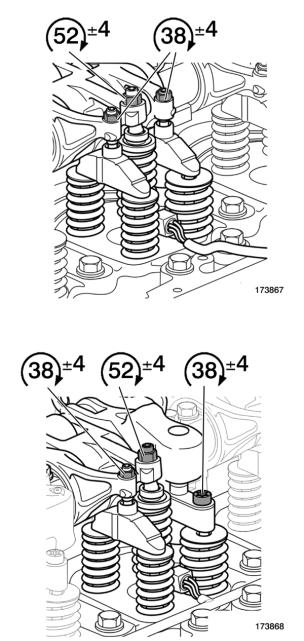

Andrew Burrows Rocker arms / Tightening torques 13/02/16

Rocker arms, tightening torques

Without "Optibrake" / "Optibrake +"

With "Optibrake"

1 / 2

Andrew Burrows Rocker arms / Tightening torques 13/02/16 |

With "Optibrake +"

2 / 2

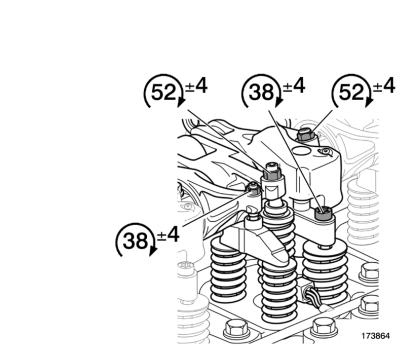

Andrew Burrows Camshaft / Tightening torques 13/02/16

Rocker shaft and camshaft bearing caps, tightening torques

Camshaft |

1 / 2 |

|

Andrew Burrows Camshaft / Tightening torques 13/02/16

Stage 1: bolts (1 › 7) |

40±3 Nm |

Stage 2: bolts (8 › 13 - 20) |

60±5 Nm |

For the 2th stage, tighten bolts gradually in the following order: 11 - 10 - 12 - 9 - 13 - 8 - 20, so that the rocker shaft can be lowered without being damaged.

Stage 3: bolts (1 › 7) |

90±5 ° |

Stage 4: bolts (8 › 13 - 20) |

Loosen the bolts |

Rocker shaft |

|

Stage 5: bolts (8 › 13 - 20) |

60±5 Nm |

For the 5th stage, tighten bolts gradually in the following order: 11 - 10 - 12 - 9 - 13 - 8 - 20, so that the rocker shaft can be lowered without being damaged.

Stage 6: bolts (14 › 19) |

40±3 Nm |

Stage 7: bolts (14 › 19) |

120±5 ° |

Stage 8: bolts (8 › 13) |

Loosen the bolts |

Stage 9: bolts (8 › 13) |

40±3 Nm |

Stage 10: bolts (8 › 13 - 20) |

120±5 ° |

2 / 2

Andrew Burrows Retarders / Tightening torques 13/02/16

"Optibrake/Optibrake +" retarder, tightening torques

Control solenoid valve |

24±4 Nm |

Rocker arms elastic blades securing bolts |

25±3 Nm |

1 / 1

Andrew Burrows Injectors / Tightening torques 13/02/16

Pump injector mounting flange, tightening torques

Assembly type A

A = Socket with boss.

Tightening procedure for already used copper injector sleeves

Stage1 |

20+5 Nm |

Stage2 |

60±5 ° |

1 / 3

Andrew Burrows Injectors / Tightening torques 13/02/16

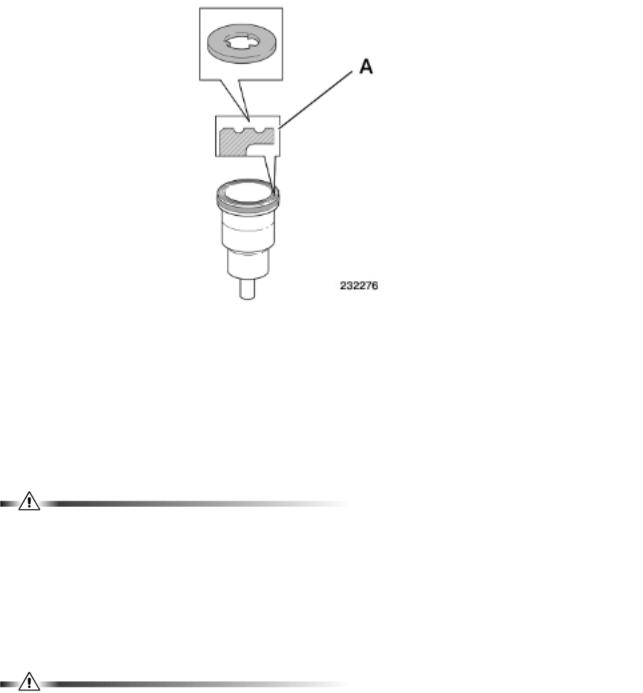

Assembly type B

A = Double groove flat socket with washer.

Tightening procedure for new copper injector sleeves

Stage1 |

|

20+5 Nm |

Stage2 |

|

180±5 ° |

Fully loosen the yoke securing bolt before proceeding with |

stage 3. |

|

Stage3 |

|

20+5 Nm |

Stage4 |

|

90±5 ° |

At each disassembly operation, change the washer.

Tightening procedure for a used injector socket or removing an injector.

Stage1 |

20+5 Nm |

Stage2 |

180±5 ° |

Fully loosen the yoke securing bolt before proceeding with stage 3.

Stage3 |

20+5 Nm |

Stage4 |

90±5 ° |

At each disassembly operation, change the washer. |

2 / 3 |

|

Andrew Burrows Injectors / Tightening torques 13/02/16

Retightening at valve maintenance

Injector flange attachment bolts |

45+5 Nm |

3 / 3

Andrew Burrows Cylinder head / Tightening torques 13/02/16

Cylinder head, tightening torques

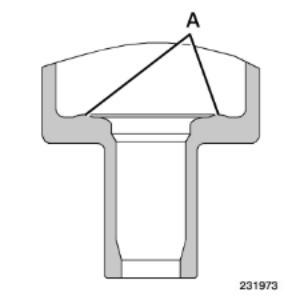

The bolts can be re-used no more than 5 times maximum. Mark the bolt head with an indentation (A) after tightening each time using a centre punch. In this case, apply engine oil to the screw-threads and under the bolt heads.Do not apply engine oil to new bolts, which are already pre-lubricated.

1 / 3

Andrew Burrows Cylinder head / Tightening torques 13/02/16

Tap the screw-threads in the cylinder block then blow through with compressed air.

2 / 3

Andrew Burrows Cylinder head / Tightening torques 13/02/16

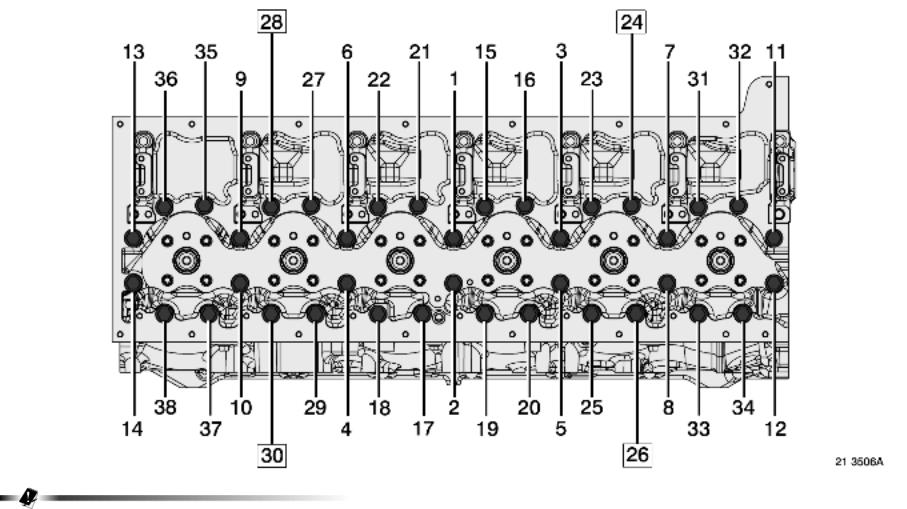

The cylinder head must be positioned and tightened in accordance with the instructions given in the method (see page ).

The item numbers indicate the tightening sequence.

Stage1 |

100±5 Nm |

Stage2 (check tightening) |

100±5 Nm |

Stage3 |

120±5 ° |

Stage4 |

90±5 ° |

3 / 3

Andrew Burrows Blanking plug / cap / Tightening torques 13/02/16

Cylinder head plugs, tightening torques

Plug M10 x 1.00 |

25±3 Nm |

Plug M16 x 1.50 |

50±3 Nm |

1 / 1

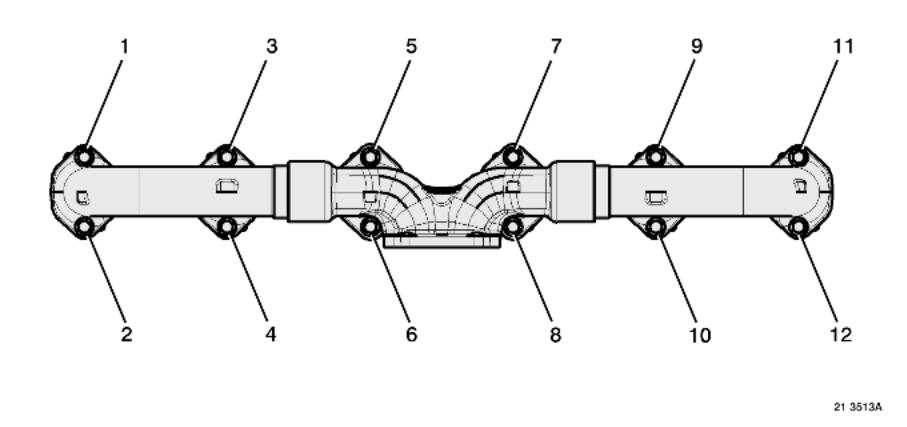

Andrew Burrows Exhaust manifold / Tightening torques 13/02/16

Exhaust manifold, tightening torques

Stage 1: bolts (1 |

› 12) |

5±1.5 Nm |

|

Stage 2: bolts (1 - 4 |

- 5 |

- 8 - 9 - 12) |

10±1.5 Nm |

Stage 3: bolts (3 - 2 - 7 - 6 - 11 |

- 10 - 1 - 4 - 5 - 8 - 9 - 12) |

48±8 Nm |

|

1 / 1

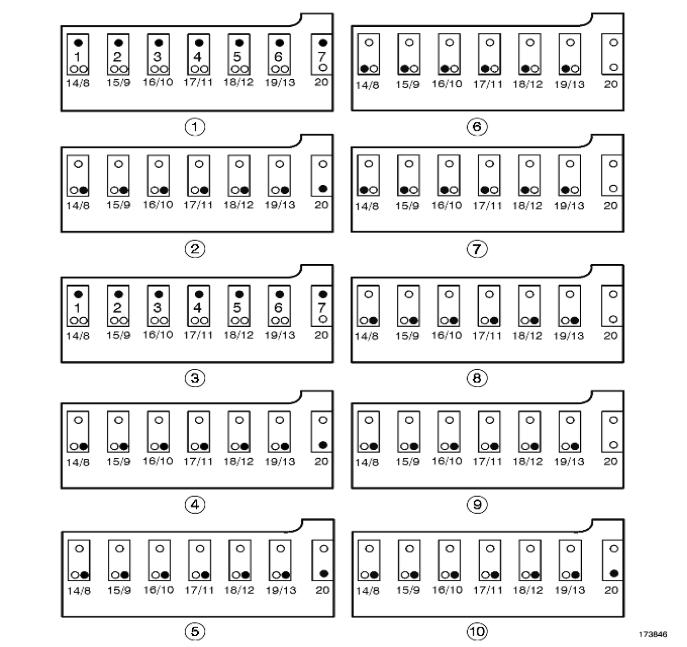

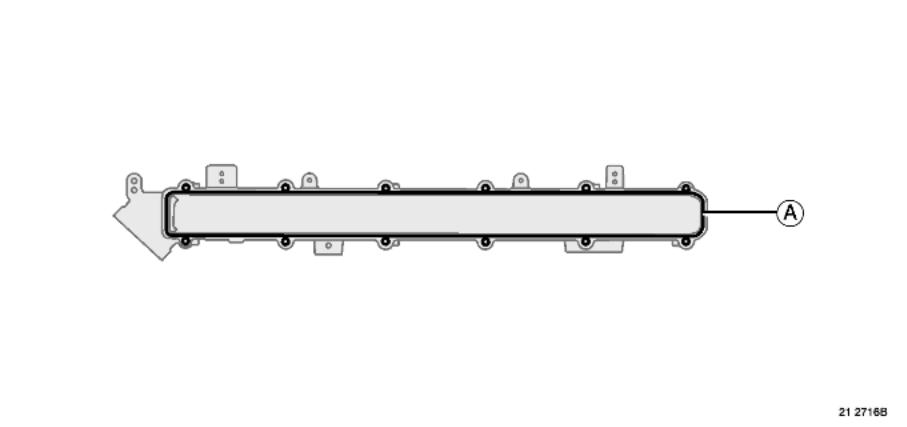

Andrew Burrows Intake manifold / Tightening torques 13/02/16

Intake manifold, tightening torques

Apply a fine coat of sealing compound in the gasket housing (A).

Apply "

ADHESIF SILICONE 7091

".

Install seal.

Carry out the assembly work within 20 minutes following application of the sealing compound.

1 / 3

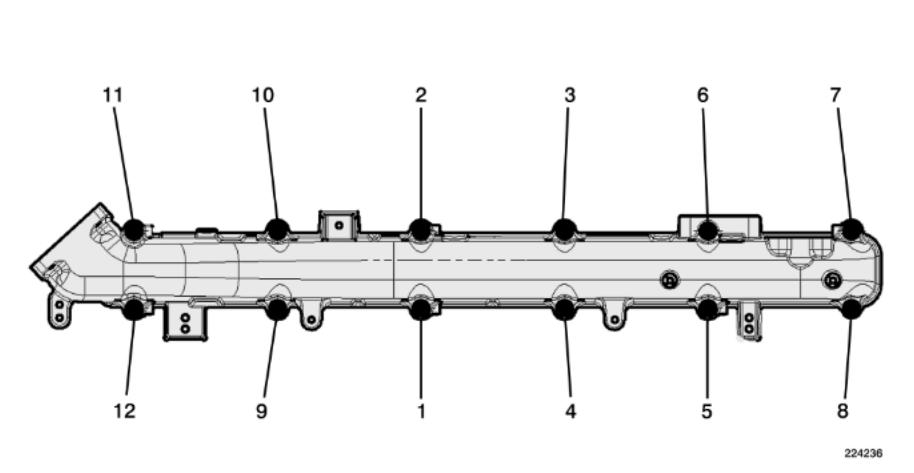

Andrew Burrows Intake manifold / Tightening torques 13/02/16 |

The item numbers indicate the tightening sequence.

Intake manifold securing bolts |

24±4 Nm |

Plug M10 |

20±3 Nm |

Boost air pressure / temperature sensor |

12±2 Nm |

2 / 3

Andrew Burrows Intake manifold / Tightening torques 13/02/16 |

The item numbers indicate the tightening sequence.

Stage1 |

10±2 Nm |

Stage2 |

24±4 Nm |

Intake air heater supply cable securing nut |

10±1.5 Nm |

Consumables

Automotive part N° |

Industrial reference N° |

|

56 89 501 292 |

Silicon adhesive 7091 |

|

3 / 3

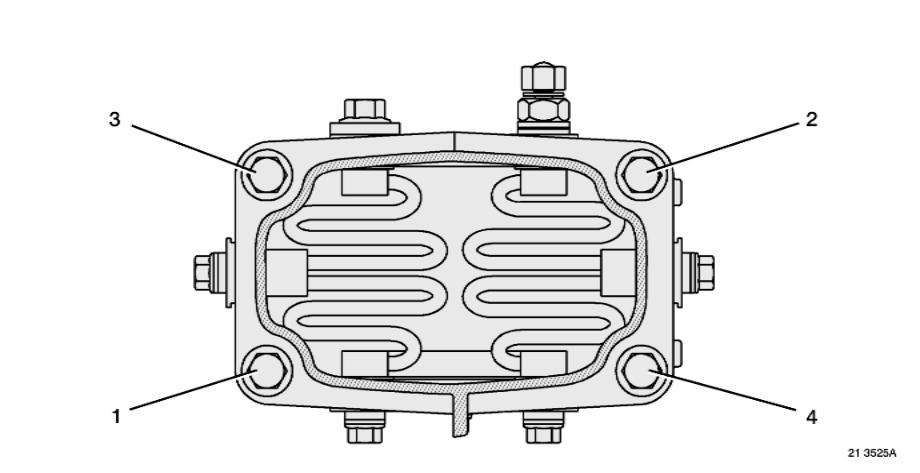

Andrew Burrows Air compressor / Tightening torques 13/02/16

Air compressor, tightening torques

Air compressor 636 cm³ drive pinion securing nut |

200+ 50 Nm |

Air compressor 636 cm³ securing nut |

85±15 Nm |

Lubrication union |

25±4 Nm |

1 / 1

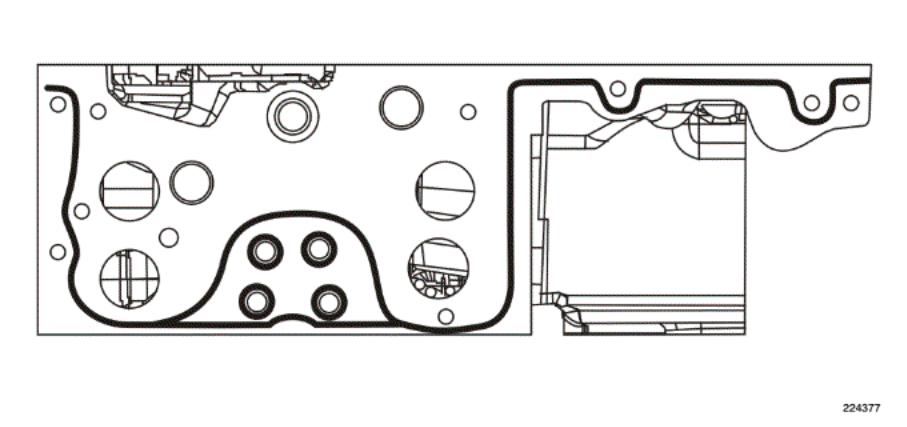

Andrew Burrows Distribution / Tightening torques 13/02/16

Timing system, tightening torques

Assembly type A

1 / 10

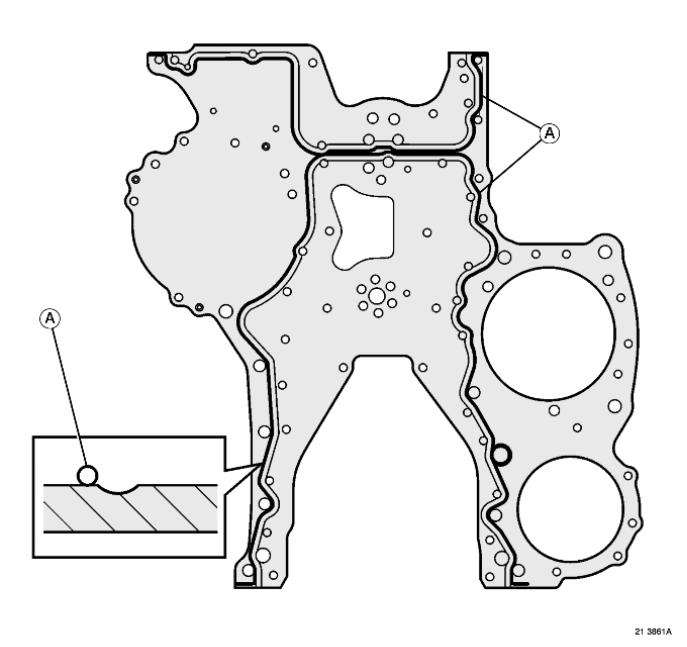

Andrew Burrows Distribution / Tightening torques 13/02/16

Apply a bead of silicone dia. 2 mm (A) as shown in the drawing. Perform assembly within 20 minutes of application of the silicone.

Use a silicone sealant "

ADHESIF SILICONE 7091

".

Apply a bead of silicone dia. 2 mm (A) as shown in the drawing. Perform assembly within 20 minutes of application of the silicone.

Use a silicone sealant "

ADHESIF SILICONE 7091

".

2 / 10

Loading...

Loading...