Mitsubishi Outlander 2007 User Manual

2007 Outlander Service Manual,

Technical Information & Body Repair

Manual Data

Volume 1

Volume 2

Volume 3

Technical Information

Manual

Body Repair Manual

1

)4172

)'0'4#.

%106'065

*19 61 75' 6*+5 /#07#.

6#4)'65 1( &'8'.12/'06

6'%*0+%#. ('#674'5

':6'4+14 +06'4+14 '0)+0' 64#05#:.' 5752'05+10 #%6+8' 5#('6; 2#55+8' 5#('6; '08+410/'06#. 2416'%6+10 5'48+%'#$+.+6; #0& 4'.+#$+.+6;

8'*+%.' +&'06+(+%#6+10

)'0'4#. # #0& 52'%+(+%#6+105

|

)'0'4#. |

|

*19 61 75' 6*+5 /#07#. |

||

|

||

|

HOW TO USE THIS MANUAL |

ABBREVIATIONS

The following abbreviations are used in this manual for classification of model types.

016'

MFI: Indicates the multiport fuel injection, or engines equipped with the multiport injection.

M20000000290USA0000010000

A/T: Indicates the automatic transaxle, or models equipped with automatic transaxle.

FWD: Indicates 2-wheel drive vehicles. AWD: Indicates 4-wheel drive vehicles. A/C: Indicates air conditioning.

Keyless Operation System (KOS): Indicates the Free-hand Security Transmitter (F.A.S.T.-key)

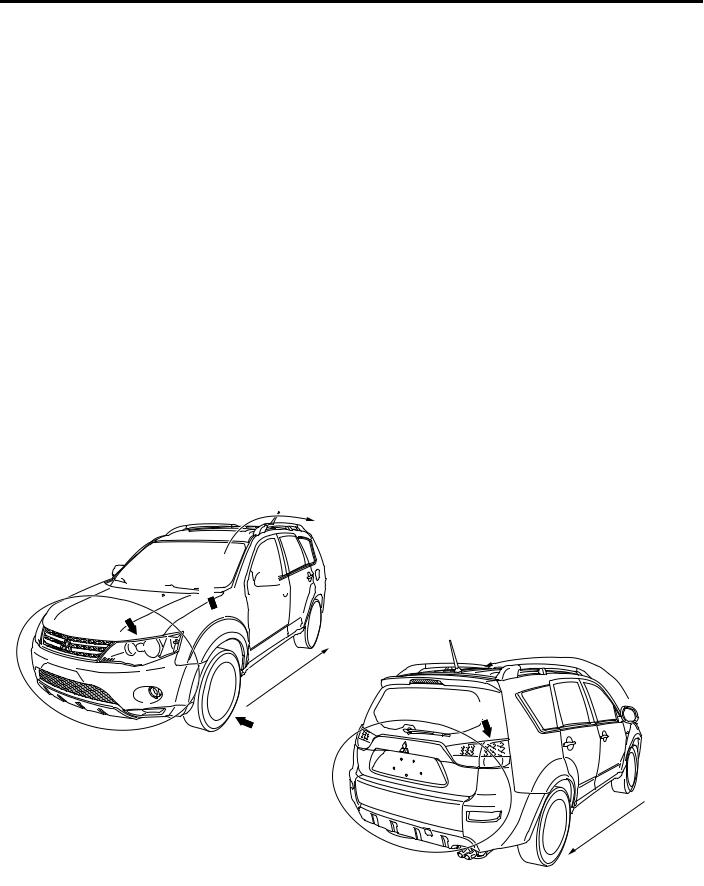

TARGETS OF DEVELOPMENT

The new OUTLANDER has an improved SUV appearance and cruising performance in any road conditions. This car has been developed as the new

M20000000040USA0000010000

generation of SUV proposed by Mitsubishi, aiming to be an all-round car for various applications from daily use to cruising and leisure use.

6'%*0+%#. ('#674'5

EXTERIOR

M20000000170USA0000010000

DESIGN FEATURES

Fine athletic image of powerfulness and driving performance.

Smart styling with high functionality and stylish exterior

Representing feelings of refreshment with a highly refined styling

MAIN FEATURES

6

5

5

4

4

6

|

5 |

2, 3 |

8 |

1 |

7 |

5 |

|

ZC5018290007

)'0'4#. |

|

|

6'%*0+%#. ('#674'5 |

||

|

Good stance which combines wide tread with 18inch tire <XLS model>

Progressive diamond-cut nose with neat cornersAggressive and handsome face design with sharp

styling

Headlights with mechanical styling emphasizing aggressiveness

Tough lower body with the overfender covering a large size tire, the undercover, and black underbody parts

Dynamic cabin which consists of the roof line with uplifting feeling and sharp window graphic

Stylish rear end which comfortably integrates the unique horizontally split upper/lower tailgates

Rear combination lights with a sense of integrity with the glass area, presenting a high-tech image

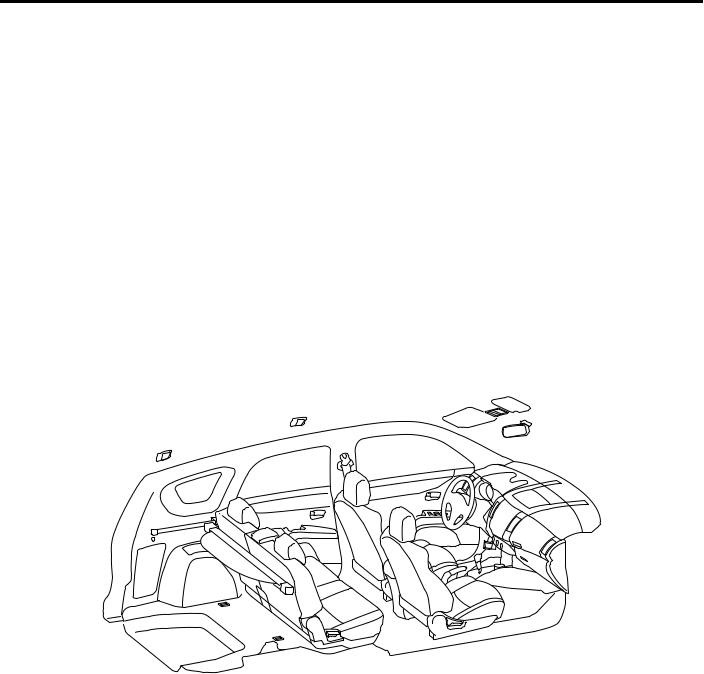

INTERIOR

M20000000180USA0000010000

DESIGN PURPOSE

Presenting well-trimmed interior space with a sporty feel

Combining high functionality with stylish design Neat and carefully established details

MAIN FEATURES

Sporty and dynamic styled instrument panel with uplifting feeling

Unique audio panel integrated in the instrument panel, representing high quality

ZC6022030000

Door trim, floor console, and air outlet panel with powerful silver accent parts in the sculpturesque styling

Drive mode selector dial in mechanical design Bucket-type front seats in sporty three dimensional shape

Functional luggage area equipped with the tonneau cover, luggage hook, and utility bar

|

)'0'4#. |

|

6'%*0+%#. ('#674'5 |

||

|

ENGINE

M20000000200USA0000010000

The 6B31 engine has been developed to achieve high performance, better fuel economy, smaller size, and weight reduction.

TRANSAXLE

The F6AJA-type <FWD> or the W6AJA-type <AWD> 6-speed sport mode automatic transaxle has been

M20000000210USA0000010001

developed to achieve excellent fuel economy, further improved operation, and driving pleasure.

SUSPENSION

M20000000230USA0000010000

<Front suspension>

Coil spring

Stabilizer link

Stabilizer bar

Shock absorber

Lower arm

Front axle crossmember (Flat crossmember)

ZC6011770000

)'0'4#. 6'%*0+%#. ('#674'5

<Rear suspension>

<FWD>

Coil spring

Shock absorber

Trailing arm

Toe control arm

Rear crossmember

Stabilizer bar

<AWD>

Coil spring

Rear crossmember

Shock absorber

Trailing arm

Stabilizer bar

Toe control arm

Upper arm

The well-proven McPherson strut suspension (front) and trailing arm type multi-link suspension (rear) have been adopted.

ZC6011830000

|

)'0'4#. |

|

6'%*0+%#. ('#674'5 |

||

|

ACTIVE SAFETY

M20000000310USA0000010000

<Except vehicles for CANADA> |

<Vehicles for CANADA> |

||||||||||||

ABS warning |

Brake warning |

ABS warning |

|

|

|

Brake warning |

|||||||

light |

light |

light |

|

|

|

light |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ASC

OFF

SE R VIC E |

CHECK |

RE Q UIRE D |

ABS warning light Brake warning light

Stoplight switch

G-sensor <AWD>, hydraulic unit, ABS-ECU

AWD-ECU <AWD> |

Magnetic |

encoder for |

|

Wheel speed sensor |

wheel speed |

Wheel speed sensor |

|

Data link connector |

detection |

Magnetic encoder for wheel speed detection |

ZC6006610001 |

The ABS*1has been installed as standard equipment to prevent the wheels from locking and optimize the longitudinal brake force distribution depending on the road surface and loading conditions. In addition, the

ASC*2has also been installed to suppress side slip and wheel spin during steep steering or on a slippery road surface, ensuring the ideal brake force and

braking stability through the integrated control of brake and engine output <standard: LS, optional: XLS>.

016'

*1: Electronic Brake-force Distribution *2: Active Stability Control

)'0'4#. |

|

|

6'%*0+%#. ('#674'5 |

||

|

PASSIVE SAFETY

M20000000320USA0000010000

SRS AIR BAGS

Driver's air bag module

Passenger's (front) Seat belt with air bag module pre-tensioner

Side-airbag module

Curtain air bag module

ZC6008500000

Dual Supplemental Restraint System (SRS) front air bags deploy only upon detection of frontal impact. When used in combination with the 3-point ELR seat belts, they significantly reduce head and upper torso injury to front-seat occupants.

The seat belts with pre-tensioner work simultaneously with the SRS. The pre-tensioner takes up seat slack immediately when a collision takes place by restraining the front passengers sooner than the SRS. This prevents the passengers from moving forward.

SIDE-AIRBAGS AND CURTAIN AIR BAGS

During a side collision, the SRS side-airbags embedded in the front seat side area soften blows to the front passenger's chest area, and the SRS curtain

air bags integrated into the roof side area soften blows to the front/rear passenger's head area.

FRONT SEAT BELT

A seat belt with double pre-tensioner for shoulder and lap has been installed on the driver's seat. A seat belt with pre-tensioner is on the front passenger's seat. This retracts the belt to eliminate slack, and increases the initial restraint for passengers to limit movement of the passenger, increasing safety. In addition, the variable force limiter has been installed on the seat belts (driver's/front passenger's seats) to properly absorb the load on a passenger by extending the belt if the belt tension exceeds a certain level, increasing safety against an accident with a collision.

|

)'0'4#. |

|

6'%*0+%#. ('#674'5 |

||

|

BODY CONSTRUCTION

The body structure combines a high-energy absorbing structure (front and rear) and high rigidity cabin structure to reduce the level of injury to passengers upon front, rear and side impact, as well as secure cabin space and to improve passenger rescue upon impact.

Employment of a top/bottom one-piece door outer panel and door inner panel pressed door structure improves door panel rigidity.

ZC6012910000

SAFETY-ENHANCED FRONT SEATS

The front seats are designed to minimize the risk of whiplash in a collision from the rear.

The head restraints have been ideally angled forward, while the seat frame was moved toward the rear.

OTHER SAFETY FEATURES

3-point ELR seat belts Front fog lamps

Child-protection rear door locks Brake pedal recede-control device

ENVIRONMENTAL PROTECTION

M20000000270USA0000010000

RECYCLING

Recyclable thermoplastic resin and recycled materials have been actively used, and multilayer materials have been integrated into thermoplastic resin.

Classification |

Main contents |

|

Components made |

Chip materials produced during manufacturing process have been reused for the |

|

of |

recycled |

following components: Bumper, instrument panel, door trims, and radiator grille. |

materials |

|

Waste materials produced by other industries have been reused for the following |

|

|

components: Sound absorbing materials for dash panel or roof, and oil level gauge. |

Components made |

Thermoplastic resin has been used for the purge hose in the engine control system. |

|

of materials which |

Thermoplastic resin has been used for all the materials for the floor carpet. |

|

can be |

easily |

Thermoplastic resin has been used for the bumper, instrument panel, door trims, and |

recycled |

|

radiator grille. |

|

|

|

|

|

)'0'4#. |

|

|

|

|

6'%*0+%#. ('#674'5 |

||

|

|

|

||

REDUCTION OF MATERIAL BURDEN ON |

radiator, heater core, and rubber parts. |

|

||

ENVIRONMENT |

|

|

|

|

Lead-free materials have been used for the fuel tank, |

|

|

||

Item |

|

Main contents |

|

|

Elimination |

of |

Lead-free materials have been used for the components such as the fuel tank, radiator, |

||

environmental |

heater core, battery cable terminal, wheel balance weight, power steering high-pressure |

|||

burden materials |

hose, glass ceramic print, electrostatic coating, crank bearing metal, connecting rod |

|||

|

|

bearing metal, crankshaft, connecting rod, harnesses, and intake valve seat. |

|

|

|

|

PVC (polyvinyl chloride)-free materials have been used for the waterproofing film. |

||

Ozone |

layer |

Air conditioning filled with new refrigerant (HFC 134a) has been installed. |

|

|

protection |

|

|

|

|

Prevention |

of air |

Organic solvent drainage amount for body painting has been reduced. |

|

|

pollution |

|

|

|

|

SERVICEABILITY AND RELIABILITY

MAINTENANCE-FREE FEATURES

The chain timing belt has been adopted to eliminate a regular replacement.

ENHANCED DIAGNOSIS SYSTEM

Diagnosis functions have been included for the following systems, so that it is possible to use the M.U.T.-III to read the diagnosis codes and service data and to carry out actuator tests. In addition, it is also possible to read the diagnosis codes by the flashing of the warning light in some systems.

Multiport fuel injection system (MFI) Electronically-controlled AWD

6-speed sport mode automatic transaxle ABS (with EBD)

Active Stability Control (ASC) Power windows

Keyless Operation System (KOS) SRS air bag

Immobilizer Combination meter Headlight auto leveling

6-disc CD changer, and AM/FM radio ETACS

M20000000280USA0000010000

Heater and air conditioning

016' 6JG ( # 5 6 MG[ (TGG JCPF #FXCPEGF 5GEWTKV[ 6TCPUOKVVGT KU FGUETKDGF CU VJG -G[NGUU 1RGTCVKQP 5[UVGO -15 KP VJKU OCPWCN

BETTER SERVICEABILITY AND HANDLING

The power steering oil pump has been installed at the front of the vehicle for better workability.

The engine control module has been installed in the engine room for better workability.

The instrument panel components can be removed and installed individually and the frame part is smaller in size to allow it to be removed and installed without lowering the steering shaft.

The floor console panel can be removed and installed individually without tools for parking brake lever adjustment.

The joint connector has been relocated for better CAN-related workability.

The service hole for the rear shock absorber tightening check has been located on the quarter trim for better workability.

A partial slit has been added on the floor carpet for easier access to the fuel pump module.

|

)'0'4#. |

|

8'*+%.' +&'06+(+%#6+10 |

||

|

||

|

VEHICLE IDENTIFICATION |

M20000000010USA0000010000

VEHICLE IDENTIFICATION NUMBER LOCATION

The vehicle identification number (VIN) is located on a plate attached to the left top side of the instrument panel.

ZC6012650000

VEHICLE IDENTIFICATION CODE CHART PLATE

All vehicle identification numbers contain 17 digits. The vehicle number is a code which tells country, make, vehicle type, etc.

J A 4 M S 3 1 X 1 7 U 0 0 0 0 0 1

12

1 2 3 4 5 6 7 8 9 10 11

ZC6009480000

No. |

Item |

Content |

1 |

Country |

J: Japan |

2 |

Make |

A: Mitsubishi |

3 |

Vehicle type |

4: Multi-purpose vehicle |

4 |

Others |

GROSS VEHICLE WEIGHT |

|

|

RATING/BRAKE SYSTEM |

|

|

M: 5001-6000 lbs/HYDRAULIC |

5 |

Line |

S: OUTLANDER FWD |

|

|

T: OUTLANDER AWD |

6 |

Price class |

3: Medium |

|

|

4: High |

7 |

Body |

1: 5-door wagon |

8 |

Engine |

X: 3.0L (6B31) MIVEC |

9 |

Check digits* |

0, 1, 2, 3, -----------9, X |

10 |

Model year |

7: 2007 year |

11 |

Plant |

U: Mizushima |

12 |

Serial number |

000001 to 999999 |

)'0'4#. |

|

|

8'*+%.' +&'06+(+%#6+10 |

||

|

016' %JGEM FKIKV OGCPU C UKPING PWODGT QT NGVVGT :

WUGF VQ XGTKH[ VJG CEEWTCE[ QH VTCPUETKRVKQP QH XGJKENG KFGPVKHKECVKQP PWODGT

VEHICLE IDENTIFICATION NUMBER LIST

VEHICLES FOR USA

(FOR FEDERAL EMISSION REGULATION)

VIN (except sequence number) Brand Engine Model code displacement

JA4MS31X_7U |

MITSUBISHI |

3.0L |

CW6WXLSYL2M |

JA4MS41X_7U |

OUTLANDER |

|

CW6WXLHYL2M |

|

|

||

|

|

|

CW6WXLXYL2M |

JA4MT31X_7U |

|

|

CW6WXLSYZL2M |

JA4MT41X_7U |

|

|

CW6WXLHYZL2M |

|

|

|

CW6WXLXYZL2M |

(FOR CALIFORNIA EMISSION REGULATION) |

|

||

VIN (except sequence number) |

Brand |

Engine |

Model code |

|

|

displacement |

|

JA4MS31X_7U |

MITSUBISHI |

3.0L |

CW6WXLSYL7M |

JA4MS41X_7U |

OUTLANDER |

|

CW6WXLHYL7M |

|

|

||

|

|

|

CW6WXLXYL7M |

JA4MT31X_7U |

|

|

CW6WXLSYZL7M |

JA4MT41X_7U |

|

|

CW6WXLHYZL7M |

|

|

|

CW6WXLXYZL7M |

VEHICLES FOR PUERTO RICO |

|

|

|

VIN (except sequence number) |

Brand |

Engine |

Model code |

|

|

displacement |

|

JA4MS31X_7U |

MITSUBISHI |

3.0L |

CW6WXLSYL2M |

|

OUTLANDER |

|

CW6WXLMYL2M |

|

|

|

|

JA4MS41X_7U |

|

|

CW6WXLXYL2M |

JA4MT31X_7U |

|

|

CW6WXLSYZL2M |

VEHICLES FOR CANADA |

|

|

|

VIN (except sequence number) |

Brand |

Engine |

Model code |

|

|

displacement |

|

JA4MS31X_7U |

MITSUBISHI |

3.0L |

CW6WXLSYL3M |

JA4MS41X_7U |

OUTLANDER |

|

CW6WXLXYL3M |

|

|

||

JA4MT31X_7U |

|

|

CW6WXLSYZL3M |

JA4MT41X_7U |

|

|

CW6WXLXYZL3M |

|

)'0'4#. |

|

)'0'4#. # #0& 52'%+(+%#6+105 |

||

|

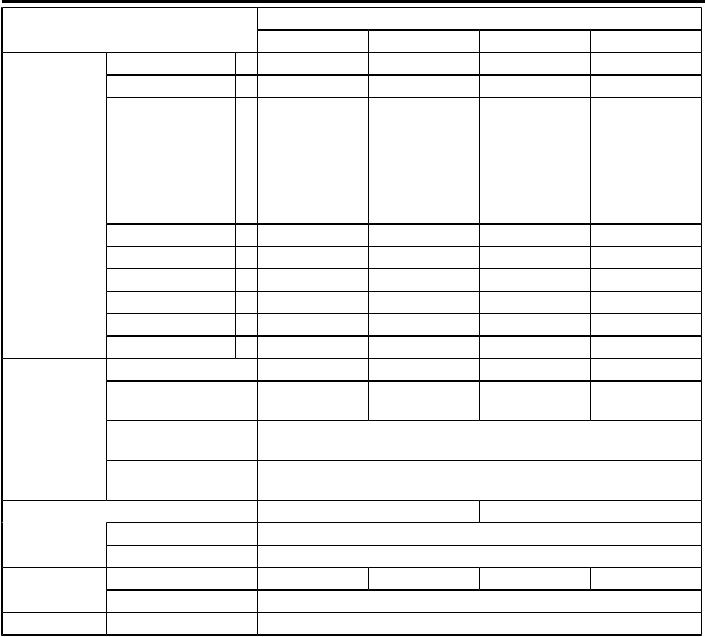

GENERAL DATA AND SPECIFICATIONS

M20000000300USA0000010000

<Except vehicles for CANADA>

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

5 |

|

9 |

7 |

|

|

4 |

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

||||

2 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ZC5019470000 |

||

Item |

|

|

|

CW6W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

XLSYL2M/7M |

XLHYL2M/7M |

XLSYZL2M/7M |

XLHYZL2M/7M |

||||||||

Vehicle |

Overall length |

1 |

4,640 |

(182.7) |

4,640 |

(182.7) |

4,640 |

(182.7) |

4,640 |

(182.7) |

|||||

dimension mm |

Overall width |

2 |

1,800 |

(70.9) |

1,800 |

(70.9) |

1,800 |

(70.9) |

1,800 |

(70.9) |

|||||

(in) |

Overall |

height |

3 |

1,680 |

(66.1) |

1,720 |

(67.7) |

1,680 |

(66.1) |

1,720 |

(67.7) |

||||

|

|||||||||||||||

|

(unladen) |

|

|

<Vehicles |

|

<Vehicles |

with |

<Vehicles |

|

<Vehicles |

with |

||||

|

|

|

|

without |

roof |

roof rail> |

|

without |

roof |

roof rail> |

|

||||

|

|

|

|

rail> |

|

|

|

|

|

rail> |

|

|

|

|

|

|

|

|

|

1,720 |

(67.7) |

|

|

|

1,720 |

(67.7) |

|

|

|

||

|

|

|

|

<Vehicles |

with |

|

|

|

<Vehicles |

with |

|

|

|

||

|

|

|

|

roof rail> |

|

|

|

|

roof rail> |

|

|

|

|

||

|

Wheelbase |

|

4 |

2,670 |

(105.1) |

2,670 |

(105.1) |

2,670 |

(105.1) |

2,670 |

(105.1) |

||||

|

Tread-front |

|

5 |

1,540 |

(60.6) |

1,540 |

(60.6) |

1,540 |

(60.6) |

1,540 |

(60.6) |

||||

|

Tread-rear |

|

6 |

1,540 |

(60.6) |

1,540 |

(60.6) |

1,540 |

(60.6) |

1,540 |

(60.6) |

||||

|

Overhang-front |

7 |

965 (38.0) |

|

965 (38.0) |

|

965 (38.0) |

|

965 (38.0) |

|

|||||

|

Overhang-rear |

8 |

1,005 |

(39.6) |

1,005 |

(39.6) |

1,005 |

(39.6) |

1,005 |

(39.6) |

|||||

|

Ground clearance |

9 |

215 (8.5) |

|

215 (8.5) |

|

215 (8.5) |

|

215 (8.5) |

|

|||||

Vehicle weight |

Curb weight |

|

1,615 |

(3,560) |

1,635 |

(3,604) |

1,680 |

(3,703) |

1,700 |

(3,747) |

|||||

kg (lb) |

Gross vehicle weight |

2,300 |

(5,071) |

|

|

|

2,350 |

(5,181) |

2,350 |

(5,181) |

|||||

|

rating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gross axle weight 1,090 (2,403) rating-front

|

Gross axle weight |

1,280 (2,822) |

|

|

rating-rear |

|

|

Seating capacity |

5 |

|

|

Engine |

Model No. |

6B31 |

|

|

Piston displacement |

3.0 L |

|

Transaxle |

Model No. |

F6AJA |

W6AJA |

|

Type |

6-speed automatic |

|

Fuel system |

Fuel supply system |

Multiport fuel injection |

|

|

|

|

|

|

|

|

)'0'4#. |

|

|

|

|

|

|

|

|

|

)'0'4#. # #0& 52'%+(+%#6+105 |

|

|

||||||

|

|

|

|

|

|

|

||||||

Item |

|

|

|

|

CW6W |

|

|

|

|

|

|

|

|

|

|

|

|

XLMYL2M |

XLXYL2M/7M |

XLXYZL2M/7M |

|||||

Vehicle |

Overall length |

|

1 |

4,640 |

(182.7) |

4,640 |

(182.7) |

4,640 |

(182.7) |

|||

dimension mm |

Overall width |

|

2 |

1,800 |

(70.9) |

1,800 |

(70.9) |

1,800 |

(70.9) |

|||

(in) |

Overall |

height |

3 |

1,680 |

(66.1) |

1,720 |

(67.7) |

1,680 |

(66.1) |

|||

|

||||||||||||

|

(unladen) |

|

|

<Vehicles |

without |

<Vehicles with |

roof <Vehicles |

without |

||||

|

|

|

|

|

roof rail> |

|

rail> |

|

roof rail> |

|

||

|

|

|

|

|

1,720 |

(67.7) |

|

|

1,720 |

(67.7) |

||

|

|

|

|

|

<Vehicles |

with roof |

|

|

<Vehicles |

with roof |

||

|

|

|

|

|

rail> |

|

|

|

|

rail> |

|

|

|

Wheelbase |

|

4 |

2,670 |

(105.1) |

2,670 |

(105.1) |

2,670 |

(105.1) |

|||

|

Tread-front |

|

5 |

1,540 |

(60.6) |

1,540 |

(60.6) |

1,540 |

(60.6) |

|||

|

Tread-rear |

|

6 |

1,540 |

(60.6) |

1,540 |

(60.6) |

1,540 |

(60.6) |

|||

|

Overhang-front |

|

7 |

965 (38.0) |

|

965 (38.0) |

965 (38.0) |

|

||||

|

Overhang-rear |

|

8 |

1,005 |

(39.6) |

1,005 |

(39.6) |

1,005 |

(39.6) |

|||

|

Ground clearance |

9 |

215 (8.5) |

|

215 (8.5) |

215 (8.5) |

|

|||||

Vehicle weight |

Curb weight |

|

|

1,675 |

(3,692) |

1,670 |

(3,681) |

1,735 |

(3,825) |

|||

kg (lb) |

Gross vehicle |

weight |

2,300 |

(5,071) |

|

|

2,350 |

(5,181) |

||||

|

rating |

|

|

|

|

|

|

|

|

|

|

|

|

Gross |

axle |

weight |

1,090 |

(2,403) |

|

|

|

|

|

||

|

rating-front |

|

|

|

|

|

|

|

|

|

|

|

|

Gross |

axle |

weight |

1,280 |

(2,822) |

|

|

|

|

|

||

|

rating-rear |

|

|

|

|

|

|

|

|

|

|

|

Seating capacity |

|

|

|

7 |

|

|

|

|

|

|

|

|

Engine |

Model No. |

|

|

6B31 |

|

|

|

|

|

|

|

|

|

Piston displacement |

3.0 L |

|

|

|

|

|

|

|

|||

Transaxle |

Model No. |

|

|

F6AJA |

|

|

|

W6AJA |

|

|||

|

Type |

|

|

|

6-speed automatic |

|

|

|

|

|

||

Fuel system |

Fuel supply system |

|

Multiport fuel injection |

|

|

|

|

|

||||

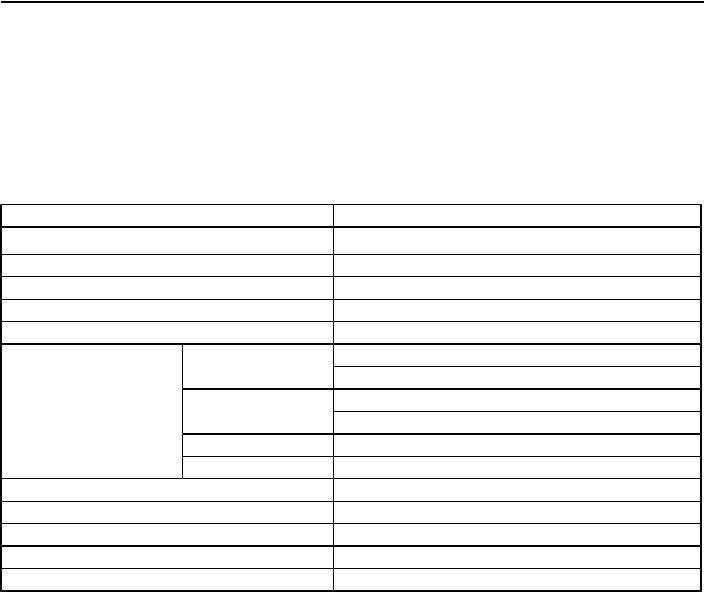

<Vehicles for CANADA> |

|

|

|

|

|

|

|

|

3 |

9 |

7 |

4 |

8 |

|

5 |

6 |

|||

2 |

|

1 |

|

|

|

|

|

|

ZC5019470000 |

|

|

|

|

|

|

|

)'0'4#. |

|

|

|

|

|

|

|

|

|

|

)'0'4#. # #0& 52'%+(+%#6+105 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||

Item |

|

|

|

|

CW6W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

XLSYL3M |

XLSYZL3M |

XLXYL3M |

|

XLXYZL3M |

|||||

Vehicle |

Overall length |

|

1 |

4,640 |

(182.7) |

4,640 |

(182.7) |

4,640 |

(182.7) |

4,640 |

(182.7) |

|||

dimension mm |

Overall width |

|

2 |

1,800 |

(70.9) |

1,800 |

(70.9) |

1,800 |

(70.9) |

1,800 |

(70.9) |

|||

(in) |

Overall |

height |

3 |

1,680 |

(66.1) |

1,720 |

(67.7) |

1,680 |

(66.1) |

1,720 |

(67.7) |

|||

|

||||||||||||||

|

(unladen) |

|

|

<Vehicles |

|

<Vehicles with |

<Vehicles |

|

<Vehicles with |

|||||

|

|

|

|

|

without |

roof |

roof rail> |

without |

roof |

roof rail> |

||||

|

|

|

|

|

rail> |

|

|

|

|

rail> |

|

|

|

|

|

|

|

|

|

1,720 |

(67.7) |

|

|

1,720 |

(67.7) |

|

|

||

|

|

|

|

|

<Vehicles |

with |

|

|

<Vehicles |

with |

|

|

||

|

|

|

|

|

roof rail> |

|

|

|

roof rail> |

|

|

|

||

|

Wheelbase |

|

4 |

2,670 |

(105.1) |

2,670 |

(105.1) |

2,670 |

(105.1) |

2,670 |

(105.1) |

|||

|

Tread-front |

|

5 |

1,540 |

(60.6) |

1,540 |

(60.6) |

1,540 |

(60.6) |

1,540 |

(60.6) |

|||

|

Tread-rear |

|

6 |

1,540 |

(60.6) |

1,540 |

(60.6) |

1,540 |

(60.6) |

1,540 |

(60.6) |

|||

|

Overhang-front |

|

7 |

965 (38.0) |

|

965 (38.0) |

965 (38.0) |

|

965 (38.0) |

|||||

|

Overhang-rear |

|

8 |

1,005 |

(39.6) |

1,005 |

(39.6) |

1,005 |

(39.6) |

1,005 |

(39.6) |

|||

|

Ground clearance |

9 |

215 (8.5) |

|

215 (8.5) |

215 (8.5) |

|

215 (8.5) |

||||||

Vehicle weight |

Curb weight |

|

|

1,615 |

(3,560) |

1,680 |

(3,703) |

1,670 |

(3,681) |

1,735 |

(3,825) |

|||

kg (lb) |

Gross vehicle |

weight |

2,300 |

(5,071) |

2,350 |

(5,181) |

2,300 |

(5,071) |

2,350 |

(5,181) |

||||

|

rating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gross |

axle |

weight |

1,090 |

(2,403) |

|

|

|

|

|

|

|

||

|

rating-front |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gross |

axle |

weight |

1,100 |

(2,425) |

|

|

|

|

|

|

|

||

|

rating-rear |

|

|

|

|

|

|

|

|

|

|

|

|

|

Seating capacity |

|

|

|

5 |

|

|

|

|

7 |

|

|

|

|

|

Engine |

Model No. |

|

|

6B31 |

|

|

|

|

|

|

|

|

|

|

|

Piston displacement |

3.0 L |

|

|

|

|

|

|

|

|

|

|||

Transaxle |

Model No. |

|

|

F6AJA |

|

W6AJA |

F6AJA |

|

W6AJA |

|||||

|

Type |

|

|

|

6-speed automatic |

|

|

|

|

|

|

|||

Fuel system |

Fuel supply system |

|

Multiport fuel injection |

|

|

|

|

|

|

|||||

)4172

'0)+0'

%106'065

)'0'4#. &'5%4+26+10

$#5' '0)+0'

|

'0)+0' |

|

)'0'4#. &'5%4+26+10 |

||

|

||

|

GENERAL DESCRIPTION |

This vehicle is equipped with the newly developed 6B31 engine, a 3.0L V6 Single Over Head Camshaft (SOHC) 24-valve engine.

6JG HGCVWTGU QH VJKU GPIKPG CTG CU HQNNQYU

M21102000001USA0000010000

The 3.0L engine employs the Mitsubishi Innovative Valve timing and lift Electronic Control system (MIVEC).

An aluminum alloy cylinder block is used to be lightweight and compact.

The cylinders are offset from the center of the crankshaft.

MAJOR SPECIFICATIONS

ITEMS |

|

SPECIFICATIONS |

Total displacement cm3(cu in) |

2,998 (182.9) |

|

Bore × Stroke mm (in) |

|

87.6 (3.45) × 82.9 (3.26) |

Compression ratio |

|

9.5 |

Combustion chamber |

|

Pentroof type |

Camshaft arrangement |

|

SOHC |

Valve timing |

Intake Open |

-1° BTDC Low speed cam |

|

|

18° BTDC High speed cam |

|

Intake Close |

37° ABDC Low speed cam |

|

|

86° ABDC High speed cam |

|

Exhaust Open |

55° BBDC |

|

Exhaust Close |

17° ATDC |

Maximum output kW/r/min (HP/r/min) |

164/6,250(220/6,250) |

|

Maximum torque N·m/r/min (lbs-ft/r/min) |

276/4,000(204/4,000) |

|

Lash adjuster |

|

Exhaust side only |

Fuel system |

|

Electronic-controlled multiport fuel injection |

Ignition system |

|

Electronic-controlled 6-coil |

'0)+0' |

|

|

$#5' '0)+0' |

||

|

||

BASE ENGINE |

|

|

|

M21102000010USA0000010000 |

CYLINDER HEAD

Plug guide

Exhaust side |

Intake side |

Valve guide

Valve seat

ZK602589AA00

A cylinder head made of an aluminum alloy, which is lightweight and offers a high level of cooling efficiency, has been adopted. A pent roof combustion chamber with a center spark plug has been adopted. It has a small valve compound angle to create a compact chamber.

Cross-flow type intake and exhaust ports have been adopted. Two intake ports and two exhaust ports are provided independently on the right and left sides.

Four camshaft bearings are provided at the intake and exhaust sides, respectively. The No. 4 bearing sustains the thrust load of the camshaft.

VALVE SEAT

The valve stem seals use springs with good seal performance to prevent oil draining down.

The oversize valve guides are available as spare parts: 0.3.

VALVE GUIDE

A sintered alloy material is used for the valve guides.

The three kinds of the oversize valve guides are available as spare parts: 0.05, 0.25 and 0.50.

|

'0)+0' |

|

$#5' '0)+0' |

||

|

CYLINDER HEAD GASKET

Oil hole

Oil hole

Water hole

Water hole |

Water hole |

ZK602583AA00

A 2-layer metal gasket with good sealability and heat resistance is used for the cylinder head gasket.

Timing belt side |

Blow by nipple |

Blow by nipple |

P.C.V. valve |

ZK602584AA00 |

ROCKER COVER

A lightweight resin material is used for the cylinder gasket cover.

'0)+0' |

|

|

$#5' '0)+0' |

||

|

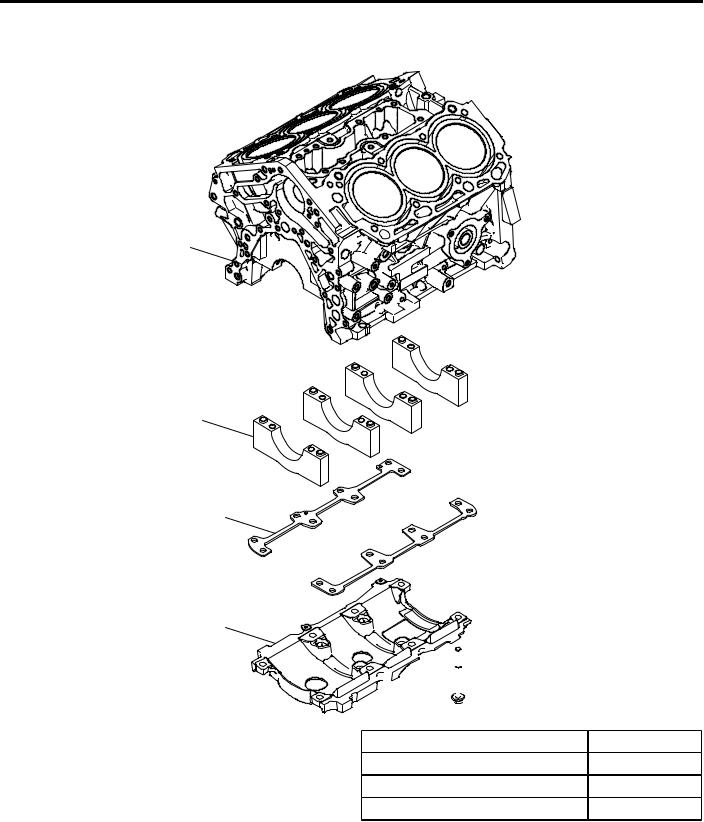

CYLINDER BLOCK

Cylinder block

Bearing cap

Right plate

Left plate

Left plate

Beam

An aluminum alloy material is used for the cylinder block to be lightweight.

The crankshaft journal has 4 bearings. The No.3 bearing carries the thrust load of the crankshaft.

A full Siamese type water jacket is used.

|

|

|

|

|

|

|

|

|

|

|

ZK602585AA00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Items |

Specifications |

||||||||||

Bore mm (in.) |

87.6(3.45) |

||||||||||

Bore pitch mm (in.) |

98(3.86) |

||||||||||

Stroke mm (in.) |

82.9(3.26) |

||||||||||

|

|

|

'0)+0' |

|

|

$#5' '0)+0' |

|

|

|

|

|

|

|

|

The cylinders are offset from the center of the crankshaft. |

|

|

Offset crankshaft |

|

|

|

layout |

|

Crank journal |

|

center |

ZK603515AA00 |

Front mark

Piston off set 0.5 mm

ZK602586AA00

PISTON

Special aluminum alloy is adopted to improve heat efficiency and achieve lower weight.

That contributes to higher engine performance and better fuel economy. Piston pinhole center is offset by 0.5 mm from piston center towards the thrust side.

Out side surface of piston skirt has striation-like finishing better oil holding ability (and superior durability against scuffing.)

Items |

Specifications |

Basic diameter mm (in.) |

87.6(3.45) |

Pin hole diameter mm (in.) |

22(0.87) |

Overall height mm (in.) |

47.78(1.88) |

d2 d1 D

h

ZK602587AA00

PISTON PIN

Semi-floating piston pin is adopted. Piston pin is into the small end of connecting rod so that it floats in piston.

Items |

Specifications |

Outer diameter (D) mm (in.) |

22(0.87) |

Inner diameter (d1) mm (in.) |

13.5(0.53) |

Inner diameter (d2) mm (in.) |

12.5(0.49) |

Overall length (h) mm (in.) |

58(2.28) |

'0)+0' |

|

|

$#5' '0)+0' |

||

|

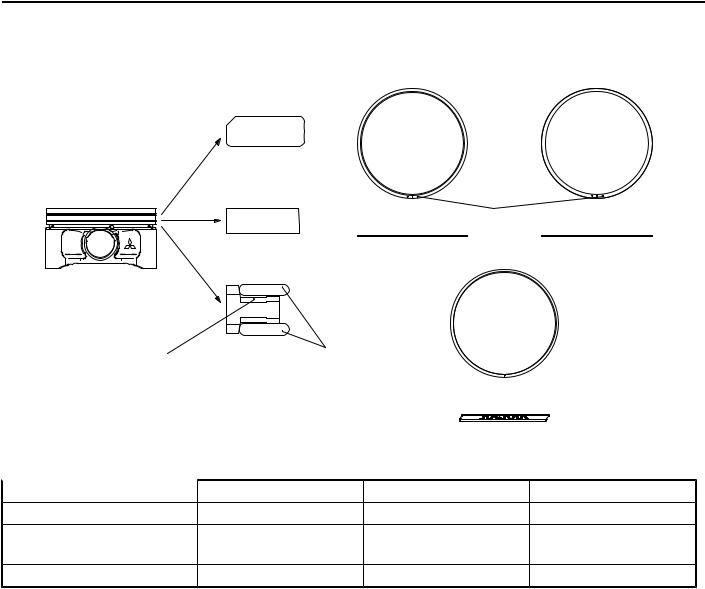

PISTON RING

Piston ring No.1 |

Piston ring No.2 |

Piston ring No.1

Piston ring No.2

Maker mark

Oil ring

Oil ring

Specer |

Side rail |

|

|

|

ZK602588AA00 |

Piston ring consists of ring No.1, No. 2, and oil ring. |

|

|

|

Items |

Piston ring No.1 |

Piston ring No.2 |

Oil ring |

Shape |

Barrel |

Taper |

3-piece, Barrel |

Surface treatment |

(cylinder Chrome nitride (PVD) |

Parkerizing + |

resin Hard plated Parkerizing |

contact surface) |

|

coating |

|

Supplier mark |

1T |

2T |

None |

|

|

d |

D |

|

L |

|

ZK602591AA00 |

|

|

'0)+0' $#5' '0)+0'

CONNECTING ROD

High strength carbon steel (forging) material is adopted. Rod has "H" shaped cross section.

Big-end is lubricated through crankshaft oil passage between main journal and pin.

Items |

Specifications |

Small end hole diameter (d) |

22(0.87) |

mm (in.) |

|

Big end hole diameter (D) |

56(2.20) |

mm (in.) |

|

Center-to-center distance (L) |

145(5.71) |

mm (in.) |

|

|

Identification |

|

color |

H |

A |

|

|

|

ZK602592 AA00 |

CONNECTING BEARING

Upper and lower bearings are same parts.

This part consists of overlay (surface), copper alloy plate (middle) and steel plate (back side).

To reduce friction loss, width of connecting rod bearing is designed as short as possible composed with crankshaft journal.

Items |

Specifications |

Width (H) mm (in.) |

14.4(0.57) |

Thickness (A) mm (in.) |

1.5(0.06) |

'0)+0' |

|

|

$#5' '0)+0' |

||

|

CRANKSHAFT

Balance weight |

Crankshaft journal |

identification mark |

Oil hole

Crankshaft pin identification mark

Balance weight |

Oil hole |

Balance weight |

ZK602593AA00

Forging steel is adopted.

This crankshaft has 4-main bearings and 5-balancing weights.

Crankshaft pins are located in every 60 degrees. Lubrication oil is lead from main journal to pin.

Timing belt sprocket and crankshaft pulley are assembled at front end.

Items |

Specifications |

Pin outer diameter mm (in.) |

53(2.09) |

Journal outer diameter mm (in.) |

69(2.72) |

CRANKSHAFT BEARING AND THRUST BEARING

Thrust bearing

Groove

Crankshaft bore identification mark

Cylinder bore identification mark

Main bearing consists of aluminum alloy (surface) and steel plate (backside).

Thrust bearing, which controls axial movement of crankshaft, is assembled at No.3 journal.

Items |

Specifications |

Crankshaft bearing Width |

18.5(0.73) |

Engine front

Upper bearing

Oil groove

Oil hole

Identification color

Lower bearing

|

|

Identification color |

|

|

ZK602594 |

Items |

mm (in.) |

Specifications |

|

|

|

|

Thickness |

2.0(0.08) |

|

mm (in.) |

|

Crankshaft |

thrust Thickness |

2.0(0.08) |

bearing |

mm (in.) |

|

|

'0)+0' |

|

$#5' '0)+0' |

||

|

Timing mark |

Damper |

ZK602595AA00 |

|

CRANKSHAFT PULLEY

The outer ring has 6-rib for power steering pump and 4-rib for alternator and air-compressor drive belt.

Timing mark notch is applied at the flange of 4-rib side.

DRIVE PLATE

The drive plate is made of sheet metal. The drive plate is mounted with 8 bolts.

ZK602596AA00

'0)+0' |

|

|

$#5' '0)+0' |

||

|

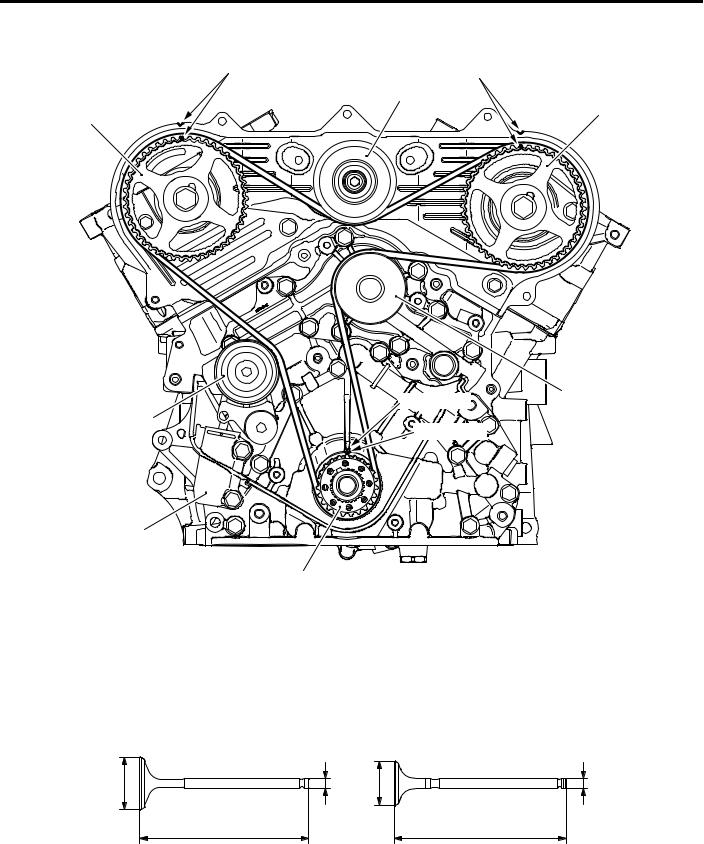

TIMING BELT

Timing mark |

Timing mark |

|

|

|

Idler pulley |

Camshaft sprocket

Camshaft sprocket

Timing mark |

Water pump |

|

idler pulley |

||

Tensioner pulley |

||

|

||

Timing mark |

|

Auto tensioner

Crankhaft sprocket

ZK602597AA00

By using the highly strengthen timing belt, the belt is narrow and long-lasting. This allows the friction to be decreased, and the engine weight to be lightweight.

By abolishing a traditional eccentric pulley, the tensioner is designed to be lightweight.

By applying the projection of the timing belt cover, the timing belt is prevented from coming off the tooth.

VALVE

|

Intake |

|

Exhaust |

D |

d |

D |

d |

|

L |

|

L |

ZK602600

|

'0)+0' |

|

$#5' '0)+0' |

||

|

The valve is made of heat resistant steel and has nitride processing on its entire surface.

Items |

Intake valve |

Exhaust |

|

|

valve |

Head diameter |

(D) 35.0(1.38) |

29.5(1.16) |

mm (in.) |

|

|

Items |

Intake valve |

Exhaust |

|

|

valve |

Stem diameter (d) mm |

6.0(0.24) |

6.0(0.24) |

(in.) |

|

|

Overall length (L) |

111.84(4.40) |

114.04(4.49) |

mm (in.) |

|

|

|

|

|

h |

|

|

|

ZK602590AA00 |

|

|

|

|

AB C BA |

AB C BA |

AB C BA |

|

AB C BA AB C BA |

AB C BA |

||

|

|

|

ZK602602AA00 |

|

|

|

|

VALVE STEM SEAL

Oil is prevented from seeping down by using a good sealing spring on the valve stem seal.

VALVE SPRINGS

To prevent surging during high speed, variable pitch springs are used.

Items |

Intake |

Exhaust |

|

valve |

valve |

Free height (h) mm (in.) |

59.15(2.33) |

57.7(2.27) |

Total number of windings |

10.61 |

9.39 |

CAMSHAFT

The camshaft has the two kinds of the cams, for high speed and low speed, at the intake side.

Items |

Cam height mm (in) |

A: Intake low speed cam |

37.28(1.468) |

B: Intake low speed cam |

36.23(1.426) |

C: Exhaust cam |

37.84(1.490) |

'0)+0' |

|

|

$#5' '0)+0' |

||

|

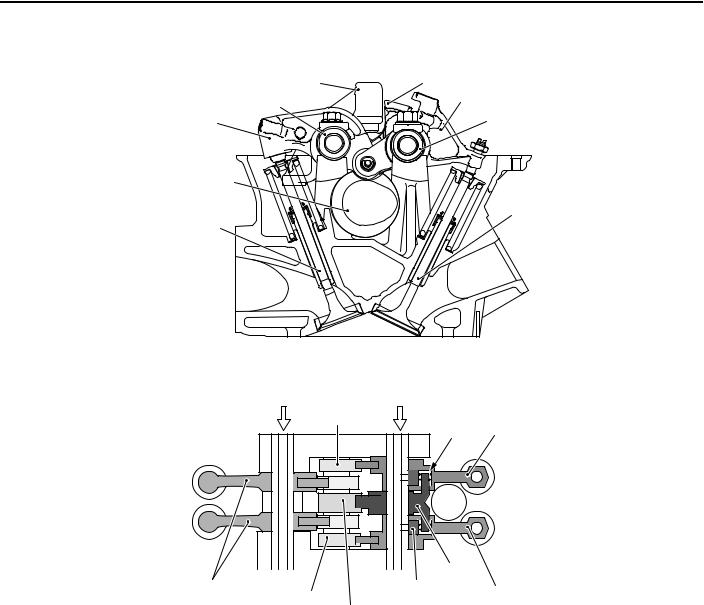

MITSUBISHI INNOVATIVE VALVE TIMING AND LIFTING ELECTRONIC CONTROL SYSTEM (MIVEC)

Piston arm assy |

T lever assy |

Rocker arm shaft |

Rocker arm assy |

Rocker arm assy |

Rocker arm shaft |

Camshaft |

|

Exhaust valve |

Intake valve |

|

ZK602599AA00

Lubricating oil |

Switch-over oil pressure |

(lubricating oil) |

Exhaust side

Exhaust rocker arm

Low lift cam

Wing |

Plug |

Intake rocker arm for low lift cam

Intake side

|

|

|

|

T-lever |

|

|

|

|

|

Middle lift cam |

Switch-over |

|||

piston |

||||

High lift cam

ZK602601AA00

MIVEC has an additional switching system on the two intake valves in the conventional SOHC 4 valve engine. This switching system has two cams for the low mode having a difference between the valve-lifts and for the high mode keeping both valve lifts high.

In the range of the low engine speed, the flow within the valves is enhanced by the difference between the valve-lifts. Also, the stabilization of the combustion is designed for low fuel economy, low exhaust gas and high torque. At high engine speeds, the high output due to the increment in the intake air amount is reached by increasing the open valve period and the lift.

A T-lever moves following the high lift cams and is arranged between the high lift cam and two rocker

arms, in addition to the low & middle lift cams and two rocker arms that drive the two intake valves respectively.

In the range of the low engine speed, the low and the middle lift cams drive each valve respectively because the wing of the T-lever moves freely. At high engine speeds, the oil pressure moves the switch-over piston within the rocker arm. The T-lever reaches the rocker arm and pushes it, and then the high lift cam lifts both valves.

|

'0)+0' |

|

$#5' '0)+0' |

||

|

The cam switching is carried out when the torque produced in the low speed mode and the one produced in the high-speed mode crosses each other at an engine speed. An accumulator ensures oil pressure at the instant of switching and prevents switching mistakes.

T-lever

Rocker arm piston

Power train control module(PCM)

The oil passage is divided into two, one for the intake rocker shaft and the other for the exhaust rocker shaft, just in front of the oil control valve (OCV). Oil is always supplied to the exhaust rocker shaft.

Oil supply to the intake rocker shaft is controlled by ON/OFF of the oil control valve (OCV) and carries out the switching for the low, middle and high lift cams.

Oil control |

valve filter |

Oil control

valve <OFF>

valve <OFF>

When the OCV is in the OFF position, the switch-over piston does not operate because the switch-over oil pressure within the intake rocker shaft is below the

ZK602603AA00

specified pressure, and so the wing of the T-lever does not reach the switch-over piston. Accordingly, the intake valve is driven by the rocker arm for low and middle lift cam.

'0)+0' |

|

|

$#5' '0)+0' |

||

|

||

T-lever |

|

Rocker arm piston

Power train control module(PCM)

Oil control |

valve filter |

Oil control

valve <ON>

valve <ON>

When the OCV is in the ON position, the switch-over piston is pushed by the oil pressure because the switch-over oil pressure within the intake rocker shaft

ZK602611AA00

is above the specified pressure, and so the wing of the T-lever reaches the switch-over piston. Accordingly, the intake valve is driven by the T-lever.

Loading...

Loading...