Mitsubishi electric MXZ-8B160VA User Manual [ru]

Air-Conditioners OUTDOOR UNIT

MXZ-8B140,160VA

MXZ-8B140,160YA

HFC

utilized

R410A

INSTALLATION MANUAL |

FOR INSTALLER |

|

English |

||

For safe and correct use, please read this installation manual thoroughly |

before installing the air-conditioner |

||||

unit. |

|

|

|

|

|

INSTALLATIONSHANDBUCH |

|

|

|

|

|

|

FÜR INSTALLATEURE |

|

Deutsch |

||

Zum sicheren und ordnungsgemäßen Gebrauch der Klimaanlage das |

Installationshandbuch gründlich |

|

|||

durchlesen. |

|

|

|

|

|

MANUEL D’INSTALLATION |

|

|

|

|

|

|

POUR L’INSTALLATEUR |

|

Français |

||

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur |

pour éviter tout accident et |

vous |

|||

assurer d’une utilisation correcte. |

|

|

|

|

|

INSTALLATIEHANDLEIDING |

|

|

|

|

|

|

VOOR DE INSTALLATEUR |

|

Nederlands |

||

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig |

doorlezen voordat u de airconditioner |

||||

installeert. |

|

|

|

|

|

MANUAL DE INSTALACIÓN |

|

|

|

|

|

|

PARA EL INSTALADOR |

|

Español |

||

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de |

|||||

aire acondicionado. |

|

|

|

|

|

MANUALE DI INSTALLAZIONE |

|

|

|

|

|

|

PER L’INSTALLATORE |

|

|

Italiano |

|

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore |

|||||

d’aria. |

|

|

|

|

|

EΓXEIPIΔIO OΔHΓIΩN EΓKATAΣTAΣHΣ |

|

|

|

|

|

|

ΓΙΑ ΑΥΤΟΝ ΠΟΥ ΚΑΝΕΙ ΤΗΝ ΕΓΚΑΤΑΣΤΑΣΗ |

|

Ελληνικά |

||

Για ασφάλεια και σωστή χρήση, παρακαλείστε διαβάσετε προσεχτικά αυτό |

το εγχειρίδιο εγκατάστασης |

πριν |

|||

αρχίσετε την εγκατάσταση της μονάδας κλιματισμού. |

|

|

|

|

|

MANUAL DE INSTALAÇÃO |

|

|

|

|

|

|

PARA O INSTALADOR |

|

|

Português |

|

Para segurança e utilização correctas, leia atentamente este manual de |

instalação antes de instalar a |

unidade |

|||

de ar condicionado. |

|

|

|

|

|

INSTALLATIONSMANUAL |

|

|

|

|

|

|

TIL INSTALLATØREN |

sikker og |

Dansk |

||

Læs venligst denne installationsmanual grundigt, før De installerer airconditionanlægget, af hensyn til |

|||||

korrekt anvendelse. |

|

|

|

|

|

INSTALLATIONSMANUAL |

|

|

|

|

|

|

FÖR INSTALLATÖREN |

|

Svenska |

||

Läs denna installationsmanual noga för säkert och korrekt bruk innan |

luftkonditioneringen installeras. |

|

|||

MONTAJ ELKİTABI |

|

|

|

|

|

|

|

|

|

|

|

|

MONTÖR İÇİN |

|

|

Türkçe |

|

Emniyetli ve doğru biçimde nasıl kullanılacağını öğrenmek için lütfen klima |

cihazını monte etmeden önce bu |

||||

elkitabını dikkatle okuyunuz. |

|

|

|

|

|

РУКОВОДСТВО ПО УСТАНОВКЕ |

|

|

|

|

|

|

ДЛЯ УСТАНОВИТЕЛЯ |

|

Русский |

||

Для осторожного и правильного использования прибора необходимо |

тщательно ознакомиться с |

данным |

|||

руководством по установке до выполнения установки кондиционера. |

|

|

|

|

|

|

|

|

|

|

|

Contents

1. |

Safety precautions..................................................................................... |

2 |

6. |

Drainage piping work............................................................................... |

10 |

2. |

Installation diagram & parts....................................................................... |

3 |

7. |

Electrical work ......................................................................................... |

10 |

3. |

Installation location.................................................................................... |

4 |

8. |

Test run.................................................................................................... |

14 |

4. |

Installing the outdoor unit .......................................................................... |

6 |

9. |

Special Functions.................................................................................... |

15 |

5. |

Installing the refrigerant piping .................................................................. |

6 |

|

|

|

Note: This symbol mark is for EU countries only.

This symbol mark is according to the directive 2002/96/EC Article 10 Information for users and Annex IV.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and components which can be recycled and reused. This symbol means that electrical and electronic equipment, at their end-of-life, should be disposed of separately from your household waste. Please, dispose of this equipment at your local community waste collection/recycling centre.

In the European Union there are separate collection systems for used electrical and electronic product. Please, help us to conserve the environment we live in!

Caution:

Caution:

•Do not vent R410A into the Atmosphere.

•R410A is a Fluorinated Greenhouse gas, covered by the Kyoto Protocol, with a Global Warming Potential (GWP)=1975.

1.Safety precautions

|

|

► Before installing the unit, make sure you read all the “Safety precautions”. |

|

After installation work has been completed, explain the “Safety Precautions,” use, and |

|||

|

|

|

maintenance of the unit to the customer according to the information in the Operation |

||||

|

|

► Please report to or take consent by the supply authority before connec- |

|

||||

|

|

|

Manual and perform the test run to ensure normal operation. Both the Installation |

||||

|

|

tion to the system. |

|

||||

|

|

|

Manual and Operation Manual must be given to the user for keeping. These manuals |

||||

|

|

► Equipment complying with IEC/EN 61000-3-12 |

|

||||

|

|

|

must be passed on to subsequent users. |

||||

|

|

|

|

||||

|

|

Warning: |

|

|

|

: Indicates a part which must be grounded. |

|

|

|

|

|

|

|||

|

Describes precautions that must be observed to prevent danger of injury or |

|

|

|

|||

|

|

|

|

|

|||

|

death to the user. |

|

|

|

Warning: |

||

|

|

|

|

|

|

|

|

|

|

Caution: |

Carefully read the labels affixed to the main unit. |

||||

|

Describes precautions that must be observed to prevent damage to the unit. |

|

|

|

|

||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Warning: |

|

|

(If an intermediate connection is necessary, be sure to take measures to |

||

|

• The unit must not be installed by the user. Ask a dealer or an authorized |

|

|

||||

|

|

technician to install the unit. If the unit is installed incorrectly, water leakage, |

|

|

prevent water from entering the cords and wires.) |

||

|

|||||||

|

|

electric shock, or fire may result. |

• Use C1220 copper phosphorus, for copper and copper alloy seamless pipes, |

||||

|

• For installation work, follow the instructions in the Installation Manual and use |

|

|

to connect the refrigerant pipes. If the pipes are not connected correctly, the |

|||

|

|

tools and pipe components specifically made for use with R410A refrigerant. |

|

|

unit will not be properly grounded and electric shock may result. |

||

|

|

The R410A refrigerant in the HFC system is pressurized 1.6 times the pressure |

• Use only specified cables for wiring. The connections must be made securely |

||||

|

|

of usual refrigerants. If pipe components not designed for R410A refrigerant are |

|

|

without tension on the terminals. If the cables are connected or installed |

||

|

|

used and the unit is not installed correctly, the pipes may burst and cause dam- |

|

|

incorrectly, overheating or fire may result. |

||

|

|

age or injuries. In addition, water leakage, electric shock, or fire may result. |

• The terminal block cover panel of the outdoor unit must be firmly attached. If |

||||

|

• The unit must be installed according to the instructions in order to minimize |

|

|

the cover panel is mounted incorrectly and dust and moisture enter the unit, |

|||

|

|

the risk of damage from earthquakes, typhoons, or strong winds. An incor- |

|

|

electric shock or fire may result. |

||

|

|

rectly installed unit may fall down and cause damage or injuries. |

• When installing or relocating, or servicing the air conditioner, use only the |

||||

|

• The unit must be securely installed on a structure that can sustain its weight. |

|

|

specified refrigerant (R410A) to charge the refrigerant lines. Do not mix it with |

|||

|

|

If the unit is mounted on an unstable structure, it may fall down and cause |

|

|

any other refrigerant and do not allow air to remain in the lines. |

||

|

|

damage or injuries. |

|

|

If air is mixed with the refrigerant, then it can be the cause of abnormal high |

||

|

• If the air conditioner is installed in a small room, measures must be taken to |

|

|

pressure in the refrigerant line, and may result in an explosion and other |

|||

|

|

prevent the refrigerant concentration in the room from exceeding the safety |

|

|

hazards. |

||

|

|

limit in the event of refrigerant leakage. Consult a dealer regarding the appro- |

|

|

The use of any refrigerant other than that specified for the system will cause |

||

|

|

priate measures to prevent the allowable concentration from being exceeded. |

|

|

mechanical failure or system malfunction or unit breakdown. In the worst |

||

|

|

Should the refrigerant leak and cause the concentration limit to be exceeded, |

|

|

case, this could lead to a serious impediment to securing product safety. |

||

|

|

hazards due to lack of oxygen in the room may result. |

• Use only accessories authorized by Mitsubishi Electric and ask a dealer or an |

||||

|

• Ventilate the room if refrigerant leaks during operation. If refrigerant comes |

|

|

authorized technician to install them. If accessories are incorrectly installed, |

|||

|

|

into contact with a flame, poisonous gases will be released. |

|

|

water leakage, electric shock, or fire may result. |

||

|

• All electric work must be performed by a qualified technician according to |

• Do not alter the unit. Consult a dealer for repairs. If alterations or repairs are |

|||||

|

|

local regulations and the instructions given in this manual. The units must be |

|

|

not performed correctly, water leakage, electric shock, or fire may result. |

||

|

|

powered by dedicated power lines and the correct voltage and circuit breakers |

• The user should never attempt to repair the unit or transfer it to another loca- |

||||

|

|

must be used. Power lines with insufficient capacity or incorrect electrical |

|

|

tion. If the unit is installed incorrectly, water leakage, electric shock, or fire |

||

|

|

work may result in electric shock or fire. |

|

|

may result. If the air conditioner must be repaired or moved, ask a dealer or |

||

|

• Be sure to connect the power supply cords and the connecting wires for |

|

|

an authorized technician. |

|||

|

|

the indoor units, outdoor units, and branch boxes directly to the units (no |

• After installation has been completed, check for refrigerant leaks. If refriger- |

||||

|

|

intermediate connections). |

|

|

ant leaks into the room and comes into contact with the flame of a heater or |

||

|

|

Intermediate connections can lead to communication errors if water enters |

|

|

portable cooking range, poisonous gases will be released. |

||

|

|

the cords or wires and causes insufficient insulation to ground or a poor |

• Refrigerant leakage may cause suffocation. Provide ventilation in accordance |

||||

|

|

electrical contact at the intermediate connection point. |

|

|

with EN378-1. |

||

1.1. Before installation

Caution:

Caution:

•Do not use the unit in an unusual environment. If the air conditioner is installed in areas exposed to steam, volatile oil (including machine oil), or sulfuric gas, areas exposed to high salt content such as the seaside, or areas where the unit will be covered by snow, the performance can be significantly reduced and the internal parts can be damaged.

•Do not install the unit where combustible gases may leak, be produced, flow, or accumulate. If combustible gas accumulates around the unit, fire or explosion may result.

•The outdoor unit produces condensation during the heating operation. Make

sure to provide drainage around the outdoor unit if such condensation is likely to cause damage.

•When installing the unit in a hospital or communications office, be prepared for noise and electronic interference. Inverters, home appliances, high-frequency medical equipment, and radio communications equipment can cause the air conditioner to malfunction or breakdown. The air conditioner may also affect medical equipment, disturbing medical care, and communications equipment, harming the screen display quality.

1.2. Before installation (relocation)

Caution:

Caution:

•Be extremely careful when transporting the units. Two or more persons are needed to handle the unit, as it weighs 20 kg or more. Do not grasp the packaging bands. Wear protective gloves to remove the unit from the packaging and to move it, as you can injure your hands on the fins or other parts.

•Be sure to safely dispose of the packaging materials. Packaging materials, such as nails and other metal or wooden parts may cause stabs or other injuries.

2

•The base and attachments of the outdoor unit must be periodically checked for looseness, cracks or other damage. If such defects are left uncorrected, the unit may fall down and cause damage or injuries.

•Do not clean the air conditioner unit with water. Electric shock may result.

•Tighten all flare nuts to specification using a torque wrench. If tightened too much, the flare nut can break after an extended period and refrigerant can leak out.

1. Safety precautions

1.3. Before electric work

Caution:

Caution:

• Be sure to install circuit breakers. If not installed, electric shock may result.

IMPORTANT

Make sure that the current leakage breaker is one compatible with higher harmonics.

Always use a current leakage breaker that is compatible with higher harmonics as this unit is equipped with an inverter.

The use of an inadequate breaker can cause the incorrect operation of inverter.

•For the power lines, use standard cables of sufficient capacity. Otherwise, a short circuit, overheating, or fire may result.

•When installing the power lines, do not apply tension to the cables. If the connections are loosened, the cables can snap or break and overheating or fire may result.

•Be sure to ground the unit. Do not connect the ground wire to gas or water pipes, lighting rods, or telephone grounding lines. If the unit is not properly grounded, electric shock may result.

•Use circuit breakers (ground fault interrupter, isolating switch (+B fuse), and molded case circuit breaker) with the specified capacity. If the circuit breaker capacity is larger than the specified capacity, breakdown or fire may result.

1.4. Before starting the test run

Caution:

Caution:

•Turn on the main power switch more than 12 hours before starting operation. Starting operation just after turning on the power switch can severely damage the internal parts. Keep the main power switch turned on during the operation season.

•Before starting operation, check that all panels, guards and other protective parts are correctly installed. Rotating, hot, or high voltage parts can cause injuries.

•Do not touch any switch with wet hands. Electric shock may result.

•Do not touch the refrigerant pipes with bare hands during operation. The refrigerant pipes are hot or cold depending on the condition of the flowing refrigerant. If you touch the pipes, burns or frostbite may result.

•After stopping operation, be sure to wait at least five minutes before turning off the main power switch. Otherwise, water leakage or breakdown may result.

1.5. Using R410A refrigerant air conditioners

Caution:

•Use C1220 copper phosphorus, for copper and copper alloy seamless pipes, to connect the refrigerant pipes. Make sure the insides of the pipes are clean and do not contain any harmful contaminants such as sulfuric compounds, oxidants, debris, or dust. Use pipes with the specified thickness. (Refer to page 6) Note the following if reusing existing pipes that carried R22 refriger-

ant.

-Replace the existing flare nuts and flare the flared sections again.

-Do not use thin pipes. (Refer to page 6)

•Store the pipes to be used during installation indoors and keep both ends of the pipes sealed until just before brazing. (Leave elbow joints, etc. in their packaging.) If dust, debris, or moisture enters the refrigerant lines, oil deterioration or compressor breakdown may result.

•Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration oil applied to the flared sections. If mineral oil is mixed in the refrigeration oil, oil deterioration may result.

•Do not use refrigerant other than R410A refrigerant. If another refrigerant is used, the chlorine will cause the oil to deteriorate.

•Use the following tools specifically designed for use with R410A refrigerant. The following tools are necessary to use R410A refrigerant. Contact your nearest dealer for any questions.

|

Tools (for R410A) |

|

Gauge manifold |

|

Flare tool |

Charge hose |

|

Size adjustment gauge |

Gas leak detector |

|

Vacuum pump adapter |

Torque wrench |

|

Electronic refrigerant charging scale |

•Be sure to use the correct tools. If dust, debris, or moisture enters the refrigerant lines, refrigeration oil deterioration may result.

•Do not use a charging cylinder. If a charging cylinder is used, the composition of the refrigerant will change and the efficiency will be lowered.

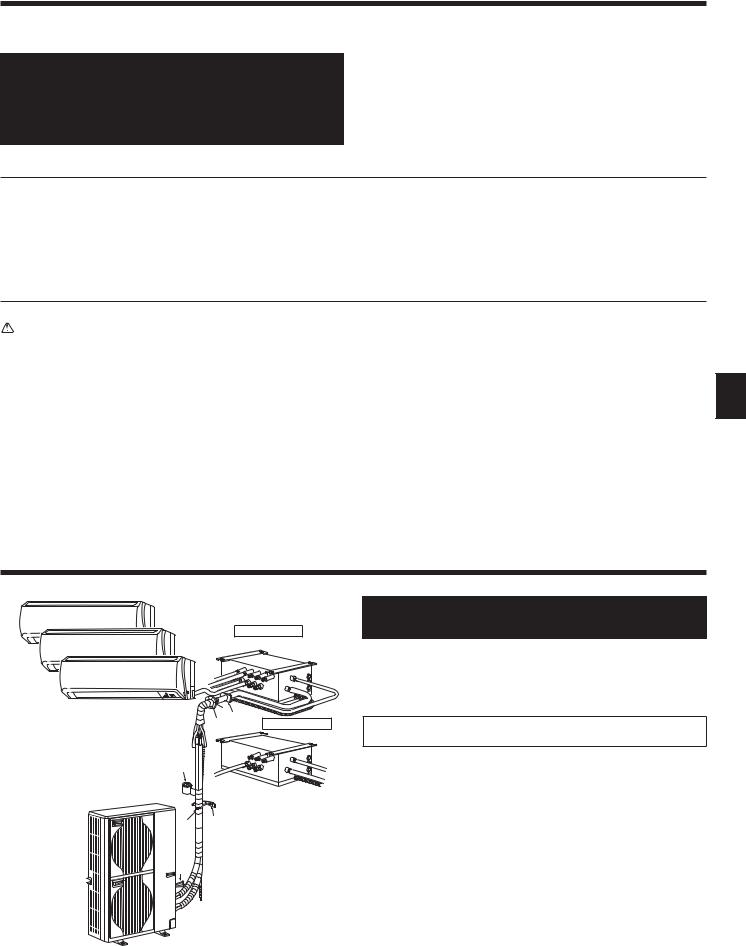

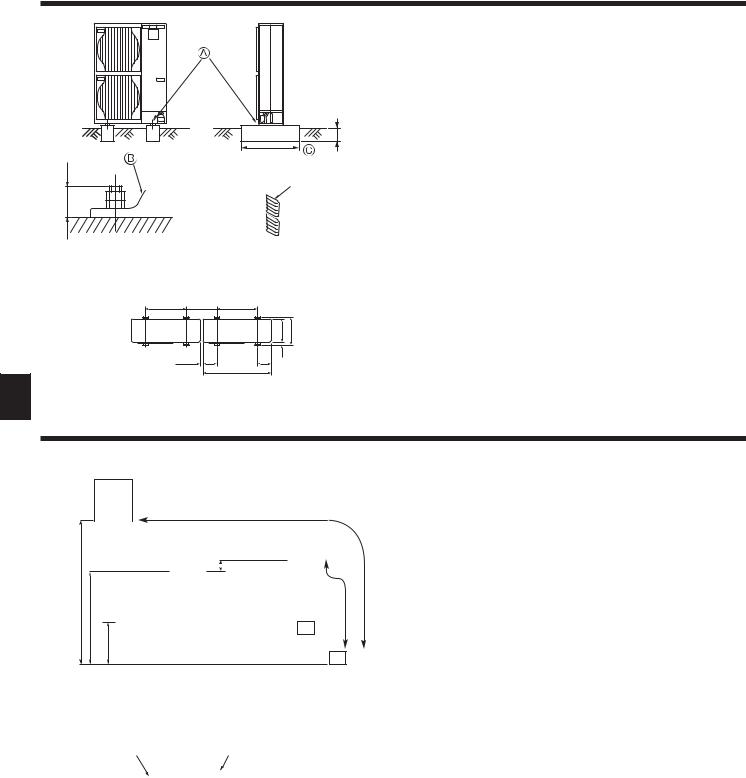

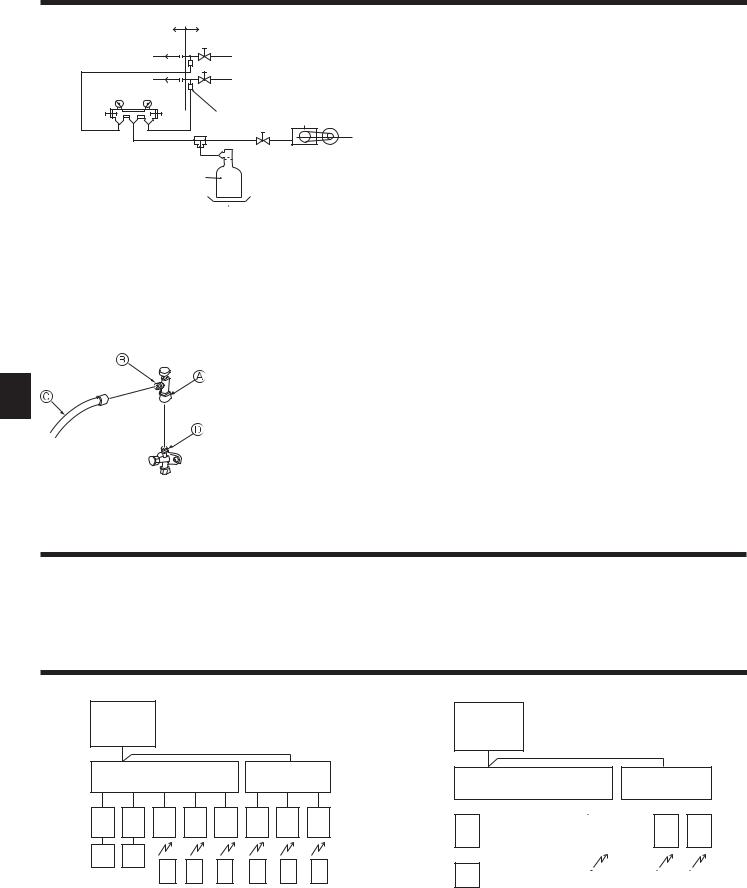

2. Installation diagram & parts

Branch box

5-branches type

[D] |

[C] |

[H] |

3-branches type |

[G]

Outdoor unit

[F]  [E]

[E]

[B]

[B]

[A]  [K]

[K]

[I]

[I]

Fig. 2-1

2.1. Before installation (Fig. 2-1)

This installation manual is only for the outdoor unit installation. In installing the indoor units and branch box, refer to the installation manual attached to each unit.

Any structural alterations necessary for the installation must comply with the local building code requirements.

This diagram is intended to show the configuration of accessories. For actual installation, the outdoor unit is to be turned 180°.

Units should be installed by licensed contractor according to local code requirement.

Note:

The dimensions given along the arrows above are required to guarantee the air conditioner’s performance. Install the unit in as wide a place as possible for later service or repairs.

Parts to be locally procured

[A] |

Branch box/outdoor unit connecting wire |

1 |

|

(3-core, Refer to 7.3. External wiring procedure) |

|||

|

|

||

[B] |

Extension pipe |

1 |

|

[C] |

Wall hole sleeve |

1 |

|

[D] |

Wall hole cover |

1 |

|

[E] |

Pipe fixing band |

2 to 7 |

|

(The quantity depends on the pipe length.) |

|||

|

|

||

[F] |

Fixing screw for [E] 4 × 20 mm |

2 to 7 |

|

(The quantity depends on the pipe length.) |

|||

|

|

||

[G] |

Piping tape |

1 |

|

[H] |

Putty |

1 |

|

[I] |

Drain hose (hard PVC pipe VP16) |

1 |

|

[J] |

Refrigeration oil |

1 |

|

[K] |

Power supply cord |

1 |

|

(2-core, Refer to 7.3. External wiring procedure) |

|||

|

|

3

3. Installation location

3.1. Refrigerant pipe

Refer to 5.2. Pipe length and height difference.

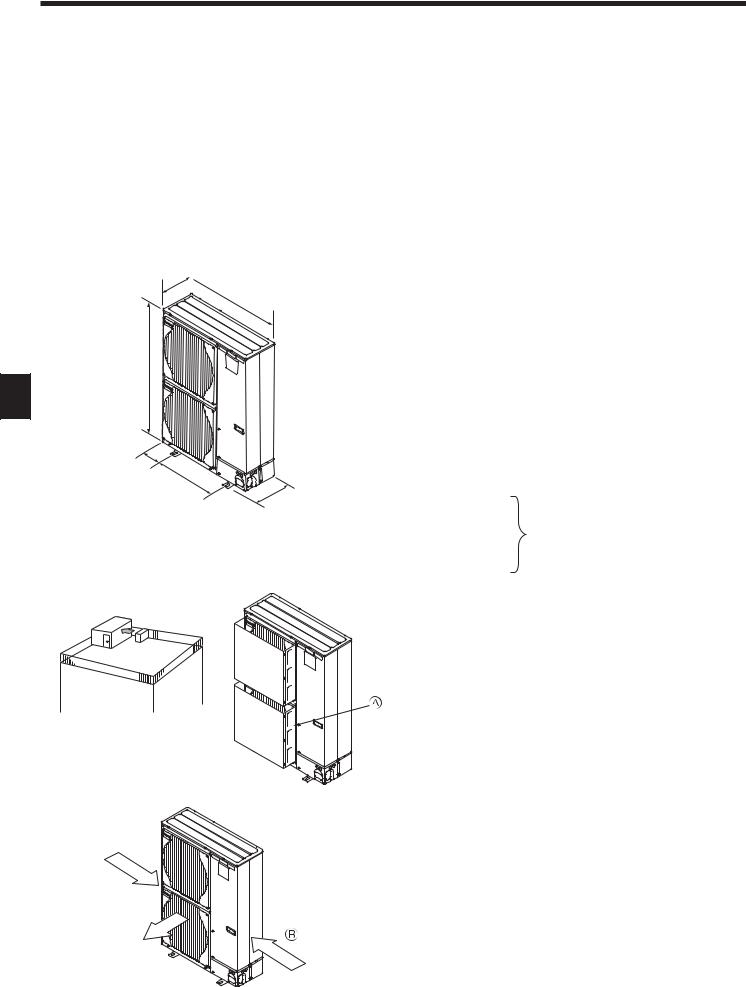

330+30

1350

950

3.2. Choosing the outdoor unit installation location

•Avoid locations exposed to direct sunlight or other sources of heat.

•Select a location from which noise emitted by the unit will not inconvenience neighbors.

•Select a location permitting easy wiring and pipe access to the power source and indoor unit.

•Avoid locations where combustible gases may leak, be produced, flow, or accumulate.

•Note that water may drain from the unit during operation.

•Select a level location that can bear the weight and vibration of the unit.

•Avoid locations where the unit can be covered by snow. In areas where heavy snow fall is anticipated, special precautions such as raising the installation location or installing a hood on the air intake must be taken to prevent the snow from blocking the air intake or blowing directly against it. This can reduce the airflow and a malfunction may result.

•Avoid locations exposed to oil, steam, or sulfuric gas.

•Use the transportation handles of the outdoor unit to transport the unit. If the unit is carried from the bottom, hands or fingers may be pinched.

(mm)

3.3. Outline dimensions (Outdoor unit) (Fig. 3-1)

Constraints on indoor unit installation

You should note that indoor units that can be connected to this outdoor unit are the following models.

• Indoor units with model numbers 15, 20, 22, 25, 35, 42, 50, 60, 71, 80, 100 can be connected. Refer to the table below for possible 2-8 room, indoor unit combinations.

Verification

The rated capacity should be determined by observing the table below. The unit’s quantities are limited in 2 to 8 units. For the next step, make sure that the total rated capacity selected will stay in a range as shown below.

1 |

|

75 |

600 |

|

0 37

Fig. 3-1

Fig. 3-2

• MXZ-8B140 |

3.0~18.5kw |

|

|

|

|

|

|

|

|

|

|

|

||||

• MXZ-8B160 |

3.0~20.2kw |

|

|

|

|

|

|

|

|

|

|

|

||||

Example: MXZ-8B140 |

|

|

|

|

|

|

|

|

|

|

|

|

||||

MSZ-60 |

= |

6.0 |

|

|

|

|

|

|

|

|

|

|

|

|

||

SEZ-35 |

= |

+ |

|

Total rated capacity |

|

|

|

|

|

|||||||

3.5 |

|

|

|

|

|

|

||||||||||

|

|

|

+ |

|

18.0 |

|

18.5 kW |

|

|

|

|

|

|

|||

SLZ-35 |

= |

3.5 |

|

|

|

|

|

|

|

|||||||

SEZ-25 |

= |

+ |

|

|

|

|

|

|

|

|

|

|

|

|

||

2.5 |

|

|

|

|

|

|

|

|

|

|

|

|

||||

SLZ-25 |

= |

+ |

|

|

|

|

|

|

|

|

|

|

|

|

||

2.5 |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indoor unit type |

|

|

15 |

|

20 |

22 |

25 |

|

35 |

42 |

50 |

60 |

71 |

80 |

100*1 |

|

Rated capacity |

|

|

1.5 |

|

2.0 |

2.2 |

2.5 |

|

3.5 |

4.2 |

5.0 |

6.0 |

7.1 |

8.0 |

10.0 |

|

(Cooling) (kW) |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Combinations in which the total capacity of indoor units exceeds the capacity of the outdoor unit will reduce the cooling capacity of each indoor unit below their rated cooling capacity. Thus, combine indoor units with an outdoor unit within the outdoor unit’s capacity, if possible.

*1 When connecting the indoor unit with the model number 100, use the PAC-AK52BC branch box. Along with this, the PAC-AK52YP-E Y-shape connection pipe is required.

The capacity of outdoor unit

• MXZ-8B140 |

14.0kw |

• MXZ-8B160 |

15.5kw |

Fig. 3-3

3.4. Ventilation and service space

3.4.1. Windy location installation

When installing the outdoor unit on a rooftop or other location unprotected from the wind, situate the air outlet of the unit so that it is not directly exposed to strong winds. Strong wind entering the air outlet may impede the normal airflow and a malfunction may result.

The following shows three examples of precautions against strong winds.

Face the air outlet towards the nearest available wall about 50 cm away from the wall. (Fig. 3-2)

Install an optional air guide if the unit is installed in a location where strong winds from a typhoon, etc. may directly enter the air outlet. (Fig. 3-3)

Air guide

Position the unit so that the air outlet blows perpendicularly to the seasonal wind direction, if possible. (Fig. 3-4)

Wind direction

Fig. 3-4

4

3. Installation location

.500  Max

Max

|

150 |

Fig. 3-5 |

Fig. 3-6 |

1000

|

200 |

300 |

200 |

Fig. 3-7

.500 Max

1500

300

300

1000

Fig. 3-8

150

150

1000

Fig. 3-9

250

250

Fig. 3-10

300

500

Fig. 3-11

.300 |

1500 |

|

Max |

||

|

1500

500

500

Fig. 3-12

150

2000

600

1000

Fig. 3-15

500

500

1500 |

1500 |

Fig. 3-13 |

Fig. 3-14 |

500

3000

600

1500

Fig. 3-16

1500

Fig. 3-17

150

800

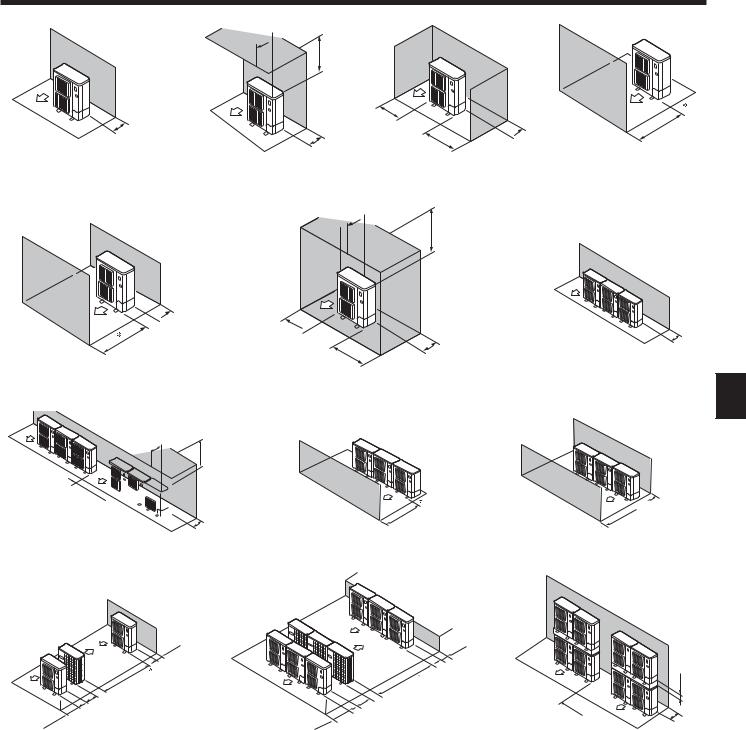

3.4.2. When installing a single outdoor unit

Minimum dimensions are as follows, except for Max., meaning Maximum dimensions, indicated.

Refer to the figures for each case.Obstacles at rear only (Fig. 3-5)

Obstacles at rear and above only (Fig. 3-6)Obstacles at rear and sides only (Fig. 3-7)

Obstacles at front only (Fig. 3-8)

When using an optional air outlet guide, the clearance is 500 mm or more.

Obstacles at front and rear only (Fig. 3-9)

When using an optional air outlet guide, the clearance is 500 mm or more.

Obstacles at rear, sides, and above only (Fig. 3-10)

• Do not install the optional air outlet guides for upward airflow.

3.4.3. When installing multiple outdoor units

Leave 10 mm space or more between the units.Obstacles at rear only (Fig. 3-11)

Obstacles at rear and above only (Fig. 3-12)

•No more than three units must be installed side by side. In addition, leave space as shown.

•Do not install the optional air outlet guides for upward airflow.

Obstacles at front only (Fig. 3-13)

When using an optional air outlet guide, the clearance is 1000 mm or more.

Obstacles at front and rear only (Fig. 3-14)

When using an optional air outlet guide, the clearance is 1000 mm or more.

Single parallel unit arrangement (Fig. 3-15)

When using an optional air outlet guide installed for upward airflow, the clearance is 1000 mm or more.

Multiple parallel unit arrangement (Fig. 3-16)

When using an optional air outlet guide installed for upward airflow, the clearance is 1500 mm or more.

Stacked unit arrangement (Fig. 3-17)

•The units can be stacked up to two units high.

•No more than two stacked units must be installed side by side. In addition, leave space as shown.

5

4. Installing the outdoor unit

Max. 30 |

|

D |

|

|

|

M10 (3/8”) bolt |

|

|

Base |

|

|

As long as possible. |

|

|

Vent |

|

|

600 Min. 360 |

600 |

|

|

330 |

370 |

Min. 10 175 |

25 |

|

175 |

|

|

|

950 |

|

Fig. 4-1

•Be sure to install the unit in a sturdy, level surface to prevent rattling noises during

(mm)operation. (Fig. 4-1)

<Foundation specifications>

Foundation bolt |

M10 (3/8”) |

Thickness of concrete |

120 mm |

Length of bolt |

70 mm |

Weight-bearing capacity |

320 kg |

•Make sure that the length of the foundation bolt is within 30 mm of the bottom surface of the base.

•Secure the base of the unit firmly with four-M10 foundation bolts in sturdy locations.

Installing the outdoor unit

•Do not block the vent. If the vent is blocked, operation will be hindered and breakdown may result.

•In addition to the unit base, use the installation holes on the back of the unit to attach wires, etc., if necessary to install the unit. Use self-tapping screws (ø5 × 15

mm or less) and install on site.

Warning:

Warning:

•The unit must be securely installed on a structure that can sustain its weight. If the unit is mounted on an unstable structure, it may fall down and cause damage or injuries.

•The unit must be installed according to the instructions in order to minimize the risk of damage from earthquakes, typhoons, or strong winds. An incorrectly installed unit may fall down and cause damage or injuries.

Caution:

Caution:

•Install the unit on a rigid structure to prevent excessive operation sound or vibration.

5. Installing the refrigerant piping

Outdoor unitBranch box

Indoor unit

L

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b2 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

h2 |

|

|

|

|

|

|

|

|

|||

H |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

*1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

h1 |

|

|

a1 |

|

|

|

|

|

|

|

|

|

|

|

a5 |

|

a6 |

|

a7 |

a8 |

|

||||||||

|

|

|

|

|

|

|

a2 |

|

a3 |

|

|

a4 |

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

h3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 5-1

*1 Although two refrigerant pipes are used between the branch box and the Y-shape connection pipe when connecting the P100 indoor unit, calculate the piping lengths using only the length of one pipe. (Fig. 5-2)

|

|

|

|

|

|

|

Indoor unit [P100 type] |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Y-shape connection pipe |

|

|

|

|

|

|

|

|

|

a1 = c1 + c2 |

|

|

|

|

|

|

|

|

|

|

|

c1 |

|

|

|

c2 |

|

|

|

|

|

|

|

|

|

|

|

|||

Fig. 5-2

5.1. Precautions for devices that use R410A refrigerant

•Refer to page 3 for precautions not included below on using air conditioners with R410A refrigerant.

•Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration oil applied to the flared sections.

•Use C1220 copper phosphorus, for copper and copper alloy seamless pipes, to connect the refrigerant pipes. Use refrigerant pipes with the thicknesses specified in the table to the below. Make sure the insides of the pipes are clean and do not contain any harmful contaminants such as sulfuric compounds, oxidants, debris, or dust.

Warning:

Warning:

When installing or relocating, or servicing the air conditioner, use only the specified refrigerant (R410A) to charge the refrigerant lines. Do not mix it with any other refrigerant and do not allow air to remain in the lines.

If air is mixed with the refrigerant, then it can be the cause of abnormal high pressure in the refrigerant line, and may result in an explosion and other hazards. The use of any refrigerant other than that specified for the system will cause mechanical failure or system malfunction or unit breakdown. In the worst case, this could lead to a serious impediment to securing product safety.

ø6.35, ø9.52, ø12.7 |

Thickness 0.8 mm |

ø15.88 |

Thickness 1.0 mm |

• Do not use pipes thinner than those specified above.

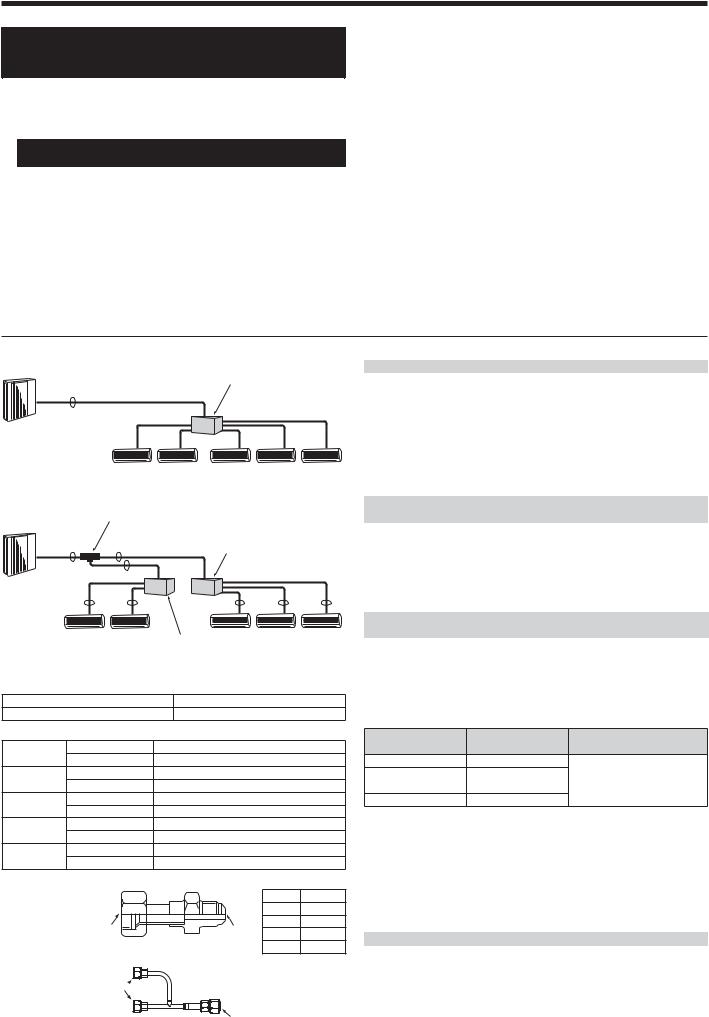

5.2. Pipe length and height difference (Fig. 5-1)

Flared connections

•This unit has flared connections on each indoor unit and branch box and outdoor unit sides.

•Remove the valve cover of the outdoor unit, then connect the pipe.

•Refrigerant pipes are used to connect the branch box and outdoor unit.

|

Total piping length |

b1+b2+a1+a2+a3+a4+a5+a6+a7+a8 115 m |

||

Permissible |

Farthest piping length (L) |

b2+a8 70 m (b2 55 m, a8 15 m) |

||

length |

Piping length between outdoor unit and branch boxes |

b1+b2 55 m |

||

(one-way) |

Farthest piping length after branch box (l) |

a8 |

15 m |

|

|

Total piping length between branch boxes and indoor units |

a1+a2+a3+a4+a5+a6+a7+a8 60 m |

||

Permissible |

In indoor/outdoor section (H)*2 |

H 30 m (In case of outdoor unit is set higher than indoor unit) |

||

|

H 20 m (In case of outdoor unit is set lower than indoor unit) |

|||

height differ- |

|

|||

In branch box/indoor unit section (h1) |

h1 |

+ h2 15 m |

||

ence |

||||

In each branch unit (h2) |

h2 |

15 m |

||

(one-way) |

||||

In each indoor unit (h3) |

h3 |

12 m |

||

|

||||

Number of bends |

|

| b1+a1 |, | b1+a2 |, | b1+a3 |, | b1+a4 |, | b1+a5 |, | b2+a6 |, | b2+a7 |, | b2+a8 | 15 |

||

*2 Branch box should be placed within the level between the outdoor unit and indoor units.

6

5. Installing the refrigerant piping

5.3. Addition of refrigerant

•Additional charging is not necessary for this unit if the total pipe length (b1+b2+a1+a2+a3+a4+a5+a6+a7+a8) does not exceed 40 m.

•If the total pipe length exceeds 40 m, charge the unit with additional R410A refrigerant according to the permitted pipe lengths in the chart below.

* When the unit is stopped, charge the unit with the additional refrigerant through the liquid stop valve after the pipe extensions and indoor unit have been vacuumized.

When the unit is operating, add refrigerant to the gas check valve using a safety charger. Do not add liquid refrigerant directly to the check valve.

After charging the unit with refrigerant, note the added refrigerant amount on the service label (attached to the unit).

Refer to the “1.5. Using R410A refrigerant air conditioners” for more information.

Table 1

Total piping length |

41 - 50 m |

51 - 70 m |

71 - 90 m |

91 - 115 m |

(b1+b2+a1+a2+a3+a4+a5+a6+a7+a8) |

||||

Additional refrigerant charging amount |

0.6 kg |

1.4 kg |

2.2 kg |

3.2 kg |

If connecting an indoor unit with ø9.52 liquid pipes (model number 71 or more for M- and S-Series and model number 60 or more for P-Series), the additional refrigerant charging amount in Table 1 must be corrected (add the following R value from the value given in Table 1).

Additional refrigerant charging correction amount

R=0.01 [kg/m] × ø9.52 branch pipe (liquid pipe) total length [m]

Example) b1=20 m, b2=25 m

Indoor unit A |

ø9.52 Liquid pipe |

a1=12 m |

Indoor unit B |

ø6.35 Liquid pipe |

a2=11 m |

Indoor unit C |

ø6.35 Liquid pipe |

a6=14 m |

Indoor unit D |

ø9.52 Liquid pipe |

a7=13 m |

Total piping length : b1+b2+a1+a2+a6+a7=95 m

→ According to Table 1, the additional refrigerant charging amount is 3.2 kg. Because indoor units with ø9.52 liquid pipes are connected (indoor units A and D in this example), the additional refrigerant charging amount must be corrected.

Additional refrigerant charging correction amount

R=0.01 [kg/m] × ø9.52 branch pipe (liquid pipe) total length (a1+a7) =0.01 × (12+13 m)

=0.25 kg

Therefore, the additional refrigerant charging amount is 3.2 kg + 0.25 kg = 3.45 kg.

*Although two ø6.35 liquid pipes are used between the branch box and the Y-shape connection pipe when connecting the P100 indoor unit, calculate the additional refrigerant charging amount assuming only one ø9.52 liquid pipe is used.

N In case of using 1-branch box

Flare connection employed. (No. brazing)

Branch box

A

B

B  B

B  B

B  B

B  B

B

N In case of using 2-branch boxes

2 branches pipe (joint)

|

: optional parts. |

|

|

|

A |

A |

Branch box #1 |

|

|

|

A |

|

|

|

B |

B |

B |

B |

B |

|

Branch box #2 |

|

|

|

|

Fig. 5-3 |

|

|

|

(1)Valve size for outdoor unit |

|

|

|

|

For liquid |

|

ø9.52 mm |

|

|

For gas |

|

ø15.88 mm |

|

|

(2)Valve size for branch box |

|

|

|

|

Liquid pipe |

|

ø6.35 mm |

|

|

UNIT |

|

ø9.52 mm |

|

|

Gas pipe |

|

|

|

|

Liquid pipe |

|

ø6.35 mm |

|

|

UNIT |

|

ø9.52 mm |

|

|

Gas pipe |

|

|

|

|

Liquid pipe |

|

ø6.35 mm |

|

|

UNIT |

|

ø9.52 mm |

|

|

Gas pipe |

|

|

|

|

Liquid pipe |

|

ø6.35 mm |

|

|

UNIT |

|

ø9.52 mm |

|

|

Gas pipe |

|

|

|

|

Liquid pipe |

|

ø6.35 mm |

|

|

UNIT |

|

ø12.7 mm |

|

|

Gas pipe |

|

|

|

|

* 3-branch type : only , , unit |

Conversion formula |

|||

|

|

|

1/4 F |

ø6.35 |

|

|

|

3/8 F |

ø9.52 |

A |

|

B |

1/2 F |

ø12.7 |

|

5/8 F |

ø15.88 |

||

|

|

|

||

|

Fig. 5-4 |

|

3/4 F |

ø19.05 |

|

|

|

|

A

Fig. 5-5 |

B |

5.4. Selecting pipe size (Fig. 5-3)

|

A |

B |

|

|

|

|

The piping connection size differs according to the type |

|

|

Liquid (mm) |

ø9.52 |

and capacity of indoor units. Match the piping connec- |

|

|

tion size of branch box with indoor unit. |

|

|

||

|

|

|

|

|

|

|

If the piping connection size of branch box does not |

|

|

|

|

|

||

|

|

match the piping connection size of indoor unit, use |

|

|

Gas (mm) |

ø15.88 |

optional different-diameter (deformed) joints to the |

|

|

branch box side. (Connect deformed joint directly to |

|

|

||

|

|

|

|

|

|

|

the branch box side.) |

|

|

Different-diameter joint (optional parts) (Fig. 5-4)

Model name |

Connected pipes diameter |

Diameter A |

Diameter B |

|

mm |

mm |

mm |

||

|

||||

MAC-A454JP |

ø9.52 → ø12.7 |

ø9.52 |

ø12.7 |

|

MAC-A455JP |

ø12.7 → ø9.52 |

ø12.7 |

ø9.52 |

|

MAC-A456JP |

ø12.7 → ø15.88 |

ø12.7 |

ø15.88 |

|

PAC-493PI |

ø6.35 → ø9.52 |

ø6.35 |

ø9.52 |

|

PAC-SG76RJ-E |

ø9.52 → ø15.88 |

ø9.52 |

ø15.88 |

Y-shape connection pipe for 100 type indoor unit (optional parts) (Fig. 5-5)

Model name |

Connected pipe diameter |

Diameter A |

Diameter B |

||

mm |

mm |

mm |

|||

|

|

||||

PAC-AK52YP-E |

Liquid |

ø6.35 → ø9.52 |

ø6.35 |

ø9.52 |

|

Gas |

ø9.52 → ø15.88 |

ø9.52 |

ø15.88 |

||

|

|||||

N Installation procedure (Y-shape connection pipe)

Refer to the installation manuals of PAC-AK52YP-E.

Piping preparation

Table below shows the specifications of pipes commercially available.

Outside diameter |

Insulation thickness |

|

|

|

Insulation material |

mm |

|

|

mm |

||

6.358

9.52 |

8 |

Heat resisting foam plastic |

12.7 |

8 |

0.045 specific gravity |

15.888

Ensure that the 2 refrigerant pipes are insulated to prevent condensation.Refrigerant pipe bending radius must be 100 mm or more.

Caution:

Caution:

Be sure to use the insulation of specified thickness. Excessive thickness may cause incorrect installation of the indoor unit and branch box, and lack of thickness may cause dew drippage.

2-branch pipe (Joint) : Optional parts (According to the connection method, you can choose the favorite one.)

Model name |

Connection method |

MSDD-50AR-E |

flare |

MSDD-50BR-E |

brazing |

N Installation procedure (2 branches pipe (Joint))

Refer to the installation manuals of MSDD-50AR-E and MSDD-50BR-E.

7

5. Installing the refrigerant piping

B

|

452 |

± 0.5° |

øA |

90° |

R0 |

|

|

|

. |

|

4~R0 |

|

. |

|

8 |

Flare cutting dimensionsFlare nut tightening torque

C

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

||

(Fig. 5-6) |

|

|

Fig. 5-6 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

Copper pipe O.D. |

Flare dimensions |

|

||||||||

(mm) |

øA dimensions (mm) |

|

||||||||

ø6.35 |

8.7 |

- 9.1 |

|

|

|

|

||||

ø9.52 |

12.8 |

- 13.2 |

|

|

|

|

||||

ø12.7 |

16.2 |

- 16.6 |

|

|

|

|

||||

ø15.88 |

19.3 |

- 19.7 |

|

|

|

|

||||

(Fig. 5-6)

Copper pipe O.D. |

Flare nut O.D. |

Tightening torque |

|

(mm) |

(mm) |

(N·m)* |

|

ø6.35 |

17 |

14 |

- 18 |

ø6.35 |

22 |

34 |

- 42 |

ø9.52 |

22 |

34 |

- 42 |

ø9.52 |

26 |

49 |

- 61 |

ø12.7 |

26 |

49 |

- 61 |

ø12.7 |

29 |

68 |

- 82 |

ø15.88 |

29 |

68 |

- 82 |

ø15.88 |

36 |

100 |

- 120 |

* 1 N·m 10 kgf·cm

10 kgf·cm

A

Die

Copper pipe

A

B

Fig. 5-7

Refrigerant collection when relocating the indoor and outdoor units (pump down)

Connect a gauge manifold valve (pressure gauge included) to the service port near the gas stop valve of the outdoor unit so that the refrigerant pressure can be measured.

Turn on the power supply (circuit breaker).

Close the liquid stop valve, and then perform the test run for cooling operation (SW4-1: ON and SW4-2: OFF).

* Be sure to wait at least 3 minutes after turning on the power supply before setting SW4-1 and SW4-2. If the DIP switches are set before 3 minutes has elapsed, the test run may not start.

Fully close the gas stop valve when the pressure reading on the gauge drops to 0.05 - 0.00 MPa* (approximately 0.5 - 0.0 kgf/cm2).

* If too much refrigerant has been added to the air conditioner system, the pressure may not drop to 0.5 kgf/cm2. If this occurs, use a refrigerant collecting device to collect all of the refrigerant in the system, and then recharge the system with the correct amount of refrigerant after the indoor and outdoor units have been relocated.

Stop the air conditioner operation (SW4-1: OFF and SW4-2: OFF).Turn off the power supply (circuit breaker).

5.5. Connecting pipes (Fig. 5-6)

•When commercially available copper pipes are used, wrap liquid and gas pipes with commercially available insulation materials (heat-resistant to 100 °C or more, thickness of 12 mm or more).

•The indoor parts of the drain pipe should be wrapped with polyethylene foam insulation materials (specific gravity of 0.03, thickness of 9 mm or more).

•Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening flare nut.

•Use two wrenches to tighten piping connections.

•Use leak detector or soapy water to check for gas leaks after connections are completed.

•Apply refrigerating machine oil over the entire flare seat surface.

•Use the flare nuts as follows.

NPipe size (Outdoor unit-Branch box)

Pipe size |

Liquid |

ø9.52 |

|

The lineup of a connectable indoor unit |

(ømm) |

Gas |

ø15.88 |

|

depends on a district/areas/country. |

|

|

|

|

|

NPipe size (Branch box-Indoor unit) *Case of M series or S series Indoor unit

Indoor |

(kW) |

15 |

20 |

22 |

25 |

35 |

42 |

50 |

60 |

71 |

80 |

unit type |

|||||||||||

Pipe size |

Liquid |

ø6.35 |

ø6.35 |

ø6.35 |

ø6.35 |

ø6.35 |

ø6.35 |

ø6.35 |

ø6.35 |

ø9.52 |

ø9.52 |

(ømm) |

Gas |

ø9.52 |

ø9.52 |

ø9.52 |

ø9.52 |

ø9.52 |

ø9.52 |

ø12.7 |

ø15.88 * |

ø15.88 |

ø15.88 |

*When using 60 type indoor unit of MEXZ series, use the flare nut in the indoor unit accessory for the gas side connecting of indoor unit.

Do not use the flare nut (gas side) attached to the indoor unit. If it is used, a gas leakage or even a pipe extraction may occur.

NPipe size (Branch box-Indoor unit) *Case of P series indoor unit

Indoor unit |

(kW) |

*1 |

35 |

*1 |

|

|

|

*2 |

type |

|

|

50 |

60 |

71 |

100 |

||

Pipe size |

Liquid |

|

ø6.35 |

|

ø6.35 |

ø9.52 |

ø9.52 |

ø9.52 |

(ømm) |

Gas |

|

ø12.7 |

|

ø12.7 |

ø15.88 |

ø15.88 |

ø15.88 |

*1 When using 35, 50 type indoor unit of P series, use the flare nut attached to the indoor unit.

Do not use the flare nut in the indoor unit accessory. If it is used, a gas leakage or even a pipe extraction may occur.

*2 For details about connecting the pipes for the P100 indoor unit, refer to the installation manual of the Y-shape connection pipe (PAC-AK52YP-E).

•When bending the pipes, be careful not to break them. Bend radii of 100 mm to 150 mm are sufficient.

•Make sure the pipes do not contact the compressor. Abnormal noise or vibration may result.

Pipes must be connected starting from the indoor unit. Flare nuts must be tightened with a torque wrench.

Flare the liquid pipes and gas pipes and apply a thin layer of refrigeration oil (Applied on site).

•When usual pipe sealing is used, refer to Table 2 for flaring of R410A refrigerant pipes.

The size adjustment gauge can be used to confirm A measurements.

Caution:

Caution:

•Be sure to wrap insulation around the piping. Direct contact with the bare piping may result in burns or frostbite.

Table 2 (Fig. 5-7)

Copper pipe O.D. |

|

A (mm) |

||

Flare tool for R410A |

|

Flare tool for R22·R407C |

||

(mm) |

|

|||

Clutch type |

||||

|

||||

ø6.35 (1/4”) |

0 - 0.5 |

|

1.0 - 1.5 |

|

ø9.52 (3/8”) |

0 - 0.5 |

|

1.0 - 1.5 |

|

ø12.7 (1/2”) |

0 - 0.5 |

|

1.0 - 1.5 |

|

ø15.88 (5/8”) |

0 - 0.5 |

|

1.0 - 1.5 |

|

8

5. Installing the refrigerant piping

Front piping cover

Piping cover

Stop valve

Service panel

Band radius : 100 mm - 150 mm

Fig. 5-8

(1)(2)

BB

A |

|

A |

D |

|

|

|

|

E |

|

|

|

|

|

|

K |

|

E |

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

C |

F |

G |

|

H |

|

H |

|

|

|

|

|

|

|

Type A |

|

Type B |

|

|

|

|

Fig. 5-9 |

|

|

(3) |

B C |

|

I |

|

|

|

E

E

|

J |

|

|

|

|

H |

|

|

|

|

Type C |

|

|

|

|

Fig. 5-10 |

|

|

|

|

|

E |

F |

|

|

|

|

G |

|

|

|

|

H |

|

|

|

B |

I |

|

|

|

|

||

A |

LO |

HI |

|

|

C |

D |

K |

||

|

||||

|

|

|||

|

Fig. 5-11 |

|

|

5.6. Refrigerant piping (Fig. 5-8)

Remove the service panel (three screws) and the front piping cover (two screws) and rear piping cover (two screws).

Refrigerant pipes are protectively wrapped

• The pipes can be protectively wrapped up to a diameter of ø90 before or after connecting the pipes. Cut out the knockout in the pipe cover following the groove and wrap the pipes.

Pipe inlet gap

•Use putty or sealant to seal the pipe inlet around the pipes so that no gaps remain.

(If the gaps are not closed, noise may be emitted or water and dust will enter the unit and breakdown may result.)

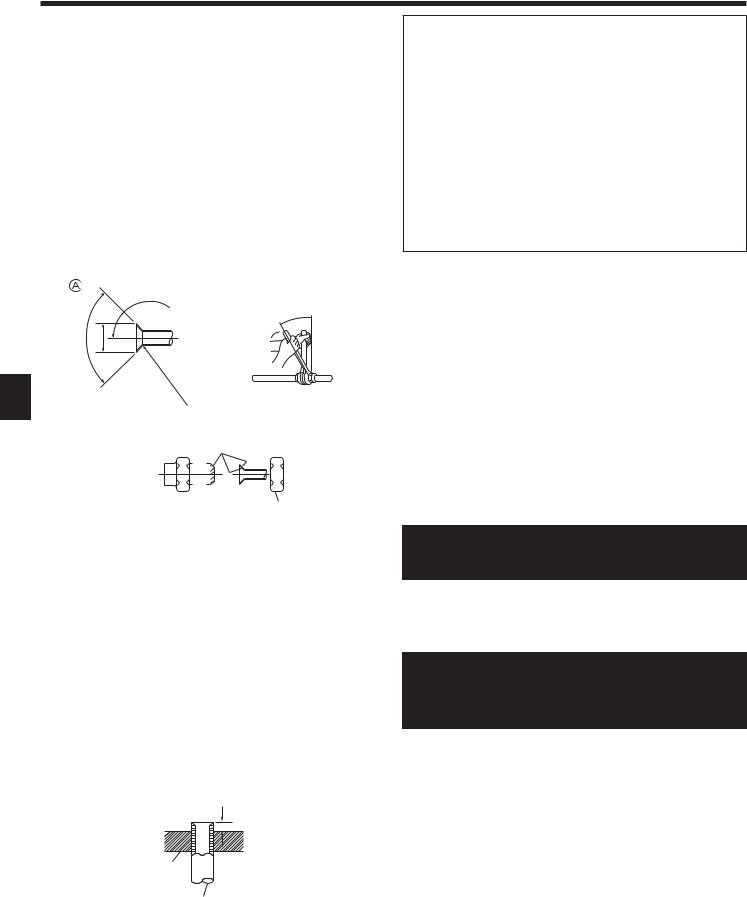

5.7. Caution for piping connection/valve operation

•Conduct piping connection and valve operation accurately by following the figure below.

•Apply sealer along the insulator to prevent water entering the insulator covering the refrigerant pipe joints.

•After evacuation and refrigerant charge, ensure that the handle is fully open. If operating with the valve closed, abnormal pressure will be imparted to the highor low-pressure side of the refrigerant circuit, giving damage to the compressor, etc.

•Determine the amount of additional refrigerant charge (refer “5.3. Addition of refrigerant”), and charge refrigerant additionally through the service port after completing piping connection work.

•After completing work, tighten the service port (12 - 15 N·m) and cap (20 - 25 N·m) securely to prevent gas leak.

*1 N·m 10 kgf·cm

10 kgf·cm

Method of completely opening the stop valve

The stop valve opening method varies according to the outdoor unit model. Use the appropriate method to open the stop valves.

(1) Type A (Fig. 5-9)

Remove the cap, then turn one-quarter rotation counter-clockwise with a flat-bladed screwdriver to complete open.

Check that the valves are fully open, then return the cap to its original state and tighten it down.

(2) Type B (Fig. 5-9)

Remove the cap, pull the handle toward you and rotate 1/4 turn in a counterclockwise direction to open.

Make sure that the stop valve is open completely, push in the handle and rotate the cap back to its original position.

(3) Type C (Fig. 5-10)

Remove the cap and turn the valve rod counterclockwise as far as it will go with the use of a 4 mm hexagonal wrench. Stop turning when it hits the stopper.

Make sure that the stop valve is open completely and rotate the cap back to its original position.

|

Valve |

|

Completely open |

|

Unit side |

|

(On-side installation) Refrigerant |

|

Service port |

|

piping side |

|

Handle |

Direction the refrigerant flows in |

|

|

Cap |

|

Wrench hole |

|

Completely closed |

|

Operation section |

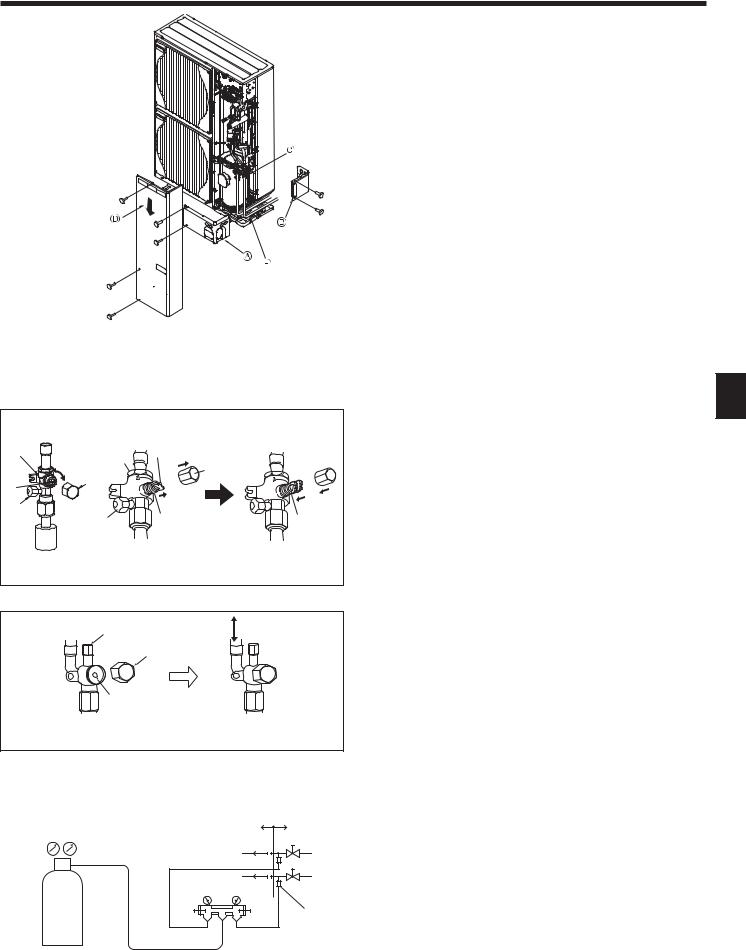

5.8. Airtight test and evacuation

Airtight test (Fig. 5-11)

Airtight test should be made by pressurizing nitrogen gas. For the test method, refer to the following figure.

(1)Connecting the testing tool. Make a test with the stop valve closed. Be also sure to pressurize both liquid or high-pressure pipe and gas or low pressure pipe.

(2)Do not add pressure to the specified pressure all at once; add pressure little by little.

Pressurize to 0.5 MPa (5 kgf/cm2G), wait five minutes, and make sure the pressure does not decrease.

Pressurize to 1.5 MPa (15 kgf/cm2G), wait five minutes, and make sure the pressure does not decrease.

Pressurize to 4.15 MPa (41.5 kgf/cm2G) and measure the surrounding temperature and refrigerant pressure.

(3)If the specified pressure holds for about one day and does not decrease, the pipes have passed the test and there are no leaks.

• If the surrounding temperature changes by 1 °C, the pressure will change by about 0.01 MPa (0.1 kgf/cm2G). Make the necessary corrections.

(4)If the pressure decreases in steps (2) or (3), there is a gas leak. Look for the source of the gas leak.

|

Nitrogen gas |

|

Stop valve |

|

System analyzer |

|

Liquid pipe or high-pressure |

|

Lo-knob |

|

pipe |

|

Hi-knob |

Gas pipe or low-pressure pipe |

|

|

To branch box |

|

Service port |

Outdoor unit

9

5. Installing the refrigerant piping

IJ K

L

|

F |

|

M |

LO |

|

|

|

HI |

|

|

|

G |

H |

D N |

C |

|

|

C |

|

E |

|

|

|

A |

|

|

|||

|

|

|

B |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

||

Freon cylinder |

|

Hi-knob |

|

|

||

Scale |

|

To branch box |

|

|

||

Valve |

|

Outdoor unit |

|

|

||

3-way joint |

|

Stop valve |

|

|

||

Vacuum pump |

|

Liquid pipe or high-pressure pipe |

||||

System analyzer |

|

|

Gas pipe or low-pressure pipe |

|||

Lo-knob |

|

! Service port |

|

|

||

Evacuation (Fig. 5-12)

Evacuation should be made from the service port provided on the outdoor unit’s stop valve to the vacuum pump commonly used for both liquid or high-pressure pipe and gas or low-pressure pipe. (Make evacuation from both liquid or high-pressure pipe and gas or low-pressure pipe with the stop valve closed.)

Remember: Never carry out air purge by refrigerant.

Warning:

Warning:

When installing or moving a unit to another place, do not mix anything other than specified refrigerant into the refrigeration cycle. If air is mixed, the refrigeration cycle may obtain abnormally high pressure, resulting in a burst pipe.

*A high-precision gravimeter measurable up to 0.1 kg should be used. If you are unable to prepare such a high-precision gravimeter, you may use a charging cylinder.

Note:

•Use a gauge manifold, changing hose, and other parts for the refrigerant indicated on the unit.

•Use a gravimeter. (One that can measure down to 0.1 kg)

Fig. 5-12

* The figure to the left is an example only. The stop valve shape, service port position, etc., may vary according to the model.

* Turn section only.

(Do not further tighten sections and together.)

Charge hoseService port

Fig. 5-13

Precautions when using the charge valve (Fig. 5-13)

Do not tighten the service port too much when installing it, otherwise, the valve core could be deformed and become loose, causing a gas leak.

After positioning section in the desired direction, turn section only and tighten it.

Do not further tighten sections and together after tightening section .

6. Drainage piping work

Outdoor unit drainage pipe connection

When drain piping is necessary, use the drain socket or the drain pan (option).

Drain socket |

PAC-SG61DS-E |

Drain pan |

PAC-SG64DP-E |

7. Electrical work

[1] Basic systems

OC: Outdoor unit BC: Branch box

OC IC: Indoor unit

RC: Remote controller

|

BC (5-branch type) |

|

BC (3-branch type) |

||||

A |

B |

C |

D |

E |

A |

B |

C |

IC |

IC |

IC |

IC |

IC |

IC |

IC |

IC |

RC |

RC |

R |

R |

R |

R |

R |

R |

|

|

||||||

|

|

C |

C |

C |

C |

C |

C |

*For details about connecting the wires for the P100 indoor unit, refer to the installation manual of the Branch box (PAC-AK52BC).

OC

BC (5-branch type)

A B C D

Note:

The indoor units can be connected to any of the 5 connectors (5-branch type) or 3 connectors (3-branch type) of the branch box.

BC (3-branch type)

E A B C

|

|

|

|

|

|

|

|

|

|

|

|

IC |

IC |

|

|

IC |

|

|

IC |

|

IC |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RC |

RC |

|

|

|

|

|

|

|

|

|

|

R |

|

|

R |

|

R |

||||||

|

|

|

|

|

C |

|

|

C |

|

C |

|

|

|

|

|

|

|||||||

10

Loading...

Loading...