Metrohm 885 User Manual

885 Compact Oven SC

Manual

8.885.8002EN

Metrohm AG

CH-9101 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

885 Compact Oven SC

Manual

8.885.8002EN 05.2011 dm

Teachware

Metrohm AG

CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.1.1 Instrument components .......................................................... 1

1.1.2 Intended use ........................................................................... 2

1.2 About the documentation ................................................... 2

1.2.1 Symbols and conventions ........................................................ 2

1.3 Safety instructions ................................................................ 3

1.3.1 General notes on safety ........................................................... 3

1.3.2 Electrical safety ........................................................................ 3

1.3.3 Tubing and capillary connections ............................................. 4

1.3.4 Personnel safety ...................................................................... 5

1.3.5 Flammable solvents and chemicals ........................................... 6

1.3.6 Recycling and disposal ............................................................. 6

2 Overview of the instrument 7

Table of contents

3 Installation 9

3.1 Setting up the instrument .................................................... 9

3.1.1 Packaging ................................................................................ 9

3.1.2 Checks .................................................................................... 9

3.1.3 Location .................................................................................. 9

3.2 Mounting the stand plate .................................................... 9

3.3 Removing the safety shield ............................................... 10

3.4 Mounting the needles ........................................................ 11

3.5 Assembling the drying flasks ............................................ 13

3.6 Mounting the heating tubing ............................................ 15

3.7 Mounting the safety shield ................................................ 16

3.8 Mounting the dust filter .................................................... 17

3.9 Assembling the air/nitrogen connector ............................ 18

3.10 Inserting the heating tube into the KF titration cell ....... 19

3.11 Remote connections ........................................................... 21

3.11.1 Remote cable ........................................................................ 21

3.11.2 Example systems .................................................................... 21

885 Compact Oven SC

3.12 Connecting a keyboard, printer and other USB devi-

ces ........................................................................................ 23

3.13 Connecting the mains cable .............................................. 25

■■■■■■■■

III

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

4 Automation sequence 26

4.1 Execution sequences .......................................................... 26

4.2 Oven heating ....................................................................... 27

5 Operation 28

5.1 Switching the instrument on and off ............................... 28

5.2 Fundamentals of operation ............................................... 28

5.2.1 The keypad ............................................................................ 28

5.2.2 Structure of the dialog windows ............................................ 29

5.2.3 Navigating in the dialog ......................................................... 29

5.2.4 Entering text and numbers ..................................................... 29

5.3 Methods .............................................................................. 30

5.3.1 Creating a new method ......................................................... 30

5.3.2 Saving a method ................................................................... 31

5.3.3 Loading a method ................................................................. 32

5.3.4 Exporting a method ............................................................... 33

5.4 Performing a sample series ............................................... 34

5.4.1 Starting the sample series ...................................................... 34

5.4.2 Pausing a sample series and continuing ................................. 35

5.5 Printing a report manually ................................................. 36

5.6 Manual control ................................................................... 37

5.6.1 Rotating the sample rack ....................................................... 37

5.6.2 Moving the lift ....................................................................... 38

5.6.3 Switching the oven on/off ..................................................... 39

5.6.4 Entering the oven temperature .............................................. 39

5.6.5 Switching the gas flow on/off ................................................ 39

5.6.6 Entering the flow rate ............................................................ 40

6 System settings 41

6.1 Basic settings ...................................................................... 41

6.2 File management ................................................................ 44

6.3 Oven settings (heater) ........................................................ 45

6.4 Lift settings (Lift) ................................................................ 46

6.5 Configuring external devices ............................................. 47

6.6 Instrument diagnosis .......................................................... 49

6.6.1 Loading program versions and language files ......................... 49

6.6.2 Diagnosis functions ............................................................... 50

7 Parameters 51

■■■■■■■■

IV

7.1 Automation ......................................................................... 51

7.2 Reports ................................................................................ 53

885 Compact Oven SC

■■■■■■■■■■■■■■■■■■■■■■

8 Carrying out a determination 54

9 Handling and maintenance 58

10 Appendix 60

Table of contents

8.1 Conditioning the system .................................................... 54

8.1.1 Preparing the KF titration cell ................................................. 54

8.1.2 Preparing the 885 Compact Oven SC ..................................... 55

9.1 General ................................................................................ 58

9.2 Quality Management and validation with Metrohm ....... 58

10.1 Practical notes .................................................................... 60

10.2 Remote interface ................................................................ 61

10.2.1 Pin assignment of the remote interface .................................. 61

10.2.2 Status diagram of the remote interface .................................. 62

10.3 System initialization ........................................................... 62

10.4 Literature ............................................................................. 64

11 Troubleshooting 65

11.1 885 Compact Oven SC ........................................................ 65

12 Technical specifications 66

12.1 Lift ........................................................................................ 66

12.2 Turntable ............................................................................. 66

12.3 Oven ..................................................................................... 66

12.4 Gas flow .............................................................................. 67

12.5 Outlet heater ....................................................................... 67

12.6 Interfaces and connectors ................................................. 67

12.7 Mains connection ............................................................... 67

12.8 Reference conditions .......................................................... 67

12.9 Safety specifications ........................................................... 68

12.10 Electromagnetic compatibility (EMC) ................................ 68

12.11 Ambient temperature ......................................................... 68

12.12 Dimensions .......................................................................... 69

13 Conformity and warranty 70

885 Compact Oven SC

13.1 Declaration of Conformity ................................................. 70

13.2 Warranty (guarantee) ......................................................... 71

13.3 Quality Management Principles ........................................ 72

■■■■■■■■

V

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

14 Accessories 74

14.1 Scope of delivery 2.885.0010 ............................................ 74

14.2 Optional accessories ........................................................... 80

Index 82

■■■■■■■■

VI

885 Compact Oven SC

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

Figure 1 Mounting the stand plate ................................................................ 10

Figure 2 Removing the coverings .................................................................. 10

Figure 3 Mounting the needles ..................................................................... 12

Figure 4 Connecting the tubing to the gas outlet .......................................... 13

Figure 5 Preparing the drying flasks ............................................................... 13

Figure 6 Mounting drying flasks and tubings ................................................. 14

Figure 7 Mounting the heating tubing .......................................................... 15

Figure 8 Connecting the heating tubing ........................................................ 16

Figure 9 Mounting the coverings .................................................................. 17

Figure 10 Mounting the dust filter .................................................................. 18

Figure 11 External gas supply connection ........................................................ 18

Figure 12 Coulometric KF titration cell ............................................................ 19

Figure 13 Volumetric KF titration cell .............................................................. 20

Figure 14 Remote connection 885 Compact Oven SC - Coulometer or 7xx KF

Titrino ............................................................................................. 22

Figure 15 Remote connection 885 Compact Oven SC - Remote Box - 851/852

Titrando .......................................................................................... 22

Figure 16 Connecting USB devices .................................................................. 23

Figure 17 Connecting the USB stick ................................................................ 24

Figure 18 Connecting the 6.2147.000 USB keyboard with USB stick and

printer ............................................................................................. 25

Figure 19 Connecting the mains cable ............................................................ 25

Figure 20 Keypad 885 Compact Oven SC ........................................................ 28

Figure 21 Directory structure on the USB stick ................................................. 44

Figure 22 Pin assignment of remote socket and plug ...................................... 61

Figure 23 Remote status diagram .................................................................... 62

Table of figures

885 Compact Oven SC

■■■■■■■■

VII

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 885 Compact Oven SC is used whenever the heating up of a sample

and/or the thermal expulsion of moisture in solids or liquids is required. In

combination with a coulometric or volumetric KF titrator, the 885 Compact Oven SC is the ideal analysis system for water determination in samples that contain disruptive components or from which moisture can be

removed only with difficulty.

One of its decisive advantages is the reduction of sample preparation to a

minimum. Thanks to the use of hermetically sealed sample vessels ("headspace vials"), the filling of the samples can be accomplished directly onsite. The PTFE-coated septa guarantee a constant, non-falsified water content, even after prolonged holding times.

1 Introduction

Thanks to the combination of a sample changer with an oven module,

automated processing of several samples in a single sample series is possible. This ensures that only the smallest possible amount of work is

required.

The sample heated in the oven module releases its moisture in the form of

water vapor, which is conveyed into a measuring cell with the aid of a gas

flow. An air pump is installed for the purpose of generating the gas flow.

An inlet valve is available for nitrogen or other inert gases. The determination of the moisture can be accomplished in the measuring cell either coulometrically or volumetrically according to Karl Fischer.

1.1.1 Instrument components

The 885 Compact Oven SC has the following components:

■ Turntable

Permanently mounted sample rack with 17 positions for sample vials

and 1 position for a conditioning vessel.

■ Lift with working head

Working head with needle adapter and tubing for the gas flow.

■ Oven

Oven module made of aluminum with software-operated temperature

control for heating the sample vessel.

■ Fan

Propeller fan for cooling the oven module.

■ Inlet valve

Valve for switching over the source of the gas flow.

885 Compact Oven SC

■■■■■■■■

1

1.2 About the documentation

■ Air pump

■ Outlet heater

■ Operating unit

1.1.2 Intended use

The 885 Compact Oven SC is designed for usage as an auxiliary device for

automated sample preparation in analytical laboratories. Its main area of

application is moisture determination according to Karl Fischer (coulometric or volumetric). The 885 Compact Oven SC enables the application of

thermal gas extraction technology.

This instrument is suitable for processing chemicals and flammable samples. The usage of the 885 Compact Oven SC therefore requires that the

user has basic knowledge and experience in the handling of toxic and

caustic substances. Knowledge with respect to the application of the fire

prevention measures prescribed for laboratories is also mandatory.

■■■■■■■■■■■■■■■■■■■■■■

Pump for generating the gas flow.

Heating tubing for preventing the condensation of moisture.

Monochrome LCD display and keyboard.

1.2 About the documentation

Caution

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

1.2.1 Symbols and conventions

The following symbols and styles are used in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the

second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Method Dialog text, parameter in the software

■■■■■■■■

2

File ▶ New

Menu or menu item

[Next] Button or key

885 Compact Oven SC

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

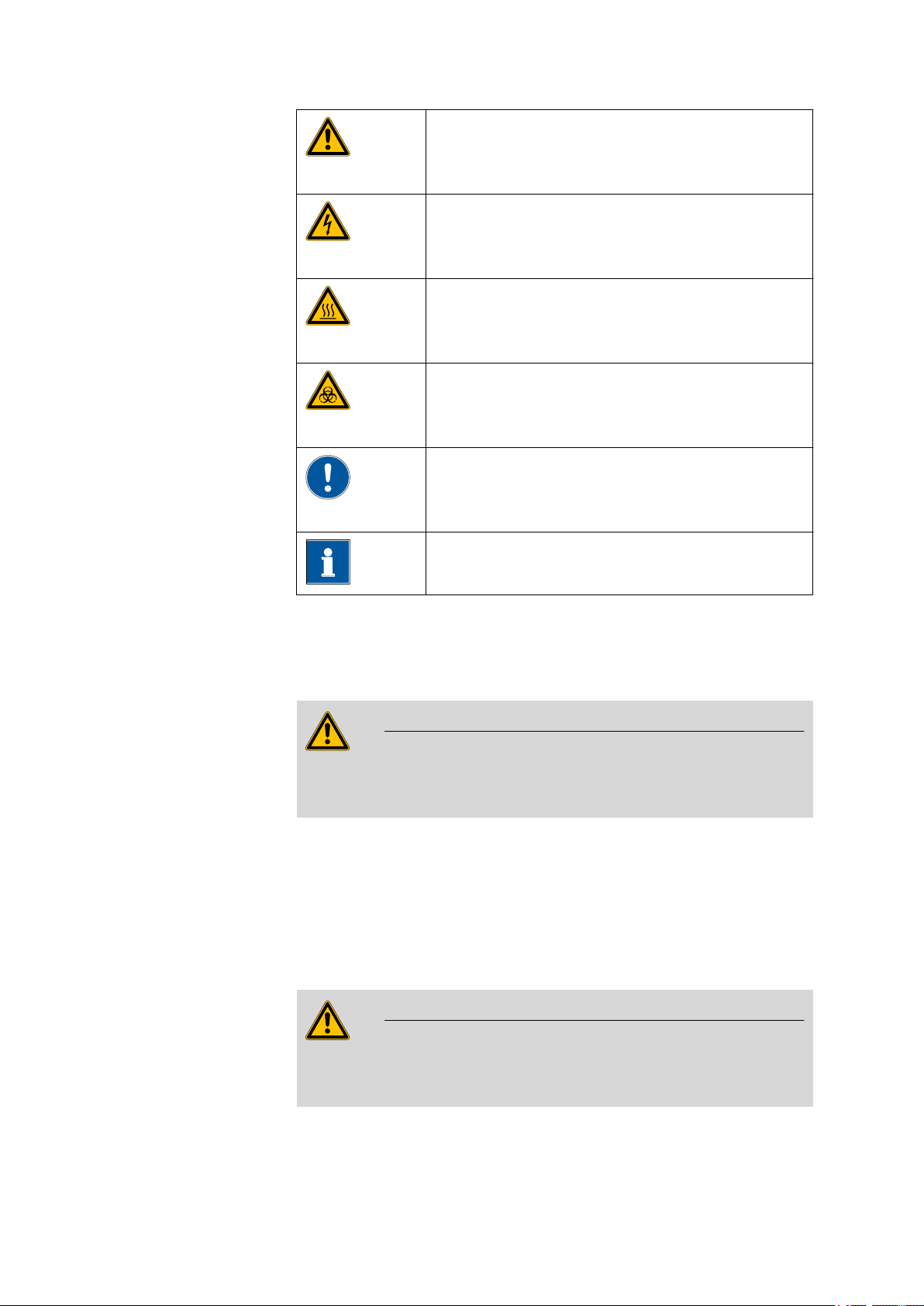

Warning

This symbol draws attention to a possible life hazard

or risk of injury.

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

Warning

This symbol draws attention to a possible biological

hazard.

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

1.3 Safety instructions

1.3.1 General notes on safety

Warning

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

1.3.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

Note

This symbol marks additional information and tips.

885 Compact Oven SC

Warning

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

■■■■■■■■

3

1.3 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

Warning

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Mains voltage

Warning

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

Protection against electrostatic charges

Warning

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Always pull the mains cable out of the mains connection socket before

connecting or disconnecting electrical appliances on the rear panel of

the instrument.

1.3.3 Tubing and capillary connections

Caution

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

■■■■■■■■

4

885 Compact Oven SC

■■■■■■■■■■■■■■■■■■■■■■

1.3.4 Personnel safety

Wear protective goggles and working clothes suitable for laboratory

work while operating the 885 Compact Oven SC. It is also advisable to

wear gloves when caustic liquids are used or in situations where glass

vessels could break.

The oven module can exhibit temperatures of up to 250 °C. Sample

vessels and components of the sample rack can also become so hot

(<60 °C), that the skin could suffer burns in the event of contact.

Never touch the rack, sample vessels or oven when the heating is

turned on. Be aware of the current value on the temperature display.

1 Introduction

Warning

Warning

Wear working gloves.

Do not fail to switch off the device before attempting to clean it and

wait until the oven has cooled down.

Warning

Always install the safety shield supplied with the equipment before

using the instrument for the first time. Pre-installed safety shields are

not allowed to be removed.

The 885 Compact Oven SC may not be operated without a safety

shield!

Warning

Personnel are not permitted to reach into the working area of the

instrument while operations are running!

A considerable risk of injury exists for the user.

885 Compact Oven SC

■■■■■■■■

5

1.3 Safety instructions

Warning

In the event of a possible jamming of a drive, the mains plug must be

pulled out of the socket immediately. Do not attempt to free jammed

sample vessels or other parts while the instrument is switched on. A

jamming can only be cleared when the instrument is in a voltage-free

status; this action generally involves a considerable risk of injury.

Warning

The 885 Compact Oven SC is not suitable for usage in biochemical,

biological or medical environments in its basic equipment version.

Appropriate protective measures must be implemented in the event

that potentially infectious samples or reagents are being processed.

1.3.5 Flammable solvents and chemicals

■■■■■■■■■■■■■■■■■■■■■■

Warning

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location.

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

1.3.6 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

■■■■■■■■

6

885 Compact Oven SC

■■■■■■■■■■■■■■■■■■■■■■

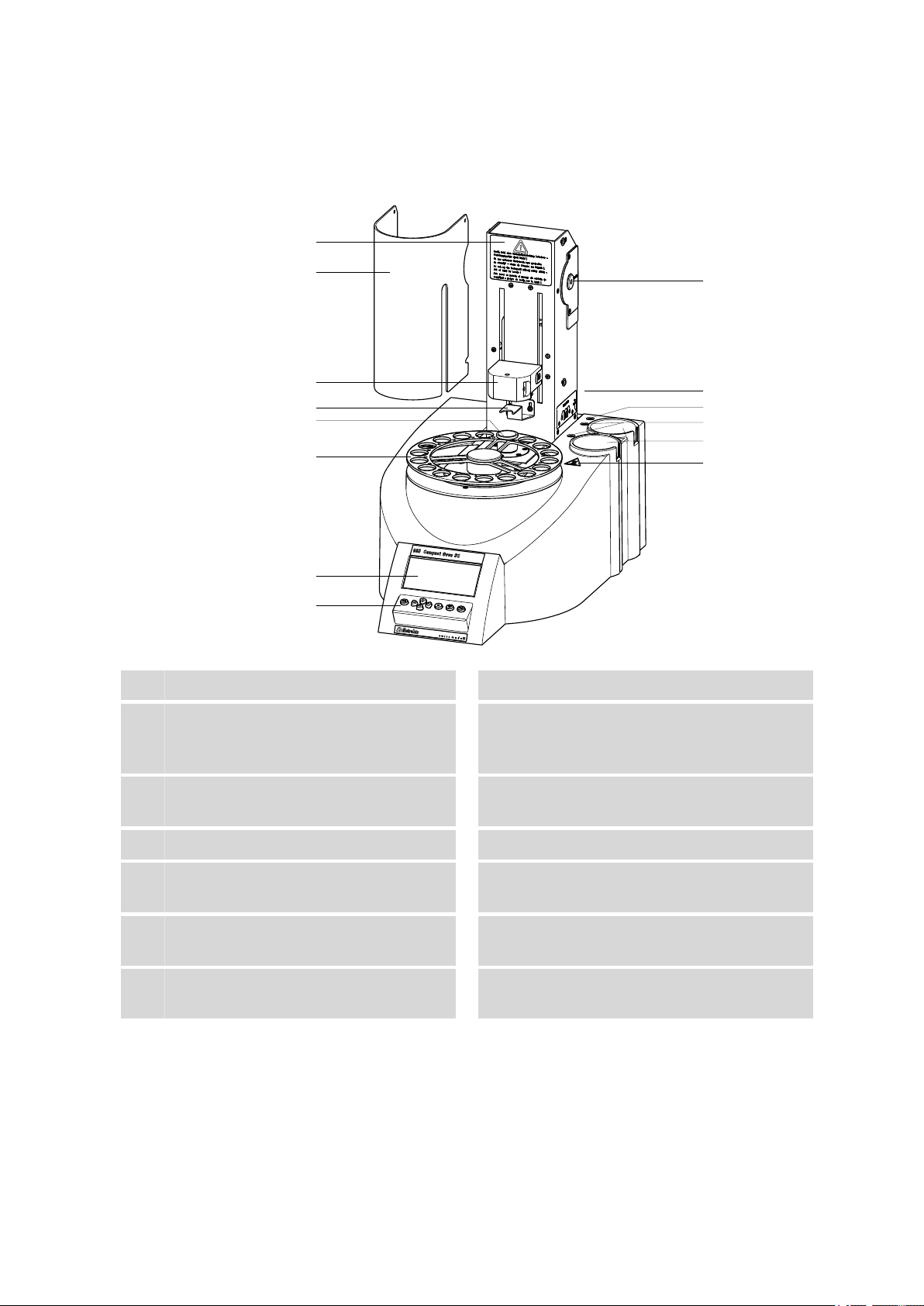

1

2

3

4

5

6

7

8

9

10

11

12

13

14

2 Overview of the instrument

2 Overview of the instrument

Warning instruction

1

Lift with distributor

3

Conditioning position

5

For a conditioning vial.

Display

7

Air pump inlet

9

With 6.2724.010 dust filter.

Gas outlet

11

For the tubing for testing. With M6 thread.

Recesses in the housing

13

For the drying flasks.

Safety shield (6.2751.170)

2

Deflector sheet

4

For deflecting the vial while the lift is traveling upwards.

Sample rack

6

For 17 samples.

Keypad

8

Instruction sign

10

Displays the tubing of the drying flasks.

Gas connections

12

For the drying flasks. With M6 thread.

Warning symbol

14

Warns against hot surfaces.

885 Compact Oven SC

■■■■■■■■

7

■■■■■■■■■■■■■■■■■■■■■■

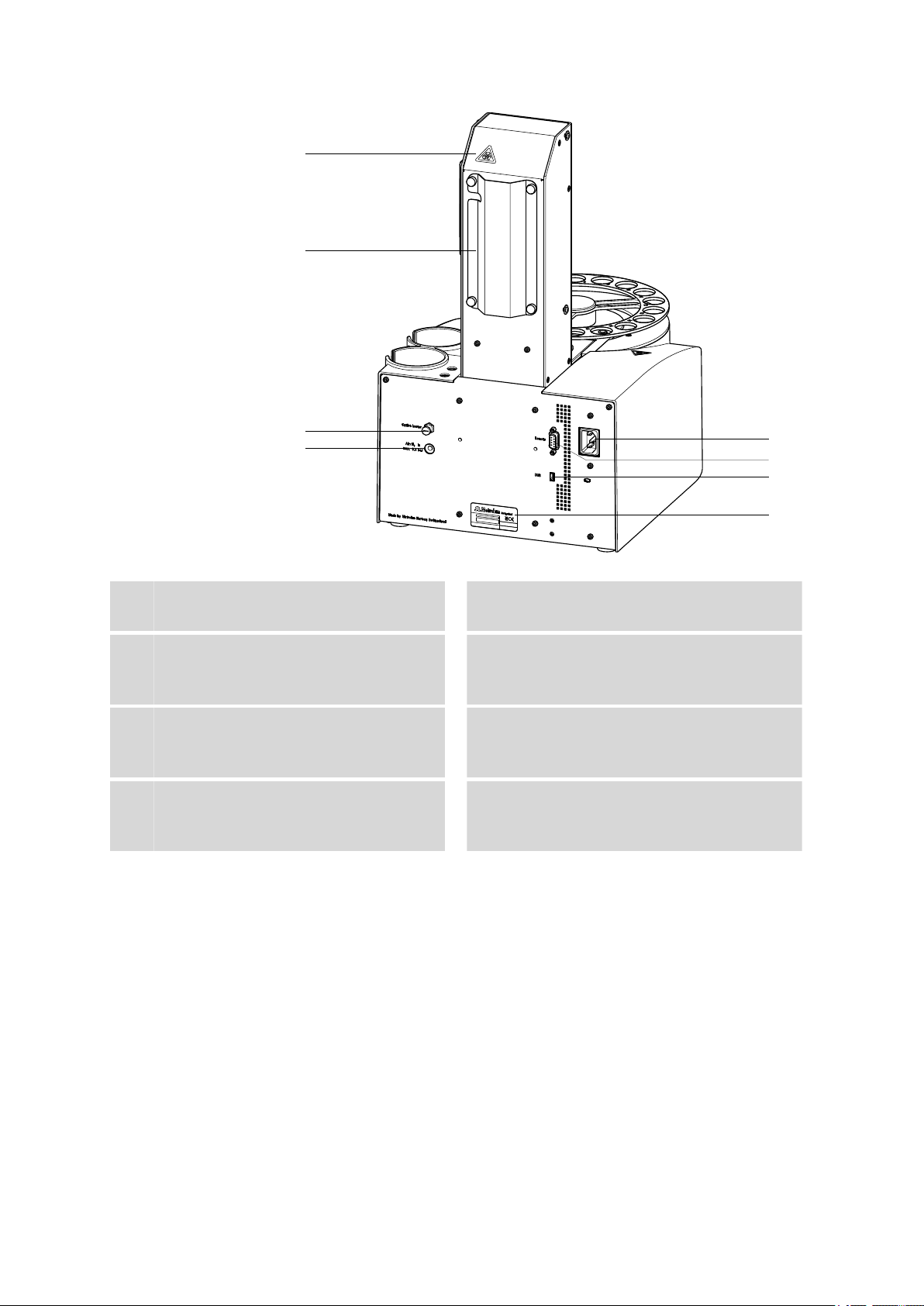

1

2

3

4

5

6

7

8

Warning symbol

1

See page 5

Outlet heater connection

3

For the heating tubing.

Mains connection socket

5

USB (OTG) connector

7

For connecting printers, USB sticks, USB

hubs, etc.

Tubing and cable cover

2

Air/nitrogen connector

4

With M6 inner thread. Inlet for external gassing.

Remote connector

6

For connecting instruments with a remote

interface. D-Sub, 9-pin.

Type plate

8

Contains specifications concerning mains

voltage and serial number.

■■■■■■■■

8

885 Compact Oven SC

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

3.1 Setting up the instrument

3.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

3.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

3 Installation

Place the instrument in a location of the laboratory which is suitable for

operation, free of vibrations, protected from corrosive atmosphere, and

contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

3.2 Mounting the stand plate

The titration cell must be fitted as close to the device as possible. Two

stand plates (6.2001.050 and 6.2001.060) with support rods are available

for this purpose, each of which is supplied with a KF titrator.

885 Compact Oven SC

■■■■■■■■

9

3.3 Removing the safety shield

1

2

3

6.2001.060 6.2001.050

6.2016.030

1

1

2

■■■■■■■■■■■■■■■■■■■■■■

Figure 1 Mounting the stand plate

Proceed as follows:

Screw the stand plate to the base of the 885 Compact Oven SC with

1

the screws provided, see figure.

Guide the large cylinder screw into the opening of the stand plate

2

from the bottom.

Screw the 6.2016.030 support rod tight on the cylinder screw. Fas-

3

ten in place with a hexagon key.

3.3 Removing the safety shield

Figure 2 Removing the coverings

■■■■■■■■

10

885 Compact Oven SC

■■■■■■■■■■■■■■■■■■■■■■

If you remove the safety shield before, the installation of the accessories is

easier to carry out. Proceed as follows:

Loosen the hexagon screws on the sides of the tower and remove

1

the safety shield.

Loosen the knurled screws on the rear of the tower and remove the

2

cable cover.

Do not forget to refasten the safety shields after the installation of the

accessories.

3.4 Mounting the needles

The length of the needle holder defines how deeply the piercing needle

penetrates the sample vessel.

If there is a danger that the heated sample could clog the needle, then

use the 6.2049.050 needle holder which is 73 mm in length. In this

case the piercing needle penetrates the sample vessel only slightly deeper

than the exhaust air needle and has no contact with the sample itself.

3 Installation

Caution

Movement with the needle holder 6.2049.050 may not extend more

deeply than up to Lift position 78 mm.

The 6.2049.040 needle holder, which is 58 mm in length, ensures that

the needle penetrates the liquid or powdery sample. The carrier gas can

flow through the sample and effect an efficient expulsion of the moisture

it contains. The 6.2049.040 needle holder can be ordered from Metrohm

if required.

885 Compact Oven SC

■■■■■■■■

11

3.4 Mounting the needles

1

4

2

3

6.1805.060

6.2049.050

6.2816.080

6.2816.070

■■■■■■■■■■■■■■■■■■■■■■

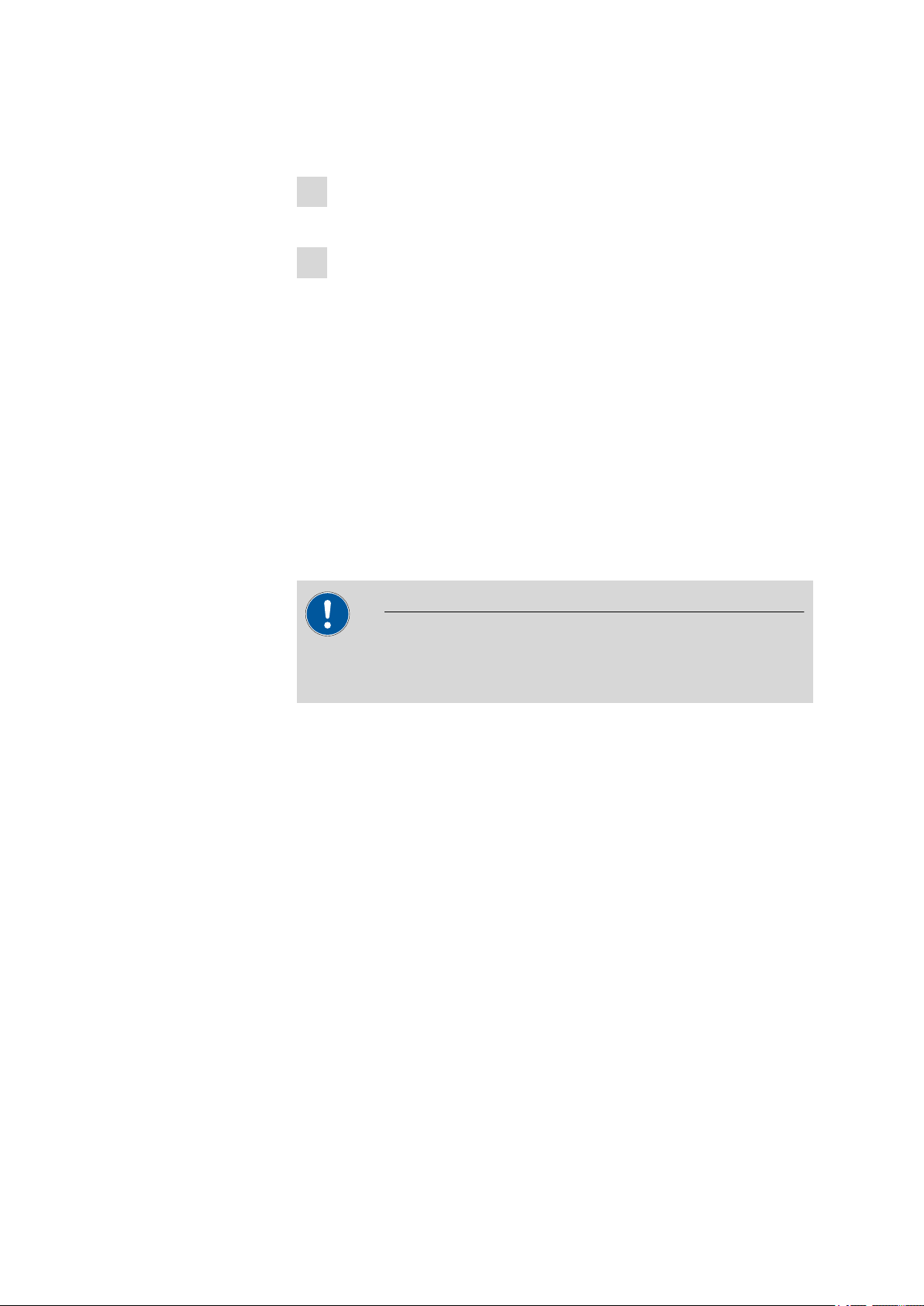

Figure 3 Mounting the needles

Mount the needles as follows:

Screw the 6.2049.050 needle holder into the distributor on the

1

guide head.

Screw the 6.2816.080 exhaust air needle onto the Luer connec-

2

tor of the needle holder.

Carefully guide the 6.2816.070 piercing needle into the opening

3

of the distributor from above and allow it to drop down.

■■■■■■■■

12

Note

Take care to ensure that the white PTFE seal is positioned securely

on the needle.

Screw the 6.1805.060 FEP tubing by hand onto the opening of

4

the distributor.

Tightly screw the other end of the tubing to the gas outlet opening

5

(labeled with to sample) next to the tower, see figure.

885 Compact Oven SC

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

6.1608.050

6.1821.040

6.1602.145

6.2811.000

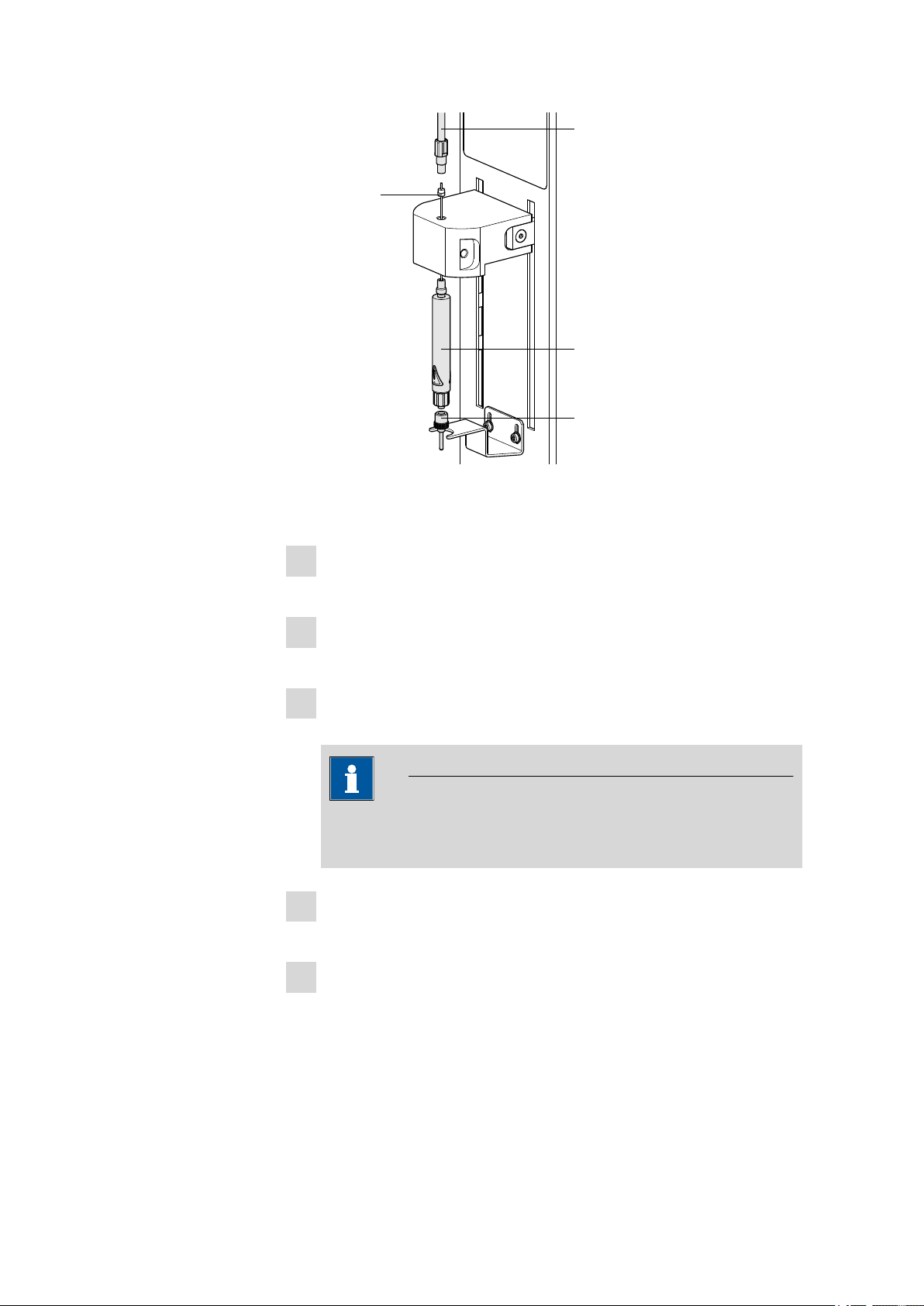

Figure 4 Connecting the tubing to the gas outlet

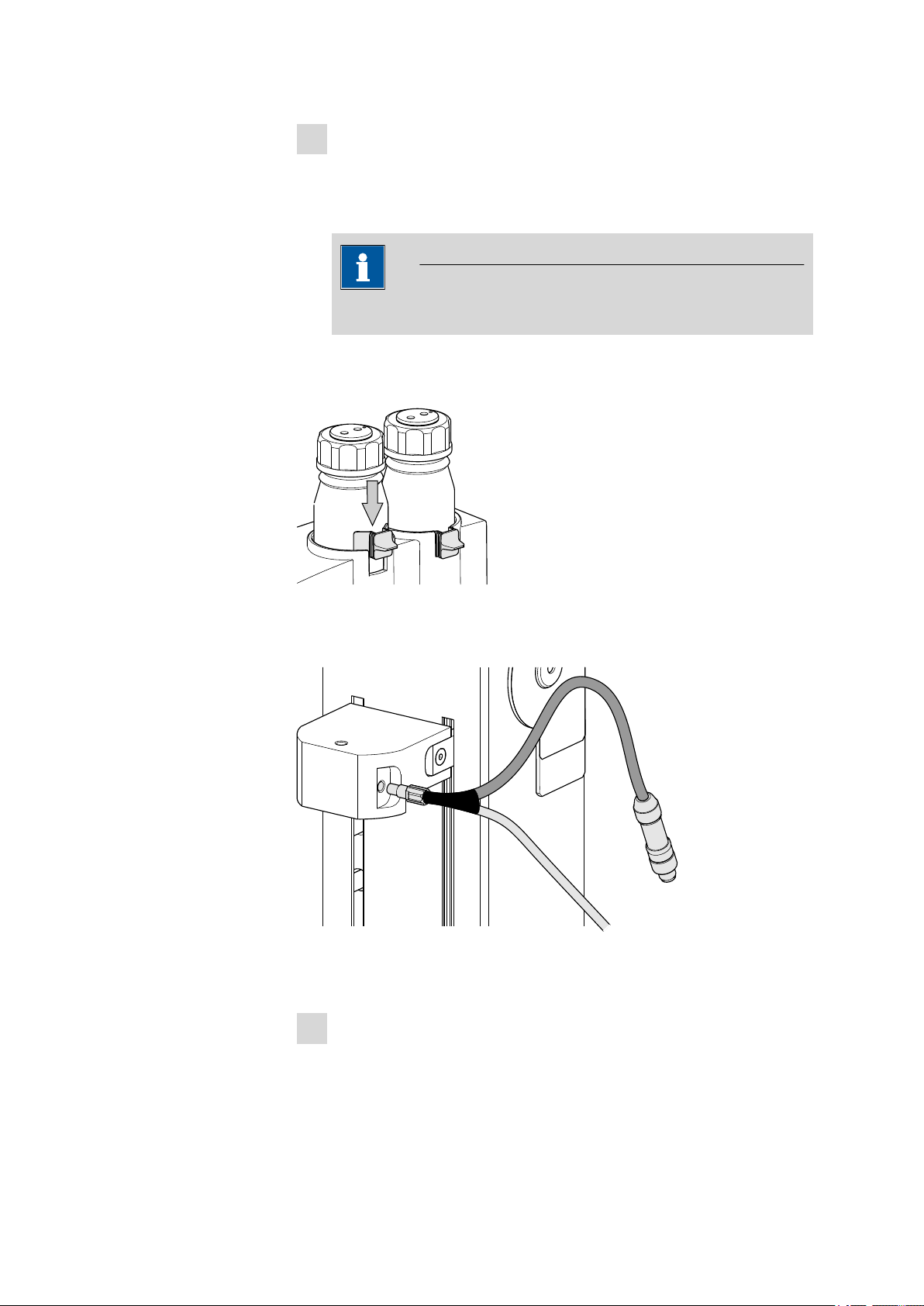

3.5 Assembling the drying flasks

Two drying flasks with desiccant are integrated into the gas flow in order

to dry the gas that is conveyed. Dust (e.g. from the desiccant) must be

prevented from finding its way into the sample vessel.

3 Installation

885 Compact Oven SC

Figure 5 Preparing the drying flasks

Prepare both drying flasks as follows:

Fill both 6.1608.050 drying flasks with 6.2811.000 molecular

1

sieve.

Screw one 6.1821.040 filter tube into each of the 6.1602.145

2

drying flask covers from below. Tighten the filter tubes well by

hand.

Screw the two drying flask covers with the filter tubes onto the dry-

3

ing flasks. Tighten the covers well by hand.

■■■■■■■■

13

3.5 Assembling the drying flasks

1

2

2

3

3

4

1

6.1805.080

6.1805.080

6.1805.010

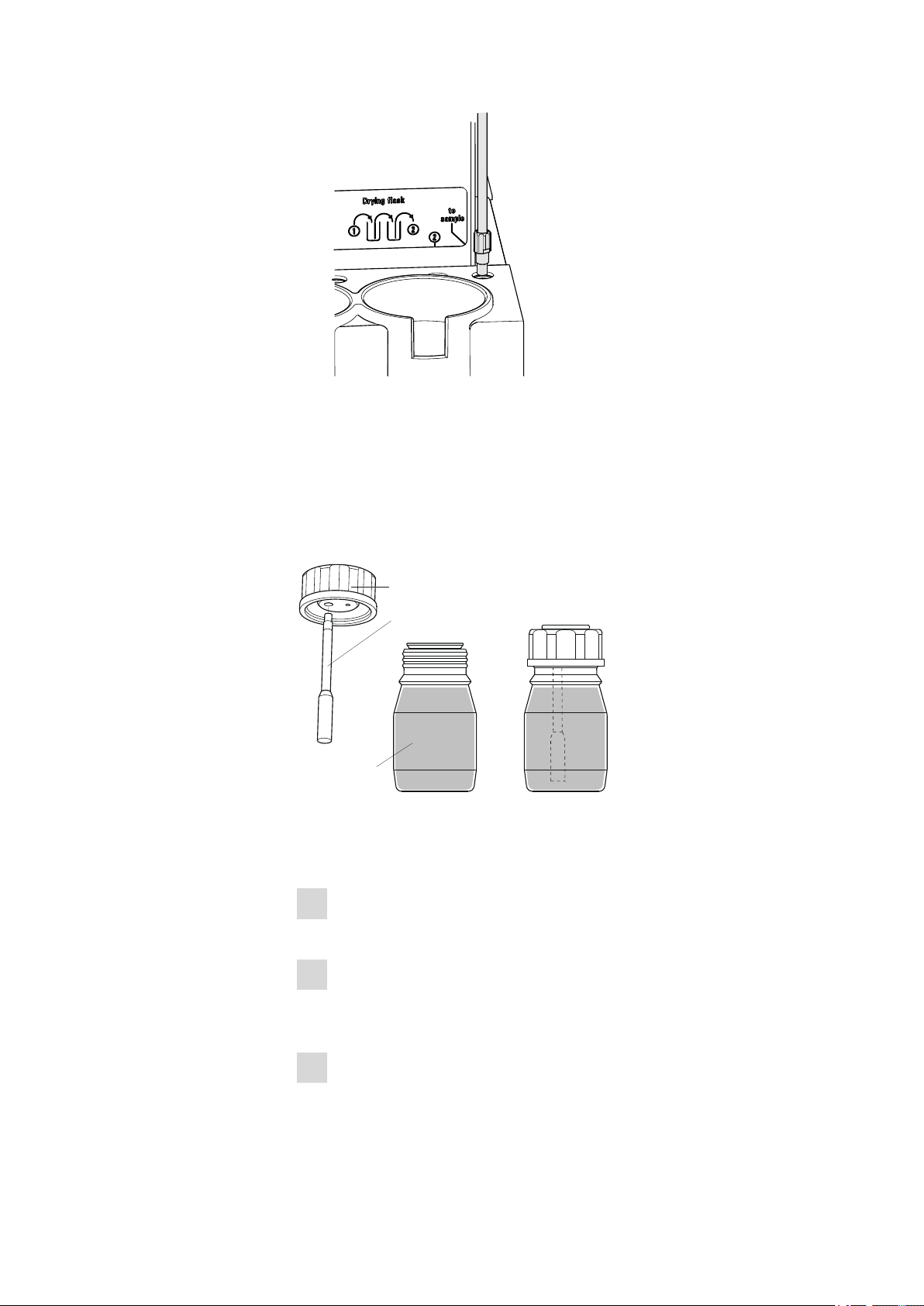

■■■■■■■■■■■■■■■■■■■■■■

Note

If drying flask covers or filter tubes are not sufficiently tightly

screwed on, then this will prevent a precise, regular gas flow. The

error message "Flow rate error" will appear as a rule when there

are leaks in the threaded connections.

■■■■■■■■

14

Figure 6 Mounting drying flasks and tubings

Mount the FEP tubings as follows:

Insert the two drying flasks that have been prepared into the holders,

1

see figure.

Screw one 6.1805.080 FEP tubing (25 cm in length) to the gas outlet

2

(at the rear on the left, labeled 1). Screw the other tubing end on the

front drying flask to the M6 connector without point marking (see

left-hand arrow).

Screw the second 6.1805.080 FEP tubing (25 cm in length) to the

3

gas inlet (at the rear on the right, labeled 2). Screw the other tubing

end on the rear drying flask to the M6 connector with point marking

(see right-hand arrow).

885 Compact Oven SC

■■■■■■■■■■■■■■■■■■■■■■

6.2043.005

6.1830.030

3 Installation

Screw the 6.1805.010 FEP tubing (13 cm in length) tightly onto the

4

remaining M6 connectors of the drying flasks.

The figure Drying flask on the right-hand side of the instrument displays the diagram for the tubing.

Note

Tighten the screw connections well by hand.

You can fasten the drying flasks with the 6.2043.005 holding clamps, see

figure.

3.6 Mounting the heating tubing

Figure 7 Mounting the heating tubing

Proceed as follows:

Screw the M6 connector of the 6.1830.030 heating tubing into

1

the side opening of the distributor on the guide head.

885 Compact Oven SC

■■■■■■■■

15

3.7 Mounting the safety shield

■■■■■■■■■■■■■■■■■■■■■■

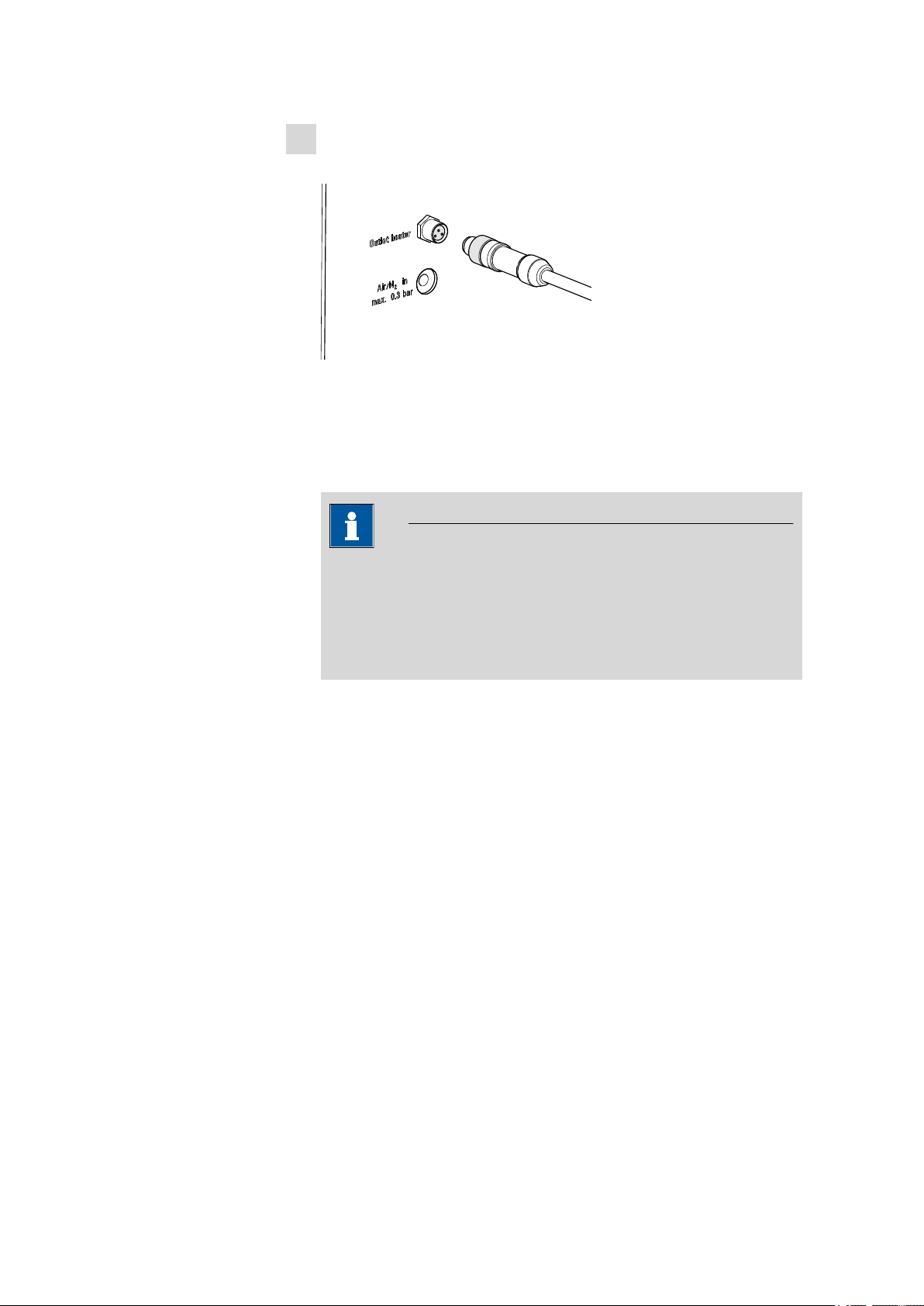

Connect the heating tubing cable to the Outlet heater connector

2

on the rear of the instrument.

Figure 8 Connecting the heating tubing

Rotate the plug in such a way that the three contact pins match the

alignment of the corresponding openings on the socket. Press the

plug against the socket and rotate the front knurled screw in a clockwise direction.

Note

The heating jacket of the heating tubing is heated up to approx.

40…50 °C as soon as the instrument is switched on. This prevents

the condensation of moisture in the tubing when this is expelled

from the sample and transferred with the aid of a carrier gas into a

KF titration cell.

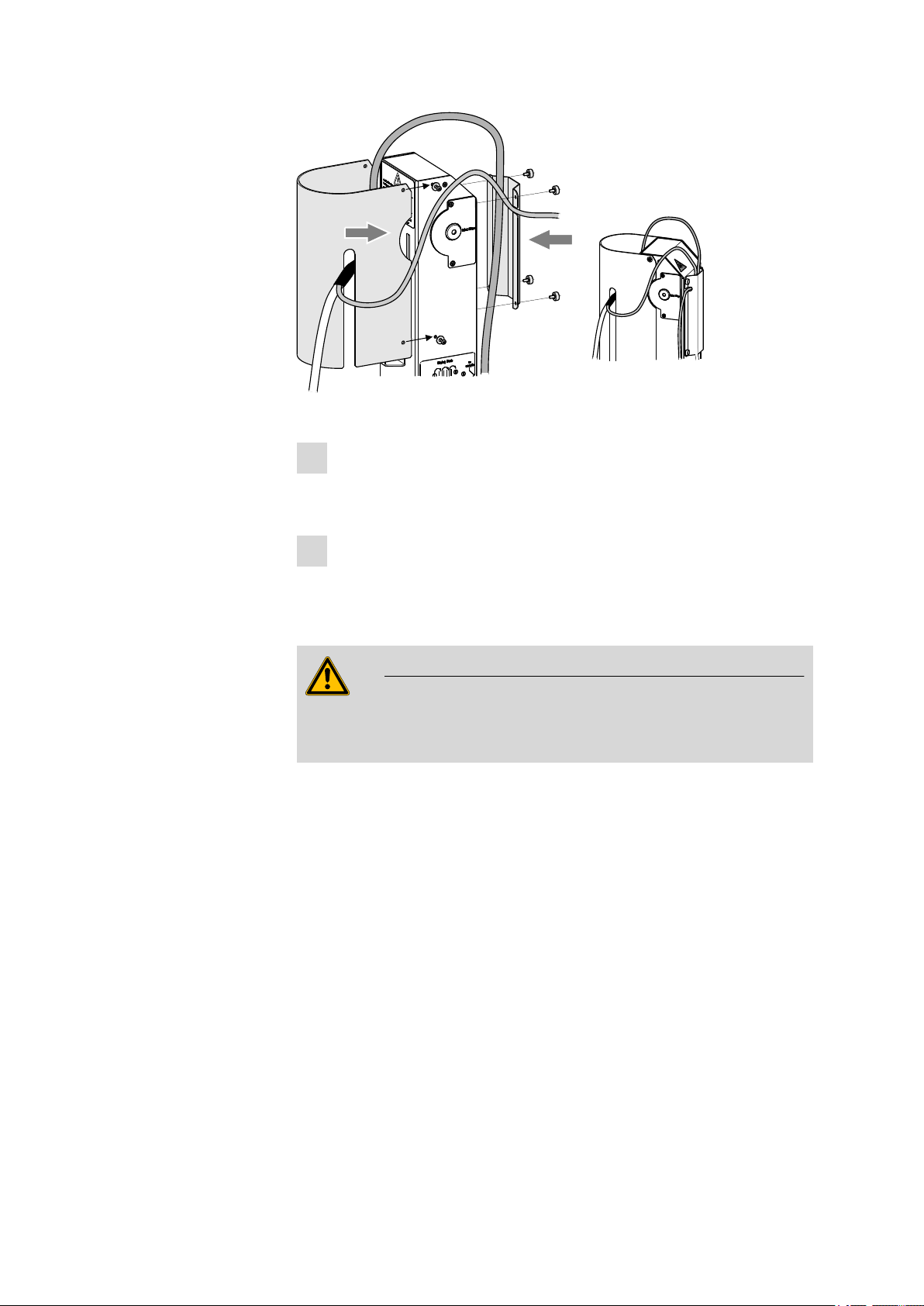

3.7 Mounting the safety shield

Now you can remount the safety shield. Proceed as follows:

■■■■■■■■

16

885 Compact Oven SC

■■■■■■■■■■■■■■■■■■■■■■

1

1

2

2

Figure 9 Mounting the coverings

Fasten the safety shield with the four hexagon screws to the sides of

1

the tower. The heating tubing and its connection cable must be guided through the slot of the cover.

Fasten the cable cover with the four knurled screws to the rear side

2

of the tower. The gas supply tubing must be guided underneath the

cover. The connection cable of the heating tubing must be guided

through the lateral recess of the cover, see figure.

3 Installation

Warning

The 885 Compact Oven SC may not be operated without a safety

shield!

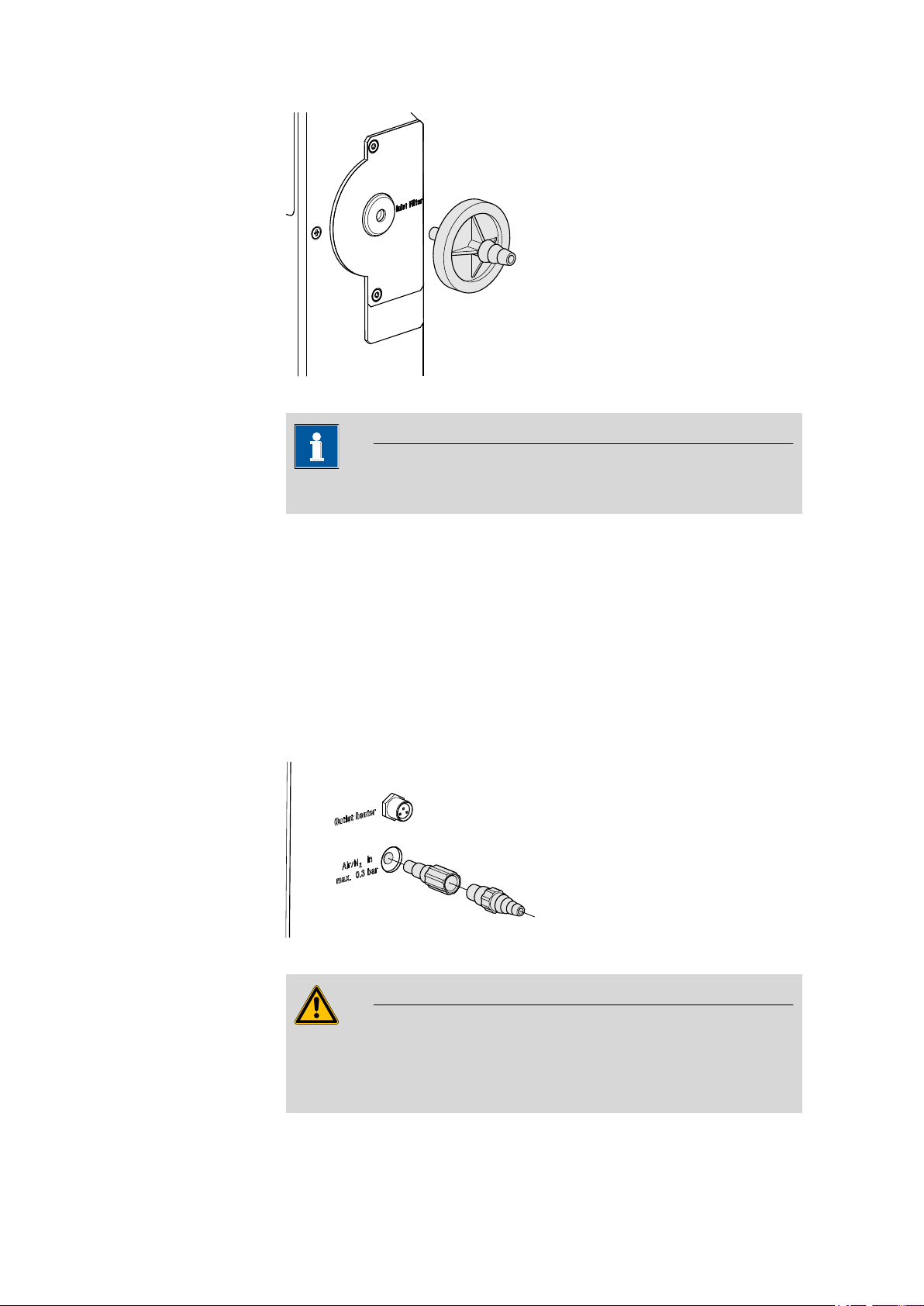

3.8 Mounting the dust filter

The built-in air pump must be protected against dust. A 6.2724.010

dust filter must be placed on the air inlet (Inlet filter) on the right-hand

side of the housing for this reason.

885 Compact Oven SC

■■■■■■■■

17

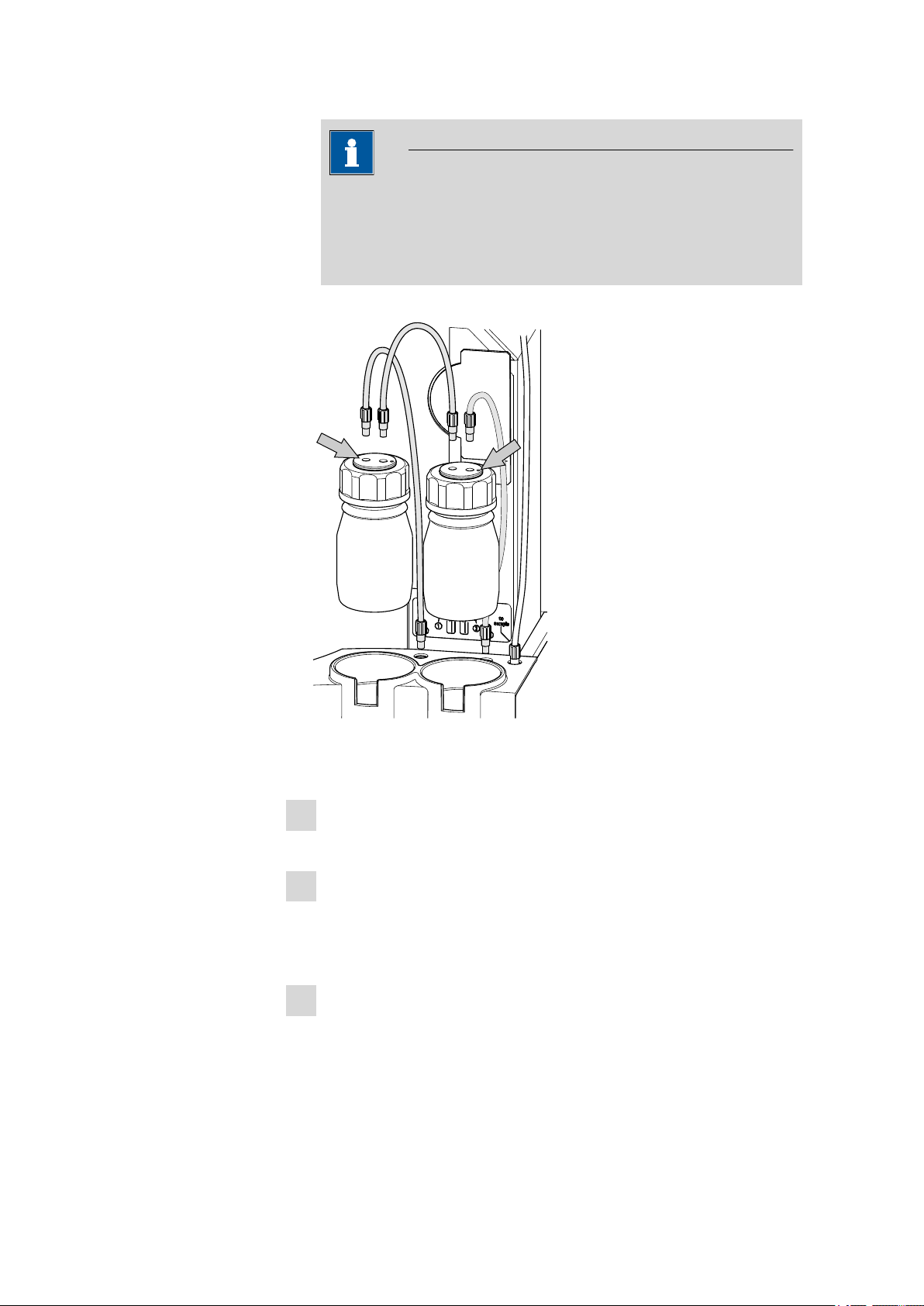

3.9 Assembling the air/nitrogen connector

6.2724.010

6.1808.050

6.1808.040

Figure 10 Mounting the dust filter

The dust filter should be replaced once a year.

■■■■■■■■■■■■■■■■■■■■■■

Note

3.9 Assembling the air/nitrogen connector

If compressed air, nitrogen or another gas is to be used for transferring

the expelled moisture, then a separate connector is available on the rear

of the instrument.

A tubing with M6 thread can be connected directly to the connector Air/

N2 in. Enclosed with the instrument is the 6.1808.040 M6/M8 tubing

adapter for a tubing with an M8 thread. The 6.1808.050 M8/tubing

olive can also be put in place in order to connect a simple tubing.

Figure 11 External gas supply connection

Warning

■■■■■■■■

18

If gas is supplied from a pressure line or a pressure vessel, then it is

imperative that a pressure reduction valve be placed upstream. The gas

pressure may not exceed a maximum overpressure level of 0.3 bar.

885 Compact Oven SC

Loading...

Loading...