Metrohm 806 User Manual

806 Exchange Unit

Manual

8.806.8003EN

Metrohm AG

CH-9101 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

806 Exchange Unit

Manual

8.806.8003EN 09.2012 ek/dm

Teachware

Metrohm AG

CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

806 Exchange Unit

■■■■■■■■

III

Table of contents

1

Introduction 1

1.1 About the documentation ................................................... 1

1.1.1 Symbols and conventions ........................................................ 1

1.2 Safety instructions ................................................................ 2

1.2.1 Tubing and capillary connections ............................................. 2

1.2.2 Flammable solvents and chemicals ........................................... 2

1.2.3 Filling the dosing cylinder ........................................................ 3

1.3 Recycling and disposal ......................................................... 3

2 Construction of the 806 Exchange Unit 4

2.1 Total view .............................................................................. 4

2.2 Components of the 806 Exchange Unit .............................. 6

3 Installation 9

3.1 Setting up the instrument .................................................... 9

3.1.1 Packaging ................................................................................ 9

3.1.2 Checks .................................................................................... 9

3.1.3 Location .................................................................................. 9

3.2 Start-up .................................................................................. 9

3.2.1 Preparing the exchange unit .................................................... 9

3.2.2 Attaching the exchange unit .................................................. 10

3.2.3 Filling the tubings .................................................................. 12

3.2.4 Buret tips ............................................................................... 13

3.2.5 Removing the exchange unit ................................................. 14

3.3 Mounting the components ................................................ 14

3.3.1 Mounting the thermostat casing ............................................ 14

3.3.2 Mounting the flat stopcock ................................................... 16

3.3.3 Mounting the tubings on the flat stopcock ............................ 17

4 Mode of operation 19

4.1 Filling the dosing cylinder and dosing .............................. 19

5 Handling and maintenance 21

5.1 Care and upkeep ................................................................. 21

5.1.1 Disassembling the exchange unit ........................................... 21

5.1.2 Cleaning the cylinder and piston ............................................ 22

5.1.3 Assembling the exchange unit ............................................... 23

5.1.4 Flat stopcock blocked ............................................................ 24

5.2 Chemical resistance and materials .................................... 25

5.2.1 Solutions ............................................................................... 25

5.2.2 Body ...................................................................................... 25

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

IV

■■■■■■■■

806 Exchange Unit

5.2.3 Materials ............................................................................... 25

5.3

GLP - Validation .................................................................. 26

6 Troubleshooting 27

6.1 Problems ............................................................................. 27

7 Appendix 30

7.1 Buret data ........................................................................... 30

7.2 Dosing accuracy .................................................................. 30

7.2.1 Typical measurement deviation .............................................. 30

7.2.2 The ISO/EN/DIN standard 8655-3 ........................................... 31

8 Accessories 32

8.1 Scope of delivery ................................................................ 32

8.1.1 806 Exchange Unit 6.3026.xxx .............................................. 32

8.2 Optional accessories ........................................................... 34

Index 36

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

806 Exchange Unit

■■■■■■■■

V

Table of figures

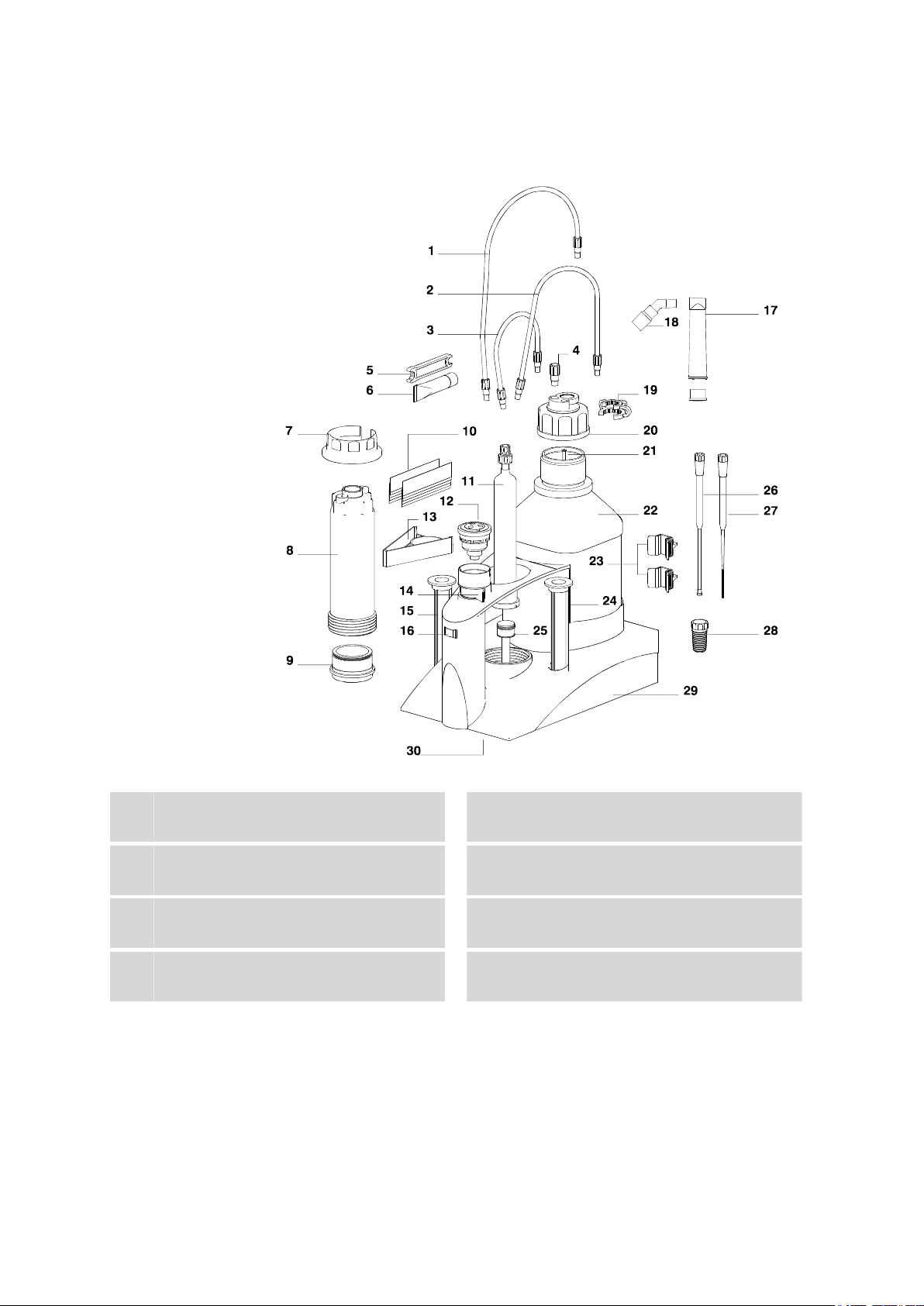

Figure 1 806 Exchange Unit ............................................................................ 4

Figure 2 806 Exchange Unit - Components ..................................................... 6

Figure 3 Thermostat casing ........................................................................... 15

Figure 4 Flat stopcock ................................................................................... 16

Figure 5 Dosing/Filling .................................................................................. 19

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

806 Exchange Unit

■■■■■■■■

1

1 Introduction

The 806 Exchange Unit is a versatile buret unit which can be operated

with various Metrohm dosing devices or titrators. The 806 Exchange Unit

is suitable for simple dosings or titrations.

Specifications concerning the exchange unit and the reagent can be

stored in the integrated data chip. This data can be read out and updated

by a suitable instrument.

1.1

About the documentation

1.1.1 Symbols and conventions

The following symbols and styles are used in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the

second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Method Dialog text, parameter in the software

File ▶ New Menu or menu item

[Next] Button or key

Warning

This symbol draws attention to a possible life hazard

or risk of injury.

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

Warning

This symbol draws attention to a possible biological

hazard.

1.2 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

2

■■■■■■■■

806 Exchange Unit

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

Note

This symbol marks additional information and tips.

1.2 Safety instructions

1.2.1

Tubing and capillary connections

CAUTION

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are manda-

tory.

1.2.2 Flammable solvents and chemicals

WARNING

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location.

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

806 Exchange Unit

■■■■■■■■

3

1.2.3 Filling the dosing cylinder

CAUTION

If a buret tip is clogged, then it could happen that no liquid will be aspi-

rated when the dosing cylinder is being filled. A vacuum can arise as a

result.

If you then remove the exchange unit from the instrument, the piston

could destroy the dosing cylinder.

Do not fail to loosen the tubing connections on the dosing cylinder

first, before you remove the exchange unit. This will eliminate the vac-

uum.

1.3

Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

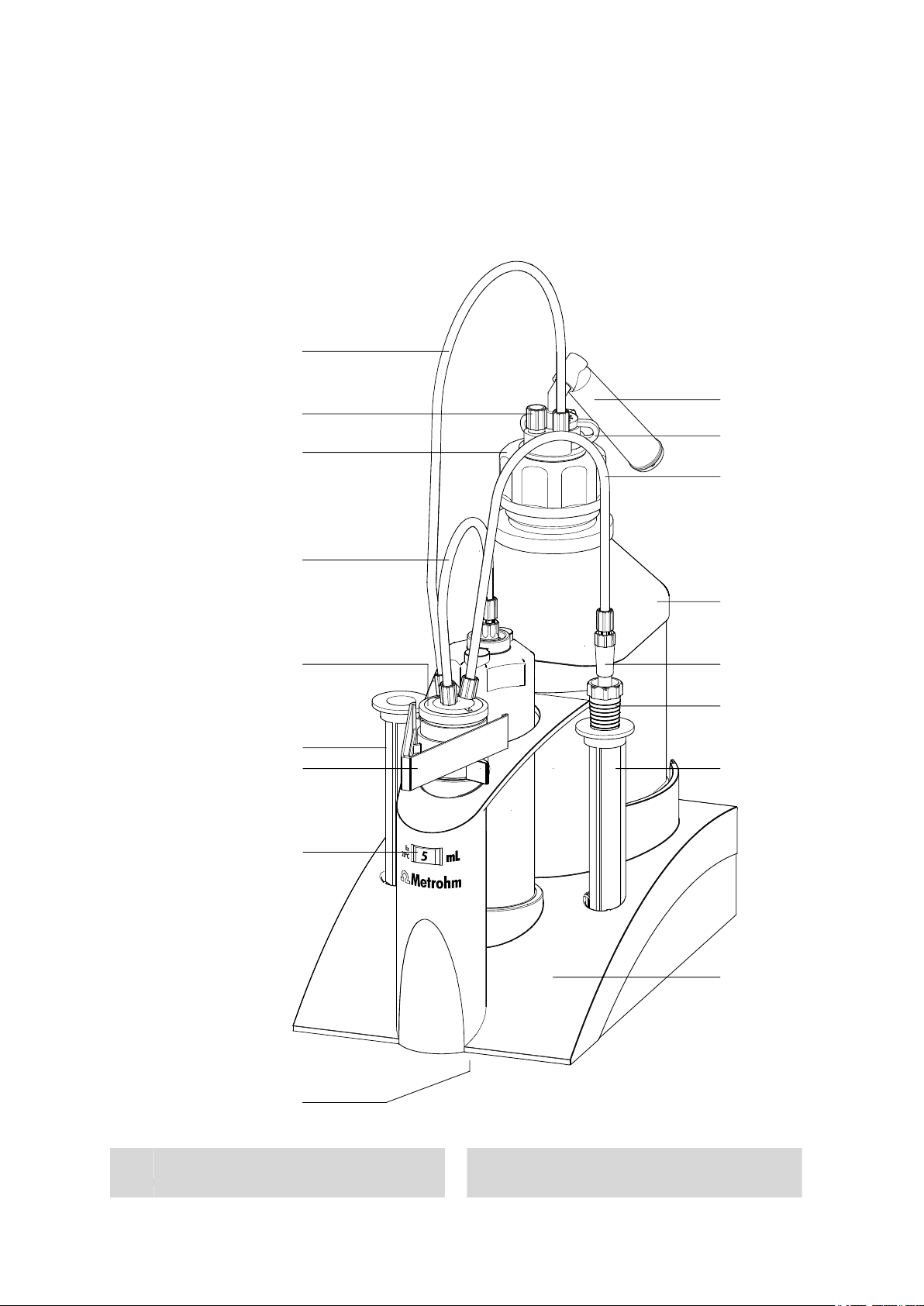

2.1 Total view

■■■■■■■■■■■■■■■■■■■■■■

4

■■■■■■■■

806 Exchange Unit

2 Construction of the 806 Exchange Unit

2.1

Total view

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Figure 1 806 Exchange Unit

1

Tubing connection (6.1805.080)

Length 25 cm

2

Threaded stopper (6.1446.080)

■■■■■■■■■■■■■■■■■■■■■■

2 Construction of the 806 Exchange Unit

806 Exchange Unit

■■■■■■■■

5

3

Bottle attachment (6.1602.105)

Of PFA/PP, thread GL45

4

Tubing connection (6.1805.010)

Length 13 cm (6.1805.050 with 1 mL cyl.)

5

PCTFE/PTFE flat stopcock (6.1542.020)

Or ceramic stopcock 6.1542.010

6

Storage vessel (6.1228.000)

For buret tips or electrodes

7

Plate holder (6.2046.070)

For name plates

8

Nominal volume

9

Data chip

On the underside of the buret

10

Adsorber tube (6.1619.010)

Adsorber tube 6.1619.010

11

SGJ clip (6.2023.020)

Of POM

12

Tubing connection (6.1805.100)

Length 40 cm

13

Bottle with thread (6.1608.23)

Amber glass, thread GL45

14

Antidiffusion tip (6.1543.200)

Of ETFE/FEP, for titrations

15

Link stopper (6.1446.030)

16

Storage vessel (6.1228.000)

For buret tips or electrodes

17

Body (6.1576.XXX)

.110 for 1 mL cylinder

.150 for 5 mL cylinder

.210 for 10 mL cylinder

.220 for 20 mL cylinder

.250 for 50 mL cylinder

2.2 Components of the 806 Exchange Unit

■■■■■■■■■■■■■■■■■■■■■■

6

■■■■■■■■

806 Exchange Unit

2.2 Components of the 806 Exchange Unit

Figure 2 806 Exchange Unit - Components

1

Tubing connection (6.1805.080)

Length 25 cm

2

Tubing connection (6.1805.100)

Length 40 cm

3

Tubing connection (6.1805.010)

Length 13 cm (6.1805.050 with 1 mL cyl.)

4

Threaded stopper (6.1446.080)

5

Torque key (6.2739.000)

For loosening tubing nipples

6

Paraffin fat (6.2803.010)

For dosing pistons, 2 g

7

Insert for key (6.2739.030)

For loosening the light protection

8

Light protection (6.1563.030)

Of PETG

Loading...

Loading...