Metrohm 832KF User Manual

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

832 KF Thermoprep

Instructions for Use

8.832.1023 |

10.2004/ dm |

Teachware

Metrohm AG

Oberdorfstr. 68

CH-9101 Herisau teachware@metrohm.com

These instructions are protected by copyright. All rights reserved.

Although all the information given in these instructions has been checked with great care, errors cannot be entirely excluded. Should you notice any mistakes please inform the author at the address given above.

© Metrohm Ltd. 2002

Printed in Switzerland

II |

832 KF Thermoprep |

Table of contents

1 |

Introduction |

1 |

|

|

1.1 |

Description of the instrument .......................................................... |

1 |

|

1.2 |

Information about these Instructions for Use................................. |

2 |

|

1.3 |

Parts and controls ............................................................................ |

3 |

|

1.3.1 |

Individual parts and standard accessories .............................................. |

3 |

|

1.3.2 |

Rear view................................................................................................... |

4 |

|

1.3.3 |

Temperature controller.............................................................................. |

5 |

|

1.3.4 |

Sample holder for standard vials.............................................................. |

5 |

2 |

Safety information |

6 |

|

|

2.1 |

General .............................................................................................. |

6 |

|

2.2 |

Electrical safety ................................................................................ |

6 |

3 |

Installation |

7 |

|

|

3.1 |

Instrument setup............................................................................... |

8 |

|

3.1.1 |

Packaging ................................................................................................. |

8 |

|

3.1.2 |

Checks ...................................................................................................... |

8 |

|

3.1.3 |

Location..................................................................................................... |

8 |

|

3.2 |

Mains connection ............................................................................. |

8 |

|

3.3 |

Assembling the 832 KF Thermoprep............................................ |

10 |

|

3.3.1 |

Assembling the needles.......................................................................... |

10 |

|

3.3.2 |

Attaching the drying bottles .................................................................... |

11 |

|

3.3.3 |

Attaching the dust filter ........................................................................... |

11 |

|

3.4 |

Assembling the coulometric cell .................................................. |

12 |

|

3.5 |

Assembling the titration vessel for volumetric KF titrators ........ |

12 |

4 |

Operation |

13 |

|

|

4.1 |

Inserting and removing sample vials ........................................... |

13 |

|

4.2 |

Needle penetration ........................................................................ |

13 |

|

4.3 |

The pump ....................................................................................... |

14 |

|

4.4 |

The temperature controller ........................................................... |

15 |

|

4.4.1 |

Two set temperatures ............................................................................. |

15 |

|

4.4.2 |

Setting a temperature.............................................................................. |

15 |

|

4.4.3 |

Self-optimization of the control parameters............................................ |

16 |

|

4.4.4 |

Key lock function..................................................................................... |

16 |

|

4.5 |

Working procedure........................................................................ |

17 |

|

4.5.1 |

Preparing the 832 KF Thermoprep/756/831 Coulometer system .......... |

18 |

|

4.5.2 |

Determination with blank value subtraction............................................ |

18 |

|

4.5.3 |

Determination without blank value subtraction....................................... |

19 |

|

4.6 |

Practical information ..................................................................... |

20 |

5 |

Maintenance information |

21 |

|

6 |

GLP validation |

21 |

|

832 KF Thermoprep |

III |

7 |

Troubleshooting |

22 |

|

|

7.1 |

Problems ........................................................................................ |

22 |

8 |

Annex |

23 |

|

|

8.1 |

Technical data................................................................................ |

23 |

|

8.1.1 |

Oven........................................................................................................ |

23 |

|

8.1.2 |

Air pump.................................................................................................. |

23 |

|

8.1.3 |

Temperature controller............................................................................ |

23 |

|

8.1.4 |

Power supply .......................................................................................... |

23 |

|

8.1.5 |

Safety specifications ............................................................................... |

23 |

|

8.1.6 |

Electromagnetic compatibility (EMC) ..................................................... |

24 |

|

8.1.7 |

Ambient temperature .............................................................................. |

24 |

|

8.1.8 |

Dimensions and materials ...................................................................... |

24 |

|

8.2 |

Standard equipment ...................................................................... |

25 |

|

8.2.1 |

832 KF Thermoprep................................................................................ |

25 |

|

8.3 |

Optional accessories..................................................................... |

27 |

|

8.3.1 |

Sample vials............................................................................................ |

27 |

|

8.4 |

Warranty and conformity............................................................... |

28 |

|

8.4.1 |

Warranty .................................................................................................. |

28 |

|

8.4.2 |

EU Declaration of Conformity for 832 KF Thermoprep .......................... |

29 |

|

8.4.3 |

Declaration of Conformity ....................................................................... |

30 |

|

Index |

31 |

|

|

List of illustrations |

|

Fig. 1 |

Front view ................................................................................................................... |

3 |

Fig. 2 |

Rear view .................................................................................................................... |

4 |

Fig. 3 |

Temperature controller ............................................................................................... |

5 |

Fig. 4 |

Sample holder .......................................................................................................... |

5 |

Fig. 5: |

832 KF Thermoprep – peripheral devices .................................................................. |

7 |

Fig. 6 |

Fuse holder................................................................................................................. |

9 |

Fig. 7 |

Needle assembly ...................................................................................................... |

10 |

Fig. 8 |

Guide head with needles.......................................................................................... |

10 |

Fig. 9 |

Coulometer cell......................................................................................................... |

12 |

Fig. 10 |

Volumetric KF cell ..................................................................................................... |

12 |

Fig. 11 |

Crimping pliers.......................................................................................................... |

13 |

Fig. 12 |

Loosening the guide head........................................................................................ |

13 |

Fig. 13 |

Needle in lowered position ....................................................................................... |

14 |

IV |

832 KF Thermoprep |

1.1 Description of the instrument

1 Introduction

Thanks to its reliability and simple handling, the Metrohm 832 KF Thermoprep is a very versatile instrument. It has been designed for use in production and laboratories and covers a wide range of applications.

The 832 KF Thermoprep can be used wherever it is necessary to heat up a solid or liquid sample and/or to drive off water by the application of heat.

When combined with a coulometric or volumetric KF titrator, the 832 KF Thermoprep forms the ideal analytical system for determining the water content of samples which contain interfering components or which only release their moisture slowly.

Among the decisive advantages of the KF Thermoprep is the reduction of sample preparation to a minimum. By using hermetically sealed sample vessels (headspace vials) the samples can be filled directly on site. The PTFE-coated septa guarantee a constant and true water content, even when the sample have been allowed to stand for a long time.

1.1 Description of the instrument

The 832 KF Thermoprep has been designed primarily for the determination of moisture by the oven method. The samples are heated in the oven block and release their moisture in the form of water vapor; this is transferred to a measuring cell by a carrier gas. The carrier gas stream is produced by a built-in air pump. An inlet valve is also provided for the use of nitrogen or other inert gases. The determination of moisture in the measuring cell can be carried out either coulometrically or volumetrically according to the Karl Fischer method.

The 832 KF Thermoprep is characterized by its compact construction; the oven heating block, air pump, temperature controller, flowmeter and flow controller as well as the drying bottles are already built in.

832 KF Thermoprep, Introduction |

1 |

1.2 Information about these Instructions for Use

1.2 Information about these Instructions for Use

Please read through these Instructions for Use before you start to use the 832 KF Thermoprep.

The following notations and pictograms are used in these instructions:

Operating element

35The operating elements are explained on pages 3ff.

Danger

This symbol indicates a possible risk of death or injury to the user and possible damage to the instrument or its components by electricity.

Danger/Warning

This symbol indicates a possible risk of death or injury to the user and possible damage to the instrument or its components.

Attention

This symbol indicates important information. Read the information provided before you continue.

2 |

832 KF Thermoprep, Introduction |

1.3 Parts and controls

1.3 Parts and controls

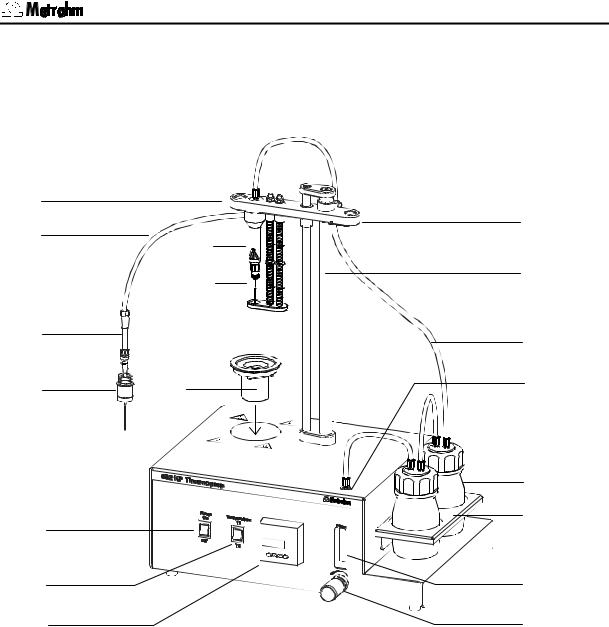

1.3.1 Individual parts and standard accessories

1

2 |

|

|

11 |

|

3 |

|

|

|

|

|

|

|

|

4 |

12 |

|

|

|

|

5 |

|

|

13 |

|

|

|

|

6 |

7 |

|

14 |

|

|

|

15 |

8 |

16 |

|

|

9 |

17 |

10 |

18 |

|

Fig. 1 |

Front view |

|

|

|

|

|

|

|

|

|

1 |

Guide head |

10 |

Temperature controller |

||

|

|

|

|

|

|

2 |

Transfer tubing 6.1805.460 |

11 |

Clamping lever |

||

|

|

|

|

|

|

3 |

Spacer 4.832.4190 |

12 |

Guide rod |

||

|

|

|

|

|

|

4 |

Penetration and outlet needle |

13 |

Inlet tubing 6.1805.020 |

||

|

6.2816.070 and 6.2816.080 |

|

|

|

|

5 |

Dosing tip 6.1543.060 |

14 |

Air/Nitrogen outlet |

||

|

|

|

|

|

|

6 |

Septum stopper 6.2730.050 |

15 |

Drying bottles 6.1608.050 |

||

|

|

|

|

With 6.1602.140 inset, filled with |

|

|

|

|

|

6.2811.000 molecular sieve |

|

7 |

Sample holder |

16 |

Bottle holder |

||

|

|

|

|

|

|

8 |

Pump switch |

17 |

Flow indicator |

||

|

|

|

|

|

|

9 |

Temperature selection switch |

18 |

Flow controller |

||

|

|

|

|

|

|

832 KF Thermoprep, Introduction |

|

|

3 |

||

1.3 Parts and controls

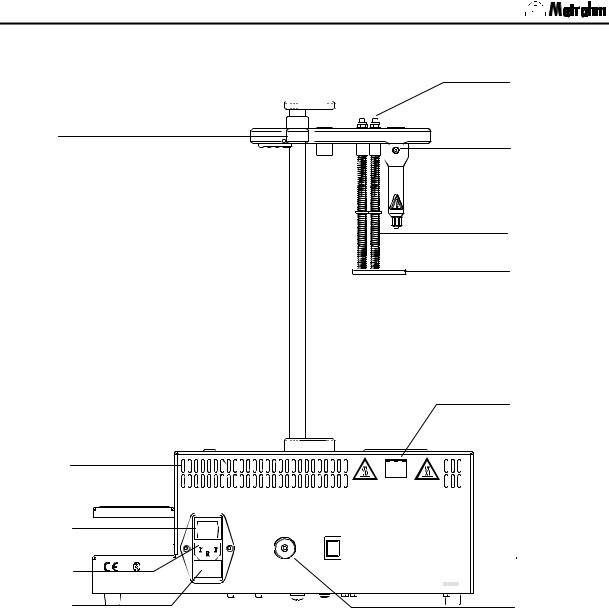

1.3.2 Rear view |

24 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

19

20

21

22

WARNING - Fire Hazard -

for continued protection replace only with the same type and rating of fuse

25

26

27

28

|

|

Vorsicht: Heisse Gehäuseteile |

Cuidado: Partes calientes |

|

100 - 120 V: 4 A (T) |

|

(über 60°C) |

(mas de 60°C) |

|

|

Attention: Hot parts |

Attention: Parties chaudes |

||

220 - 240 V: 2 A (T) |

|

|||

f = 50/60 Hz |

|

(above 60°C) |

(plus de 60°C) |

|

S = 350 VA |

|

|

|

|

|

Inlet filter |

|

|

|

|

Key lock |

|

|

|

|

On |

|

|

|

|

|

|

|

29 |

|

Off |

|

||

|

|

|

||

|

|

|

Type 1.832.0010 Nr0010/01104. |

|

|

|

|

Made by Metrohm Switzerland |

|

|

23 |

|

|

|

|

30 |

|

|

Rear view |

||||

|

Fig. 2 |

|

||||

|

|

|

|

|

|

|

19 |

Tubing guide |

25 |

Transfer tubing connection |

|||

|

|

|

|

|

|

|

20 |

Ventilation slots |

26 |

Guide spring |

|||

|

|

|

|

|

|

|

21 |

Mains switch |

27 |

Needle base |

|||

|

|

|

|

|

|

|

22 |

Mains connection |

28 |

Hot air outlet |

|||

|

|

|

|

|

|

|

23 |

Fuse holder |

29 |

Key lock switch |

|||

|

|

|

|

|

|

|

24 |

Adjustment nuts |

30 |

Air/nitrogen outlet |

|||

|

|

|

|

|

|

Connection for dust filter (6.2724.010) |

|

|

|

|

|

|

|

4 |

832 KF Thermoprep, Introduction |

1.3 Parts and controls

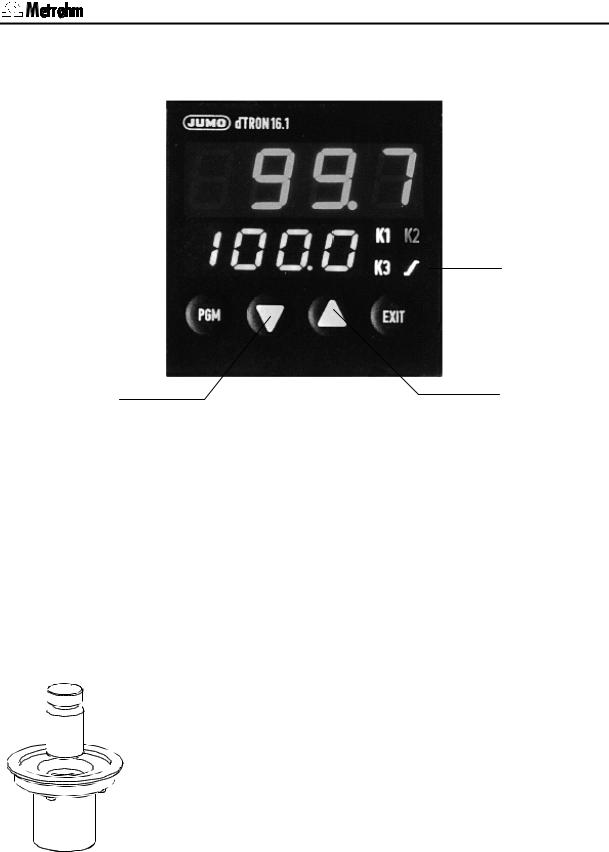

1.3.3 Temperature controller

|

31 |

|

|

|

|

|

|

|

|

|

35 |

|

|

|

|

|

|

|

|

|

|

||

|

32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

36 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

33 |

|

|

|

|

|

|

|

|

|

37 |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

34 |

|

|

Fig. 3 |

Temperature controller |

38 |

|||||

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

31 |

Actual value display |

|

35 |

Output status display |

|||||||

|

red, 4-place |

|

|

|

|

yellow, for outputs 1 to 3 |

|||||

|

|

|

|

|

|

|

|

(K1 and K3: oven heating, K2: fan) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

32 |

Set value display |

|

36 |

LED for ramp/program function |

|||||||

|

green, 4-place |

|

|

|

|

green, lights if configured |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

33 |

Program key |

|

37 |

EXIT key |

|

||||||

|

for selecting the parameters |

|

|

|

to exit the dialog levels |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

34 |

Decrement key |

|

38 |

Increment key |

|

||||||

|

for changing values |

|

|

|

|

for changing values |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

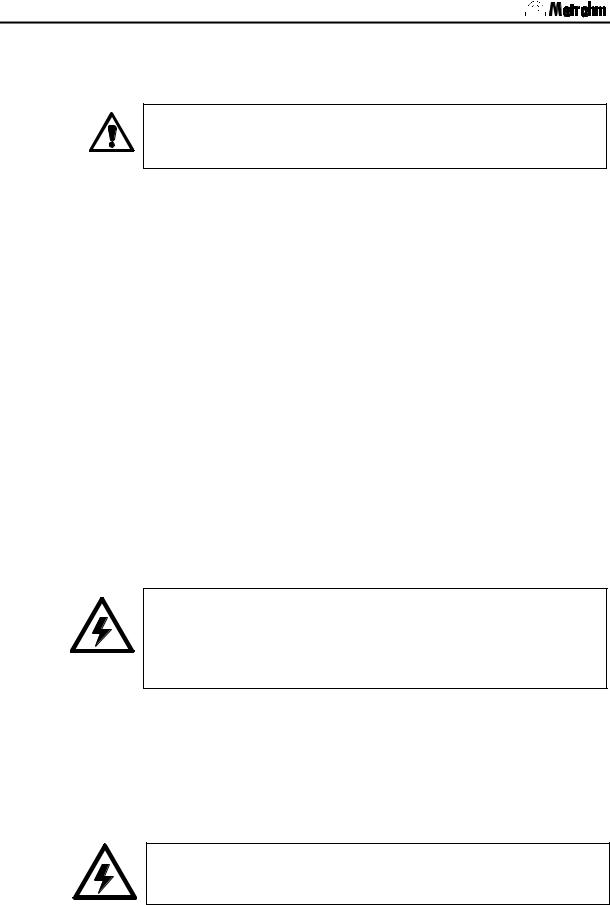

1.3.4 Sample holder for standard vials

The dimensions of the 6.2063.000 sample holder are optimized for the

Metrohm 6.2419.007 standard sample vials (6 mL). This ensures the highest possible heat flow from the oven to the sample.

If other sample containers with different dimensions shall be used custom made sample holders can be delivered. For this the precise dimensions (incl. dimensional tolerances) must be known.

The measures of non-standard sample containers must vary within the following dimensional limits:

Diameter 10.0 … 32.0 mm

Fig. 4 Sample holder Depth of immersion 20.0 … 45.0 mm

832 KF Thermoprep, Introduction |

5 |

2.1 General

2 Safety information

Warning!

This instrument should only be used in accordance with the information given in these Instructions for Use.

2.1 General

This instrument left our works in perfect condition from the point of view of its operational safety (see Technical data, safety specification). To keep it in this condition and to continue to operate safely the following information must be carefully observed.

2.2 Electrical safety

Please observe the following guidelines:

•Only qualified Metrohm personnel should carry out service work on electronic components.

•Do not open the instrument housing as this could damage the instrument. The housing contains no components which could be serviced or exchanged by the user.

Electrical safety when handling the instrument is guaranteed within the scope of Standard IEC 61010. However, please observe the following point:

Protection against electrostatic charges

Warning!

Electronic components are sensitive to electrostatic charges and can be destroyed by a discharge. Always remove the mains connection cable from socket 12 before making or breaking electrical connections on the rear panel of the instrument.

Connection to the electricity supply:

This instrument must only be operated at the specified mains voltage.

Repair and maintenance:

If faults or malfunctions occur while using the 832 KF Thermoprep we recommended that you first check that the connection to the control instrument has been made correctly.

The instrument must not be opened. This is reserved exclusively for authorized service personnel.

6 |

832 KF Thermoprep, Safety information |

2.2 Electrical safety

3 Installation

This section describes the things you should pay attention to when unpacking and starting up the 832 KF Thermoprep. It also tells you how a complete automation system is built up.

The following illustration provides an overview of the peripheral devices which can be used with an 832 KF Thermoprep:

PC

USB |

|

|

|

|

|

|

|

|

|

RS232 |

RS232 |

|

|

LPT |

1 |

|

|

|

COM 1 |

||||||

|

|

|

USB |

|

|

|

|

COM 2 |

|

|

||

|

|

|

|

|

|

|

|

|

USB |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PC Software |

|

|

PC Control |

tiamo |

Tinet 2.x / VESUV 3.0 |

756 KF |

|

|

|

831 KF |

800800 |

|

|

|

DosinoDosino |

|

|

|

|

|

|

KF Coulometer |

|

|

|

831 / 756 |

KF |

|

|

|

TitriermittelKF |

|

|

|

|

|

|

Titriermittel |

|

|

|

Titriermittel |

|

|

|

KFD 758 |

|

|

832 TP |

KFP 785 |

835 |

|

|

KFP 795 |

Titrando |

|

832 Thermoprep |

|

836 |

|

|

|

Titrando |

|

|

|

Touch Control |

|

|

|

|

|

|

|

|

|

|

|

KF Titrino |

|

|

|

|

|

|

|

|

|

||

Titrandos |

|

|

|

|

|

|

|||

795 / 787 / 758 |

|||||||||

|

|

||||||||

Fig. 5: 832 KF Thermoprep – peripheral devices

832 KF Thermoprep, Installation |

7 |

Loading...

Loading...