Metrohm 855 User Manual

855 Robotic Titrosampler

Manual

8.855.8001EN

Metrohm AG CH-9101 Herisau Switzerland

Phone +41 71 353 85 85 Fax +41 71 353 89 01 info@metrohm.com www.metrohm.com

855 Robotic Titrosampler

Manual

8.855.8001EN |

04/2010 dm |

Teachware Metrohm AG CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been checked with great care, errors cannot be entirely excluded. Should you notice any mistakes please send us your comments using the address given above.

|

Table of contents |

Table of contents

1 Introduction |

1 |

|

1.1 |

The 855 Robotic Titrosampler in the Titrando sys- |

|

|

tem ......................................................................................... |

1 |

1.2 |

Instrument description ......................................................... |

2 |

1.2.1 |

Model versions ........................................................................ |

3 |

1.2.2 |

Instrument components .......................................................... |

3 |

1.2.3 |

Intended use ........................................................................... |

4 |

1.3 |

About the documentation ................................................... |

4 |

1.3.1 |

Symbols and conventions ........................................................ |

4 |

1.4 |

Safety instructions ................................................................ |

5 |

1.4.1 |

General notes on safety ........................................................... |

5 |

1.4.2 |

Electrical safety ........................................................................ |

5 |

1.4.3 |

Tubing and capillary connections ............................................. |

6 |

1.4.4 |

Personnel safety ...................................................................... |

7 |

1.4.5 |

Flammable solvents and chemicals ........................................... |

8 |

1.4.6 |

Recycling and disposal ............................................................. |

8 |

2 Overview of the instrument |

9 |

|

2.1 |

Front and rear ....................................................................... |

9 |

2.2 |

Rear panel ........................................................................... |

11 |

2.3 |

Sensor connectors .............................................................. |

11 |

2.4 |

Sample racks ....................................................................... |

12 |

3 Installation |

|

13 |

3.1 |

Setting up the instrument .................................................. |

13 |

3.1.1 |

Packaging .............................................................................. |

13 |

3.1.2 |

Checks .................................................................................. |

13 |

3.1.3 |

Location ................................................................................ |

13 |

3.2 |

Preparing the Sample Processor ....................................... |

13 |

3.2.1 |

Connecting a mains cable ...................................................... |

13 |

3.3 |

Connecting a computer ................................................... |

14 |

3.4 |

Connecting the Swing Head .............................................. |

15 |

3.5 |

Configuring the robotic arm .............................................. |

16 |

3.6 |

Mounting the robotic arm ................................................. |

18 |

3.7 |

Robotic arms with beaker sensor ..................................... |

20 |

3.8 |

Installing rinsing and aspiration equipment .................... |

21 |

3.9 |

Guide chain for cables and tubing .................................... |

24 |

855 Robotic Titrosampler |

III |

Table of contents |

|

|

|

|

|

3.10 |

Equipping the titration head ............................................. |

|

25 |

|

3.11 |

Connecting the tower stirrer ............................................. |

|

27 |

|

3.12 |

Connecting external pumps ............................................... |

|

28 |

|

3.13 |

Connecting MSB devices ................................................... |

|

29 |

|

3.13.1 |

Connecting dosing devices .................................................... |

|

30 |

|

3.13.2 Connecting a stirrer or titration stand .................................... |

|

31 |

|

|

3.13.3 Connecting a remote box ...................................................... |

|

32 |

|

|

3.14 |

Connecting USB devices ..................................................... |

|

33 |

|

3.14.1 Connecting a barcode reader ................................................. |

|

33 |

|

|

3.15 |

Mounting the base plate ................................................... |

|

34 |

|

3.16 |

Mounting the drip pan ....................................................... |

|

35 |

|

3.17 |

Attaching the sample rack ................................................. |

|

36 |

|

3.18 |

Mounting the safety shield ................................................ |

|

37 |

4 |

Handling and maintenance |

|

39 |

|

|

4.1 |

General ................................................................................ |

|

39 |

|

4.2 |

Care ...................................................................................... |

|

39 |

|

4.3 |

Quality Management and validation with Metrohm ....... |

39 |

|

5 |

Troubleshooting |

|

40 |

|

|

5.1 |

Sample Processor ............................................................... |

|

40 |

|

5.2 |

Robotic arm ......................................................................... |

|

40 |

|

5.3 |

Pump .................................................................................... |

|

41 |

6 |

Appendix |

|

|

42 |

|

6.1 |

Beaker sensor ..................................................................... |

|

42 |

|

6.2 |

Rinsing nozzles ................................................................... |

|

42 |

|

6.3 |

Remote interface ................................................................ |

|

43 |

|

6.3.1 Pin assignment of the remote interface .................................. |

|

44 |

|

|

6.4 |

Stirring rate ......................................................................... |

|

45 |

|

6.5 |

Robotic arms ....................................................................... |

|

46 |

|

6.5.1 Robotic arms for titration ....................................................... |

|

46 |

|

|

6.5.2 Robotic arms for sample preparation ..................................... |

|

48 |

|

|

6.5.3 Robotic arms for special applications ..................................... |

|

49 |

|

7 |

Technical specifications |

|

50 |

|

|

7.1 |

Measuring interface ........................................................... |

|

50 |

|

7.1.1 |

Potentiometry ........................................................................ |

|

50 |

|

7.1.2 |

Polarizer ................................................................................ |

|

50 |

|

7.1.3 |

Temperature .......................................................................... |

|

51 |

IV |

855 Robotic Titrosampler |

|

|

Table of contents |

|

|

7.2 |

Lift and turntable ............................................................... |

51 |

|

7.3 |

Membrane pump(s) with valve .......................................... |

52 |

|

7.4 |

786 Swing Head ................................................................. |

52 |

|

7.5 |

Interfaces and connectors ................................................. |

52 |

|

7.6 |

Mains connection ............................................................... |

53 |

|

7.7 |

Safety specifications ........................................................... |

53 |

|

7.8 |

Electromagnetic compatibility (EMC) ................................ |

53 |

|

7.9 |

Ambient temperature ......................................................... |

54 |

|

7.10 |

Reference conditions .......................................................... |

54 |

|

7.11 |

Dimensions .......................................................................... |

54 |

8 |

Conformity and warranty |

55 |

|

|

8.1 |

Declaration of Conformity ................................................. |

55 |

|

8.2 |

Quality Management Principles ........................................ |

56 |

|

8.3 |

Warranty (guarantee) ......................................................... |

57 |

9 |

Accessories |

|

58 |

|

9.1 |

Scope of delivery 2.855.0010 ............................................ |

58 |

|

9.2 |

Scope of delivery 2.855.0020 ............................................ |

63 |

|

9.3 |

Optional accessories ........................................................... |

68 |

|

Index |

|

76 |

855 Robotic Titrosampler |

V |

Table of figures |

|

Table of figures |

|

|

Figure 1 |

The Titrando system .......................................................................... |

1 |

Figure 2 |

Front 855 Robotic Titrosampler ........................................................ |

9 |

Figure 3 |

Rear 855 Robotic Titrosampler ........................................................ |

10 |

Figure 4 |

Connector strip ............................................................................... |

11 |

Figure 5 |

Sensor connectors ........................................................................... |

11 |

Figure 6 |

6.2041.840 Sample rack ................................................................. |

12 |

Figure 7 |

Connecting the mains cable ............................................................ |

13 |

Figure 8 |

Connecting the computer ............................................................... |

14 |

Figure 9 |

Connecting Swing Head .................................................................. |

15 |

Figure 10 |

Robotic arms - standard model versions: ......................................... |

16 |

Figure 11 |

Configuration data of the robotic arms ............................................ |

17 |

Figure 12 |

Limitation screw at the robotic arm ................................................. |

18 |

Figure 13 |

Mounting the robotic arm ............................................................... |

19 |

Figure 14 |

Connecting a beaker sensor (for example 6.1462.150) .................... |

20 |

Figure 15 |

Mounting the rinsing and aspiration tubings .................................... |

22 |

Figure 16 |

Mounting the distributor ................................................................. |

23 |

Figure 17 |

Guide chain - Opening chain links ................................................... |

24 |

Figure 18 |

Installing the rinsing tubings and the aspiration tip .......................... |

25 |

Figure 19 |

Rod stirrer 802 Stirrer ...................................................................... |

27 |

Figure 20 |

Magnetic stirrer 741 Stirrer .............................................................. |

27 |

Figure 21 |

Connecting the tower stirrer ............................................................ |

27 |

Figure 22 |

Connecting pumps .......................................................................... |

28 |

Figure 23 |

Connecting a dosing device ............................................................. |

30 |

Figure 24 |

Connecting MSB stirrer .................................................................... |

31 |

Figure 25 |

Rod stirrer and titration stand .......................................................... |

31 |

Figure 26 |

Connecting a remote box ................................................................ |

32 |

Figure 27 |

USB connectors ............................................................................... |

33 |

Figure 28 |

Mounting the base plate ................................................................. |

34 |

Figure 29 |

Installing the drip pan ...................................................................... |

35 |

Figure 30 |

Attaching the rack ........................................................................... |

36 |

Figure 31 |

Mount the safety shield ................................................................... |

37 |

Figure 32 |

Beaker sensor on the tower ............................................................. |

42 |

Figure 33 |

Spray nozzles - Functioning ............................................................. |

43 |

Figure 34 |

Connectors of the remote box ......................................................... |

43 |

Figure 35 |

Pin assignment of the remote socket and plug ................................ |

44 |

Figure 36 |

Rotational speed depending on stirring rate .................................... |

45 |

VI |

855 Robotic Titrosampler |

|

1 Introduction |

1 Introduction

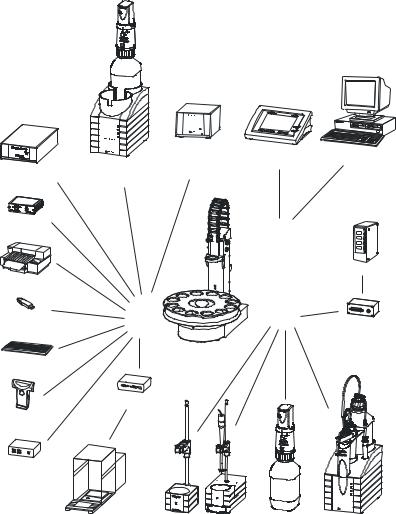

1.1The 855 Robotic Titrosampler in the Titrando system

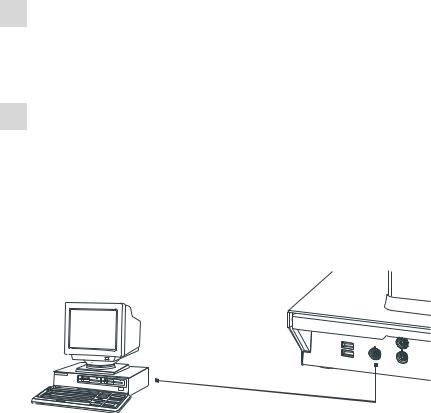

The 855 Robotic Titrosampler is a component of the modular Titrando system. Operation is carried out by a Touch Control with touch-sensitive screen ("Stand alone" titrator) or by a computer with a corresponding software.

A Titrando system can contain numerous, various kinds of devices. The following figure provides an overview of the peripheral devices you can connect to the 855 Robotic Titrosampler .

|

|

pH Module |

Touch Control |

Personal Computer |

|

Titrando |

Conductivity Module |

|

|

Dosing Interface |

|

|

|

|

|

|

|

|

|

USB Lab Link |

|

|

Controller |

|

|

|

|

|

|

|

|

|

|

Relay Box |

Printer |

|

|

|

|

Bluetooth USB |

|

USB |

MSB |

Remote Box |

Adapter |

|

|

|

|

|

|

|

|

|

|

|

USB Sample Processor |

|

|

PC Keyboard |

|

Robotic Titrosampler |

|

|

|

|

|

|

RS-232/USB Box

Barcode

Reader

USB Hub

|

|

|

8mDi50soa |

|

|

|

Mrothe |

Balance |

Stirrer / Ti Stand |

Dosino |

Dosimat |

Figure 1 The Titrando system

Up to three control devices (Titrandos, Dosing Interfaces, USB Sample Processors etc.) can be controlled via USB connection by PC Control/Touch

855 Robotic Titrosampler |

1 |

1.2 Instrument description |

|

Control. With the tiamo software the system can arbitrarily be extended with control devices.

Updating the device software is described in the manual for PC Control/

Touch Control or in the tiamo help, respectively.

1.2Instrument description

The 855 Robotic Titrosampler is a combined analysis instrument, unifying the functionality of a titrator and a sample changer. It can be seamlessly incorporated as a system component and control device into a Metrohm Titrando system.

The 855 Robotic Titrosampler is a versatile instrument. It has been designed exclusively for usage in factories and laboratories and thereby covers a wide range of applications.

Thanks to the integration of high-performance USB interfaces, it can be incorporated seamlessly into a Metrohm Titrando system. The various communication possibilities of the Titrando system (Remote Box, LIMS connection etc.) can thus all be used. Thanks to these abilities, a 855 Robotic Titrosampler is predetermined for all kind of automation tasks in a modern laboratory, especially for highly integrated laboratory data systems.

The user interface of the Touch Control or the tiamo™software guarantees comfortable operation and programming of the 855 Robotic Titrosampler . The comprehensive range of commands and the various configuration possibilities can comfortably and efficiently be used this way. The integration into the Titrando system also guarantees a 100% conformity of the complete automation system according to the regulations of the FDA (Federal Drug Administration), especially to the regulation 21 CFR part 11, electronic records and signatures.

There are exchangeable standard sample racks available for many vessel dimensions. Freely selectable "Special beaker" positions can be defined for e.g. rinsing or conditioning beakers on every rack.

The equipment with a 786 Swing Head allows to process a large number of samples in one single sample series. The robotic arms for the 786 Swing Head make it possible to move to any given point on a sample rack. This way the number (a maximum of 999 rack positions) and sequencing of the samples is almost completely unlimited.

Customer-specific special racks for individual requirements can be fabricated upon request.

2 |

855 Robotic Titrosampler |

|

1 Introduction |

1.2.1Model versions

The 855 Robotic Titrosampler is available in the following versions with different components.

2.855.0010

1-Tower version

1 membrane pumpe and 1 valve1 connector for an external pump1 stirrer connector (tower stirrer)1 786 Swing Head

1 measuring interface

3 MSB connectors for dosing devices or stirrers2 USB connectors

1 controller connection

2.855.0020

1-Tower version

2 membrane pumps and 2 valves1 stirrer connector (tower stirrer)1 786 Swing Head

1 measuring interface

3 MSB connectors for dosing devices or stirrers2 USB connectors

1 controller connection

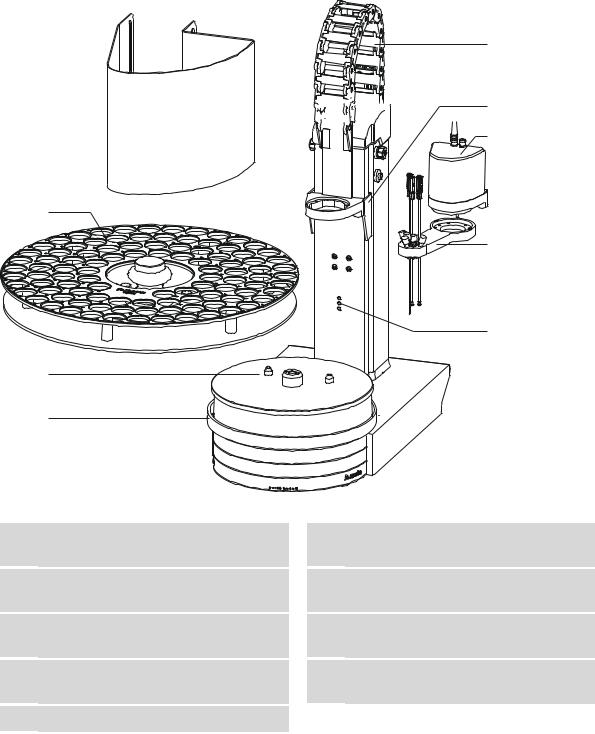

1.2.2Instrument components

The 855 Robotic Titrosampler has the following components:

Turntable

For sample racks with a diameter of up to 48 cm.

One tower with lift

With 786 Swing Head. Any robotic arm can be mounted.

One or two membrane pumps per tower

Instead of an integrated pump, an external pump connector is available depending on the model version.

One stirrer connector on the tower

For connecting a rod stirrer (802 Stirrer) or a magnetic stirrer (741 Stirrer).

Sensor connectors

Four connectors for the following sensor types:

–pH or redox electrodes

–reference electrodes

–polarizable electrodes

–temperature sensors (Pt1000 or NTC)

855 Robotic Titrosampler |

3 |

1.3 About the documentation |

|

Controller connection

For connecting a PC or Touch Control.

Two USB connectors

For connecting a printer, barcode reader or other control devices (Titrando, Dosing Interface etc.).

Three MSB connectors (Metrohm Serial Bus)

For connecting dosing devices (Dosimat with exchange unit or Dosino with dosing unit), stirrers or Remote Boxes.

1.2.3Intended use

The 855 Robotic Titrosampler is designed for usage as an automation system in analytical laboratories. It is not suitable for usage in biochemical, biological or medical environments in its basic equipment version.

The present instrument is suitable for processing chemicals and flammable samples. The usage of the 855 Robotic Titrosampler therefore requires that the user has basic knowledge and experience in the handling of toxic and caustic substances. Knowledge with respect to the application of the fire prevention measures prescribed for laboratories is also mandatory.

1.3About the documentation

Caution

Please read through this documentation carefully before putting the instrument into operation. The documentation contains information and warnings which the user must follow in order to ensure safe operation of the instrument.

1.3.1Symbols and conventions

The following symbols and styles are used in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Warning

This symbol draws attention to a possible life hazard or risk of injury.

4 |

855 Robotic Titrosampler |

|

1 Introduction |

Warning

This symbol draws attention to a possible hazard due to electrical current.

Warning

This symbol draws attention to a possible hazard due to heat or hot instrument parts.

Warning

This symbol draws attention to a possible biological hazard.

Caution

This symbol draws attention to a possible damage of instruments or instrument parts.

Note

This symbol marks additional information and tips.

1.4Safety instructions

1.4.1General notes on safety

Warning

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical safety. To maintain this state and ensure non-hazardous operation of the instrument, the following instructions must be observed carefully.

1.4.2Electrical safety

The electrical safety when working with the instrument is ensured as part of the international standard IEC 61010.

Warning

Only personnel qualified by Metrohm are authorized to carry out service work on electronic components.

855 Robotic Titrosampler |

5 |

1.4 Safety instructions |

|

Warning

Never open the housing of the instrument. The instrument could be damaged by this. There is also a risk of serious injury if live components are touched.

There are no parts inside the housing which can be serviced or replaced by the user.

Mains voltage

Warning

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see rear panel of the instrument).

Protection against electrostatic charges

Warning

Electronic components are sensitive to electrostatic charges and can be destroyed by discharges.

Always pull the mains cable out of the mains connection socket before connecting or disconnecting electrical appliances on the rear panel of the instrument.

1.4.3Tubing and capillary connections

Caution

Leaks in tubing and capillary connections are a safety risk. Tighten all connections well by hand. Avoid applying excessive force to tubing connections. Damaged tubing ends lead to leakage. Appropriate tools can be used to loosen connections.

Check the connections regularly for leakage. If the instrument is used mainly in unattended operation, then weekly inspections are mandatory.

6 |

855 Robotic Titrosampler |

|

1 Introduction |

1.4.4Personnel safety

Warning

Wear protective goggles and working clothes suitable for laboratory work while operating the 855 Robotic Titrosampler . It is also advisable to wear gloves when caustic liquids are used or in situations where glass vessels could break.

Warning

Always install the safety shield supplied with the equipment before using the instrument for the first time. Pre-installed safety shields are not allowed to be removed.

The 855 Robotic Titrosampler may not be operated without a safety shield!

Warning

Personnel are not permitted to reach into the working area of the instrument while operations are running!

A considerable risk of injury exists for the user.

Warning

In the event of a possible blockage of a drive, the mains plug must be pulled out of the socket immediately. Do not attempt to free jammed sample vessels or other parts while the device is switched on. Blockages can only be cleared when the instrument is in a voltage-free status; this action generally involves a considerable risk of injury.

Warning

The 855 Robotic Titrosampler is not suitable for utilization in biochemical, biological or medical environments in its basic equipment version.

Appropriate protective measures must be implemented in the event that potentially infectious samples or reagents are being processed.

855 Robotic Titrosampler |

7 |

1.4 Safety instructions |

|

1.4.5Flammable solvents and chemicals

Warning

All relevant safety measures are to be observed when working with flammable solvents and chemicals.

Set up the instrument in a well-ventilated location.

Keep all sources of flame far from the workplace.

Clean up spilled liquids and solids immediately.

Follow the safety instructions of the chemical manufacturer.

1.4.6Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative effects on the environment and public health.

More details about the disposal of your old equipment can be obtained from your local authorities, from waste disposal companies or from your local dealer.

8 |

855 Robotic Titrosampler |

|

2 Overview of the instrument |

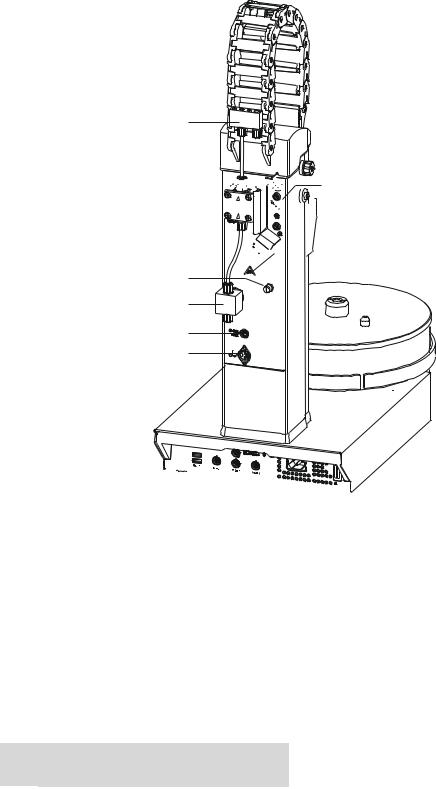

2 Overview of the instrument

2.1Front and rear

5

6 1

6 1

7

2

8

9

3

4

Figure 2 Front 855 Robotic Titrosampler

1Safety shield (6.2751.100)

Other models, see chap. Accessories.

3Turntable

With guide bolts.

5Guide chain

For cables and tubings.

7786 Swing Head (2.786.0020)

Drive for a robotic arm.

9Beaker sensor

2Sample rack (6.2041.800)

Other models, see chap. Accessories.

4Assembly rail

For magnetic stirrer (741 Stirrer).

6Lift

With titration head holder.

8Robotic arm (6.1462.050)

With aspiration and dosing tips.

855 Robotic Titrosampler |

9 |

2.1 Front and rear |

|

1

8 2

8 2

9 3

9 3

4

5

6

USB 2

7

Figure 3 Rear 855 Robotic Titrosampler

1 |

Distributor |

|

2 |

Membrane pump |

|

For rinsing equipment. |

|

|

Pump 1. |

|

|

|

|

|

|

|

|

|

|

3 |

Pump connection |

|

4 |

Pump valve |

|

Pump 2. For external pumps (e. g. 722 Pump |

|

|

|

|

Unit or 823 Pump Unit). |

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

Swing Head connector |

|

6 |

Stirrer connector |

|

Mini DIN socket (9-pin). |

|

|

DIN socket. For rod stirrer (802 Stirrer) or |

|

|

|

|

magnetic stirrer (741 Stirrer). |

|

|

|

|

|

|

|

|

|

|

7 |

Connector strip |

|

8 |

Measuring interface |

|

|

|

|

With different sensor connectors. |

|

|

|

|

|

9Warning symbols

See chapter Safety instructions.

10 |

855 Robotic Titrosampler |

|

2 Overview of the instrument |

2.2Rear panel

1 |

2 |

3 |

|

4 |

5 |

WARNING - Fire Hazard - |

|

MSB 1 |

P: 115W |

U: 100 - 240 V |

f: 50 - 60 Hz |

For continued protection replace only |

|

|

|

|

|

with the same type and rating of fuse |

|

|

Made by Metrohm |

|

|

|

|

|

|

|

|

USB 2 |

|

|

Herisau Switzerland |

|

|

|

|

|

|

|

|

USB 1 |

Contr. |

MSB 2 |

MSB 3 |

|

Nr. |

Figure 4 Connector strip

1 |

USB connectors |

|

2 |

Controller connector |

|

|

|

|

For the connection to the PC or Touch Con- |

|

|

|

|

trol. |

|

|

|

|

|

|

|

|

|

|

3 |

MSB connector |

|

4 |

Mains connection |

|

For stirrers, dosing devices, Remote Box. |

|

|

|

|

|

|

|

|

5Type plate

Contains specifications concerning mains voltage and serial number.

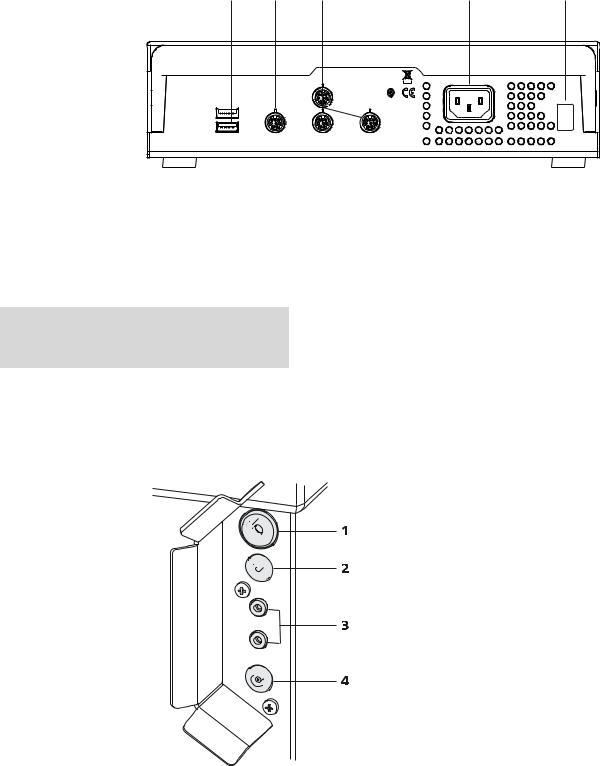

2.3Sensor connectors

The connectors for electrodes and temperature sensors are located on the rear of the tower.

Ref.

Ind.

Temp.

Pol.

Figure 5 Sensor connectors

855 Robotic Titrosampler |

11 |

2.4Sample racks

1 Electrode connector (Ref.)

For connecting reference electrodes. Socket B, 4 mm.

3Temperature sensor connector

For connecting temperature sensors of the Pt1000 or NTC types. Two B sockets, 2 mm.

2Electrode connector (Ind.)

For connecting pH or redox electrodes with integrated or separate reference electrode. Socket F.

4Electrode connector (Pol.)

For connecting polarizable electrodes, e.g. double Pt electrodes. Socket F.

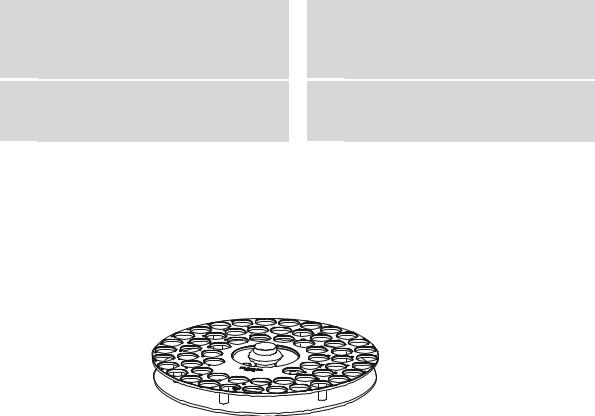

2.4Sample racks

A sample rack is a turntable that acts as a receptacle for sample vessels. Various types of sample racks are available for different numbers and types of sample vessels.

The 855 Robotic Titrosampler requires sample racks with up to a maximum of 42 cm diameter.

Figure 6 6.2041.840 Sample rack

Other user-defined racks can be supplied upon request and the required rack data can be loaded and configured in the control software. Any arrangement of rack positions is possible.

Magnet codes

Every single sample rack can be unambiguously identified by means of a magnet code. The Sample Processor can thus recognize automatically which rack is in place.

When replacing a rack, this should first be returned to starting position using the Rack initialization function (see "Manual Control" in the control software). This will enable an unambiguous recognition of the rack and thus the correct positioning of the beaker. A positioning table is assigned to each rack type in which each rack position is defined.

12 |

855 Robotic Titrosampler |

|

3 Installation |

3 Installation

3.1Setting up the instrument

3.1.1Packaging

The instrument is supplied in highly protective special packaging together with the separately packed accessories. Keep this packaging, as only this ensures safe transportation of the instrument.

3.1.2Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

3.1.3Location

The instrument has been developed for operation indoors and may not be used in explosive environments.

Place the instrument in a location of the laboratory suitable for operation and free of vibrations, if possible protected from corrosive atmospheres and contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

3.2Preparing the Sample Processor

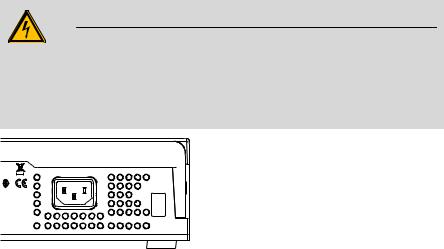

3.2.1Connecting a mains cable

Warning

This instrument must not be operated except with the mains voltage specified for it (see rear panel of the instrument).

Protect the connection sockets against moisture.

P: 115W |

U: 100 - 240 V |

f: 50 - 60 Hz |

|

|

Nr. |

Figure 7 Connecting the mains cable

855 Robotic Titrosampler |

13 |

3.3 Connecting a computer |

|

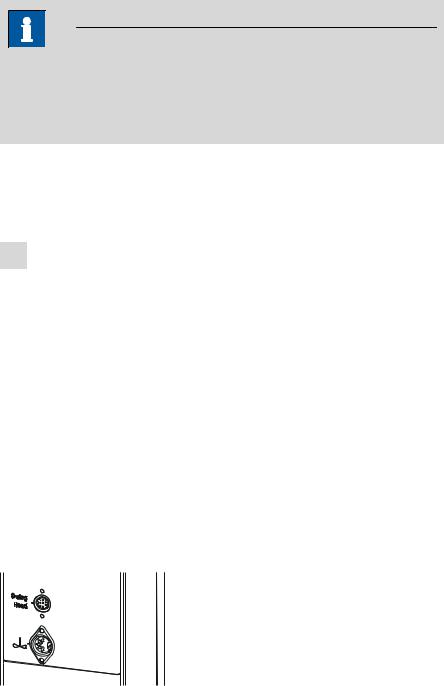

3.3Connecting a computer

The 855 Robotic Titrosampler requires a USB connection to a computer in order to be able to be controlled by a PC software. When a 6.2151.000 controller cable is used, the instrument can be connected directly, either to a USB socket on a computer, to a connected USB hub or to a different Metrohm control instrument.

Cable connection and driver installation

A driver installation is required in order to ensure that the 855 Robotic Titrosampler is recognized by the PC software. To accomplish this, you must comply with the procedures specified. The following steps are necessary:

1Installing the software

Insert the PC software installation CD and carry out the installation program directions.

Exit the program if you have started it after the installation.

2 Establishing cable connections

Connect all peripheral devices to the instrument (see Chapter 3.13, page 29).

Connect the 855 Robotic Titrosampler to the mains supply if you have not already done this.

Connect the instrument to your computer through a USB connector (Type A) (see Instructions for Use for your computer). The 6.2151.000 cable is used for this purpose.

6.2151.000

USB 2

USB 1

Contr.

MSB 2

Figure 8 Connecting the computer

For Windows 2000: The instrument is recognized and the driver is installed automatically.

For Windows XP: The instrument is recognized and the installation assistant for the driver is started automatically. Select the option "Install software automatically" and click on [Continue]. Exit the assistant with

[Finish].

14 |

855 Robotic Titrosampler |

|

3 Installation |

For Windows Vista: The instrument is recognized and the installation assistant for the driver is started automatically. Select the option "Find and install driver software". Agree to all subsequent requests. The installation assistant will be exited automatically.

Note

The plug on the instrument end of the 6.2151.000 controller cable is protected with an anti-pull device to prevent the cable from being pulled out accidentally. If you wish to pull out the plug, then you must first retract the outer plug sleeve marked with arrows.

Registering and configuring the instrument in the PC software

The instrument must be registered in the configuration of your PC software. Once that has been done, you can then configure it according to your requirements. Proceed as follows:

1Setting up the instrument

Start up the PC software.

The instrument is recognized automatically. The configuration dialog for the instrument is displayed.

Make configuration settings for the instrument and its connectors.

More detailed information concerning the configuration of the instument can be found in the documentation for the respective PC software.

3.4Connecting the Swing Head

Take care to ensure that the Swing Head is connected before the instrument is started up. Check the connection cable.

The connection socket (Mini DIN) for the Swing Head drive is each located on the rear of the tower next to the stirrer connector.

Figure 9 Connecting Swing Head

855 Robotic Titrosampler |

15 |

3.5 Configuring the robotic arm |

|

If the Swing Head is not connected, connect it as follows:

1Plug in the cable

Guide the connection cable of the Swing Head through the guide chain of the tower (see Chapter 3.9, page 24).

Plug the Mini DIN plug into the socket 'Swing Head'.

3.5Configuring the robotic arm

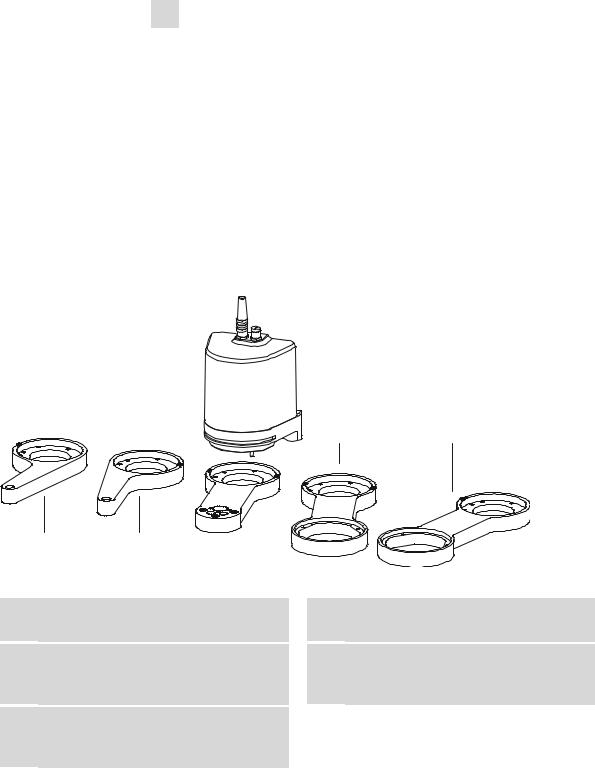

A variety of differently constructed robotic arms is available for enabling a wide range of applications. They differ from one another in their geometric sizes, e.g. swing radius or maximum permissible swing angle. The configuration data must be entered in the Sample Processor or in the control software prior to the assembly of the robotic arm. The data required is engraved on the underside of the robotic arm. Examples of the most common robotic arms are shown in the illustration below.

4 |

5 |

1 |

2 |

3 |

Figure 10 Robotic arms - standard model versions:

1Transfer robotic arm (6.1462.030)

For sample transfer, left-swinging.

3Titration robotic arm (6.1462.050)

With titration head, left-/right-swinging *).

5Macro robotic arm (6.1462.070)

With holder for a 6.1458.XXX titration head insert, right-swinging.

2Transfer robotic arm (6.1462.040)

For sample transfer, right-swinging.

4Macro robotic arm (6.1462.060)

With holder for a 6.1458.XXX titration head insert, left-swinging.

*) can be mounted in two ways

16 |

855 Robotic Titrosampler |

|

3 Installation |

Note

A detailed list of the available robotic arms, along with the necessary configuration data, can be found in Chapter Robotic arms, page 46ff.

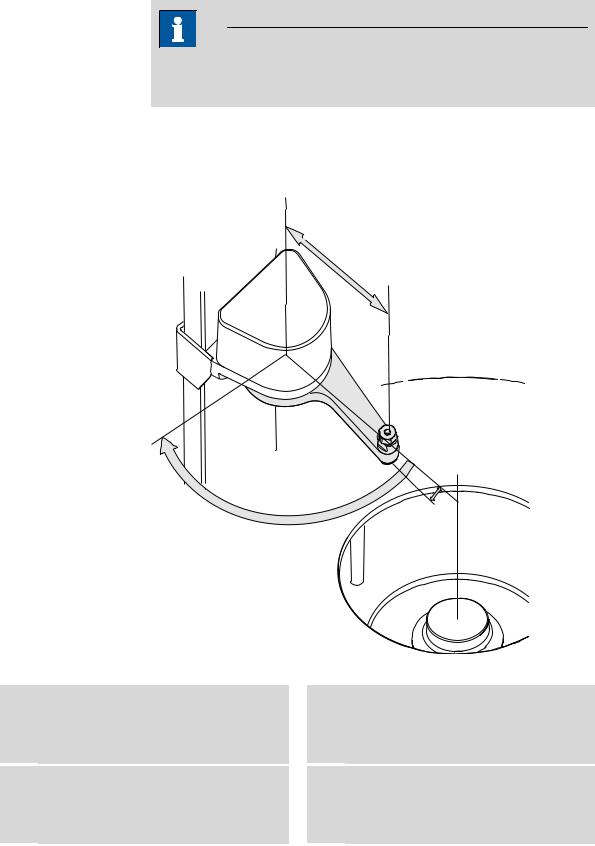

The following figure illustrates the most important configuration data that needs to be set in the control software to ensure correct usage of a robotic arm (left-swinging, here).

1

2

3

5 |

4 |

Figure 11 Configuration data of the robotic arms

1Swing axis

This runs through the middle of the Swing Head drive.

2Swing radius

This is determined by the length of the robotic arm. The radius runs from the axis of rotation to the midpoint of the tip of the robotic arm.

3Source axis

This runs from the swing axis to the midpoint of the sample rack and marks the initial position of the robotic arm.

4Swing offset

This determines the 0° position of the robotic arm.

855 Robotic Titrosampler |

17 |

3.6 Mounting the robotic arm |

|

5Max. swing angle

This stands for the swing range that the robotic arm can reach. The range runs from the source axis to the maximum possible robotic arm position.

Swing direction

Left-swinging (swing direction +) or right-swinging (swing direction –) model versions are available as different types of robotic arms. Left-swinging means swinging from the initial position (pointing towards the middle of the rack) outwards to the left.

In the case of a Sample Processor with two towers, a right-swinging robotic arm must be mounted on Tower 1, a left-swinging robotic arm on Tower 2. If the alignment is incorrect, the two robotic arms could possibly come into contact with one another, resulting in damage to the drives.

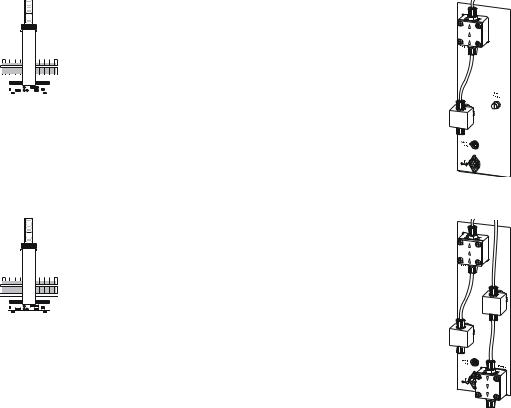

3.6Mounting the robotic arm

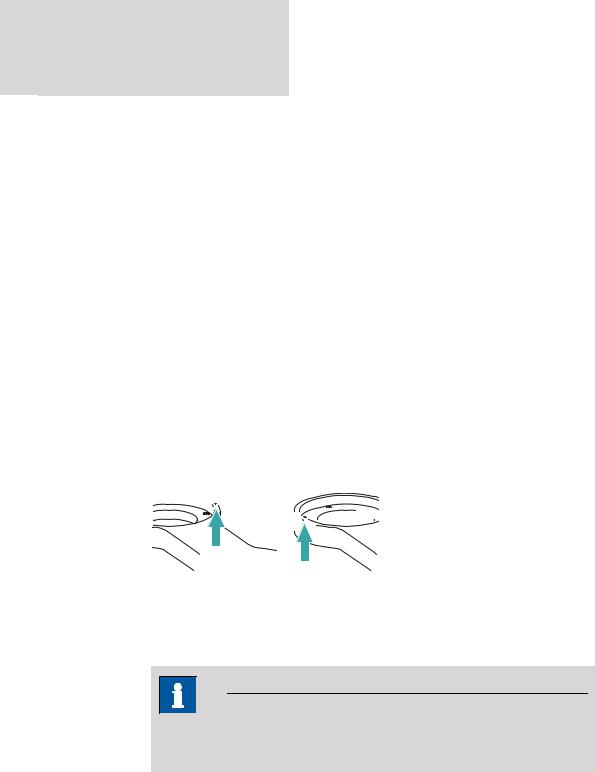

Depending on the model, robotic arms can be mounted as either rightswinging or left-swinging. The position of the limitation screw of the robotic arm must be taken into account during assembly. The limitation screw must face the tower of the Sample Processor during the mounting of the robotic arm. The following illustration shows on the left the position of the limitation screw at a right-swinging robotic arm (Position 1) and on the right with a left-swinging robotic arm (Position 2).

1

1

2

Figure 12 Limitation screw at the robotic arm

For robotic arms which can be mounted in two different ways (e.g. 6.1462.050), the limitation screw can be fitted in accordance with the required assembly direction (see above).

Note

The configuration data of a robotic arm must be configured in the control software before it is mounted (see Chapter 3.5, page 16).

18 |

855 Robotic Titrosampler |

Loading...

Loading...