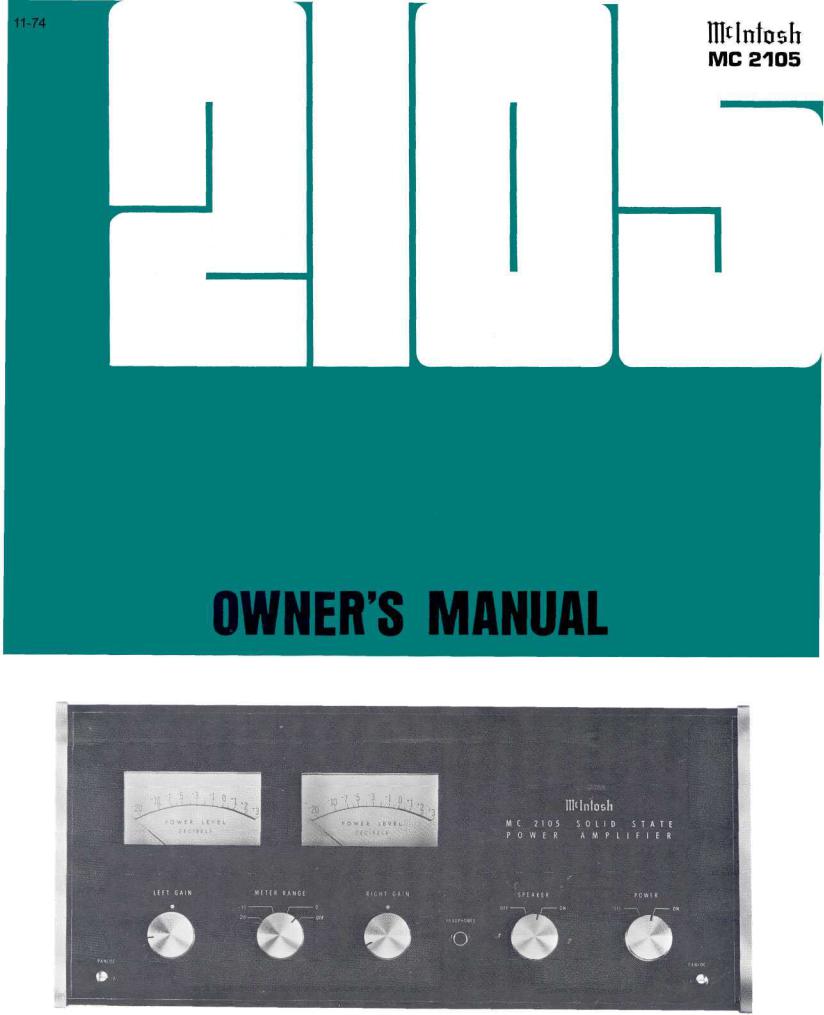

McIntosh MC-2105 User Manual

THE MCINTOSH MC 2105 SOLID STATE STEREO POWER AMPLIFIER

Reading Time: 28 Minutes

Price $1.25

Your MC 2105 Stereo Power Amplifier will give you many years of pleasant and satisfactory performance. If you have any questions, please contact:

CUSTOMER SERVICE

Mclntosh Laboratory Inc.

2 Chambers Street

Binghamton, New York 13903

Phone:607-723-3512

WARNING: TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS UNIT TO RAIN OR MOISTURE.

Take Advantage of 3 years of FREE Factory Service . . .

Fill in the Application NOW.

CONTENTS

SERVICE CONTRACT |

1 |

INSTALLATION |

2,3 |

HOW TO CONNECT |

4,5 |

HOW TO USE THE DYNAMIC PEAK LOCKING METERS ... 6

FRONT PANEL INFORMATION . . . 8

PERFORMANCE LIMITS |

|

AND RATINGS |

9 |

TYPICAL PERFORMANCE CHARTS |

.. 10 |

TECHNICAL DESCRIPTION |

11 |

BLOCK DIAGRAM |

12 |

THREE YEAR FACTORY SERVICE CONTRACT

AnapplicationforaFREETHREEYEARFACTORYSERVICECONTRACTisincludedwiththismanual.

The terms of the contract are: |

or mishandling is not covered by the SERV- |

|

ICE CONTRACT. |

1. Mclntosh will provide all parts, materials and labor needed to return the measured performance of the instrument to the original performance limits free of any charge. The SERVICE CONTRACT does not cover any shipping costs to and from the authorized service agency or the factory.

2.Any Mclntosh authorized service agency will repair all Mclntosh instruments at normal service rates. To receive the free service under the terms of the SERVICE CONTRACT, the SERVICE CONTRACT CERTIFICATE must accompany the instrument when taken to the service agency.

3.Always have service done by a Mclntosh

authorized service agency. If the instrument is modified or damaged, as a result of un-

authorized repair |

the SERVICE CONTRACT |

will be cancelled. |

Damage by improper use |

4. The SERVICE CONTRACT is issued to you as the original purchaser. To protect you from misrepresentation this contract cannot be transferred to a second owner.

5.For your protection Mclntosh selects its dealers carefully. Only one dealer in ten qualifies for a Mclntosh franchise. To receive the SERVICE CONTRACT your purchase must be made from a Mclntosh franchised dealer.

6.Your completely filled in application for a SERVICE CONTRACT must be postmarked within 30 days of the date of purchase of the instrument.

7.To receive the SERVICE CONTRACT all information on the application must be filled in. The SERVICE CONTRACT will be issued

when the completely filled in application is received at Mclntosh Laboratory Incorporated in Binghamton, New York.

1

Copyright © 1970 By Mclntosh Laboratory Inc.

Adequate ventilation extends the trouble-free life of electronic instruments. It is generally found that each 10° centigrade (18° F) rise in temperature reduces the life of electrical insulation by one half. Adequate ventilation is an inexpensive and effective means of preventing insulation breakdown that results from unnecessarily high operating temperatures. The direct benefit of adequate ventilation is longer, trouble-free life.

Allow at least 15 inches deep x 17 inches wide x 8 inches high for mounting the MC2105. Always allow for air flow by either ventilation holes or space next to the bottom of the amplifier and a means for a warm air to escape at the top. With adequate ventilation the amplifier can be mounted in any position.

To prepare the MC 2105 for installation remove the plastic protective covering. Turn it upside down so that it rests on its top on the shipping pallet. Remove the four plastic feet fastened to the bottom of the chassis.

Next, place the mounting brackets, the parts bag and the mounting template at hand.

The PANLOC professional mounting design eliminates the need for any shelf or bracket to support the MC 2105. It is completely supported by its own mounting brackets.

The design of the mounting template allows you to position or locate the cutout from the front or rear of the panel to which the instrument is to be mounted. Position the plastic mounting template over the area of the panel to be cut out for installation.

If the cutout is to be located from the front of the panel, begin at 2. If the cutout is to be located from the rear of the panel, begin here.

1. On the back of the cabinet panel, scribe a vertical centerline through the exact center of the area in which the cutout is to be made.

Place the template against the back of the panel and match the template centerline with the centerline on the cabinet panel.

Make sure that there is at least ¼ inch clearance between the bottom of the dashed line of the cutout area on the template and any shelf or brace below the proposed cutout.

Mark the two locating holes ("C" holes on the mounting template).

Drill the two locating holes. Be certain the drill is perpendicular to the panel.

Now position the template on the front of the panel by aligning the "C" locating holes on the template with the drill holes.

2. If the cutout is to be located from the front of the panel:

With the template in place against the cabinet panel, mark the "A" and "B" drill holes and the four small holes that identify the corners of the cutout. Join the corner marks with a pencil. The edge of the template can be used as a straight edge.

IMPORTANT: DRILL THE 6 HOLES BEFORE MAKING THE CUTOUT.

Accurately drill the three holes on each side of the cutout area with a3/16inch drill.

With the saw on the INSIDE OF THE PENCIL LINES carefully cut out the rectangular opening.

Secure the mounting strips to the rear of the cabinet panel using two screws from the hardware package.

Insert the screws in the center holes of the cabinet panel ("B" holes on the template) and tighten. The screw head should pull into the wood slightly. (Use two % inch long screws for panels under ½ inch, or two 1¼ inch long screws for panels ½ inch thick and larger.)

2

Attach the mounting brackets to the cabinet panel using four screws.

Place the template over the mounting screws. The mounting screws should be centered in the "A" and "B" holes on the template. The sides of the mounting brackets should match the vertical dash lines on the template. If necessary, loosen the screws and push the brackets into alignment and retighten.

Insert the power cord through the opening. Carefully slide the MC 2105 into the opening so the rails on the bottom of the equipment slide in the track of the mounting brackets. Slide the instrument in until it stops at the adjust position latches. Press the latches in and continue to slide the instrument in until the front panel is against the cabinet panel. At the bottom front corners of the PANLOC instruments are the PANLOC buttons. Depressing the PANLOC buttons will lock the instrument firmly in the installation. Depressing the PANLOC buttons a second time (as with a ballpoint pen) will release the instrument. You can then slide the instrument forward to the inspection-adjustment position. Depressing the inspection-adjustment position latches will allow the instrument to be slid completely out of the installation.

3

Loading...

Loading...