KROHNE IFC-100 User Manual

IFC 100 Handbook

IFC 100 Handbook

Signal converter for electromagnetic flowmeters

Electronic Revision: ER 2.1.xx

(SW.REV. 3.0x)

The documentation is only complete when used in combination with the relevant documentation for the sensor.

© KROHNE 07/2010 - 4000041004 - MA IFC 100 R04 en

:IMPRINT ::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2010 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

|

|

CONTENTS |

|

|

|

|

IFC 100 |

|

|

|

|||

|

|

|

|

|

|||

1 |

Safety instructions |

6 |

|||||

|

|

|

|

|

|

||

|

|

|

1.1 |

Software history ............................................................................................................... |

6 |

||

|

|

|

1.2 |

Intended use ..................................................................................................................... |

7 |

||

|

|

|

1.3 |

Certifications .................................................................................................................... |

7 |

||

|

|

|

1.4 |

Safety instructions from the manufacturer ..................................................................... |

8 |

||

|

|

|

1.4.1 Copyright and data protection ................................................................................................ |

8 |

|||

|

|

|

1.4.2 Disclaimer ............................................................................................................................... |

8 |

|||

|

|

|

1.4.3 Product liability and warranty ................................................................................................ |

9 |

|||

|

|

|

1.4.4 Information concerning the documentation........................................................................... |

9 |

|||

|

|

|

1.4.5 Warnings and symbols used................................................................................................. |

10 |

|||

|

|

|

1.5 |

Safety instructions for the operator............................................................................... |

10 |

||

|

|

2 Device description |

11 |

||||

|

|

|

|

|

|

||

|

|

|

2.1 |

Scope of delivery............................................................................................................. |

11 |

||

|

|

|

2.2 |

Device description .......................................................................................................... |

12 |

||

|

|

|

2.3 |

Nameplates .................................................................................................................... |

13 |

||

|

|

|

2.3.1 Nameplate (example)............................................................................................................ |

13 |

|||

3 |

Installation |

14 |

|||||

|

|

|

|

|

|

||

|

|

|

3.1 |

Notes on installation ...................................................................................................... |

14 |

||

|

|

|

3.2 |

Storage ........................................................................................................................... |

14 |

||

|

|

|

3.3 |

Transport ........................................................................................................................ |

14 |

||

|

|

|

3.4 |

Installation specifications .............................................................................................. |

14 |

||

|

|

|

3.5 |

Mounting of the compact version................................................................................... |

15 |

||

|

|

|

3.6 |

Mounting the wall-mounted housing, remote version .................................................. |

15 |

||

|

|

|

3.6.1 Wall mounting ....................................................................................................................... |

15 |

|||

|

|

4 Electrical connections |

17 |

||||

|

|

|

|

|

|

||

|

|

|

4.1 |

Safety instructions.......................................................................................................... |

17 |

||

|

|

|

4.2 |

Important notes on electrical connection...................................................................... |

17 |

||

|

|

|

4.3 |

Electrical cables for remote device versions, notes...................................................... |

18 |

||

|

|

|

4.3.1 Notes on signal cable A ........................................................................................................ |

18 |

|||

|

|

|

4.3.2 Notes on field current cable C.............................................................................................. |

18 |

|||

|

|

|

4.3.3 Requirements for signal cables provided by the customer ................................................. |

19 |

|||

|

|

|

4.4 |

Preparing the signal and field current cables ............................................................... |

20 |

||

|

|

|

4.4.1 Signal cable A (type DS 300), construction........................................................................... |

20 |

|||

|

|

|

4.4.2 Preparing signal cable A, connection to signal converter ................................................... |

21 |

|||

|

|

|

4.4.3 Length of signal cable A........................................................................................................ |

22 |

|||

|

|

|

4.4.4 Preparing field current cable C, connection to signal converter......................................... |

23 |

|||

|

|

|

4.4.5 Preparing signal cable A, connection to measuring sensor................................................ |

25 |

|||

|

|

|

4.4.6 Preparing field current cable C, connection to measuring sensor ..................................... |

26 |

|||

|

|

|

4.5 |

Connecting the signal and field current cables............................................................. |

27 |

||

|

|

|

4.5.1 Connecting the signal and field current cables to the signal converter, remote version... |

28 |

|||

|

|

|

4.5.2 Connection diagram for signal and field current cable ....................................................... |

30 |

|||

|

|

|

4.6 |

Grounding the measuring sensor .................................................................................. |

31 |

||

|

|

|

4.6.1 Classical method................................................................................................................... |

31 |

|||

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

3 |

|

CONTENTS |

|

|

|

IFC 100 |

|

|

|

|

|

|

4.7 |

Connecting the power..................................................................................................... |

32 |

4.8 |

Overview of outputs ........................................................................................................ |

34 |

4.8.1 Description of the CG number .............................................................................................. |

34 |

|

4.8.2 Fixed, non-alterable output versions ................................................................................... |

34 |

|

4.9 |

Description of the outputs.............................................................................................. |

35 |

4.9.1 Current output ...................................................................................................................... |

35 |

|

4.9.2 Pulse and frequency output.................................................................................................. |

36 |

|

4.9.3 Status output and limit switch .............................................................................................. |

37 |

|

4.10 Electrical connection of the outputs ............................................................................ |

38 |

|

4.10.1 Electrical connection of the outputs................................................................................... |

38 |

|

4.10.2 Laying electrical cables correctly....................................................................................... |

39 |

|

4.11 Connection diagrams of outputs .................................................................................. |

39 |

|

4.11.1 Important notes................................................................................................................... |

39 |

|

4.11.2 Description of the electrical symbols................................................................................. |

40 |

|

4.11.3 Basic outputs....................................................................................................................... |

41 |

|

4.11.4 HART® connection .............................................................................................................. |

44 |

|

5 Start-up |

45 |

|

5.1 |

Switching on the power .................................................................................................. |

45 |

5.2 |

Starting the signal converter ......................................................................................... |

45 |

6 Operation |

46 |

|

6.1 |

Display and operating elements .................................................................................... |

46 |

6.1.1 Display in measuring mode with 2 or 3 measured values ................................................... |

47 |

|

6.1.2 Display for selection of sub-menu and functions, 3 lines.................................................... |

47 |

|

6.1.3 Display when setting parameters, 4 lines ............................................................................ |

48 |

|

6.1.4 Display when changing parameters, 4 lines ........................................................................ |

48 |

|

6.2 |

Menu structure............................................................................................................... |

49 |

6.3 |

Function tables ............................................................................................................... |

51 |

6.3.1 Menu A, quick setup.............................................................................................................. |

51 |

|

6.3.2 Menu B, test .......................................................................................................................... |

53 |

|

6.3.3 Menu C, setup ....................................................................................................................... |

55 |

|

6.3.4 Set free units......................................................................................................................... |

68 |

|

6.4 |

Description of functions ................................................................................................. |

69 |

6.4.1 Reset counter in quick setup menu...................................................................................... |

69 |

|

6.4.2 Deleting error messages in the quick setup menu.............................................................. |

69 |

|

6.5 |

Status messages and diagnostic information................................................................ |

70 |

7 Service |

74 |

|

7.1 |

Spare parts availability................................................................................................... |

74 |

7.2 |

Availability of services .................................................................................................... |

74 |

7.3 |

Returning the device to the manufacturer..................................................................... |

74 |

7.3.1 General information.............................................................................................................. |

74 |

|

7.3.2 Form (for copying) to accompany a returned device............................................................ |

75 |

|

7.4 |

Disposal .......................................................................................................................... |

75 |

4 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

IFC 100 |

|

CONTENTS |

8 Technical data |

76 |

|

8.1 |

Measuring principle........................................................................................................ |

76 |

8.2 |

Technical data................................................................................................................. |

77 |

8.3 |

Dimensions and weights ................................................................................................ |

83 |

8.3.1 Housing ................................................................................................................................. |

83 |

|

8.3.2 Mounting plate, wall-mounted version ................................................................................ |

86 |

|

8.4 |

Flow tables ..................................................................................................................... |

87 |

8.5 |

Measuring accuracy ....................................................................................................... |

89 |

9 Description of HART interface |

90 |

|

9.1 |

General description ........................................................................................................ |

90 |

9.2 |

Connection variants........................................................................................................ |

90 |

9.2.1 Point-to-Point connection - analogue / digital mode........................................................... |

91 |

|

9.2.2 Multi-Drop connection (2-wire connection) ......................................................................... |

92 |

|

9.2.3 Multi-Drop connection (3-wire connection) ......................................................................... |

93 |

|

9.3 |

Outputs and HART® Dynamic variable and device variable .......................................... |

94 |

9.4 |

Parameter for the basic configuration........................................................................... |

95 |

9.5 |

Field Communicator 375/475 (FC 375/475) ................................................................... |

96 |

9.5.1 Installation ............................................................................................................................ |

96 |

|

9.5.2 Operation............................................................................................................................... |

96 |

|

9.5.3 Parameter for the basic configuration ................................................................................. |

96 |

|

9.6 |

Asset Management Solutions (AMS).............................................................................. |

97 |

9.6.1 Installation ............................................................................................................................ |

97 |

|

9.6.2 Operation............................................................................................................................... |

97 |

|

9.6.3 Parameter for the basic configuration ................................................................................. |

97 |

|

9.7 |

Field Device Manager (FDM) .......................................................................................... |

98 |

9.7.1 Installation ............................................................................................................................ |

98 |

|

9.7.2 Operation............................................................................................................................... |

98 |

|

9.8 |

Process Device Manager (PDM)..................................................................................... |

98 |

9.8.1 Installation ............................................................................................................................ |

98 |

|

9.8.2 Operation............................................................................................................................... |

99 |

|

9.8.3 Parameter for the basic configuration ................................................................................. |

99 |

|

9.9 |

Field Device Tool / Device Type Manager (FDT / DTM)................................................ |

100 |

9.9.1 Installation .......................................................................................................................... |

100 |

|

9.9.2 Operation............................................................................................................................. |

100 |

|

9.10 Appendix A: HART® menu tree for Basic-DD ............................................................ |

100 |

|

9.10.1 Overview Basic-DD menu tree (positions in menu tree).................................................. |

101 |

|

9.10.2 Basic-DD menu tree (details for settings)........................................................................ |

102 |

|

9.11 Appendix B: HART® menu tree for AMS .................................................................... |

105 |

|

9.11.1 Overview AMS menu tree (positions in menu tree) .......................................................... |

105 |

|

9.11.2 AMS menu tree (details for settings)................................................................................ |

106 |

|

9.12 Appendix C: HART® menu tree for PDM.................................................................... |

110 |

|

9.12.1 Overview PDM menu tree (positions in menu tree).......................................................... |

110 |

|

9.12.2 PDM menu tree (details for settings) ............................................................................... |

112 |

|

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

5 |

1 SAFETY INSTRUCTIONS |

|

|

IFC 100 |

|

|

|

|

|

1.1 Software history

The "Electronic Revision" (ER) is consulted to document the revision status of electronic equipment according to NE 53 for all GDC devices. It is easy to see from the ER whether troubleshooting or larger changes in the electronic equipment have taken place and how that has affected the compatibility.

Changes and effect on compatibility

1 |

Downwards compatible changes and fault repair with no effect on operation (e.g. spelling |

|

|

mistakes on display) |

|

|

|

|

2-_ |

Downwards compatible hardware and/or software change of interfaces: |

|

|

|

|

|

H |

HART® |

|

P |

PROFIBUS |

|

|

|

|

F |

Foundation Fieldbus |

|

|

|

|

M |

Modbus |

|

|

|

|

X |

all interfaces |

|

|

|

3-_ |

Downwards compatible hardware and/or software change of inputs and outputs: |

|

|

|

|

|

I |

Current output |

|

|

|

|

F, P |

Frequency / pulse output |

|

|

|

|

S |

Status output |

|

|

|

|

C |

Control input |

|

|

|

|

CI |

Current input |

|

|

|

|

X |

all inputs and outputs |

|

|

|

4 |

Downwards compatible changes with new functions |

|

|

|

|

5 |

Incompatible changes, i.e. electronic equipment must be changed. |

|

|

|

|

INFORMATION!

In the table below, "x" is a placeholder for possible multi-digit alphanumeric combinations, depending on the available version.

Release date |

Electronic Revision |

Changes and |

Documentation |

|

|

compatibility |

|

|

|

|

|

2007-12-11 |

ER 2.0.0x |

- |

- |

|

(SW.REV. 2.00 (2.00)) |

|

|

|

|

|

|

2008-02-29 |

ER 2.0.1x |

1 |

MA IFC 100 R03 |

|

(SW.REV. 2.00 (2.00)) |

|

|

|

|

|

|

2008-05-07 |

ER 2.0.2x |

1 |

MA IFC 100 R04 |

|

(SW.REV. 2.00 (2.00)) |

|

|

|

|

|

|

2008-06-27 |

ER 2.0.3x |

1 |

MA IFC 100 R04 |

|

(SW.REV. 2.00 (2.00)) |

|

|

|

|

|

|

2010-01-04 |

ER 2.0.4x |

1 |

MA IFC 100 R04 |

|

(SW.REV. 2.00 (2.00)) |

|

|

|

|

|

|

2010-01-04 |

ER 2.1.0x |

1; 2-H |

MA IFC 100 R04 |

|

(SW.REV. 2.10 (3.00)) |

|

|

|

|

|

|

6 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

SAFETY INSTRUCTIONS 1 |

|

IFC 100 |

|

|

|

|

1.2 Intended use

The electromagnetic flowmeters are designed exclusively to measure the flow and conductivity of electrically conductive, liquid media.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex documentation.

WARNING!

If the device is not used according to the operating conditions (refer to chapter "Technical data), the intended protection could be affected.

1.3 Certifications

CE marking

The device fulfils the statutory requirements of the following EC directives:

•Low Voltage Directive 2006/95/EC

•EMC Directive 2004/108/EC

as well as

•EN 61010

•EMC specification acc. to EN 61326/A1

•NAMUR recommendations NE 21 and NE 43

The manufacturer certifies successful testing of the product by applying the CE marking.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex documentation.

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

7 |

1 SAFETY INSTRUCTIONS |

|

|

IFC 100 |

|

|

|

|

|

1.4 Safety instructions from the manufacturer

1.4.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to German copyright. Contributions from third parties are identified as such. Reproduction, processing, dissemination and any type of use beyond what is permitted under copyright requires written authorisation from the respective author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the manufacturer's documents is always on a voluntary basis whenever possible. Whenever feasible, it is always possible to make use of the offerings and services without providing any personal data.

We draw your attention to the fact that data transmission over the Internet (e.g. when communicating by e-mail) may involve gaps in security. It is not possible to protect such data completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish an imprint for the purpose of sending us any advertising or informational materials that we have not expressly requested.

1.4.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including, but not limited to direct, indirect, incidental, punitive and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross negligence. In the event any applicable law does not allow such limitations on implied warranties or the exclusion of limitation of certain damages, you may, if such law applies to you, not be subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable in any way for possible consequences of such changes.

8 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

SAFETY INSTRUCTIONS 1 |

|

IFC 100 |

|

|

|

|

1.4.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose. The manufacturer accepts no liability for the consequences of misuse by the operator. Improper installation and operation of the devices (systems) will cause the warranty to be void. The respective "Standard Terms and Conditions" which form the basis for the sales contract shall also apply.

1.4.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the information in this document and observe applicable national standards, safety requirements and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the text, we advise you to contact your local office for assistance. The manufacturer can not accept responsibility for any damage or injury caused by misunderstanding of the information in this document.

This document is provided to help you establish operating conditions, which will permit safe and efficient use of this device. Special considerations and precautions are also described in the document, which appear in the form of underneath icons.

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

9 |

1 SAFETY INSTRUCTIONS |

|

|

IFC 100 |

|

|

|

|

|

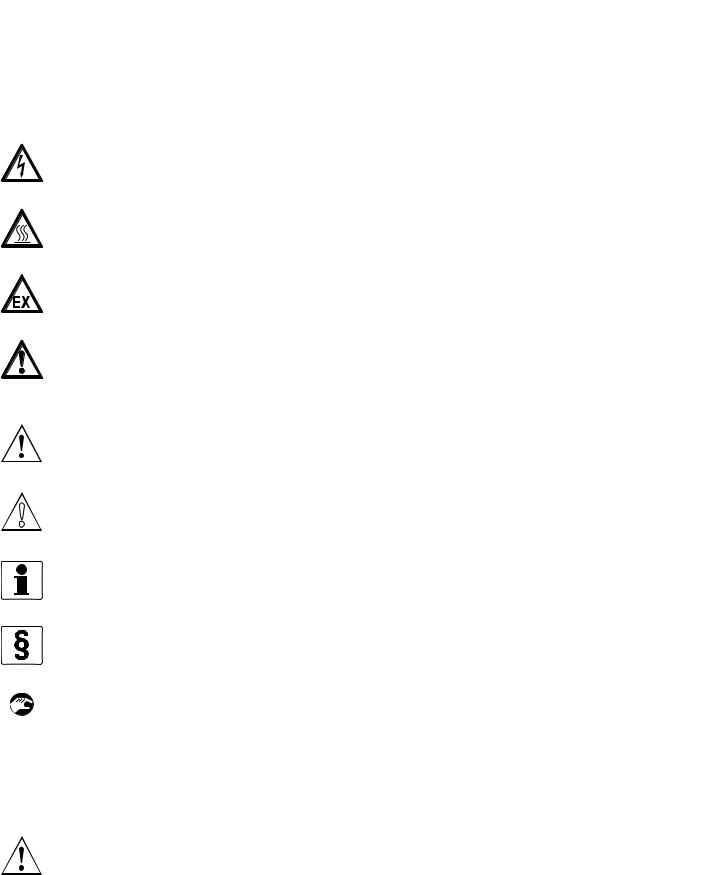

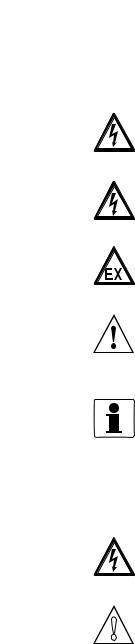

1.4.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to serious health problems and even death. There is also the risk of seriously damaging the device or parts of the operator's plant.

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems. There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

This symbol designates all instructions for actions to be carried out by the operator in the specified sequence.

iRESULT

This symbol refers to all important consequences of the previous actions.

1.5Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and efficient use of this device.

10 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

DEVICE DESCRIPTION 2 |

|

IFC 100 |

|

|

|

|

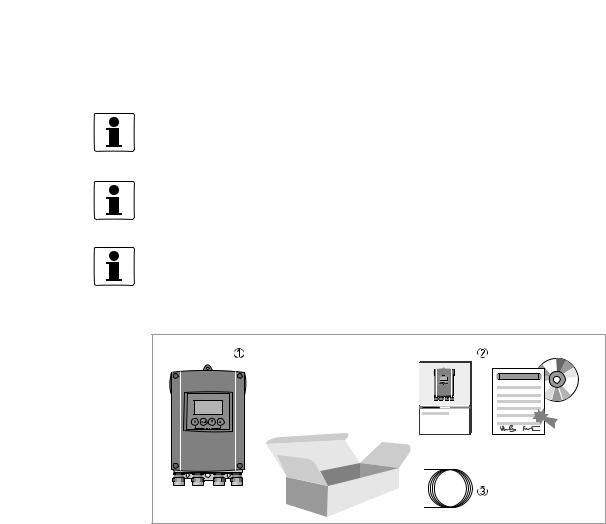

2.1 Scope of delivery

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order. Check for the correct supply voltage printed on the nameplate.

Figure 2-1: Scope of delivery

1Device in the version as ordered

2Documentation (calibration report, Quick Start, CD-ROM with product documentation for measuring sensor and signal converter)

3Signal cable (only for remote version)

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

11 |

2 DEVICE DESCRIPTION |

|

|

IFC 100 |

|

|

|

|

|

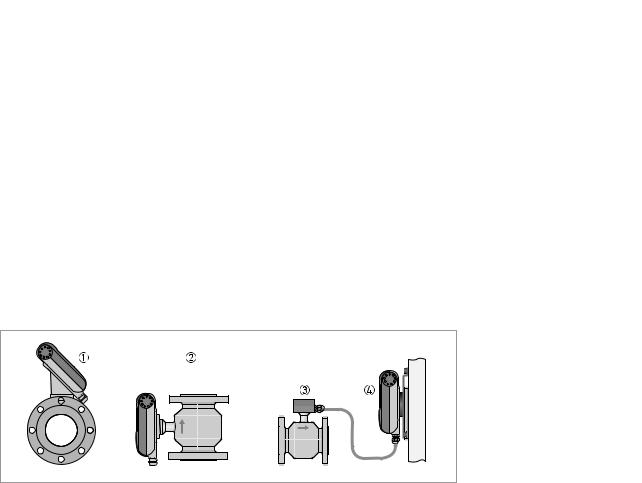

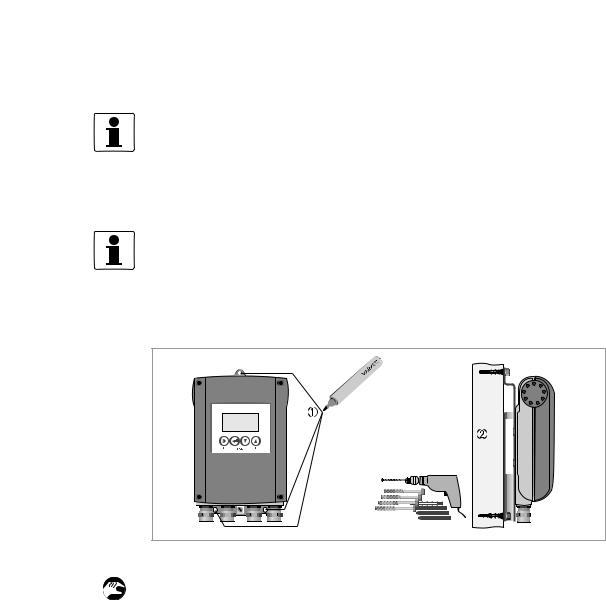

2.2 Device description

Electromagnetic flowmeters are designed exclusively to measure the flow and conductivity of electrically conductive, liquid media.

Your measuring device is supplied ready for operation. The factory settings for the operating data have been made in accordance with your order specifications.

The following versions are available:

•Compact version (the signal converter is mounted directly on the measuring sensor)

•Remote version (electrical connection to the measuring sensor via field current and signal cable)

Figure 2-2: Device versions

1Compact 45° version

2Compact 0° version

3Measuring sensor with connection box

4Wall-mounted version

12 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

DEVICE DESCRIPTION 2 |

|

IFC 100 |

|

|

|

|

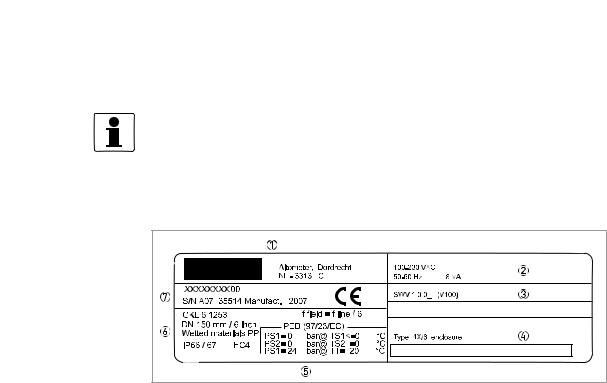

2.3 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order. Check for the correct supply voltage printed on the nameplate.

2.3.1 Nameplate (example)

Figure 2-3: Example of a nameplate

1Manufacturer

2Power supply data

3Software version

4Tag name

5Approvals-related pressure and temperature thresholds

6GK/GKL values (measuring sensor constants); size (mm /inches); field frequency; protection category; materials of wetted parts

7Product designation, serial number and manufacturing date

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

13 |

3 INSTALLATION |

|

|

IFC 100 |

|

|

|

|

|

3.1 Notes on installation

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order. Check for the correct supply voltage printed on the nameplate.

3.2Storage

•Store the device in a dry, dust-free location.

•Avoid continuous direct sunlight.

•Store the device in its original packing.

•Storage temperature: -40...+70°C / -40...+158°F

3.3Transport

Signal converter

• No special requirements.

Compact version

•Do not lift the device by the signal converter housing.

•Do not use lifting chains.

•To transport flange devices, use lifting straps. Wrap these around both process connections.

3.4Installation specifications

INFORMATION!

The following precautions must be taken to ensure reliable installation.

•Make sure that there is adequate space to the sides.

•Protect the signal converter from direct sunlight and install a sun shade if necessary.

•Signal converters installed in control cabinets require adequate cooling, e.g. by fan or heat exchanger.

•Do not expose the signal converter to intense vibration. The flowmeters are tested for a vibration level in accordance with IEC 68-2-3.

14 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

INSTALLATION 3 |

|

IFC 100 |

|

|

|

|

3.5 Mounting of the compact version

INFORMATION!

The signal converter is mounted directly on the measuring sensor. For installation of the flowmeter, please observe the instructions in the supplied product documentation for the measuring sensor.

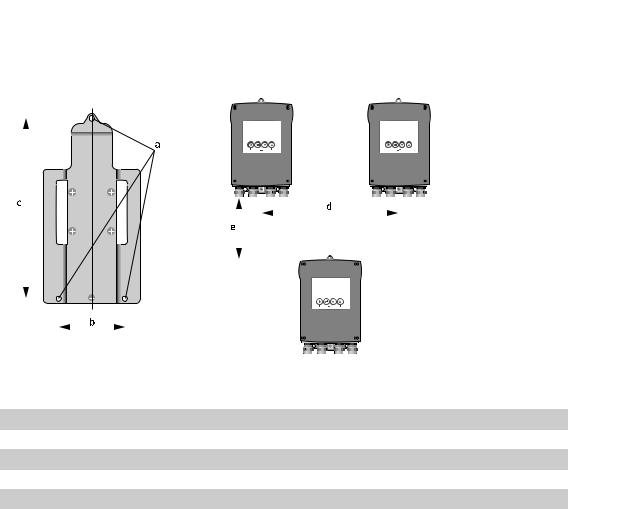

3.6 Mounting the wall-mounted housing, remote version

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools in compliance with the applicable occupational health and safety directives.

3.6.1 Wall mounting

Figure 3-1: Mounting the wall-mounted housing

1 Prepare the holes with the aid of the mounting plate. For further information refer to Mounting plate, wall-mounted version on page 86.

2 Fasten the device securely to the wall with the mounting plate.

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

15 |

3 INSTALLATION |

|

|

IFC 100 |

|

|

|

|

|

Mounting multiple devices next to each other

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[mm] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[inches] |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ø6.5 |

Ø0.26 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

87.2 |

3.4 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

c |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

241 |

9.5 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

d |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

310 |

12.2 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

257 |

10.1 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

ELECTRICAL CONNECTIONS 4 |

|

IFC 100 |

|

|

|

|

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the electrical components of the measuring device may only be carried out by properly trained specialists.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order. Check for the correct supply voltage printed on the nameplate.

4.2 Important notes on electrical connection

DANGER!

Electrical connection is carried out in conformity with the VDE 0100 directive "Regulations for electrical power installations with line voltages up to 1000 V" or equivalent national regulations.

CAUTION!

•Use suitable cable entries for the various electrical cables.

•The sensor and converter are configured together in the factory. For this reason, please connect the devices in pairs. Ensure that the sensor constant GK/GKL (see type plates) are identically set.

•If delivered separately or when installing devices that were not configured together, set the converter to the DN size and GK/GKL of the sensor, refer to Function tables on page 51.

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

17 |

4 ELECTRICAL CONNECTIONS |

|

|

IFC 100 |

|

|

|

|

|

4.3 Electrical cables for remote device versions, notes

4.3.1 Notes on signal cable A

INFORMATION!

Signal cable A (type DS 300) with double shielding ensures proper transmission of measured values.

Observe the following notes:

•Lay the signal cable with fastening elements.

•It is permissible to lay the signal cable in water or in the ground.

•The insulating material is flame-retardant to EN 50625-2-1, IEC 60322-1.

•The signal cable does not contain any halogens and is unplasticized, and remains flexible at low temperatures.

•The connection of the inner shield is carried out via the stranded drain wire (1).

•The connection of the outer shield (60) is carried out via the stranded drain wire (6).

4.3.2Notes on field current cable C

DANGER!

A shielded two-wire copper cable is used as the field current cable. The shielding MUST be connected in the housing of the measuring sensor and signal converter.

INFORMATION!

The field current cable is not part of the scope of delivery.

18 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

ELECTRICAL CONNECTIONS 4 |

|

IFC 100 |

|

|

|

|

4.3.3 Requirements for signal cables provided by the customer

INFORMATION!

If the signal cable was not ordered, it is to be provided by the customer. The following requirements regarding the electrical values of the signal cable must be observed:

Electrical safety

• To EN 60811 (Low Voltage Directive) or equivalent national regulations.

Capacitance of the insulated conductors

•Insulated conductor / insulated conductor < 50 pF/m

•Insulated conductor / shield < 150 pF/m

Insulation resistance

•Riso > 100 GΩ x km

•Umax < 24 V

•Imax < 100 mA

Test voltages

•Insulated conductor / inner shield 500 V

•Insulated conductor / insulated conductor 1000 V

•Insulated conductor / outer shield 1000 V

Twisting of the insulated conductors

• At least 10 twists per meter, important for screening magnetic fields.

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

19 |

4 ELECTRICAL CONNECTIONS |

|

|

IFC 100 |

|

|

|

|

|

4.4 Preparing the signal and field current cables

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools in compliance with the applicable occupational health and safety directives.

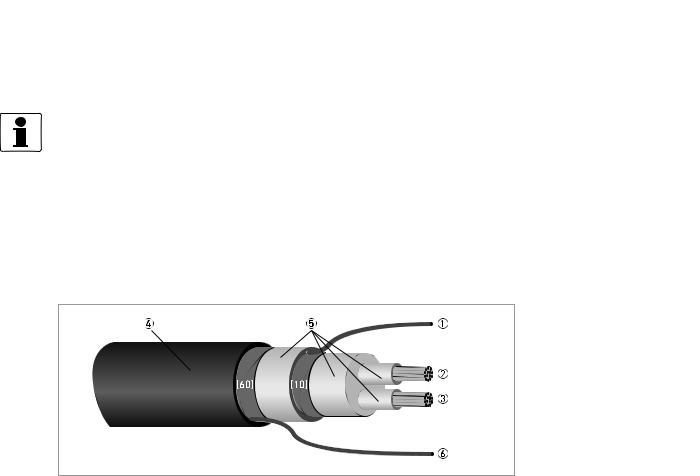

4.4.1Signal cable A (type DS 300), construction

•Signal cable A is a double-shielded cable for signal transmission between the measuring sensor and signal converter.

•Bending radius: ≥ 50 mm / 2"

Figure 4-1: Construction of signal cable A

1Stranded drain wire (1) for the inner shield (10), 1.0 mm2 Cu / AWG 17 (not insulated, bare)

2Insulated wire (2), 0.5 mm2 Cu / AWG 20

3Insulated wire (3), 0.5 mm2 Cu / AWG 20

4Outer sheath

5Insulation layers

6Stranded drain wire (6) for the outer shield (60)

20 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

ELECTRICAL CONNECTIONS 4 |

|

IFC 100 |

|

|

|

|

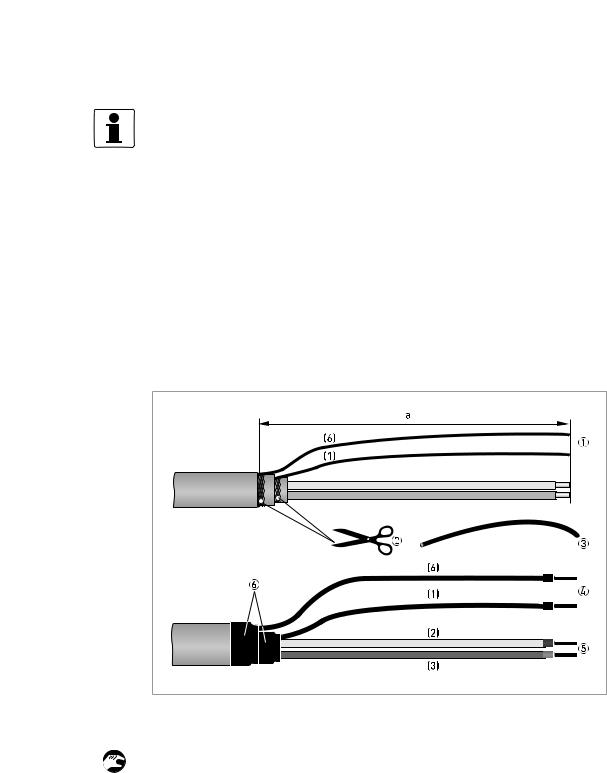

4.4.2 Preparing signal cable A, connection to signal converter

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools in compliance with the applicable occupational health and safety directives.

•Connection of the two shields in the signal converter is carried out via the stranded drain wires.

•Bending radius: ≥ 50 mm / 2"

Required materials

•PVC insulating tube, Ø2.5 mm / 0.1"

•Heat-shrinkable tubing

•2x wire end ferrules to DIN 46 228: E 1.5-8 for the stranded drain wires (1, 6)

•2x wire end ferrules to DIN 46 228: E 0.5-8 for the insulated conductors (2, 3)

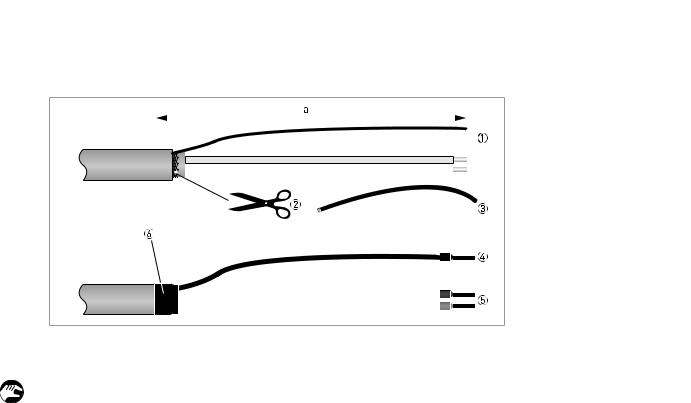

Figure 4-2: Preparation of signal cable A a = 80 mm / 3.15"

1 Strip the conductor to dimension a.

2Cut off the inner shield (10) and the outer shield (60). Make sure not to damage the stranded drain wires (1, 6).

3Slide the insulation tubing over the stranded drain wires (1, 6).

4Crimp the wire end ferrules onto the stranded drain wire.

5Crimp the wire end ferrules onto the conductors (2, 3).

6Pull the heat-shrinkable tubing over the prepared signal cable.

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

21 |

4 ELECTRICAL CONNECTIONS |

|

|

IFC 100 |

|

|

|

|

|

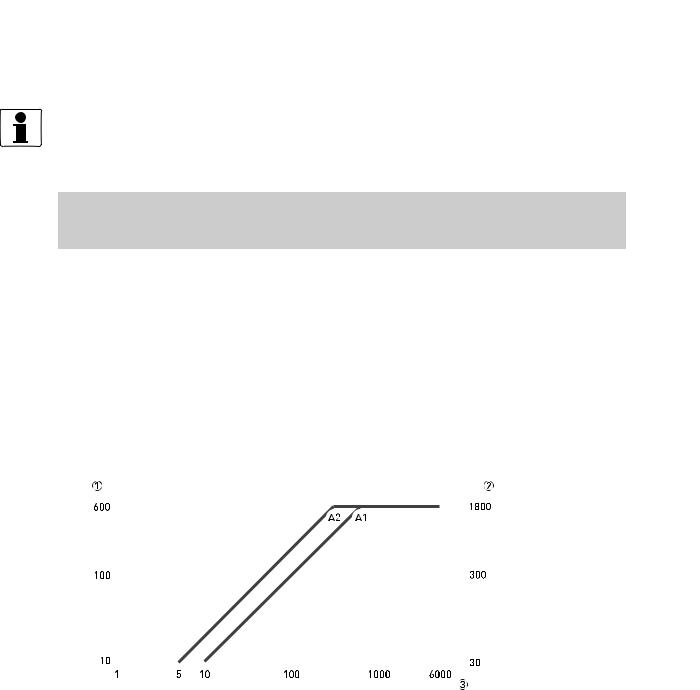

4.4.3 Length of signal cable A

INFORMATION!

For temperatures of the medium above 150°C / 300°F, a special signal cable and a ZD intermediate socket are necessary. These are available including the changed electrical connection diagrams.

Measuring sensor |

Nominal size |

|

|

|

|

|

|

|

Min. electrical |

Curve for signal |

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

conductivity |

cable A |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

DN [mm] |

[inches] |

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

[µS/cm] |

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIFLUX 1000 F |

10... |

|

150 |

|

|

|

|

3/8 6... |

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

A1 |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIFLUX 2000 F |

25... |

|

150 |

|

|

|

|

1... |

6 |

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

A1 |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

200... |

1200 |

|

|

8... |

48 |

|

|

|

|

20 |

|

|

|

|

|

|

|

|

A2 |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIFLUX 4000 F |

2.5... |

150 |

|

|

|

1/10... |

|

6 |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

A1 |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

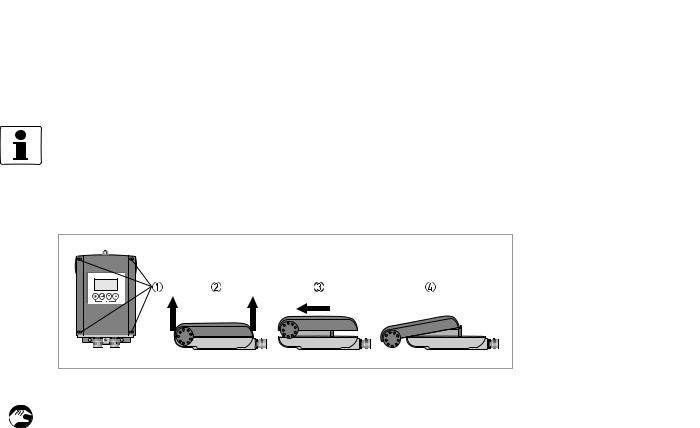

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

200... |

1200 |

|

|

8... |

48 |

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

A2 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIFLUX 5000 F |

2.5... |

100 |

|

|

|

1/10... |

|

4 |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

A1 |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

150... |

250 |

|

|

|

6... |

10 |

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

A2 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIFLUX 6000 F |

2.5... |

150 |

|

|

|

1/10... |

|

6 |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

A1 |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WATERFLUX 3000 F |

25... |

|

600 |

|

|

|

|

1... |

24 |

|

|

|

|

20 |

|

|

|

|

|

|

|

|

A1 |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 4-3: Maximum length of signal cable A

1Maximum length of signal cable A between the measuring sensor and signal converter [m]

2Maximum length of signal cable A between the measuring sensor and signal converter [ft]

3Electrical conductivity of the medium being measured [μS/cm]

22 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

ELECTRICAL CONNECTIONS 4 |

|

IFC 100 |

|

|

|

|

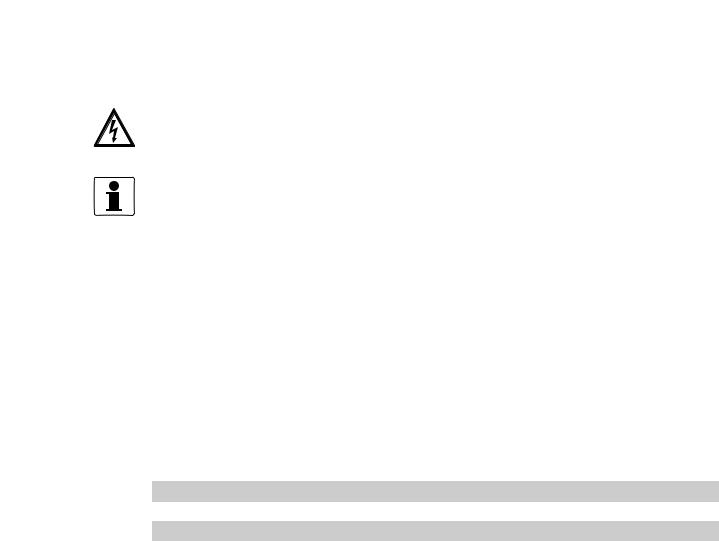

4.4.4 Preparing field current cable C, connection to signal converter

DANGER!

A shielded two-wire copper cable is used as the field current cable. The shielding MUST be connected in the housing of the measuring sensor and signal converter.

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools in compliance with the applicable occupational health and safety directives.

•Field current cable C is not part of the scope of delivery.

•Bending radius: ≥ 50 mm / 2"

Required materials:

•Shielded, at least 2-wire copper cable with suitable heat-shrinkable tubing

•Insulating tube, size according to the cable being used

•DIN 46 228 wire end ferrules: size according to the cable being used

Length and cross-section of field current cable C

Length |

|

Cross-section AF (Cu) |

|||

[m] |

|

[ft] |

[mm2] |

|

[AWG] |

0...150 |

|

0...500 |

2 x 0.75 Cu |

1 |

2 x 18 |

|

|

|

|

|

|

150...300 |

|

500...1000 |

2 x 1.50 Cu |

1 |

2 x 14 |

|

|

|

|

|

|

300...600 |

|

1000...2000 |

2 x 2.50 Cu |

1 |

2 x 12 |

|

|

|

|

|

|

1 Cu = copper cross-section

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

23 |

4 ELECTRICAL CONNECTIONS |

|

|

|

|

|

|

||||

|

|

|

|

IFC 100 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

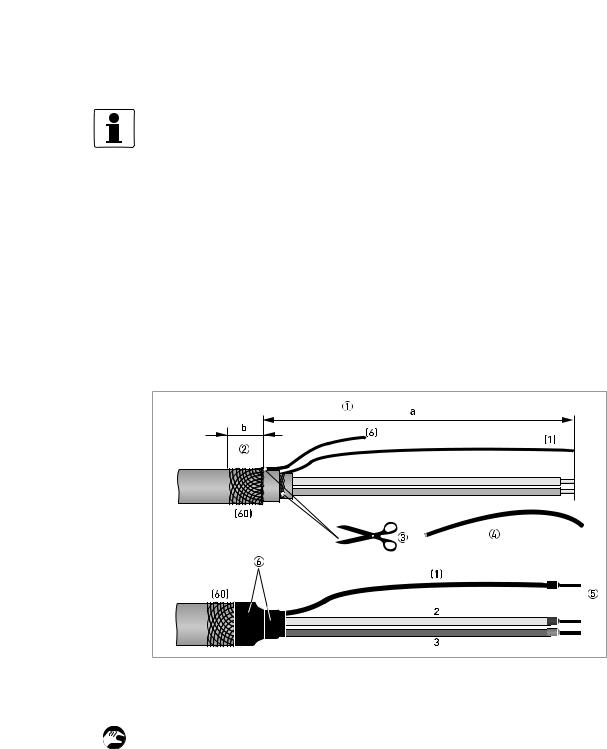

Figure 4-4: Field current cable C, preparation for the signal converter a = 80 mm / 3.15"

1 Strip the conductor to dimension a.

2If a stranded drain wire is present, remove the shield that is present. Make sure not to damage the stranded drain wire.

3Slide an insulating tube over the stranded drain wire.

4Crimp a wire end ferrule onto the stranded drain wire.

5Crimp wire end ferrules onto the conductors.

6Pull a shrinkable tube over the prepared cable.

24 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

ELECTRICAL CONNECTIONS 4 |

|

IFC 100 |

|

|

|

|

4.4.5 Preparing signal cable A, connection to measuring sensor

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools in compliance with the applicable occupational health and safety directives.

•The outer shield (60) is connected in the terminal compartment of the measuring sensor directly via the shield and a clip.

•Bending radius: ≥ 50 mm / 2"

Required materials

•PVC insulating tube, Ø2.0...2.5 mm / 0.08...0.1"

•Heat-shrinkable tubing

•Wire end ferrule to DIN 46 228: E 1.5-8 for the stranded drain wire (1)

•2x wire end ferrules to DIN 46 228: E 0.5-8 for the insulated conductors (2, 3)

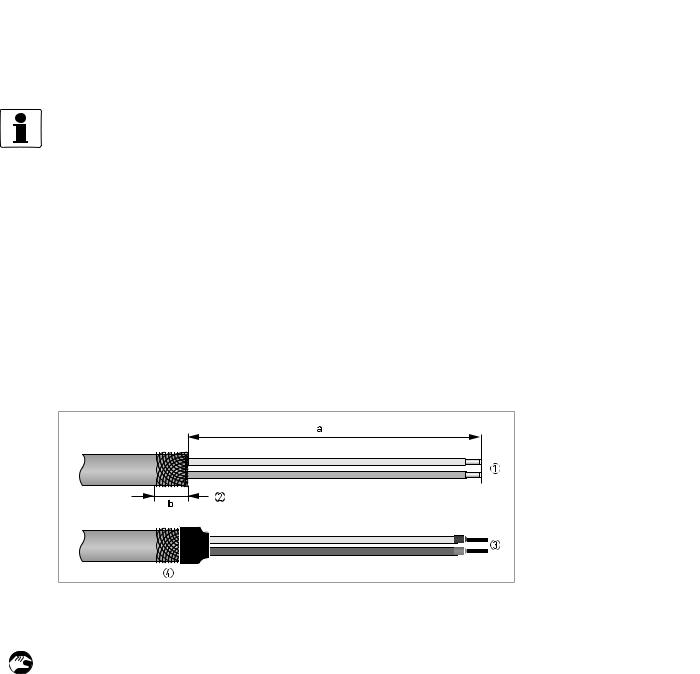

Figure 4-5: Preparing signal cable A, connection to measuring sensor

a = 50 mm / 2"

b = 10 mm / 0.39"

1 Strip the conductor to dimension a.

2Trim the outer shield (60) to dimension b and pull it over the outer sheath.

3Remove the stranded drain wire (6) of the outer shield and the inner shield (10). Make sure not to damage the stranded drain wire (1) of the inner shield.

4Slide an insulating tube over the stranded drain wire (1).

5Crimp the wire end ferrules onto conductors 2 and 3 and the stranded drain wire (1).

6Pull the heat-shrinkable tubing over the prepared signal cable.

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

25 |

4 ELECTRICAL CONNECTIONS |

|

|

IFC 100 |

|

|

|

|

|

4.4.6 Preparing field current cable C, connection to measuring sensor

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools in compliance with the applicable occupational health and safety directives.

•The field current cable is not part of the scope of delivery.

•The shield is connected in the terminal compartment of the measuring sensor directly via the shield and a clip.

•Bending radius: ≥ 50 mm / 2"

Required materials

•Shielded 2-wire insulated copper cable

•Insulating tube, size according to the cable being used

•Heat-shrinkable tubing

•DIN 46 228 wire end ferrules: size according to the cable being used

Figure 4-6: Preparation of field current cable C

a = 50 mm / 2" b = 10 mm / 0.4"

1 Strip the conductor to dimension a.

2Trim the outer shield to dimension b and pull it over the outer sheath.

3Crimp wire end ferrules onto both conductors.

4Pull a shrinkable tube over the prepared cable.

26 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

ELECTRICAL CONNECTIONS 4 |

|

IFC 100 |

|

|

|

|

4.5 Connecting the signal and field current cables

DANGER!

Cables may only be connected when the power is switched off.

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel against electric shocks.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the electrical components of the measuring device may only be carried out by properly trained specialists.

07/2010 - 4000041004 - MA IFC 100 R04 en |

www.krohne.com |

27 |

4 ELECTRICAL CONNECTIONS |

|

|

IFC 100 |

|

|

|

|

|

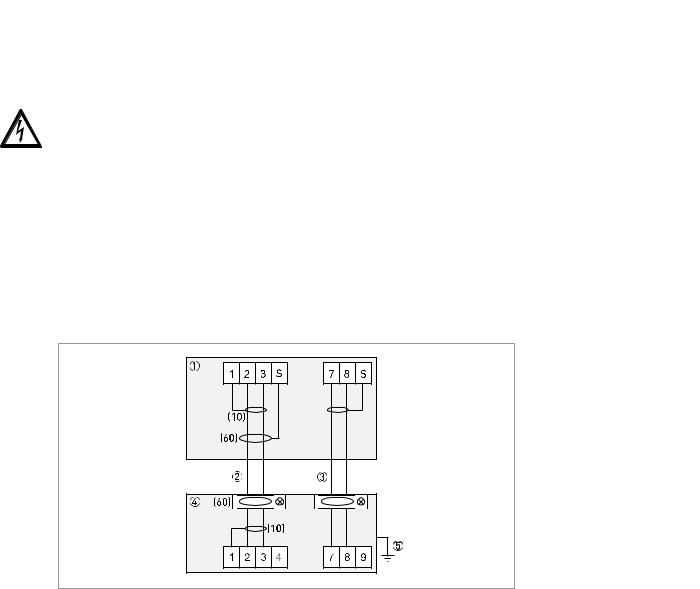

4.5.1Connecting the signal and field current cables to the signal converter, remote version

INFORMATION!

The compact version is supplied preassembled from the factory.

Open housing

Figure 4-7: Open housing

1 Loosen the 4 screws with a suitable tool.

2Lift the housing at the top and bottom at the same time.

3Slide the housing cover upward.

4The housing cover is guided and held by the inside hinge.

28 |

www.krohne.com |

07/2010 - 4000041004 - MA IFC 100 R04 en |

|

|

ELECTRICAL CONNECTIONS 4 |

|

IFC 100 |

|

|

|

|

Connecting the signal and field current cables

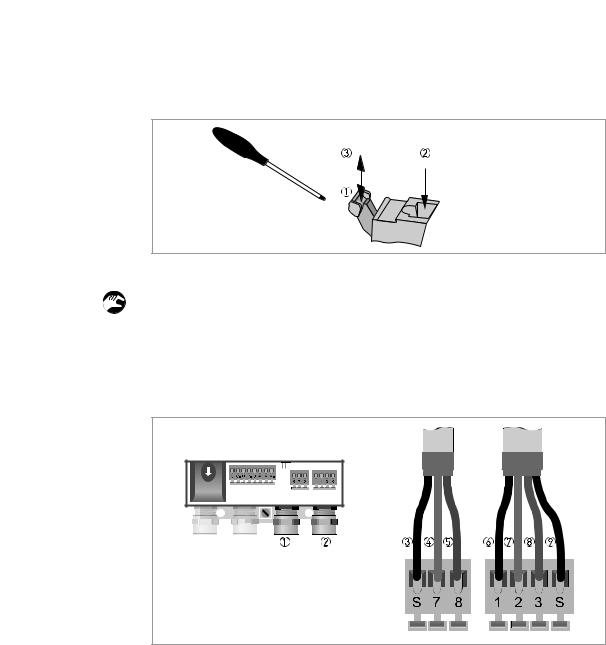

Figure 4-8: Function of the electrical connection terminal

Connect the electrical conductors as follows:

1Push the lever downwards with a screwdriver in good condition (blade: 3.5 mm wide and

0.5mm thick).