KROHNE OPTISWITCH-5200C User Manual

Operating Instructions

OPTISWITCH 5200 C, 5250 C with two-wire output

Contents

2

Contents

1About this document

1.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 Symbolism used . . . . . . . . . . . . . . . . . . . . . . . 4

2For your safety

2.1 |

Authorised personnel . . . . . . . . . . . . . . . . . . . . |

5 |

2.2 |

Appropriate use. . . . . . . . . . . . . . . . . . . . . . . . |

5 |

2.3 |

Warning about misuse . . . . . . . . . . . . . . . . . . . |

5 |

2.4 |

CE conformity . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

2.5 |

SIL conformity . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

2.6 Safety instructions for Ex areas . . . . . . . . . . . . |

6 |

|

3 Product description |

|

|

3.1 |

Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

3.2 |

Principle of operation . . . . . . . . . . . . . . . . . . . . |

7 |

3.3 |

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

3.4 |

Storage and transport . . . . . . . . . . . . . . . . . . . |

9 |

4Mounting

4.1 General instructions. . . . . . . . . . . . . . . . . . . . . 10 4.2 Mounting instructions . . . . . . . . . . . . . . . . . . . . 13

5Connecting to voltage supply

5.1 Preparing the connection . . . . . . . . . . . . . . . . . 16

5.2 Connection steps. . . . . . . . . . . . . . . . . . . . . . . 16

5.3 Wiring plan, single chamber housing. . . . . . . . . 17

6Set up

6.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 6.2 Adjustment elements . . . . . . . . . . . . . . . . . . . . 21 6.3 Function chart . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4 Recurring test and function test . . . . . . . . . . . . 22

7Maintenance and fault rectification

7.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 25 7.2 Rectify faults . . . . . . . . . . . . . . . . . . . . . . . . . . 25 7.3 Instrument repair . . . . . . . . . . . . . . . . . . . . . . . 26

8Dismounting

8.1 Dismounting procedure . . . . . . . . . . . . . . . . . . 27 8.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

OPTISWITCH 5200 C, 5250 C - with two-wire output

060831-EN-30435

Contents

9Supplement

9.1 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . 28 9.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

30435-EN-060831

OPTISWITCH 5200 C, 5250 C - with two-wire output

3

About this document

1 About this document

1.1 Function

This operating instructions manual has all the information you need for quick setup and safe operation. Please read this manual before you start setup.

1.2 Target group

This operating instructions manual is directed to trained, qualified personnel. The contents of this manual should be made available to these personnel and put into practice by them.

4

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or malfunctions can result.

Warning: If this warning is ignored, injury to persons and/or serious damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

•List

The dot set in front indicates a list with no implied sequence.

àAction

This arrow indicates a single action.

1Sequence

Numbers set in front indicate successive steps in a procedure.

OPTISWITCH 5200 C, 5250 C - with two-wire output |

060831-EN-30435 |

|

30435-EN-060831

For your safety

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the operator. For safety and warranty reasons, any internal work on the instruments must be carried out only by personnel authorised by the manufacturer.

2.2 Appropriate use

OPTISWITCH 5200 C, 5250 C is a sensor for level detection.

Detailed information on the application range of OPTISWITCH 5200 C, 5250 C is available in chapter "Product description".

2.3 Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to application-specific hazards, e.g. vessel overfill or damage to system components through incorrect mounting or adjustment.

2.4 General safety instructions

OPTISWITCH 5200 C, 5250 C is a high-tech instrument requiring the strict observance of standard regulations and guidelines. The user must take note of the safety instructions in this operating instructions manual, the country-specific installation standards (e.g. the VDE regulations in Germany) as well as all prevailing safety regulations and accident prevention rules.

2.5 CE conformity

OPTISWITCH 5200 C, 5250 C is in CE conformity with EMC (89/336/EWG), fulfils NAMUR recommendation NE 21 and is in CE conformity with LVD (73/23/EWG).

Conformity has been judged according to the following standards:

•EMC:

-Emission EN 61326/A1: 1998 (class B)

-Susceptibility EN 61326: 1997/A1:1998

•LVD: EN 61010-1: 1993

OPTISWITCH 5200 C, 5250 C - with two-wire output |

5 |

For your safety

6

2.6 SIL conformity

OPTISWITCH 5200 C, 5250 C fulfills the requirements of functional safety according to IEC 61508/IEC 61511. You can find further information in the supplementary instructions manual "Safety Manual - Functional safety (SIL) OPTISWITCH

5XXX".

2.7 Safety instructions for Ex areas

Please note the Ex-specific safety information for installation and operation in Ex areas. These safety instructions are part of the operating instructions manual and come with the Exapproved instruments.

OPTISWITCH 5200 C, 5250 C - with two-wire output |

060831-EN-30435 |

|

Product description

|

3 |

Product description |

|

3.1 Configuration |

|

Scope of delivery |

The scope of delivery encompasses: |

|

|

• OPTISWITCH 5200 C, 5250 C level sensor |

|

|

• |

Documentation |

|

|

- this operating instructions manual |

|

|

- Ex specific safety instructions (with Ex versions), if |

|

|

necessary further certificates |

Components |

OPTISWITCH 5200 C, 5250 C consists of the following |

|

|

components: |

|

|

• |

Housing cover |

|

• Housing with electronics |

|

|

• process fitting with tuning fork |

|

|

|

1 |

|

|

2 |

|

|

3 |

30435-EN-060831

|

Fig. 1: OPTISWITCH 5200 C, 5250 C with plastic housing |

|

|

1 |

Housing cover |

|

2 |

Housing with electronics |

|

3 |

Process fitting |

|

3.2 |

Principle of operation |

Area of application |

OPTISWITCH 5200 C, 5250 C is a level sensor with tuning |

|

|

fork for level detection. |

|

OPTISWITCH 5200 C, 5250 C - with two-wire output |

7 |

Product description

Physical principle

Power supply

8

It is designed for industrial use in all areas of process technology and can be used in liquids.

Typical applications are overfill and dry run protection. With a tuning fork of only 40 mm length, OPTISWITCH 5200 C, 5250 C can be also mounted, e.g. in pipelines from DN 25. The small tuning fork allows use in vessels, tanks and pipes. Thanks to its simple and robust measuring system, OPTISWITCH 5200 C, 5250 C is virtually una ected by the chemical and physical properties of the liquid.

It functions even under di cult conditions such as turbulence, air bubbles, foam generation, buildup, strong external vibration or changing products.

Fault monitoring

The electronics module of OPTISWITCH 5200 C, 5250 C continuously monitors via frequency evaluation the following criteria:

•Strong corrosion or damage on the tuning fork

•loss of vibration

•Line break to the piezo drive

If one of these faults is detected, the electronics signals it via a defined current to the signal conditioning instrument. The connection cable to the sensor is also monitored on line break and short-circuit.

The tuning fork is piezoelectrically energised and vibrates at its mechanical resonance frequency of approx. 1200 Hz. The piezos are fastened mechanically and are hence not subject to temperature shock limitations. When the tuning fork is submerged in the product, the frequency changes. This change is detected by the integrated oscillator, transferred to the signal conditioning instrument as current value and converted into a switching command.

Depending on your requirements, OPTISWITCH 5200 C, 5250 C with two-wire electronics can be connected to di erent signal conditioning instruments. Compatible signal conditioning instruments are listed under "Technical data".

The exact range of the power supply is stated in the "Technical data" in the "Supplement".

OPTISWITCH 5200 C, 5250 C - with two-wire output

060831-EN-30435

Product description

3.3 Operation

The switching condition of OPTISWITCH 5200 C, 5250 C with plastic housing can be checked when the housing is closed (signal lamp). With the basic setting, products with a density >0.7 g/cm³ (>0.025 lbs/in³) can be detected. The instrument can be adapted if products with lower density should be measured.

On the electronics module you will find the following indicating and adjustment elements:

• signal lamp for indication of the switching condition (green/ red)

• DIL switch for adaptation to the product density

|

3.4 Storage and transport |

Packaging |

Your instrument was protected by packaging during transport. |

|

Its capacity to handle normal loads during transport is assured |

|

by a test according to DIN 55439. |

|

The packaging of standard instruments consists of environ- |

|

ment-friendly, recyclable cardboard. In addition, the sensor is |

|

provided with a protective cover of ABS. For special versions |

|

PE foam or PE foil is also used. Dispose of the packaging |

|

material via specialised recycling companies. |

Storage and transport tem- |

• Storage and transport temperature see "Supplement - |

perature |

Technical data - Ambient conditions" |

|

• Relative humidity 20 … 85 % |

30435-EN-060831

OPTISWITCH 5200 C, 5250 C - with two-wire output

9

Mounting

4 Mounting

4.1 General instructions

Switching point |

In general, OPTISWITCH 5200 C, 5250 C can be mounted in |

any position. The instrument must be mounted in such a way that the tuning fork is at the height of the requested switching point.

The tuning fork has lateral markings (notches), marking the switching point with vertical mounting. The switching point refers to water with the basic setting of the sensitivity switch >=0.7 g/cm³ (>=0.025 lbs/in³). When mounting OPTISWITCH 5200 C, 5250 C, make sure that this marking is at the height of the requested switching point. Keep in mind that the switching point of the instrument is shifted if the medium has a density other than water - water =1 g/cm³ (=0.036 lbs/in³). For products <0.7 g/cm³ (<0.025 lbs/in³) and >0.5 g/cm³

(>0.018 lbs/in³) the density switch must be set to >=0.5 g/cm³.

|

2 |

1 |

4 |

|

|

|

3 |

10

Fig. 2: Vertical mounting

1 Switching point approx. 13 mm (approx. 0.51 in) 2 Switching point with lower density

3Switching point with higher density

4Switching point approx. 27 mm (approx. 1.06 in)

OPTISWITCH 5200 C, 5250 C - with two-wire output

060831-EN-30435

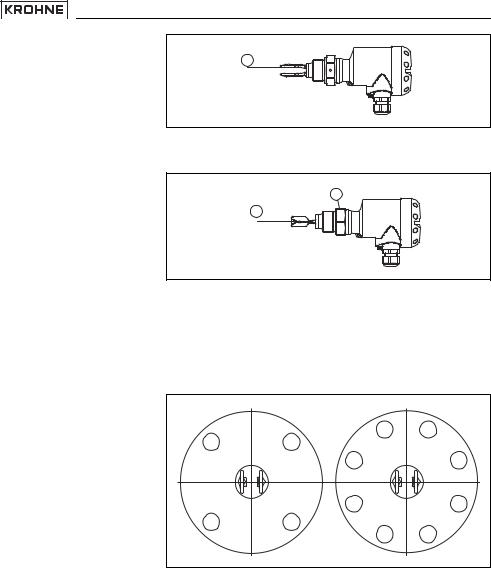

Mounting

1

Fig. 3: Horizontal mounting

1Switching point

2

1

30435-EN-060831

Fig. 4: Horizontal mounting (recommended installation location - particularly for adhesive products)

1Switching point

2Marking with screwed version on top - with flange versions directed to the flange holes

With flange versions, the fork is directed to the flange holes in the following way.

|

Fig. 5: Fork position with flange versions |

|

|

Moisture |

Use the recommended cables (see chapter "Connecting to |

||

|

power supply") and tighten the cable gland. |

|

|

|

You can give your OPTISWITCH 5200 C, 5250 C additional |

||

|

protection against moisture penetration by leading the con- |

||

|

nection cable downward in front of the cable entry. Rain and |

||

|

|

|

|

OPTISWITCH 5200 C, 5250 C - with two-wire output |

11 |

|

|

Loading...

Loading...